Environmental Performance of Hypothetical Canadian Pre-Combustion Carbon Dioxide Capture Processes Using Life-Cycle Techniques

Abstract

:1. Introduction

2. Methodology

2.1. Environmental Life-Cycle Assessment Methodology

2.1.1. Goal and Scope Definition

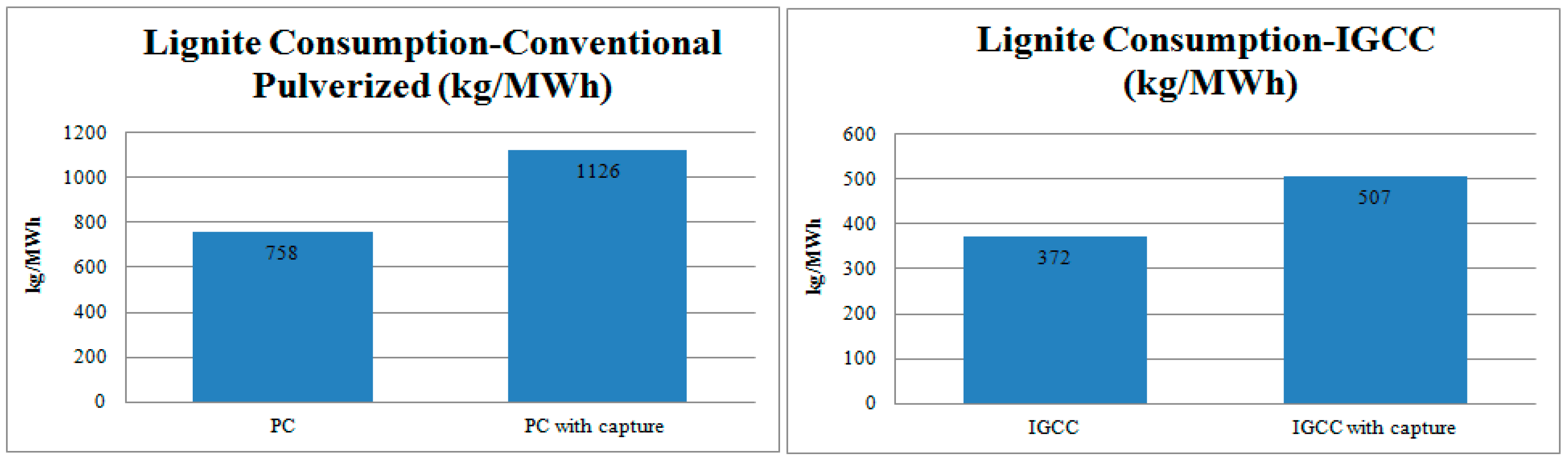

- conventional lignite coal-fired electricity generation without a post-combustion CO2 capture process;

- conventional lignite coal-fired electricity generation with an amine post-combustion CO2 capture process;

- integrated Gasification Combined Cycle (IGCC) without a pre-combustion CO2 capture process;

- integrated Gasification Combined Cycle (IGCC) with Selexol® as the chosen pre-combustion CO2 capture process.

Functional Unit

System Boundaries

2.1.2. Life-Cycle Inventory Data Quality, Sources and Assumptions

2.1.3. Life-Cycle Assessment Modeling

2.1.4. Life-Cycle Impact Assessment

2.2. Air Dispersion Modeling Methodology.

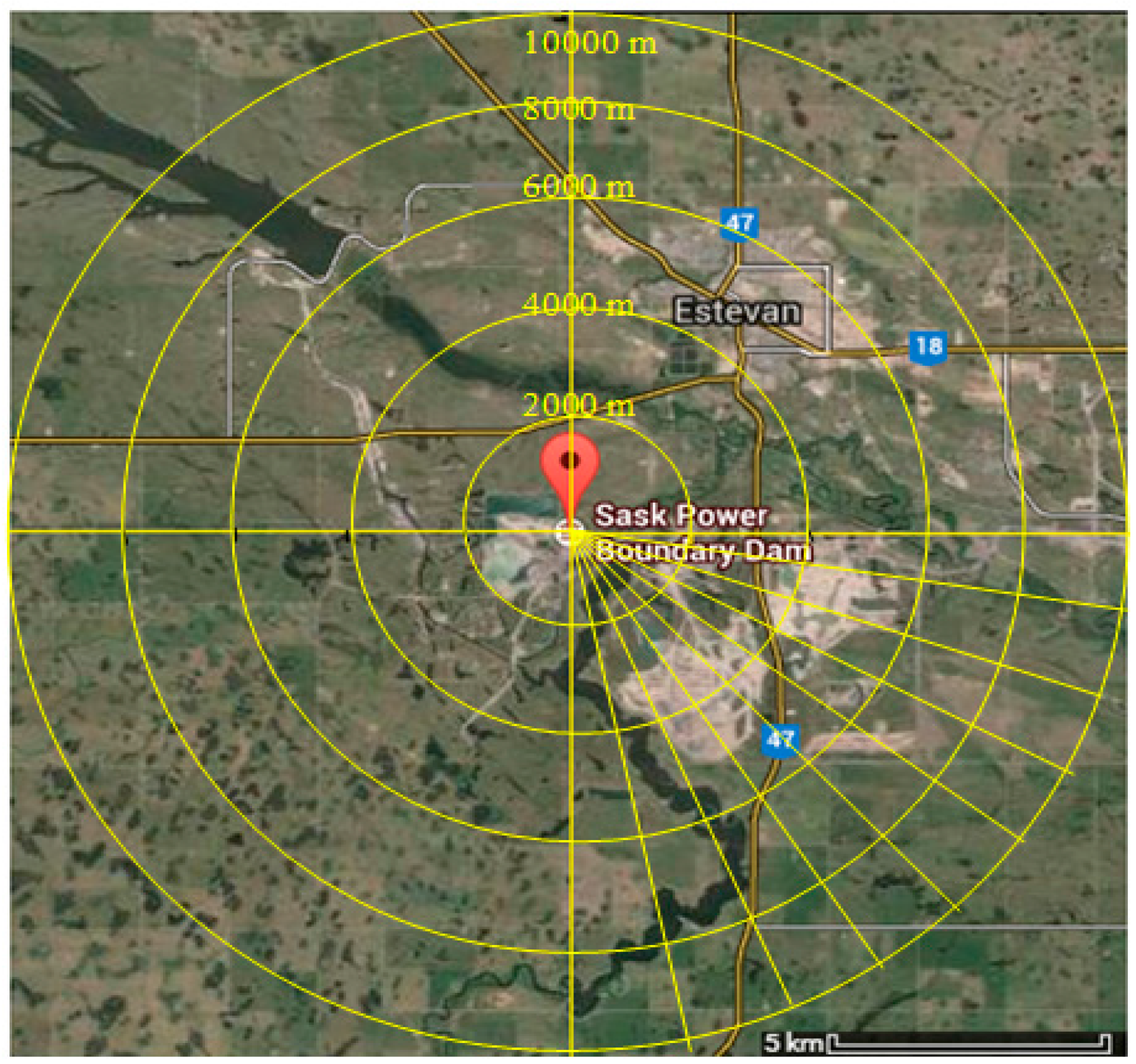

2.2.1. Facility Regional Setting and Study Area

2.2.2. Meteorology, Receptors and Terrain

2.2.3. Emission Source Characterization

3. Data Inventory Modeling and Systems Descriptions

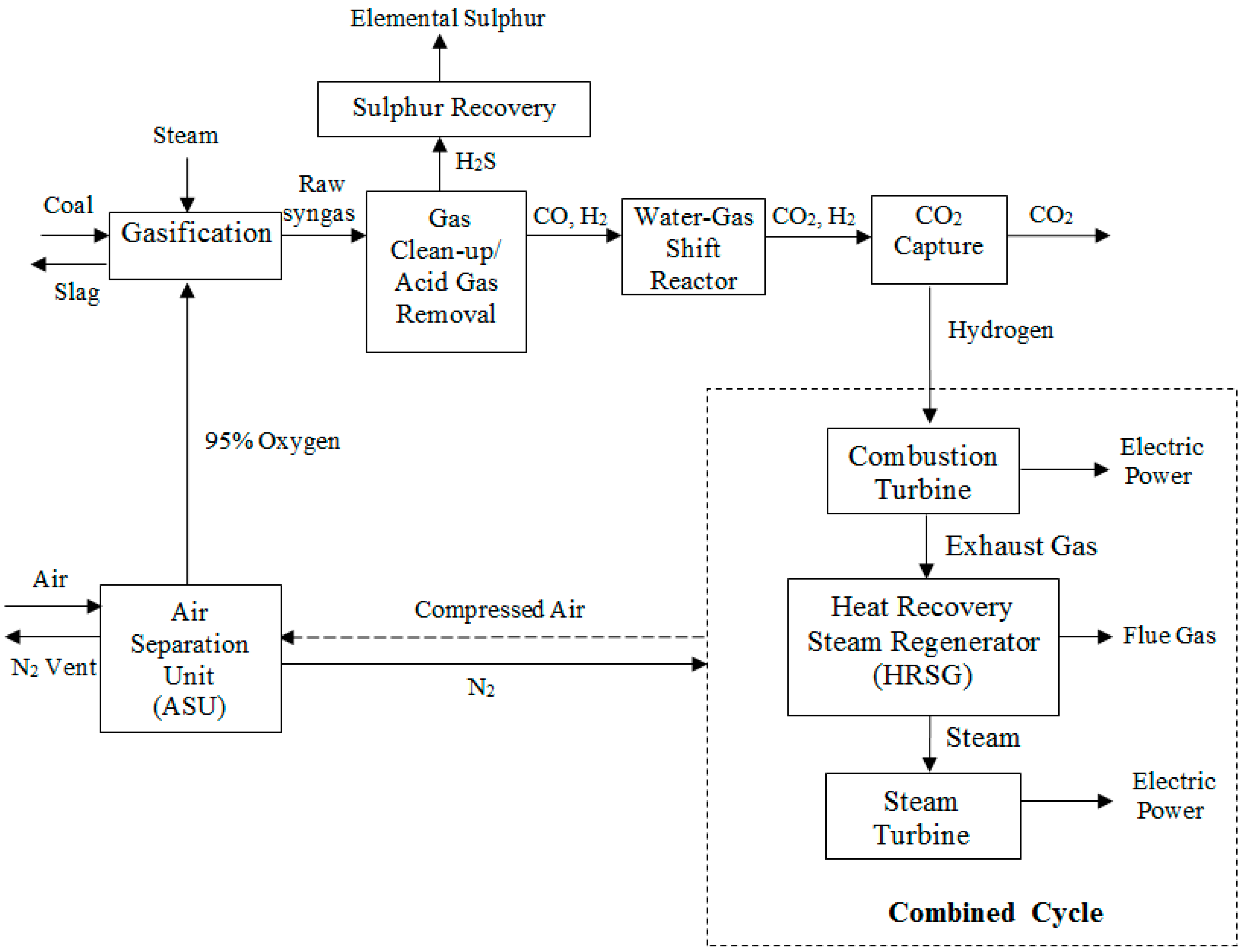

3.1. Integrated Gasification Combined Cycle (IGCC) with Pre—Combustion CO2 Capture Process

3.1.1. Air Separation Unit (ASU)

3.1.2. Gasification

3.1.3. Acid Gas Removal and Sulfur Recovery Process

3.1.4. Water Gas Shift and CO2 Removal Unit

3.1.5. Electrical Generation Unit

3.1.6. Combined Cycle Electricity Generation

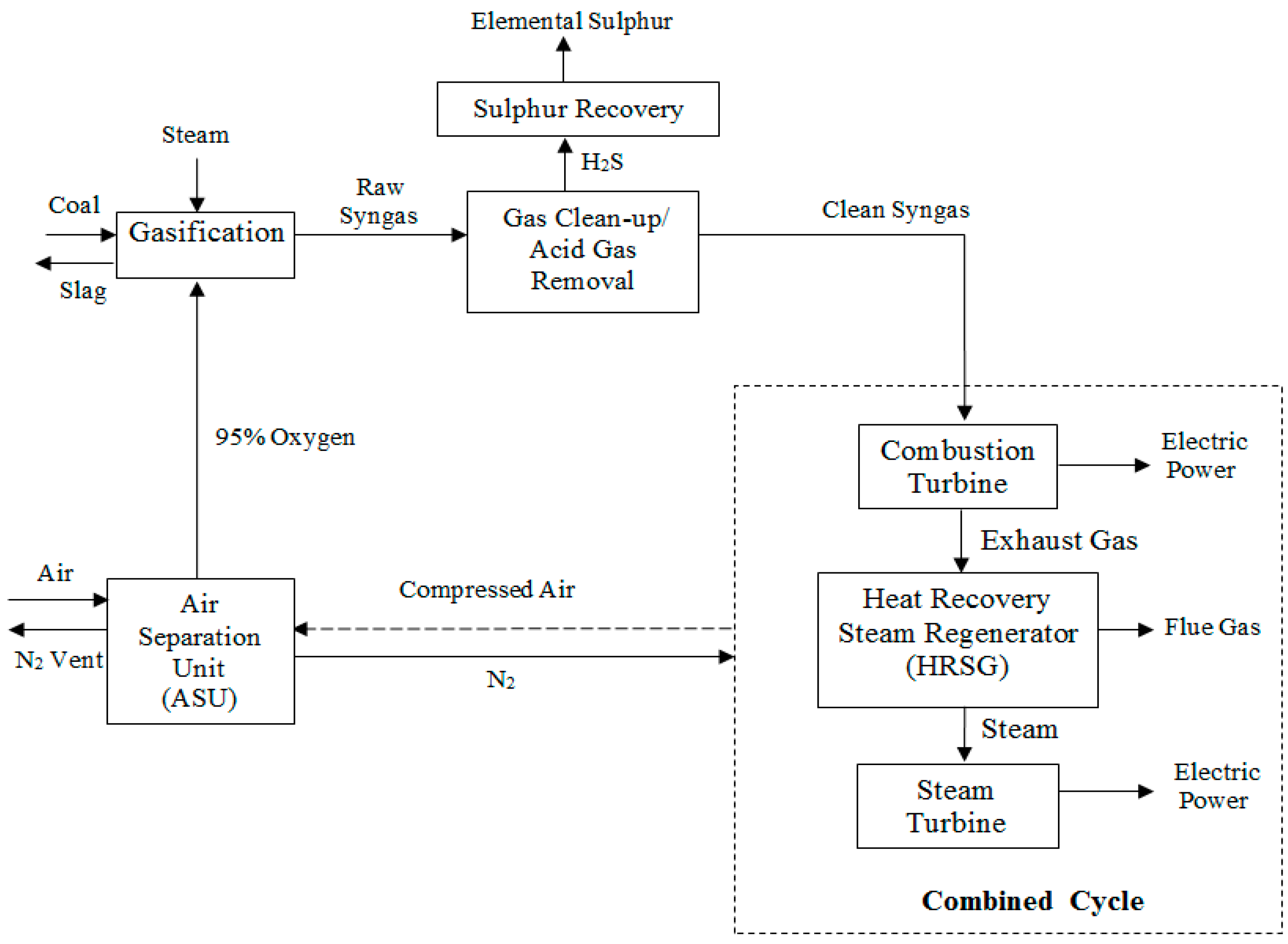

3.2. Integrated Gasification Combined Cycle (IGCC) Without Pre-Combustion CO2 Capture

3.3. The Conventional Lignite Coal-Fired Electricity Generation With and Without Post Combustion CO2 Capture Process

4. Results and Discussions

4.1. LCA Results

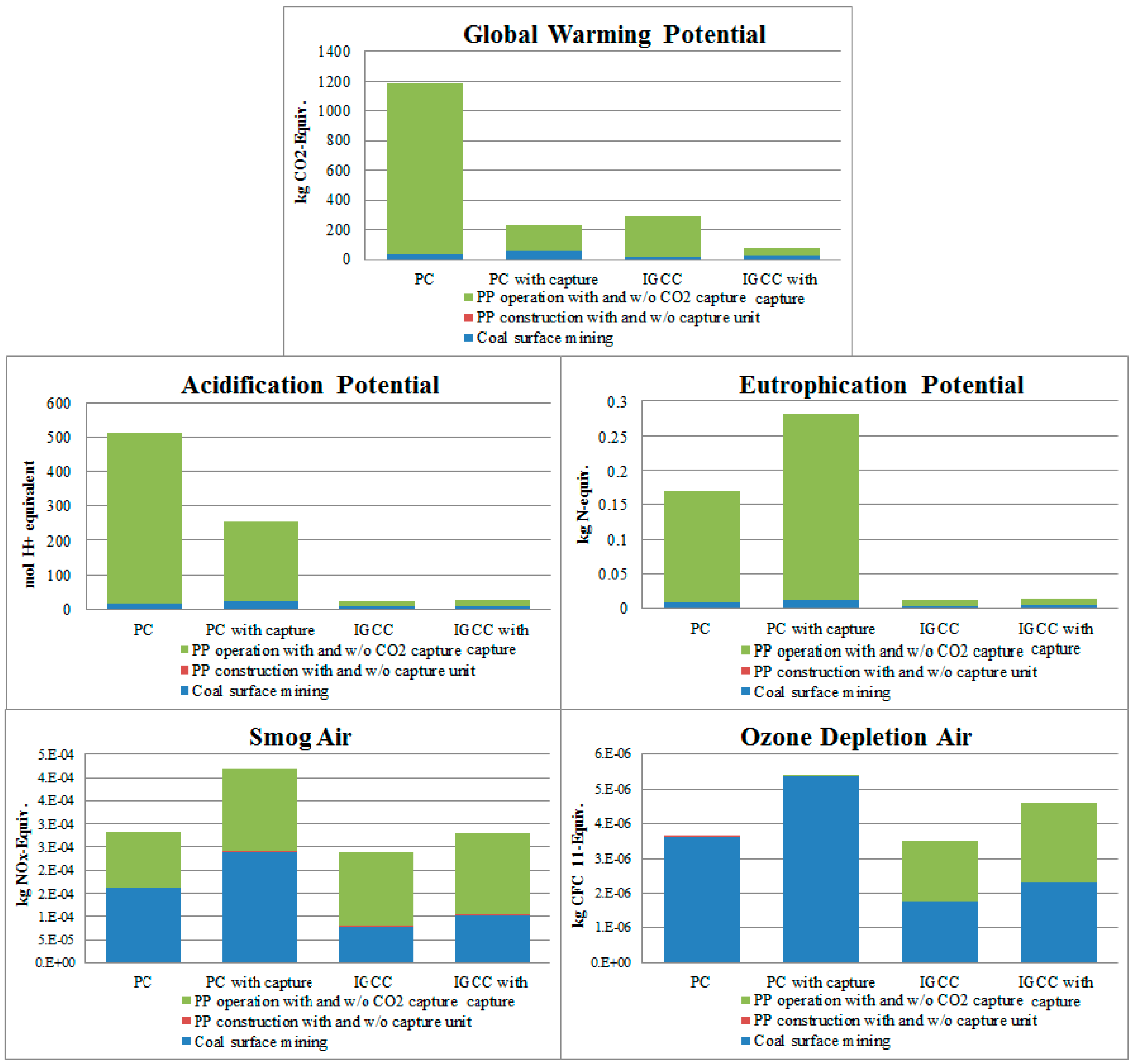

4.1.1. Global Warming Potential

4.1.2. Acidification

4.1.3. Eutrophication

4.1.4. Ozone Depletion

4.1.5. Smog Air

4.2. Air Dispersion Modeling Results

4.2.1. NO2 Predictions

4.2.2. SO2 Predictions

4.2.3. PM2.5 Predictions

4.2.4. Arsenic (As) Predictions

4.2.5. Cadmium (Cd) Predictions

4.2.6. Chromium (Cr) Predictions

4.2.7. Elemental Mercury (Hg) Predictions

4.2.8. Manganese (Mn) Predictions

4.2.9. Lead (Pb) Predictions

4.2.10. Other Trace Elements

4.3. Discussions

5. Conclusions and Recommendations for Future Work

5.1. Conclusion

5.2. Future Perspective

Acknowledgments

Author Contributions

Conflicts of Interest

References

- National Inventory Report 1990–2013: Greenhouse Gas Sources and Sinks in Canada—Executive Summary. Available online: https://www.ec.gc.ca/ges-ghg/default.asp?lang=En&n=5B59470C-1&offset=4&toc=show (accessed on 29 February 2016).

- Economic Review 2013 (Number Sixty-Seven) of Government of Saskatchewan. Available online: http://www.stats.gov.sk.ca/stats/ER2013.pdf (accessed on 29 February 2016).

- Rai, H.; Bharti, A.; Singh, R.; Prasad, N.K. Energy Efficienct Coal Gasification for IGCC Power Plant. Int. J. Innov. Technol. Explor. Eng. 2013, 2, 203–206. [Google Scholar]

- Ratafia-Brown, J.A.; Manfredo, L.M.; Hoffmann, J.W.; Ramezan, M.; Stigel, G.J. An environmental assessment of IGCC power systems. In Proceedings of the Nineteenth Annual Pittsburgh Coal Conference, Pittsburgh, PA, USA, 23–27 September 2002.

- Commercial Power Production Based On Gasification: Integrated Gasification Combined Cycle without Carbon Capture and Storage. Available online: http://www.netl.doe.gov/research/Coal/energy-systems/gasification/gasifipedia/igcc (accessed on 2 March 2016).

- Wall, T.F. Combustion processes for carbon capture. Proc. Combust. Inst. 2007, 31, 31–47. [Google Scholar] [CrossRef]

- Burr, B.; Lyddon, L. A Comparison of Physical Solvents for Acid Gas Removal; Bryan Research & Engineering, Inc.: Bryan, TX, USA, 2013. [Google Scholar]

- Davison, J.; Thambimuthu, K. Technologies for capture of carbon dioxide. In Greenhouse Gas Control Technologies 7; Rubin, E.S., Keith, D.W., Gilboy, C.F., Wilson, M., Morris, T., Gale, J., Thambimuthu, K., Eds.; Elsevier Science Ltd: Oxford, UK, 2005; pp. 3–13. [Google Scholar]

- Odeh, N.; Cockerill, T. Life-Cycle GHG Assessment of Fossil Fuel Electrical generating stations with Carbon Capture and Storage. Energy Policy 2008, 36, 367–380. [Google Scholar] [CrossRef]

- Emissions of substances other than CO2 from power plants with CCS. Available online: https://www.globalccsinstitute.com/publications/emissions-substances-other-co2-power-plants-ccs (accessed on 2 March 2016).

- Hoffmann, B.S.; Szklo, A. Integrated gasification combined cycle and carbon capture: A risky option to mitigate CO2 emissions of coal-fired power plants. Appl. Energy 2011, 88, 3917–3929. [Google Scholar] [CrossRef]

- CO2 Capture and Storage. A key carbon abatement option. Available online: https://www.iea.org/publications/freepublications/publication/CCS_2008.pdf (accessed on 3 March 2016).

- Carbon capture and storage technologies database at MIT. Available online: http://sequestration.mit.edu/index.html (accessed on 3 March 2016).

- Major Commercial Examples of IGCC Plants. Available online: http://www.netl.doe.gov/research/coal/energy-systems/gasification/gasifipedia/igcc-config (accessed on 3 March 2016).

- Suebsiri, J. An Environmental Model of Carbon Capture and Storage with Demonstration to Carbon Footprint and Resource Deletion Evaluation. PhD. Thesis, University of Regina, Regina, SK, Canada, 2010. [Google Scholar]

- Manuilova, A. Evaluation of Environmental Performance of Carbon Capture and Storage Project in Canada Using Life-Cycle Assessment Methodology. PhD. Thesis, University of Regina, Regina, SK, Canada, 2011. [Google Scholar]

- Baumann, H.; Tillman, A. The Hitch Hiker’s Guide to LCA; Student Literature: Lund, Sweden, 2014. [Google Scholar]

- Pehnt, M.; Henkel, J. Life-cycle assessment of carbon dioxide capture and storage from lignite electrical generating stations. Int. J. Greenh. Gas Control 2009, 3, 49–66. [Google Scholar] [CrossRef]

- Polk Power Station. Available online: http://www.tampaelectric.com/company/ourpowersystem/powergeneration/polk/ (accessed on 29 February 2016).

- Rubin, E.S.; Berkenpas, M.B.; Frey, H.C.; Chen, C.; McCoy, S.T.; Zaremsky, C.J. Technical Documentation: Integrated Gasification Combined Cycle Systems (IGCC) with Carbon Capture and Storage (CCS). Available online: http://repository.cmu.edu/cgi/viewcontent.cgi?article=1073&context=epp (accessed on 29 February 2016).

- Koiwanit, J.; Piewkhaow, L.; Zhou, Q.; Manuilova, A.; Chan, C.W.; Wilson, M.; Tontiwachwuthikul, P. A life-cycle assessment study of a Canadian post-combustion carbon dioxide capture process system. Int. J. Life-Cycle Assess. 2014, 19, 357–369. [Google Scholar] [CrossRef]

- Saskatchewan Air Quality Modeling Guideline; Saskatchewan Environment Technical Resources Branch: Regina, SK, Canada, 2012.

- Air Monitoring Guideline for Saskatchewan; Saskatchewan Environment Technical Resources Branch: Regina, SK, Canada, 2012.

- Air Quality Assessment Report: Rainy River Gold Project. Available online: http://www.ceaa-acee.gc.ca/050/documents_staticpost/80007/97751/Vol3_AppQ-1_RRP_Final_EA_AQ_Assess.pdf (accessed on 29 February 2016).

- Mokhtar, M.M.; Hassim, M.H.; Taib, R.M. Health risk assessment of emissions from a coal-fired power plant using AERMOD modelling. Process Saf. Environ. Prot. 2014, 92, 476–485. [Google Scholar] [CrossRef]

- Gibson, D.M.; Kundu, S.; Satish, M. Dispersion model evaluation of PM2.5, NOX and SO2 from point and major line sources in Nova Scotia, Canada using AERMOD Gaussian plume air dispersion model. Atmos. Pollut. Res. 2013, 4, 157–167. [Google Scholar] [CrossRef]

- Climate and Weather Term Glossary. Available online: http://www.wrcc.dri.edu/ams/glossary.html (accessed on 29 February 2016).

- Al-Jiboori, M.H.; Al-Draji, A.G. Aerodynamic Surface Roughness Length of Baghdad city. J. Al-Nahrain Univ. 2010, 13, 96–102. [Google Scholar]

- Appendix R: Kemper County IGCC Project Hazardous Air Pollutant Risk Screening Analyses. Available online: https://www.netl.doe.gov/File%20Library/Library/Environmental%20Policy/eis%20kemper%20draft/19_Appendix-R.pdf (accessed on 29 February 2016).

- SNC-Lavalin Inc. From Engineering to Procurement to Construction of the Boundary Dam Carbon Capture System. In Proceedings of SaskPower CCS Consortium 2013 Information & Planning Symposium, Regina, SK, Canada, 21–23 May 2013.

- Govin, R.; Shah, J. Modeling and Simulation of An Entrained Flow Coal Gasifier. AIChE J. 1984, 30, 79–91. [Google Scholar] [CrossRef]

- Christou, C.; Hadjipaschalis, I.; Poullikkas, A. Assessment of integrated gasification combined cycle technology competitiveness. Renew. Sustain. Energy Rev. 2008, 12, 2459–2471. [Google Scholar] [CrossRef]

- Fiaschi, D.; Lombardi, L. Integrated Gasifier Combined Cycle Plant with Integrated CO2-H2S and Removal: Performance Analysis, Life-Cycle Assessment and Exergetic Life-Cycle Assessment. Int. J. Appl. Thermodyn. 2002, 5, 13–24. [Google Scholar]

- Kohl, A.L.; Nielsen, R.B. Gas Purification, 5th ed.; Gulf Publishing Company: Houstun, TX, USA, 1997. [Google Scholar]

- Zhu, Y. Evaluation of Gas Turbine and Gasifier-based Power Generation System. PhD. Thesis, North Carolina State University, Raleigh, NC, USA, 2004. [Google Scholar]

- Zhu, Y.; Frey, H.C. Simplified Performance Model of Gas Turbine Combined Cycle System. J. Energy Eng. 2007, 133, 82–90. [Google Scholar] [CrossRef]

- Volkart, K.; Bauer, C.; Boulet, C. Life cycle assessment of carbon capture and storage in power generation and industry in europe. Int. J. Greenh. Gas Control 2013, 16, 91–106. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Moisture | % | 35.00 |

| Carbon | % | 41.70 |

| Hydrogen | % | 2.61 |

| Nitrogen | % | 0.79 |

| Sulfur | % | 0.54 |

| Ash | % | 9.47 |

| Oxygen | % | 9.90 |

| Mercury | ppb | 79.00 |

| Chlorine | ppm | 10.20 |

| Impact Category | Abbreviation | Short Description | Relevant LCI Data | Characterization Factor |

|---|---|---|---|---|

| Global warming potential | GWP | Radiative forcing of atmosphere, causing a temperature rise | CO2, N2O, CH4, SF6, CHCL3, CF4, CFCs, HCFCs, CH3Br | kg CO2-equivalent |

| Acidification potential | AP | Emission of acid-forming substances | SO2, NOx, NH3, HCL, HF, H2S | kg SO2-equivalent |

| Eutrophication potential | EP | Excessive supply of nutrients | NOx, NH3, PO43− | kg N-equivalent |

| Ozone depletion potential | ODP | The relative amount of degradation to the ozone layer | R 11, R 114, R12, and R13 | kg CFC 11-Equivalent |

| Photochemical oxidation potential (Summer smog) | POCP | The complex reactions during the formation of reactive chemical compounds by action of sunlight on primary pollutants | NOx, PAH, NMVOC, CH4 | kg ethylene-equivalent |

| Parameters | PC | PC with Capture | IGCC | IGCC with Capture |

|---|---|---|---|---|

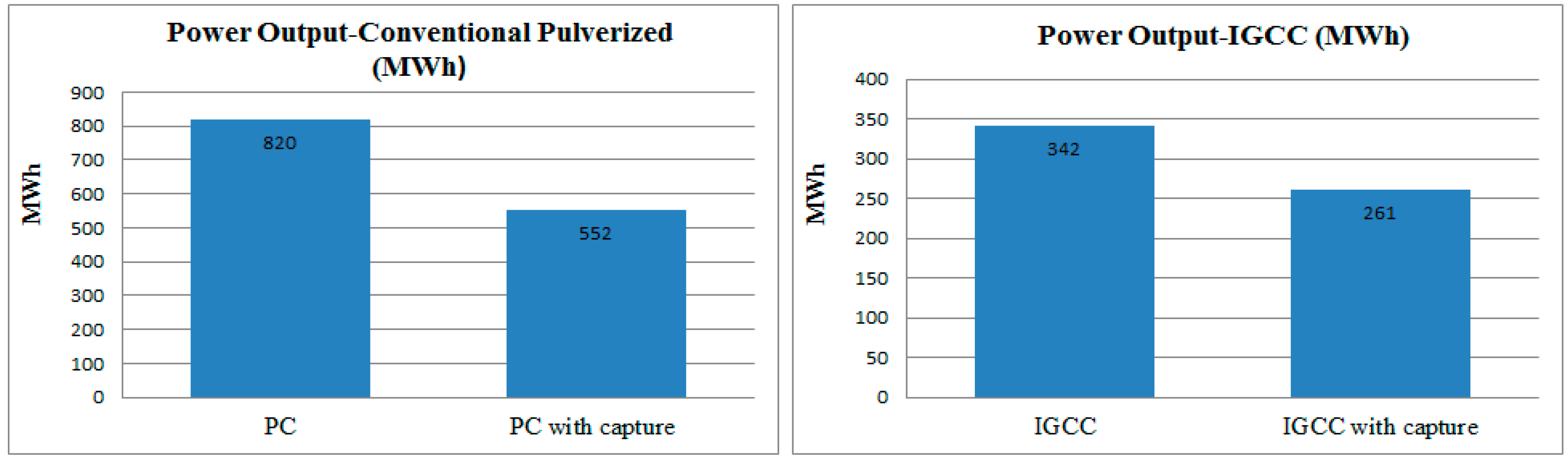

| Net Electricity Output (MW) | 820 | 552 | 342 | 261 |

| Stack Height (m) | 92 | 55 | 99.06 | 99.06 |

| Stack Diameter (m) | 5.18 | 3 | 7.3 | 7.3 |

| Stack Exit Velocity (m/s) | 24.4 | 24.4 | 14.02 | 14.02 |

| Exit Gas Temperature (K) | 436.15 | 340 | 373.7 | 373.7 |

| Emission rate (g/s) per MWh | ||||

| NO2 | 3.1 × 10−2 | 3.7 × 10−2 | 2.2 × 10−2 | 1.9 × 10−2 |

| SO2 | 1.8 × 10−2 | 1.42 × 10−3 | 2.6 × 10−2 | 2.9 × 10−2 |

| PM2.5 | 2.4 × 10−2 | 1.9 × 10−2 | 2.3 × 10−2 | 1.4 × 10−2 |

| As | 1.2 × 10−2 | 2.09 × 10−4 | 8.33 × 10−7 | 1.43 × 10−8 |

| Cd | 1.1 × 10−3 | 2.42 × 10−4 | 5.94 × 10−8 | 7.0 × 10−9 |

| Cr | 1.6 × 10−2 | 7.06 × 10−5 | 1.44 × 10−8 | 6.11 × 10−12 |

| Hg | 1.3 × 10−3 | 1.29 × 10−6 | 1.39 × 10−7 | 1.39 × 10−11 |

| Mn | 1.2 × 10−3 | 1.42 × 10−6 | 1.83 × 10−7 | 3.11 × 10−9 |

| Sb | 1.1 × 10−3 | 2.28 × 10−7 | 7.22 × 10−8 | 1.44 × 10−9 |

| Co | 1.9 × 10−3 | 1.92 × 10−6 | 4.03 × 10−8 | 4.03 × 10−9 |

| Cu | 6.4 × 10−4 | 3.89 × 10−6 | 1.53 × 10−7 | 3.06 × 10−9 |

| Pb | 8.3 × 10−3 | 1.25 × 10−5 | 1.08 × 10−6 | 1.62 × 10−8 |

| Mo | 1.1 × 10−2 | 2.11 × 10−5 | 8.89 × 10−9 | 1.78 × 10−10 |

| Se | 1.1 × 10−1 | 2.4 × 10−2 | 2.0 × 10−6 | 9.89 × 10−7 |

| V | 2.4 × 10−2 | 4.06 × 10−5 | 3.14 × 10−6 | 6.28 × 10−8 |

| Ni | 1.6 × 10−1 | 5.64 × 10−4 | 2.94 × 10−7 | 7.36 × 10−9 |

| Parameter | Value |

|---|---|

| Ambient Pressure (psia) | 14.7 (101.35 kPa) |

| Ambient Temperature (K) | 288 |

| Compressor Pressure Ratio | 15.7 |

| Combustor Pressure Drop (psia) | 4 (27.5 kPa) |

| Turbine Backpressure (psia) | 2 (13.8 kPa) |

| Turbine Inlet Temperature (K) | 1600 |

| Turbine Inlet Reference Mass flow (kg/s) | 455 |

| Cooling Air Extraction Fraction (%) | 12 |

| Nitrogen Injection (%) | 70 |

| Nitrogen/Syngas molar ratio | 0.6–0.8 |

| Adiabatic Compressor Efficiency | 0.77 |

| Adiabatic Turbine Efficiency | 0.87 |

| Shaft/generator Efficiency | 0.98 |

| Steam Cycle Heat Rate (106 J/kWh, LHV) | 9.653 |

| HRSG Outlet Temperature (K) | 386 |

| Process | Parameter | Value |

|---|---|---|

| ASU | Type and number of ASU | One cryogenic separation train |

| O2 purity | 95% | |

| Excess Nitrogen Injection | 70% | |

| Gasification | Type and number of Gasifier | One oxygen-blow GE gasifier |

| Gasifier temperature, °C | 1250 | |

| Gasifier pressure, Mpa | 6 | |

| Steam input to gasifier, mol H2O/mol C | 0.54 | |

| Oxidant pressure (at outlet of ASU), MPa | 4 | |

| Particulate removal efficiency from syngas,% | 50 | |

| AGR | COS to H2S conversion efficiency, % | 96 |

| H2S removal sufficiency, % | 98 | |

| COS removal efficiency, % | 40 | |

| Sulfur recovery system | Claus plant and Bravon-Stretford tail gas unit | |

| Sulfur recovery efficiency, % | 95 | |

| CO2 capture | Steam added to shift reactor, mol H2O/mol CO converted | 1 |

| CO2 removal efficiency, % | 95 | |

| Combined cycle electricity output | Combined cycle electricity output, MW net | 342.41 (without CO2 capture), |

| 261.22 (with CO2 capture) |

| Syngas Compositions (% by Volume) | IGCC without Pre-Combustion CO2 Capture | IGCC with Pre-Combustion CO2 Capture (95% CO2 Removal) | |

|---|---|---|---|

| AR+N2 | 5.53 | 6.55 | |

| O2 | 0.36 | 0.75 | |

| CH4 | 0.4 | 0.45 | |

| CO2 | 53.63 | 7.66 | |

| H2S | 0.02 | 0.02 | |

| H2 | 12.62 | 68.05 | |

| CO | 27.62 | 13.07 | |

| H2O | 1.73 | 3.03 | |

| Total | 100 | 100 | |

| H2/CO | 0.45 | 5.22 | |

| Fuel heating value (HHV) (J/g) | 47,915.4 | 53,665.3 | |

| Gas turbine power output | 202.45 | 184.60 | |

| Steam turbine power output (MWh) | 252.34 | 241.1 | |

| Combined cycle power output (MWgross) | 454.79 | 425.7 | |

| Misc. Power Block Use (MW) | 11.35 | 9.60 | |

| Air Separation Unit Use(MW) | 77.09 | 76.77 | |

| Gasifier Use (MW) | 14.24 | 14.39 | |

| Sulfur Capture Use (MW) | 5.90 | 6.47 | |

| Claus Plant Use (MW) | 0.49 | 0.51 | |

| Beavon-Stretford Use (MW) | 1.49 | 1.55 | |

| WGS and Selexol Use (MW) | - | 49.5 | |

| Net electricity output (MWnet) | 342 | 261 | |

| Plant Efficiency (%) | 64.63 | 49.3 | |

| Parameter | Value | ||

|---|---|---|---|

| MEA concentration in sorbent, % | 30 | ||

| Lean sorbent CO2 loading, mole CO2/mole MEA | 0.2 | ||

| Temperature of the flue gas entering the CO2 absorber, °C | 50 | ||

| Desired CO2 product pressure, psig | 2000 (13.8 MPa) | ||

| MEA losses, kg MEA/tonne CO2 | 1.3607 | ||

| Reclaimer waste, kg/tonne CO2 captured | 3.2 | ||

| Activated carbon consumption, kg C/tonne CO2 captured | 0.075 | ||

| Caustic consumption, kg NaOH/tonne CO2 captured | 0.13 | ||

| Ammonia formation, kg NH3/tonne CO2 | 0.136 | ||

| Water consumption, tonne/MWh | 1.1 | ||

| Sorbent regeneration heat requirement, kJ/kg | 3600 | ||

| Enthalpy of steam, kJ/kg steam | 2000 | ||

| Reboiler efficiency, % | 85 | ||

| Steam requirement, kg/MWh | 2045 | ||

| Parameter | ESP * | FGD ** | CO2 Capture and Compression |

| Particulates removal efficiency, % | 99 | 70 | 50 |

| CO2 removal efficiency, % | - | - | 90 |

| SO2 removal efficiency, % | - | 99 | 99.5 |

| SO3 removal efficiency, % | 25 | 50 | 99.5 |

| HCl removal efficiency, % | - | 90 | 95 |

| NO2 removal efficiency, % | - | - | 25 |

| Hg2+ removal efficiency, % | 7.5 | 25 | 80 |

| Auxiliary power requirements, % MWgross | 6.9 *** | 3.8 | 34.6 |

| Substance | Averaging Period | Ambient Background Concentration (μg/m3) | Limited Ambient Air Quality Standard (μg/m3) | AERMOD Results of Maximum Predicted Ground Level Concentration (μg/m3) per MW Net Electricity | |||

|---|---|---|---|---|---|---|---|

| PC | PC with Capture | IGCC | IGCC with Capture | ||||

| NO2 | One-hour | 2.2 × 10−2 | 400 | 3.1 × 10−2 | 1.3 × 10−1 | 2.3 × 10−2 | 2.1 × 10−2 |

| Daily | 2.0 × 10−2 | 200 | 2.9 × 10−3 | 1.4 × 10−2 | 2.5 × 10−3 | 2.2 × 10−3 | |

| Annual | 1.0 × 10−2 | 100 | 6.1 × 10−4 | 9.6 × 10−4 | 1.7 × 10−4 | 1.6 × 10−4 | |

| SO2 | One-hour | 3.0 × 10−3 | 450 | 1.8 × 10−2 | 4.9 × 10−3 | 2.8 × 10−2 | 3.0 × 10−2 |

| Daily | 2.0 × 10−3 | 150 | 1.7 × 10−3 | 5.5 × 10−4 | 2.9 × 10−3 | 3.2 × 10−3 | |

| Annual | 0 | 30 | 3.5 × 10−4 | 4.0 × 10−5 | 2.1 × 10−4 | 2.2 × 10−4 | |

| PM2.5 | Daily | 8.3 | 30 | 2.3 × 10−4 | 7.5 × 10−3 | 2.6 × 10−3 | 1.6 × 10−3 |

| Annual | 3.7 | 15 | 2.0 × 10−5 | 5.0 × 10−4 | 1.8 × 10−4 | 1.1 × 10−4 | |

| As | Daily | - | 0.3 | 1.6 × 10−4 | 8.0 × 10−5 | 0 | 0 |

| Cd | Daily | - | 2 | 1.1 × 10−4 | 9.0 × 10−5 | 0 | 0 |

| Cr | Daily | - | 1.5 | 1.5 × 10−3 | 3.0 × 10−5 | 0 | 0 |

| Hg | Daily | - | 2 | 1.3 × 10−3 | 0 | 0 | 0 |

| Mn | Daily | - | 0.15 | 1.1 × 10−4 | 0 | 0 | 0 |

| Sb | Daily | - | 25 | 1.1 × 10−4 | 0 | 0 | 0 |

| Co | Daily | - | 0.1 | 1.8 × 10−4 | 0 | 0 | 0 |

| Cu | Daily | - | 50 | 6.0 × 10−5 | 0 | 0 | 0 |

| Pb | Daily | - | 0.5 | 7.8 × 10−4 | 0 | 0 | 0 |

| Mo | Daily | - | 120 | 9.9 × 10−5 | 1.0 × 10−4 | 0 | 0 |

| Se | Daily | - | 10 | 1.1 × 10−2 | 9.1 × 10−3 | 0 | 0 |

| V | Daily | - | 2 | 2.3 × 10−3 | 0 | 0 | 0 |

| Ni | Daily | - | 0.2 | 1.5 × 10−3 | 2.2 × 10−4 | 0 | 0 |

| Substance | Averaging Period | Ambient Background Concentration (μg/m3) | Limited Ambient Air Quality Standard (μg/m3) | AERMOD Results of Maximum Predicted Ground Level Concentration Including Ambient Background Concentration (μg/m3) Per MW Net Electricity | |||

|---|---|---|---|---|---|---|---|

| PC | PC with Capture | IGCC | IGCC with Capture | ||||

| NO2 | One-hour | 2.2 × 10−2 | 400 | 5.3 × 10−2 | 1.5 × 10−1 | 4.5 × 10−2 | 4.3 × 10−2 |

| Daily | 2.0 × 10−2 | 200 | 2.3 × 10−2 | 3.4 × 10−2 | 2.2 × 10−2 | 2.2 × 10−2 | |

| Annual | 1.0 × 10−2 | 100 | 1.1 × 10−2 | 1.1 × 10−2 | 1.0 × 10−2 | 1.0 × 10−2 | |

| SO2 | One-hour | 3.0 × 10−3 | 450 | 2.0 × 10−2 | 7.9 × 10−3 | 3.1 × 10−2 | 3.3 × 10−2 |

| Daily | 2.0 × 10−3 | 150 | 3.7 × 10−3 | 2.6 × 10−3 | 4.9 × 10−3 | 5.2 × 10−3 | |

| Annual | 0 | 30 | 3.5 × 10−4 | 4.0 × 10−5 | 2.1 × 10−4 | 2.2 × 10−4 | |

| PM2.5 | Daily | 8.3 | 30 | 8.30023 | 8.30752 | 8.30259 | 8.30158 |

| Annual | 3.7 | 15 | 3.70002 | 3.70050 | 3.70018 | 3.70011 | |

| As | Daily | - | 0.3 | 1.15 × 10−4 | 8.0 × 10−4 | 0 | 0 |

| Cd | Daily | - | 2 | 1.1 × 10−4 | 9.0 × 10−5 | 0 | 0 |

| Cr | Daily | - | 1.5 | 1.54 × 10−3 | 3.0 × 10−5 | 0 | 0 |

| Hg | Daily | - | 2 | 1.3 × 10−3 | 0 | 0 | 0 |

| Mn | Daily | - | 0.15 | 1.1 × 10−4 | 0 | 0 | 0 |

| Sb | Daily | - | 25 | 1.1 × 10−4 | 0 | 0 | 0 |

| Co | Daily | - | 0.1 | 1.8 × 10−4 | 0 | 0 | 0 |

| Cu | Daily | - | 50 | 6.0 × 10−5 | 0 | 0 | 0 |

| Pb | Daily | - | 0.5 | 7.8 × 10−4 | 0 | 0 | 0 |

| Mo | Daily | - | 120 | 9.9 × 10−4 | 1.0 × 10−5 | 0 | 0 |

| Se | Daily | - | 10 | 1.1 × 10−2 | 9.1 × 10−3 | 0 | 0 |

| V | Daily | - | 2 | 2.3 × 10−3 | 0 | 0 | 0 |

| Ni | Daily | - | 2 | 1.5 × 10−3 | 2.2 × 10−4 | 0 | 0 |

| Substance | Averaging Period | AERMOD Results of Maximum Predicted Ground Level Concentration Including Ambient Background Concentration (μg/m3) Per MW Net Electricity | Maximum Prediction Location | |||

|---|---|---|---|---|---|---|

| PC | PC with Capture | IGCC | IGCC with Capture | |||

| NO2 | One-hour | 5.3 × 10−2 | 1.5 × 10−1 | 4.5 × 10−2 | 4.3 × 10−2 | 2000 meters, 140 degrees, SW of the facility |

| Daily | 2.3 × 10−2 | 3.5 × 10−2 | 2.2 × 10−2 | 2.2 × 10−2 | 2000 meters, West of the facility | |

| Annual | 1.1 × 10−2 | 1.1 × 10−2 | 1.0 × 10−2 | 1.0 × 10−2 | 2000 meters, 140 degrees, SE of the facility | |

| SO2 | One-hour | 2.0 × 10−2 | 7.9 × 10−3 | 3.1 × 10−2 | 3.3 × 10−2 | 2000 meters, 130 degrees, SW of the facility |

| Daily | 3.7 × 10−3 | 2.6 × 10−2 | 4.9 × 10−3 | 5.2 × 10−3 | 2000 meters, West of the facility | |

| Annual | 3.5 × 10−4 | 4.0 × 10−5 | 2.1 × 10−4 | 2.2 × 10−4 | 2000 meters, 140 degrees, SE of the facility | |

| PM2.5 | Daily | 8.30023 | 8.30752 | 8.30259 | 8.30158 | 2000 meters, West of the facility |

| Annual | 3.70002 | 3.70050 | 3.70018 | 3.70011 | 2000 meters, 140 degrees, SE of the facility | |

| As | Daily | 1.2 × 10−4 | 8.0 × 10−5 | 0 | 0 | 2000 meters, West of the facility |

| Cd | Daily | 1.1 × 10−4 | 9.0 × 10−5 | 0 | 0 | 2000 meters, West of the facility |

| Cr | Daily | 1.5 × 10−3 | 3.0 × 10−5 | 0 | 0 | 2000 meters, West of the facility |

| Hg | Daily | 1.3 × 10−3 | 0 | 0 | 0 | 2000 meters, West of the facility |

| Mn | Daily | 1.1 × 10−4 | 0 | 0 | 0 | 2000 meters, West of the facility |

| Sb | Daily | 1.1 × 10−4 | 0 | 0 | 0 | 2000 meters, West of the facility |

| Co | Daily | 1.8 × 10−4 | 0 | 0 | 0 | 2000 meters, West of the facility |

| Cu | Daily | 6.0 × 10−5 | 0 | 0 | 0 | 2000 meters, West of the facility |

| Pb | Daily | 7.8 × 10−4 | 0 | 0 | 0 | 2000 meters, West of the facility |

| Mo | Daily | 9.9 × 10−4 | 1.0 × 10−5 | 0 | 0 | 2000 meters, West of the facility |

| Se | Daily | 1.1 × 10−2 | 9.1 × 10−3 | 0 | 0 | 2000 meters, West of the facility |

| V | Daily | 2.3 × 10−3 | 0 | 0 | 0 | 2000 meters, West of the facility |

| Ni | Daily | 1.5 × 10−3 | 2.2 × 10−4 | 0 | 0 | 2000 meters, West of the facility |

| Substance | Averaging Period | Ambient Background Concentration (μg/m3) | Limited Ambient Air Quality Standard (μg/m3) | AERMOD Results of Maximum Predicted Ground Level Concentration Including Ambient Background Concentration (μg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PC | % of Criteria | PC with Capture | % of Criteria | IGCC | % of Criteria | IGCC With Capture | % of Criteria | ||||

| NO2 | One-hour | 2.2 × 10−2 | 400 | 25.0400 | 6.3% | 70.0320 | 17.5% | 8.0110 | 2.0% | 5.5108 | 1.4% |

| Daily | 2.0 × 10−2 | 200 | 2.3898 | 1.2% | 7.9522 | 4.0% | 0.8610 | 0.4% | 0.5994 | 0.3% | |

| Annual | 1.0 × 10−2 | 100 | 0.5102 | 0.5% | 0.5399 | 0.5% | 6.8 × 10−2 | 0.1% | 5.2 × 10−2 | 0.1% | |

| SO2 | One-hour | 3.0 × 10−3 | 450 | 14.5330 | 3.2% | 2.7022 | 0.6% | 9.4830 | 2.1% | 7.8878 | 1.8% |

| Daily | 2.0 × 10−3 | 150 | 1.3796 | 0.9% | 0.3056 | 0.2% | 1.0000 | 0.7% | 0.8345 | 0.6% | |

| Annual | 0 | 30 | 0.2870 | 1.0% | 2.2 × 10−2 | 0.1% | 7.1 × 10−2 | 0.2% | 5.7 × 10−2 | 0.2% | |

| PM2.5 | Daily | 8.3 | 30 | 8.4886 | 28.3% | 12.4510 | 41.5% | 9.1850 | 30.6% | 8.7123 | 29.0% |

| Annual | 3.7 | 15 | 3.7164 | 24.8% | 3.9760 | 26.5% | 3.7610 | 25.1% | 3.7287 | 24.9% | |

| As | Daily | - | 0.3 | 9.4 × 10−2 | 31.4% | 4.4 × 10−2 | 14.7% | 0 | 0.0% | 0 | 0.0% |

| Cd | Daily | - | 2 | 9.0 × 10−2 | 4.51% | 4.9 × 10−2 | 2.48% | 0 | 0.0% | 0 | 0.0% |

| Cr | Daily | - | 1.5 | 1.2628 | 84.2% | 1.7 × 10−2 | 1.1% | 0 | 0.0% | 0 | 0.0% |

| Hg | Daily | - | 2 | 1.0438 | 52.2% | 0 | 0.0% | 0 | 0.0% | 0 | 0.0% |

| Mn | Daily | - | 0.15 | 9.0 × 10−2 | 60.1% | 0 | 0.0% | 0 | 0.0% | 0 | 0.0% |

| Sb | Daily | - | 25 | 9.0 × 10−2 | 0.36% | 0 | 0.0% | 0 | 0.0% | 0 | 0.0% |

| Co | Daily | - | 0.1 | 0.1476 | 147.6% | 0 | 0.0% | 0 | 0.0% | 0 | 0.0% |

| Cu | Daily | - | 50 | 4.9 × 10−2 | 0.098% | 0 | 0.0% | 0 | 0.0% | 0 | 0.0% |

| Pb | Daily | - | 0.5 | 0.6396 | 127.9% | 0 | 0.0% | 0 | 0.0% | 0 | 0.0% |

| Mo | Daily | - | 120 | 0.8118 | 0.6% | 5.0 × 10−3 | 0.004% | 0 | 0.0% | 0 | 0.0% |

| Se | Daily | - | 10 | 8.7658 | 87.66% | 5.0450 | 50.45% | 0 | 0.0% | 0 | 0.0% |

| V | Daily | - | 2 | 1.8778 | 93.9% | 0 | 0.0% | 0 | 0.0% | 0 | 0.0% |

| Ni | Daily | - | 0.2 | 1.2400 | 620% | 0.1214 | 60.7% | 0 | 0.0% | 0 | 0.0% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piewkhaow, L.; Manuilova, A.; Chan, C.W.; Wilson, M.; Tontiwachwuthikul, P. Environmental Performance of Hypothetical Canadian Pre-Combustion Carbon Dioxide Capture Processes Using Life-Cycle Techniques. Technologies 2016, 4, 9. https://doi.org/10.3390/technologies4010009

Piewkhaow L, Manuilova A, Chan CW, Wilson M, Tontiwachwuthikul P. Environmental Performance of Hypothetical Canadian Pre-Combustion Carbon Dioxide Capture Processes Using Life-Cycle Techniques. Technologies. 2016; 4(1):9. https://doi.org/10.3390/technologies4010009

Chicago/Turabian StylePiewkhaow, Lakkana, Anastassia Manuilova, Christine W. Chan, Malcolm Wilson, and Paitoon Tontiwachwuthikul. 2016. "Environmental Performance of Hypothetical Canadian Pre-Combustion Carbon Dioxide Capture Processes Using Life-Cycle Techniques" Technologies 4, no. 1: 9. https://doi.org/10.3390/technologies4010009

APA StylePiewkhaow, L., Manuilova, A., Chan, C. W., Wilson, M., & Tontiwachwuthikul, P. (2016). Environmental Performance of Hypothetical Canadian Pre-Combustion Carbon Dioxide Capture Processes Using Life-Cycle Techniques. Technologies, 4(1), 9. https://doi.org/10.3390/technologies4010009