Challenges in Aquaculture Hybrid Energy Management: Optimization Tools, New Solutions, and Comparative Evaluations

Abstract

1. Introduction

- Explicitly articulate the novel contributions of HY4RES beyond validation.

- Highlight case-specific insights gained through its application to fish processing facilities.

- Clarify the limitations of HOMER Pro in this context and how HY4RES addresses them.

2. Materials and Methods

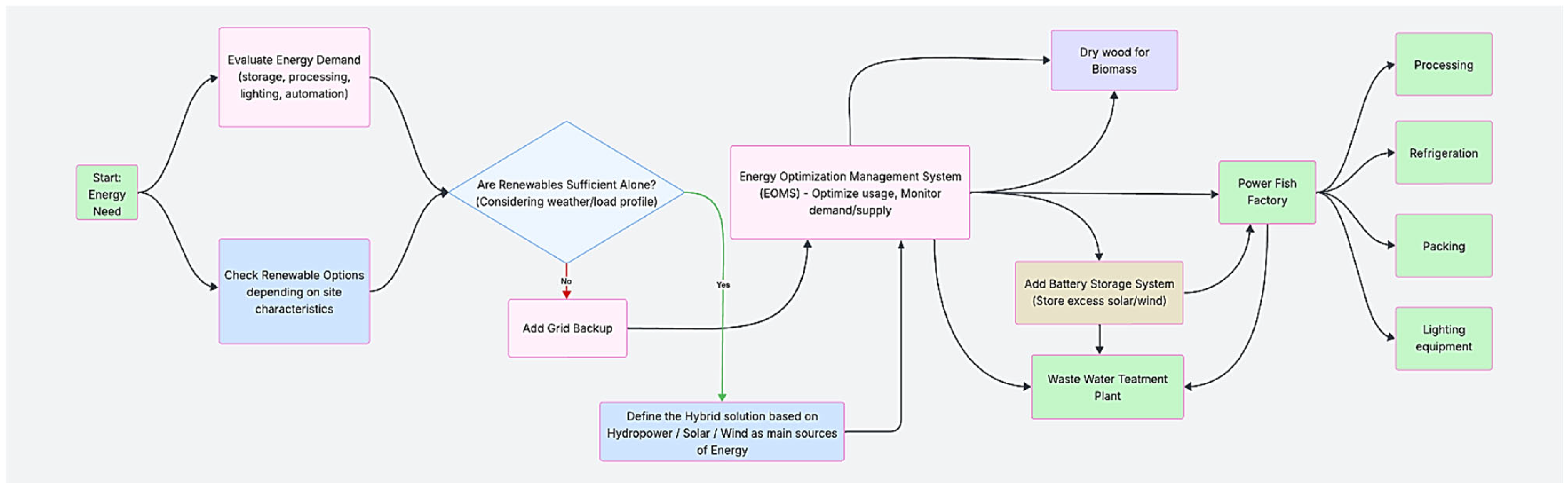

2.1. Methodology

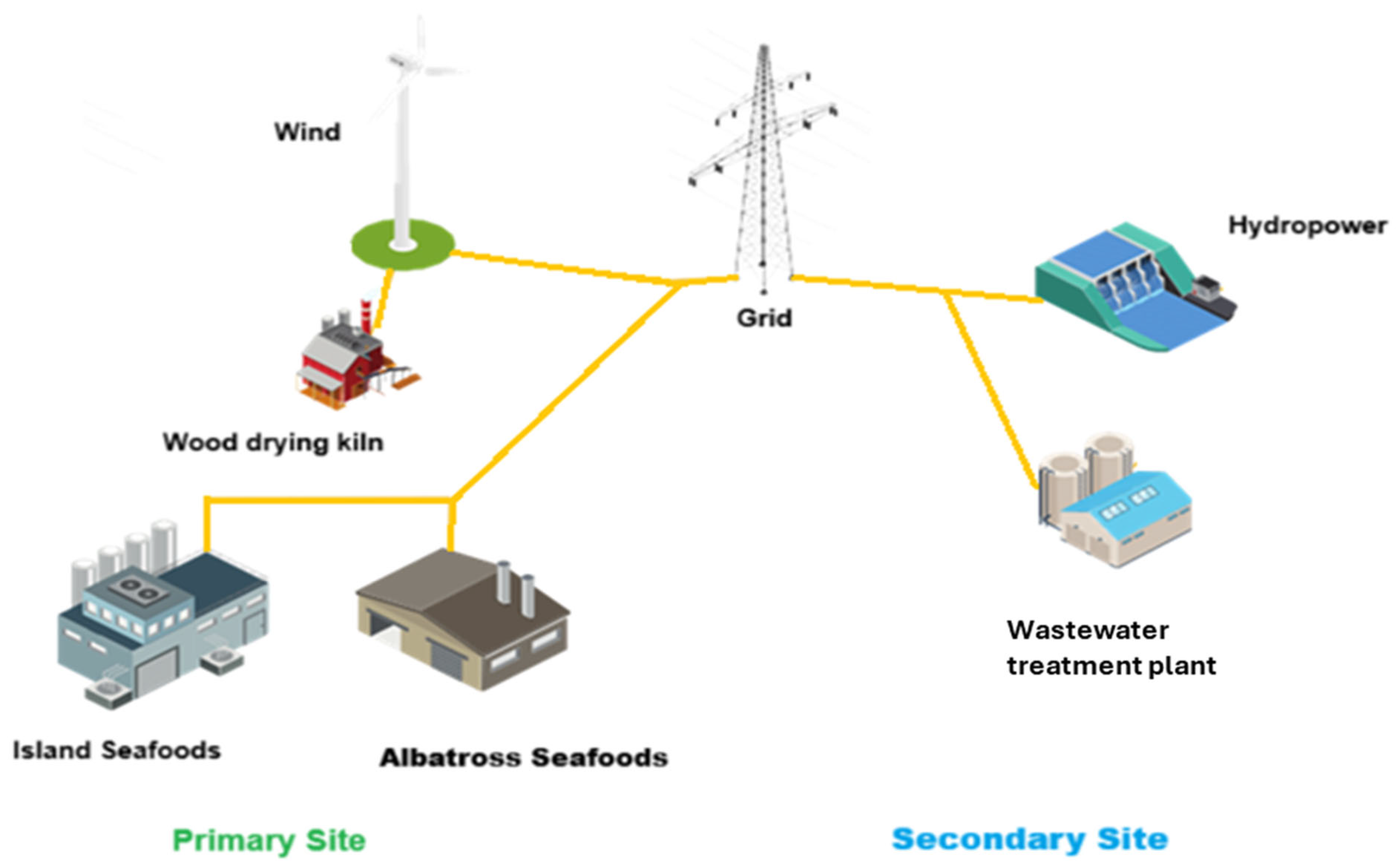

2.2. Aquaculture Case Study

2.3. Model Adaptation

2.3.1. Input Data

- (i)

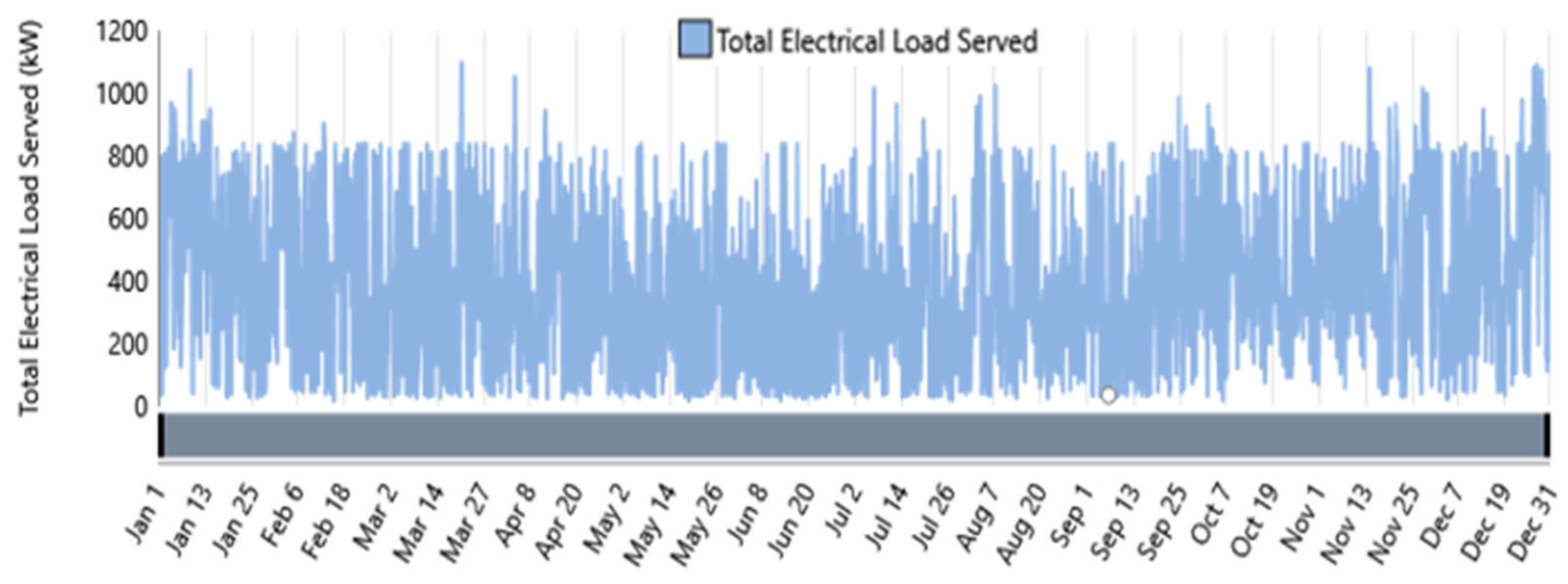

- Fish processing facilitiesFor the Primary site, the electricity load data of Island Seafoods for each 15 min of the year 2023 is available. The data was combined to express the electric load for each hour of the same year. As there is no recorded consumption data for Albatross Seafoods, it was assumed that its consumption is 0.9292 of Island Seafoods’ [6]. With this approach, the combined load at the Primary site could be computed and was available as an input to the HY4RES model.

- (ii)

- Wastewater treatment plantThe same approach as for the fish processing facilities was repeated for the data from the wastewater treatment plant. For certain timestamps, data was missing, or too many timestamps were recorded. In this case, the surplus timestamp data was added to another timestamp where the load was zero, to reach the correct yearly total. In HOMER Pro, a different approach is chosen. A commercial electricity consumption profile from the library with 1200 kWh/day and 430.72 kW peak is used.

- (iii)

- Wood drying kilnAs a means of utilizing excess energy from the wind turbine that cannot be fed into the grid due to feed-in restrictions, a wood drying kiln was installed at the Primary site. The typical primary wood used for drying in Ireland is Sitka spruce with a density of 400−500 kg/m3. It is assumed that 2000 kWh are needed to dry 1 t of Sitka spruce [5]. The installed kiln for the drying of this wood has a rated power of 300 kW. Hence, 1.8 t of wood can be dried per day, considering a 12 h operation of the drying kiln. This results in 657 t of dried wood per year. To consider the biomass drying kiln in the simulation, the excess electricity from the base case was assumed to be available for its operation. Operation for 12 h per day between 08:00 a.m. to 08:00 p.m. with a constant power of 300 kW was plotted for every hour of the year. In HOMER Pro, a load of 3600 kWh/day and 516.86 kW peak was chosen to represent the biomass drying kiln.

- (iv)

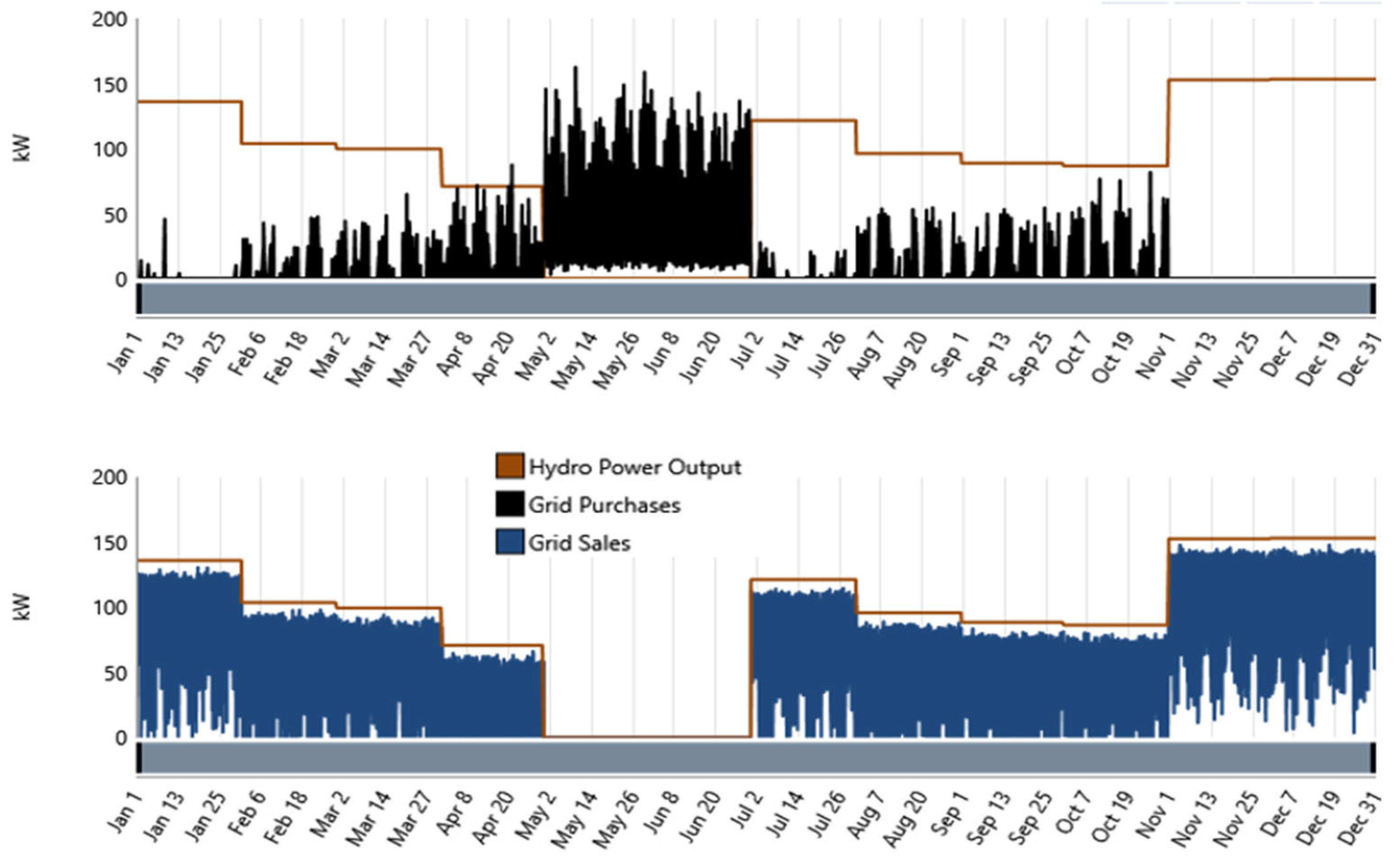

- Small hydropower plantOn the Secondary site, a small hydropower plant was installed in 2007. It utilizes the river flow and has the parameters shown in Table 1. Due to an installation error, it does not operate at rated power but only at 250 kW. It directly supplies the load of the wastewater treatment facility and feeds excess electricity directly to the grid.Table 1. Parameters of the SHP at the secondary site.

Name Value Note Pr 380 kW Only operates at 250 kW Type Francis Reaction turbine Hb 61 m Medium head n 1000 rpm Rated conditions Q 0.7 m3/s Rated flow ηT 80% Turbine efficiency ηElec 95% Electric conversion For the SHP, monthly generation data is available from Island Seafoods. To take the monthly variation into account, each month’s electricity generation was split equally over the hours of the month. The monthly generation data was then compiled into one yearly file to serve as an input for the HY4RES model. In HOMER Pro a different approach was chosen. The SHP was modeled in the program directly with the data from Table 1 and a design flow rate of 0.522 m3/s to reflect the limited power of 250 kW. - (v)

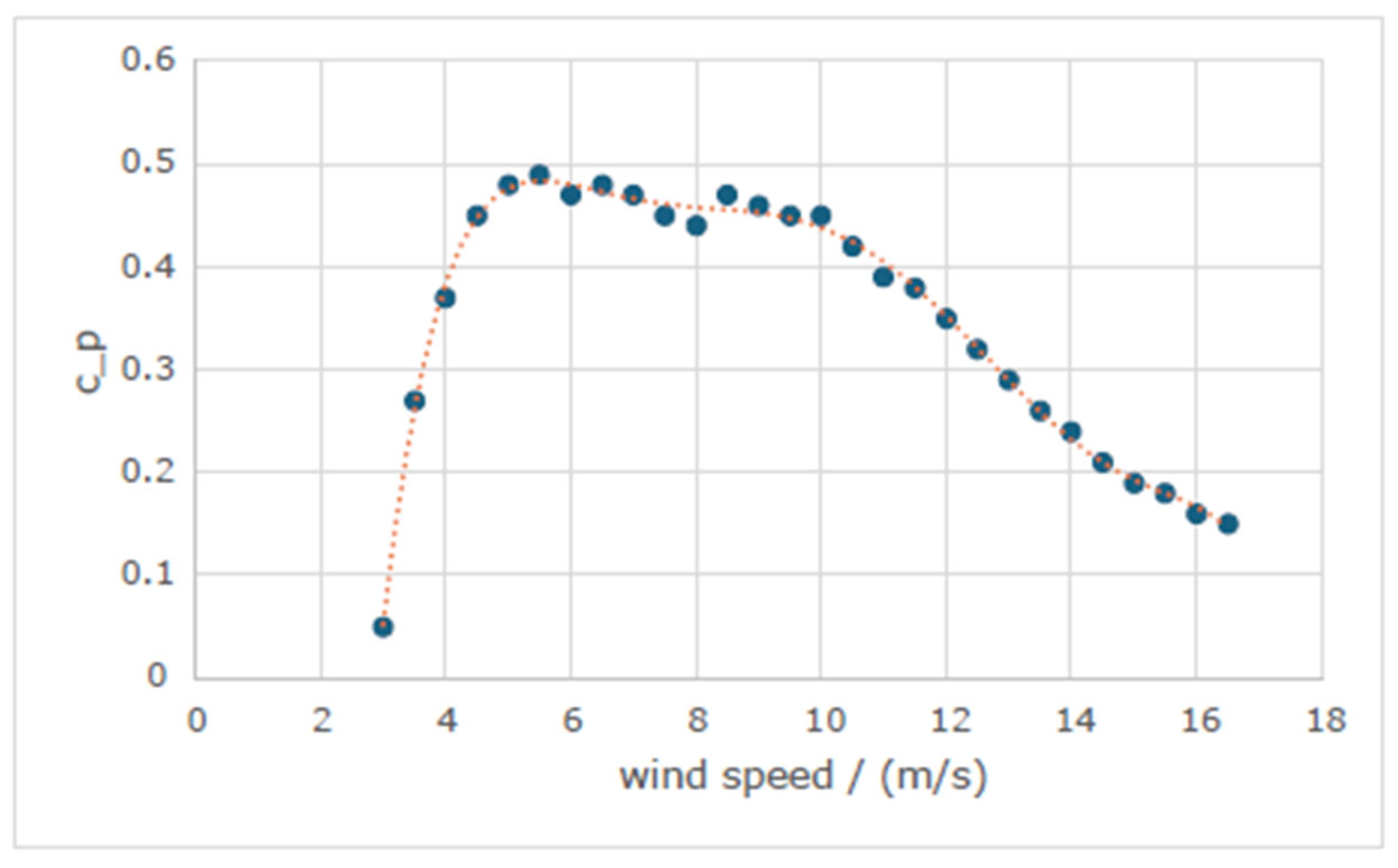

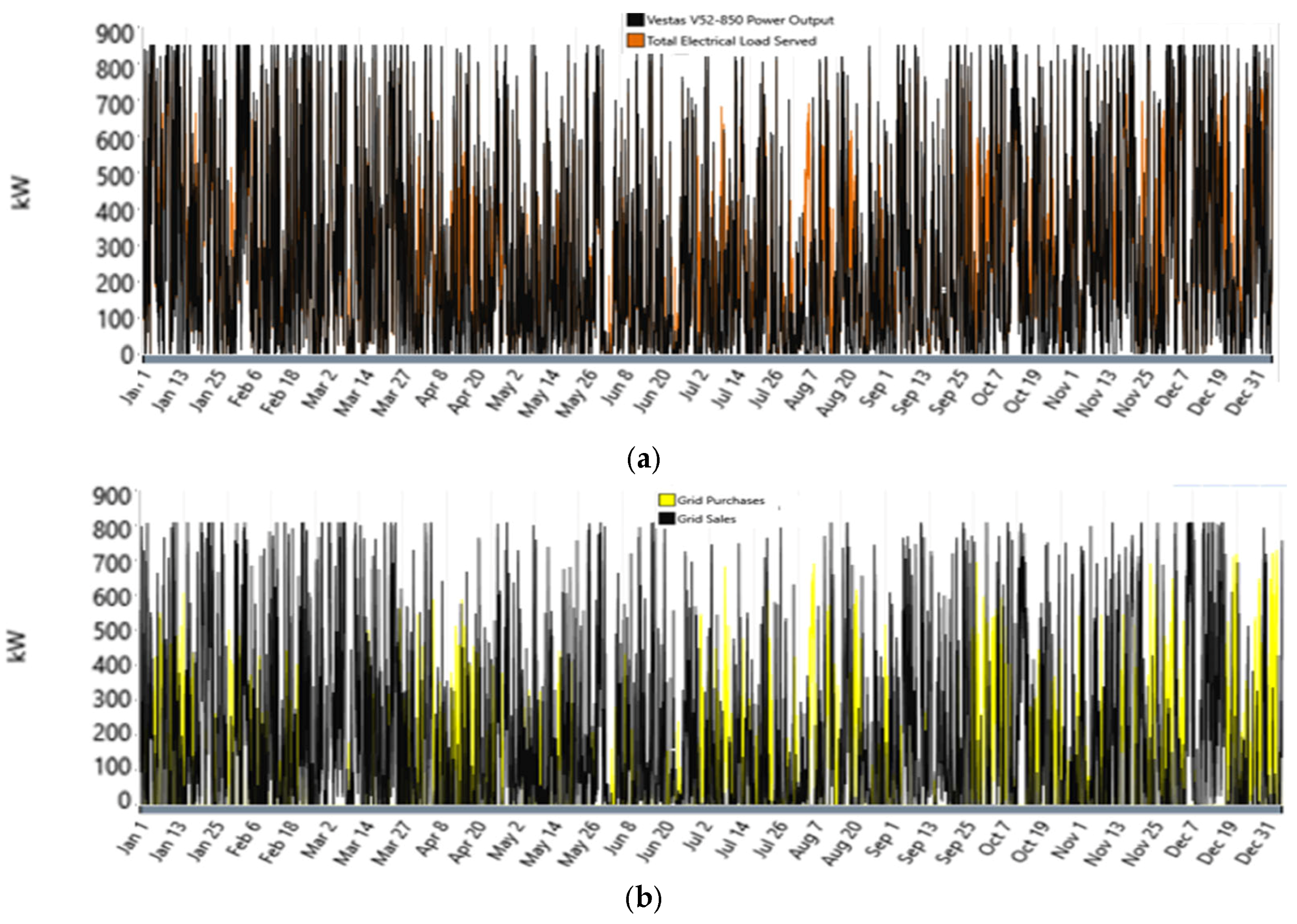

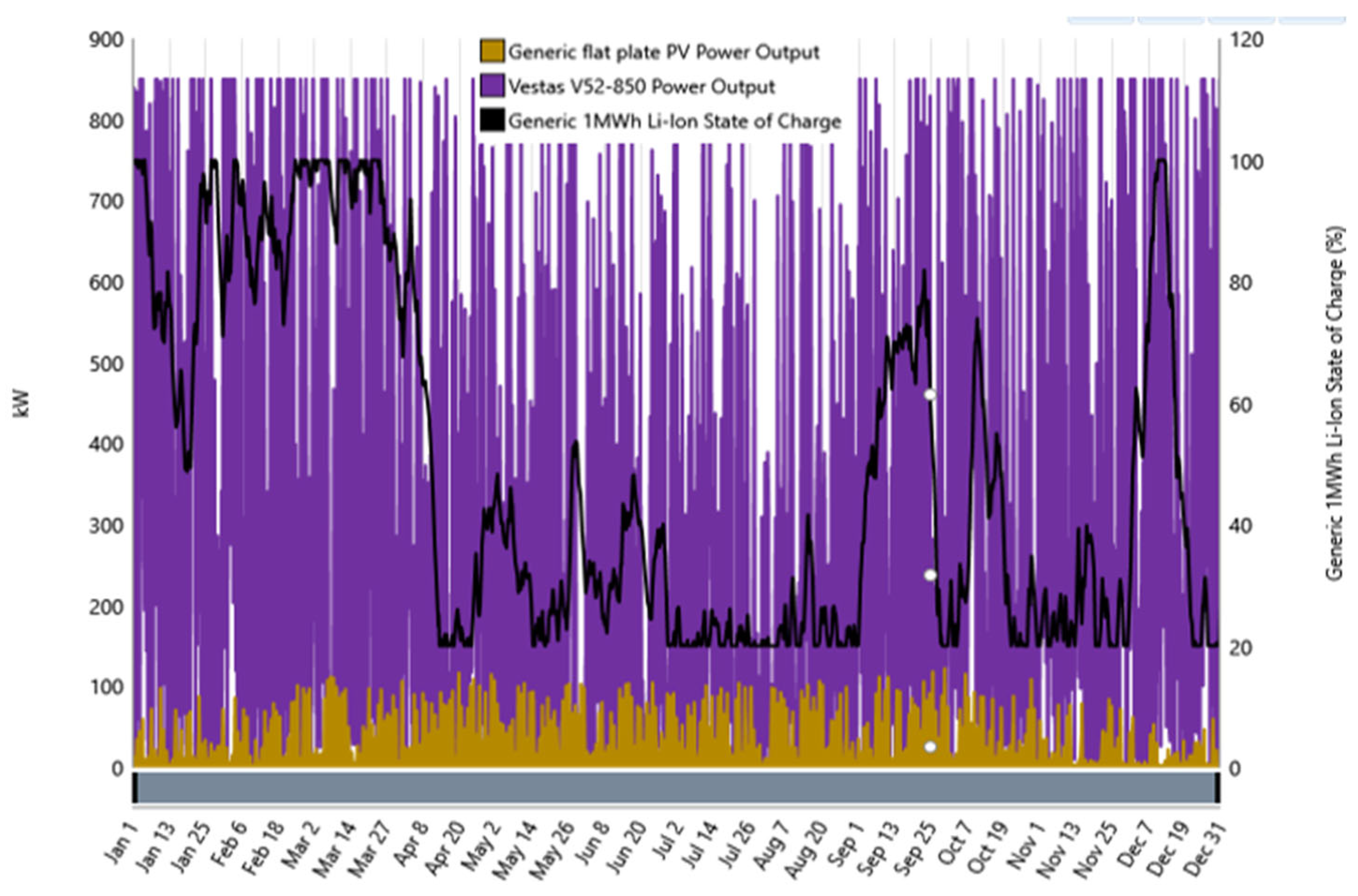

- Wind turbineA single Vestas V52-850 wind turbine was commissioned in 2021. It is directly connected to the primary site’s electrical network, supplying the demand of the two processing facilities and feeding excess electricity into the grid. Due to feed-in limitations, the turbine is only allowed to feed in 120 kW. Approximately 80 kW is used directly in the two processing facilities, while 180 kW is used for heating purposes. This situation leaves 300 kW of unused potential. The key parameters of the turbine are found in Table 2.Table 2. Parameters of the Vestas V52 850 wind turbine at the primary site.

Name Value Note Pr 850 kW Maximum operation at 500 kW due to grid injection limitations Hhub 44 m halt 60 m above sea level Lat. 54.673 Long. −8.422 Data merra2 for 2023

- (vi)

- Solar PVTo simulate the PV system, PVGIS 5.3 was used with the input displayed in Table 3 to generate hourly electric energy values. PVGIS was run with a 1 kWp nominal power; its generation was then scaled to 120 kWp. Due to availability restrictions, the year 2020 was used for the PVGIS simulation. Both slope and azimuth angle were optimized automatically by PVGIS.

- (vii)

- Biomass generatorTo utilize only parts of the dried wood in a biomass generator on site, a 25 kW generator was chosen, thus still leaving dried wood to be sold on the local market. It is assumed that the 25 kW is constantly available throughout each hour of the year, amounting to a yearly energy generation through biomass of 219,000 kWh.

- (viii)

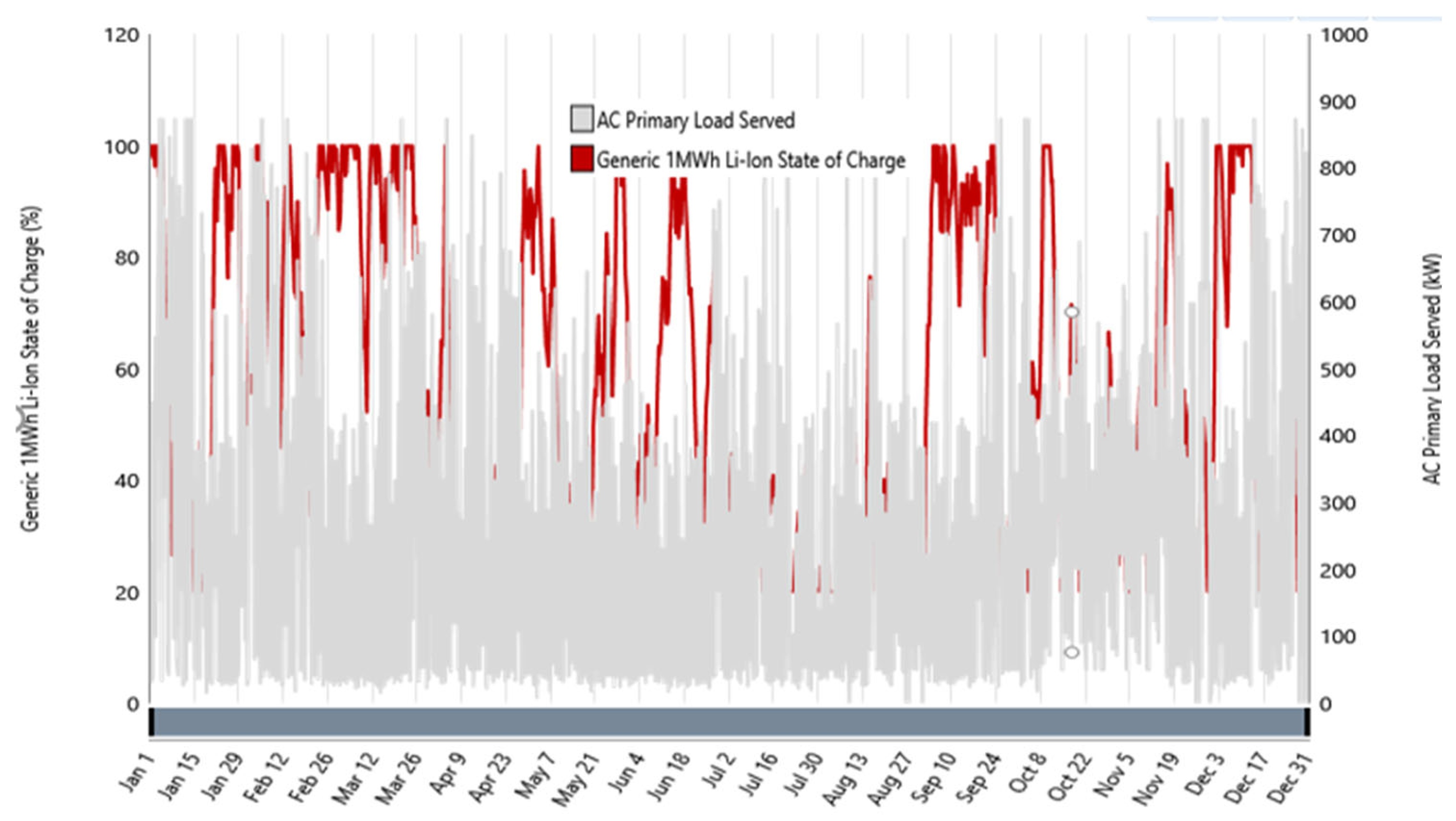

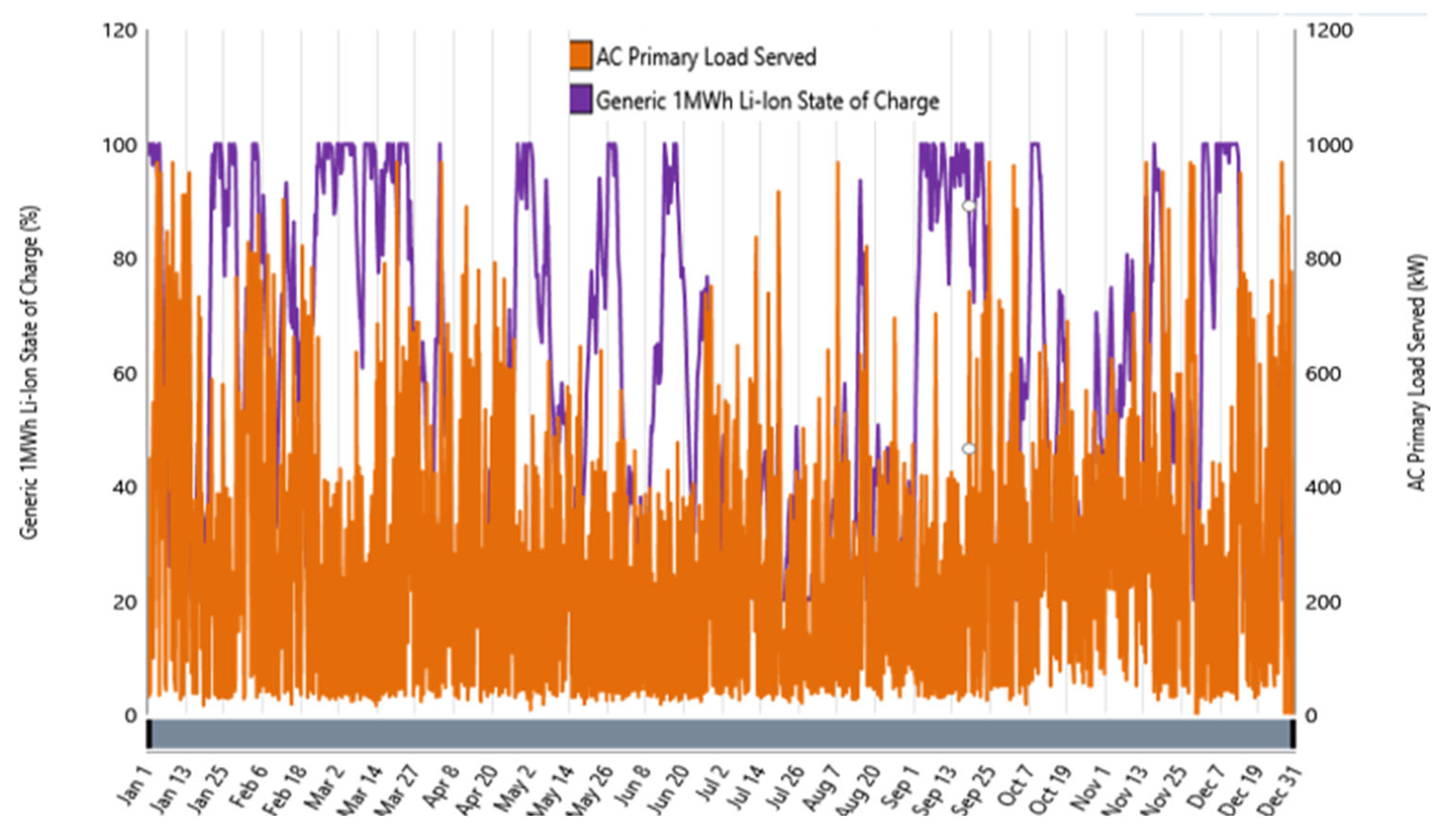

- Energy storageWhen the scenario to be compared encompasses a BESS, it was decided upon to use the nominal capacity of the BESS as an input in HY4RES. HOMER Pro uses a more sophisticated BESS simulation and regards the usable capacity. This is used in any scenario where a BESS is present. If not stated otherwise, Li-ion BESSs are used.

- (ix)

- Financial parametersTo achieve similar results in terms of cash flows, the electricity feed-in price and purchase price from HOMER Pro are used. These are 0.195 EUR/kWh and 0.3808 EUR/kWh, respectively. They remain constant throughout each hour of the average year.

2.3.2. Model Comparisons: Scenario Definitions

3. Simulation Results

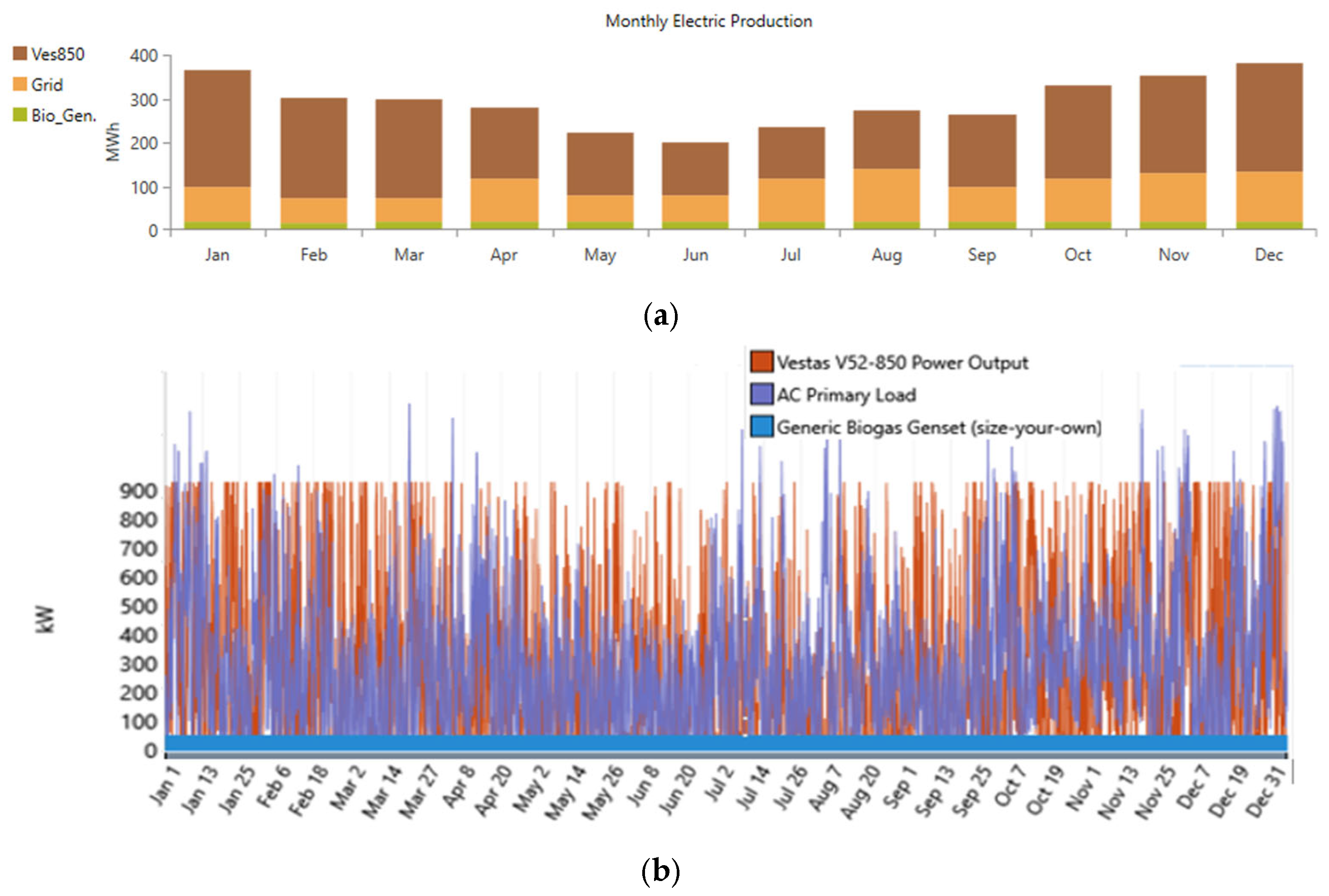

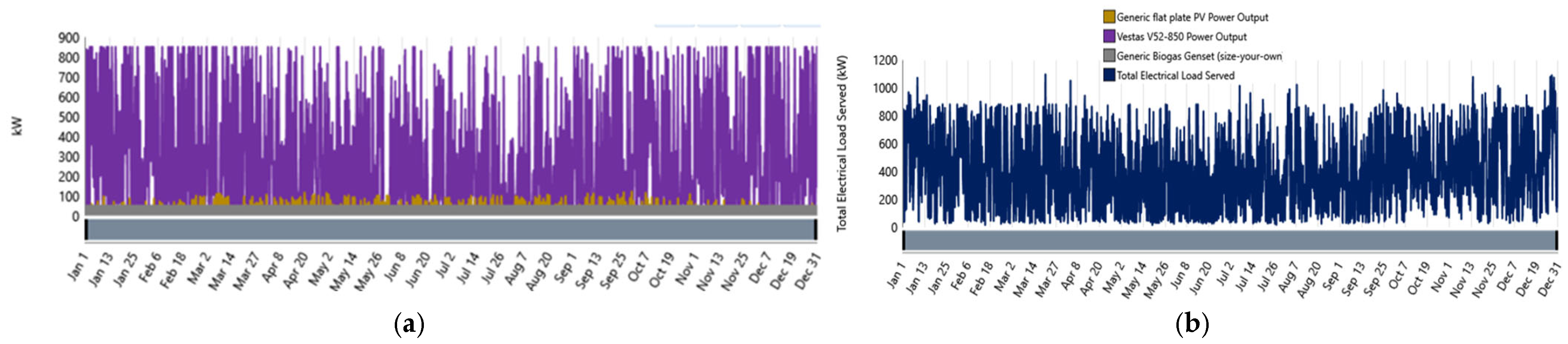

3.1. Operational Behavior

3.2. Grid Balance Cash Flow

4. Discussion

4.1. Primary Site

4.2. Secondary Site

4.3. Limitations of the Models

5. Conclusions

- Base Case (Primary Site): Includes the combined hourly loads of Island and Albatross Seafoods with wind generation. No wood drying kiln or feed-in limits are considered.

- Scenario 1: Adds biomass drying kiln and a 25 kW biomass generator to the base load.

- Scenario 2: Extends Scenario 1 with 120 kWp solar PV.

- Scenario 3 (Off-grid): Uses only wind, biomass, and a 22 MWh BESS. Load reductions are based on unmet demand; less wood is dried.

- Scenario 4: Scenario 3 + solar PV; similar energy balance, unmet demand remains.

- Scenario 5: Biomass generator removed; kiln still operates. Due to unmet demand, drying is reduced. A larger 63 MWh BESS is needed to maintain the same deficit level.

- Scenario 6: Returns to grid-tied; full kiln operation resumes, 657 t of wood dried/year, and cash flow is recorded.

- Base Case (Secondary Site): It uses the hourly generation data from the small hydropower plant (SHP) as the tertiary generation input, and the hourly load profile of the wastewater treatment facility is entered as the site’s electrical consumption.

- Scenario 1 (Grid-tied): Adds rooftop solar PV, and its hourly generation is included in the simulation.

- Scenario 2 (Off-grid): Replaces the grid connection with a 400 kWh BESS. The system does not fully meet demand in summer due to low hydro generation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramos, H.M.; Morani, M.C.; Carravetta, A.; Fecarrotta, O.; Adeyeye, K.; López-Jiménez, P.A.; Pérez-Sánchez, M. New Challenges towards Smart Systems Efficiency by Digital Twin in Water Distribution Networks. Water 2022, 14, 1304. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, T.; Wang, Y.; Short, M. An optimisation approach for the design and operation of recirculating aquaculture systems integrated with sustainable hybrid energy systems. J. Clean. Prod. 2024, 477, 143860. [Google Scholar] [CrossRef]

- Nguyen, N.T.; Matsuhashi, R. Tran Thi Bich Chau Vo, A design on sustainable hybrid energy systems by multi-objective optimization for aquaculture industry. Renew. Energy 2021, 163, 1878–1894. [Google Scholar] [CrossRef]

- Erdemir, D.; Dincer, I. Development of renewable energy based green hydrogen and oxygen production and electricity generation systems for sustainable aquaculture. J. Clean. Prod. 2024, 434, 140081. [Google Scholar] [CrossRef]

- Dewi, T.; Risma, P.; Oktarina, Y.; Dwijayanti, S.; Mardiyati, E.N.; Sianipar, A.B.; Hibrizi, D.R.; Azhar, M.S.; Linarti, D. Smart integrated aquaponics system: Hybrid solar-hydro energy with deep learning forecasting for optimized energy management in aquaculture and hydroponics. Energy Sustain. Dev. 2025, 85, 101683. [Google Scholar] [CrossRef]

- Li, P.; Wang, Y.; Liu, J.; Liang, M. Evaluation of Carbon Emission Efficiency and Analysis of Influencing Factors of Chinese Oil and Gas Enterprises. Energy Sci. Eng. 2025, 13, 1156–1170. [Google Scholar] [CrossRef]

- Ferreira, R.F.; Lameirinhas, R.A.M.; Bernardo, C.P.C.V.; Torres, J.P.N.; Santos, M. Agri-PV in Portugal: How to combine agriculture and photovoltaic production. Energy Sustain. Dev. 2024, 79, 101408. [Google Scholar] [CrossRef]

- Khalaf, K.A.; Gamil, A.; Attiya, B.; Cuello, J. Exploring the potential of concentrating solar power technologies for vertical farming in arid regions: The case of Western Iraq. Energy Sustain. Dev. 2023, 77, 101310. [Google Scholar] [CrossRef]

- Shreesha, S.; Pai, M.M.M.; Pai, R.M.; Verma, U. Pattern detection and prediction using deep learning for intelligent decision support to identify fish behavior in aquaculture. Ecol. Inform. 2023, 78, 102287. [Google Scholar] [CrossRef]

- Cao, J.; Liu, J.; Liu, X.; Zeng, C.; Hu, H.; Luo, Y. A Review of Marine Renewable Energy Utilization Technology and Its Integration with Aquaculture. Energies 2025, 18, 2343. [Google Scholar] [CrossRef]

- Alnemari, A.M.; Elmessery, W.M.; Moghanm, F.S.; Espinosa, V.; Shams, M.Y.; Elwakeel, A.E.; Saeed, O.; Eid, M.H.; Alhag, S.K.; Al-Shuraym, L.A.; et al. Energy optimization in large-scale recirculating aquaculture systems: Implementation and performance analysis of a hybrid deep learning approach. Aquac. Eng. 2025, 111, 102561. [Google Scholar] [CrossRef]

- Scroggins, R.E.; Fry, J.P.; Brown, M.T.; Neff, R.A.; Asche, F.; Anderson, J.L.; Love, D.C. Renewable energy in fisheries and aquaculture: Case studies from the United States. J. Clean. Prod. 2022, 376, 134153. [Google Scholar] [CrossRef]

- Murali, S.; Krishnan, V.S.; Amulya, P.R.; Alfiya, P.V.; Delfiya, D.S.A.; Samuel, M.P. Energy and water consumption pattern in seafood processing industries and its optimization methodologies, Clean. Eng. Technol. 2021, 4, 100242. [Google Scholar]

- Amulya, P.R.; Murali, S.; Alfiya, P.V.; Delfiya, D.S.A.; Samuel, M.P. Energy optimization in seafood processing industries. Indian Food Ind. Mag. AFST (I) 2018, 37, 49–52. [Google Scholar]

- Alzahrani, A.; Petri, I.; Rezgui, Y. Analysis and simulation of smart energy clusters and energy value chain for fish processing industries. Energy Rep. 2020, 6, 534–540. [Google Scholar] [CrossRef]

- D’Amico, G.; Ioppolo, G.; Szopik-Depczyńska, K.; Dembińska, I. Smart and sustainable logistics of Port cities: A framework for comprehending enabling factors, domains and goals. Sustain. Cities Soc. Artic. 2021, 69, 102801. [Google Scholar] [CrossRef]

- Matulić, D.; Andabaka, Ž.; Radman, S.; Fruk, G.; Leto, J.; Rošin, J.; Rastija, M.; Varga, I.; Tomljanović, T.; Čeprnja, H.; et al. Agrivoltaics and Aquavoltaics: Potential of Solar Energy Use in Agriculture and Freshwater Aquaculture in Croatia. Agriculture 2023, 13, 1447. [Google Scholar] [CrossRef]

- Jing, R.; He, Y.; Hea, J.; Liu, L.; Yang, S. Global sensitivity-based prioritizing the parametric uncertainties in economic analysis when co-locating photovoltaic with agriculture and aquaculture in China. Renew. Energy 2022, 194, 1048–1059. [Google Scholar] [CrossRef]

- Ferrer-Gisbert, C.; Ferrán-Gozálvez, J.J.; Redón-Santafé, M.; Ferrer-Gisbert, P.; Sánchez-Romero, F.J.; Torregrosa-Soler, J.B. A new photovoltaic floating cover system for water reservoirs. Renew. Energy 2013, 60, 63–70. [Google Scholar] [CrossRef]

- Pouran, H.M.; Padilha Campos Lopes, M.; Nogueira, T.; Alves Castelo Branco, D.; Sheng, Y. Environmental and technical impacts of floating photovoltaic plants as an emerging clean energy technology. iScience 2022, 25, 105253. [Google Scholar] [CrossRef]

- Das, K.; Hansen, A.D.; Leon, J.P.M.; Zhu, R.; Gupta, M.; Pérez-Rúa, J.; Long, Q.; Pombo, D.V.; Barlas, A.; Gocmen, T.; et al. Research Challenges and Opportunities of Utility-Scale Hybrid Power Plants. WIREs Energy Environ. 2025, 14, e70001. [Google Scholar]

- Coelho, J.S.T.; van de Loo, M.; Díaz, J.A.R.; Coronado-Hernández, O.E.; Perez-Sanchez, M.; Ramos, H.M. Multi-Objective and Multi-Variable Optimization Models of Hybrid Renewable Energy Solutions for Water–Energy Nexus. Water 2024, 16, 2360. [Google Scholar] [CrossRef]

- Coelho, J.S.T.; Alves, A.B.; Morillo, J.G.; Coronado-Hernández, O.E.; Perez-Sanchez, M.; Ramos, H.M. Hybrid Energy Solution to Improve Irrigation Systems: HY4RES vs. HOMER Optimization Models. Energies 2024, 17, 4037. [Google Scholar] [CrossRef]

- Ramos, H.M.; Coelho, J.S.T.; Bekci, E.; Adrover, T.X.; Coronado-Hernández, O.E.; Perez-Sanchez, M.; Koca, K.; McNabola, A.; Espina-Valdés, R. Optimization and Machine Learning in Modeling Approaches to Hybrid Energy Balance to Improve Ports’ Efficiency. Appl. Sci. 2025, 15, 5211. [Google Scholar] [CrossRef]

- Ramos, H.M.; Pina, J.; Coronado-Hernández, O.E.; Pérez-Sánchez, M.; McNabola, A. Conceptual hybrid energy model for different power potential scales: Technical and economic approaches. Renew. Energy 2024, 237, 121486. [Google Scholar] [CrossRef]

- Interreg Atlantic Area HY4RES. Aquaculture Pilot Site Ireland Online. Available online: https://hy4res.eu/pilot-sites/aquaculture/ (accessed on 4 November 2024).

- Pfenninger, S.; Staell, I. Long-term patterns of European PV output using 30 years of validated hourly reanalysis and satellite data. Energy 2016, 114, 1251–1265. [Google Scholar] [CrossRef]

- Wind-turbine-models.com. Vestas V52 Online. Available online: https://en.wind-turbine-models.com/turbines/71-vestas-v52 (accessed on 29 April 2025).

- Bekci, E. HY4RES Project—Aquaculture in Ireland HOMER Pro simulation report. IST 2024.

- Lian, Y.; Chen, Q.; Zheng, J.; Zhang, J.; Sheng, D.; Tao, L.; Yim, S.C. Effects of water level variation on the response of mooring systems for offshore floating photovoltaic platforms. Ocean. Eng. 2025, 339, 122088. [Google Scholar] [CrossRef]

- Lian, Y.; Chen, Q.; Zheng, J.; Zhang, J.; Sheng, D.; Tao, L.; Yim, S.C. Numerical study on the dynamic response of mooring systems for an offshore floating photovoltaic platform. Int. Conf. Offshore Mech. Arct. Eng. 2024, 87837, V05BT06A034. [Google Scholar]

| Scenarios | Grid | Wind | SHP | Biomass | PV | BESS |

|---|---|---|---|---|---|---|

| Primary site | ||||||

| Base Case | Yes | Yes | No | No | No | No |

| Scenario 1 | Yes | Yes | No | Yes | No | No |

| Scenario 2 | Yes | Yes | No | Yes | Yes | No |

| Scenario 3 | No | Yes | No | Yes | No | Yes |

| Scenario 4 | No | Yes | No | Yes | Yes | Yes |

| Scenario 5 | No | Yes | No | No | Yes | Yes |

| Scenario 6 | Yes | Yes | No | No | Yes | No |

| Secondary site | ||||||

| Base Case | Yes | No | Yes | No | No | No |

| Scenario 1 | Yes | No | Yes | No | Yes | No |

| Scenario 2 | No | No | Yes | No | No | Yes |

| Primary site—electricity consumption values (HY4RES vs. HOMER Pro) | |||||

| Scenario | Category | HY4RES (kWh) | HY4RES (%) | HOMER Pro (kWh) | HOMER Pro (%) |

| Base Case | Load | 1,116,896 | 43.3 | 1,116,900 | 42.1 |

| Base Case | Grid feed-in | 1,462,122 | 56.7 | 1,538,909 | 57.9 |

| Base Case | Total | 2,579,018 | 100 | 2,655,809 | 100 |

| Scenario 1: Wind, Biomass & Grid | Load | 2,430,896 | 71.1 | 2,430,900 | 71.8 |

| Scenario 1 | Grid feed-in | 990,427 | 28.9 | 955,298 | 28.2 |

| Scenario 1 | Total | 3,421,323 | 100 | 3,386,198 | 100 |

| Scenario 2: Wind, Biomass, PV & Grid | Load | 2,430,896 | 70.5 | 2,430,900 | 70.9 |

| Scenario 2 | Grid feed-in | 1,017,555 | 29.5 | 996,161 | 29.1 |

| Scenario 2 | Total | 3,448,450 | 100 | 3,427,061 | 100 |

| Scenario 3: Wind, Biomass & BESS | Load | 2,178,677 | 100 | 2,082,043 | 100 |

| Scenario 4: Wind, Biomass, PV & BESS | Load | 2,240,062 | 100 | 2,150,772 | 100 |

| Scenario 5: Wind, PV & BESS | Load | 2,134,946 | 100 | 2,083,531 | 100 |

| Scenario 6: Wind, PV & Grid | Load | 2,430,896 | 72.8 | 2,430,900 | 73 |

| Scenario 6 | Grid feed-in | 905,970 | 27.2 | 897,604 | 27 |

| Scenario 6 | Total | 3,336,866 | 100 | 3,328,504 | 100 |

| Secondary site—electricity consumption values (HY4RES vs. HOMER Pro) | |||||

| Scenario | Category | HY4RES (kWh) | HY4RES (%) | HOMER Pro (kWh) | HOMER Pro (%) |

| Base Case | Load | 438,000 | 41.3 | 438,000 | 48.6 |

| Base Case | Grid feed-in | 623,071 | 58.7 | 462,325 | 51.4 |

| Base Case | Total | 1,061,071 | 100 | 900,325 | 100 |

| Scenario 1: Hydropower, PV & Grid | Load | 438,000 | 39 | 438,000 | 45.4 |

| Scenario 1 | Grid feed-in | 684,858 | 61 | 526,993 | 54.6 |

| Scenario 1 | Total | 1,122,858 | 100 | 964,993 | 100 |

| Scenario 2: Hydropower, PV & BESS | Load | 328,824 | 100 | 387,829 | 100 |

| Primary site—electricity generation values (HY4RES vs. HOMER Pro) | |||||

| Scenario | Source | HY4RES (kWh) | HY4RES (%) | HOMER Pro (kWh) | HOMER Pro (%) |

| Base Case | Wind | 2,240,471 | 86.9 | 2,240,471 | 80.9 |

| Base Case | From grid | 338,547 | 13.1 | 527,361 | 19.1 |

| Base Case | Total | 2,579,018 | 100 | 2,767,833 | 100 |

| Scenario 1: Wind, Biomass & Grid | Wind | 2,240,471 | 65.5 | 2,240,471 | 64.4 |

| Scenario 1 | Biomass | 219,000 | 6.4 | 219,000 | 6.4 |

| Scenario 1 | From grid | 961,323 | 28.1 | 1,038,751 | 29.7 |

| Scenario 1 | Total | 3,421,323 | 100 | 3,498,222 | 100 |

| Scenario 2: Wind, Biomass, PV & Grid | Wind | 2,240,471 | 65 | 2,240,471 | 63.2 |

| Scenario 2 | Biomass | 219,000 | 6.4 | 219,000 | 6.3 |

| Scenario 2 | PV | 104,606 | 3 | 107,164 | 3 |

| Scenario 2 | From grid | 884,374 | 25.6 | 980,500 | 27.6 |

| Scenario 2 | Total | 3,448,450 | 100 | 3,547,135 | 100 |

| Scenario 3: Wind, Biomass & BESS | Wind | 2,240,471 | 91.1 | 2,240,471 | 91.1 |

| Scenario 3 | Biomass | 219,000 | 8.9 | 218,974 | 8.9 |

| Scenario 3 | Total | 2,459,471 | 100 | 2,459,445 | 100 |

| Scenario 4: Wind, Biomass, PV & BESS | Wind | 2,240,471 | 87.4 | 2,240,471 | 87.3 |

| Scenario 4 | Biomass | 219,000 | 8.5 | 218,950 | 8.5 |

| Scenario 4 | PV | 104,606 | 4.1 | 107,164 | 4.2 |

| Scenario 4 | Total | 2,564,077 | 100 | 2,566,585 | 100 |

| Scenario 5: Wind, PV & BESS | Wind | 2,240,471 | 95.5 | 2,240,471 | 87.3 |

| Scenario 5 | PV | 104,606 | 4.5 | 107,164 | 4.7 |

| Scenario 5 | Total | 2,345,077 | 100 | 2,347,635 | 100 |

| Scenario 6: Wind, PV & Grid | Wind | 2,240,471 | 67.1 | 2,240,471 | 65 |

| Scenario 6 | PV | 104,606 | 3.1 | 107,164 | 3.1 |

| Scenario 6 | From grid | 991,789 | 29.7 | 1,100,421 | 31.9 |

| Scenario 6 | Total | 3,336,866 | 100 | 3,448,057 | 100 |

| Secondary site—electricity generation values (HY4RES vs. HOMER Pro) | |||||

| Scenario | Source | HY4RES (kWh) | HY4RES (%) | HOMER Pro (kWh) | HOMER Pro (%) |

| Base Case | SHP | 884,225 | 83.3 | 809,410 | 89.9 |

| Base Case | From grid | 176,850 | 16.7 | 90,915 | 10.1 |

| Base Case | Total | 1,061,075 | 100 | 900,325 | 100 |

| Scenario 1: Hydropower, PV & Grid | SHP | 884,225 | 78.7 | 809,410 | 83.4 |

| Scenario 1 | PV | 104,606 | 9.3 | 107,164 | 11 |

| Scenario 1 | From grid | 134,031 | 11.9 | 54,110 | 5.6 |

| Scenario 1 | Total | 1,122,862 | 100 | 970,684 | 100 |

| Scenario 2: Hydropower, PV & BESS | SHP | 884,225 | 89.4 | 809,410 | 88.3 |

| Scenario 2 | PV | 104,606 | 10.6 | 107,164 | 11.7 |

| Scenario 2 | Total | 988,831 | 100 | 916,574 | 100 |

| HY4RES | HOMER Pro | ||

|---|---|---|---|

| Base Case | |||

| Revenue (EUR) | 285,114 | 300,097 | |

| Expenses (EUR) | 128,919 | 200,819 | |

| Cash flow (EUR) | 156,195 | 99,278 | |

| Scenario 1: Wind, Biomass and Grid | |||

| Revenue (EUR) | 193,133 | 186,283 | |

| Expenses (EUR) | 366,273 | 395,556 | |

| Cash flow (EUR) | −173,140 | −209,273 | |

| Scenario 2: Wind, Biomass, PV and Grid | |||

| Revenue (EUR) | 198,423 | 194,251 | |

| Expenses (EUR) | 336,769 | 373,374 | |

| Cash flow (EUR) | −138,346 | −179,123 | |

| Scenario 6: Wind, PV and Grid | |||

| Revenue (EUR) | 176,664 | 175,033 | |

| Expenses (EUR) | 377,673 | 419,040 | |

| Cash flow (EUR) | −201,009 | −244,007 | |

| HY4RES | HOMER Pro | |

|---|---|---|

| Base Case | ||

| Revenue (EUR) | 121,499 | 90,153 |

| Expenses (EUR) | 67,344 | 34,620 |

| Cash flow (EUR) | 54,154 | 55,532 |

| Scenario 1: Hydropower, PV and Grid | ||

| Revenue (EUR) | 133,547 | 102,764 |

| Expenses (EUR) | 51,039 | 20,605 |

| Cash flow (EUR) | 82,508 | 82,159 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos, H.M.; Soehlemann, N.; Bekci, E.; Coronado-Hernández, O.E.; Pérez-Sánchez, M.; McNabola, A.; Gallagher, J. Challenges in Aquaculture Hybrid Energy Management: Optimization Tools, New Solutions, and Comparative Evaluations. Technologies 2025, 13, 453. https://doi.org/10.3390/technologies13100453

Ramos HM, Soehlemann N, Bekci E, Coronado-Hernández OE, Pérez-Sánchez M, McNabola A, Gallagher J. Challenges in Aquaculture Hybrid Energy Management: Optimization Tools, New Solutions, and Comparative Evaluations. Technologies. 2025; 13(10):453. https://doi.org/10.3390/technologies13100453

Chicago/Turabian StyleRamos, Helena M., Nicolas Soehlemann, Eyup Bekci, Oscar E. Coronado-Hernández, Modesto Pérez-Sánchez, Aonghus McNabola, and John Gallagher. 2025. "Challenges in Aquaculture Hybrid Energy Management: Optimization Tools, New Solutions, and Comparative Evaluations" Technologies 13, no. 10: 453. https://doi.org/10.3390/technologies13100453

APA StyleRamos, H. M., Soehlemann, N., Bekci, E., Coronado-Hernández, O. E., Pérez-Sánchez, M., McNabola, A., & Gallagher, J. (2025). Challenges in Aquaculture Hybrid Energy Management: Optimization Tools, New Solutions, and Comparative Evaluations. Technologies, 13(10), 453. https://doi.org/10.3390/technologies13100453