Abstract

This study examines the effects of hailstorms on photovoltaic (PV) modules, focussing on damage mechanisms, testing standards, numerical simulations, damage detection techniques, and mitigation strategies. A comprehensive review of the recent literature (2017–2025), experimental results, and case studies is complemented by advanced simulation methods such as finite element analysis (FEA) and smoothed particle hydrodynamics (SPH). The research emphasises the crucial role of protective glass thickness, cell type, number of busbars, and quality of lamination in improving hail resistance. While international standards such as IEC 61215 specify test protocols, actual hail events often exceed these conditions, leading to glass breakage, micro-cracks, and electrical faults. Numerical simulations confirm that thicker glass and optimised module designs significantly reduce damage and power loss. Detection methods, including visual inspection, thermal imaging, electroluminescence, and AI-driven imaging, enable rapid identification of both visible and hidden damage. The study also addresses the financial risks associated with hail damage and emphasises the importance of insurance and preventative measures. Recommendations include the use of certified, robust modules, protective covers, optimised installation angles, and regular inspections to mitigate the effects of hail. Future research should develop lightweight, impact-resistant materials, improve simulation modelling to better reflect real-world hail conditions, and improve AI-based damage detection in conjunction with drone inspections. This integrated approach aims to improve the durability and reliability of PV modules in hail-prone regions and support the sustainable use of solar energy amidst increasing climatic challenges.

1. Introduction

Recently, the global installed capacity of photovoltaic (PV) systems has grown exponentially, reaching hundreds of gigawatts worldwide. It is predicted that the cumulative capacity will reach 2840 GW by 2030, 5680 GW by 2040, 7099 GW by 2045, and 8519 GW by 2050 [1]. This massive deployment accentuates the critical need for ensuring the long-term durability and reliability of PV modules against environmental threats to maintain continuous electricity generation within the limits of available solar conditions. Among the climatic factors, hailstorms pose a significant threat to photovoltaic modules as they can cause a wide range of damage. These range from severe effects, like complete glass shattering and cell breakage, to more subtle but critical issues such as micro-cracks and latent damage that is not immediately visible to the naked eye. Such damage can lead to increased leakage current, reduced shunt resistance, reduced energy yield, and ultimately a shortened lifetime of PV systems [2,3,4,5,6,7]. In addition, hail-related damage can impair system safety, and increase the risk of power outages and hazards for the entire PV system [2,8,9,10]. Hail is not only a threat to rooftop and ground-mounted photovoltaic systems, but also to building-integrated photovoltaic systems (BIPV). BIPV systems are not cheap and must have a very long service life. It is therefore very important that they are resistant to hail [11].

Recent scientific evidence clearly indicates that climate change is increasing the frequency, severity, and geographical distribution of extreme weather events, including hailstorms [3,4,12,13,14]. Rising global temperatures contribute to stronger convective storms and greater atmospheric instability, which in turn increases the likelihood of the formation of large and damaging hail. This evolving climatic reality poses unprecedented challenges for photovoltaic infrastructure, as conventional design and testing standards may no longer be sufficient to ensure module resilience to increasingly severe hailstorms. It is therefore essential to deepen our understanding of how climate-induced changes in hailstorms affect the durability of PV systems in order to develop adaptation strategies that protect investments in renewable energy and support the sustainable expansion of solar energy under changing environmental conditions.

Numerical simulations have become a common tool for analysing the hail resistance of photovoltaic modules [15,16]. By applying finite element (FE) methods, SPH and explicit dynamic analysis, it is possible to study the effects of hailstones of different sizes and velocities on a PV module in detail.

Significant hail damage to large solar parks emphasises the urgency of tackling this problem. For example, a 2019 event in Pecos County, Texas, caused an estimated $70 million in damage to a 178 MW facility [13]. Protecting PV systems from hail damage is essential to securing the financial viability and safety of renewable energy assets.

Accurate understanding of hail impacts and robust testing procedures are essential to evaluate module resilience and to guide the development of improved design strategies. International standards such as IEC 61215 [17], IEC 61646 [18], IEC 61730 [19], and ASTM E1038-10 [20] define rigorous protocols to assess hail resistance by simulating impacts with defined hailstone sizes and velocities. Compliance with these standards is fundamental for certifying modules intended for hail-prone regions.

In view of the growing importance of PV systems and the increase in climate extremes, continuous improvements are required. This includes better testing standards, advanced damage detection methods, and improvements in the design and materials of PV modules to ensure their long-term reliability and safety [8,12,13]. Standard inspection methods, such as visual inspection and thermography (TG), are often insufficient to detect micro-cracks, while advanced methods such as electroluminescence (EL) and UV-fluorescence (UV-F) allow for more precise detection and classification of damage [8,10,21,22,23,24,25].

Recent scientific investigations have advanced understanding of hail impacts on PV modules. Nicoletto et al. [2] investigate the effects of cracks on heterojunction silicon photovoltaic modules by analysing their electrical and thermal behaviour at low and high currents, using advanced methods such as electroluminescence and infrared thermography on hail-damaged modules. The aim of the research was to understand hidden damage and to develop a numerical model that simulates the thermal behaviour of damaged cells. This highlighted the importance of detecting latent defects for the long-term reliability and efficiency of PV modules [2].

Perry et al. [26] analysed satellite imagery following the catastrophic hailstorm in Austin in 2023 and hurricanes in Puerto Rico and the Virgin Islands in 2017 to assess the damage to over 12,800 PV installations. The study found that around 5.5% of installations were damaged by hail and 17% by hurricanes, with newer panels being more susceptible to hail damage. It was also found that the resilience of the systems was significantly related to the installation method, while hail damage was higher for sizes larger than 60 mm, regardless of the system configuration [26].

Forni et al. [27] investigate the increasing frequency and intensity of hailstorms due to climate change, especially in the Alpine regions, and the need for greater safety margins when testing the resistance of photovoltaic modules to hailstorms, which can be achieved by upgrading test stations. They experimentally tested the effects of the velocity and impact angle of ice balls of different sizes and temperatures on the modules and analysed the mechanical properties of the materials to establish empirical relationships to predict damage based on physical parameters [27].

Nicoletto et al. [2] investigated the effects of heavy hail with a diameter of up to 16 cm on a residential PV system in Padua and showed that standard tests with smaller hailstones are not sufficient to detect latent damage that can affect the safety and efficiency of the modules. The study emphasises the importance of detailed inspection of PV systems after hailstorms, including electroluminescence and infrared thermography methods, to detect and replace damaged, but apparently intact, modules in time [2].

Dai et al. [28] have developed a device to simultaneously study the effects of hail and wind on photovoltaic modules to investigate the interaction of these factors, which has been neglected in research so far. The effects of turbulence, hail size, and velocity on the impact behaviour of hail were systematically investigated and quantified. According to the analysis of variance, hail velocity is the most important factor influencing hail impact, followed by hail diameter and finally turbulence [28].

Ali et al. [8] investigate the effects of mechanical hail loads on different types of photovoltaic modules using the international standards ASTM 1038-10 and IEC 61215-2 and have developed a simulator to evaluate their reliability. The results show that monocrystalline modules are better protected against hail than polycrystalline modules, with hail causing microcracks and efficiency reductions of 4.15% and 12.59%, respectively, and power losses of 3.3% and 12.5% [8].

Johnston et al. [29] monitored outdoor PV modules damaged by golf ball-sized hail over a six-year period using flash tests, photoluminescence, electroluminescence, and thermal imaging. Although the modules with the highest number of cracks showed a 3–4% reduction in performance immediately after the hailstorm, their degradation rate did not increase over six years compared to less damaged modules outdoors [29]. Cadoni et al. [12] investigate the resistance of photovoltaic modules to strong hailstorms, which are becoming more frequent and violent in the Alpine regions due to climate change, by upgrading the standard test equipment for larger hailstones and higher impact velocities. In initial tests, ice balls with a diameter of 25, 40 and 70 mm were used at different speeds and temperatures. The effects of impact velocity, load and impact time on the modules were analysed, and provided a basis for a better assessment of the modules’ safety margins [12].

Budiman et al. [30] investigate the resistance of lightweight photovoltaic modules with a polycarbonate layer that protects the silicon cells from mechanical impacts, especially under conditions of severe winter hail. Using numerical simulations, they investigate the distribution and evolution of stresses in spiral-patterned 3D polymer composites, which could significantly increase the impact resistance, and thus improve the durability and efficiency of these modules under demanding climatic conditions [30].

Muehleisen et al. [21] investigate damage to photovoltaic modules after severe hailstorms in southern Austria, using standard methods such as data analysis and thermography, but also new non-invasive techniques such as external electroluminescence and UV fluorescence imaging. These methods enable the detection of hidden cell damage, such as microcracks, even if the module glass is not damaged and the damage is not visible to the naked eye or thermography, which helps to accurately identify modules with reduced electrical performance [21].

Nevertheless, existing literature gaps remain in understanding the multi-scale interactions between hailstorm characteristics and PV module design variations, especially regarding latent microcrack damage and long-term performance degradation. Moreover, integrating empirical testing with advanced numerical models tailored for evolving climatic extremes requires further research.

This study aims to comprehensively analyse hail impacts on PV modules by synthesizing recent findings, testing standards, numerical methods, damage detection technologies, and economic factors.

The scientific contribution lies in establishing an integrated framework guiding the design, testing, and monitoring of PV modules for enhanced hail resistance and reliable operation in harsh weather regions.

The paper is intended for all key stakeholders in the field of photovoltaic systems, including PV module designers, engineers, investors, owners of solar power plants, and service and technical teams responsible for maintenance. It is also relevant to scientists developing new methods for simulation, diagnostics, and resilience improvement. By reviewing current standards, damage mechanisms, advanced numerical and diagnostic techniques, and economic and insurance aspects, the article provides information useful for decision-making on the design, investment, risk management, and maintenance of PV modules, particularly in regions exposed to extreme climatic events.

The paper is structured as follows: Section 2 describes materials and methods used for literature review and data synthesis. Section 3 details the results on PV module structure, hail testing standards, numerical simulations, types of damage, and detection techniques. Section 4 discusses performance impacts, design comparisons, and recommendations. Section 5 concludes with a summary and proposals for future research.

2. Materials and Methods

In this study, the effects of hailstorms on PV modules are systematically investigated by analysing the relevant scientific literature, numerical simulations, and experimental data. The research methodology comprised three main components: Literature review, data analysis, and synthesis of the findings relevant to hail impact on PV modules.

A comprehensive literature search was conducted in the Web of Science Core Collection database using the keywords “Hailstorm Impact on Photovoltaic Modules” and “Hailstorm Photovoltaic”, which included publications from 2017 to 2025. The initial search yielded 14 and 26 results, of which 8 and 17 papers, were categorised as directly relevant to the focus of this study. All these papers have been peer-reviewed.

Additional literature was identified by snowballing from the reference lists of the selected papers and by internet searches for recent studies on “hail + PV system” to emphasise trustworthiness and scientific rigour. The selection criteria excluded non-peer-reviewed sources such as blogs and Wikipedia, and favoured reliable sources such as reports from the International Energy Agency (IEA, Headquarter Paris, France), the American Ceramic Society (Ohio, USA), and the US Department of Energy (DOE, USA), to ensure high quality and authoritative data. All collected information was systematically organised, analysed and summarised to enable a comprehensive assessment of the effects of hail on PV modules.

The data collected included studies on PV module design, materials, mechanical properties, testing standards, damage mechanisms, numerical modelling techniques, and hail damage detection methods. The analysis included:

- Review of standardised test protocols such as IEC 61215, IEC 61646, IEC 61730, and ASTM 1038-10 for hail resistance, including impact velocities, hailstone sizes, and pass/fail criteria.

- Testing of mechanical and material reports focussing on module components, including glass properties, encapsulation materials, solar cells, backsheets, and frames.

- Evaluation of numerical simulation methods (finite element methods, smoothed particle hydrodynamics, arbitrary Lagrange-Euler approaches) used for hail impact modelling and damage propagation prediction.

- Comparison of empirical data from laboratory impact tests and real hailstorms to validate the simulation results.

The findings from the literature and data analysis were integrated to clarify the relationships between module design parameters (glass thickness, cell type, number of busbars), hail characteristics (size, speed, shape), and the resulting physical and electrical damage. The study emphasises the current limitations of hail tests, the effects of latent damage, and innovative mitigation techniques.

The methodology also includes the review of damage detection and monitoring methods such as visual inspection, thermal imaging, electroluminescence, UV fluorescence, and new artificial intelligence algorithms for automatic fault detection in large PV systems.

The study is aware of the limitations resulting from the varying reliability and completeness of the available data, the different regional hailstorm conditions, and the computational challenges in numerical modelling. Nevertheless, the multi-faceted approach, combining a literature review, an analysis, of standards and a review of numerical and empirical data, allows robust conclusions relevant to the performance of PV modules in hailstorms.

3. Results

3.1. PV Module Structure

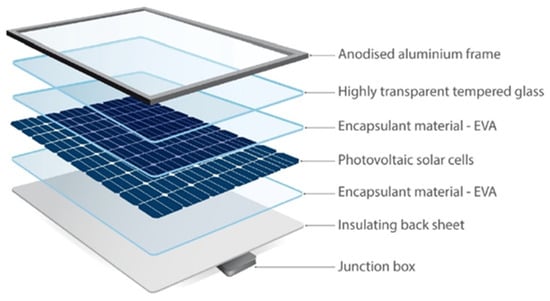

PV modules consist of several components (Figure 1), each of which contributes to their ability to utilise solar radiation and convert it into electricity. The PV glass plays a key role in a PV module. It serves as an important shield, that protects the solar cells from aggressive environmental influences such as impact, hail, moisture, salt spray and ammonia. There are mono-glass and dual-glass PV modules. Mono-glass solar modules usually use 3.2 mm thick, fully tempered glass, with a backsheet. Dual-glass PV modules typically use 2.0 mm or 1.6 mm thick semi-tempered glass for the front and backsheet.

Figure 1.

The main components of PV module [31].

Solar cells are the basic element for generating electricity. They are usually made of silicon and are connected to each other in a grid inside the module. The solar cells are covered with an encapsulation material, usually ethylene vinyl acetate (EVA), which protects them from moisture and mechanical damage. The backsheet is a protective plastic layer laminated to the back of the module, providing insulation and additional protection. The robust aluminium frame serves as a structural support and allows the module to be securely fastened to the carrier. The junction box, on the back of the module, is weatherproof and contains electrical connections that allow you to connect multiple modules to form a larger solar system.

3.2. Standards for Testing the Resistance of PV Modules to Hailstorms

Test standards and recommendations for the hail resistance of PV modules are essential to ensure the long-term reliability and safety of solar systems, especially in areas with extreme weather conditions. The most widely used international standard for testing PV modules for hail resistance is IEC 61215 [16]. According to this standard, a PV module must withstand the impact of a 25 mm hailstone shot at the module at a speed of 23 m/s without significant damage to 11 different areas of the module, including the edges, corners and areas around the busbars and fixings [2,3,12,22]. This test simulates typical weather conditions and proves that the modules are resistant to damage from average hail in most climates. The IEC 61646 standard [18], which is similar in many respects to the IEC 61215 standard, applies to thin-film photovoltaic cells based on cadmium telluride (CdTe) instead of silicon. Although such installations are currently less common, their use is gradually increasing. The IEC 61730 standard [19] focuses more on the safety aspects of PV modules, including protection against fire and electric shock, but also includes requirements for hail resistance. Panels certified to IEC 61730 are tested for mechanical resistance and safety and are designed to withstand impacts from 25 mm ice balls at similar velocities [12,21]. The standard method ASTM 1038-10 [20] is used to test the resistance of PV modules to hail. A test is carried out with hurled ice balls (simulated hailstones), that hit the module at several marked and vulnerable points. The standard specifies the procedure for mounting the test module, the selection of at least six impact points and the method for dropping the ice balls and measuring their velocities (a combination of terminal velocity and wind). A method for evaluating the physical and electrical changes in the module after impact is specified, including visual inspection and measurement of electrical properties. The test does not specify the size of the ice spheres (multiple diameters can be used), nor does it set limits for passing or failing—it allows users to set their own requirements according to local climatic conditions and needs. The test is designed to simulate the worst scenario: The ice pellets are uniform, often harder and denser than real hail, ensuring a high level of testing [8,20].

In practise, the greatest resistance to hail (hail resistance) is achieved by passing the IEC 61215 tests, as this test is directly focussed on the impact of ice balls and their consequences on the mechanical protection of the module. IEC 61730 confirms that the panel is not dangerous after hail, but the hail resistance itself is tested according to the IEC 61215 standard.

The well-known national standard that prescribes stricter criteria for the resistance of PV modules to hailstorms is the Swiss VKF standard [32]. It sets stricter requirements and demands resistance to hail with a diameter of 30 mm, which in practise means up to 40 mm or more, due to the increasingly frequent and intense storms [12].

3.3. Numerical Simulations of Hail Impacts on PV Modules

Numerical simulations are a key tool for studying and optimizing the resistance of PV modules to hail strikes. Given the increased frequency and intensity of climate extreme events, experimental testing is often limited by the cost and complexity of reproducing the conditions. Numerical models for the analysis of the impact of hail on photovoltaic panels use advanced simulation methods to evaluate the resistance of the modules to shock loads and optimize their construction. FE methods and explicit dynamic analysis are most often applied, simulating the impact of ice balls of different sizes and speeds on the glass surface of the module, in accordance with international standards such as IEC 61215. Explicit dynamic analysis enables evaluation of strains and internal stresses, which helps in optimizing module design and material selection [33,34]. With flexible parameter changes, numerical methods help in understanding damage mechanisms, optimizing designs and materials, and minimizing the risk of glass breakage, microcracks, and latent damage.

3.3.1. Numerical Simulation Methods

Commonly used numerical methods include Explicit Finite Elements (FE), Arbitrary Lagrangian Eulerian (ALE), Coupled Eulerian-Lagrangian (CEL) and Smoothed Particle Hydrodynamics (SPH), with SPH often being the most effective for simulating the impact of soft bodies such as hail due to its ability to model large strains and fragmentation [15,16,35,36,37]. The FE method enables precise estimation of deformations and stresses in glass and solar cells under impact loading. Explicit dynamic analysis is used to simulate brittle fracture and crack propagation, often in LS-Dyna and Abaqus programs. The SPH method is a meshless method and is known for its ability to simulate natural material flow without mesh distortion issues. It provides realistic fragment scattering dynamics and impact energy, making it more efficient for fracture simulation. ALE/CEL methods are used to model complex contacts and multilayer modules where solid and fluid elements are combined. Ideal for simulating irregular hail shapes and their interaction behaviour.

3.3.2. Hail and PV Module Modelling

The standard hail model in simulations is usually a sphere due to its simplicity and adequate description for most atmospheric conditions. Hail diameters in numerical models usually vary from 10 mm to 50 mm, with larger sizes being simulated for extreme scenarios. Some studies have attempted to describe hail in more detail with irregular, polyellipsoidal or even randomly generated surface structures, but this rarely significantly affects the resulting glass stress upon impact of ordinary dimensions. In most simulations, the density of spherical hail is assumed to be around 900 kg/m3, very close to the density of pure ice. The most important mechanical properties of ice are Young’s modulus (often around 9 GPa) and Poisson’s ratio (~0.3).

The findings of appropriate constitutive models of hailstone and PV module, primarily glass, are priority issues. Ice is sensitive to strain rate and can transition from a ductile to a brittle state. It can also change phase from a solid to a liquid state. Its behaviour differs under tension and compression, resulting in different failure modes. The material behaviour of ice is very complex and varies with the rate of deformation. These changes in the properties of ice are an important factor in its overall response to mechanical loads. Such behaviour is difficult to accurately describe with an ideal model. A number of different models have been developed. Kim and Kedward [38] were the first to develop a simple J2 elasto-plastic model of ice based on the criteria of plastic strain and tensile pressure failure criteria. Anghileri et al. developed the J2 elasto-plastic hydrodynamic model of ice that includes tensile pressure failure [37]. However, these models did not take into account the influence of strain rate, nor the difference between the behaviour of materials under tensile and compressive loads. In practical applications, it is necessary to adjust several basic parameters of the model as a function of impact velocity in order to achieve results that are consistent with experimental data. This severely limits their ability to predict realistic material responses at unknown impact velocities. Tippmann et al. [39] improved Kim’s model by developing a rate-sensitive, perfectly elastic-plastic model with a tensile pressure failure criterion. However, this model did not account for the differences in ice behaviour under tension versus compression. The resulting impact force was found to be too large for certain velocities, and the simulation of large strain, crushing, and fragmentation was not satisfactory. A rate-dependent elasto-plastic model incorporating tensile and compressive pressure failures was proposed by Carney et al. [40], while Sain and Narasimhan [41] added a damage evolution law to this model. Starting from the Drucker-Prager plasticity criteria, Pernas-Sanchez and his team [42] developed their own rate-sensitivity elastic–plastic model that allows for the consideration of different characteristics in tension and compression of ice. Although these models have covered a relatively complete spectrum of ice properties, their results at various impact velocities of importance to aviation are considered to be weaker than those of simpler, previously used approaches. Qi Xie [15] used an J2 elastic-plastic failure model in his study of hail impacts on photovoltaic panels, which proved to be satisfactory for this application.

Constitutive models of photovoltaic (PV) modules in numerical simulations represent a key element for a realistic description of the mechanical behaviour of layers within the module under load, such as hail impact. These models define the relationship between stress and deformation of materials, including elasticity, plasticity, fracture and other phenomena that occur during impacts. A PV module consists of several layers: a front protective glass sheet, an EVA layer that serves as a laminating layer, silicon solar cells and a backsheet (see Figure 1). Each layer has its own specific mechanical characteristics that are modelled separately. Glass is often modelled as a brittle material with “piecewise linear plastic” or elastic-brittle models that may include variations in properties to simulate realistic cracks and fractures. In more advanced simulations, stochastic variances (stochastic variance, SV) are introduced, which better represent unpredictable breaks and glass fragmentation. EVA is modelled as an elastic-plastic or viscoelastic material, because it shows a certain ductility and ability to absorb energy from an impact. Some models treat the EVA layer as an elastic layer with a viscosity that can absorb forces. Silicon is a brittle material and upon impact is modelled with a focus on fracture and microcracks using elastoplastic models with the ability for crack initiation and propagation through thin layers. Depending on the material (most often polymer layers), it is modelled using a plastic or viscoelastic model with the possibility of large deformations without fracture.

3.3.3. Contact and Interaction Models

When simulating a hail impact, the contact models between the hail ball and the module surface are important, which defines the transmission of forces, friction and the duration of the impact. Typically, “surface to surface” contact with friction parameters or “soft contact” is used in SPH methods. SPH is a meshless method suitable for simulating extreme fractures and fragmentation of materials. In SPH method, the interaction of particles is achieved through a smoothing kernel function that determines the degree of influence of one particle on another. In this way, various physical quantities, such as density, pressure, and stress, can be calculated, allowing the simulation of the behaviour of materials under different conditions. In SPH, the so-called “soft contact” approach is used, which allows for smooth interaction between the SPH hail particles and the contact body (module). This model does not require a fixed mesh, so it better simulates explosive and non-linear fractures without the computational downtime that can occur with traditional mesh FEA models. Soft contact enables a realistic display of glass breaking, scattering of fragments and explosive energy transfer. In simulations, the range of 20–100 m/s is most often used, and in laboratory tests, the reference is 23 m/s (according to the IEC 61215 standard) [15]. An impact normal to the surface is simulated, but models with different angles are increasingly common for more realistic impact fields.

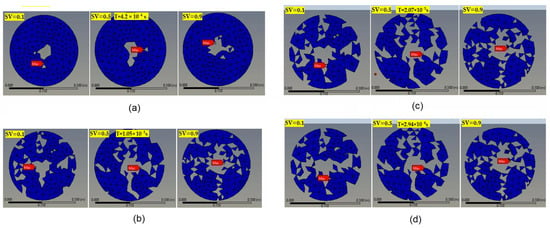

These models are implemented in finite element method (FEA) software package such as Ansys Workbench LS-Dyna ACT Extension 16.2 (2016) Abaqus, as well as methods such as SPH for fracture and fragmentation simulation. They enable the simulation of the propagation of cracks, the formation and growth of damage, the distribution of stresses and deformations through the layers of the module. The example in Figure 2 shows the propagation of module glass breakage as a function of time for the considered variance values in the glass model with stochastic failure control [15].

Figure 2.

Module glass breakage propagation as a function of time: (a) 4.2 × 10−4 s; (b) 1.05 × 10−3 s; (c) 2.07 × 10−3 s; (d) 2.94 × 10−4 s [15].

3.3.4. Validation and Limitations

The parameters of constitutive models are often adjusted based on laboratory experiments, where fracture thresholds, crack trajectories and impact dynamics are compared. Validation also includes comparison with real experimental data on hail impacts and panel damage.

Limitations include the following:

- High sensitivity to input parameters and model assumptions;

- Idealization of hail shape and velocity, without fully modelling realistic stochastic conditions;

- Limited applicability in long-term monitoring of latent damage and degradation;

- Computational complexity, especially for SPH and ALE/CEL methods.

The results of numerical simulations show that thicker PV module glass exponentially increases the resistance, so the simulations confirm the laboratory data. SPH methods provide good correlation with experiment. Numerical simulations can also be used for the development of new standards and industrial optimization of panels. Simulations encourage designs with multilayer and composite materials to increase mechanical resistance.

3.4. Impact of Hail on PV Modules

3.4.1. Damage Mechanism

Damage to photovoltaic modules is caused by the kinetic energy of hailstones, which fall at high speed and act like projectiles. On impact, the kinetic energy of the hail is dissipated through the protective front glass. The impact can cause damage ranging from damage to the glass surface that is visible to the naked eye to micro-cracks that are invisible in the cells but can cause long-term damage. Larger and faster hailstones have a higher kinetic energy, and therefore a greater potential for damage. Visible damage usually occurs when the kinetic energy of the hail exceeds the resistance threshold of tempered glass. The IEC 61215 standard requires that the modules withstand an impact of ice with a diameter of 25 mm and a speed of 23 m/s, which corresponds to a kinetic energy of 6.6 joules per impact. Thicker protective glass and a more robust design can improve the module’s resistance to hailstorms. How the kinetic energy is dissipated also depends on the tilt angle of the PV module. The tilt angle of the module should be chosen to minimise energy dissipation at the glass surface, which means that direct hail impact is reduced. When selecting more resistant modules for hail-prone areas, advanced test methods such as the hail resistance curve (HRC) are usually used to assess the probability of module failure over a wide range of impact energies [43]. The standard test for hail resistance certification according to IEC 61215 only shows the pass or fail of the module at limited impact energies at 11 preselected positions. Such a test does not simulate the real conditions of a hailstorm, in which numerous impacts with different, often very high energies, sometimes more than 100 joules, occur, and does not distinguish between modules that have merely passed the test and modules that are really more resistant.

3.4.2. Types of Damage

Hail impacts can cause various types of damage to PV modules, including glass breakage, cell damage, microcracks, and structural deformation. The consequences of this damage include reduced energy production, increased electrical resistance, and a shortened lifespan of the solar modules. The severity of the damage is determined by the size and speed of the hailstones, the quality and thickness of the module’s front glass, the module, the technology and the wind conditions (speed and direction) [13,14].

Large hailstones can break through the front glass of a solar module, leaving the internal components unprotected from the weather conditions. This is the most severe form of damage, in which the front glass breaks completely and the solar cells shatter. Such modules lose electrical insulation, resulting in uneven current flow and heat radiation, so the modules must be replaced immediately to ensure the safety and reliability of the system [2,13,21]. Even if the glass surface is not visibly damaged, hailstorms can cause microcracks in solar cells and other internal module components. Such microcracks are often microscopic and therefore cannot be recognised during initial inspections. However, they are critical defects that can lead to a deterioration in the electrical properties of the cells over time and consequently to a reduction in the energy yield of the PV system [2,8,13,21]. Damage within the solar cells can lead to a reduction in electrical efficiency, which can result in the formation of hot spots and further deterioration of the module material and performance [13]. In certain situations, hail can lead to deformation of the module frames or other supporting structures, which can have a negative impact on the mechanical stability and overall operational performance of the PV system. Hail impacts can also lead to breakage or separation of the busbars, resulting in the deactivation of certain areas of the solar cells and thus a reduction in the overall efficiency of the PV module [8,22]. In the case of thin-film solar cells, hail strikes can damage the electrical contacts, which can lead to short circuits and a lower module output. Any hail impact can reduce the insulation resistance of a module, which increases the risk of electrical failures and safety issues, especially in humid conditions [13]. Exposure of internal components through cracks can lead to electrochemical corrosion, especially in the metallisation area (metal contacts) of solar cells and their interconnections (e.g., solder joints), which further impairs the electrical performance of the module and accelerates degradation [44].

Damage to the front glass or the cells can not only reduce the output power of the PV module but also has other consequences. Damage to the module components can accelerate the degradation process, resulting in a shortened service life of the PV module. The manufacturers of new PV modules guarantee a service life of 25 years with an expected degradation rate of 0.8% power per year. In most cases, the degradation process within the expected limits, with an annual decrease in rated power of up to 0.8%, does not pose a significant threat to the PV system, unless this rate is exceeded and the system enters a critical phase of power degradation [45]. Damaged PV modules may require more frequent inspections and replacement of components, resulting in increased maintenance costs for the PV system. In certain cases, damaged PV modules may be susceptible to overheating, leading to an increased risk of fire, especially in older modules with fewer busbars.

3.4.3. The Influence of PV Module Design and Materials

The resistance of PV modules to hailstorms depends largely on the thickness of the glass, the cell type (monocrystalline vs. polycrystalline), the number of busbars and the type of lamination. More specifically, the greater thickness of the glass, the use of monocrystalline solar cells, a greater number of busbars, and the use of special lamination techniques contribute significantly to improving the hail resistance of photovoltaic modules [8,13]. Thicker glass acts as a more robust barrier against the mechanical effects of hail, as it can absorb a greater amount of impact energy before cracking or fracturing occurs. Modules with thicker glass (4 mm) show significantly less damage and power loss compared to modules with thinner glass (2.8 mm or 3 mm) [13]. Thanks to their homogeneous crystalline structure, monocrystalline solar cells are more resistant to mechanical damage caused by hail than polycrystalline cells. Research results show that monocrystalline PV modules exhibit a lower loss of output power when exposed to hail than polycrystalline modules [8]. Busbars represent conductive lines on the surface of the solar cells, and a larger number of busbars allows a more even distribution of the mechanical impact force, reducing the localised stress on individual cells and the risk of cracking [8,14]. The type of lamination material (encapsulation) used in the production of the module has a significant impact on the resistance of the module to hail impacts. The use of high-quality lamination materials enables better distribution of impact forces, reduces the risk of delamination and helps to protect the module from further mechanical damage after a hailstorm [8,13,46]. Impacts at the edges of the module are more likely to cause glass and cell breakage than impacts in the centre of the module [8,13,47,48]. The edge areas of the PV module often do not have the structural support of the solar cells and busbars, and the encapsulation layer may be reduced in these areas. For this reason, the edges of the module are more susceptible to mechanical bending and cracking due to external loads [49]. Mechanical stresses caused by factors such as wind, hail or improper handling are mainly concentrated on the edges of the module. Such stress concentration can lead to cracks, especially in the glass components of the module [8]. The glass used in photovoltaic modules has a high compressive strength but is more susceptible to cracking due to tension or bending, especially at the edges of the module. During the manufacturing process, the edge areas of the module can be more susceptible to variations in material thickness or inconsistencies in bonding, further increasing the risk of breakage in these areas. In double-glazed photovoltaic modules, crushing of the glass layers at the edges can occur during the lamination process, resulting in concentrated stress points that increase the likelihood of breakage under mechanical impact. Although delamination can occur in any area of the module, it is more problematic at the edges, where there is more moisture penetration and solar radiation is more intense, which can lead to electrical risks and lower reliability of the module [46,50]. Although the glass thickness, the type of solar cells, the number of busbars and the quality of lamination are key factors, the resistance of modules to hail impacts is also influenced by external factors such as the size, speed and angle of incidence of the hailstones, and the mounting system of the module [8,13]. Larger and faster hailstones generate greater impact forces on the PV module, which increases the risk of mechanical damage. A photovoltaic module installed at an angle of 0° is exposed to greater impact energy and is more susceptible to greater damage than a module installed at an angle of 30° or 60° [51]. Modules with larger glass areas are technically more susceptible to hail damage than smaller modules under the same exposure conditions. Proper installation of the modules according to the manufacturer’s instructions is critical to maintaining the structural integrity of the system and minimising the risk of hail damage. In hail-prone areas, adequate insurance for solar panels is critical to mitigate the financial risk associated with hail damage.

3.4.4. Case Study Examples

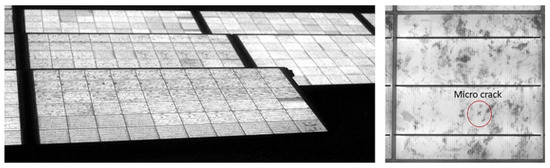

Hail can cause significant mechanical damage to PV panels, resulting in reduced electricity production and a potential fire risk. The case studies illustrate the impact of hail on solar farms and demonstrate the importance of designing and installing PV modules with improved hail resistance. Figure 3 shows an example of damage to a PV module caused by a hailstorm [8]. Although manufacturers guarantee resistance to hail up to a diameter of 25 mm, these standards are often exceeded in practise. For example, there are reports from Padua (Italy), where PV modules were exposed to hail with a diameter of up to 16 cm, which is more than double the standard test conditions [2].

Figure 3.

Damage to PV modules in Australia caused by hailstorm [8].

After a violent hailstorm in Padua, Italy, in which hail up to 16 cm in diameter occurred on some solar modules despite the intact glass layer, advanced diagnostic methods (EL and TG) were used to detect latent damage and reduced shunt resistance [2]. The results showed that the modules had to be replaced even without visible cracks in the glass. In three solar power plants in Austria, advanced methods (TG, UV-F and EL) were able to detect microcracks and partial cell fractures even when the glass was not damaged, which led to a reduction in electrical efficiency [21]. Figure 4 shows the EL image of modules damaged by hail.

Figure 4.

EL image of modules affected by hail [21].

The hail in the Netherlands caused damage to PV installations, which was detected using energy performance monitoring and management systems, such as the SolarEdge platform [52]. This platform enabled the rapid detection of module failures and malfunctions and reduced the need for extensive manual inspections and testing. A 178 MW solar power plant in Texas suffered $70 million in hail damage, and damaged more than 400,000 PV modules [13].

Hail impact simulations show a significant impact on the output power of PV modules, with modules with thinner glass showing higher power losses compared to modules with thicker glass. Specifically, modules with a glass thickness of 2.8 mm and 3.2 mm showed a power loss of 21.8% and 11.74%, respectively, while the module with 4 mm glass only showed a loss of 1.1% [13]. Thicker glass also has a higher crack resistance and a lower wet leakage current, which indicates a longer durability in hail-prone areas.

In May 2019, a 178 MW solar plant known as the Midway Solar Project in Pecos County, Texas, suffered severe hail damage costing around 70 to 80 million dollars. More than 400,000 photovoltaic modules were damaged or destroyed in this hailstorm, representing one of the largest weather-related losses to a single project in the US solar industry [13,53]. More recently, in June 2023, a solar farm in Nebraska was also severely damaged by hail, highlighting the ongoing risk of hail to solar power infrastructure in hail-prone regions. These events have led to higher insurance premiums and the development of better risk assessment and mitigation strategies for solar projects in high hail risk areas [53].

Hail can crack or even break the glass of PV modules, leading to significant power losses and shortening the lifespan of the modules. In some cases, the modules may have microcracks that are not visible to the naked eye but can reduce the short-circuit current and increase the series resistance. This electrical hiccup can lead to the formation of hotspots and possibly even fires. An electrical interruption can also occur, causing part of the cell to become inactive [53].

3.5. Damage Detection Methods

Hail damage to PV modules can be detected using a combination of visual inspection, thermal imaging (infrared thermography), and electroluminescence or UV-F imaging. Visual inspection enables the identification of visible damage such as broken glass or dents, while thermal imaging reveals temperature anomalies that indicate possible problems with cells or connections. Electroluminescence and ultraviolet fluorescence imaging are particularly effective in detecting hidden cell damage, such as micro-cracks, even if the outer layer of glass is completely undamaged.

After a hailstorm, a visual inspection from the ground can detect damage such as broken or cracked glass, dents in the frame, and loose wires or connections [21,45]. This inspection is a basic but crucial first step in assessing the condition of the module. Techniques for visualising damage to photovoltaic modules are demonstrated and evaluated in accordance with the international standard IEC 61215 [17]. Figure 5 shows the module with broken glass after a severe hailstorm [21].

Figure 5.

Module with shattered glass after heavy hailstorm [21].

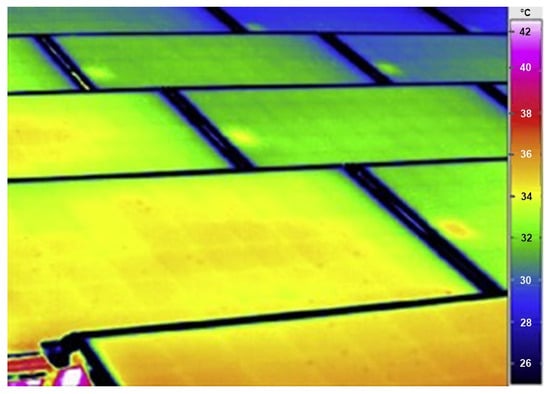

Infrared thermography (TG) uses a thermal camera to detect temperature fluctuations on the surface of a photovoltaic panel. The presence of hot spots can indicate damaged cells, faulty connections, or other defects that may be due to hail damage [2,23,54]. Figure 6 shows an example of a thermal image [21].

Figure 6.

Example of a thermal image [21].

Thermal imaging cameras are often used together with drones to inspect large solar installations, which significantly reduces the time and cost of the inspection. Figure 7 shows a drone equipped with a thermal imaging camera.

Figure 7.

Drone equipped with a thermal camera (The image was created using an AI tool).

In electroluminescence (EL) testing, a low electrical current is applied to a PV panel and the light emitted by the cells is recorded. Defective cells or microcracks appear as dark spots or lines, revealing hidden damage that is not visible to the naked eye or TG (see Figure 4). EL is very accurate but requires specialised equipment and is often used in laboratory or service environments [13,21,23,44,55,56,57].

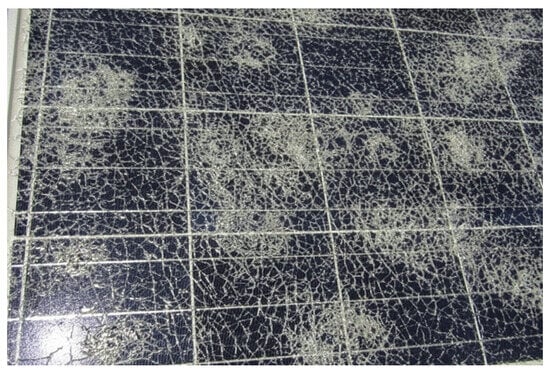

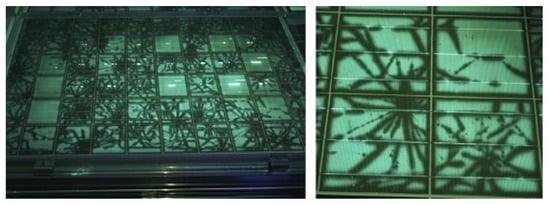

Ultraviolet fluorescence (UV-F) imaging enables the detection of hidden damage by illuminating a PV panel with UV radiation and observing the fluorescence [21,24]. Similarly to electroluminescence, this method can detect microcracks and other defects that affect panel performance. Figure 8 shows an example of UV-F images of a PV module damaged by hail and details with spider web optics due to micro-cracks.

Figure 8.

UV-F images of a hail damaged module and micro cracks [21].

Monitoring platforms for solar installations allow you to monitor the power output of individual modules compared to their original reference values before the hailstorm [52]. Significant drops in output or deviations between modules can indicate hail damage, even if there is no visible damage.

Although the measurement of electrical parameters such as current, voltage, power and resistance can detect the presence of a fault in a PV module, these measurements are not sufficient to precisely localise or determine the nature of the damage [13,23,58]. Such analyses serve as initial fault detection but require additional methods or techniques to characterise and diagnose the problem in detail. By monitoring electrical parameters (current, voltage, power), it is possible to detect deviations from expected values, that can indicate the presence of potential faults. For example, a significant drop in current or voltage can indicate a short circuit or shading within a PV module. By measuring the resistance, problems can be recognised, such as increased series resistance, which can have a negative effect on the output power of the PV module. Analysing the I-V curve (current-voltage relationship) provides more detailed information about the type and severity of a fault in a photovoltaic module. Deviations from the reference curve may indicate the presence of shading, cell mismatch, or module degradation [59].

Conventional methods for detecting damage and failures in PV modules are no longer suitable for large solar parks due to their slowness, cost, and inaccuracy. Therefore, in recent years, research has focused heavily on the use of artificial intelligence (AI), especially machine learning (ML) and deep learning (DL), to automatically detect and classify faults by analysing complex data such as thermal images and current-voltage (I-V) curves [60]. Various AI methods have been developed and applied for the detection and classification of damage in photovoltaic systems. Computer vision and deep learning, especially algorithms such as YOLOv3 and Mask R-CNN, have proven to be very effective in detecting and classifying damage to PV panels based on aerial images, taken by drones, for example. Thanks to the ability of deep learning to autonomously recognise complex patterns in the data, these methods achieve high accuracy (up to 99%) and fast processing, which is crucial when analysing large solar parks [61,62,63,64,65,66,67]. Deep learning models, especially convolutional neural networks (CNNs), are characterised by their excellent ability to recognise patterns and visual features, making them particularly suitable for detecting damage to PV panels. Algorithms such as YOLOv3, Mask R-CNN and Deeplab-YOLO have been adapted for this purpose, and numerous studies confirm a very high level of accuracy. Depending on the algorithm used and the type of data, typical detection accuracy rates are between 73% and 95% [60,68]. Dynamic analysis of the I–V curve is an effective method for real-time fault detection and localisation in PV systems, which is particularly important for large or remote installations. By systematically monitoring the relationship between the current and voltage of PV modules, deviations in these parameters can signal potential malfunctions, enabling timely intervention and reducing the risk of further damage or energy loss [69,70]. Fuzzy logic and neural networks are powerful methods for automatic classification and fault diagnosis, especially for systems with a large number of input parameters and complex relationships. Their ability to achieve high accuracy and continuously learn from new data enables continuous adaptation and incremental improvement of performance [71,72,73,74]. Table 1 shows a brief comparison of damage detection methods.

Table 1.

Comparison of damage detection methods.

3.6. Economic and Insurance Aspects of the Effects of Hail on PV Modules

Financial risks due to hail damage to PV systems have become an important issue due to the increasing investments in solar power plants and the increase in extreme weather events. Hail risk is not only important for owners and operators, but also for insurers, investors and the energy sector in general. Hail damage has increased many times over in the last decade, and the insurance market urgently needs solutions that bridge the gap between the technical resilience of the technology and the financial sustainability of the investment. The financial consequences of hail damage are:

- Direct repair and replacement costs: The main financial burden is the cost of replacing or maintaining damaged modules, replacing busbars and the associated labour. The damage can amount to several million euros for large photovoltaic systems.

- Loss of energy production: Damaged modules and their partial or complete shutdown lead to a reduction in total annual income and thus to an extension of the return on investment (ROI).

- Invisible and latent damage: Even if they are not immediately recognised, subsequent performance losses and increased operating costs can significantly reduce the economic results of the project.

Insurance policies for PV systems regularly cover property damage caused by weather events, but in recent years the trend has been towards ever stricter conditions and more precise risk quantification through “exception clauses”, higher deductibles (franchises) and differentiation according to regional risk. The assessment of the “probable maximum loss” (PML) [75] is based on climatological models and historical hail risk maps, which enable a better assessment of the potential maximum loss and determine the required cover fund. In addition to traditional insurance, financial instruments for risk mitigation also include time derivatives and contracts for difference (property damage swaps), which are increasingly being used because they offer protection against extreme damage regardless of the individual damage assessment.

The trends and innovations are as follows:

- Integration of inspection technologies and insurance: Insurers favour owners/projects that use automated damage detection (e.g., via drones, AI inspection) and prevention methods (hail dams, advanced materials), offering better terms and lower premiums to those who use them.

- Incorporating the results of numerical simulations and real measurements into insurance calculations: Software that predicts the areas with the highest risk based on simulations, geolocalisation and meteorological data will become a mandatory tool for both insurance quotes and investment decisions.

- Performance-based insurance and new standards: There are more and more policies on the market that cover power outages due to latent damage, subject to regular inspections and validation of module condition after each major storm.

According to insurance industry reports, hail accounts for less than 2% of insurance claims for solar projects—but more than 50% of total dollar losses [76]. So, although such incidents are relatively rare, their financial consequences are disproportionately large. This suggests that the design of PV systems should not ignore rare but very expensive events, as this can and does lead to significant financial risks for investors. In general, the core of design is not only optimizing the system for the most frequent incidents but also managing risk and limiting the resulting losses. According to the principles of engineering risk management, it is justified to analyze and propose ways to increase resistance to hail, even when the probability of the incident itself remains low. Although severe hail events are unavoidable at some project sites, stakeholders can prevent or limit catastrophic hail damage through increased diligence, technical knowledge and risk mitigation.

4. Discussion

4.1. Hail Impact on Performance and Long-Term Reliability

Hailstorms can have significant but very different effects on the performance and long-term reliability of PV modules. The greatest loss of performance and degradation occurs with severe damage, while minor or latent damage may go unnoticed but have long-term effects on the safety and operation of the system [8]. Depending on the severity of the damage, hail can cause an immediate reduction in the output power of a PV module. Monocrystalline modules lose about 3–4% of their output, while polycrystalline modules can lose up to 12–13% after a hailstorm [8]. For modules with thinner glass, losses are significantly higher than for modules with thicker glass, as already explained in Section 3.4.3 of this paper and reference [13]. Even without visible glass breakage, microcracks and a reduction in shunt resistance can occur, which increases the leakage current and reduces efficiency in the long term [2,3,8,14]. Hail can cause latent structural damage to PV panels, which is not always immediately visible, but can affect their electrical parameters in the long term. Some damage is limited to surface or aesthetic defects, others can lead to micro-fractures in the cells, disruption of the lamination or degradation of the protective glass, resulting in reduced energy production and potentially shortening the lifetime of the modules. Studies show that most power losses occur immediately after a hailstorm, while the long-term degradation rate is similar to that of undamaged modules [8,22]. Modules with the most cracks, for example, had 3–4% less power, but did not show accelerated degradation after six years compared to less damaged modules [47]. Latent damage can lead to a reduction in insulation resistance and increase the risk of electrical failures (even safety risks such as fire or explosion), requiring regular inspection and possibly replacement of modules, even without visible damage [3,21]. If latent damage is detected and the affected modules are found to be unreliable, their replacement may be necessary to ensure the long-term safety and reliable operation of the electrical system. To ensure long-term reliability and reduce the risk of degradation, especially after hail, it is crucial to use thicker glass and higher quality materials in the design of PV modules. After hailstorms, regular inspections, including EL and infrared TG, are essential for the timely detection of latent damage and maintaining the long-term safety of the system [14].

4.2. Comparison of PV Module Technologies and Designs

Choosing the right PV module for hail-prone regions requires a detailed analysis of the design and the materials used. Studies show that factors such as glass thickness, cell type, and module design have a significant impact on hail resistance and the long-term reliability and performance of the system [8,13]. The thickness of the front glass has a direct influence on the resistance of the module, as already explained in the previous text of the paper and reference [13]. Thicker glass also provides better insulation resistance and reduces the risk of breakdown and leakage currents, which is crucial for long-term reliability in areas with frequent hailstorms [3,13]. Compared to polycrystalline PV modules, monocrystalline PV modules are more resistant to hailstorms. After simulated hailstorms, monocrystalline modules lose around 4.15% of their efficiency, while polycrystalline modules lose up to 12.59%. Similarly, the decrease in output power is 3.3% for monocrystalline and 12.5% for polycrystalline modules [8]. Monocrystalline silicon N-type cells with back contact (BC), as well as heterojunction (HJT) and tunnel oxide passivated contact cells (TOPCon), are characterised by high efficiency and can have a longer service life. A higher number of busbars also increases resistance to mechanical damage [2]. Innovative solutions in the design of photovoltaic modules, such as the use of tempered borosilicate glass (e.g., Pyrex), can significantly increase their resistance to hail. Glass-free lightweight modules utilise multilayer polymer materials and composite backsheets, that have lower mass and higher impact resistance. The key lies in the balance between the design of the frontsheet and the stiffness of the backsheet, which enables global and localised dissipation of impact energy. Such modules can pass relevant hail tests with a performance degradation of less than 5% [77,78]. 3D polymer composites inspired by the structure of natural materials (e.g., mantis shrimps) enable significantly higher energy absorption and better protection of cells against breakage, paving the way for the development of new generations of lightweight and durable PV modules [30,79]. Flexible thin-film PV laminates require additional polymer layers to achieve sufficient hail resistance. An optimal combination of elastic and rigid layers can significantly reduce stresses and prevent cell breakage, but requires careful design [80,81].

4.3. Recommendations for Improving the Resistance of PV Modules to Hail

To increase the resistance of photovoltaic modules to hailstorms, it is advisable to favour panels with appropriate certifications, such as IEC 61730, and a protection rating of IP68. The IEC 61730 standard specifies requirements that confirm that photovoltaic modules can withstand hailstorms of a certain size and speed. The IP68 classification guarantees the watertightness of the photovoltaic module and reduces the risk of consequential damage caused by cracks or water ingress.

In addition, it is necessary to consider optimised design solutions, including adjusting the tilt of the modules, applying protective covers during hailstorms, and implementing monitoring systems with hail protection functions. Increasing the tilt angle of the modules can reduce the impact of vertical hail. The optimal range is often between 45° and 60° [82], but factors such as energy yield and wind load must be considered when choosing the final angle. For larger installations, it is advisable to consider installing a tracking system with hail detection. Such systems automatically bring the modules into an almost vertical position in the event of a hailstorm, thus reducing the risk of damage. Smaller solar modules, e.g., with 60 cells, are generally more resistant to damage than modules with a larger format. If hail is forecast, the use of protective covers is recommended. Hard covers offer greater protection, but block sunlight completely, so they must be removed after the storm. Soft covers or spray-on methacrylate protective coatings, on the other hand, are easier to apply and allow some of the solar radiation through. Installing a protective wire mesh with optimally sized openings allows solar radiation to pass through, and at the same time protects the photovoltaic modules from the impact of larger hailstones.

Regular maintenance, and comprehensive insurance policies, are key elements for long-term protection and rational cost management. It is recommended to schedule and carry out a regular, inspection by qualified professionals at least once a year in order to recognise and eliminate possible signs of damage in good time. Make sure that the insurance covers damage to photovoltaic modules caused by hail. It is recommended to choose photovoltaic modules with robust frames and, if possible, with support poles to increase structural integrity and resilience.

4.4. The Impact of Glass Thickness on Cost-Effectiveness

The thickness of the front glass of a PV panel affects the efficiency of the panel, primarily through its effect on light transmission. Thicker glass generally transmits slightly less sunlight to the solar cells, which slightly reduces the efficiency of the panel. For example, the efficiency of a PV panel with 4 mm thick glass is slightly lower compared to a panel with 3 mm glass. This reduction in efficiency, or light transmission, is even less with the use of anti-reflective coatings. According to PV panel manufacturers, the typical light transmittance for a panel with 3.2 mm thick glass is around 93.5%, and for a panel with 4 mm thick glass it is around 92.8%.

PV panels with thicker glass initially have a higher base cost and their mass increases proportionally, because thicker glass requires more material, leading to a higher price and greater weight. For a commercial PV panel measuring 2.0 m × 1.0 m, the mass of the panel increases by an average of 4 kg when using 4 mm thick glass instead of 3.2 mm glass. The increased weight affects installation conditions, such as structural load-bearing capacity and handling.

On the other hand, thicker glass is more mechanically durable and offers greater protection against hail and other impacts, resulting in lower annual degradation rates and extended panel life under warranty. In the long run, this results in reduced operating costs, repairs, and emergency replacements.

Because of the above, a compromise is required during the design phase of a PV system. Optimizing the thickness and type of PV panel glass for a given location can generate the maximum amount of energy while also withstanding environmental challenges such as hail and wind. The economic benefits are greatest in regions with more frequent weather extremes, where the investment in thicker glass is justified through fewer failures, reduced revenue losses due to downtime, and reduced insurance premiums. Industry guidelines and professional literature support this approach, suggesting an individualized selection of glass thickness and type based on local risk assessment and project requirements.

5. Conclusions

This study has comprehensively analysed the effects of hailstorms on photovoltaic (PV) modules, focusing on damage mechanisms, testing standards, detection methods, and strategies to improve module resilience. Using recent literature, numerical simulations, and case studies, the study shows that key factors such as the thickness of the front glass, the cell type, the number of busbars and the quality of the lamination have a decisive influence on hail resistance. Numerical simulations confirm that optimised module designs with thicker, higher quality materials significantly reduce damage and power loss. Advanced detection techniques—including electroluminescence, thermal imaging, and AI-powered visual inspection—are critical for identifying visible and hidden damage and enabling timely maintenance and replacement decisions. Economic and insurance considerations emphasise the need for improved PV module durability and comprehensive risk mitigation. Key recommendations include:

- the use of thicker and higher quality glass;

- the use of more resistant materials and multi-layered structures;

- the integration of simulations into the design and certification process;

- carrying out regular inspections after storms using advanced diagnostic techniques.

The long-term reliability of PV systems under conditions of increasingly pronounced climate extremes can only be achieved through a combination of more resilient design, accurate predictive analyses using numerical simulations, and systematic maintenance. Such an approach not only extends the lifetime and maintains energy efficiency but also increases the economic viability and safety of investments in renewable energy sources.

For future research, it is recommended to focus on the development of novel composites and polymer-based materials for glass-free, lightweight PV modules that exhibit high hail resistance while reducing weight and cost. Further refinement and validation of numerical models that take into account realistic, stochastic hail geometries and multi-angle impacts will improve prediction accuracy. In addition, research into automatic damage detection in real time using improved AI algorithms integrated into drone platforms can increase the efficiency of monitoring large solar parks. Long-term field studies to assess the degradation and performance of PV modules after a hailstorm will provide valuable empirical data to assess the development of latent damage. Finally, the further development of standardised testing protocols that incorporate extreme hail conditions beyond current standards will better prepare the industry for the increasing intensity and frequency of hailstorms due to climate change.

This integrated approach promises to extend PV module lifetimes, improve energy yields, reduce financial risks, and support sustainable solar energy deployment in hail-prone regions worldwide.

Author Contributions

Conceptualization, M.K. and M.B.; methodology, M.B.; validation, M.K. and M.B.; formal analysis, M.K. and M.B.; investigation, M.K. and M.B.; resources, M.K. and M.B.; data curation, M.K. and M.B.; writing—original draft preparation, M.K.; writing—review and editing, M.B.; visualization, M.K.; project administration, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is available on the reasonable request sent to the corresponding author.

Acknowledgments

During the preparation of this manuscript, the authors used Perplexity pro (https://www.perplexity.ai/) for the purposes of generating Figure 7 and a graphical abstract of the paper. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Artificial Intelligence |

| ALE | Arbitrary Lagrangian Eulerian |

| ASTM | American Society for Testing and Materials |

| BC | Back Contact |

| BIPV | Building-integrated photovoltaic systems |

| CdTe | Cadmium Telluride |

| CEL | Coupled Eulerian-Lagrangian |

| EL | Electroluminescence |

| EVA | Ethylene Vinyl Acetate |

| FEA | Finite element analysis |

| HJT | Heterojunction |

| HRC | Hail Resistance Curve |

| IEA | International Energy Agency |

| IEC | International Electrotechnical Commission |

| ML | Machine Learning |

| PML | Probable Maximum Loss |

| PV | Photovoltaic |

| R-CNN | Region-based Convolutional Neural Networks |

| ROI | Return on Investment |

| SPH | Smoothed Particle Hydrodynamics |

| TG | Thermography |

| TOPCon | Tunnel oxide passivated contact cells |

| UV-F | Ultraviolet-Fluorescence |

| VKF | Vereinigung Kantonaler Feuerversicherungen (Association of Cantonal Fire Insurers) |

| YOLOv3 | (You Only Look Once, Version 3) is a real-time object detection algorithm that identifies specific objects in videos, live feeds, or images. |

References

- Bošnjaković, M.; Galović, M.; Kuprešak, J.; Bošnjaković, T. The End of Life of PV Systems: Is Europe Ready for It? Sustainability 2023, 15, 16466. [Google Scholar] [CrossRef]

- Nicoletto, M.; Panizzon, D.; Caria, A.; Trivellin, N.; de Santi, C.; Buffolo, M.; Meneghesso, G.; Zanoni, E.; Meneghini, M. Hail Damage Investigation in Heterojunction Silicon Photovoltaic Modules: A Real-World Case Study. IEEE J. Photovolt. 2025, 15, 478–483. [Google Scholar] [CrossRef]

- Bošnjaković, M.; Stojkov, M.; Katinić, M.; Lacković, I. Effects of Extreme Weather Conditions on PV Systems. Sustainability 2023, 15, 16044. [Google Scholar] [CrossRef]

- Botzena, W.J.W.; Bouwera, L.M.; van den Bergh, J.C.J.M. Climate change and hailstorm damage: Empirical evidence and implications for agriculture and insurance. Resour. Energy Econ. 2010, 32, 341–362. [Google Scholar] [CrossRef]

- Pucik, T. Hailstorms of 2024. European Severe Storms Laboratory 2025. Available online: https://www.essl.org/cms/hailstorms-of-2024/ (accessed on 18 August 2025).

- Büşra Artaş, S.; Kocaman, E.; Hüseyin Bilgiç, H.; Tutumlu, H.; Yağlı, H.; Yumrutaş, R. Why PV panels must be recycled at the end of their economic life span? A case study on recycling together with the global situation. Process Saf. Environ. Prot. 2023, 174, 63–78. [Google Scholar] [CrossRef]

- Peters, I.M.; Hauch, J.A.; Brabec, C.J. The role of innovation for economy and sustainability of photovoltaic modules. iScience 2022, 25, 105208. [Google Scholar] [CrossRef] [PubMed]

- Ali, H.B.; Kamran, M.A.; Gul, R.; Yasir, M.; Alabdullah, F.T.; Usman, C.; Tariq, A. Mechanical integrity of photovoltaic panels under hailstorms: Mono vs. poly-crystalline comparison. Heliyon 2024, 10, e25865. [Google Scholar] [CrossRef]

- Aghaei, M.; Fairbrother, A.; Gok, A.; Ahmad, S.; Kazim, S.; Lobato, K.; Oreski, G.; Reinders, A.; Schmitz, J.; Theelen, M.; et al. Review of degradation and failure phenomena in photovoltaic modules. Renew. Sustain. Energy Rev. 2022, 159, 112160. [Google Scholar] [CrossRef]

- Akram, M.W.; Li, G.; Jin, Y.; Chen, X. Failures of Photovoltaic modules and their Detection: A Review. Appl. Energy 2022, 313, 118822. [Google Scholar] [CrossRef]

- Bošnjaković, M.; Santa, R. Strategic Assessment of Building-Integrated Photovoltaics Adoption: A Combined SWOT-AHP Approach. Energies 2025, 18, 4221. [Google Scholar] [CrossRef]

- Cadoni, E.; Forni, D.; Dotta, M.; Bellenda, G.; Caccivio, M. Advanced characterisation of photovoltaics for hail resistance. Mater. Lett. 2024, 354, 135371. [Google Scholar] [CrossRef]

- Chakraborty, S.; Haldkar, A.; Manoj Kumar, N. Analysis of the hail impacts on the performance of commercially available photovoltaic modules of varying front glass thickness. Renew. Energy 2022, 203, 345–356. [Google Scholar] [CrossRef]

- Gupta, V.; Sharma, M.; Pachauri, R.; Dinesh Babu, K.N. Impact of hailstorm on the performance of PV module: A review. Energy Sources A: Recovery Util. Environ. Eff. 2019, 44, 1923–1944. [Google Scholar]

- Xie, Q. Numerical Study of the Hail Impact on PV Panel by Specific Constitutive Models. Int. J. Eng. Sci. Appl. 2023, 7, 1–7. [Google Scholar]

- Macdonald, J.R.; Stack, M.M. Some Thoughts on Modelling Hail Impact on Surfaces. J. Bio-Tribo-Corros. 2021, 7, 37. [Google Scholar] [CrossRef]

- IEC 61215-2:2021; Terrestrial Photovoltaic (PV) Modules-Design Qualification and Type Approval-Part 2: Test Procedures. International Electrotechnical Commission: Geneva, Switzerland, 2021.

- IEC 61464:2008; Thin-Film Terrestrial Photovoltaic (PV) Modules-Design Qualification and Type Approval. International Electrotechnical Commission: Geneva, Switzerland, 2008.

- IEC 61730-1:2023; Photovoltaic (PV) Module Safety Qualification—Part 1: Requirements for Construction. International Electrotechnical Commission: Geneva, Switzerland, 2023.

- ASTM E1038-10; Standard Test Method Determining Resistance of Photovoltaic Modules to Hail by Impact with Propelled Ice Balls. ASTM International: West Conshohocken, PA, USA, 2019.

- Muehleisen, W.; Eder, G.; Voronko, Y.; Spielberger, M.; Sonnleitner, H.; Knoebl, K.; Ebner, R.; Ujvari, G.; Hirschl, C. Outdoor detection and visualization of hailstorm damages of photovoltaic plants. Renew. Energy 2018, 118, 138–145. [Google Scholar] [CrossRef]

- Gabor, A.; Knodle, P.J.; Covino, M.; Fioresi, J.; Colvin, D.; Davis, K. Electroluminescence Analysis and Grading of Hail Damaged Solar Panels. IEEE J. Photovolt. 2022, 12, 1308–1313. [Google Scholar] [CrossRef]

- Buerhopa, C.; Schlegela, D.; Niessb, M.; Vodermayerb, C.; Weißmanna, R.; Brabec, C.J. Reliability of IR-imaging of PV-plants under operating conditions. Sol. Energy Mater. Sol. Cells 2012, 107, 154–164. [Google Scholar] [CrossRef]

- Morlier, A.; Siebert, M.; Kunze, I.; Mathiak, G.; Köntges, M. Detecting Photovoltaic Module Failures in the Field During aytime with Ultraviolet Fluorescence Module Inspection. IEEE J. Photovolt. 2017, 7, 1710–1716. [Google Scholar] [CrossRef]

- Rödera, B.; Ermilova, E.A.; Philippb, D.; Köhlb, M. Observation of polymer degradation processes in photovoltaic modules via luminescence detection. In Proceedings of the SPIE, Volume 7048, Reliability of Photovoltaic Cells, Modules, Components, and Systems, San Diego, CA, USA, 11–13 August 2008. [Google Scholar]

- Perry, K.; Jordan, D.C.; Nguyen, Q. Assessing the Impacts of Extreme Weather Events on Photovoltaic Installations using Remote Sensing Imagery. Prog. Photovolt.: Res. Appl. 2025, 3, 1012–1023. [Google Scholar] [CrossRef]

- Forni, D.; Caccivio, M.; Chudy, D.; Cadoni, E. An experimental investigation of ice ball impact behaviour to improve PV panel hailstone safety. Int. J. Impact Eng. 2025, 202, 105315. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, W.; Xu, Y.; Li, Y.; Liu, T. Experimental study on the influence of turbulence on hail impacts. Sci. Rep. 2024, 14, 18317. [Google Scholar] [CrossRef]

- Johnston, S.; Terwilliger, K.; Wai, R.; Kern, D.; Jordan, D. Photovoltaic Module Performance for Six Years After Hail Damage. In Proceedings of the IEEE 52nd Photovoltaic Specialist Conference (PVSC), Seattle, WA, USA, 9–14 June 2024; pp. 270–273. [Google Scholar]

- Budiman, A.S.; Sahay, R.; Agarwal, K.; Fajarna, R.; Gunawan, F.E.; Baji, A.; Raghavan, N. Modeling Impact Mechanics of 3D Helicoidally Architected Polymer Composites Enabled by Additive Manufacturing for Lightweight Silicon Photovoltaics Technology. Polymers 2022, 14, 1228. [Google Scholar] [CrossRef] [PubMed]

- Bošnjaković, M. Advance of Sustainable Energy Materials: Technology Trends for Silicon-Based Photovoltaic Cells. Sustainability 2024, 16, 7962. [Google Scholar] [CrossRef]

- SIA 261:2020; Effects on Structures, Ref. no. 505261:2020. Swiss Engineer and Architects Association: Zurich, Switzerland, 2020.

- Janda, M.; Jandová, K. Simulation of the Influence of Hail Mechanical Action on Photovoltaic Panels. ECS Trans. 2015, 70, 239–243. [Google Scholar] [CrossRef]

- Makarskas, V.; Jurevičius, M.; Zakis, J.; Kilikevičius, A.; Borodinas, S. Simulation Study of Hail Impact on Photovoltaic Modules. In Proceedings of the IEEE 7th IEEE Workshop on Advances in Information, Electronic and Electrical Engineering (AIEEE) 2019, Liepaja, Latvia, 15–16 November 2019; pp. 1–4. [Google Scholar]

- Matos, N.; Gomes, M.; Infante, V. Numerical modelling of soft body impacts: A review. Eng. Fail. Anal. 2023, 153, 107595. [Google Scholar] [CrossRef]

- Ivančević, D.; Badurina Žakan, I.; Smojver, I. Numerical Methodology for Aerostructures Hail Impact Damage Predictio. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 10th EASN International Conference on Innovation in Aviation & Space to the Satisfaction of the European Citizens (10th EASN 2020), Salerno, Italy, 2–5 September 2020; IOP Publishing Ltd.: Bristol, UK, 2021; Volume 1024. [Google Scholar]

- Anghileri, M.; Castelletti, L.; Invernizzi, F.; Mascheroni, M. A survey of numerical models for hail impact analysis using explicit finite element codes. Int. J. Impact Eng. 2005, 31, 929–944. [Google Scholar] [CrossRef]