Review of Converter Circuits with Power Factor Correction

Abstract

1. Introduction

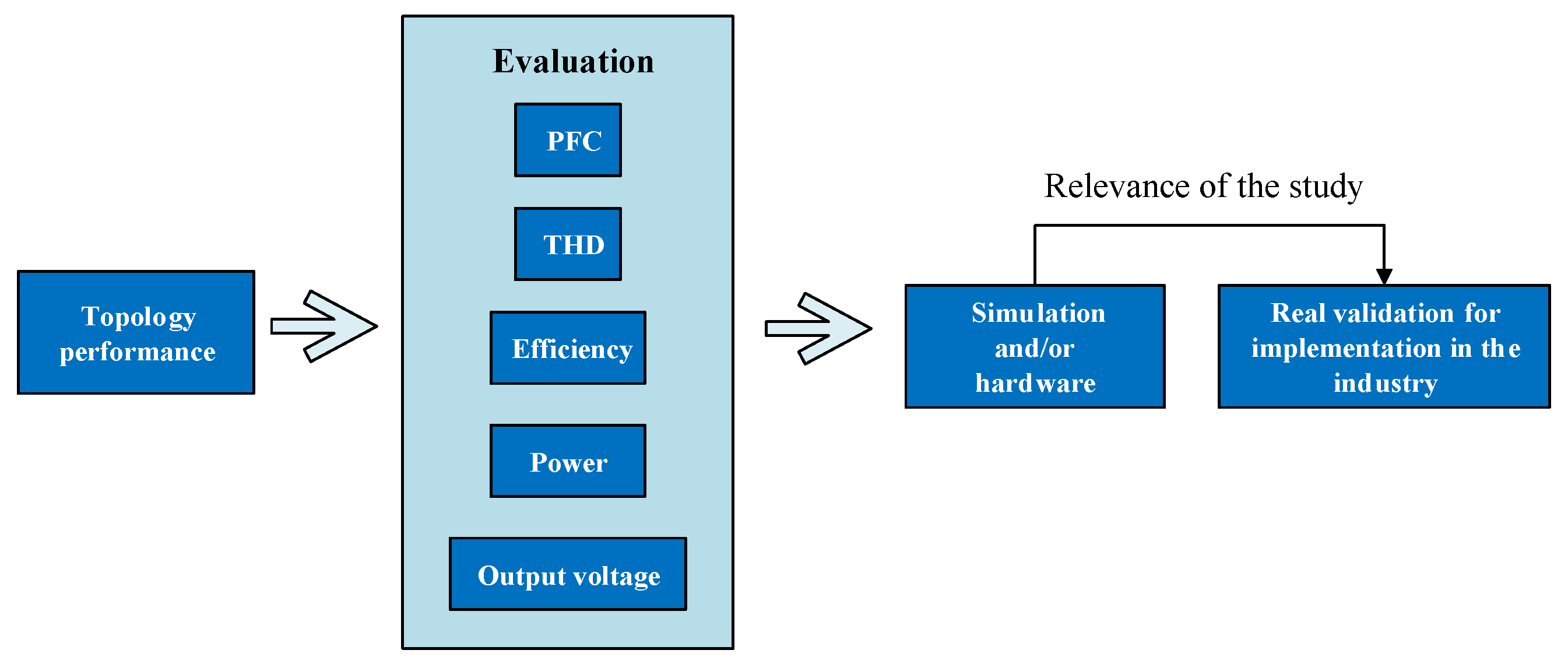

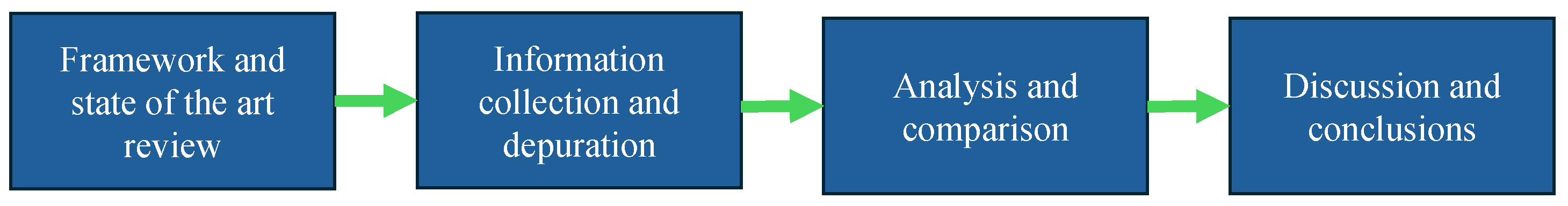

Paper Approach and Organization

2. Methodology

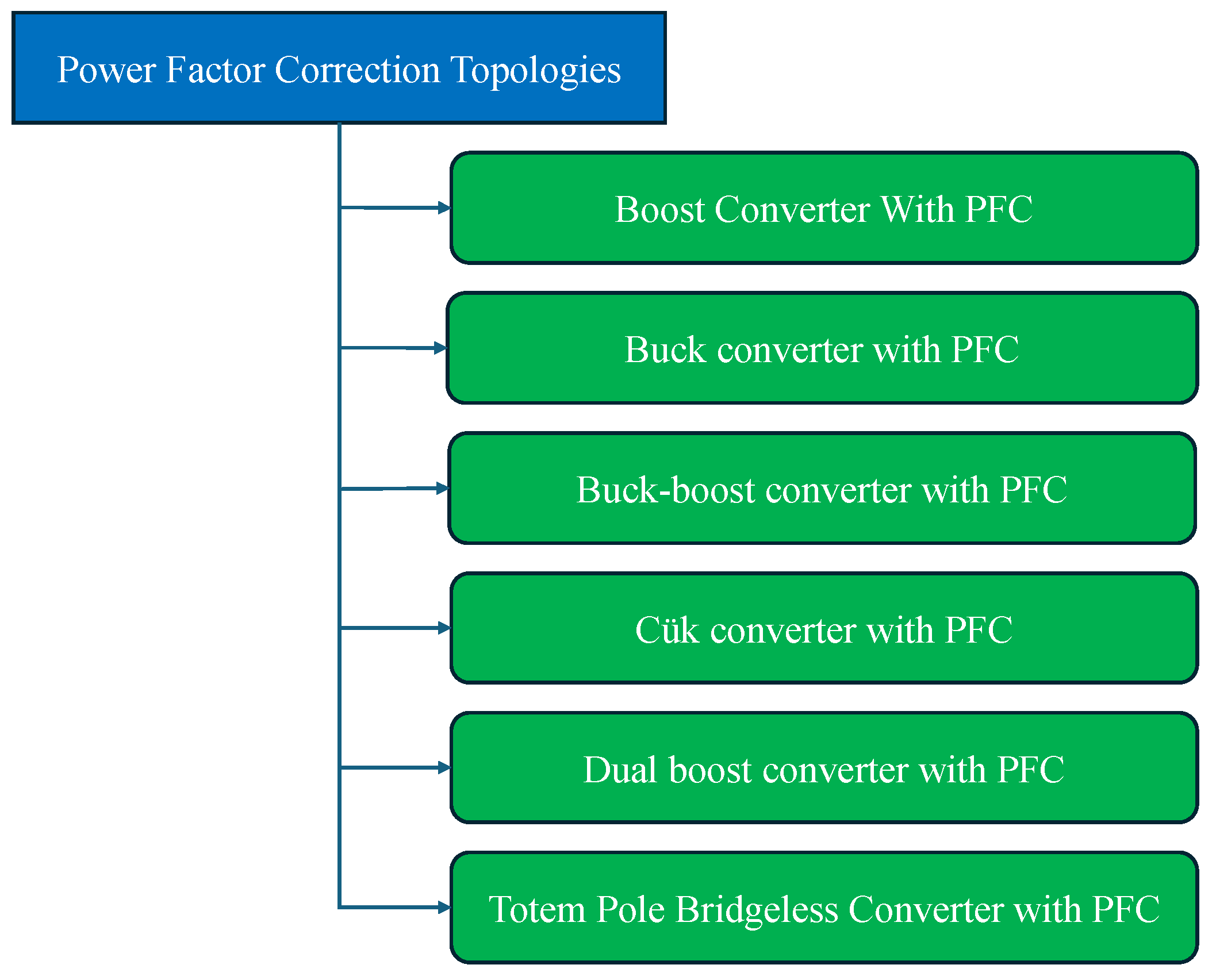

3. Recent Works on Topologies with PFC

3.1. Boost Converter with PFC

- Load of 500 W: FP equal to , and THD of .

- Load of 750 W: FP equal to , and THD of .

- Load of 1250 W: FP equal to , and THD of .

- Load of 2000 W: FP equal to , and THD of .

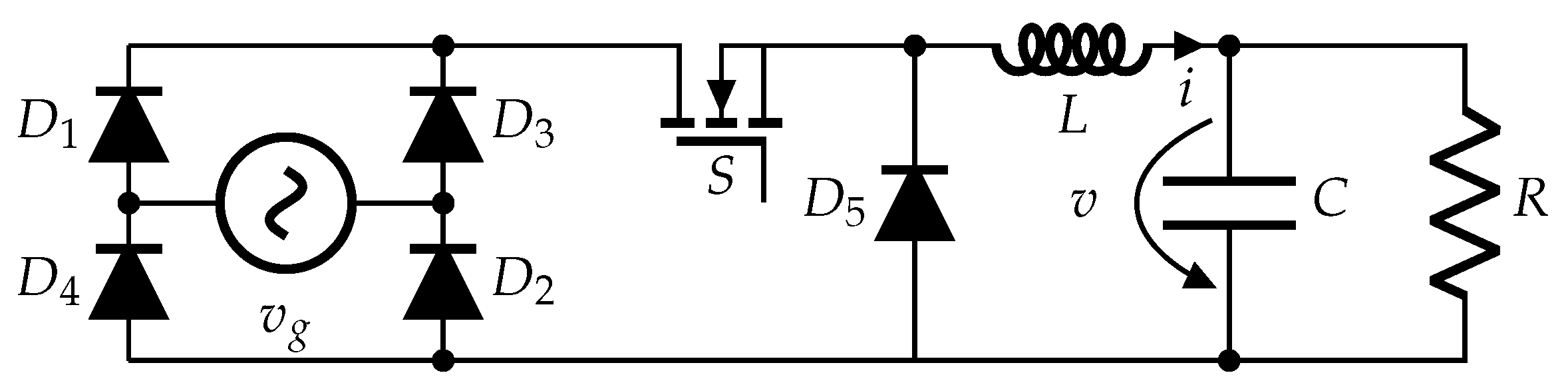

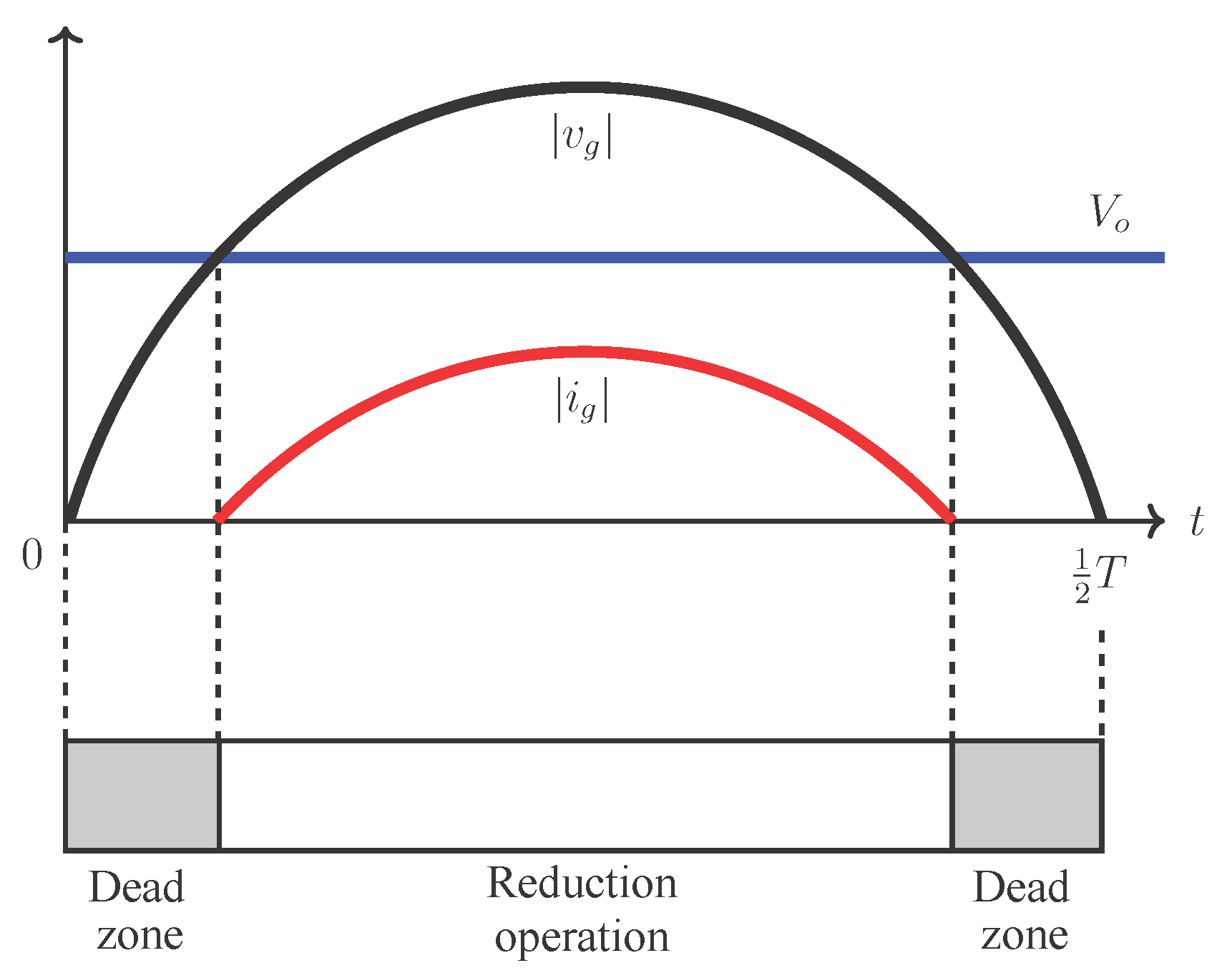

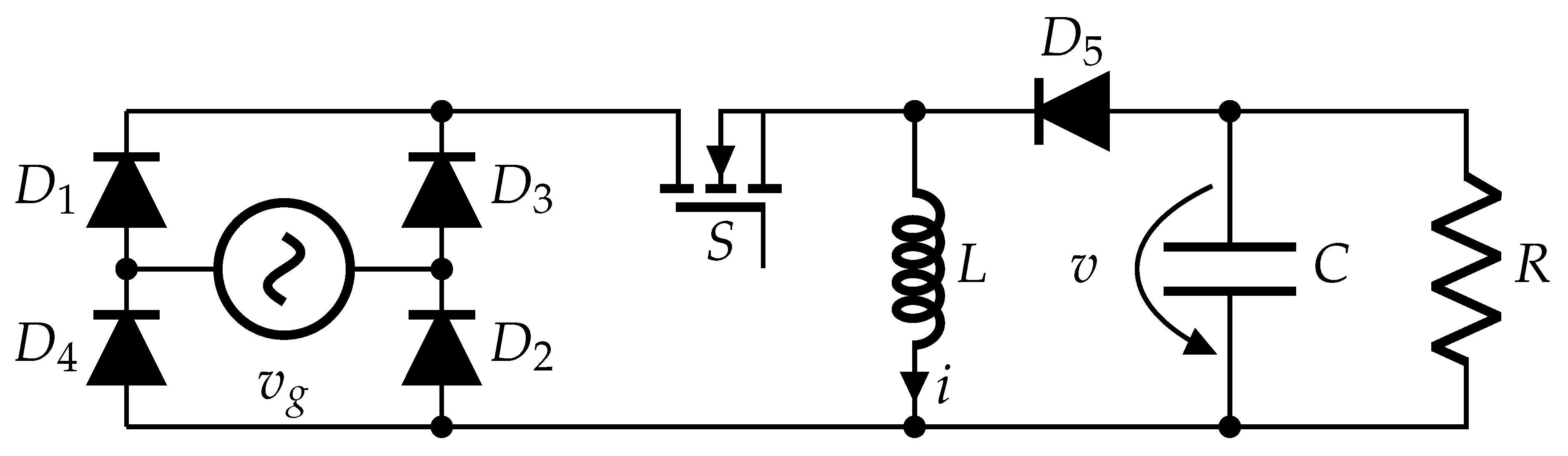

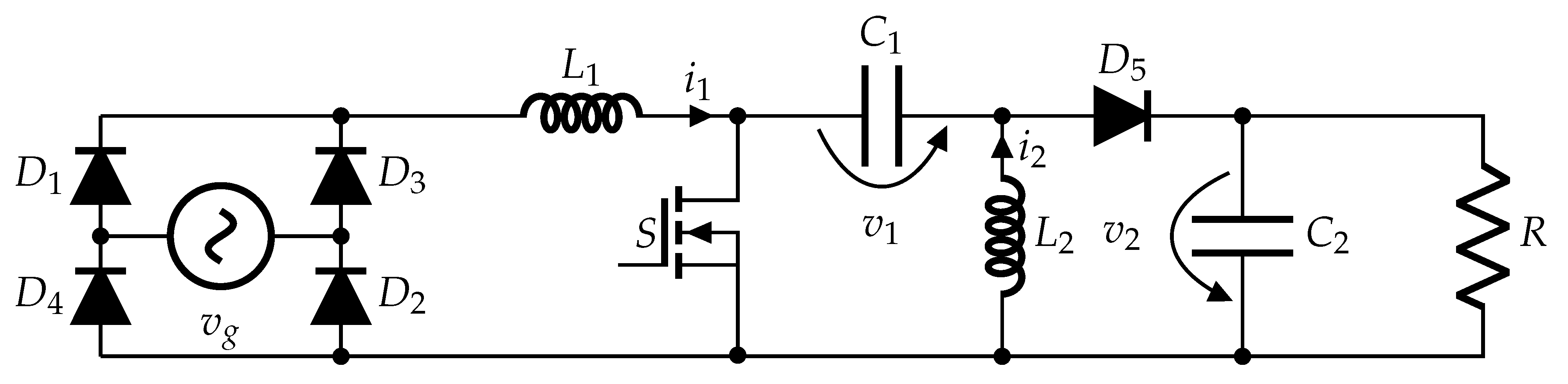

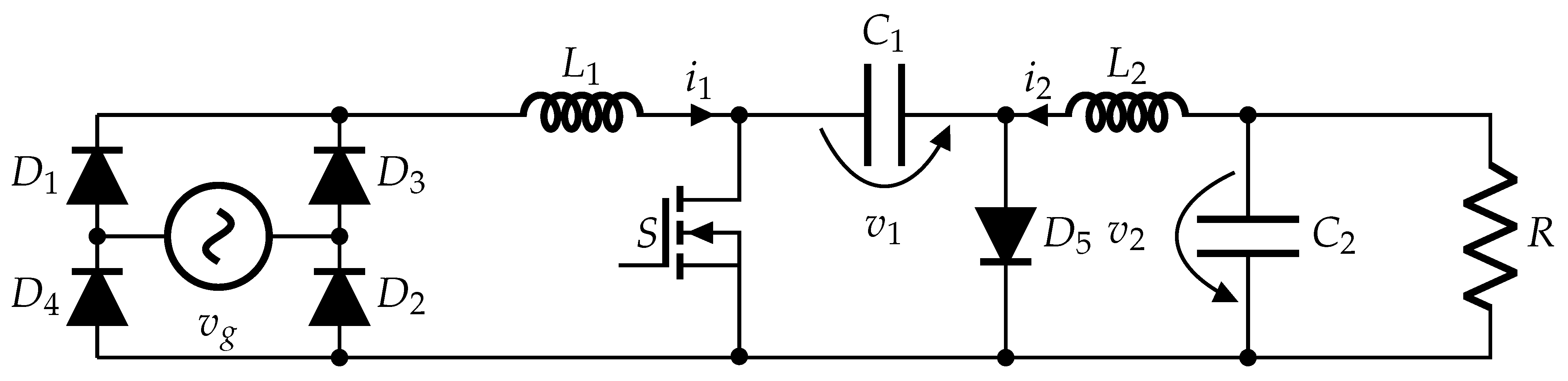

3.2. Buck Converter with PFC

- Buck Converter: THDi equal to , FP of , and efficiency of .

- Dual Bridgeless: THDi equal to , FP of , and efficiency of .

- Hybrid converter proposed: THDi equal to , FP of , and efficiency of .

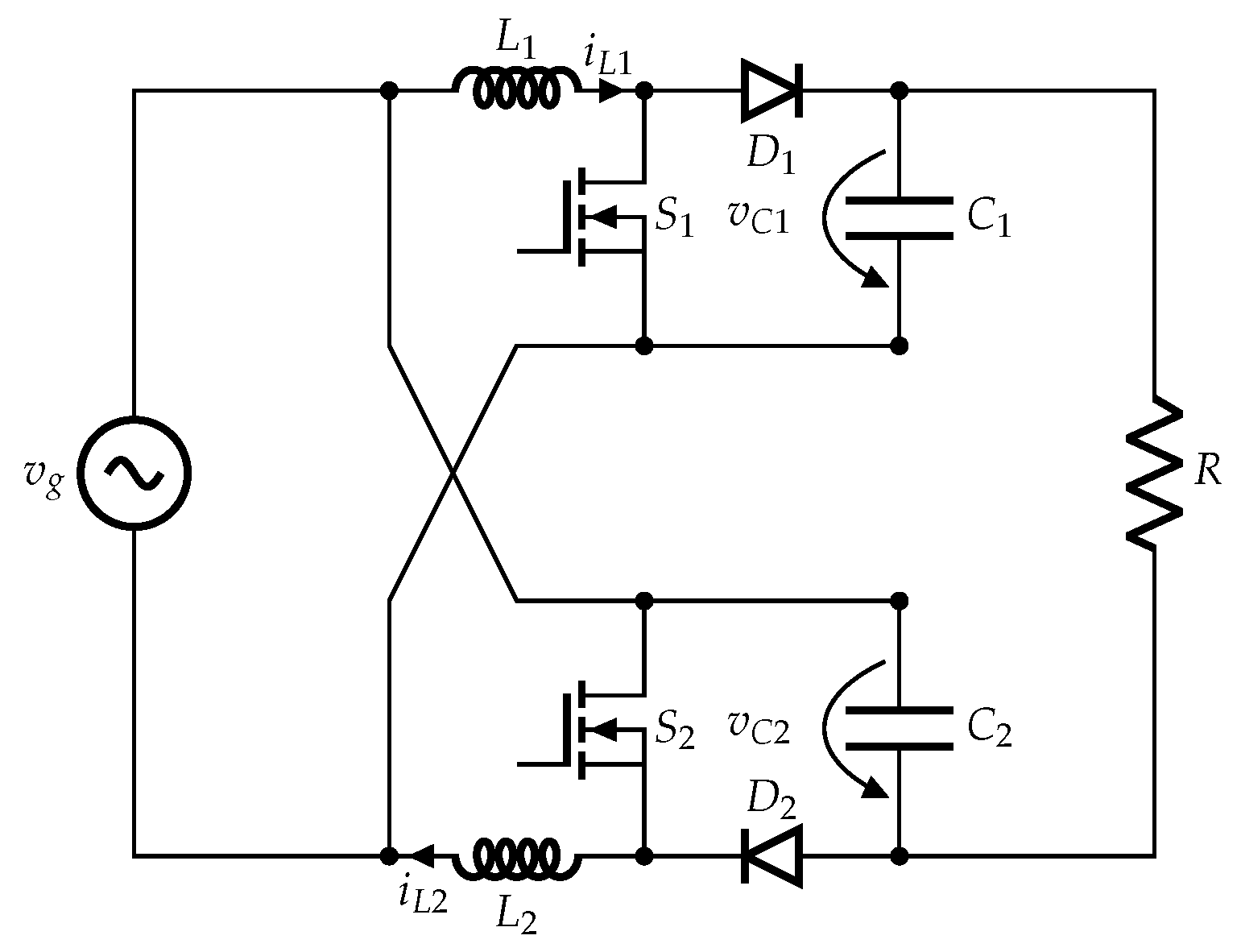

3.3. Buck-Boost Converter with PFC

- MCD, experimental implementation: Operation under boost condition and active power decoupling were used, obtaining a THDi of , a FP of and an efficiency of .

- MCT, simulation implementation: Operation under boosting conditions and active power decoupling were also used, obtaining a THDi of , a FP of and a higher efficiency than that obtained in MCD.

3.4. Cük Converter with PFC

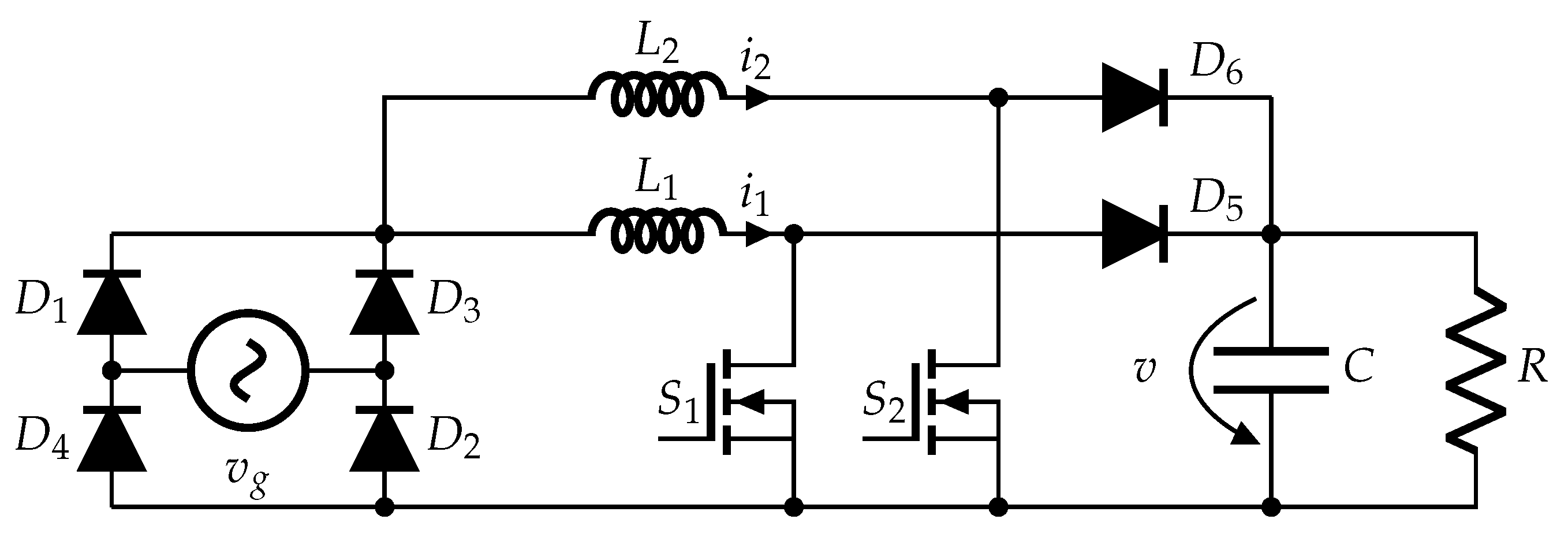

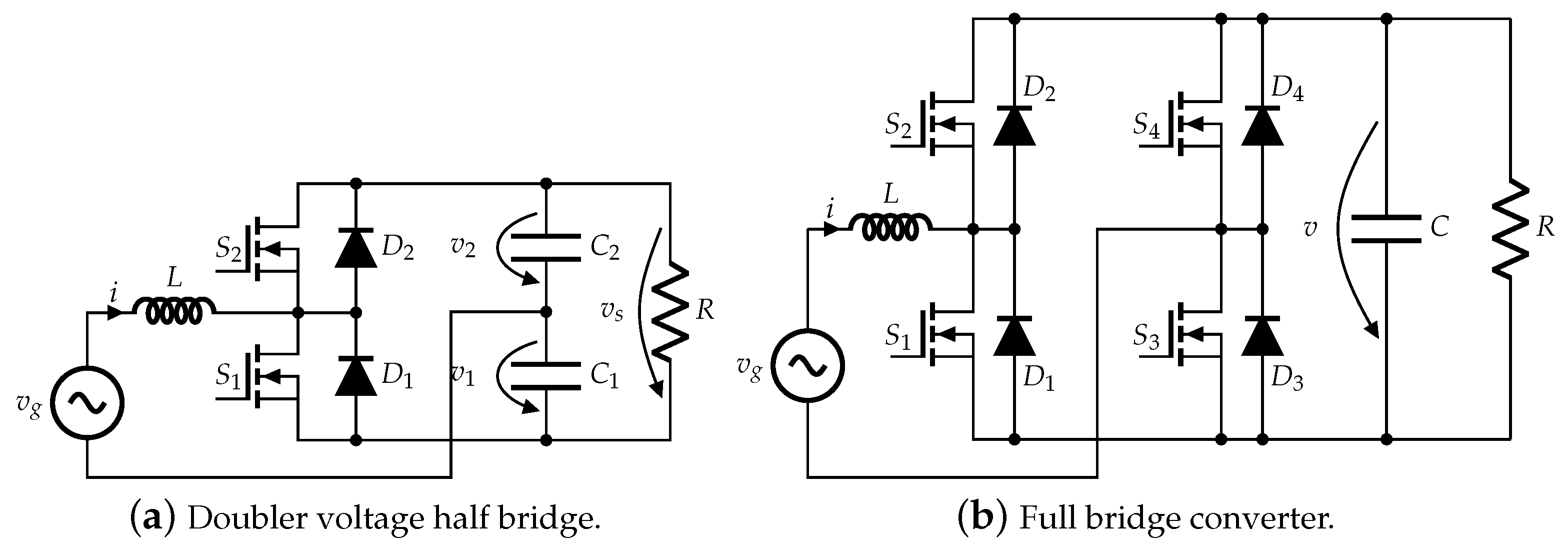

3.5. Dual Boost Converter with PFC

- Using a input voltage of : THD equal to , FP of , and an efficiency of .

- Using a input voltage of : THD equal to , FP of , and an efficiency of .

- Using a input voltage of : THD equal to , FP of , and an efficiency of .

3.6. Totem Pole Bridgeless Converter with PFC

- Power Factor: .

- Total Harmonic Distortion: .

- Efficiency: .

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krishna, L. Automatic Power Factor Correction Using Arduino Micro Controller; Archers & Elevators Publishing House: Bangalore, India, 2023. [Google Scholar]

- Noh, M.A.M.; RodhiSahid, M.; Duraikannan, S. Implementation of A New Single-Stage Bridgeless Boost Half-Bridge AC/DC Converter with Bidirectional Switch. Turk. J. Comput. Math. Educ. 2021, 12, 1331–1341. Available online: https://turcomat.org/index.php/turkbilmat/article/view/4394 (accessed on 4 June 2024).

- Bayona, J.; Guarnizo, J.; Gelves, N. Pulse Width Prediction Control Technique Applied to a Half-Bridge Boost. Tecciencia 2018, 13, 47–54. [Google Scholar] [CrossRef]

- Lo, Y.-K.; Ho, C.-T.; Wang, J.-M. Elimination of the Output Voltage Imbalance in a Half-Bridge Boost Rectifier. IEEE Trans. Power Electron. 2007, 22, 1352–1360. [Google Scholar] [CrossRef]

- Jiang, S.; Cao, D.; Li, Y.; Peng, F.Z. Grid-Connected Boost-Half-Bridge Photovoltaic Micro Inverter System Using Repetitive Current Control and Maximum Power Point Tracking. IEEE Trans. Power Electron. 2012, 27, 4711–4722. [Google Scholar] [CrossRef]

- Vinnikov, D.; Chub, A.; Liivik, E.; Blaabjerg, F.; Siwakoti, Y. Boost Half-Bridge DC-DC Converter with Reconfigurable Rectifier for Ultra-Wide Input Voltage Range Applications. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 4–8 March 2018. [Google Scholar] [CrossRef]

- Le, T.T.; Lee, J.; Choi, S. Single-Stage Totem-Pole AC-DC Converter Based on Boost Half-Bridge Structure for Battery Chargers. IEEE Trans. Power Electron. 2024, 39, 1060–1073. [Google Scholar] [CrossRef]

- Singh, A.; Tiwari, A.N. Analysis of Bridge and Bridgeless type PFC AC-DC Boost Converter. In Proceedings of the International Conference on Electrical Engineering (ICE3), Gorakhpur, India, 14–15 February 2020. [Google Scholar] [CrossRef]

- Makkapati, S.; Ramalingam, S. Comparative Analysis of Different Single Stage PFC Integrated Half Bridge LLC converter for LED Lighting. In Proceedings of the International Conference on Electrical Engineering (ICPECTS), Chennai, India, 8–9 December 2022. [Google Scholar] [CrossRef]

- Tamayo, M.T. El Proceso de la Investigación Científica, 5th ed.; Limusa: México City, México, 2011. [Google Scholar]

- Creswell, J.W. RESEARH DESIGN, Qualitative, Quantitative, and Mixed Methods Approachs, 4th ed.; SAGE Publications: Los Angeles, CA, USA; London, UK; New Delhi, India; Singapore; Washington, DC, USA, 2014. [Google Scholar]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate health care interventions: Explanation and elaboration. PLoS Med. 2009, 6, 339. [Google Scholar] [CrossRef]

- Urrutia, G.; Bonfill, X. Declaración PRISMA: Una propuesta para mejorar la publicación de revisiones sistematicas y metaanálisis. Med. ClÍnica 2010, 135, 507–511. [Google Scholar] [CrossRef]

- Campos, H.; Soares, J.; Badin, A.; Cortez, D. Single-Phase Hybrid Switched-Capacitor PFC Boost Rectifier with Low Voltage Gain. IEEE Trans. Power Electron. 2023, 38, 968–976. [Google Scholar] [CrossRef]

- Akhmetov, Z.; Abdelraziq, M.; Pantic, Z. Low Conducted-EMI Single-Phase Boost PFC with Sliding Frequency Modulation. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA, 19–23 March 2023; pp. 1784–1789. [Google Scholar] [CrossRef]

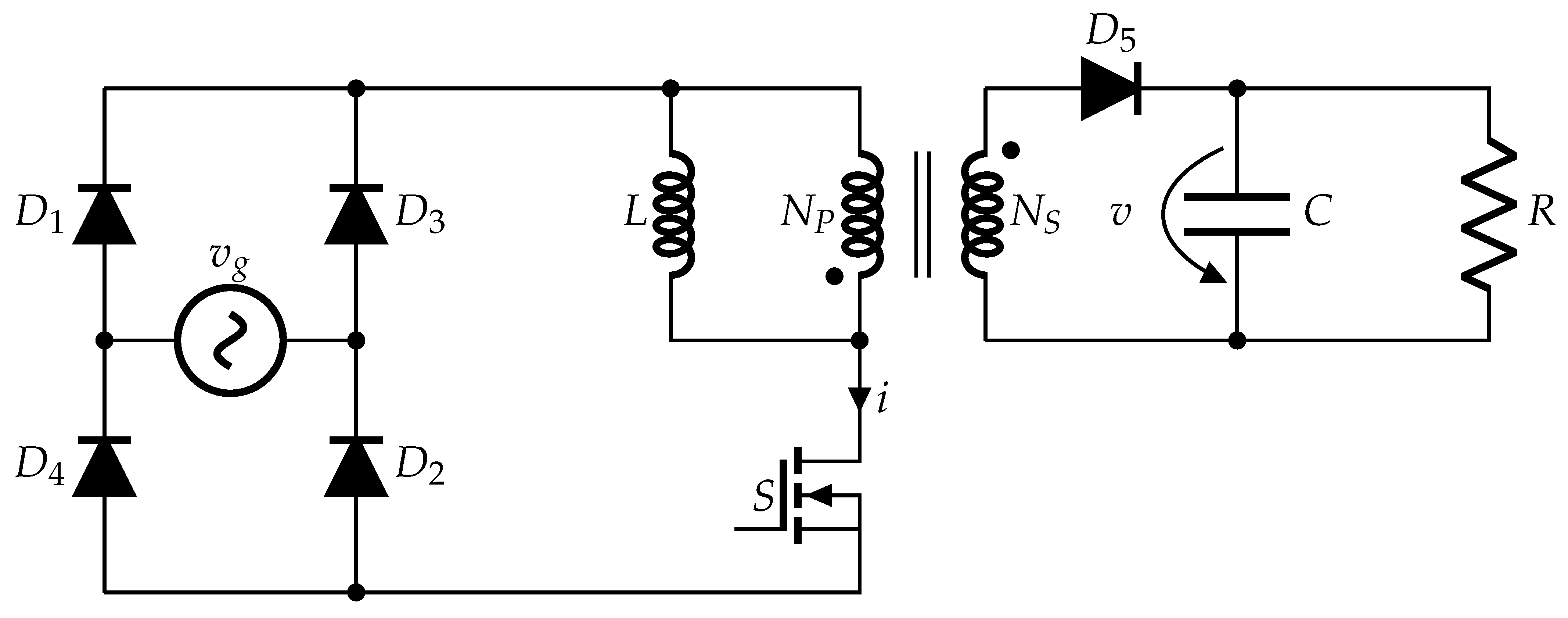

- Li, J.; Yan, T.S.; Feng, C.Y.; Yue, H. Flicker-Free LED Driver Based on Tapped Inductor Boost-Flyback PFC Converter. In Proceedings of the Panda Forum on Power and Energy (PandaFPE), Chengdu, China, 27–30 April 2023; pp. 538–543. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, N. A Boost PFC fed LLC Resonant Converter for Electric Vehicle Application. In Proceedings of the International Conference on Power, Instrumentation, Control and Computing (PICC), Thrissur, India, 19–21 April 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Kranda, E.; Gokdag, M.; Gulbudak, O.; Prabaharan, N. Enhancement of Steady-State Performance of PFC Boost Rectifier using Modulated Model Predictive Control. In Proceedings of the 5th Global Power, Energy and Communication Conference (IEEE GPECOM), Nevsehir, Turkiye, 14–16 June 2023; pp. 50–55. [Google Scholar] [CrossRef]

- Kumar, G.; Chenchireddy, K.; Begum, T.; Aniketh, M.; Kumar, P.; Sayeed, Z. Design and Simulation of Interleaved Boost PFC Converter with PR Controller. In Proceedings of the International Conference on Sustainable Communication Networks and Application (ICSCNA), Theni, India, 15–17 November 2023; pp. 778–782. [Google Scholar] [CrossRef]

- Lu, S.; Ma, H.; Zhang, T.; Tang, L.; Chen, Z. A Novel Boost PFC Converter with Inherent Boundary Conduction Mode Operation. In Proceedings of the IEEE 4th China International Youth Conference On Electrical Engineering (CIYCEE), Chengdu, China, 8–10 December 2023; pp. 1304–1308. [Google Scholar] [CrossRef]

- Correia, W.B.; Júnior, D.O.d.; Vasconce, F.J.d.S.; Medeiros, J.W. Improvements on PFC boost self-control structure. In Proceedings of the IEEE 8th Southern Power Electronics Conference (SPEC), Florianopolis, Brazil, 26–29 November 2023; pp. 1–5. [Google Scholar] [CrossRef]

- de Melo, I.D.F.; Teixeira, G.A.; Barbosa, E.A.O.; Neto, R.C.; Bradaschia, F.; Neves, F.A.S. Comparison Analysis of Current Controllers Applied to a Boost Power Factor Correction Converter. In Proceedings of the IEEE 8th Southern Power Electronics Conference (SPEC), Florianopolis, Brazil, 26–29 November 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Purohit, R.; Bhalla, V. Comparative Analysis of Boost, Cuk and Zeta PFC Converters in Continuous Current Mode. In Proceedings of the 9th IEEE India International Conference on Power Electronics (IICPE), Sonipat, India, 28–30 November 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Ramos, C.; Saavedra, A.; Bastidas, J. Co-Design of the Control and Power Stages of a Boost-Based Rectifier with Power Factor Correction Depending on Performance Criteria. Computation 2022, 10, 61. [Google Scholar] [CrossRef]

- Okilly, A.H.; Baek, J. Design and Fabrication of an Isolated Two-Stage AC-DC Power Supply with a 99.50% PF and ZVS for High-Power Density Industrial Applications. Electronics 2022, 11, 1898. [Google Scholar] [CrossRef]

- Zhang, R.; Dong, J.; Wang, L.; Ma, W.; Yin, G. Stabilizing the Boost PFC Converter with a Time Delay Feedback Controller. Electronics 2023, 12, 2291. [Google Scholar] [CrossRef]

- Han, J.-K. Frequency Modulation Scheme for CCM Boost PFC Converter to Improve THDinLight-Load Condition. Electronics 2024, 13, 256. [Google Scholar] [CrossRef]

- Tayar, T.; Abramovitz, A.; Shmilovitz, D. DCM Boost PFC for High Brightness LED Driver Applications. Energies 2021, 14, 5486. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, D.; Wang, W.; Zhang, F.; Yuan, J.; Liu, N. Adaptive Charge-Compensation-Based Variable On-Time Control to Improve Input Current Distortion for CRM Boost PFC Converter. Energies 2022, 15, 4021. [Google Scholar] [CrossRef]

- Ortiz-Castrillón, J.R.; Saldarriaga-Zuluaga, S.D.; noz-Galeano, N.M.; López-Lezama, J.M.; Benavides-Córdoba, S.; Cano-Quintero, J.B. Optimal Sliding-Mode Control of Semi-Bridgeless Boost Converters Considering Power Factor Corrections. Energies 2023, 16, 6282. [Google Scholar] [CrossRef]

- Han, J.-K. Efficiency and PF Improving Techniques with a Digital Control for Totem-Pole Bridgeless CRM Boost PFC Converters. Energies 2024, 17, 369. [Google Scholar] [CrossRef]

- Cheng, C.-A.; Cheng, H.-L.; Chang, C.-H.; Chang, E.-C.; Tsai, C.-Y.; Lan, L.-F. A Novel and Cost-Effective Drive Circuit for Supplying a Piezoelectric Ceramic Actuator with Power-Factor-Correction and Soft-Switching Features. Micromachines 2021, 12, 1229. [Google Scholar] [CrossRef]

- Kishore, G.I.; Tripathi, R.K. Single-phase unidirectional AC-DC PFC converter with switched capacitors. Int. J. Electron. 2021, 108, 305–321. [Google Scholar] [CrossRef]

- Fusic, J.; Shunmathi, M.; Sitharthan, R.; OV, G.S.; Ramesh, H.; Kumar, A. Efficient power factor correction in single phase AC-DC boost converter for retrofitted electric bicycle battery charging: A finite element analysis approach. Comput. Electr. Eng. 2024, 119, 109549. [Google Scholar] [CrossRef]

- Li, G.; Huang, H.; Song, S.; Liu, B. A nonlinear control scheme based on input-output linearized method achieving PFC and robust constant voltage output for boost converters. Energy Rep. 2021, 7, 5386–5393. [Google Scholar] [CrossRef]

- Ganesh, R.J.; Kodeeswaran, S.; Kavitha, M.; Ramkumar, T. Performance analysis of piezoelectric energy harvesting system employing bridgeless power factor correction boost rectifier. Mater. Today Proc. 2021, 45, 486–494. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Dong, Z.; Feng, K.; Liu, C. A True Bridgeless Buck-Type PFC Converters with Low Total Harmonics Distortion. In Proceedings of the 49th Annual Conference of the IEEE Industrial Electronics Society (IECON), Singapore, 16–19 October 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, J.; Liu, Y.; Liu, C. High Power Factor Buck-Type Bridgeless Topology Family with Hybrid Converter Cells. IEee Trans. Power Electron. 2023, 39, 8024–8039. [Google Scholar] [CrossRef]

- Jain, A.; Gupta, K.K.; Jain, S.K.; Bhatnagar, P.; Vahedi, H. A V2G Enabled Bidirectional Single/Three-Phase EV Charging Interface Using Modular Multilevel Buck PFC Rectifier. Electronics 2022, 11, 1891. [Google Scholar] [CrossRef]

- Echalih, S.; Abouloifa, A.; Lachkar, I.; Guerrero, J.M.; Hekss, Z.; Giri, F. Hybrid automaton-fuzzy control of single phase dual buck half bridge shunt active power filter for shoot through elimination and power quality improvement. Electr. Power Energy Syst. 2021, 131, 106986. [Google Scholar] [CrossRef]

- Echalih, S.; Abouloifa, A.; Hekss, Z.; Lachkar, I.; Aroudi, A.E.; Giri, F. Advanced Nonlinear Control of Single Phase Shunt Active Power Filter Based on Full Bridge Dual Buck Converter. IFAC Pap. 2022, 55, 659–664. [Google Scholar] [CrossRef]

- Singh, N.K.; Veerachary, M.; Singh, B. Bridgeless Buck-Boost PFC Rectifier using Switched Capacitor Configuration. In Proceedings of the IEEE IAS Global Conference on Renewable Energy and Hydrogen Technologies (GlobConHT), Male, Maldives, 1–12 March 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Ghorbanian, M.; Maghsoudi, M.; Hosseinabadi, F.; Adib, E.; Barzegarkhoo, R.; Blaabjerg, F. A Soft-Switching Bridgeless Buck-Boost Power Factor Correction Converter with Simple Auxiliary Circuit and Low Input Current THD. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 4245–4254. [Google Scholar] [CrossRef]

- Kumar, G.K.N.; Verma, A.K. A Single-Phase Interleaved Buck-Boost PFC Based On-Board EV Charger. IEEE Trans. Ind. Appl. 2023, 59, 7163–7174. [Google Scholar] [CrossRef]

- Yang, J.; Li, Y.; Shu, Z. A Buck-Boost Common Ground Bridgeless PFC Rectifier with Power Decoupling Ability. In Proceedings of the IEEE 14th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Shanghai, China, 9–12 June 2023; pp. 174–179. [Google Scholar] [CrossRef]

- Miyada, Y.; Ohata, K.; Watanabe, H. Buck-Boost PFC Converter with Active Power Decoupling Capability Using Time-sharing Control. In Proceedings of the IEEE Energy Conversion Congress and Exposition (ECCE), Nashville, TN, USA, 29 October–2 November 2023; pp. 3325–3332. [Google Scholar] [CrossRef]

- González-Castaño, C.; Restrepo, C.; Sanz, F.; Chub, A.; Giral, R. DC Voltage Sensorless Predictive Control of a High-Efficiency PFC Single-Phase Rectifier Based on the Versatile Buck-Boost Converter. Sensors 2021, 21, 5107. [Google Scholar] [CrossRef]

- Sánchez, J.S.; Trujillo, C.L.; Montoya, O.D. Implementation of a strategy to improve the efficiency of battery chargers with double conversion topology, high power factor, and low THDi. Ain Shams Eng. J. 2024, 15, 102379. [Google Scholar] [CrossRef]

- Perumal, R.B.; Chittibabu, K. An effective power quality battery charger using modified high gain buckboost converter. Energy Rep. 2025, 13, 3456–3468. [Google Scholar] [CrossRef]

- Krismer, F.; Menzi, D.; Ziegler, P.; Yang, A.; Kolar, J.W. Optimal Space Vector Modulation of a New Bidirectional Dual-Active-Bridge-Type Single-Stage Isolated Three-Phase Buck-Boost PFC Rectifier System. IEEE J. Emerg. Sel. Top. Power Electron. 2025, 13, 72–90. [Google Scholar] [CrossRef]

- Yang, J.-W.; Do, H.-L. Single-Stage Two-Flyback PFC Converter with Low Voltage Stress on a Switch. IEEE Trans. Ind. Electron. 2025, 72, 1466–1474. [Google Scholar] [CrossRef]

- Ma, C.; Yao, K.; Shao, F.; Mao, C. Fixed Switching Frequency Controls for Integrated Buck PFC Converters in Critical Conduction Mode. IEEE J. Emerg. Sel. Top. Ind. Electron. 2025, 6, 790–801. [Google Scholar] [CrossRef]

- Khan, H.R.; Kazmi, M.; Ashraf, H.B.; Khalid, M.H.B.; Hasan, A.; Qazi, S.A. An Isolated Power Factor Corrected Cuk Converter with Integrated Magnetics for Brushless DC Ceiling Fan Applications. Electronics 2021, 10, 1720. [Google Scholar] [CrossRef]

- Yan, T.; Chen, T.; Huang, A.; Chen, W.; Cao, T. CukPFCConverter Based on Variable Inductor. Electronics 2023, 12, 2245. [Google Scholar] [CrossRef]

- Sehirli, E. LCL Trap Filter Analysis with a PFC Isolated Cuk Converter Using SiC MOSFET for DCM. Energies 2024, 17, 758. [Google Scholar] [CrossRef]

- Shameli, A.; Farzanehfard, H. Bridgeless Cuk PFC converter with full load range soft switching operation by using a simple auxiliary circuit. Comput. Electr. Eng. 2025, 122, 109905. [Google Scholar] [CrossRef]

- Singh, V.K.; Singh, B. Sensorless control using single current sensor with PFC assisted SRM drive for cost-effective domestic appliances. e-Prime-Adv. Electr. Eng. Electron. Energy 2024, 9, 100720. [Google Scholar] [CrossRef]

- Szekely, N.C.; Salcu, S.I.; Suciu, V.M.; Pintilie, L.N.; Fasola, G.I.; Teodosescu, P.D. Power Factor Correction Application Based on Independent Double-Boost Interleaved Converter (IDBIC). Appl. Sci. 2022, 12, 7209. [Google Scholar] [CrossRef]

- Jin, N.-Z.; Wu, Z.-Q.; Zhang, L.; Feng, Y.; Wu, X.-G. Bridgeless PFC Converter without Electrolytic Capacitor Based on Power Decoupling. Electronics 2023, 12, 321. [Google Scholar] [CrossRef]

- Cheng, C.-A.; Lee, C.-M.; Chang, E.-C.; Hou, S.-H.; Lan, L.-F.; Lin, C.-K. A Novel Integrated Electronic Lighting Driver Circuit for Supplying an LED Projection Lamp with High Power Factor and Soft Switching Characteristics. Electronics 2023, 12, 4642. [Google Scholar] [CrossRef]

- Soares, J.W.M.; Badin, A.A. High-Efficiency Interleaved Totem-Pole PFC Converter With Voltage Follower Characteristics. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 1879–1887. [Google Scholar] [CrossRef]

- Kumar, G.K.N.; Verma, A.K. Switched-Capacitor Based Bridgeless Totem-Pole PFC Converter for EV Applications. In Proceedings of the 49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 16–19 October 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Akbar, S.Q.U.A.; Yeon, J. Cost-and Energy-Efficient Bridgeless Totem-pole PFC Using CoolSiC™ Hybrid Discrete IGBT for High Power SMPS Application Achieves 80 PLUS Titanium Grade. In Proceedings of the PCIM Europe, Nuremberg, Germany, 9–11 May 2023. [Google Scholar] [CrossRef]

- Li, J.; Chen, Z.; Zhang, S.; Wu, X. Implementation of Close-Loop Control for Interleaved CrM Totem-Pole PFC Converters with GaN Devices. In Proceedings of the IEEE 14th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Shanghai, China, 9–12 June 2023; pp. 137–140. [Google Scholar] [CrossRef]

- Hyeon, Y.; Lee, D.; Jeong, S.; Lim, J.; Youn, H. Inductor Design of Interleaved Totem-pole Bridgeless Boost PFC Based on Pareto Optimization. In Proceedings of the 49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 16–19 October 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Barath Narayanan, A.; Sampath Kumar, S. Bridgeless Boost Totem Pole Power Factor Correction for EV on Board Charger Applications. In Proceedings of the Second International Conference on Smart Technologies for Smart Nation (SmartTechCon), Singapore, 18–19 August 2023; pp. 961–968. [Google Scholar] [CrossRef]

- Kumar, V.; Yi, K. Single-Phase, Bidirectional, 7.7 kW Totem Pole On-Board Charging/Discharging Infrastructure. Appl. Sci. 2022, 12, 2236. [Google Scholar] [CrossRef]

- Fu, H.; Duan, S.; Li, Y.; Li, Q. Improved Control Strategy for Zero-Crossing Distortion Elimination in Totem-Pole PFC Converter with Coupled Inductor. Energies 2022, 15, 5437. [Google Scholar] [CrossRef]

- Dimitrov, B.; Hayatleh, K.; Konaklieva, S. Power converters design and experimental verification for electromagnetic contactors to reduce the impact of the voltage sag in the power system. e-Prime-Adv. Electr. Eng. Electron. Energy 2024, 9, 100721. [Google Scholar] [CrossRef]

- Li, G.; Lv, Q.; Zhang, Z.; Dong, H. AC-DC Fuzzy Linear Active Disturbance Rejection Control Strategy of Front Stage of Bidirectional Converter Based on V2G. Energy Eng. 2023, 120, 1045–1065. [Google Scholar] [CrossRef]

- Seyezhai, R.; Ammaiyappan, A.B.S.; Heera, N.; Keerthana, P.; Srinivasan, M. Simulation and hardware development of AC-DC power converter for Off- board charger of EV. Mater. Today Proc. 2022, 62, 1189–1196. [Google Scholar] [CrossRef]

- Pallekonda, A.K.; Ch, R.K. High gain interleaved PFC converter for torque ripple minimization in industrial PMBLDC motor based drives. Results Eng. 2024, 23, 102413. [Google Scholar] [CrossRef]

- Ravinchandra, K.; Freddy, T.K.S.; Thiruchelvam, V. Review of Electrical Characteristics for Wide Bandgap Power Devices. In Proceedings of the IEEE 12th Energy Conversion Congress & Exposition-Asia (ECCE-Asia), Singapore, 24–27 May 2021. [Google Scholar] [CrossRef]

- Tigira, S.; Diaz, F.J.; Pigazo, A.; Azcondo, F.J.; Lamo, P.; Branas, C.; Casanueva, R. A Phase-Locked Loop (PLL) based Strategy for Accurate Blanking Times in Bridgeless Totem-Pole PFCs. In Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nürnberg, Germany, 11–13 June 2024. [Google Scholar] [CrossRef]

- Pourmirasghariyan, M.; Milimonfared, J.; Yazdi, S.S.H.; Biglo, A.H.A.; Rouzbehi, K. Application of Max Flow-Min Cut Theory To Find The Best Placement of Electronic-based DC-PFCs for Enhancing Static Security In MT-HVDC Meshed Grids. In Proceedings of the 30th International Conference on Electrical Engineering (ICEE), Tehran, Iran, 17–19 May 2022. [Google Scholar] [CrossRef]

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| Studies published in Spanish, English, or Portuguese. | Publications prior to 1 January 2000. |

| Research focused on solutions with converter circuits with power factor correction for the academic and industrial sector. | Low-quality papers where the results are not clearly presented. |

| Terms related to converter circuits with power factor correction in the titles, abstracts, and keywords of the publications. In this regard, the search term “Power*Converter" or “Electrical* Converter*” was used. | Articles of low scientific relevance. |

| Studies published from 1 January 2000 to 2 December 2024 (updated to 16 May 2025). | |

| Publications such as scientific research or review articles published in scientific journals or conferences. |

| Reference | Implementation | Control (Operation) Strategy | PF | THDi | Efficiency | Output Power | Input Voltage | Output Voltage |

|---|---|---|---|---|---|---|---|---|

| [14] | Hardware | PI Voltage Loop Current Loop | - | 1 kW | Vac | Vdc | ||

| [15] | Hardware | Sliding Frequency Modulation (SFM) | - | 300 W | 170 Vac | 383 Vdc | ||

| [16] | Hardware | PI Controller | 18 W | Vac | Vdc | |||

| [17] | Simulation | PI Pulse Frequency Modulation (PFM) | - | 576 W | Vac | - | ||

| [18] | Hardware | Modulated Model Predictive Controller (MMPC) | - | - | 500 W | 110 Vac | 250 Vdc | |

| [19] | Simulation | PI, PR (Proportional Resonant) Voltage Loop, Dual Current Loop | - | - | 350 W | 177 Vac | 400 Vdc | |

| [20] | Hardware | PI (Voltage Loop), Pulse Frequency Modulation (PFM) | - | 120 W | Vac | 400 Vdc | ||

| [21] | Hardware | PI, Inductor Current Regulation | - | - | - | 615 W | 220 Vac | 400 Vdc |

| [22] | Simulation | Repetitive Controller (RC), Current Control Loop (CCL) | - | - | - | - | ||

| Hardware | PI | - | - | 6 W | 12 Vac | 24 Vdc | ||

| [23] | Simulation | PI (Voltage Loop) PI (Current Loop) | - | - | 600 W | 35 Vac | Vdc | |

| [24] | Simulation | Sliding Mode Controller (SMC) for current PI controller for output voltage Adaptive Control | - | 440 W | 120 Vac | 220 Vdc | ||

| [25] | Hardware | PI (Voltage Loop), PI (Current Loop), Zero-Voltage Switching | - | 500 W 750 W 1250 W 2000 W | Vac | Vdc | ||

| [26] | Simulation | Delayed Feedback Controller | - | W | 66 Vac | 167 Vdc | ||

| [27] | Hardware | Integrated Circuit (ICE3PCS03G - Infineon CCM PFC Controller), Frequency Control | 850 W 425 W | 220 Vac | 380 Vdc | |||

| [28] | Hardware | Outer current loop, One Cycle Control (OCC) | W | 110 Vac | - | |||

| [29] | Hardware | Adaptive charge-compensation-based variable on-time (ACTOV) controller | 200 W kW | Vac Vac | 400 Vdc 450 Vdc | |||

| [30] | Hardware | Sliding Mode Control (SMC), Optimization using PSO and GA | - | - | - | 15 W | 12 Vac | 40 Vdc |

| [31] | Hardware | Critical conduction mode | kW | Vac | 450 Vdc | |||

| [32] | Hardware | Discontinuous conduction mode | - | 50 W | 110 Vac | - | ||

| [33] | Hardware | PI, Average Current Control | kW | 75 Vac | 300 Vdc | |||

| [34] | Hardware | PI, Voltage Loop. Output Current Loop Power Control | - | 250 W | 240 Vac | Vdc | ||

| [35] | Hardware | Controller made with simple math operations (addition and multiplication) PWM module. Transformation for the linearization of the nonlinear system | - | 200 W | 100 Vac | 200 Vdc | ||

| [36] | Simulation | Logic gates with PI controller. Voltage Loop Current Loop | - | W | Vac | Vdc |

| Reference | Implementation | Control (Operation) Strategy | PF | THDi | Efficiency | Output Power | Input Voltage | Output Voltage |

|---|---|---|---|---|---|---|---|---|

| [37] | Simulation | Voltage Loop | - | 150 W | 220 Vac | 200 Vdc | ||

| [38] | Hardware | PI (Buck Converter) PI (Dual Bridgeless) PI (Hybrid Converter) | 100 W | Vac | 160 Vdc | |||

| [39] | Hardware | Level shifted PWM signals for each phase, Voltage Loop, Currents Loop | 969 W | 170 Vac | 100 Vdc | |||

| [40] | Simulation | Fuzzy Logic Controller. Multi-loop structure, Inner Loop: Hybrid Automaton Representation (Power Factor Control), Outer Loop: Fuzzy Logic (Converter Out Voltage) | - | - | 230 Vac | 900 Vdc | ||

| [41] | Simulation | Sliding Mode Controller (SMC) for inner loop PI Controller for outer loop. Inner Loop: Input Current, Outer Loop: Output Voltage | - | - | - | 110 Vac | 400 Vdc |

| Reference | Implementation | Control (Operation) Strategy | PF | THDi | Efficiency | Output Power | Input Voltage | Output Voltage |

|---|---|---|---|---|---|---|---|---|

| [42] | Simulation | Voltage Loop, Current Loop | - | 1 kW | 220 Vac | 200 Vdc | ||

| [43] | Hardware | PI, PWM control | 500 W | Vac | 96 Vdc | |||

| [44] | Hardware | PI, Pulse Frequency Modulation (PFM) | 1 kW | Vac | 55 Vdc | |||

| [45] | Simulation | PI, Voltage Control, Current Control | - | 300 W | 110 Vac | 200 Vdc | ||

| [46] | Simulation Hardware | PI, Time sharing control using Triangular Current Mode (TCM) | >90.2% | 200 W | 100 Vac | 200 Vdc | ||

| [47] | Simulation | PI, Predictive digital current programmed control (PDCC) | - | - | 900 W | 220 Vac | 200 Vdc | |

| [48] | Hardware | PI, Outer Loop: Output Voltage, Inner Loop: Input Current | 1 kW | Vac | 140 Vdc | |||

| [49] | Hardware | PI for voltage control, PI for current control. Active PFC Control, Outer Loop: Output Voltage, Inner Loop: Input Current | 750 W | Vac | 48 Vdc | |||

| [50] | Hardware | Space vector calculation to determine the steady-state waveform | 4500 W | 230 Vac | 401 Vdc | |||

| [51] | Hardware | Active PFC controller NCP1607. Critical conduction mode operation | - | 100 W | Vac | 48 Vdc | ||

| [52] | Hardware | Fixed switching frequency controller (FFC). Switching frequency controlled by the peak current feedforward loop with critical conduction mode | 120 W | Vac | 80 Vdc |

| Reference | Implementation | Control (Operation) Strategy | PF | THDi | Efficiency | Output Power | Input Voltage | Output Voltage |

|---|---|---|---|---|---|---|---|---|

| [53] | Simulation | PI, PWM control | 0.99 | 4.72% | - | 50 W | 90–270 Vac | 15 Vdc |

| [54] | Hardware | Variable Inductor | 0.997 | 5% | 90.50% | 108 W | 90 Vac | 72 Vdc |

| [55] | Hardware | PI, Voltage Loop | 0.998 | 4.83% | 85% | 50 W | 140 Vac | 25.9 Vdc |

| [23] | Simulation | PI, Voltage Loop, Current Loop | - | 0.75% | - | 800 W | - | - |

| [56] | Hardware | PI Voltage Loop | 200 W | 110 Vac | 80 Vdc | |||

| [57] | Hardware | Voltage Loop | - | 500 W | 220 Vac | Vdc |

| Reference | Implementation | Control (Operation) Strategy | PF | THDi | Efficiency | Output Power | Input Voltage | Output Voltage |

|---|---|---|---|---|---|---|---|---|

| [58] | Hardware | PI, Voltage Loop, Current Loop | 550 W | 90 Vac 110 Vac 130 Vac | 350 Vdc | |||

| [59] | Simulation | PI, Average Current Control | - | - | 210 W | 220 Vac | 400 Vdc | |

| [60] | Hardware | High-voltage resonant controller | 100 W | 110 Vac | 36 Vdc |

| Reference | Implementation | Control (Operation) Strategy | PF | THDi | Efficiency | Output Power | Input Voltage | Output Voltage |

|---|---|---|---|---|---|---|---|---|

| [61] | Hardware | PI, Voltage Loop, One half-line cycle detector | 1 kW | 127 Vac | 400 Vdc | |||

| [62] | Hardware | PI (Voltage Loop), PR (Inner Current Loop), PWM control | - | 1 kW | 270 Vac | 400 Vdc | ||

| [63] | Hardware | Hybrid discrete IGBT | - | - | kW | - | - | |

| [64] | Hardware | PI, Master-Slave Strategy | - | - | - | kW | 220 Vac | 400 Vdc |

| [65] | Hardware | Pareto optimal inductor design | - | - | kW | 220 Vac | 650 Vdc | |

| [66] | Simulation | Fractional Propotional-Integral-Derivative (FOPID), Artificial Neural Network (ANN), Voltage Loop Inner Current Loop | - | - | kW | 230 Vac | 400 Vdc | |

| [67] | Simulation | PI, Voltage Loop, Current Loop | - | kW | 230 Vac | 400 Vdc | ||

| [68] | Hardware | PI (Voltage Loop), Proportional Integral Resonant (PIR) - (Current Loop), Zero-Crossing Distortion Inhibitory Strategy | kW | 220 Vac | 390 Vdc | |||

| [69] | Simulation | PWM controller | - | 500 W | 230 Vac | Vdc | ||

| [70] | Hardware | PI controller Fuzzy LADRC controller (Linear Active Disturbance Rejection Control), Outer Loop: Output Voltage Inner Loop: Input Current | - | > | 3 kW | 220 Vac | Vdc | |

| [71] | Simulation | PWM controller ( Duty Cycle) Open Loop | 60 W | 12 Vac | 25 Vdc | |||

| [72] | Hardware | Adaptive Cascaded Fuzzy Controller PWM generator Hysteresis Controller, Voltage Loop Current Loop | - | - | Vac | 300 Vdc |

| Topology | Efficiency | Complexity | Applications | Note |

|---|---|---|---|---|

| Boost | High | Low | Switching power supplies, LED, general | DC input current |

| Interleaved boost | Very High | Average | High power, industry | Reduced current ripple |

| Bridgeless boost | Very High | Average | High efficiency, chargers VE | Lower current conduction losses |

| Buck | Low | Low | Low | Reduced set of applications |

| Buck-boost | Average | Low | Variable voltages, Low power | Reverse polarity, higher EMI |

| Flyback | Average | Average | Consumer electronics, low power | Galvanically isolated, suitable for <150 W |

| Cük | Average | High | Industrial equipment | Reverse polarity, remarkable ripple attenuation |

| SEPIC | Average | High | Automotive industry, adaptive PFC | Positive polarity, more components |

| Dual boost | Very High | High | Fast chargers, server power supplies | Ideal for GaN/SiC, high density and efficiency |

| Totem pole bridgeless | Very High | High | Server power supplies, fast chargers | Half and Full Bridge, Ideal for GaN/SiC, high density and efficiency |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quiroga, A.; Bayona, J.; Espitia, H. Review of Converter Circuits with Power Factor Correction. Technologies 2025, 13, 221. https://doi.org/10.3390/technologies13060221

Quiroga A, Bayona J, Espitia H. Review of Converter Circuits with Power Factor Correction. Technologies. 2025; 13(6):221. https://doi.org/10.3390/technologies13060221

Chicago/Turabian StyleQuiroga, Angel, Jhon Bayona, and Helbert Espitia. 2025. "Review of Converter Circuits with Power Factor Correction" Technologies 13, no. 6: 221. https://doi.org/10.3390/technologies13060221

APA StyleQuiroga, A., Bayona, J., & Espitia, H. (2025). Review of Converter Circuits with Power Factor Correction. Technologies, 13(6), 221. https://doi.org/10.3390/technologies13060221