A Novel Sustainable and Cost-Effective Triboelectric Nanogenerator Connected to the Internet of Things for Communication with Deaf–Mute People

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Working Mechanism

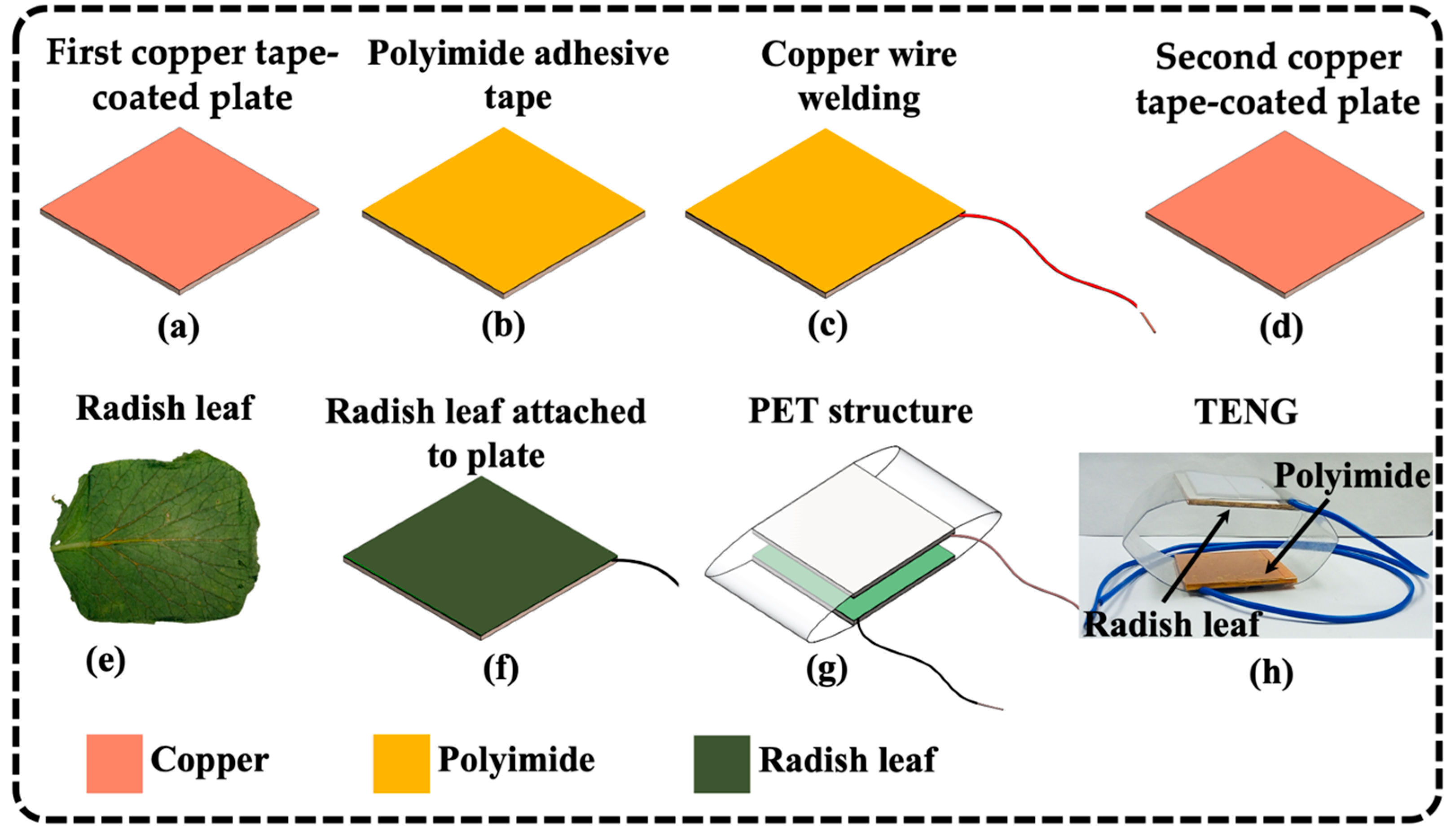

2.3. TENG Manufacturing and Setup

3. Results and Discussion

3.1. Fourier Transform Infrared Spectroscopy (FTIR)

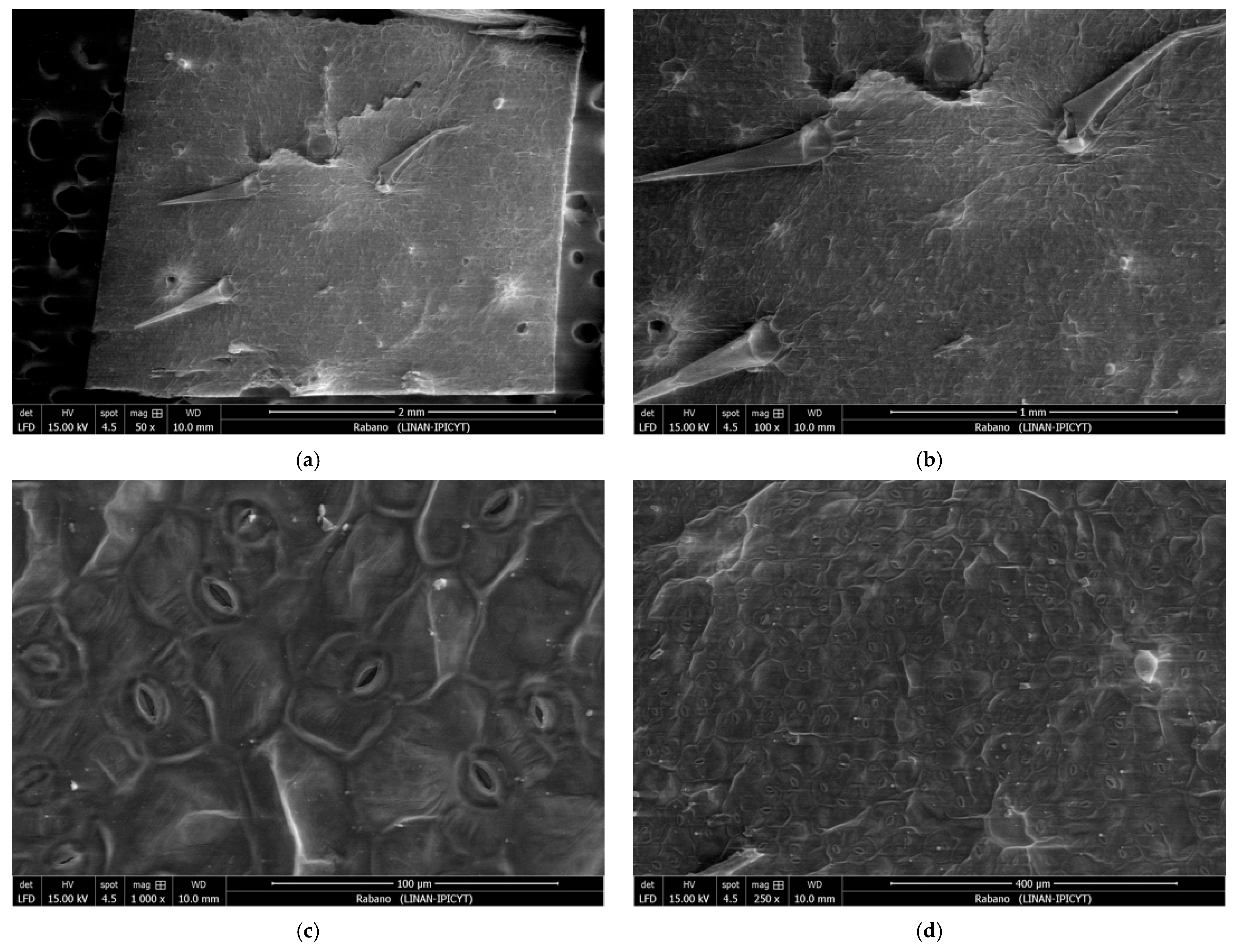

3.2. Scanning Electron Microscopy (SEM)

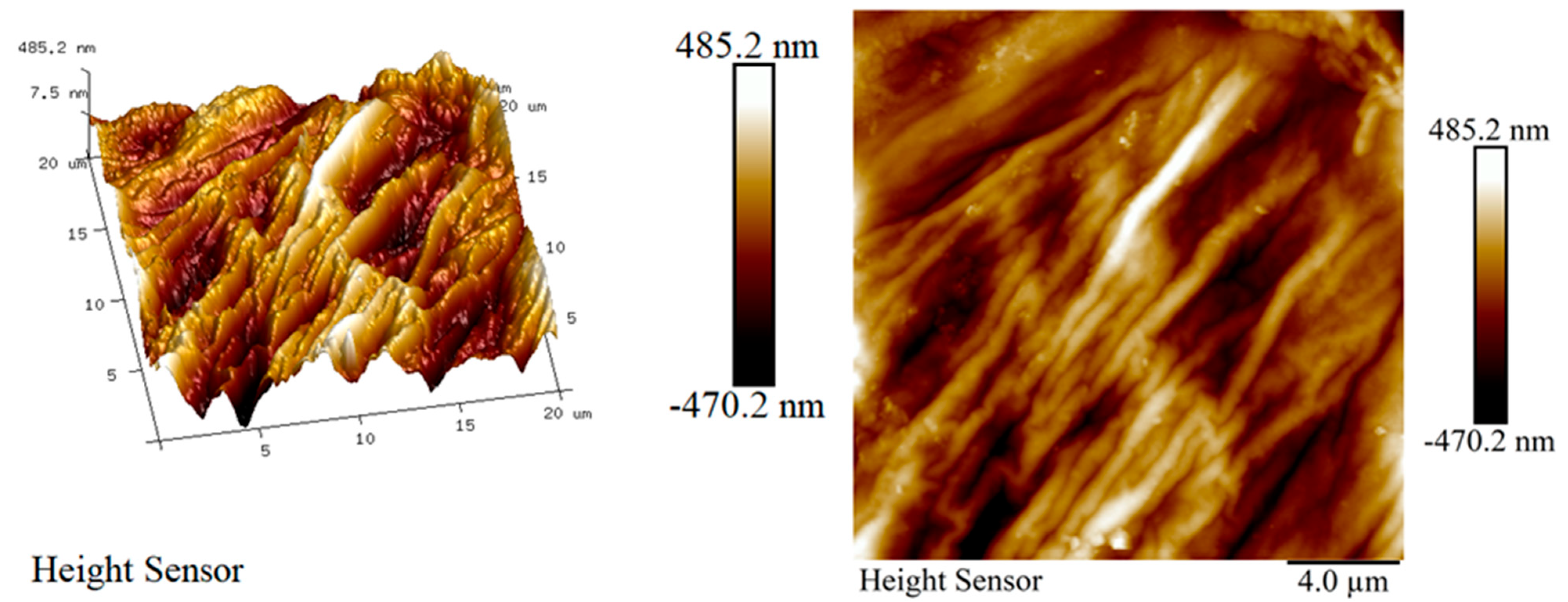

3.3. Atomic Force Microscopy (AFM)

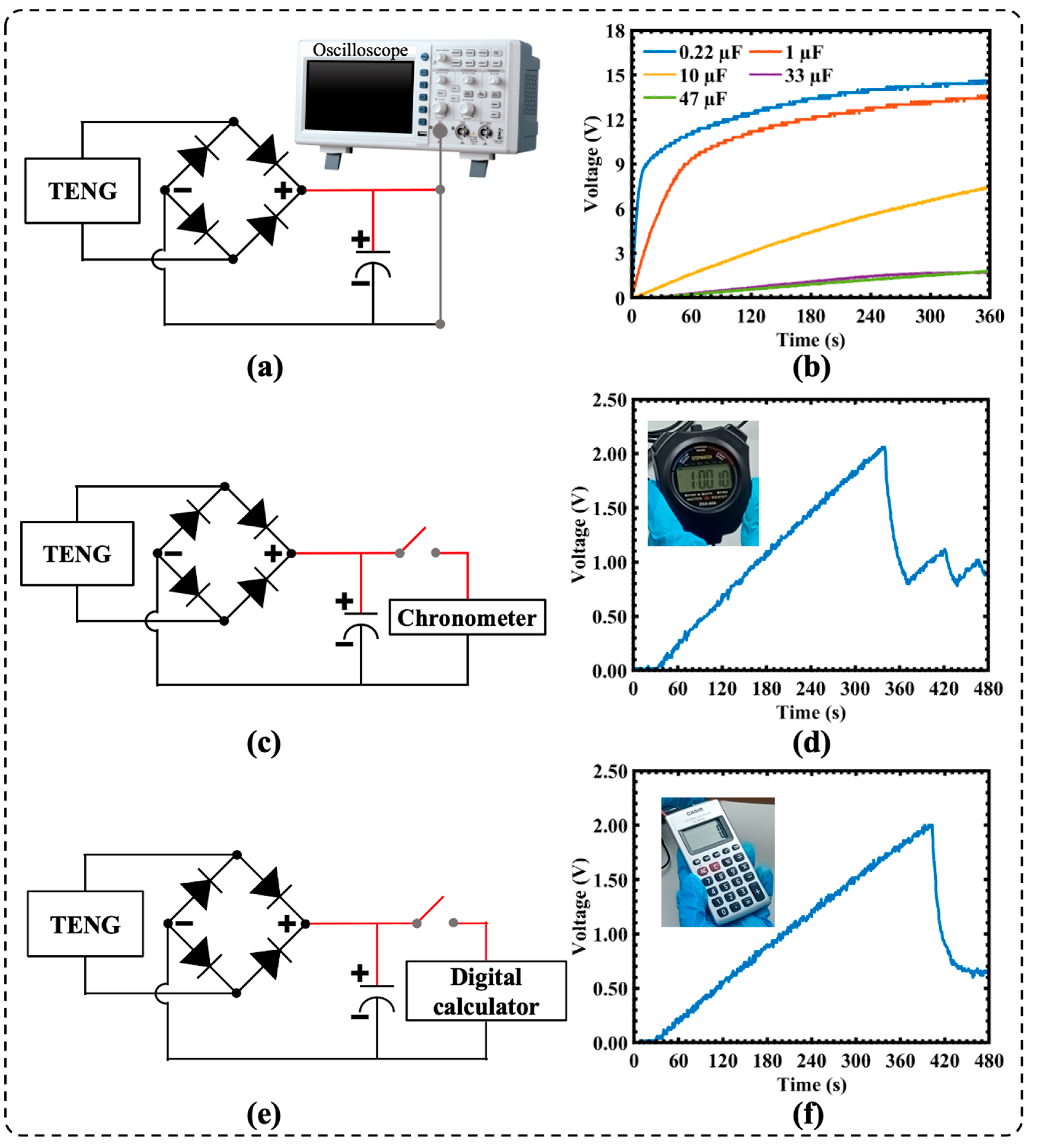

3.4. Output Performance of the TENG

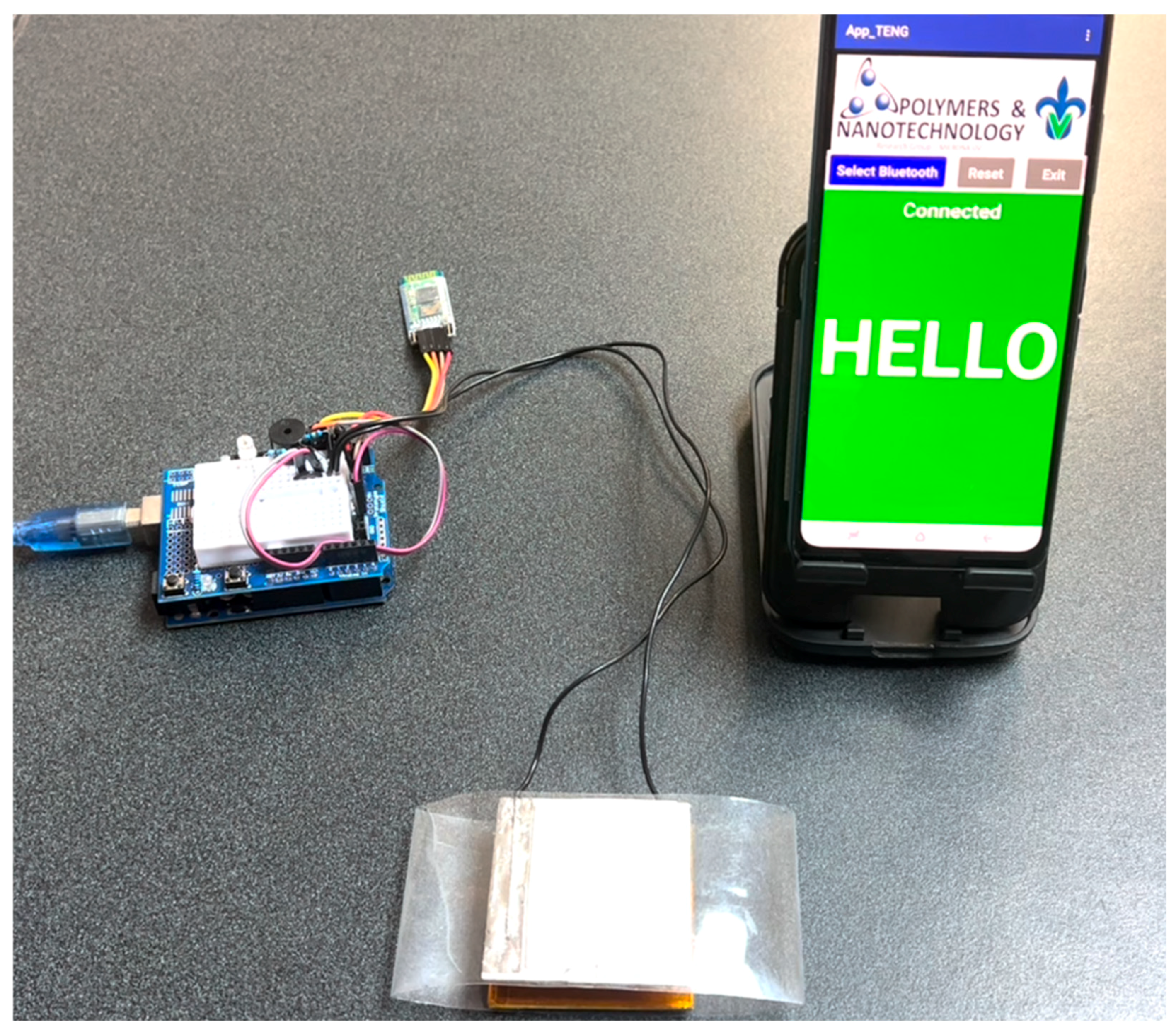

3.5. Applications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Talaat, F.M.; El-Shafai, W.; Soliman, N.F.; Algarni, A.D.; El-Samie, F.E.A.; Siam, A.I. Real-time Arabic avatar for deaf-mute communication enabled by deep learning sign language translation. Comput. Electr. Eng. 2024, 119, 109475. [Google Scholar] [CrossRef]

- ZainEldin, H.; Baghdadi, N.A.; Gamel, S.A.; Aljohani, M.; Talaat, F.M.; Malki, A.; Badawy, M.; Elhosseini, M. Active convolutional neural networks sign language (ActiveCNN-SL) framework: A paradigm shift in deaf-mute communication. Artif. Intell. Rev. 2024, 57, 162. [Google Scholar] [CrossRef]

- Azman, S.; Ralim, N.M.; Baharudin, S.A.; Kadir, D.A.; Ahmad, N.Z. Smart Glove: The Sign Language Translator for Mute-Deaf Citizens. In Applied Problems Solved by Information Technology and Software; Ismail, A., Zulkipli, F.N., Mohd Daril, M.A., Öchsner, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar] [CrossRef]

- Mosa, D.T.; Nasef, N.A.; Lotfy, M.A.; Abohany, A.A.; Essa, R.M.; Salem, A. A real-time Arabic avatar for deaf–mute community using attention mechanism. Neural Comput. Appl. 2023, 35, 21709–21723. [Google Scholar] [CrossRef]

- Babour, A.; Bitar, H.; Alzamzami, O.; Alahmadi, D.; Barsheed, A.; Alghamdi, A.; Almshjary, H. Intelligent gloves: An IT intervention for deaf-mute people. J. Intell. Syst. 2023, 32, 20220076. [Google Scholar] [CrossRef]

- Mahamud, M.S.; Islam, M.; Shila, A.S.; Asif Fuad, K.A.; Islam, M.R. Watch IT Version-II: An Assistive Device for Hearing and Speaking Impaired. In Intelligent Systems and Applications; Arai, K., Kapoor, S., Bhatia, R., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 253–264. [Google Scholar]

- Farooq, U.; Rahim, M.S.M.; Sabir, N.; Hussain, A.; Abid, A. Advances in machine translation for sign language: Approaches, limitations, and challenges. Neural Comput. Appl. 2021, 33, 14357–14399. [Google Scholar] [CrossRef]

- Delgado-Alvarado, E.; Figueroa-Navarro, M.A.; Martínez-Castillo, J.; García-González, L.; Elvira-Hernández, E.A.; Vallejo-Montesinos, J.; Pawar, T.J.; Olivares-Romero, J.L.; Herrera-May, A.L. Sustainable, eco-friendly, and cost-effective energy generation based on coffee grounds for self-powered devices and alarm systems. Sens. Actuators A Phys. 2024, 378, 115816. [Google Scholar] [CrossRef]

- Ali, N.U.H.L.; Pazhamalai, P.; Sathyaseelan, A.; Dongale, T.D.; Kim, S.-J. A self-integration via dual-active mode structural-SC-TENG energy device for electrochemical energy storage and triboelectric energy harvesting. Appl. Energy 2024, 376, 124265. [Google Scholar] [CrossRef]

- Lai, S.-N.; Hsu, H.-T.; Wu, J.M. Smart ping-pong paddle with triboelectric self-powered wireless sensors. Nano Energy 2024, 131, 110158. [Google Scholar] [CrossRef]

- Delgado-Alvarado, E.; Martínez-Castillo, J.; Morales-González, E.A.; González-Calderón, J.A.; Armendáriz-Alonso, E.F.; Rodríguez-Liñán, G.M.; López-Esparza, R.; Hernández-Hernández, J.; Elvira-Hernández, E.A.; Herrera-May, A.L. Eco-friendly, compact, and cost-efficient triboelectric nanogenerator for renewable energy harvesting and smart motion sensing. Heliyon 2024, 10, e28482. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, T.; Li, M.; Sun, H.; Wu, H.; Wu, W.; Li, Y.; Jiang, H. Multifunctional wearable triboelectric nanogenerators prepared by combined crystallization and diffusion method: High-output, breathable, antimicrobial, and Janus-wettability for smart control and self-powered biosensing. Nano Energy 2024, 131, 110214. [Google Scholar] [CrossRef]

- Delgado-Alvarado, E.; Elvira-Hernández, E.A.; Hernández-Hernández, J.; Huerta-Chua, J.; Vázquez-Leal, H.; Martínez-Castillo, J.; García-Ramírez, P.J.; Herrera-May, A.L. Recent Progress of Nanogenerators for Green Energy Harvesting: Performance, Applications, and Challenges. Nanomaterials 2022, 12, 2549. [Google Scholar] [CrossRef] [PubMed]

- Xiang, T.; Chen, X.; Sun, H.; Liu, D.; Jiang, Y.; Chen, S.; Xie, Y.; Zhang, S. Advances in liquid-solid triboelectric nanogenerators and its applications. J. Mater. Sci. Technol. 2025, 214, 153–169. [Google Scholar] [CrossRef]

- Hu, J.; Iwamoto, M.; Chen, X. A Review of Contact Electrification at Diversified Interfaces and Related Applications on Triboelectric Nanogenerator. Nano-Micro Lett. 2023, 16, 7. [Google Scholar] [CrossRef] [PubMed]

- Behera, S.A.; Panda, S.; Hajra, S.; Kaja, K.R.; Pandey, A.K.; Barranco, A.; Jeong, S.M.; Vivekananthan, V.; Kim, H.J.; Achary, P.G.R. Current Trends on Advancement in Smart Textile Device Engineering. Adv. Sustain. Syst. 2024, 8, 2400344. [Google Scholar] [CrossRef]

- Tang, Y.; Fu, H.; Xu, B. Advanced design of triboelectric nanogenerators for future eco-smart cities. Adv. Compos. Hybrid Mater. 2024, 7, 102. [Google Scholar] [CrossRef]

- Nguyen, M.P.; Huynh, N.D.; Luu, D. Choi, Recent progress towards smart transportation systems using triboelectric nanogenerators. J. Phys. Energy 2024, 6, 022001. [Google Scholar] [CrossRef]

- Zhang, H.; Wen, N.; Gong, X.; Li, X. Application of triboelectric nanogenerator (TENG) in cancer prevention and adjuvant therapy. Colloids Surf. B Biointerfaces 2024, 242, 114078. [Google Scholar] [CrossRef]

- Cao, X.; Xiong, Y.; Sun, J.; Xie, X.; Sun, Q.; Wang, Z.L. Multidiscipline Applications of Triboelectric Nanogenerators for the Intelligent Era of Internet of Things. Nano-Micro Lett. 2022, 15, 14. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, T.; Zou, X.; Zhu, Y.; Chi, M.; Wu, D.; Jiang, K.; Zhu, S.; Zhai, W.; Wang, S.; et al. Real-time data visual monitoring of triboelectric nanogenerators enabled by Deep learning. Nano Energy 2024, 130, 110186. [Google Scholar] [CrossRef]

- Delgado-Alvarado, E.; Martínez-Castillo, J.; Zamora-Peredo, L.; Gonzalez-Calderon, J.A.; López-Esparza, R.; Ashraf, M.W.; Tayyaba, S.; Herrera-May, A.L. Triboelectric and Piezoelectric Nanogenerators for Self-Powered Healthcare Monitoring Devices: Operating Principles, Challenges, and Perspectives. Nanomaterials 2022, 12, 4403. [Google Scholar] [CrossRef]

- Li, W.; Guo, Y.; Wang, K.; Zhang, S.; Qiu, J.; Li, J.; Suk, C.H.; Wu, C.; Zhou, X.; Zhang, Y.; et al. Research advances in triboelectric nanogenerators based on theoretical simulations. Nano Energy 2024, 127, 109724. [Google Scholar] [CrossRef]

- Panda, S.; Jeong, H.; Hajra, S.; Rajaitha, P.M.; Hong, S.; Kim, H.J. Biocompatible polydopamine based triboelectric nanogenerator for humidity sensing. Sens. Actuators B Chem. 2023, 394, 134384. [Google Scholar] [CrossRef]

- Hou, T.; Li, W.; Wang, H.; Zheng, Y.; Chen, C.; Zhang, H.; Chen, K.; Xie, H.; Li, X.; He, S.; et al. An ultra thin, bright, and sensitive interactive tactile display based on organic mechanoluminescence for dual-mode handwriting identification. InfoMat 2024, 6, e12523. [Google Scholar] [CrossRef]

- Ibrahim, M.; Jiang, J.; Wen, Z.; Sun, X. Surface Engineering for Enhanced Triboelectric Nanogenerator. Nanoenergy Adv. 2021, 1, 58–80. [Google Scholar] [CrossRef]

- Panda, S.; Hajra, S.; Kim, H.G.; Jeong, H.; Achary, P.G.R.; Hong, S.; Dudem, B.; Silva, S.R.P.; Vivekananthan, V.; Kim, H.J. Carbohydrate-protein interaction-based detection of pathogenic bacteria using a biodegradable self-powered biosensor. J. Mater. Chem. B 2023, 11, 10147–10157. [Google Scholar] [CrossRef] [PubMed]

- Elvira-Hernández, E.A.; Hernández-Hernández, J.; de León, A.; Gallardo-Vega, C.; Delgado-Alvarado, E.; López-Huerta, F.; Herrera-May, A.L. Green energy harvesting to power electronic devices using portable triboelectric nanogenerator based on waste corn husk and recycled polystyrene. Energy Rep. 2024, 11, 276–286. [Google Scholar] [CrossRef]

- Yang, T.; Xie, J.; Huang, Z.; Liu, J.; Luo, H.; Jing, X. Bio-inspired vibration isolator with triboelectric nanogenerator for self-powered monitoring. Mech. Syst. Signal Process. 2025, 223, 111854. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L.; Wang, S.; Wang, S.; Wang, D.; Yu, L.; Xu, X.; Liu, H.; Chen, C. Cellulose nanofiber-mediated manifold dynamic synergy enabling adhesive and photo-detachable hydrogel for self-powered E-skin. Nat. Commun. 2024, 15, 3859. [Google Scholar] [CrossRef]

- Du, G.; Shao, Y.; Luo, B.; Liu, T.; Zhao, J.; Qin, Y.; Wang, J.; Zhang, S.; Chi, M.; Gao, C.; et al. Compliant Iontronic Triboelectric Gels with Phase-Locked Structure Enabled by Competitive Hydrogen Bonding. Nano-Micro Lett. 2024, 16, 170. [Google Scholar] [CrossRef]

- Zhao, W.; Zhou, H.; Li, W.; Chen, M.; Zhou, M.; Zhao, L. An Environment-Tolerant Ion-Conducting Double-Network Composite Hydrogel for High-Performance Flexible Electronic Devices. Nano-Micro Lett. 2024, 16, 99. [Google Scholar] [CrossRef]

- Bi, X.; Huang, Z.; Yao, M.; Wang, Z.; Yu, P.; Jiang, C. Highly conductive rubber-based electrode with a robust wrinkled mesh-like copper coating for stretchable triboelectric nanogenerator. Colloids Surf. A Physicochem. Eng. Asp. 2024, 700, 134786. [Google Scholar] [CrossRef]

- Patra, N.R.; Sethi, S.K.; Garg, R.; Goel, A.R.; Negi, Y.S.; Parida, K. Van der Waals interactions enhanced multiple-times all-waste-recycled triboelectric nanogenerator for ultra-high lifetime stability. Nano Energy 2024, 130, 110168. [Google Scholar] [CrossRef]

- Lu, J.; He, Z.; Lin, Z.; Deng, X.; Huang, B.; Lin, B.; Fu, L.; Xu, C. Flexible, wearable triboelectric rubber with tunable surface charge density enabled by regulation of surface functional group density and permittivity. Chem. Eng. J. 2024, 498, 155315. [Google Scholar] [CrossRef]

- Babu, A.; Rakesh, D.; Supraja, P.; Mishra, S.; Kumar, K.U.; Kumar, R.R.; Haranath, D.; Mamidala, E.; Nagapuri, R. Plant-based triboelectric nanogenerator for biomechanical energy harvesting. Results Surf. Interfaces 2022, 8, 100075. [Google Scholar] [CrossRef]

- Luo, Y.; Cao, X.; Wang, Z.L. Self-powered smart agriculture sensing using triboelectric nanogenerators based on living plant leaves. Nano Energy 2023, 107, 108097. [Google Scholar] [CrossRef]

- Li, M.; Jiang, T.; Liu, S.; Sun, H.; Zhang, S.; Wu, W.; Li, Y.; Jiang, H. A high output wool felt-based double-ring triboelectric nanogenerator with durability and humidity resistance for ocean navigation. Nano Energy 2025, 135, 110654. [Google Scholar] [CrossRef]

- Mao, Y.; Zhang, N.; Tang, Y.; Wang, M.; Chao, M.; Liang, E. A paper triboelectric nanogenerator for self-powered electronic systems. Nanoscale 2017, 9, 14499–14505. [Google Scholar] [CrossRef]

- Amini, S.; Ahmed, R.F.S.M.; Kumar, S.; Ankanathappa, S.M.; Sannathammegowda, K. Electrifying waste textiles: Transforming fabric scraps into high-performance triboelectric nanogenerators for biomechanical energy harvesting. Waste Manag. 2024, 190, 477–485. [Google Scholar] [CrossRef]

- Zhao, L.; Han, J.; Zhang, X.; Wang, C. Fish Scale for Wearable, Self-Powered TENG. Nanomaterials 2024, 14, 463. [Google Scholar] [CrossRef]

- Vikingotek. Available online: https://vikingotek.com/products/cinta-kapton-5cm-de-ancho?_pos=3&_sid=10c54c37a&_ss=r (accessed on 15 January 2025).

- Elvira-Hernández, E.A.; Nava-Galindo, O.I.; Martínez-Lara, E.K.; Delgado-Alvarado, E.; López-Huerta, F.; De León, A.; Gallardo-Vega, C.; Herrera-May, A.L. A Portable Triboelectric Nanogenerator Based on Dehydrated Nopal Powder for Powering Electronic Devices. Sensors 2023, 23, 4195. [Google Scholar] [CrossRef]

- Jie, Y.; Jia, X.T.; Zou, J.D.; Chen, Y.D.; Wang, N.; Wang, N.Z.L.; Cao, X. Natural Leaf Made Triboelectric Nanogenerator for Harvesting Environmental Mechanical Energy. Adv. Energy Mater. 2018, 8, 1703133. [Google Scholar] [CrossRef]

- Chi, Y.; Xia, K.; Zhu, Z.; Fu, J.; Zhang, H.; Du, C.; Xu, Z. Rice Paper-Based Biodegradable Triboelectric Nanogenerator. Microelectron. Eng. 2019, 216, 111059. [Google Scholar] [CrossRef]

| No | Peak Vales | Functional Group |

|---|---|---|

| 1 | 3262.95 | O-H |

| 2 | 2917.76 | O-CH3 |

| 3 | 2848.33 | C-H in aldehydes and acids |

| 4 | 1596.76 | N-H |

| 5 | 1411.63 | CH2 |

| 6 | 1027.87 | P-O |

| 7 | 593.96 | N=C=S |

| Operating Cycles | Vp-p (V) | Vmax (V) | Vmin (V) | Temperature (°C) |

|---|---|---|---|---|

| 1 | 5.4 | 2.0 | −3.4 | 19.3 |

| 3000 | 5.2 | 2.1 | −3.8 | 19.4 |

| 6000 | 7.5 | 2.8 | −4.7 | 19.6 |

| 9000 | 8.4 | 3.0 | −5.4 | 19.6 |

| 12,000 | 7.8 | 2.9 | −4.9 | 19.6 |

| 15,000 | 7.8 | 2.9 | −4.9 | 19.6 |

| 18,000 | 8.1 | 3.0 | −5.1 | 19.6 |

| 21,000 | 8.3 | 3.1 | −5.2 | 19.6 |

| 24,000 | 8.9 | 3.4 | −5.5 | 19.6 |

| 27,000 | 8.9 | 3.4 | −5.5 | 19.6 |

| 30,000 | 8.8 | 3.4 | −5.4 | 19.6 |

| 33,000 | 8.2 | 3.1 | −5.1 | 19.6 |

| 36,000 | 8.2 | 3.1 | −5.1 | 19.6 |

| Operating Cycles | Vp-p (V) | Vmax (V) | Vmin (V) | Temperature (°C) |

|---|---|---|---|---|

| 1 | 2.8 | 1.0 | −1.8 | 19.9 |

| 3000 | 4.1 | 1.4 | −2.7 | 20.0 |

| 6000 | 4.2 | 1.5 | −2.7 | 20.0 |

| 9000 | 4.5 | 1.6 | −2.9 | 20.0 |

| 12,000 | 5.3 | 1.9 | −3.4 | 19.9 |

| 15,000 | 6.0 | 2.2 | −3.8 | 20.2 |

| 18,000 | 5.6 | 2.0 | −3.6 | 20.3 |

| 21,000 | 5.6 | 2.0 | −3.6 | 20.3 |

| 24,000 | 6.1 | 2.2 | −3.9 | 20.2 |

| 27,000 | 6.0 | 2.1 | −3.9 | 20.2 |

| 30,000 | 5.9 | 2.1 | −3.8 | 20.1 |

| 33,000 | 5.9 | 2.0 | −3.9 | 20.1 |

| 36,000 | 5.8 | 2.1 | −3.7 | 20.2 |

| Operating Cycles | Vp-p (V) | Vmax (V) | Vmin (V) | Temperature (°C) |

|---|---|---|---|---|

| 1 | 1.4 | 0.6 | −0.8 | 22.0 |

| 3000 | 2.5 | 1.1 | −1.4 | 22.0 |

| 6000 | 3.0 | 1.3 | −1.7 | 22.0 |

| 9000 | 3.0 | 1.3 | −1.7 | 22.0 |

| 12,000 | 3.2 | 1.4 | −1.8 | 22.0 |

| 15,000 | 2.8 | 1.2 | −1.6 | 22.0 |

| 18,000 | 2.8 | 1.2 | −1.6 | 22.0 |

| 21,000 | 2.3 | 1.0 | −1.3 | 22.0 |

| 24,000 | 2.4 | 1.0 | −1.4 | 22.0 |

| 27,000 | 2.4 | 1.1 | −1.3 | 22.0 |

| 30,000 | 3.1 | 1.3 | −1.8 | 22.1 |

| 33,000 | 2.6 | 1.1 | −1.5 | 22.1 |

| 36,000 | 2.5 | 1.1 | −1.4 | 22.1 |

| Triboelectric Materials | Triboelectric Layer Area | Open-Circuit Voltage | Power Density | Advantages | Drawbacks | Ref. |

|---|---|---|---|---|---|---|

| Rumex vesicarius and poly(ethylene terephthalate) (PET)/polytetrafluoro | 50 × 50 mm2 | 3.86 V | 1.894 mWm−2 at RL of 20 MΩ | Easy design, cost-effective fabrication, and voltage stability | Fragile support frame | [36] |

| Coffee grounds and polyimide | 52.2 × 52.2 mm2 | 90.7 V | 75.48 mWm−2 at RL of 39.97 MΩ | Portable configuration, low-cost eco-friendly materials, and easy processing signal | Wear of triboelectric layers and humidity affects its performance | [8] |

| Nopal powder and polyimide | 52.2 × 52.2 mm2 | 16.4 V | 0.556 mWm−2 at RL of 76.89 MΩ | Compact design, simple operating principle, and low-cost manufacturing | Wear of triboelectric layers | [43] |

| Hosta plantaginea leaf and PMMA | 80 × 80 mm2 | 230 V | 45 mWm−2 with RL of 10 MΩ | Eco-friendly materials | Limited service time | [44] |

| Rice paper and PVC | 30 × 30 mm2 | 244 V | 376.4 mWm−2 with RL of 70 MΩ | Low-cost recycled materials and stable performance | Wear of triboelectric layers | [45] |

| Radish leaf and polyimide | 52.2 × 52.2 mm2 | 26 V | 0.340 mWm−2 at RL of 20.51 MΩ | Eco-friendly materials, portable design, cost-effective fabrication, voltage stability, and easy signal processing | Humidity affects its performance | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delgado-Alvarado, E.; Ashraf, M.W.; Tayyaba, S.; González-Calderon, J.A.; López-Esparza, R.; Pérez-Pérez, M.C.I.; Champac, V.; Hernandéz-Hernández, J.; Figueroa-Navarro, M.A.; Herrera-May, A.L. A Novel Sustainable and Cost-Effective Triboelectric Nanogenerator Connected to the Internet of Things for Communication with Deaf–Mute People. Technologies 2025, 13, 188. https://doi.org/10.3390/technologies13050188

Delgado-Alvarado E, Ashraf MW, Tayyaba S, González-Calderon JA, López-Esparza R, Pérez-Pérez MCI, Champac V, Hernandéz-Hernández J, Figueroa-Navarro MA, Herrera-May AL. A Novel Sustainable and Cost-Effective Triboelectric Nanogenerator Connected to the Internet of Things for Communication with Deaf–Mute People. Technologies. 2025; 13(5):188. https://doi.org/10.3390/technologies13050188

Chicago/Turabian StyleDelgado-Alvarado, Enrique, Muhammad Waseem Ashraf, Shahzadi Tayyaba, José Amir González-Calderon, Ricardo López-Esparza, Ma. Cristina Irma Pérez-Pérez, Victor Champac, José Hernandéz-Hernández, Maximo Alejandro Figueroa-Navarro, and Agustín Leobardo Herrera-May. 2025. "A Novel Sustainable and Cost-Effective Triboelectric Nanogenerator Connected to the Internet of Things for Communication with Deaf–Mute People" Technologies 13, no. 5: 188. https://doi.org/10.3390/technologies13050188

APA StyleDelgado-Alvarado, E., Ashraf, M. W., Tayyaba, S., González-Calderon, J. A., López-Esparza, R., Pérez-Pérez, M. C. I., Champac, V., Hernandéz-Hernández, J., Figueroa-Navarro, M. A., & Herrera-May, A. L. (2025). A Novel Sustainable and Cost-Effective Triboelectric Nanogenerator Connected to the Internet of Things for Communication with Deaf–Mute People. Technologies, 13(5), 188. https://doi.org/10.3390/technologies13050188