1. Introduction

The increasing demand for energy efficiency, material sustainability, and high-quality output in modern manufacturing has intensified the focus on production tool maintenance, particularly in the field of injection molding [

1,

2]. Mold tools are critical assets in mass-production sectors such as automotive, aerospace, consumer goods, and medical devices, where part quality and cycle time are tightly linked to mold condition. Over time, the repeated use of these tools leads to contamination from polymer residues, additives, mold release agents, and thermal degradation byproducts [

3]. This buildup compromises the surface integrity and dimensional precision of molded parts, increases demolding forces, and accelerates tool wear [

4,

5]. Therefore, maintaining clean mold cavities is essential not only for ensuring part quality but also for extending tool life and supporting continuous production.

Cleaning techniques for injection molding tools have evolved over decades, yet many still rely on methods that interrupt production and carry significant operational or environmental trade-offs [

6,

7]. Manual cleaning is the most commonly employed method due to its low entry cost and flexibility. Operators typically use brushes or abrasives combined with solvent-based cleaners to remove surface contaminants. However, this method is labor-intensive, inconsistent in results, and often requires complete disassembly of the mold tool. The prolonged downtime associated with manual intervention significantly reduces production efficiency. To address these challenges, chemical cleaning methods using solvent-based or aqueous solutions have been developed to dissolve polymer residues and additives more consistently and with reduced reliance on manual labor [

8]. Solvent-based agents are effective for a broad range of polymers including epoxies and thermoplastics, but they pose safety and environmental hazards [

9]. Prolonged exposure to volatile organic compounds (VOCs) can endanger worker health, and strict regulations require controlled disposal and ventilation [

10,

11,

12]. Aqueous-based cleaners are safer and environmentally preferred but typically require elevated temperatures and extended immersion times to achieve adequate performance, which limits their practicality for rapid, inline maintenance [

13,

14]. In contrast, thermal cleaning methods such as oven pyrolysis and induction heating apply high temperatures more directly and intensively to decompose organic buildup in shorter time frames, though they introduce their own set of challenges [

15,

16]. Although effective, these methods risk introducing thermal fatigue to the mold surface, leading to microcracks or surface oxidation. They also require dismounting and remounting of tools, which adds risk of alignment errors and process variability. Moreover, the energy input required for thermal cleaning is substantial, making it an undesirable option for frequent use [

17,

18].

Mechanical cleaning approaches like dry ice blasting, plastic media blasting, and bead blasting are non-chemical alternatives that aim to physically dislodge contaminants. Dry ice blasting is valued for its non-abrasive nature and minimal residue. However, it lacks effectiveness against stubborn, chemically bonded residues and may struggle with fine features or deep cavities [

19,

20,

21]. More aggressive media like glass beads can clean more thoroughly but introduce the risk of surface erosion, requiring post-treatment polishing. Among non-contact techniques, ultrasonic cleaning offers a powerful alternative due to its ability to penetrate complex geometries [

22,

23,

24]. It relies on the generation of high-frequency acoustic waves in a fluid medium, creating cavitation microbubbles that collapse near the tool surface [

25]. These collapses generate localized high-pressure jets capable of dislodging contaminants without mechanical abrasion. Traditional ultrasonic cleaning, however, demands that the mold tool be fully immersed in a bath, which again necessitates tool removal and disassembly [

26]. This limits its utility for inline or high-frequency cleaning applications. Across all conventional approaches, the core limitation remains the interruption of production. Taking a mold tool offline for cleaning introduces production losses, labor requirements, and requalification delays. Furthermore, the frequent handling and reassembly of precision molds increase the likelihood of surface damage, wear, and human error. There is a growing industrial demand for a solution that minimizes manual labor, reduces solvent and energy usage, maintains surface quality, and integrates directly into the production line without requiring tool removal.

This work focuses on the Resin Transfer Molding (RTM) process, a subcategory of injection molding widely used for producing fiber-reinforced composite parts [

27]. In RTM, dry fiber preforms are placed into a closed mold cavity, and a liquid thermoset resin is injected under pressure to impregnate the fibers and form a consolidated part [

28]. The process relies heavily on vacuum sealing and precise surface conditions to ensure complete resin infiltration and high part quality [

29,

30]. Even small amounts of residue near sealing edges or on cavity surfaces can compromise vacuum integrity, disrupt resin flow, and lead to defects or incomplete parts.

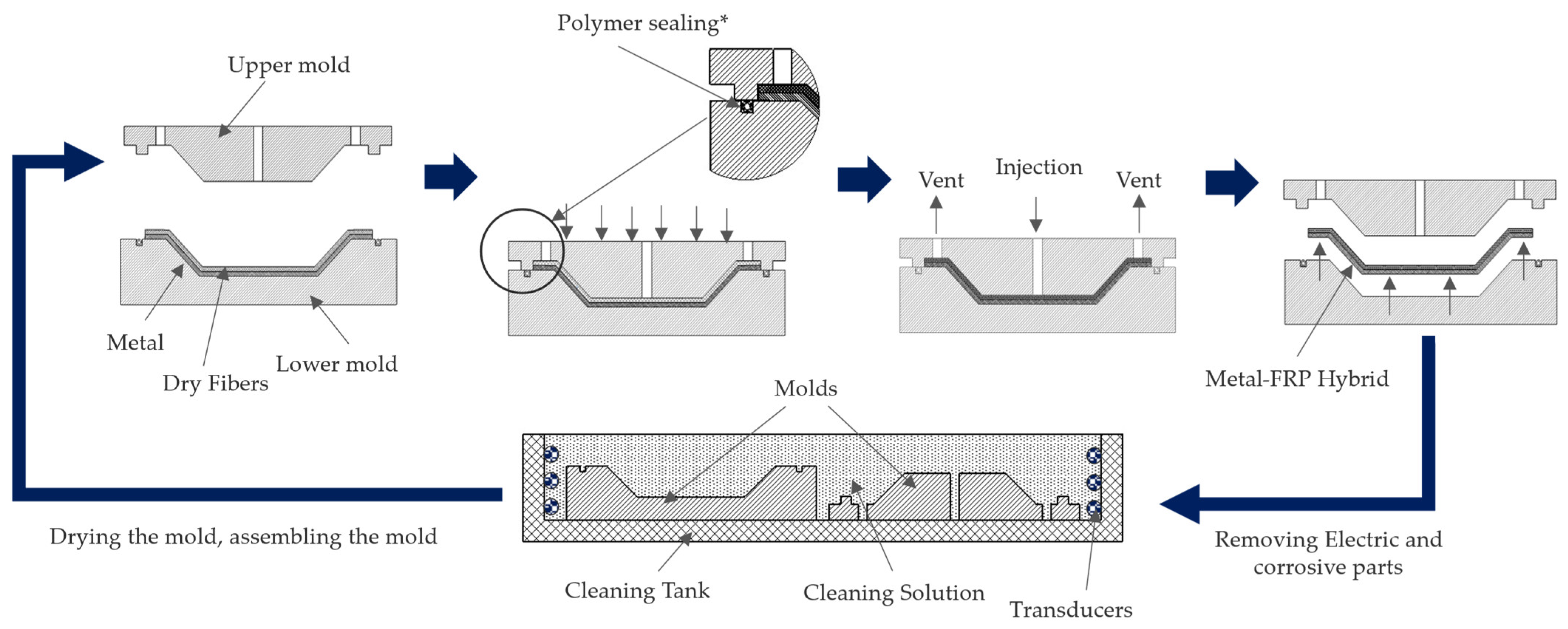

Figure 1 illustrates the complete RTM production cycle, highlighting the integration of cleaning after a predefined number of production cycles. In the conventional approach, this involves fully dismantling the mold from the press, performing an external cleaning process, reassembling the tool, and then resuming production. To address these challenges, this work introduces a localized ultrasonic cleaning method designed for in situ use within RTM mold tools.

3. Results

Surface roughness (R

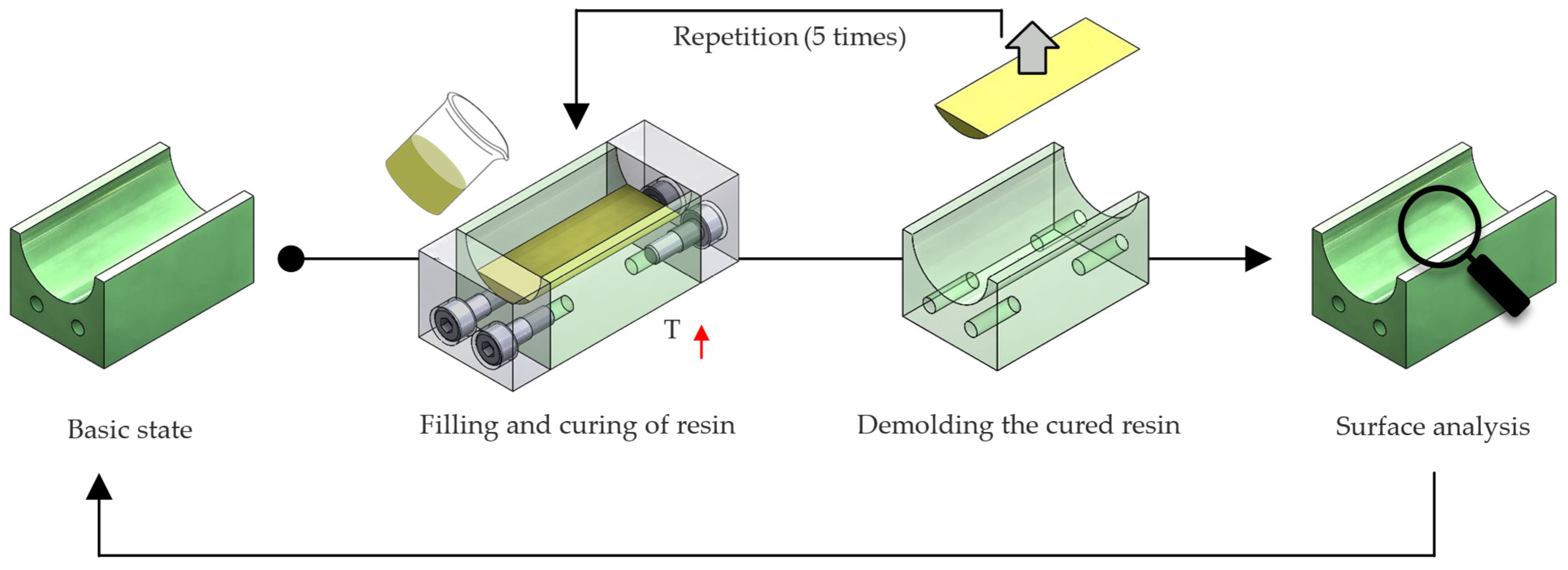

a) was used as a quantitative indicator of contamination buildup in RTM tooling under two processing temperatures: 120 °C and 250 °C. Surface roughness measurements were performed using a MarSurf M 310 portable profilometer (Mahr GmbH, Wiesbaden, Germany) equipped with a PHT 6-350 stylus probe. The device provides high-resolution 2D profile data and is suitable for both flat and curved technical surfaces, making it well-suited for on-site evaluation of mold cavities. Five mold insert geometries were investigated, each representing a typical cavity feature commonly found in RTM tools. These included a bent profile (Type A), cylindrical surface (Type B), S-shaped profile (Type C), sealing notch (Type D), and a drilled injection point (Type E). Each insert was subjected to 15 molding cycles, and R

a was measured at five predefined surface positions after cycles 0, 5, 10, and 15. The influence of both resin type and the use of internal release agents were evaluated. At 120 °C, four material configurations were tested, combining epoxy and polyester systems with and without internal release agents. For the higher-temperature study at 250 °C, only epoxy-based systems were examined, based on their stronger tendency to accumulate surface contamination observed in the earlier phase.

Figure 6,

Figure 7,

Figure 8 and

Figure 9 show the results at 120 °C. Among these,

Figure 6 illustrates epoxy systems with internal release agent (Type 1). Surface roughness increased steadily across all geometries, with final R

a values between 3.5 µm and 11.6 µm. The most stable geometries were Types A and C, where gradual surface profiles and better flow helped delay buildup. In contrast, the drilled injection point geometry, represented by sample E1, showed the highest roughness increase. R

a rose from an initial 2.33 µm to 11.61 µm by the 15th cycle, indicating a strong tendency for resin buildup in enclosed or hard-to-reach cavity regions.

In

Figure 7, the epoxy without internal release agent (Type 2) shows significantly faster and more uneven contamination. E2 reached a final R

a of 19.31 µm from a starting point of 2.25 µm, a 758% increase. Similarly, for B2, the cylindrical geometry, R

a rose from 2.45 µm to 9.25 µm. These results confirm that epoxy exhibits stronger chemical bonding to the tool surface and that release agents play a critical role in mitigating this effect. Standard deviations for these samples also increased noticeably, indicating patchy and inconsistent contamination.

Figure 8 presents the performance of polyester systems with internal release agents (Type 3). While overall trends mirrored those of the epoxy samples, R

a values remained lower throughout the 15-cycle test. For example, E3 finished at 9.58 µm and B3 at 6.75 µm, both significantly below their epoxy counterparts. The difference is attributed to polyester’s lower viscosity, reduced chemical bonding, and slower thermal degradation under these conditions. In

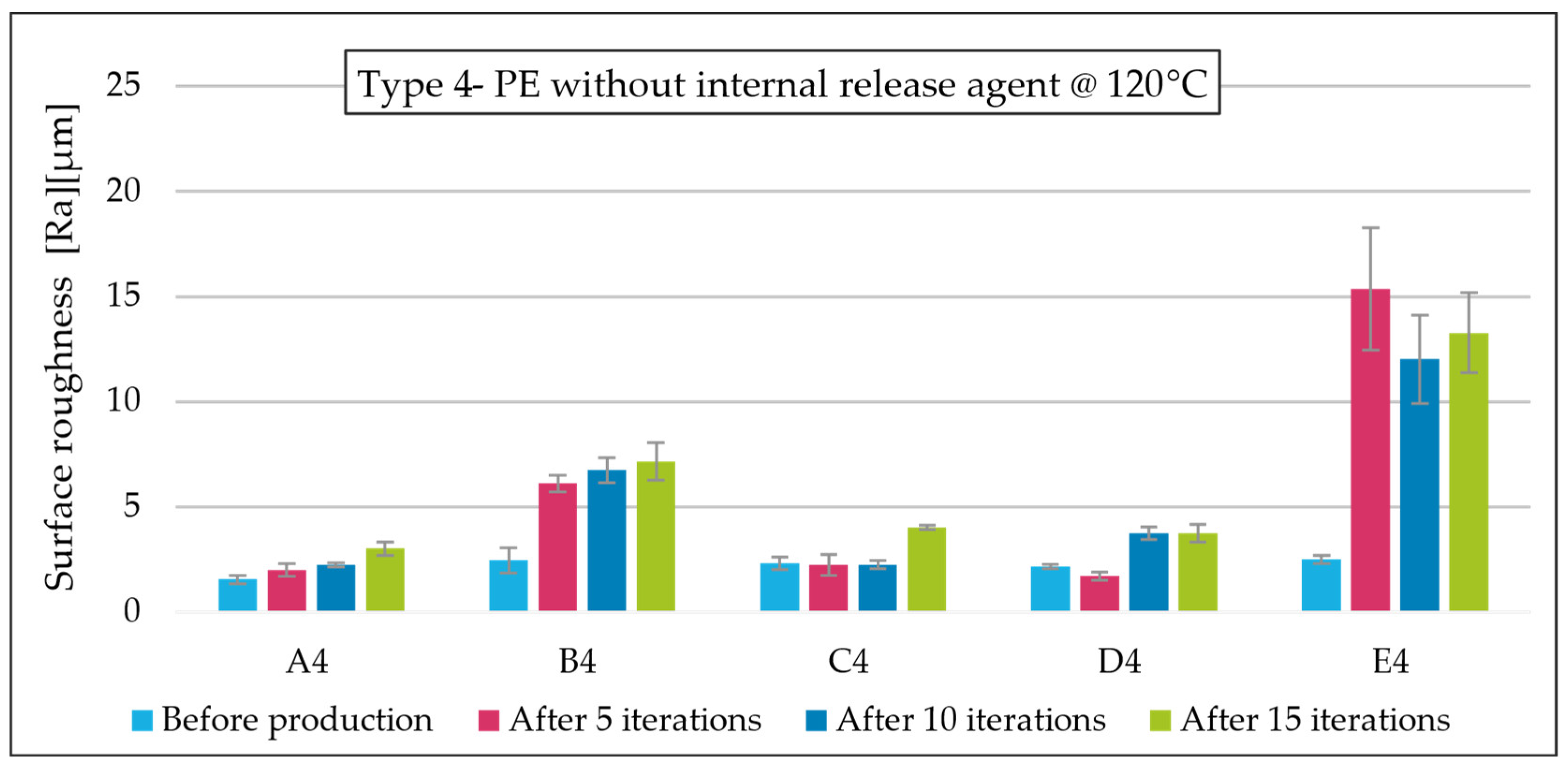

Figure 9, the polyester without release agent (Type 4) showed greater roughness growth than Type 3, but still remained less aggressive than the epoxy. Notably, E4 increased from 2.51 µm to 13.27 µm (a 428% increase), indicating that even polyester systems can lead to critical contamination in high-risk zones if no release agent is used. In contrast, geometries like C4 and D4 stayed below 4.0 µm, reinforcing that open contours and sealing regions are more manageable under controlled flow.

To investigate contamination behavior under elevated temperature conditions, only epoxy-based systems were selected for testing at 250 °C, as epoxy is more widely used in high-performance applications and exhibits greater surface degradation than polyester at 120 °C.

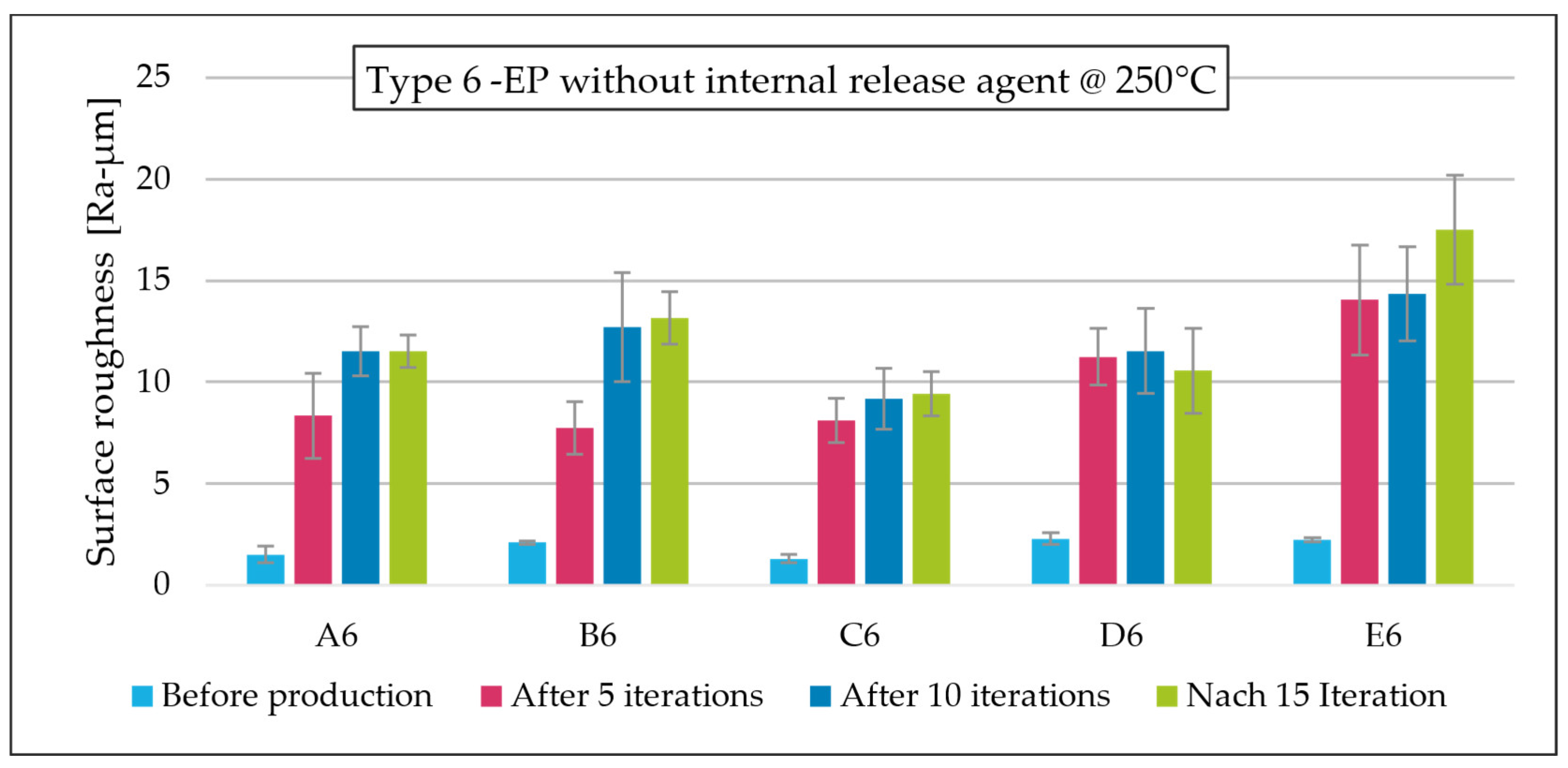

Figure 10 and

Figure 11 summarize the R

a evolution at this elevated temperature across all five geometries, comparing epoxy with (Type 5) and without (Type 6) internal release agents. In the bent geometry (A5 and A6), roughness increased steeply beyond 8 µm in both cases, with A6 rising from 1.53 µm to 11.51 µm: a 652% increase. This confirms that higher thermal energy accelerates crosslinking and residue formation, even in geometries that previously showed more stable behavior at 120 °C. Cylindrical geometry (B6) reached a peak of 13.16 µm, with particularly sharp growth between cycles 5 and 10, indicating a likely contamination threshold that should inform future cleaning intervals. For S-profile cavities (C5 and C6), final R

a values converged near 9.4 µm, suggesting that even open geometries are prone to thermal residue buildup under repeated exposure. Sealing notch geometries (D5 and D6) followed a moderate increase, ending slightly above 10 µm, and exhibited only small differences between configurations. This may be due to mechanical entrapment, where narrow grooves inhibit both flow and cleaning, reducing the release agent’s effectiveness. The most critical results were again found in the injection point geometry. Sample E6, without release agent, increased from 2.25 µm to 17.51 µm, representing the steepest R

a increase (678%) of the entire dataset. E5 also reached a high value of 13.25 µm, confirming that even release agent application cannot prevent thermal fouling in enclosed and drilled geometries. This highlights the cumulative effect of thermal exposure, cavity shape, and chemical protection on surface roughness progression. In addition, according to the material datasheet, exposure to 250 °C induces degradation and post-curing effects in thermoset epoxies, including excessive viscosity reduction, breakdown of adhesion promoters, and possible surface oxidation, all of which diminish interfacial bonding and contribute to easier resin detachment during demolding.

Across both temperatures, contamination buildup was highly geometry-dependent. Enclosed and concave surfaces such as those in Types B and E experienced greater fouling(contamination), while more gradual profiles (Types A and C) allowed for improved resin flow and agent coverage, resulting in lower roughness progression. Additionally, standard deviations increased consistently with cycle count, especially in geometries without release agents, supporting the hypothesis of uneven and uncontrolled surface contamination. These variations are critical for part quality, as they can lead to inconsistent demolding forces and poor surface finish. Release agents were effective in reducing both the magnitude and variability of increase in surface roughness, particularly at 120 °C. However, their performance decreased significantly at 250 °C, where epoxy showed strong affinity for the tool surface regardless of chemical separation. This behavior reinforces the need for targeted, geometry-specific in situ cleaning strategies particularly focused on high-risk zones such as injection ports and cylindrical features.

In addition to the roughness measurements, compression-shear tests were conducted to examine how surface changes over repeated cycles affect the force required to demold the resin from the steel surface. To assess how surface contamination affects demolding, compression-shear tests were carried out using a custom fixture. The test setup included a steel punch and a holding device with a cut-out that kept the specimen in place using four side walls and a screw. This fixture was mounted inside a universal testing machine, with a force sensor installed above the punch to measure the force needed to separate the resin from the steel. The testing speed was set to 0.2 mm/min. The complete setup and the recorded force curves are shown in

Figure 12. The force curve for the epoxy sample with internal release agent shows a regular pattern, but the overall level of force stays about the same over all cycles. This means that the demolding effort remained stable throughout. For the epoxy sample without release agent, the demolding force increased steadily from cycle 1 to cycle 9. This suggests that the bond between the resin and steel became stronger with each cycle, likely due to increasing contamination on the tool surface. After the 10th cycle, the force values stayed at about the same level as before and followed a similar pattern to the sample with a release agent. In the third sample, which was also made without an internal release agent but cured at 250 °C, no significant force was recorded. The resin detached very easily from the steel without any noticeable resistance. This indicates that at higher temperatures, the resin may not bond as strongly to the steel surface, possibly due to changes in the material near the contact area caused by the heat. Overall, the results show that demolding forces are higher when curing is performed at lower temperatures and when no release agent is used. Higher curing temperatures seem to reduce the bonding between the resin and the mold surface, making it easier to separate.

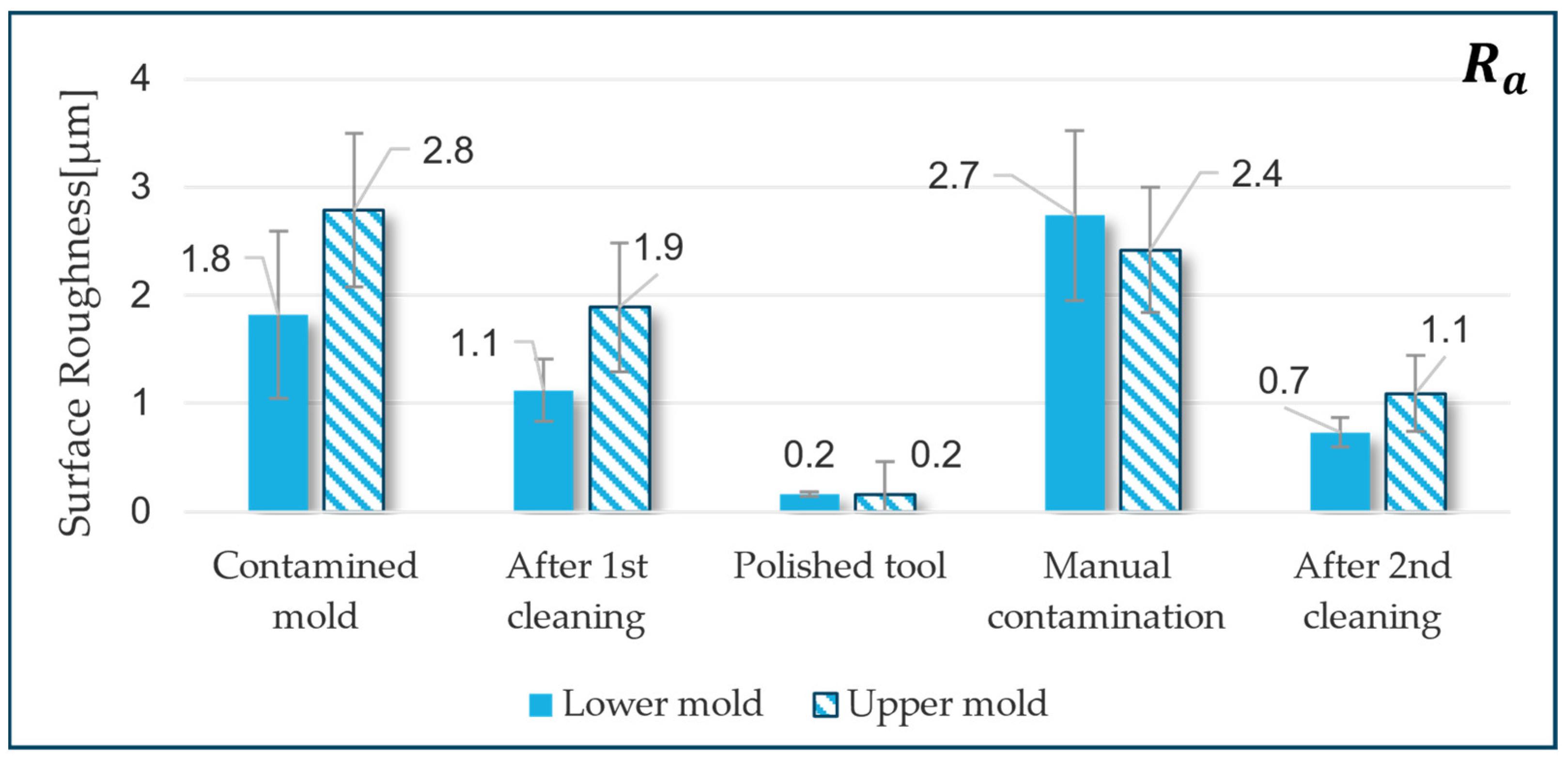

After analyzing surface roughness and demolding behavior in earlier trials, the localized ultrasonic cleaning method was applied to a full-scale RTM tool to evaluate its cleaning performance under realistic production conditions. Surface roughness was measured at 20 fixed locations across both the lower and upper mold halves, and average values were tracked throughout five key process stages. The evolution of surface conditions is summarized in

Figure 13. It is also evident that the surface roughness measured directly on the RTM tool remained lower than those observed in the earlier insert-based trials, indicating that large-scale cavity surfaces may accumulate contamination less aggressively than localized or complex geometries. Initial contamination levels were higher on the upper mold half (2.8 µm) compared to the lower mold half (1.8 µm), likely due to reduced contact with cleaning fluid in upward-facing areas and greater exposure to evaporative loss. After the first cleaning iteration using a citric acid–acetone solution with continuous ultrasonic activation, roughness decreased to 1.1 µm on the lower mold and 1.9 µm on the upper mold. Although both surfaces showed improvement, the difference highlighted the need for better solution coverage and vapor control in the upper cavity region.

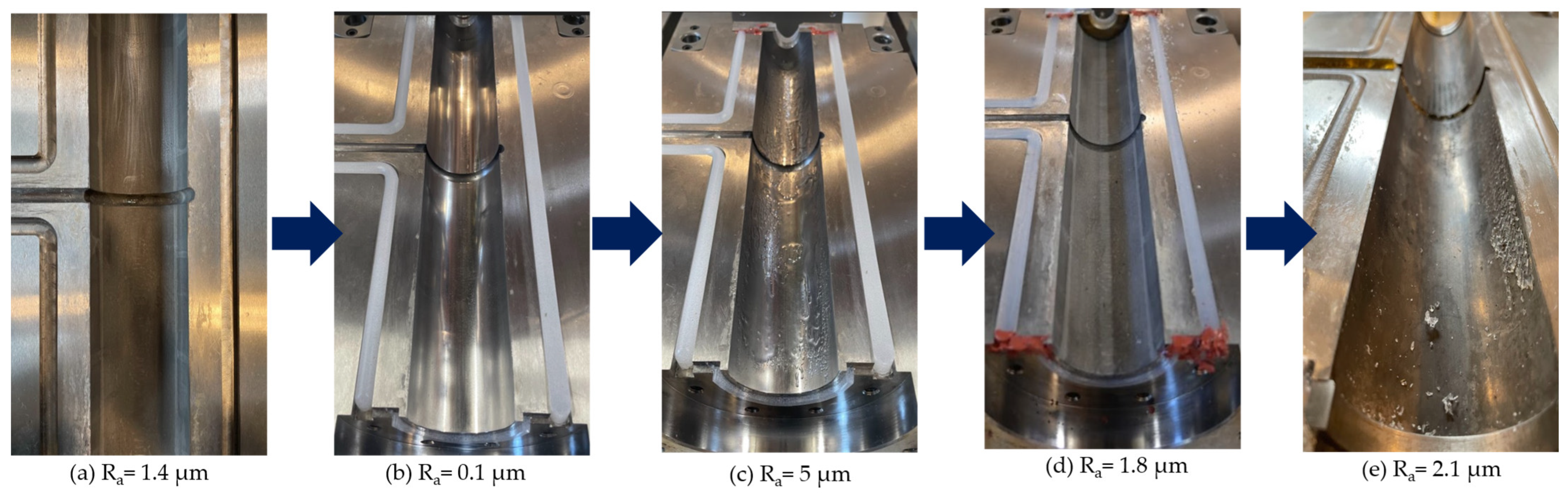

Both mold halves were then repolished, and an additional fine polishing stage was applied to further improve the tool surface, reducing the roughness from the original D1 finish (~2 µm) down to approximately 0.2 µm (A3 finish). To replicate mid-cycle contamination, the cavity was manually coated with resin instead of running a full series of molded parts. Roughness values after this step rose to 2.7 µm for the lower mold and 2.4 µm for the upper mold, reflecting typical buildup observed during RTM processing. It should be noted, however, that this manual contamination approach introduces a deviation compared to actual processing conditions, particularly due to the absence of injection pressure. During normal RTM operation, the resin is introduced under a pressure of approximately 5 bar, which promotes uniform wetting and penetration along the flow front. In contrast, manual application lacks this pressure-driven gradient, especially near the injection zone, potentially altering the local resin–tool interaction. A second cleaning iteration was then carried out using an optimized strategy. This involved switching to a benzyl alcohol–water solution, reducing ultrasonic power to 50%, and activating cavitation in three 1 min intervals separated by 10 min pauses. This method aims to preserve tool integrity while maintaining cleaning effectiveness. The lower mold surface improved to 0.7 µm and the upper mold to 1.1 µm. While slightly higher than the post-polish condition, these results confirm a successful cleaning effect with reduced energy input. The cleaning setup is illustrated in

Figure 14, showing the lower tool over the various stages. To verify whether post-polishing could be avoided, a hybrid shaft was molded directly after the second cleaning. While the part was successfully produced, some minor surface adhesion was observed during demolding, indicating that polishing might still be beneficial under the current conditions.

Figure 15 shows the results of a supplementary interlaminar shear test conducted on the produced steel-composite shaft. During demolding of the hybrid shaft produced after the second cleaning cycle, a noticeable resistance was observed, suggesting that internal shear stress may have built up between the metallic and composite layers. To investigate this further, an interlaminar shear strength (ILSS) test was conducted. The molded shaft was sectioned into 20 specimens, each 5 mm wide, and tested using a MTS with a fixture designed to push the metal insert out of the CFRP layer. This setup simulates interfacial stress conditions and allows evaluation of adhesion quality within the hybrid component. The test results revealed a reduction in interlaminar shear strength from 13.9 N/mm

2 (reference sample) to 7.3 N/mm

2 for the cleaned and molded shaft. These results suggest that the demolding forces applied may have contributed to local deformation or disruption within the fiber layers. However, this interpretation remains unverified, as no microscopic characterization was performed to confirm internal damage mechanisms. Future work will include such analyses to verify whether localized fiber–matrix separation or microcracking occurred during the demolding process. Despite the improved surface roughness achieved through cleaning (reduced to below 2.4 µm), the lack of a final polishing step appears to have adversely affected the interfacial adhesion between composite layers. This underscores the importance of incorporating a fine polishing stage to ensure consistent and optimal interface strength in subsequent molding cycles.

4. Discussion

Conventional mold cleaning methods used in Resin Transfer Molding (RTM) rely heavily on manual disassembly and external solvent cleaning, often leading to inconsistent surface quality, long downtimes, and potential tool damage. To address this, a localized ultrasonic cleaning process was proposed, allowing in situ cleaning directly inside the mold cavity without removing the tool from the press. The approach was tested in both laboratory-scale trials and a full-scale industrial mold, focusing on surface roughness changes and cleaning effectiveness.

Laboratory-scale testing was carried out using five representative cavity geometries machined in tool steel, each subjected to up to 15 molding cycles using epoxy and polyester resins at 120 °C and 250 °C. Surface roughness (Ra) was tracked throughout using a contact profilometer. Among the geometries, sharp corners and sealing grooves showed the most rapid roughness increase, validating their vulnerability to contamination buildup. To understand how this surface change impacts mold–part interaction, demolding forces were measured on flat specimens using a shear-compression test setup. Results showed a clear increase in adhesion force with cycle count in samples without internal release agents. In contrast, specimens using release agents exhibited fluctuating behavior due to possible uneven separation layers. At elevated temperatures (250 °C), resin tended to detach too easily without forming a strong bond, suggesting that thermal degradation or surface oxidation may interfere with adhesion.

Building on this understanding, the ultrasonic cleaning process was integrated into a full-size RTM mold designed for producing FRP–metal hybrid cylindrical shafts. This tool included all key cavity types tested earlier and was adapted to accept a compact ultrasonic transducer through a custom insert. Cleaning fluids were circulated through the cavity using the tool’s existing vacuum infrastructure, and internal heating maintained the solution at 70 °C. Initial tool surface roughness before cleaning was ~3.6 µm Ra. After a 30 min ultrasonic cycle using a citric acid–acetone mixture, residue was removed. The tool was polished back to an A3 finish with a surface roughness of 0.2 µm, and, then, the tool was manually contaminated, after which surface roughness increased to ~2.7 µm Ra, a 35% rise due to cumulative buildup. A second cleaning cycle was performed using a benzyl alcohol–water mixture in pulsed mode (3 × 1 min cycles with 10 min intervals at reduced power), which reduced the surface roughness to ~2.1 µm Ra, recovering 22% of the smoothness. However, after producing a final part post-cleaning, roughness increased again to ~2.4 µm Ra, likely due to removal of the polishing paste layer during ultrasonic exposure.

While the results confirm the feasibility of the process, we acknowledge that a direct comparison using identical ultrasonic parameters for both cleaning agents was not performed. Due to time and scheduling constraints during the experimental phase, it was not possible to apply reduced-power pulsed ultrasonic cleaning to the citric acid–acetone mixture. We agree that such a study would help isolate the effect of cleaning chemistry from ultrasonic energy input and will consider this in future work. Additionally, although citric acid is a mild organic acid, its combination with ultrasonic excitation may cause minor pitting or surface etching under prolonged exposure. This behavior was not observed here but will be further investigated in future studies.

Despite these promising results, some limitations must be acknowledged. The current cleaning method is most effective in localized regions and relies on the tool being properly sealed. Due to the low viscosity of the cleaning fluids, any leakage through unsealed contours may reduce cleaning efficiency or pose safety risks. As such, the method is best suited for tools with built-in or well-defined sealing interfaces. Additionally, we did not investigate microscopic damage to fiber layers or subsurface structure during demolding, which remains a topic for future work.

Future developments will focus on improved fluid sealing strategies, integration of programmable ultrasonic cycles, and coupling with roughness or pressure sensors for feedback control. Further investigations are also planned to evaluate long-term tool wear, residue buildup patterns across more complex geometries, and comparative studies using matched ultrasonic parameters for all cleaning agents. To support scalability and industrial integration, future systems may incorporate AI-assisted control logic combined with laser-based surface roughness monitoring. This would enable automated detection of contaminated zones and dynamic adjustment of cleaning parameters. In such systems, cleaning cycles could be initiated autonomously based on real-time surface data, reducing manual intervention and ensuring process consistency. These steps are needed to validate the scalability and robustness of the system under diverse industrial conditions. In conclusion, this study presents a validated concept for in situ ultrasonic cleaning inside an RTM production tool. While the current implementation is a functional prototype, it provides a strong foundation for future development of automated, energy-efficient mold maintenance systems. The results support the potential of this approach to reduce downtime, maintain surface quality, and extend tool life in composite manufacturing.