Abstract

Ocean energy is an abundant, eco-friendly, and renewable energy resource that is useful for powering sensor networks connected to the maritime Internet of Things (MIoT). These sensor networks can be used to measure different marine environmental parameters that affect ocean infrastructure integrity and harm marine ecosystems. This ocean energy can be harnessed through hybrid nanogenerators that combine triboelectric nanogenerators, electromagnetic generators, piezoelectric nanogenerators, and pyroelectric generators. These nanogenerators have advantages such as high-power density, robust design, easy operating principle, and cost-effective fabrication. However, the performance of these nanogenerators can be affected by the wear of their main components, reduction of wave frequency and amplitude, extreme corrosion, and sea storms. To address these challenges, future research on hybrid nanogenerators must improve their mechanical strength, including materials and packages with anti-corrosion coatings. Herein, we present recent advances in the performance of different hybrid nanogenerators to harvest ocean energy, including various transduction mechanisms. Furthermore, this review reports potential applications of hybrid nanogenerators to power devices in marine infrastructure or serve as self-powered MIoT monitoring sensor networks. This review discusses key challenges that must be addressed to achieve the commercial success of these nanogenerators, regarding design strategies with advanced simulation models or digital twins. Also, these strategies must incorporate new materials that improve the performance, reliability, and integration of future nanogenerator array systems. Thus, optimized hybrid nanogenerators can represent a promising technology for ocean energy harvesting with application in the maritime industry.

1. Introduction

Ocean energy is the most abundant renewable energy resource on Earth, with a theoretical energy generation of approximately 151,300 TWh per year, depending on the frequency of extreme environmental conditions [1,2]. The oceans are clean and sustainable energy sources that can be harvested using hybrid nanogenerators composed of triboelectric nanogenerators (TENGs), piezoelectric nanogenerators (PENGs), electromagnetic generators (EMs), or thermoelectric generators (TEGs). These generators can integrate eco-friendly systems to harness and store ocean energy, converting it into electricity [3,4]. Thus, these systems can power device networks connected to the maritime Internet of Things (MIoT) for real-time monitoring of different marine environmental parameters. However, the use of hybrid nanogenerators in oceans involves challenges such as performance stability and mechanical durability that can be affected by corrosion and harsh marine environments. To address these challenges, more research on the reliability of hybrid nanogenerators in oceans is required.

Recently, hybrid nanogenerators have been developed for harvesting wave energy and converting it into electrical energy. In addition, hybrid nanogenerators can function as self-powered sensors to measure environmental or wave parameters [5,6]. For instance, Hu et al. [7] designed a hybrid nanogenerator based on the electromagnetic and triboelectric transduction mechanisms. This nanogenerator harvests wind and wave energies, converting them into electrical energy. The electromagnetic and triboelectric mechanisms have power densities of 50 Wm−3 and 53 mWm−3, respectively. This hybrid nanogenerator offers an alternative power source for environmental monitoring devices. Tang et al. [8] fabricated a multi-mode hybrid generator that consisted of free-standing and contact-separation TENGs, and an electromagnetic generator. This hybrid device achieved a peak power density of 125.41 Wm−3 under a frequency of 0.5 Hz with potential application for self-powered marine sensors. Jia et al. [9] reported a hybrid nanogenerator combining a rotating TENG, two free-standing TENGs, and an EMG for omnidirectional wave energy harvesting. The free-standing TENGs and EMG modules reached a peak power density of 29.92 Wm−3 Hz−1 and 402.08 Wm−3Hz−1, respectively. This nanogenerator integrates a self-powered, real-time ocean currents monitoring buoy system connected to the IoT. This self-adaptive system can estimate the ocean pH, current type, wave direction, and wind direction and speed. Thus, this hybrid system can power distributed device nodes for smart MIoT. Gao et al. [10] developed a hybrid nanogenerator for a smart MIoT network, which incorporated two TENGs, two EMGs, and two PENGs in a vessel. The geometric design of this hybrid device improved its spatial utilization efficiency, reaching a peak power density of 82.4 Wm−3. However, these hybrid nanogenerators require further study to enhance their durability and adaptability to various ocean wave conditions, optimizing wave energy harvesting. Other challenges include maintaining stable performance of the hybrid nanogenerators and ensuring efficient communication within the sensor network.

Herein, we present recent investigations on hybrid nanogenerators that harvest ocean energy and transform it into electrical energy, or function as self-powered MIoT sensors for real-time monitoring of different marine environmental conditions. Furthermore, this review reports the operating principle, materials, electrical performance results, and applications of hybrid nanogenerators in the marine environment. These hybrid devices comprise various TENG, EMG, PENG, and TEG modules. In addition, the advantages and drawbacks of hybrid nanogenerators for ocean wave energy harvesting are discussed. Also, we present various challenges of the hybrid nanogenerators, considering their design, materials, energy storage and management systems, fabrication processes, reliability, and integration. Thus, the optimal design of hybrid nanogenerators can enable their commercial application as an eco-friendly and cost-effective technology for harvesting renewable ocean energy.

2. Operating Principle of Hybrid Nanogenerators

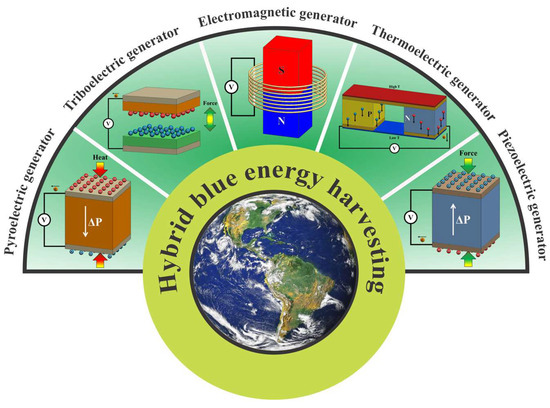

This section describes the operating principles of various transduction mechanisms that can be utilized in hybrid nanogenerators. These transduction modes include the triboelectric nanogenerators, electromagnetic generators, piezoelectric nanogenerators, and thermoelectric generators. The integration of these transduction mechanisms in hybrid nanogenerators can increase the efficiency of the harvested ocean energy. Figure 1 illustrates various transduction modules for ocean energy harvesting.

Figure 1.

Different transduction mechanisms for ocean energy harvesting.

2.1. Triboelectric Nanogenerators

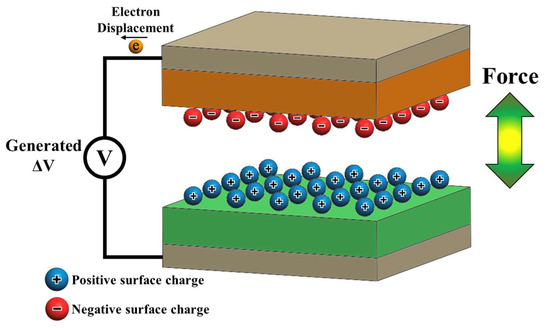

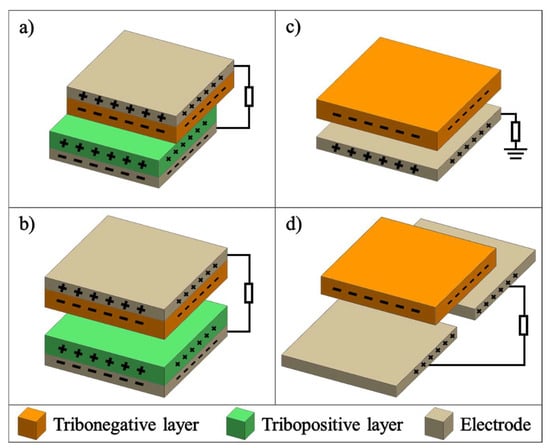

Triboelectric nanogenerators can harvest kinetic energy and convert it into electrical energy. The operating principle of a TENG is based on contact electrification (CE) and electrostatic induction, as shown in Figure 2. TENGs can perform using four transduction modes: contact-separation, side slip, single electrode, and freestanding triboelectric-layer [11,12]. The side–slip mode of a TENG involves the generation of electrical charges between the surfaces of two triboelectric layers by periodic contact and separation (see Figure 3a). Slip-induced lateral polarization facilitates the flow of electrons between the upper and lower electrodes, generating an alternating current. This side–slip mode of TENGs is suitable for harnessing the variable kinetic energy of ocean waves. In contrast, the contact–separation mode of a TENG occurs when two triboelectric layers generate opposite charges upon physical contact (see Figure 3b). Additionally, the variation in the separation distance between the two triboelectric layers induces electrostatic induction, generating an alternating voltage between the two electrodes of the nanogenerator. This contact–separation mode allows simple structural designs for TENGs. On the other hand, the single-electrode mode of a TENG generates an alternating voltage due to the contact–separation of a triboelectric layer with respect to an electrode (see Figure 3c). This operating mode of a TENG can serve as a self-powered sensor. The fourth operating mode of a TENG employs a triboelectric layer that slips between two separate electrodes (see Figure 3d). In this mode, the contact and separation of the triboelectric layer with the electrodes can produce an asymmetric charge distribution that generates a voltage difference between the electrodes.

Figure 2.

Operating mechanism of a triboelectric nanogenerator with two triboelectric layers.

Figure 3.

Four working modes of TENGs: (a) Side–slip mode, (b) contact–separation mode, (c) single-electrode mode, and (d) freestanding triboelectric-layer mode.

2.2. Piezoelectric Nanogenerators

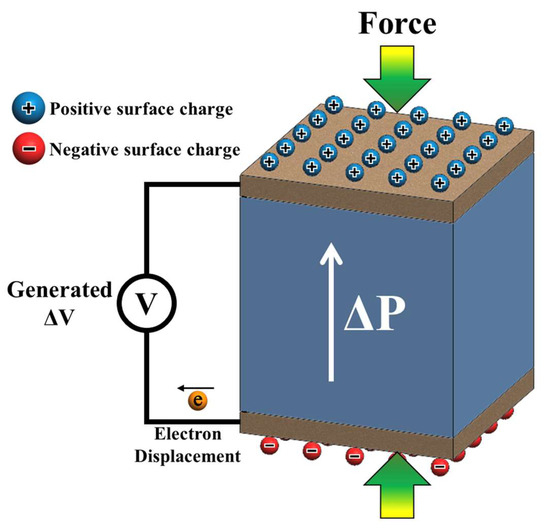

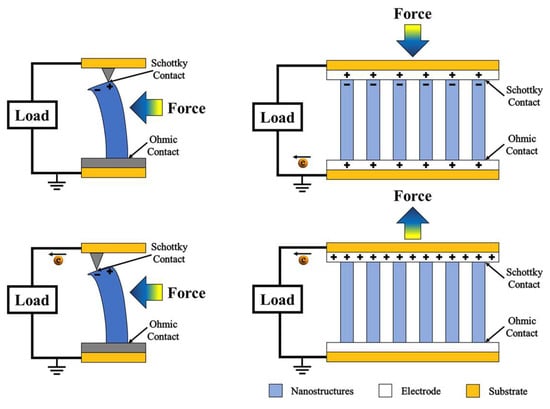

A piezoelectric nanogenerator can produce an output voltage due to the deformation of a piezoelectric material, as shown in Figure 4. Generally, a PENG uses two electrodes that are connected to opposite sides of a piezoelectric material. Due to the piezoelectric effect, a piezoelectric material under external oscillating forces can be deformed, causing an electrical potential differential. Researchers have developed piezoelectric nanogenerators based on materials such as BaTiO3, ZnO, polyvinylidene fluoride (PVDF), and copolymers [13,14,15]. For instance, Figure 5 illustrates a PENG comprising a piezoelectric nanowire and two electrodes. An external oscillating force can be applied in two directions: perpendicular and parallel to the nanowire. In both cases, the upper contact acts as a Schottky contact, while the lower contact functions as an ohmic contact. To optimize the output power of the PENG, it is necessary to integrate several nanowires to ensure that the deformation of each nanowire is synchronized.

Figure 4.

Schematic view of the piezoelectric effect in a PENG.

Figure 5.

Different operating mechanisms of a PENG: (left) force acting perpendicular to the nanowire growth direction and (right) force acting parallel to the nanowire growth direction.

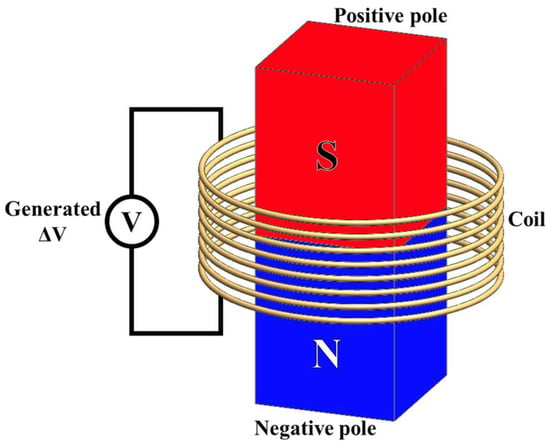

2.3. Electromagnetic Generator

Electromagnetic generators operate according to Faraday’s law of electromagnetic induction (see Figure 6), inducing an electrical potential difference in a coil when it is exposed to a variable magnetic field [16]. For applications in oceans, EMGs may require a structure that converts water flow into rotational energy. The resulting rotational energy is used to move magnets around the coils of an EMG, facilitating electromagnetic induction [17]. These generators are used to harness ocean waves under variations of amplitude and frequency of the waves [18,19]. However, EMGs face challenges in reducing their fabrication costs, volume, and weight, especially when operating on the surface of the oceans. To address these challenges, more investigations are required to enhance the design and fabrication of EMGs that integrate hybrid nanogenerators.

Figure 6.

Operating principle of an electromagnetic generator.

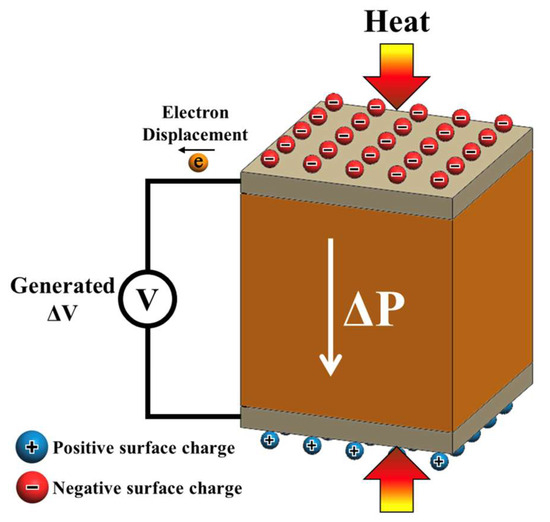

2.4. Pyroelectric Nanogenerator

A pyroelectric nanogenerator (PyNG) can convert thermal energy into electricity through the pyroelectric effect [20,21]. These materials change their electrical polarization in response to temperature shifts, generating an electric current (see Figure 7). Commonly, a PyNG is formed by a multilayer structure. The top layer, composed of metal, is combined with the middle layer of pyroelectric material, which generates an electrical charge in response to temperature variations. These temperature alterations induce the reorganization of the electric dipoles in the crystalline structure of the pyroelectric material, causing an imbalance of charges that produces an electric current. Finally, a second electrode is located at the bottom surface of the PyNG. Zinc oxide (ZnO) and potassium niobate (KNbO3) are two materials commonly used to fabricate pyroelectric nanogenerators. These materials can undergo significant changes in their electrical polarization due to thermal fluctuations, which is essential for the efficient performance of pyroelectric nanogenerators. These nanogenerators can be used to harness ocean wave energy and produce self-powered sensors for monitoring ocean wave parameters. Nevertheless, pyroelectric nanogenerators exhibit low energy conversion and dependence on temperature variation, which may limit their application in some ocean environments [22,23].

Figure 7.

Operating principle of a pyroelectric nanogenerator.

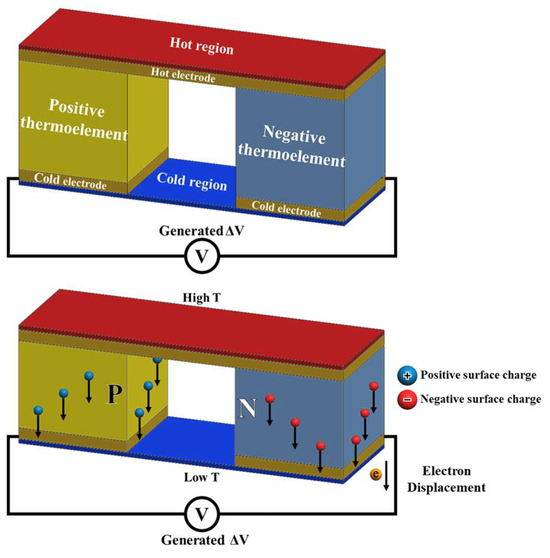

2.5. Thermoelectric Generator

A thermoelectric generator can transform thermal energy into electricity. The operating principle of this generator is based on the Seebeck effect, a thermoelectric phenomenon that generates an electric current in a semiconductor material when a temperature gradient is established across this material [24,25]. Typically, TEGs use n-type and p-type semiconductor materials (see Figure 8). The temperature difference between these materials produces electrical energy. Thermoelectric generators offer advantages such as durability, a simple working principle, and environmental sustainability [26]. However, TEGs have disadvantages such as low efficiency and high-cost fabrication [27,28]. Bismuth telluride and lead telluride are materials employed to fabricate TEGs due to their thermoelectric properties [29,30]. These materials may be useful for harvesting ocean energy and developing self-powered sensors for monitoring ocean environmental parameters. The performance of TEGs can be enhanced when the temperature difference between the outer and bottom surfaces of thermoelectric materials increases.

Figure 8.

Operating principle of a thermoelectric generator.

3. Applications

This section reports several applications in marine environments of recent hybrid nanogenerators integrated by different transduction mechanisms. Furthermore, the design, performance, and limitations of these hybrid nanogenerators are discussed. Also, a comparison of the main performance results, advantages, and disadvantages of hybrid nanogenerators is included.

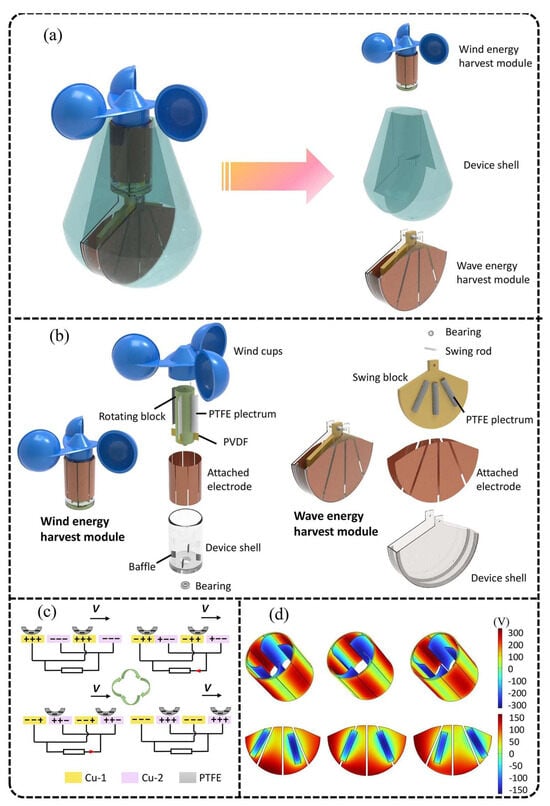

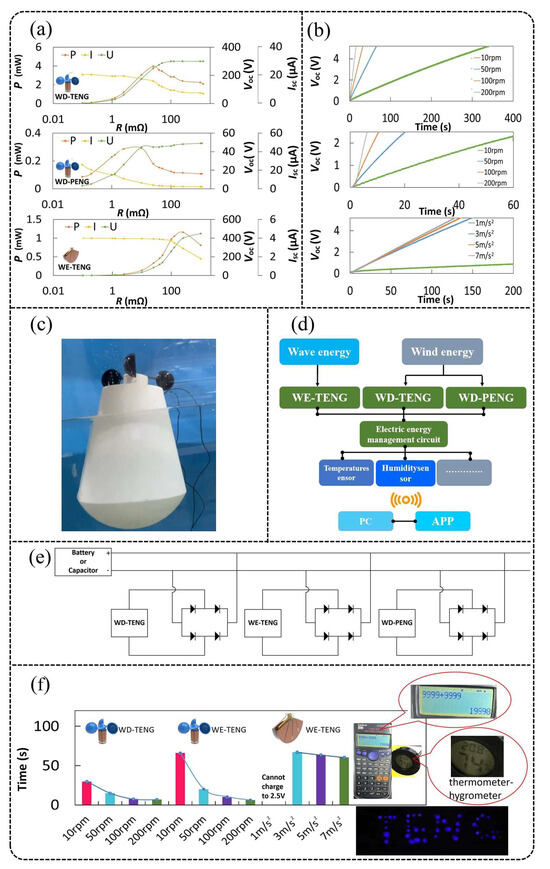

To obtain a comprehensive and systematic overview of recent hybrid nanogenerators for harvesting ocean wave energy, we conducted a search of scientific articles in Scopus journals from 2016 to 2025, using the keywords “Ocean energy” and “Hybrid nanogenerator”. In this literature search, we only considered scientific articles on hybrid nanogenerators with different transduction mechanisms to harness ocean wave energy. Finally, we identified 50 articles with potential applications for ocean wave energy harvesting, which were included in Table 1. In this table, we described the main transduction modules, materials, performance parameters, potential applications, and advantages of the hybrid nanogenerators. These nanogenerators can capture ocean wave energy and transform it into electrical energy. Thus, these nanogenerators could power sensor networks connected to MIoT for real-time monitoring of different environmental conditions, such as temperature, humidity, wind speed, and current direction and speed. Additionally, hybrid nanogenerators can be designed to serve as self-powered sensors, integrated with signal management circuits, for wireless marine data transmission. For instance, Li et al. [31] developed a hybrid nanogenerator composed of TENG and PENG modules, which can harvest energy from both wind and waves (see Figure 9). In addition, an electronic circuit for energy management was incorporated to improve the efficiency of the harvested ocean energy. This nanogenerator has three transduction modules: a wind energy harvesting triboelectric nanogenerator (WD-TENG), a wave energy harvesting triboelectric nanogenerator (WE-TENG), and a wind energy harvesting piezoelectric nanogenerator (WD-PENG). These three modules can be used individually or in combination, as shown in Figure 10. The maximum power densities of WD-TENG, WE-TENG, and WD-PENG modules were 5.064 Wm−3, 1.478 Wm−3, and 1.092 Wm−3, respectively. This hybrid generator was used to power temperature and humidity sensors, as well as LED lights. Also, this hybrid nanogenerator can be connected to the MIoT. This hybrid nanogenerator exhibited versatility to collect energy from waves and wind. Its coupled design allows the integration of the three modules, which can operate independently or collaboratively. However, this nanogenerator has a complex design that requires precise manufacturing. In addition, the performance of the device depends on environmental conditions, such as wind and wave intensity. Thus, the design of this hybrid nanogenerator can be optimized to improve its performance under alterations in wind and wave amplitudes.

Table 1.

Comparison of transduction modules, materials, performance parameters, potential applications, and advantages of recent hybrid nanogenerators.

Figure 9.

Working principle of a hybrid nanogenerator based on the triboelectric and piezoelectric effects for harvesting wind and wave energy [31]. (a) Main components of the hybrid nanogenerator. (b) Components of the wind and wave energy harvesting modules of the hybrid nanogenerator. (c) Operating mode of the triboelectric nanogenerator. (d) Simulation models of the performance of the hybrid nanogenerator. Reprinted with permission from [31]. Copyright ©2023, Elsevier B.V.

Figure 10.

Three modules of the hybrid nanogenerator [31]. (a) Performance of the three modules of the hybrid nanogenerator for harvesting wave and wind energy. (b) Charging results of the three modules of the hybrid nanogenerator using capacitors of 10 μF. (c) Test of the hybrid nanogenerator. (d) Schematic diagram of the three modules of the hybrid nanogenerator. (e) Energy management circuit of the three modules. (f) The calculator and thermometer–hygrometer are powered by a hybrid nanogenerator; the LEDs are also lit by this hybrid device. Reprinted with permission from [31]. Copyright ©2023, Elsevier B.V.

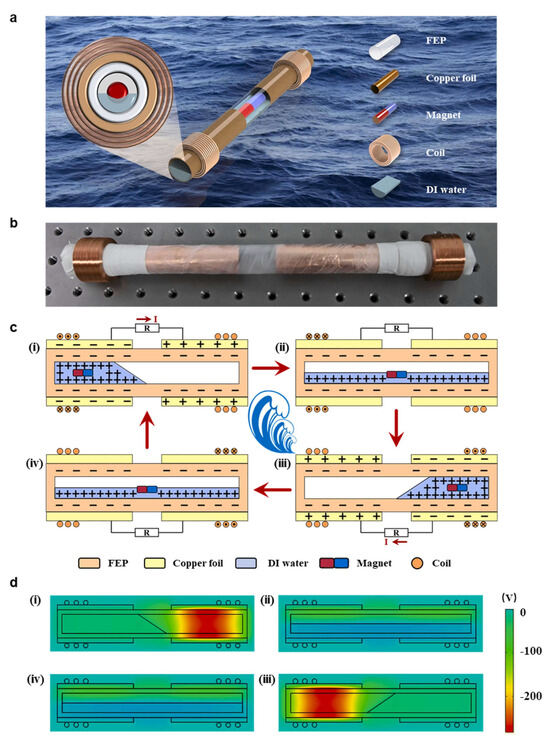

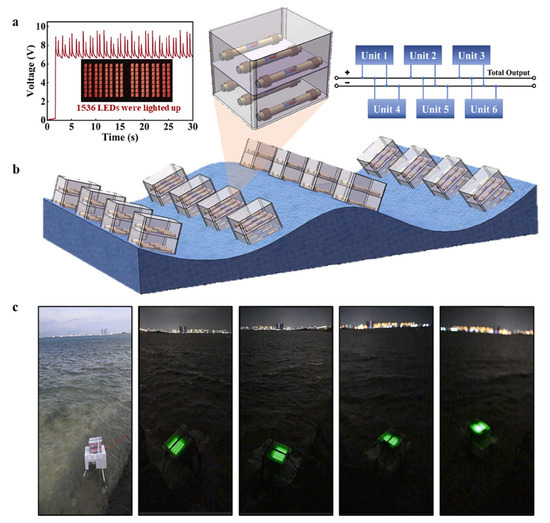

In 2023, Sun et al. [32] proposed a triboelectric–electromagnetic hybrid nanogenerator (TTEHG) to harness wave energy, as shown in Figure 11. This hybrid nanogenerator uses a tube-shaped solid–liquid interface with low friction loss and a wide energy range. This TTEHG achieved an instantaneous power density of 0.25 mWcm−3 and a current density of 5 mAcm−3 at a frequency of 1 Hz. Even at a shallow operating frequency of 0.2 Hz, the TTEHG had a high output performance with a peak current close to 15 mA. This nanogenerator can power temperature and humidity sensors for monitoring marine environmental parameters. Moreover, this hybrid device can be connected to the MIoT. This TTEHG has several advantages, including efficiency in harnessing energy from sea waves, an effective coupled design at the solid–liquid interface, and good performance at a frequency of 1 Hz (Figure 12). On the other hand, this device has a complex design that requires precise manufacturing. Also, the performance of the TTEHG is affected by variations in the wave conditions and water temperature.

Figure 11.

Working mechanism of the hybrid nanogenerator TTEHG [32] for ocean energy harvesting. (a) Design of the components of the TTEHG. (b) Fabricated TTEHG. (c) Schematic diagram of the operating principle of the TTEHG. (d) Voltage results of the FEM models of the TTEHG. Reprinted with permission from [32]. Copyright ©2022, Elsevier B.V.

Figure 12.

Application of the TTEHG as a sustainable energy source to power electronic devices [32]. (a) 1536 LEDs powered using a single TTEHG under a simulated wave at 1.4 Hz. (b) The TTEHG network was designed to harness ocean wave energy. (c) In Sanya Bay, China, the TTEHG was used to light 336 LEDs. Reprinted with permission from [32]. Copyright ©2022, Elsevier B.V.

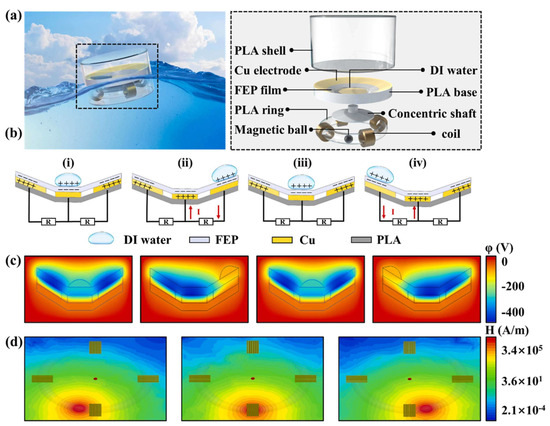

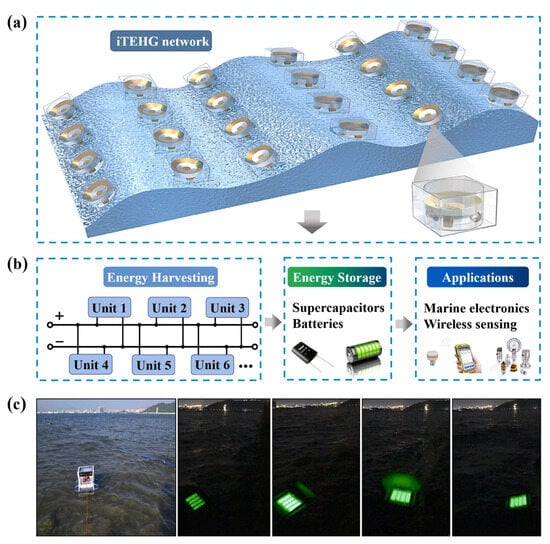

Xu et al. [33] proposed an isotropic triboelectric–electromagnetic-hybrid nanogenerator (iTEHG), as depicted in Figure 13. This device employed a pair of concentric circular electrodes, built on a plate shaped like a tilted parabolic antenna, for the gravity-guided movement of the liquid. The iTEHG was designed using a TENG module and a ring-shaped EMG module to collect the omnidirectional energy from the ocean waves. Both TENG and EMG modules were encapsulated in a self-balancing, waterproof, cylindrical housing. This cylindrical housing protects the hybrid device from external moisture and damage caused by wave impact in a marine environment. The design of the iTEHG addressed problems such as wear and insufficient wave contact, which enhanced its lifetime and control. This device has a power density of 7.25 µWcm−3 with 360° coverage. This iTEHG charged a 0.1 F supercapacitor at 3.1 V and powered a wireless thermometer for 26 min. In addition, the iTEHG harvested ocean wave energy in Sanya Bay, China, and powered 320 LEDs (see Figure 14). This hybrid device has several advantages, such as efficiency in wave energy harvesting, a unique coupled design, and good performance. However, this hybrid nanogenerator has a complex manufacturing process and a dependence on environmental conditions. These limitations of the hybrid device can be solved by optimizing its design.

Figure 13.

(a) Components of the iTEHG were designed to harness ocean wave energy [33]. (b) Operating mechanism of the iTEHG. Results of the FEM models of the (c) TENG module and (d) EMG module. Reprinted with permission from [33]. Copyright ©2023, Elsevier B.V.

Figure 14.

Application of the iTEHG to harvest ocean wave energy [33]. (a) Design of an iTEHG network that can harness ocean wave energy. (b) Self-sufficient ocean monitoring system composed of iTEHGs, supercapacitors, and batteries. (c) Application of the iTEHG to harvest ocean wave energy in Sanya Bay, China. Reprinted with permission from [33]. Copyright ©2023, Elsevier B.V.

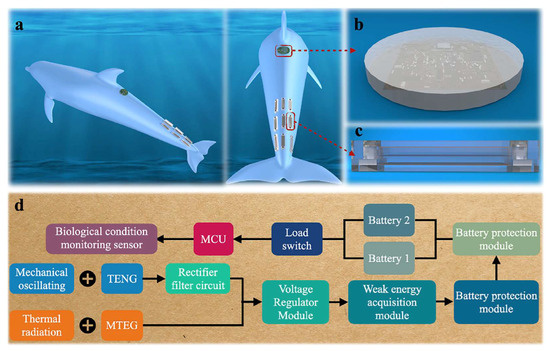

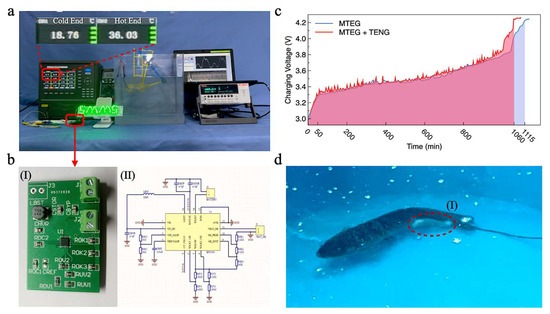

Liu et al. [34] proposed a hybrid nanogenerator composed of an oscillating triboelectric nanogenerator (O-TENG) and a micro thermoelectric generator (MTEG), which was used for monitoring marine mammals (see Figure 15). This hybrid device can harvest energy generated by the movement of marine mammals and the temperature difference between the water surface and the surrounding environment. The performance of the device was improved using a power management unit. The O-TENG and the MTEG reached high open circuit voltages of 5.85 V and 1.821 V, respectively. This device has the capability to monitor marine animals in danger of extinction, incorporating the warm-blooded characteristics of marine mammals and the mechanical energy generated during their movement. The MTEG can harness the biological thermal energy of marine mammals, while the O-TENG harnesses their kinetic energy. Thus, this hybrid nanogenerator can monitor the movement of marine mammals and collect energy from the temperature difference between the water and the surrounding environment (see Figure 16). However, this hybrid nanogenerator presents several challenges, including a complex design, dependence on environmental conditions, and limited efficiency.

Figure 15.

Main components of a self-powered marine mammal condition monitoring system (SMMS) that is integrated with an O-TENG, an EMG, and a power management unit [34]. (a) Potential application of the SMMS. (b) Schematic view of the power management unit. (c) Schematic diagram of a module composed of an O-TENG and an EMG. (d) Schematic diagram of the components and working mechanism of the SMMS. Reprinted with permission from [34]. Copyright ©2023, Elsevier B.V.

Figure 16.

(a) SMMS powered 64 LEDs [34]. (b) A printed circuit board and its circuit. (c) Charging voltage of a battery using the O-TENG and EMG. (d) Application of the SMMS in a real fish. Reprinted with permission from [34]. Copyright ©2023, Elsevier B.V.

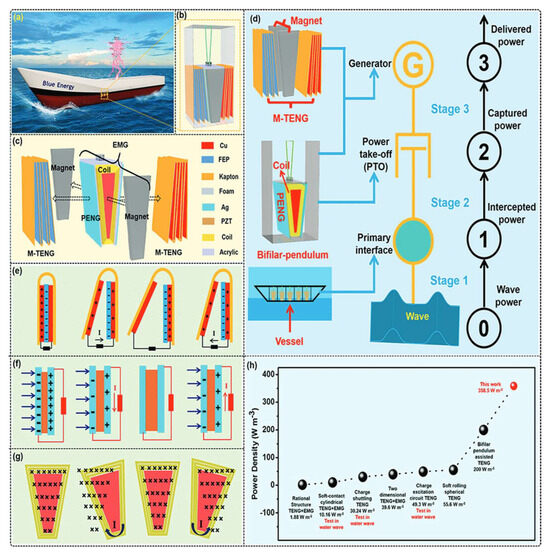

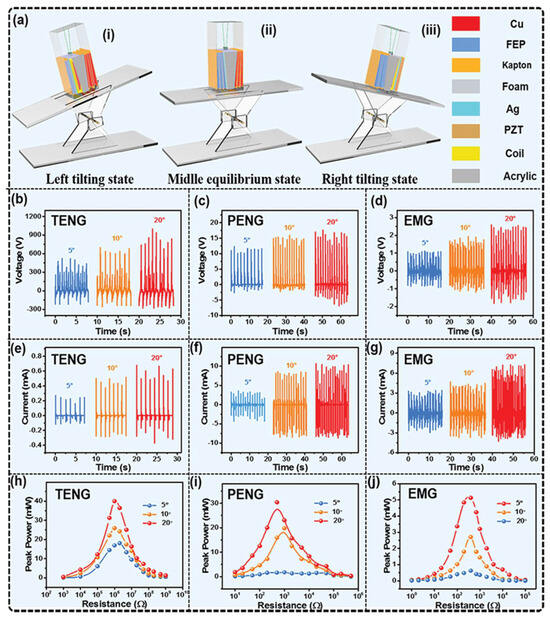

Zhang et al. [35] developed a hybrid nanogenerator coupled to a bifilar pendulum called BCHNG (see Figure 17). This nanogenerator incorporates an EMG module, two PENG modules, and two TENG modules, featuring a multilayer structure that integrates a receiving platform to harness wave energy (see Figure 18). As the BCHNG module is embedded in a vessel, the stable environment within the hull platform can facilitate the maintenance of hybrid devices and ensure long-term stable operation. The spring-damped TENG achieved a maximum power density of 1.88 Wm−3, the cylindrical soft-contact EMG-coupled TENG registered an output performance of 10.16 Wm−3, and the load-shifting TENG reached a power density of 30.24 Wm−3 in the in-water test. In addition, the TENG with a bifilar pendulum generated a power density of 200 Wm−3. The combination of these three transduction modules increased the power generation capacity from the waves, harvesting the kinetic and gravitational inertia energies of the waves. Based on two degrees of freedom of a pendulum oscillation system, this hybrid nanogenerator reported a peak power of 358.5 Wm−3. However, this hybrid nanogenerator has design and weight-related challenges, which decrease its efficiency.

Figure 17.

Operating principle and materials of a hybrid nanogenerator coupled to a bifilar pendulum (BCHNG) used in a vessel [35]. (a) A vessel with a BCHNG. (b) Structural configuration of the BCHNG (c) BCHNG composed of EMG, PENG, and M-TENG modules. (d) BCHNG components included in a vessel to harvest ocean wave energy. Operating principles of (e) triboelectric nanogenerator, (f) piezoelectric generator, and (g) electromagnetic generator. (h) Power densities of the BCHNG and other types of nanogenerators. Reprinted with permission from [35]. Copyright ©2022, Wiley.

Figure 18.

Results of the voltage, current, and power of the BCHNG working in the vertical direction [35]. (a) Operating mechanism of the BCHNG driven by a seesaw. The open-circuit voltage of (b) a triboelectric nanogenerator, (c) a piezoelectric nanogenerator, and (d) an electromagnetic generator, considering three values of seesaw angles. The short-circuit currents of (e) a triboelectric nanogenerator, (f) a piezoelectric nanogenerator, and (g) an electromagnetic generator regarding three values of seesaw angles. The peak power of (h) a piezoelectric nanogenerator, (i) a piezoelectric nanogenerator, and (j) an electromagnetic generator under different seesaw angles. Reprinted with permission from [35]. Copyright ©2022, Wiley.

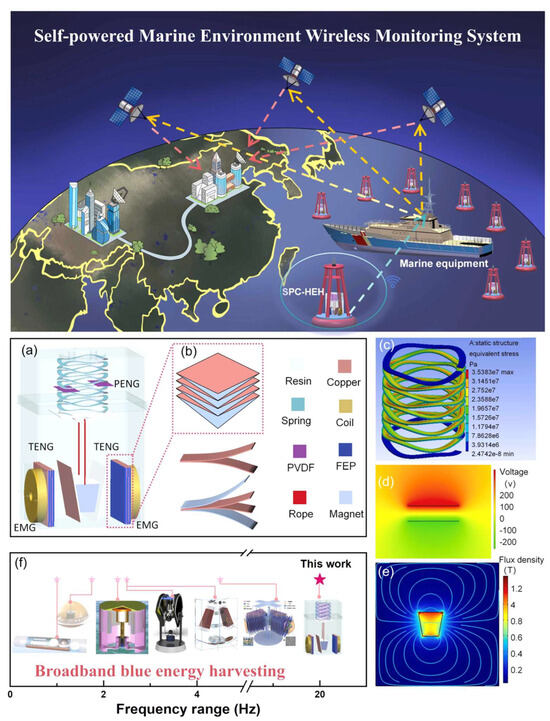

Gao et al. [10] developed a spring-pendulum-coupled hybrid nanogenerator (SPC-HNG) incorporated into a vessel, which was composed of two multilayer-structured triboelectric nanogenerators, two electromagnetic generators, and two piezoelectric nanogenerators (see Figure 19). The design of this hybrid nanogenerator enhanced its capability to harness water wave energy, considering the wave kinetic energy in both horizontal and vertical directions. This hybrid nanogenerator has a wide frequency range between 0.5 Hz and 20 Hz and can reach a peak power density of 82.4 Wm−3. The PENG was formed by a PVDF film and two silver electrodes. Additionally, the EMG is integrated with a trapezoidal magnet and annular coils. Finally, the TENG has an FEP triboelectric layer and copper electrodes. Furthermore, when coupled with a circuit, this nanogenerator can be used as a self-powered ocean buoy that measures ocean parameters, including temperature, wave frequency, and turbidity. This hybrid nanogenerator powered a water quality detector, a hygrometer, and a smart wireless alarm system for real-time monitoring of environmental parameters. Thus, this nanogenerator has potential applications in self-powered smart MIoT networks for measuring environmental parameters and marine investigations.

Figure 19.

Components, operating principle, and potential application of the hybrid nanogenerator SPC-HNG in self-powered smart ocean IoT networks [10]. (a) Modules (TENG, EMG, and PENG) of the hybrid nanogenerator SPC-HNG. (b) Configuration of the TENG module of the SPC-HNG. (c) Stress of an FEM model of the waveform spring. (d) Open-circuit voltage of an FEM model of the TENG module. (e) Magnetic flux density generated by an FEM model of the trapezoidal magnet. (f) Frequency range of the SPC-HNG compared to other nanogenerators. Reprinted with permission from [10]. Copyright ©2024, Elsevier E.V.

Li et al. [36] developed a hydrokinetic turbine-based triboelectric–electromagnetic hybrid generator (HT-TEHG) to harvest ocean current energy in a wide range of flow velocities (see Figure 20). This hybrid device included two TENGs and two EMGs, as well as a helical hydrokinetic turbine. This turbine enabled self-starting performance and adaptive capability to different flow directions. For a flow velocity of 1.0 m/s, this HT-TEHG achieved an average power density of 44.52 Wm−3. The design of this hybrid generator improved its reliability and adaptability for ocean-current energy harvesting to power sensors at MIoT nodes. Moreover, this hybrid device powered 292 LEDs and two temperature and humidity sensors.

Figure 20.

Schematic representation of the application of a hydrokinetic turbine-based triboelectric–electromagnetic hybrid generator (HT-TEHG) [36]. (a) (I) Structural configuration of the HT-TEHG and (II) the application of the hybrid generator for real-time monitoring of marine environmental parameters. (b) Schematic diagram of the triboelectric nanogenerator, considering (I) structural design, (II) rotor, and (III) stator. (c) Schematic view of the electromagnetic generator, regarding (I) structural design, (II) magnet array, and (III) coil array. Reprinted with permission from [36]. Copyright ©2025, Elsevier E.V.

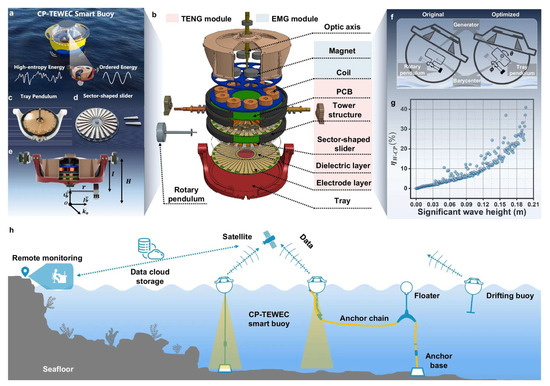

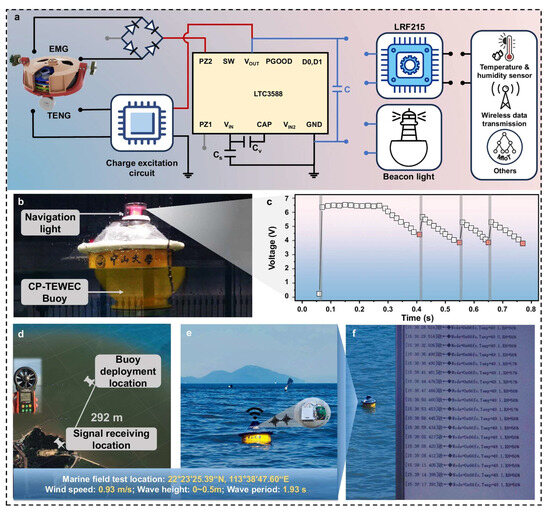

Zhao et al. [37] proposed a hybrid nanogenerator formed by a tower-shaped structure, which integrated a TENG and an EMG (Figure 21). This hybrid device uses a chaotic pendulum mechanism to harvest wave energy. In addition, the tower-shaped structure and charge–excitation circuit improved the harnessed wave energy, with peak power densities of 56.7 Wm−3Hz−1 and 192.3 Wm−3Hz−1 for the TENG and EMG modules, respectively. Thus, the design of this device allowed it to convert high-entropy wave energy into stable mechanical energy, keeping the stability of the system under irregular waves, as shown in Figure 22. Also, this hybrid nanogenerator can power temperature and humidity sensors for real-time marine monitoring. This device has a reliable self-powered operation and can be used for marine monitoring networks connected to MIoT.

Figure 21.

Illustration of the design and application of a hybrid nanogenerator developed by Zhao et al. [37]. (a) Design of the hybrid nanogenerator to harvest high-entropy wave energy. (b) Elements of the TENG and EMG modules. (c) The tray pendulum, (d) sector-shaped slider, and (e) model of the chaotic pendulum of the hybrid device. (f) Schematic diagram of the hybrid device using a rotatory pendulum in comparison with a tray pendulum. (g) Results of simulation models of the average energy conversion efficiency of the hybrid nanogenerator. (h) Scheme of the application of the hybrid device in the ocean. Reprinted with permission from [37]. Copyright ©2025, Springer Nature Limited.

Figure 22.

Application of a hybrid nanogenerator fabricated by Zhao et al. [37]. (a) Schematic diagram of the energy management circuit. (b) Hybrid nanogenerator driving a navigation light, and (c) the voltage shift of the capacitor. Location of the (d) receiver and (e) buoy for potential sustained oceanographic monitoring. (f) Transmission of temperature and humidity data to a PC. Reprinted with permission from [37]. Copyright ©2025, Springer Nature Limited.

4. Challenges

Ocean wave energy is an abundant, sustainable, and natural energy resource, which can be harvested using hybrid nanogenerators to power marine environment monitoring systems or serve as self-powered MIoT devices. However, the success of the future commercialization of hybrid nanogenerator technology depends on overcoming important challenges associated with marine environmental conditions, such as low-frequency and irregular ocean waves, extremely corrosive conditions, sea storms, the durability and reliability of electrical and mechanical components, optimization of the output performance, efficient power management modules, and integration of nanogenerator array networks. Therefore, more research to address these challenges is essential to achieve the commercial success of hybrid nanogenerators.

Many challenges of hybrid nanogenerators can be addressed through optimal design strategies that enable improvements in their electrical and mechanical performance, durability, and reliability for each specific application, considering the different and harsh marine weather conditions. Thus, the use of digital platforms, such as digital twins and advanced simulation design software, can help designers and researchers optimize the performance and reliability of hybrid nanogenerators, including the best transduction mechanism array, materials, electrical and structural configurations, power management circuits, control systems, and packaging. These advanced simulation models can provide virtual environments of ocean regions under a wide range of key parameters, including wave frequency and magnitude, impact loads, temperature, wind speeds, and ocean salinity. Thus, designers can replicate real marine environments using these simulation models, allowing them to understand the performance and reliability of new materials, electrical and mechanical configurations, and MIoT sensor arrays based on hybrid nanogenerators.

Sea storms can cause variations in the frequency and amplitude of ocean waves, resulting in strong impact loads on the outer structure or packaging of the hybrid nanogenerators. These extreme marine environments can damage the electrical and mechanical parts of the nanogenerators. In this case, an alternative solution could include high-strength materials for packaging the nanogenerators. Furthermore, these materials must have high resistance to marine corrosion. However, these materials must also have cost-effective manufacturing processes that enable their commercial application in large-scale ocean energy harvesting.

Moreover, the integration of nanogenerator array networks into power grids poses an important challenge for the efficient storage and management of electrical energy for long-distance transmission. To address this, the design of robust nanogenerators is fundamental to the development of MIoT sensor networks using different transduction mechanisms. The fabrication of low-cost and reliable nanogenerators can help facilitate their integration into real marine infrastructure that can revolutionize ocean wave energy harvesting. In the future, research will need to address these challenges to enable the commercial use of hybrid nanogenerators in MIoT sensor networks for real-time monitoring of various ocean environmental variables, including water temperature and pH, wave current amplitude and direction, wind speed, and the proximity of marine species, ships, or submarines.

5. Conclusions

In this review, we discussed the transduction mechanisms and performance results of recent hybrid nanogenerators used to harvest ocean wave energy and convert it into electrical energy. Furthermore, we presented the integration of various nanogenerators, including triboelectric nanogenerators, piezoelectric nanogenerators, electromagnetic generators, thermoelectric generators, and pyroelectric nanogenerators. A comparison of the main transduction modes, materials, performance parameters, advantages, and potential applications of hybrid nanogenerators was reported. These applications included the use of nanogenerators to power devices in maritime infrastructure or serve as self-powered MIoT sensor networks for real-time monitoring of marine environmental conditions. Also, key challenges related to the design, performance, durability, reliability, and integration of hybrid nanogenerators in extreme marine environments were introduced. These challenges can be addressed through the optimal design of hybrid nanogenerators that utilize cost-efficient materials and packages with anti-corrosion coatings. Thus, optimized hybrid nanogenerators could have future commercial success to power ocean environmental monitoring sensors.

Author Contributions

Writing—review and editing, E.D.-A., E.A.M.-G., J.A.G.-C., M.C.I.P.-P., J.D.-M., M.G.P.-J., J.H.-H., E.A.E.-H., M.A.F.-N., and A.L.H.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to thank Universidad Veracruzana for its support and for providing the facilities necessary for the publication of this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sadoughipour, M.; VanZwieten, J.; Tang, Y. Drifter-based global ocean current energy resource assessment. Renew. Energy 2025, 244, 122576. [Google Scholar] [CrossRef]

- Taveira-Pinto, F.; Rosa-Santos, P.; Fazeres-Ferradosa, T. Marine renewable energy. Renew. Energy 2020, 150, 1160–1164. [Google Scholar] [CrossRef]

- Xing, F.; Tang, G.; Wang, H.; Wang, M.; Wu, M.; Xu, M. Exploring the synergy of EMG and TENG in motion based hybrid energy harvesting. Nano Energy 2025, 134, 110584. [Google Scholar] [CrossRef]

- Salman, M.; Sorokin, V.; Aw, K. Systematic literature review of wave energy harvesting using triboelectric nanogenerator. Renew. Sustain. Energy Rev. 2024, 201, 114626. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Z.; Huang, M.; Sun, L.; Liu, H.; Lee, C. Self-Sustained Artificial Internet of Things Based on Vibration Energy Harvesting Technology: Toward the Future Eco-Society. Adv. Energy Sustain. Res. 2024, 5, 2400116. [Google Scholar] [CrossRef]

- Ding, S.; Zhai, H.; Tao, X.; Yang, P.; Liu, Z.; Qin, S.; Hong, Z.; Chen, X.; Wang, Z.L. A Triboelectric-Electromagnetic Hybrid Nanogenerator with Magnetic Coupling Assisted Waterproof Encapsulation for Long-Lasting Energy Harvesting. Small 2024, 20, 2403879. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Zeng, P.; Li, Y.; Qi, L. An electromagnetic-triboelectric hybrid wave energy harvesting system with high-output performance based on wire-stayed structure. Measurement 2025, 253, 117800. [Google Scholar] [CrossRef]

- Tang, W.; Shui, J.; Cao, L.; Guo, D.; Su, W.; Jiang, J.; Wen, H.; Liu, G.; Wan, L. Multi-Mode Hybrid Generator Utilizing Gravitational, Magnetic, and Inertial Forces Synergistically. Adv. Sustain. Syst. 2025, 9, 2500175. [Google Scholar] [CrossRef]

- Jia, S.; Yang, X.; Feng, W.; Liu, L.; Zhao, L.; Wu, L.; Li, S.; Zuo, W.; Tang, Q.; Jiang, T.; et al. Self-Adaptive Gyroscope-Structured Hybrid Triboelectric-Electromagnetic Buoy System for Real-Time Ocean Currents Monitoring. Small 2025, 21, 2501073. [Google Scholar] [CrossRef]

- Gao, L.; Xu, X.; Han, H.; Yang, W.; Zhuo, R.; Wei, Q.; Deng, Q.; Hu, N. A broadband hybrid blue energy nanogenerator for smart ocean IoT network. Nano Energy 2024, 127, 109697. [Google Scholar] [CrossRef]

- Vahidhosseini, S.M.; Rashidi, S.; Ehsani, M.H. Efficient energy harvesting using triboelectric nanogenerators (TENGs): Integration with technologies, wearable applications, and future trends. Renew. Sustain. Energy Rev. 2025, 216, 115662. [Google Scholar] [CrossRef]

- Shan, B.; Ai, T.; Wang, K. Triboelectric nanogenerator for ocean energy harvesting: A review of technological advances and future perspectives. Int. J. Electrochem. Sci. 2024, 19, 100694. [Google Scholar] [CrossRef]

- Ucar, E.F.; Ilbay, A.; Simsek, T.; Kaynar, M.B.; Ozbay, E.; Ozcan, S. Development of magnetically driven contactless piezoelectric nanogenerators utilizing ZnO nanowires with different shaped top electrodes. Semicond. Sci. Technol. 2024, 40, 015015. [Google Scholar] [CrossRef]

- Suresh, S.; Athira, B.S.; Akhila, N.S.; Vijaya, L.; Chandran, A.; Gowd, B. Anisotropic Poly(vinylidene fluoride-co-trifluoroethylene)/MXene Aerogel-Based Piezoelectric Nanogenerator for Efficient Kinetic Energy Harvesting and Self-Powered Force Sensing Applications. ACS Appl. Mater. Interfaces 2025, 17, 9818–9829. [Google Scholar] [CrossRef] [PubMed]

- Ziaee, S.; Montazer, M.; Bagherzadeh, R. Flexible copper/nickel carbon composite fabrics as electrodes for wearable PVDF/BaTiO3 composite piezoelectric nanogenerators. Compos. Struct. 2025, 357, 118868. [Google Scholar] [CrossRef]

- Huang, M.; Liao, W.; Shi, J.; Huang, X.; Gao, X.; Ding, Z.; Guo, S. A miniaturized fully enclosed spherical triboelectric and electromagnetic hybrid generator for multidimensional low-frequency vibration energy harvesting. Nano Energy 2025, 142, 111281. [Google Scholar] [CrossRef]

- Pan, J.; Sun, Y.; Sun, Q.; Jia, S.; Wang, X.; Xia, H.; Li, Q.; Xia, Y.; Shi, G. A phase-synchronized triboelectric-assisted electromagnetic energy harvesting system for omnidirectional low-frequency wave energy. Energy 2025, 328, 136529. [Google Scholar] [CrossRef]

- Zhang, C.; Hao, Y.; Lu, X.; Su, W.; Zhang, H.; Wang, J.; Li, X. Passive wireless marine Internet-of-Things buoy based on hybrid nanogenerator with omnidirectional water-wave energy harvesting. Nano Energy 2025, 138, 110809. [Google Scholar] [CrossRef]

- Liu, Y.; Hao, Y.; Wang, C.; Li, G.; Wen, G.-L.; Lai, S.-L. Engineering a motion-enhanced tri-stable hybrid energy converter for capturing low-frequency wave energy. Energy 2025, 322, 135583. [Google Scholar] [CrossRef]

- Yaseen, H.M.A.; Park, S. Improved pyroelectric nanogenerator performance of P(VDF-TrFE)/rGO thin film by optimized rgo reduction. Nanomaterials 2024, 14, 1777. [Google Scholar] [CrossRef]

- Mondal, R.; Hasan, M.A.M.; Baik, J.M.; Yang, Y. Advanced pyroelectric materials for energy harvesting and sensing applications. Mater. Today 2023, 66, 273–301. [Google Scholar] [CrossRef]

- Li, H.; Wang, H.; Li, X.; Huang, J.; Li, X.; Boong, S.K.; Lee, H.K.; Han, J.; Guo, R. Boosting solar-to-pyroelectric energy harvesting via a plasmon-enhanced solar-thermal conversion approach. Nano Energy 2022, 100, 107527. [Google Scholar] [CrossRef]

- Mistewicz, K.; Jesionek, M.; Nowak, M.; Kozioł, M. SbSeI pyroelectric nanogenerator for a low temperature waste heat recovery. Nano Energy 2019, 64, 103906. [Google Scholar] [CrossRef]

- Soltanian, S.; Mahmud, S.; Dutta, A. Analysis of a polymer-based textile-embroidered thermoelectric generator for harvesting electrical power from the human body. Appl. Therm. Eng. 2025, 269, 126156. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, W.; Guo, Z.-Y. Governing equations of thermoelectric generators. Int. J. Heat Mass Transf. 2025, 241, 126737. [Google Scholar] [CrossRef]

- Lin, H.; Zhang, X.; Liang, Y.; Liu, X.; Zhang, R.; Huang, X.; Tan, L.; Tang, S. Design and optimization of two stage annular thermoelectric generator coupling with high temperature heat pipe application. Appl. Therm. Eng. 2025, 261, 125089. [Google Scholar] [CrossRef]

- Malagutti, M.A.; Lohani, K.; Prades, I.C.; Navarro-Güell, A.; Bernard, T.; Chiappini, A.; Saucedo, E.; Ataollahi, N.; Scardi, P. CuFeS2/Cu2S/FeS2 Composite to increase the performance of thin-film thermoelectric generators based on sustainable materials. ACS Appl. Electron. Mater. 2025, 7, 21–32. [Google Scholar] [CrossRef]

- Bayendang, N.P.; Balyan, V.; Kahn, M.T. The question of thermoelectric devices (TEDs) in/efficiency—A practical research considering thermoelectric generators (TEGs). IET Renew. Power Gener. 2025, 19, e13185. [Google Scholar] [CrossRef]

- Liu, C.; Fan, Y.; Zhao, K.; Shan, B.; Wang, Y.; Gao, Y.; Han, Z.; Xu, M.; Pan, X. Design and Application of a New Self-Powered Sensing Device Based on MTEG and FTENG. J. Energy Eng. 2022, 148, 04022036. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, C.; Liu, J.; Wang, J.; Wang, Y.; Fan, Y.; Pan, X. Design and study of a combining energy harvesting system based on thermoelectric and flapping triboelectric nanogenerator. Int. J. Green Energy 2021, 18, 1302–1308. [Google Scholar] [CrossRef]

- Li, J.; Cheng, L.; Wan, N.; Ma, J.; Hu, Y.; Wen, J. Hybrid harvesting of wind and wave energy based on triboelectric-piezoelectric nanogenerators. Sustain. Energy Technol. Assess. 2023, 60, 103466. [Google Scholar] [CrossRef]

- Sun, X.; Shang, C.; Ma, H.; Li, C.; Xue, L.; Xu, Q.; Wei, Z.; Li, W.; Yalikun, Y.; Lai, Y.-C.; et al. A tube-shaped solid–liquid-interfaced triboelectric–electromagnetic hybrid nanogenerator for efficient ocean wave energy harvesting. Nano Energy 2022, 100, 107540. [Google Scholar] [CrossRef]

- Xu, Q.; Shang, C.; Ma, H.; Hong, Q.; Li, C.; Ding, S.; Xue, L.; Sun, X.; Pan, Y.; Sugahara, T.; et al. A guided-liquid-based hybrid triboelectric nanogenerator for omnidirectional and high-performance ocean wave energy harvesting. Nano Energy 2023, 109, 108240. [Google Scholar] [CrossRef]

- Liu, C.; Qu, G.; Shan, B.; Aranda, R.; Chen, N.; Li, H.; Zhou, Z.; Yu, T.; Wang, C.; Mi, J.; et al. Underwater hybrid energy harvesting based on TENG-MTEG for self-powered marine mammal condition monitoring system. Mater. Today Sustain. 2023, 21, 100301. [Google Scholar] [CrossRef]

- Zhang, C.; Yuan, W.; Zhang, B.; Yang, O.; Liu, Y.; He, L.; Wang, J.; Wang, Z.L. High Space Efficiency Hybrid Nanogenerators for Effective Water Wave Energy Harvesting. Adv. Funct. Mater. 2022, 32, 2111775. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, T.; Niu, B.; Ma, Y.; Hu, C. A hydrokinetic turbine-based triboelectric-electromagnetic hybrid generator for ocean current energy harvesting. Energy Convers. Manag. 2025, 326, 119473. [Google Scholar] [CrossRef]

- Zhao, T.; Li, Z.; Niu, B.; Xie, G.; Shangguan, L.; Zhang, M.; Zhu, Y.; Ma, Y.; Hu, C.; Li, Y. A pendulum-based nanogenerator for high-entropy wave energy harvesting. Nat. Commun. 2025, 16, 5480. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhu, H.; Xing, W.; Tohl, D.; Tang, Y. A hybrid self-powered wave sensing device enables low-amplitude wave sensing. Device 2025, 3, 100575. [Google Scholar] [CrossRef]

- Liu, H.; Guo, D.; Zhu, H.; Wen, H.; Li, J.; Wan, L. Shell-Optimized Hybrid Generator for Ocean Wave Energy Harvesting. Energies 2025, 18, 1502. [Google Scholar] [CrossRef]

- Wen, H.; Liu, H.; Wang, X.; Liu, G.; Zhou, P.; Zhou, W.; Tuo, L.; Qu, H.; Zhai, L.; Wan, L.; et al. Enhanced hybrid generator with spring coupling effect for low-grade water wave energy harvesting. Nano Energy 2025, 133, 110488. [Google Scholar] [CrossRef]

- Sun, C.; Teng, H.; Ma, X.; Chen, H.; Sun, L.; Shao, C.; Cao, F.; Liu, H. Numerical and experimental investigation of an Inertial Tilting hybrid wave energy converter for powering small-scale marine systems. Int. J. Nav. Archit. Ocean Eng. 2025, 17, 100658. [Google Scholar] [CrossRef]

- Li, S.; Chen, C.; Guo, D.; Liu, H.; Ning, H.; Liu, G.; Wan, L. Highly Sensitive Hybrid Triboelectric Nanogenerator with Ferris-Wheel-Like Structure for Ocean Wave Energy Harvesting. Adv. Sustain. Syst. 2024, 8, 2400310. [Google Scholar] [CrossRef]

- Li, M.; Lou, Y.; Hu, J.; Cui, W.; Chen, L.; Yu, A.; Zhai, J. High-Coupled Magnetic-Levitation Hybrid Nanogenerator with Frequency Multiplication Effect for Wireless Water Level Alarm. Small 2024, 20, 2402009. [Google Scholar] [CrossRef]

- Ren, J.; Fang, L.; Qu, H.; Zhou, T.; Chen, C.; Wei, Q.; Shen, P.K.; Wan, L.; Tian, Z.Q. A wave-powered capacitive deionization system with in-situ blue energy harvester. Chem. Eng. J. 2024, 498, 155530. [Google Scholar] [CrossRef]

- Cui, W.; Hu, J.; Yang, H.; Liu, X.; Wang, Y.; Lou, Y.; Li, M.; Li, Z.; Yu, A.; Wang, Z.L.; et al. Self-powered wireless sensor node enabled by ultra-high-output swinging hybrid generator toward real-time and in-situ marine meteorological observations. Nano Energy 2024, 129, 110051. [Google Scholar] [CrossRef]

- Long, H.; Li, S.; Jia, M.; Huang, D.; Zhang, P.; Wang, X.; Li, X.; Wu, J.; Hou, D.; Zhang, Q. A tubular liquid-solid triboelectric-electromagnetic hybrid nanogenerator for enhancing wave energy harvesting. Energy 2024, 304, 132119. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, S.; Dai, X.; Tu, Y.; Du, Z.; Wu, X.; Huang, Y.; Fan, J.; Hong, Z.; Jiang, T.; et al. Hybridized triboelectric-electromagnetic nanogenerators for efficient harvesting of wave energy for self-powered ocean buoy. Nano Energy 2024, 128, 109929. [Google Scholar] [CrossRef]

- Li, T.; Wang, X.; Wang, K.; Liu, Y.; Li, C.; Zhao, F.; Yao, Y.; Cheng, T. Bidirectional Rotating Turbine Hybrid Triboelectric-Electromagnetic Wave Energy Harvester for Marine Environment Monitoring. Adv. Energy Mater. 2024, 14, 2400313. [Google Scholar] [CrossRef]

- Zhai, L.; Wen, H.; Liu, H.; Guo, D.; Liu, G.; Qu, H.; Wan, L.; Yao, H.; Zhai, J. High-sensitivity blue-energy-shuttle and in-situ electrical behaviors in ocean. Nano Energy 2024, 125, 109546. [Google Scholar] [CrossRef]

- Wang, Z.; Hou, L.; Yang, D.; Zhang, M.; Liu, S.; Yu, Z.; Sun, J.; Mao, Y.; Yao, M.; Yang, T. A self-powered underwater glider using bidirectional swing-rotation hybrid nanogenerator. Nano Energy 2024, 125, 109526. [Google Scholar] [CrossRef]

- Wang, Q.; Yu, G.; Lou, Y.; Li, M.; Hu, J.; Li, J.; Cui, W.; Yu, A.; Zhai, J. Elastic Self-Recovering Hybrid Nanogenerator for Water Wave Energy Harvesting and Marine Environmental Monitoring. Sensors 2024, 24, 3770. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Wu, G.; Zhao, Z.; Wu, Y.; Zheng, H. Triboelectric–electromagnetic hybrid nanogenerator for harvesting blue energy and creating an ocean wave warning system. Nanoscale Adv. 2024, 6, 3566–3572. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Li, J.; Guan, Z.; Zhao, L.; Tian, Z.; Jia, S.; Hong, H.; He, Z.; Wen, H.; Huang, R.; et al. Ultra-high output hybrid nanogenerator for self-powered smart mariculture monitoring and warning system. Chem. Eng. J. 2023, 472, 145039. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, C.; Shao, T.; Fan, Y.; Chen, R.; Pan, X. Enhanced thermoelectric performance of Bi2Te3 by carbon nanotubes and silicate aerogel co-doping toward ocean energy harvesting. Mater. Today Sustain. 2023, 23, 100476. [Google Scholar] [CrossRef]

- Wang, Y.; Qian, Z.; Zhao, C.; Wang, Z.; Jiang, K.; Wang, J.; Meng, Z.; Li, F.; Zhu, C.; Chen, P.; et al. Highly Adaptive Triboelectric-Electromagnetic Hybrid Nanogenerator for Scavenging Flow Energy and Self-Powered Marine Wireless Sensing. Adv. Mater. Technol. 2023, 8, 2201245. [Google Scholar] [CrossRef]

- Tian, S.; Wei, X.; Lai, L.; Li, B.; Wu, Z.; Dai, Y. Frequency modulated hybrid nanogenerator for efficient water wave energy harvesting. Nano Energy 2022, 102, 107669. [Google Scholar] [CrossRef]

- Ding, J.; Jiang, J.; Lin, T.; Liu, G.; Yao, H.; Wen, H.; Li, S.; Mo, F.; Wan, L. Realization of a Sustainable Charging Power Source by In Situ Low-Frequency Water Wave Energy Harvesting with a Coaxial Triboelectric–Electromagnetic Hybrid Generator. Adv. Energy Sustain. Res. 2022, 3, 2200087. [Google Scholar] [CrossRef]

- Xue, F.; Chen, L.; Li, C.; Ren, J.; Yu, J.; Hou, X.; Geng, W.; Mu, J.; He, J.; Chou, X. A static-dynamic energy harvester for a self-powered ocean environment monitoring application. Sci. China Technol. Sci. 2022, 65, 893–902. [Google Scholar] [CrossRef]

- Hong, H.; Yang, X.; Cui, H.; Zheng, D.; Wen, H.; Huang, R.; Liu, L.; Duan, J.; Tang, Q. Self-powered seesaw structured spherical buoys based on a hybrid triboelectric–electromagnetic nanogenerator for sea surface wireless positioning. Energy Environ. Sci. 2022, 15, 621–632. [Google Scholar] [CrossRef]

- Zhao, B.; Li, Z.; Liao, X.; Qiao, L.; Li, Y.; Dong, S.; Zhang, Z.; Zhang, B. A heaving point absorber-based ocean wave energy convertor hybridizing a multilayered soft-brush cylindrical triboelectric generator and an electromagnetic generator. Nano Energy 2021, 89, 106381. [Google Scholar] [CrossRef]

- Ren, Z.; Liang, X.; Liu, D.; Li, X.; Ping, J.; Wang, Z.; Wang, Z.L. Water-Wave Driven Route Avoidance Warning System for Wireless Ocean Navigation. Adv. Energy Mater. 2021, 11, 2101116. [Google Scholar] [CrossRef]

- Mariello, M.; Fachechi, L.; Guido, F.; Vittorio, M.D. Multifunctional sub-100 µm thickness flexible piezo/triboelectric hybrid water energy harvester based on biocompatible AlN and soft parylene C-PDMS-Ecoflex™. Nano Energy 2021, 83, 105811. [Google Scholar] [CrossRef]

- Feng, Y.; Liang, X.; An, J.; Jiang, T.; Wang, Z.L. Soft-contact cylindrical triboelectric-electromagnetic hybrid nanogenerator based on swing structure for ultra-low frequency water wave energy harvesting. Nano Energy 2021, 81, 105625. [Google Scholar] [CrossRef]

- Jurado, U.T.; Pu, S.H.; White, N.M. Grid of hybrid nanogenerators for improving ocean wave impact energy harvesting self-powered application. Nano Energy 2020, 72, 104701. [Google Scholar] [CrossRef]

- Chandrasekhar, A.; Vivekananthan, V.; Kim, S.-J. A fully packed spheroidal hybrid generator for water wave energy harvesting and self-powered position tracking. Nano Energy 2020, 69, 104439. [Google Scholar] [CrossRef]

- Wu, Y.; Zeng, Q.; Tang, Q.; Liu, W.; Liu, G.; Zhang, Y.; Wu, J.; Hu, C.; Wang, H. A teeterboard-like hybrid nanogenerator for efficient harvesting of low-frequency ocean wave energy. Nano Energy 2020, 67, 104205. [Google Scholar] [CrossRef]

- Hou, C.; Chen, T.; Li, Y.; Huang, M.; Shi, Q.; Liu, H.; Sun, L.; Lee, C. A rotational pendulum based electromagnetic/triboelectric hybrid-generator for ultra-low-frequency vibrations aiming at human motion and blue energy applications. Nano Energy 2019, 63, 103871. [Google Scholar] [CrossRef]

- Hao, C.; He, J.; Zhai, C.; Jia, W.; Song, L.; Cho, J.; Chou, X.; Xue, C. Two-dimensional triboelectric-electromagnetic hybrid nanogenerator for wave energy harvesting. Nano Energy 2019, 58, 147–157. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Q.; Ding, Z.; Li, Z.; Zheng, H.; Fu, J.; Diao, C.; Zhang, X.; Tian, J.; Zi, Y. A fully-packaged ship-shaped hybrid nanogenerator for blue energy harvesting toward seawater self-desalination and self-powered positioning. Nano Energy 2019, 57, 2211–2855. [Google Scholar] [CrossRef]

- Yang, H.; Yang, H.; Lai, M.; Xi, Y.; Guan, Y.; Liu, W.; Zeng, Q.; Lu, J.; Hu, C.; Wang, Z.L. Triboelectric and Electromagnetic Hybrid Nanogenerator Based on a Crankshaft Piston System as a Multifunctional Energy Harvesting Device. Adv. Mater. Technol. 2019, 4, 1800278. [Google Scholar] [CrossRef]

- Feng, L.; Liu, G.; Guo, H.; Tang, Q.; Pu, X.; Chen, J.; Wang, X.; Xi, Y.; Hu, C. Hybridized nanogenerator based on honeycomb-like three electrodes for efficient ocean wave energy harvesting. Nano Energy 2018, 47, 217–223. [Google Scholar] [CrossRef]

- Saadatnia, Z.; Asadi, E.; Askari, H.; Zu, J.; Esmailzadeh, E. Modeling and performance analysis of duck-shaped triboelectric and electromagnetic generators for water wave energy harvesting. Int. J. Energy Res. 2017, 41, 2392–2404. [Google Scholar] [CrossRef]

- Shao, H.; Wen, Z.; Cheng, P.; Sun, N.; Shen, Q.; Zhou, C.; Peng, M.; Yang, Y.; Xie, X.; Sun, X. Multifunctional power unit by hybridizing contact-separate triboelectric nanogenerator, electromagnetic generator and solar cell for harvesting blue energy. Nano Energy 2017, 39, 608–615. [Google Scholar] [CrossRef]

- Wang, X.; Wen, Z.; Guo, H.; Wu, C.; He, X.; Lin, L.; Cao, X.; Wang, Z.L. Fully packaged blue energy harvester by hybridizing a rolling triboelectric nanogenerator and an electromagnetic generator. ACS Nano 2016, 10, 11369–11376. [Google Scholar] [CrossRef]

- Wen, Z.; Guo, H.; Zi, Y.; Yeh, M.-H.; Wang, X.; Deng, J.; Wang, J.; Li, S.; Hu, C.; Zhu, L.; et al. Harvesting broad frequency band blue energy by a triboelectric− electromagnetic hybrid nanogenerator. ACS Nano 2016, 10, 6526–6534. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).