Abstract

Over the last decades, environmental awareness has provoked scientific interest in green energy, produced, among others, from solar sources. However, for the efficient operation and longevity of green solar plants, regular inspection and maintenance are required. This work aims to review vision-based monitoring techniques for the fault detection of photovoltaic (PV) plants, i.e., solar panels. Practical implications of such systems include timely fault identification based on data-driven insights and problem resolution, resulting in enhanced energy outputs, extended lifetime spans for PV panels, cost savings, as well as safe and scalable inspections. Details regarding the main components of PV systems, operation principles and key non-destructive fault detection technologies are included. Advancements in unmanned aerial vehicles (UAVs), as well as in artificial intelligence (AI), machine learning (ML) and deep learning (DL) methods, offering enhanced monitoring opportunities, are in focus. A comparative analysis and an overall evaluation of state-of-the-art vision-based methods for detecting specific types of defects on PVs is conducted. The current performance and failures of vision-based algorithms for solar panel fault detection are identified, raising their capabilities, limitations and research gaps, towards effectively guiding future research. The results indicate that shading anomalies significantly impact the performance of PV units, while the top five fault detection methodologies, according to preset evaluation criteria, involve deep learning methods, such as CNNs and YOLO variations.

1. Introduction

Solar energy is an inexhaustible clean power source that is increasingly significant in both technological advancements and environmental sustainability. As climate changes and the depletion of traditional energy resources pose serious threats to our future, photovoltaic (PV) systems emerge as a pioneering solution. These systems harness the photovoltaic effect to convert solar radiation into electrical energy, providing a clean and limitless power source [1].

The journey of PV technology began in 1839 when French physicist Edmond Becquerel discovered the photovoltaic effect. Since then, research and technological advancements have led to the development of the first PV cells, which now offer impressive performance and applications across various needs [2].

PV systems are not just technical innovations; they are ecological necessities. Each kilowatt-hour of electricity produced by photovoltaic systems reduces carbon dioxide emissions, making them vital for environmental protection. Additionally, solar energy provides economic benefits, especially in sunny regions where investing in photovoltaics can result in significant savings and profits [3]. Therefore, it is essential that PV plants remain reliable and function effectively, referring to excellent installation, frequent maintenance, and high-quality inspections for faults. Faults may occur while manufacturing, transporting, assembling and operating PV panels. Faults need to be detected on time, so as to be repaired and prevent safety issues and energy losses.

Currently, fault detection methods have been in research focus, especially those that are not intrusive and can also provide details on the location of faults. Vision-based inspection has prevailed over other methods, due to the continuous advancements of camera technologies and graphics processing unit (GPU) architectures, as well as the progress of artificial intelligence (AI) and computer vision (CV) algorithms. The latter combination has the potential to detect, classify and localize faults, with low costs, and high reliability.

Contemporary challenges in vision-based PV fault detection systems include data overload issues due to the vast amount of produced data from various integrated sensors, creating barriers to the need for real-time fault detection. High-resolution images are needed to accurately detect faults; yet, their processing requires significant time and resources. Contemporary challenges also include the need for the improvement of fault detection accuracies by developing more advanced detection algorithms. The investigation of common faults, resulting mainly due to external environmental conditions, need to be identified so as to focus research on their effective detection.

To this end, this work aims to provide a review on AI vision-based solar panel inspection techniques, focusing on dealing with contemporary challenges. Many reviews have been recently published on the subject [1,3,4,5,6,7]. Yet, most of these review works focus on specific monitoring techniques and are not meant to be generic so as to cover multiple aspects of PV systems. These approaches aim to holistically summarize the key detection technologies, as well as machine learning and deep learning methodologies. The primary gaps we identified in these review works, and eventually aim to address in the proposed work, are the following:

- The lack of study on faults in relation to the performance of photovoltaic modules.

- The lack of evaluation of the proposed methodologies.

To this end, the contributions of this work that are not addressed cumulatively in other papers are summarized as follows:

- Presentation of PV systems’ fundamentals.

- Evolution of computer vision algorithms for PV fault detection within the decade.

- Summarization of all key monitoring techniques for PV fault detection, along with individual and comparative assessment of their capabilities and limitations.

- A focus on PV fault detection using AI-based computer vision, including machine learning and other pattern recognition methods, image processing techniques, and deep learning methods.

- Common faults detectable by CV algorithms in PV systems and how they affect the systems’ performance.

- Review of CV-based fault detection methodologies, cumulative performance tables and guidelines to select the appropriate one based on proposed criteria.

The rest of the paper is structured as follows. Section 2 presents the research methodology. Section 3 summarizes the fundamentals of PV systems. Section 4 presents the evolution of CV algorithms in PVs over the last decade. Capabilities and limitations of basic detection technologies are included in Section 5, focusing on fault detection using AI-based CV algorithms. Section 6 summarizes CV detected PV faults and related PV system performance. Section 7 provides an overview of CV-based PV fault detection methodologies and their evaluation. Finally, Section 8 and Section 9 discuss the research findings and conclude the paper, respectively.

2. Research Methodology

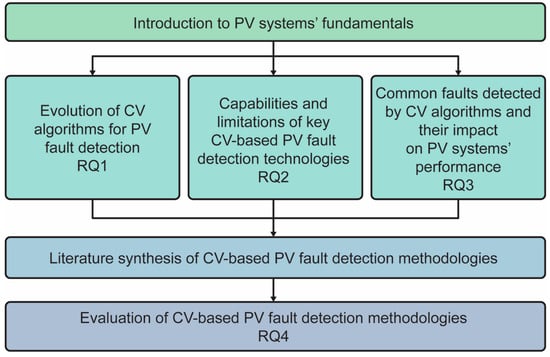

To provide a comprehensive review that manages to effectively address the identified gaps, we pose the following four research questions (RQ):

- RQ1: How have CV algorithms evolved in the context of fault detection in photovoltaic systems over the past decade?

- RQ2: What are the capabilities and limitations of key CV-based detection technologies concerning faults in photovoltaic systems?

- RQ3: What are the common faults that can be detected with CV in photovoltaic systems, and which of these significantly affect system performance?

- RQ4: What CV-based fault detection methodologies are identified in the literature, and how can the appropriate method be selected?

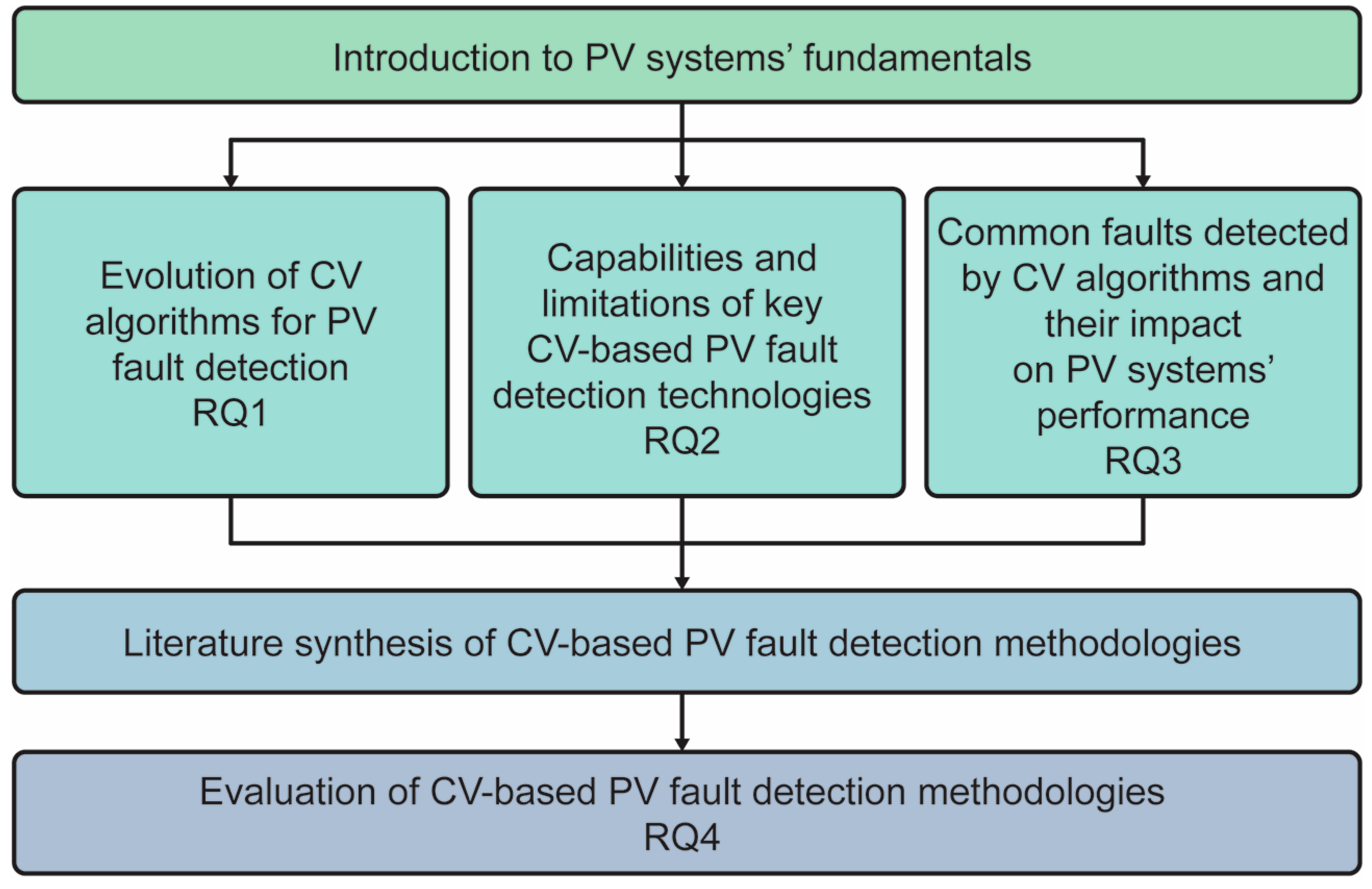

Figure 1 outlines the followed roadmap for addressing these four research questions. Research questions in this work are answered through a comprehensive review of identified articles relevant to the subject of interest. Figure 1 aims to illustrate the RQs and define the connection between them, as well as to indicate the exact order in which the questions are answered in the subsections entitled with the same name as each RQ, i.e., to align the RQs with specific subsections towards guiding the reader through the content logically.

Figure 1.

The followed roadmap. Connection of RQs and corresponding subjections where RQs are addressed.

The research of relevant articles in this work was conducted in the Scopus database within Article title, Abstract and Keywords, by using the query: “computer vision” AND “PV” AND “faults detection” OR “defects” OR “anomalies”. The search returned 52 articles ranging from 2014–2024.

To further refine the research results, the following eligibility criteria were applied:

- Language was limited to English.

- Subject area was limited to Engineering and Computer Science.

- Document types were limited to Conference papers and Articles.

By applying these limitations, 38 related documents were identified and used as sources in the following.

3. Fundamentals of PV Systems

In this section, the fundamentals of PV systems are summarized, including the main components of a PV system and PV operating principles.

3.1. Components

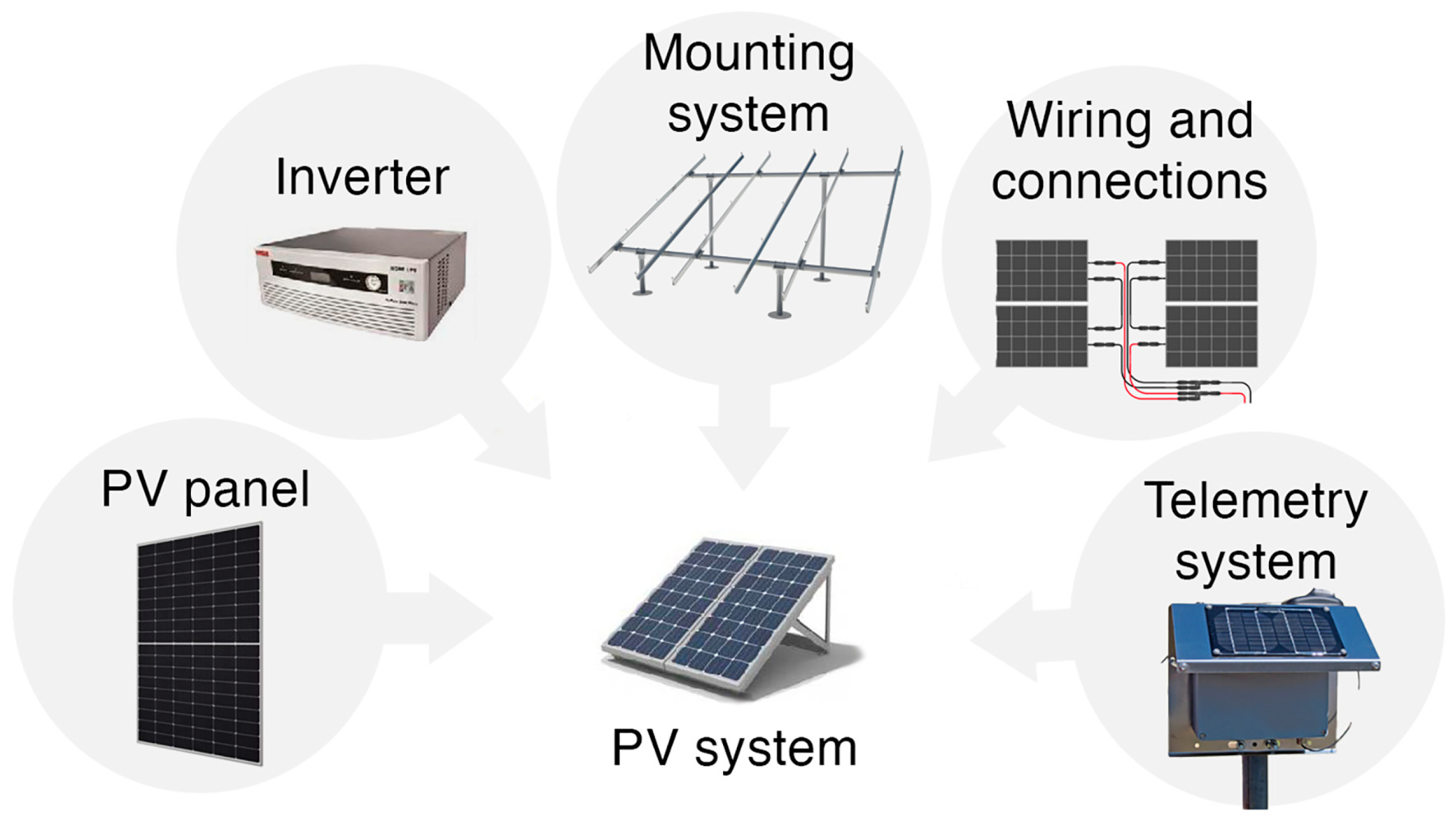

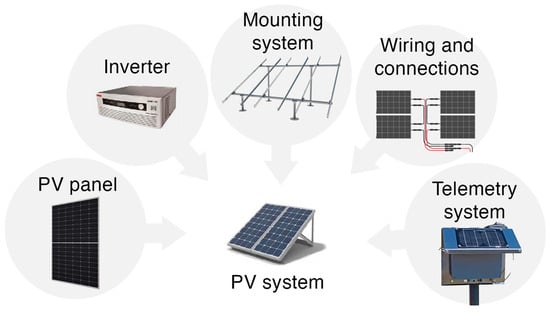

A PV system comprises the following main components, as illustrated in Figure 2:

Figure 2.

PV system main components.

- Photovoltaic Panels (PV Modules):

- a.

- Made up of photovoltaic cells that convert sunlight into electrical energy.

- b.

- Panels can be monocrystalline, polycrystalline or thin-film, each with unique performance characteristics and costs.

- Inverter:

- a.

- Converts the direct current (DC) produced by the photovoltaic panels into alternating current (AC) for use by electrical appliances or the grid.

- b.

- Different types of inverters, such as half-bridge and full-bridge, have various applications and features.

- Mounting System:

- a.

- Includes the supports and structures that hold the photovoltaic panels, either fixed or adjustable for solar tracking systems.

- Wiring and Connections:

- a.

- Essential for connecting the photovoltaic panels to the inverter and the power grid.

- b.

- Includes DC and AC cables, as well as grounding and lightning protection systems.

- Telemetry System:

- a.

- Ensures the monitoring and control of the photovoltaic system’s performance.

- b.

- May include wireless or wired connections for data transmission.

3.2. Operating Principles

The photovoltaic effect relies on semiconductor materials that convert solar radiation into electrical energy. When photons (packets of energy from sunlight) hit the photovoltaic cells, they excite the electrons in the semiconductor materials, causing an electric current to flow. This current is then collected and converted into usable electrical energy by the inverter.

The efficiency of a photovoltaic system depends on several factors, including the quality of materials, the intensity of solar radiation, and environmental conditions. Despite its limitations, photovoltaic technology continues to advance, offering more efficient and cost-effective solutions for generating clean energy.

In summary, photovoltaic systems represent an innovative and sustainable response to modern energy challenges, providing an environmentally friendly and economically viable solution. Continuous research and development in this field promise a bright future for solar energy and its role in creating a sustainable and clean environment.

4. Evolution of Computer Vision Algorithms in PVs over the Last Decade

This section provides a comprehensive overview of how computer vision algorithms have evolved in photovoltaic fault detection over the last decade (RQ1). Using Scopus, we explored over 60 relevant studies. Table 1 includes the findings we have traced regarding the advancements and shifts in focus in this scientific field. More specifically, for each distinct period within the decade, the focus of research, the current state-of-the-art technologies and algorithms, as well as the key developments and limitations of each period are identified and summarized in the table.

Table 1.

Evolution of computer vision algorithms in PV fault detection over the last decade.

In the early 2010s, traditional image processing techniques like edge detection and segmentation dominated the field [8]. These methods relied heavily on rule-based techniques and manual parameter adjustments. The latter posed limitations, since manual feature extraction can be time-consuming and may fail to capture the inherent characteristics of faults, leading to poor detection accuracies especially for complex faults. As the decade progressed, machine learning started to make its mark. Algorithms such as Support Vector Machine (SVM) [9] and Random Forest (RF) [10] appeared, employing handcrafted features and initial feature classifiers to improve detection accuracy. The limitation of feature engineering, feature extraction and selection, was still evident, while problem complexities could not efficiently be handled. Moreover, generalization issues were reported due to the varying environmental conditions and different PV systems, making algorithms difficult to generalize well. By the late 2010s, the field experienced a significant shift with the advent of deep learning, particularly Convolutional Neural Networks (CNNs) [11]. These models enabled automated feature learning, leading to substantial improvements in detection accuracy and efficiency. However, data requirements were excessive. Large benchmark datasets with annotated data were needed, while the training time of algorithms and the needs for computational resources began to augment. In the early 2020s, the focus shifted towards integrating multiple modalities, using CNNs in combination with infrared (IR), visible and electroluminescence (EL) imaging [12,13,14]. This integration resulted in enhanced fault detection capabilities under various conditions. Multiple data modalities posed many challenges, such as data overload, and data synchronization. Moreover, the need for sophisticated fusion techniques emerged. The processing of multiple data streams increased system complexity and computational burden. At the same time, the need for explainable deep learning algorithms started to show, revealing the research gap of interpretability of multimodal deep models. Currently, the trend is moving towards real-time detection and adaptability [17]. Advanced models like CNNs and YOLO are being employed for on-site processing, enabling real-time detection and adaptability to varying environmental conditions [15]. Interpretable AI algorithms, adaptability to new faults, and robustness to environmental changes were, therefore, in focus. Limitations included costs and scalability, since the size of PV installations tend to increase, producing vast amount of data and needing significant computational power.

Looking ahead, the future direction of research in this field is expected to focus on scalability and economic viability. Researchers are working on developing scalable deep learning models that can be economically viable and provide comprehensive fault detection solutions. A foreseen challenge is that of cybersecurity, since AI systems may be vulnerable to cyber and adversarial attacks, requiring robust AI models and secure communication protocols and encryption techniques to protect algorithms and data integrity.

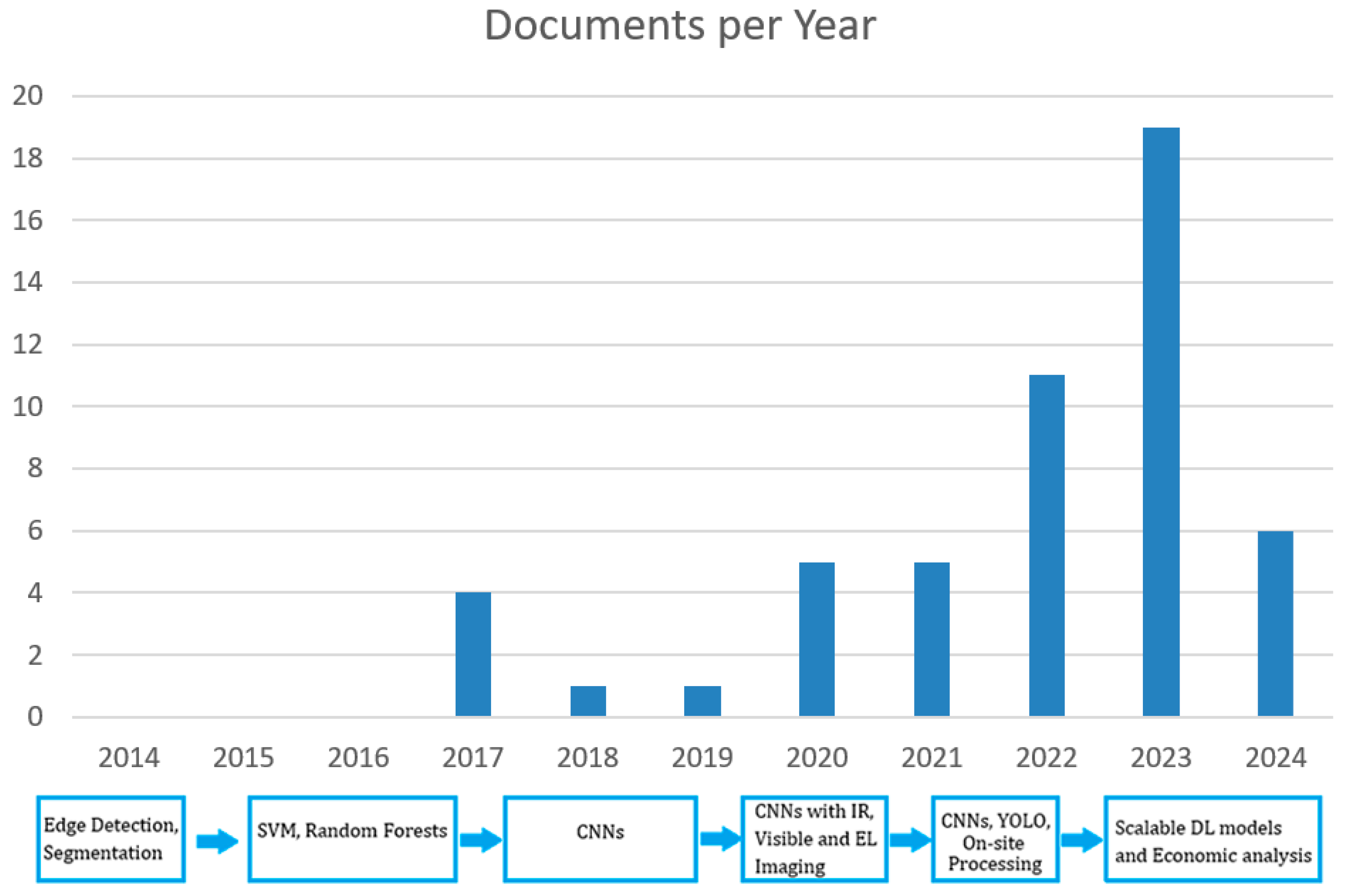

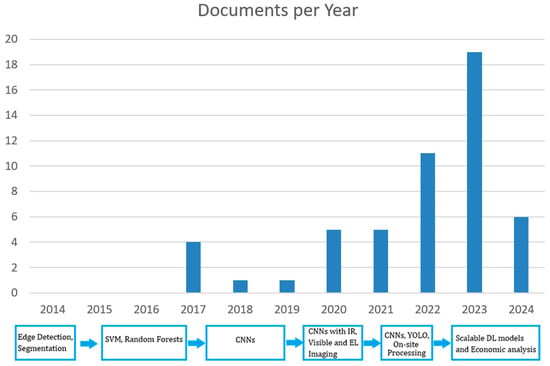

Subsequently, by analyzing the content of the studied papers, and by using the functionalities of Scopus, Figure 3 was derived. Figure 3 depicts the key developments and research efforts, in terms of published works, over the past decade regarding the use of computer vision algorithms for detecting faults, defects and anomalies in PV systems, along with the key technological developments that marked the decade. The research was conducted within Article title, Abstract and Keywords, by using the query: “computer vision” AND “PV” AND “faults detection” OR “defects” OR “anomalies”. The search returned 52 articles ranging from 2014–2024. It is clear that the introduction of CNNs in PV fault detection in the late 2010s has brought a significant increase in the number of related documents, resulting an upward trend in the following years.

Figure 3.

Evolution of trends and the corresponding number of papers on computer vision algorithms for PV fault detection according to Scopus, on the same reference timeline from 2014 to 2024.

5. Capabilities and Limitations of Basic Detection Technologies

Faults and failures in PV modules can be detected with many methods, including UAV-based or visual inspections, I-V curve and electromagnetic induction measurements, infrared thermography, electroluminescence and photoluminescence imaging, ultraviolet fluorescence methods, and spectroscopy. In what follows, the key fault detection technologies for PV systems are reviewed, reporting their capabilities and limitations. Moreover, extended research in CV based fault detection technologies is conducted (RQ2).

5.1. Key Fault Detection Technologies for PV Systems

5.1.1. UAV-Based Inspection

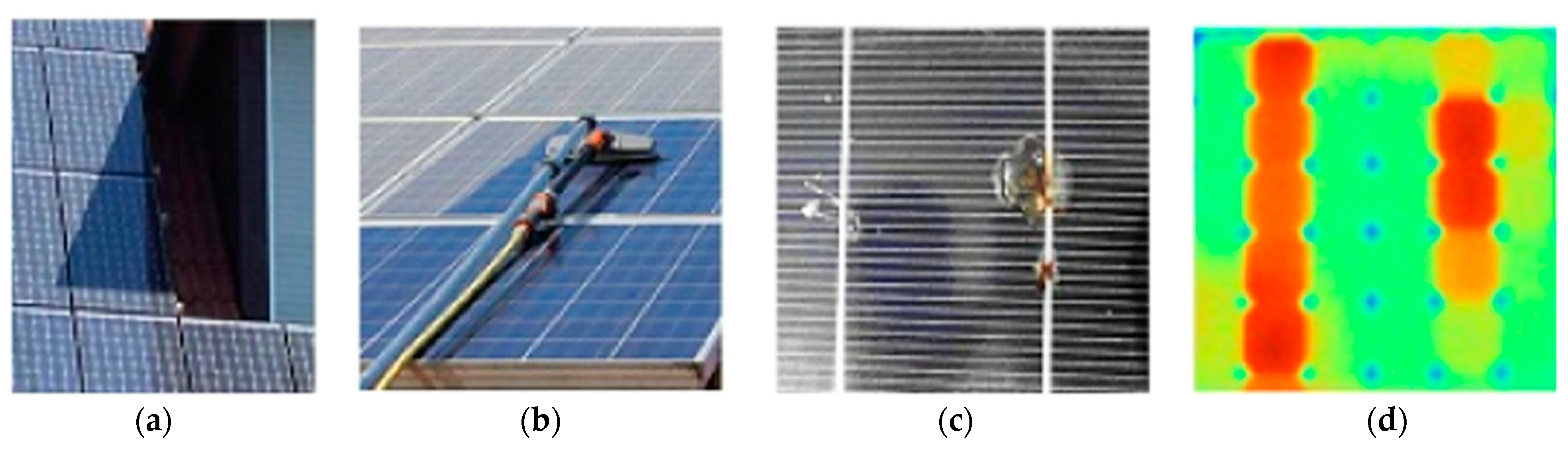

The effectiveness of basic detection technologies has been tested in several preliminary laboratory experiments. These promising results have encouraged researchers to explore using these inspection techniques for large photovoltaic installations. The solution identified by field experts, which has become a standard in recent years, involves using specialized unmanned aerial vehicles (UAVs), such as drones, equipped with cameras for fault detection [18]. This method has two main advantages: (1) it is suitable for inspecting large photovoltaic fields as the entire installation can be surveyed in a few flights (depending on the size of the installation and the UAV’s battery life), and (2) it significantly reduces the cost and time required for analysis compared to traditional inspection techniques. The suitability of this solution has been evaluated through qualitative analysis in real photovoltaic fields to verify which anomalies are visible with moving cameras and to determine the impact of flight parameters on detection capabilities, thus testing the reliability of specialized UAVs [19,20,21,22,23,24].

Specifically, two types of architectures for anomaly detection can be identified: (1) real-time image analysis of photovoltaic modules during the UAV flight, and (2) offline image analysis, examining the video recorded during the inspection. Naturally, the first solution is faster and allows the operator to verify in real-time whether the photovoltaic modules have been inspected correctly; yet it requires careful software design to accelerate the image processing algorithm. Moreover, for real-time inspection, UAVs need to operate at certain heights and at specific time in the day so as to clearly capture details without sun reflections and facilitate processing. Moreover, note that UAVs can detect only visible external defects, while internal defects are not considered, e.g., non-functional diodes.

UAVs typically carry thermal cameras, visible light RGB cameras and photoluminescence cameras. Thermal cameras are used for thermographic analysis, while visible light cameras can store color images related to potential anomalies identified by the image processing algorithm. The idea is that images of defective photovoltaic modules, accompanied by geographical coordinates measured by the GPS sensor, can serve as a powerful and effective tool for automatic photovoltaic inspection [20]. However, the current accuracy of GPS sensors is in the order of several meters, whereas the required accuracy for the geographical placement of photovoltaic panels should be within a few centimeters. Therefore, with the current state of technology, computer vision algorithms cannot utilize the geographical coordinates calculated by GPS sensors to recognize and identify each photovoltaic panel but must provide a mechanism for tracking each unit and detecting potential anomalies in the image. The latter is a challenge being addressed by several techniques, as reviewed in the following.

5.1.2. Visual Inspection

Visual inspection refers to the process of examining the PV panels visually to identify signs of damage, wear, or malfunction and it is considered the fastest and most efficient way especially when conducted by experts. However, it is not suitable for modules exposed to weather conditions and it must be conducted before and after the exposure of modules to stress, either electrical, mechanical, or environmental. Common stress testing methods to evaluate modules indoor include moisture cooling or thermal cycles, liquid heat testing, ultraviolet (UV) radiation testing, mechanical loads, application of thermal stress, etc. [25]. International Electrotechnical Commission (IEC) standards 61646 [26] and 61215 [27] require illumination of more than 1000 lux to conduct visual tests towards for considering defects visible to the naked eye. Such defects include: delamination, yellowing, and blistering on the front of the module; cracks, broken parts, and discoloration of the reflective coating on the cells; burning and oxidation of metallization; bending, breaking, scratches, and poor alignment of the module frame; delamination, yellowing, scratches, burning, and more, as referenced in [4,28].

Specifically, visible defects such as yellowing of the encapsulant have been identified as major causes of power loss [29,30]. In order to identify defects visually and assess their impact, the modules are compared with a reference similar and intact module [29]. Such approaches can be found in the literature; Bouaichi et al. in their study [29] identified discoloration on panels exposed to hot climate for a period of two years, associated to power loss of modules. The same conclusion was made by Kahoul et al. [30] who also associated power loss to modules being exposed to severe environmental conditions for more than a decade, same as in [31]. In addition to power loss, several defects have been detected in all cases, such as cell cracking, corrosion, glass breakage, discoloration and more kinds of visible degradations. It should be noted that discoloration is commonly observed to panels that operate in extreme hot conditions, such as in deserts [32].

5.1.3. I-V Curve Measurements

The current-voltage (I-V) curve measurement for PC fault detection involves the analysis of I-V characteristics of a panel towards identifying potential faults or abnormalities [33], and it is considered as the most comprehensive among all detection method [34].

Measurements can be conducted in either indoor or outdoor conditions, under artificial lighting sources or the sunlight, respectively. In both cases, measurements are first converted to standard test conditions (STC) towards being compared with the reference measurements set by the manufacturers. From the conducted comparison between the I-V reference and measured curves, any observed variations are associated to modules’ degradation. If the variations between the I-V curves are small, referring to minor failures on the panels, these may fail to be identified [35]. Moreover, it should be noted that the study of the I-V curve characteristics does not provide any information of the exact defects’ location [36]. An alternative measurement to identify faults involves electromagnetic methods [37]. Electromagnetic methods use electromagnetic waves to detect faults in PV modules through the analysis of their electrical or magnetic properties, such as electrical conductivity, electromagnetic inference (EMI), frequency responses, partial discharges, induced currents, and more. Regarding the electrical properties of PV modules, DC testings analyze and evaluate electrical parameters, such as insulation resistance, continuity and electrical output, directly related to the PV modules’ performance, [38] while in AC testing, alternating current is used to test systems that operate on AC, focusing more on parameters related to AC power quality and performance [39].

Other methods to identify electrical and morphological failures in PV modules include electron beam-induced current (EBIC) and scanning acoustic microscopy (SAM) [40,41,42]. EBIC is performed by using a scanning electron microscope, which scans the solar cells with an electron beam aiming to generate electron-hole pairs towards measuring current properties [43]. SAM methods use sound waves to map the internal structure of the materials of panels, revealing cracks, voids and delamination; thus, it is more appropriate to detect morphological failures. The combination of both methods can provide a more comprehensive understanding of both electrical and structural integrity of PV modules, allowing for more accurate fault detection assessments [44,45].

One more method that belongs in this category is the differential current analysis, which involves the comparison of the current flow entering and leaving different sections of the modules [25], by using current sensors placed in the PV system. Thus, the difference between measured input and output currents at different points is calculated, indicating potential defects if significant differences in the currents are measured. A major advantage of this method is that it can indicate the exact location of the fault, which makes it useful to accurately detect and locate faults for timely maintenance of modules.

5.1.4. Infrared Thermography

Infrared thermography (IR) involves measuring the surface heat of PV modules. By capturing and analyzing the temperature patterns emitted by the components of the system, possible defects can be detected. Studies have shown that there’s a correlation between cell power output and temperature variations in IR images [46].

In such cases, IR cameras are used, that can detect infrared variation, referring to the heat emitted by the system. All components of the PV system may emit heat, in varying levels, which may alter in case of defects. Therefore, the IR camera can capture the temperature variations across the entire system, indicating anomalies such as hot spots. Note that hot spots are known to reduce the overall efficiency of PV modules, therefore early detection can prevent significant damages and deterioration of its efficiency [47].

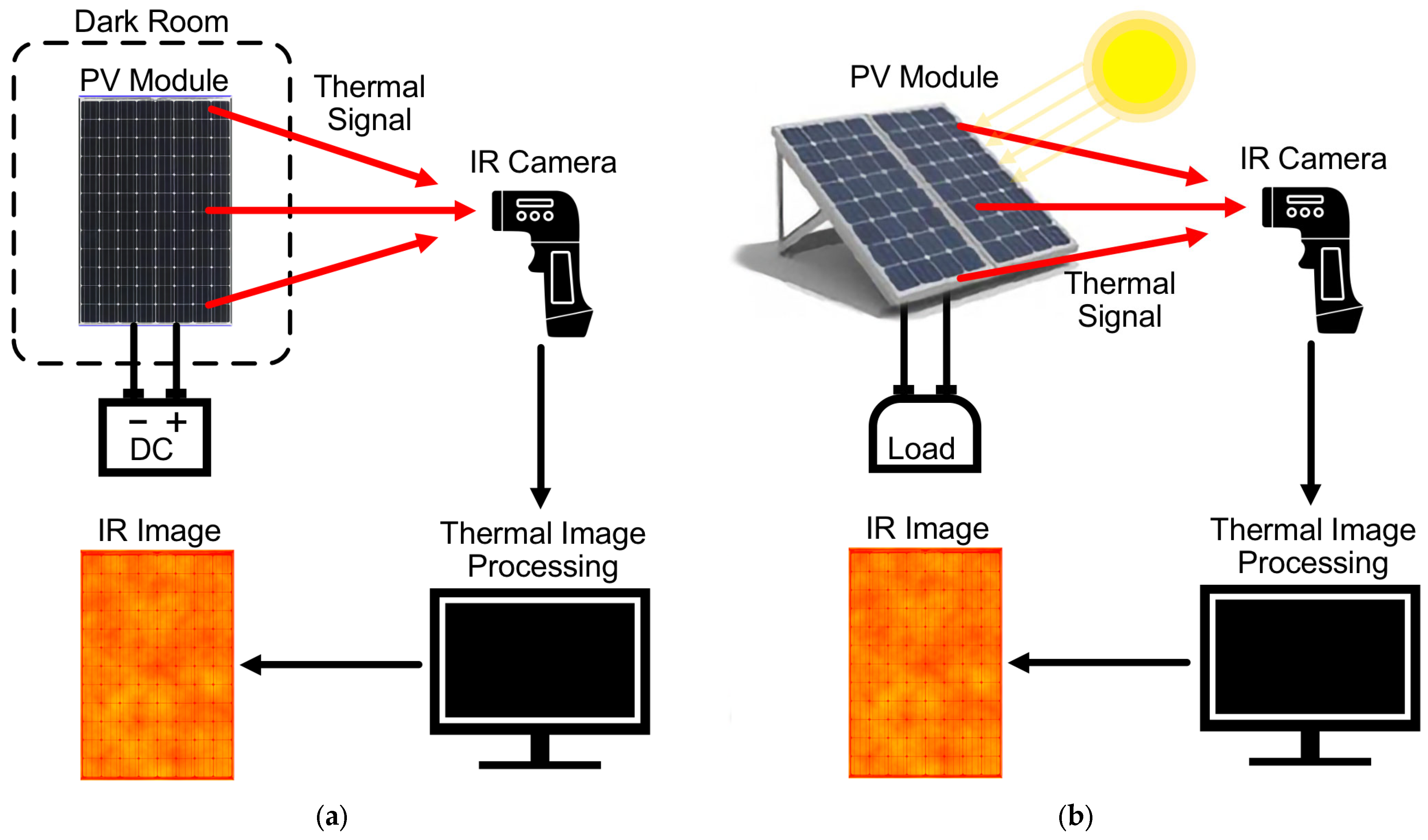

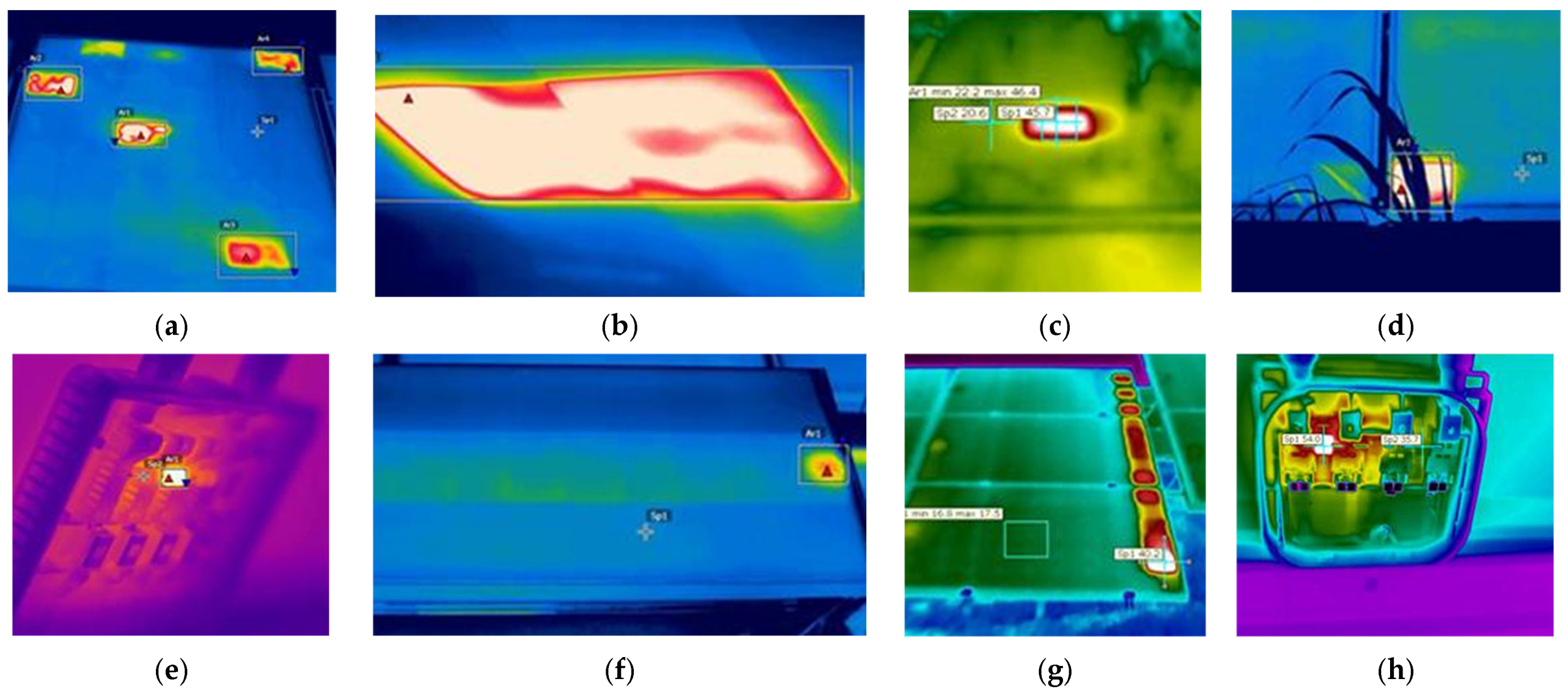

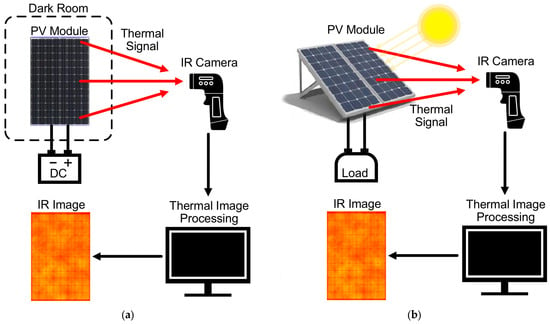

Based on the source of thermal excitation, thermographic measurements can be: (1) Passive or under steady conditions, when the module is scanned during its operation in outdoor environments and is not heated by external sources [48] (Figure 4a); it can also be performed in doors by detaching the module and take in-lab measurements [47] (Figure 4b). Setups for indoor and outdoor thermography can also be found in [49]. (2) Active or lock-in thermography when the module is heated periodically by an external source. This technique has less thermal impact on cells and can be performed in dark or illuminated conditions [50,51,52,53,54,55]; (3) Flash or pulse thermography when flashes of light are used to heat the surface of PV modules. The surface temperature rises uniformly, and a high-resolution thermal camera captures images to detect defects like bubbles and electrical connection anomalies. Various defects visible in IR images are provided in Figure 5 [56].

Figure 4.

(a) Indoor and (b) outdoor thermography setups [49].

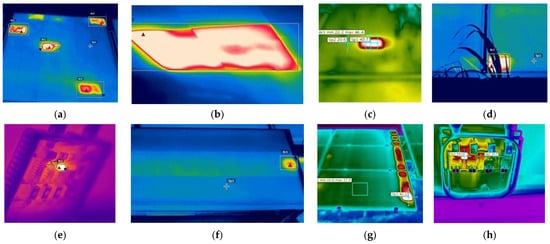

Figure 5.

Defects in IR Imaging: (a) breakage of front glass; (b) overheated cell due to internal cell problems; (c) hot spot; (d) overheating due to external shading; (e) open junction box and overheated diode; (f) overheated junction box; (g) overheating due to shading by neighboring PV module row; (h) overheated bypass diode [56]. Colors from green to red indicate cold to heat-up (defected) areas. Images serve as indicative depictions of the specified defects in IR imaging, and the letterings within them are of no significance.

Several aspects need to be considered during IR imaging [57] regarding emissivity setup, shading effect, and more, as well as regarding the setup of thermal camera such as its distance from the PV module since glass reflections can provoke measurement errors. Adjusting the camera angle can help reduce reflection issues [57]. As already mentioned, severe environmental conditions can impact defects. Modules in hot climates with detected hot spots tend to display greater degradation under IR thermography compared to those located in less hot regions [58].

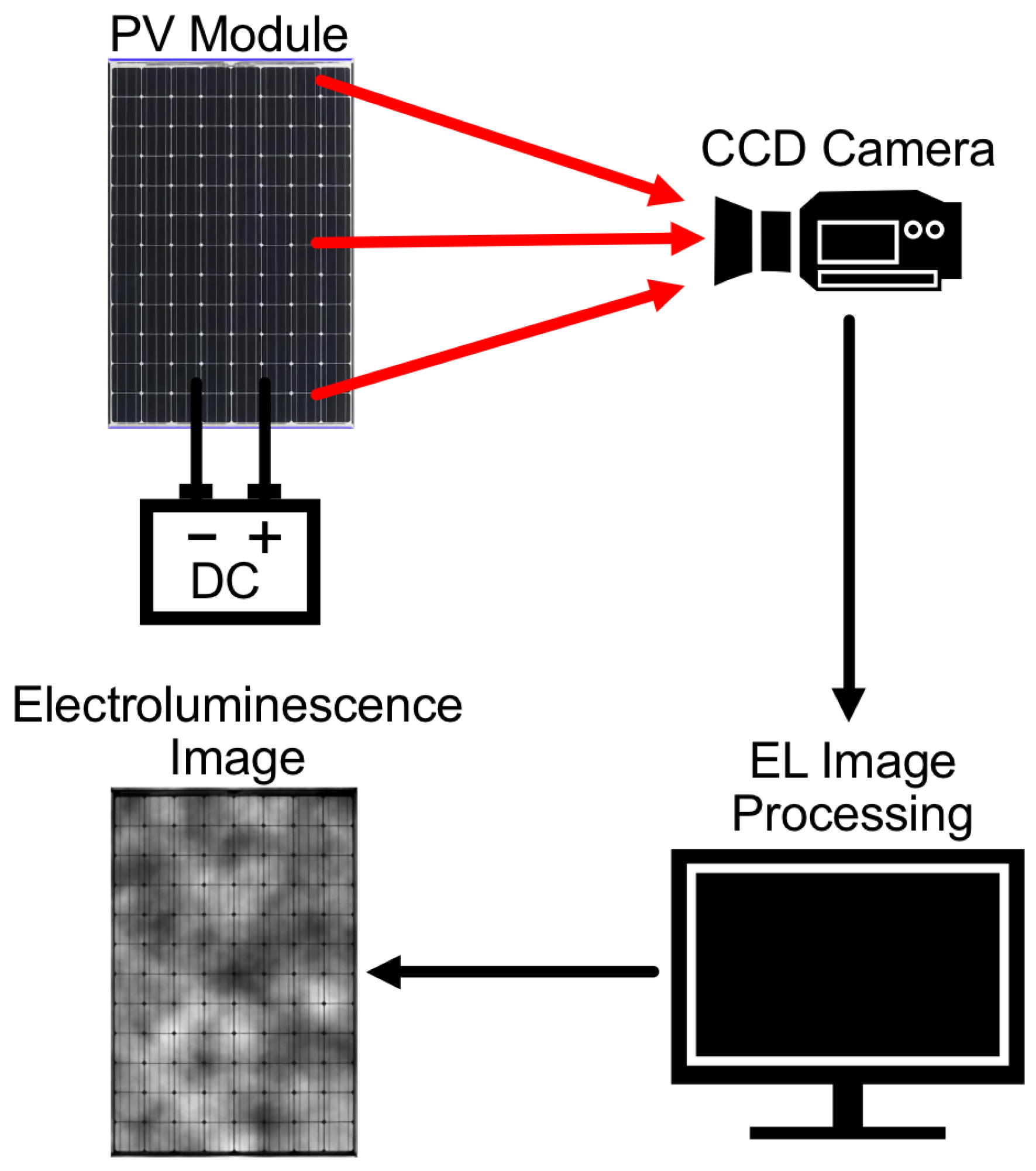

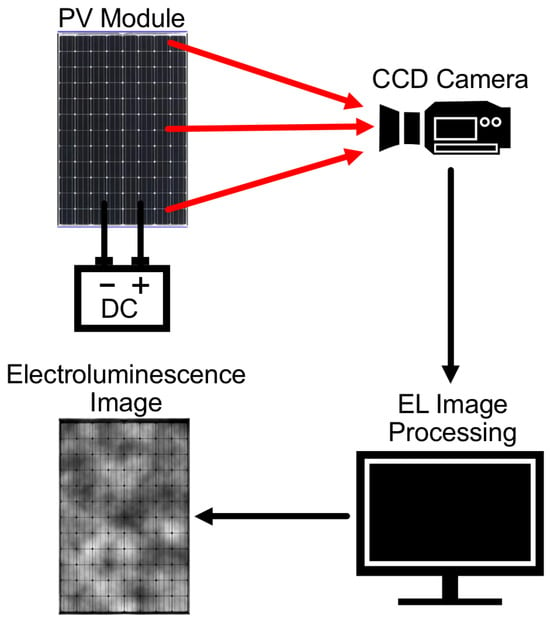

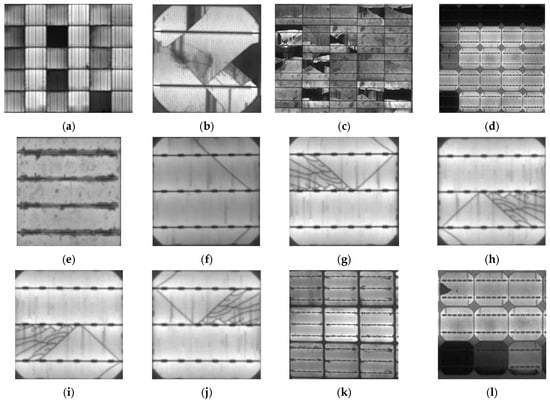

5.1.5. Electroluminescence Imaging

Electroluminescence (EL) imaging involves capturing images of the luminescent effect that is produced when an electric current comparable to the module’s short-circuit current (ISC) passes through the solar cells, causing them to emit EL radiation [59,60]. EL radiation is commonly detected by charge-coupled device (CCD) cameras that are more affordable, by indium gallium arsenide sensors that typically are more expensive, as well as by modified RGB cameras [61]. EL imaging is conducted in dark settings, with defects captured as dark areas/lines on grayscale images, and have been employed in several studies towards defects detection [62]. A reported disadvantage is due to the challenges related to the detection of faults in outdoor EL imaging due to casual dark regions and spots on the images [63] that may obstruct the process. However, it could be advantageous, i.e., quick and accurate, for indoor defects detection. An EL imaging experimental setup is illustrated in Figure 6, while typical defects in EL images can be visualized in Figure 7 [56].

Figure 6.

EL imaging setup [11].

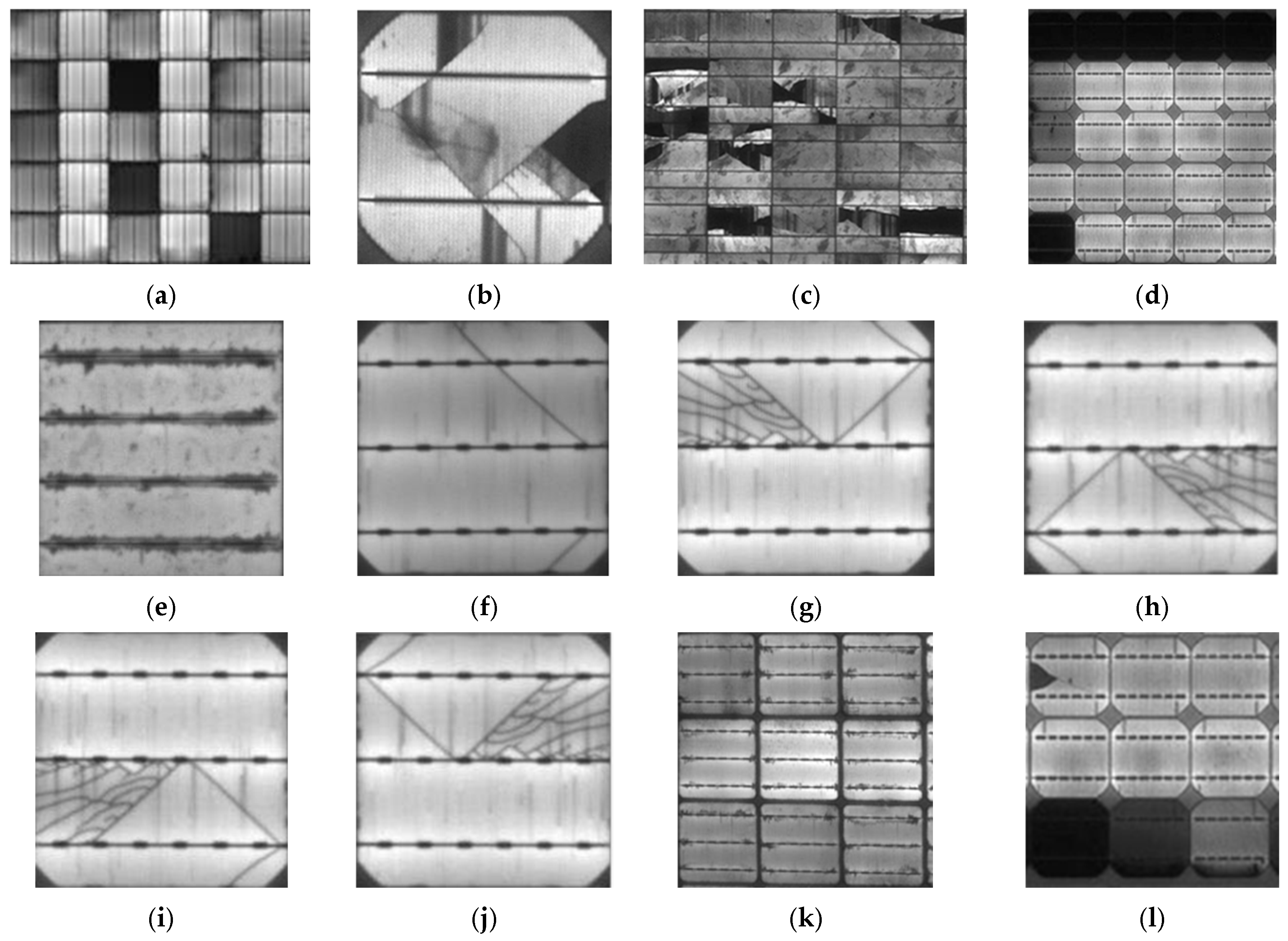

Figure 7.

Different types of defects in EL imaging [56]: (a) PID-s affected module; (b) crack pattern due to impacts; (c) polycrystalline PV module with cracked cells; (d) monocrystalline PV module with potential induced degradation; (e) busbar corrosion in cell; (f) cracked cell; (g) cracked cell of original orientation; (h) cracked cell of different orientation, rotated 180°; (i) cracked cell of different orientation, flipped about x-axis; (j) cracked cell of different orientation, flipped about y-axis; (k) module having undergone damp-heat exposure; (l) monocrystalline PV module with induced degradation.

The average pixel intensity of a cell in an EL image is strongly associated to the module’s maximum power output [62]. The latter helps to determine the degree of the module’s degradation. Moreover, EL emissions’ intensity is correlated to the degree of applied voltage, thus, defective regions can be identified by comparing EL images under different polarizations [64].

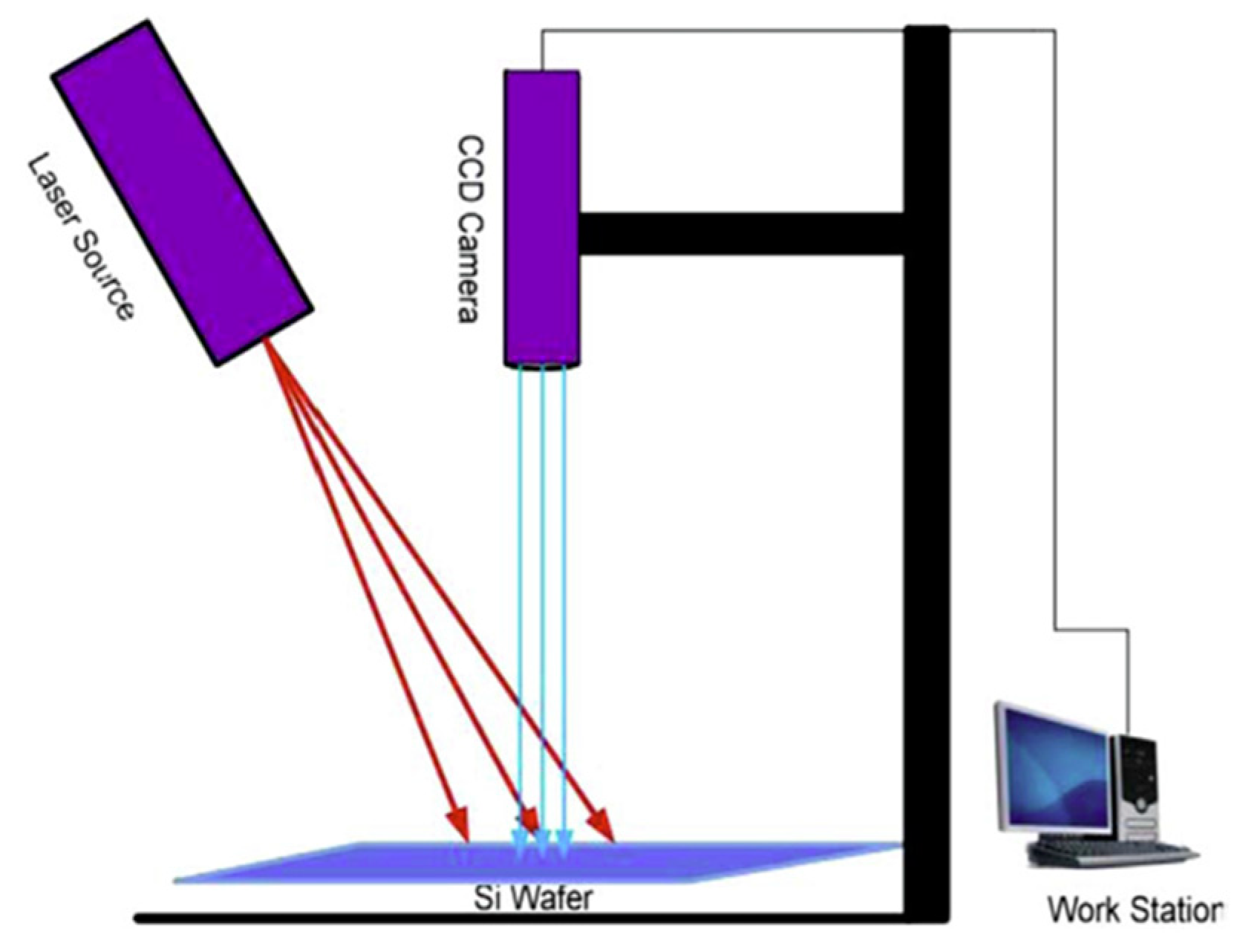

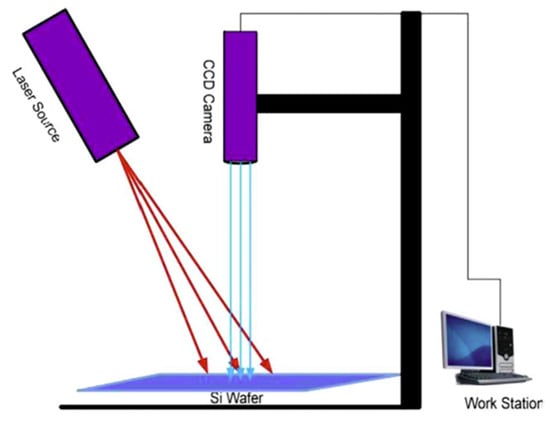

5.1.6. Photoluminescence Imaging

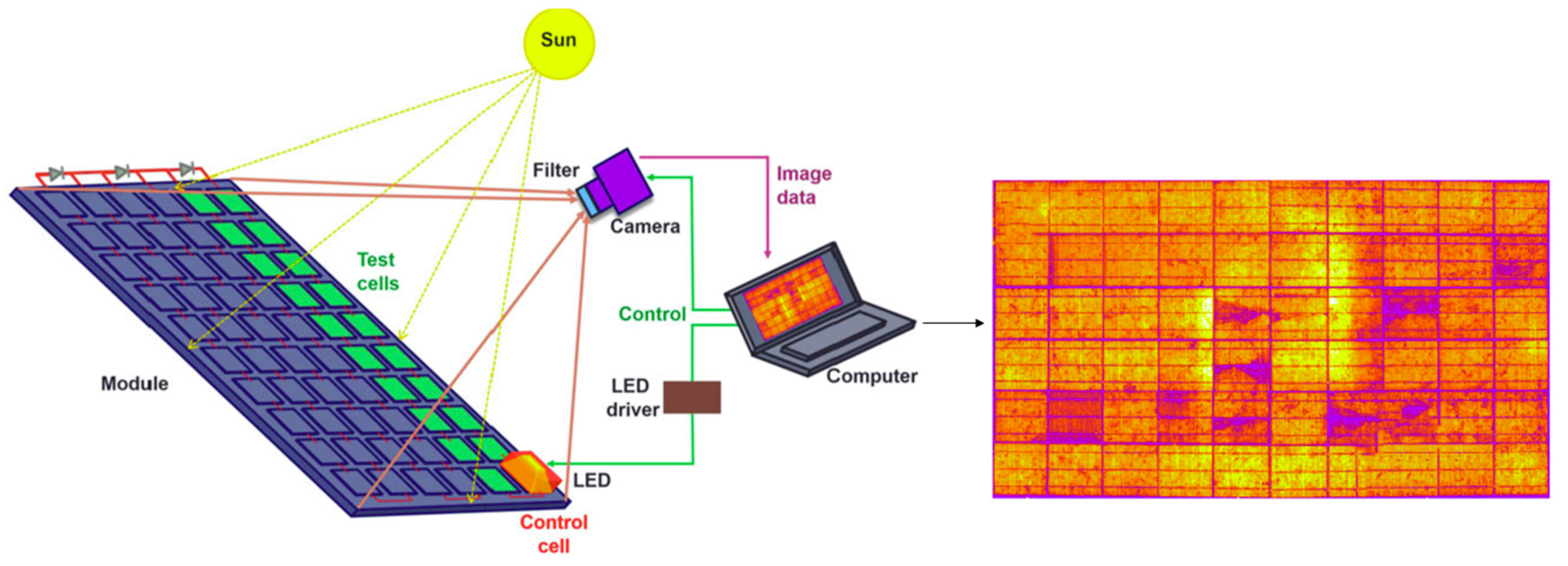

Photoluminescence (PL) imaging is another effective approach for PV modules’ defects detection, by capturing images of the luminescent effect which occurs when the PV materials absorb photons and retransmit them as light. More specifically, the PV absorbs energy that causes electrons to jump to a higher energy level triggering them to emit light when they return to their original state. Specialized camera sensors are able to capture the emitted light, which is analyzed to detect variations of the luminescence across the PV module [65]. A typical PL imaging setup is shown in Figure 8.

Figure 8.

Typical PL imaging setup [65].

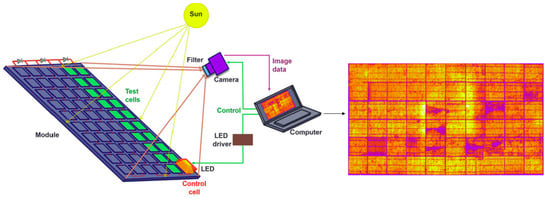

Additionally, PL imaging can be performed by using optical filters and current modulation. Optical filtering is employed to allow the selective passing of specific wavelengths of light, so as to isolate it from environmental noises. Thus, PL images are clearer and thus easier to detect underlying anomalies. Current modulation aims to improve the signal-to-noise ratio, by modulating the luminescence signal to separate it from background noises. The latter process allows for more accurate and high-quality PL imaging towards easily detecting defects in PV systems. The obtained PL images are then compared with the EL images towards identifying cracks, high-disorder areas, and poorly performing cells [66]. This enhanced PL imaging setup, and the resulting image are shown in Figure 9.

Figure 9.

Enhanced PL imaging setup using optical filtering and current modulation [66].

The combination of spectral and spatially resolved PL imaging can be used to obtain a more comprehensive understanding of the condition of materials in a PV system. The type and location of defects can be identified, providing valuable feedback for timely maintenance and quality control of modules [67].

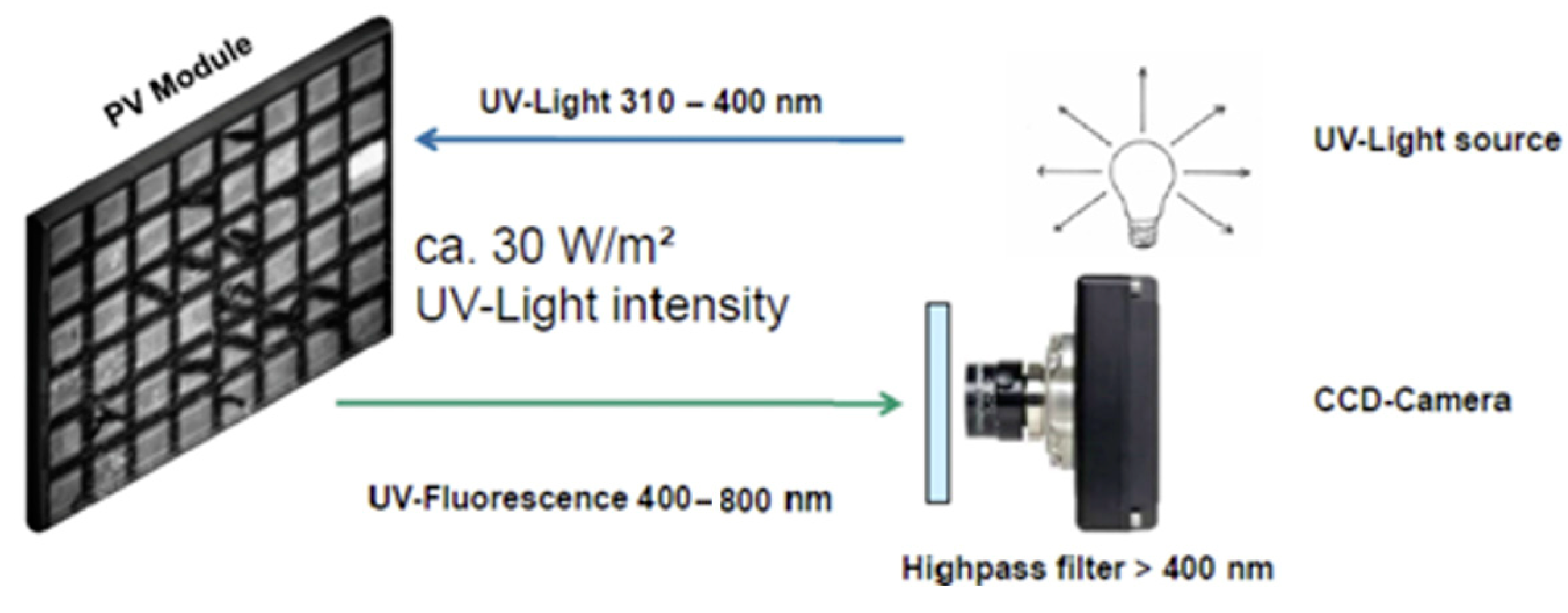

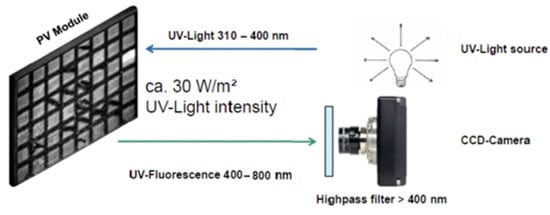

5.1.7. Ultraviolet Fluorescence Method

Ultraviolet fluorescence (UVF) was first exploited to detect discoloration issues such as yellowing effect in PV modules [28]. Later, dark lines in a UVF were associated with cracks in the panel.

UV-based detection is based on fluorescence effect of the material in PV modules namely polymeric lamination. Fluorescence refers to the emitted light by a material like the encapsulant that is active due to absorption of light [68]. A camera with UV-pass filter can capture the fluorescence, which is being interrupted by defects on solar cells. Thus, a variety of fluorescence patterns can be formed, providing information about the type of defect, their age and severity [69,70]. UVF experiments are conducted in darkness to eliminate inferences from ambient light, therefore, to capture a clearer fluorescent image. By exposing the PV module to sunlight prior imaging, helps to charge the materials within the module, resulting to more intense luminescence and high-quality images. Typically a 30-s exposure time is recommended [71]. An experimental UV fluorescence imaging setup is shown in Figure 10, including a PV module, a CCD camera, a highpass filter and a UV light source.

Figure 10.

UV-F imaging setup for cells in outdoor and laboratory conditions [4].

The emitted fluorescent falls within the visible region of the electromagnetic spectrum, thus it can be captured by a digital camera. To ensure accurate imaging, filters are typically employed to block out any remaining UV rays to prevent them from interfering with the captured images. Both UVF and EL imaging provide valuable information about PV modules defects resulting in similar visual representations of the condition of modules, where defective areas are highlighted with darker color [72]. However, UVF imaging uses external UV light while EL imaging applies electric current to the module, to excite its materials. Therefore, UVF can be implemented outdoors during the module’s operation while EL imaging requires controlled environment. Both methods can be used complementary towards providing a more comprehensive analysis of a PV module’s status [70].

5.1.8. Spectroscopy

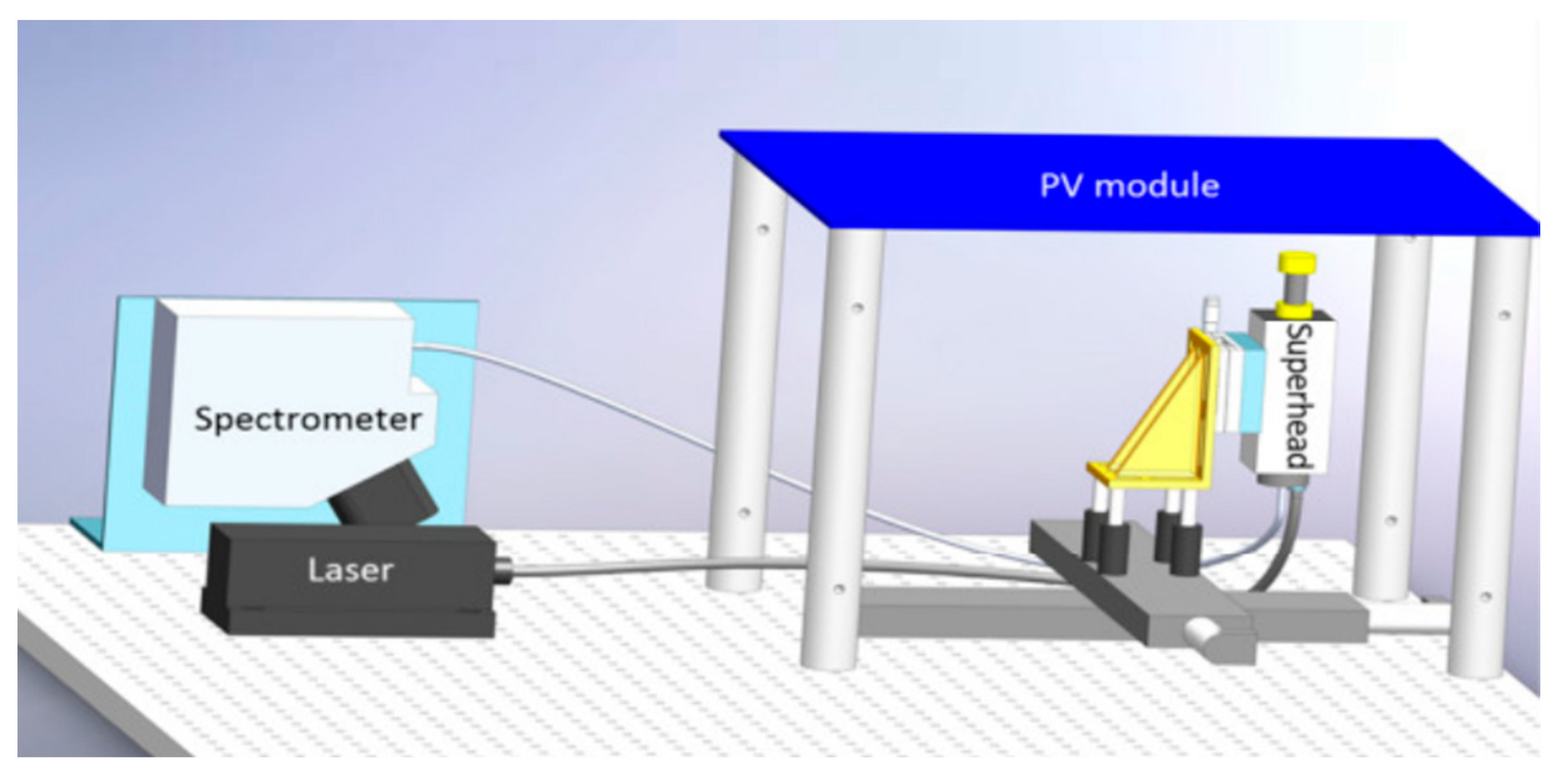

Spectroscopy is a powerful technique that is used to analyze the interaction of matter with electromagnetic radiation. When spectroscopy is applied to PV fault detection, refers to the measurements of the produced spectra by using spectrometers when the PV module is exposed to different light wavelengths. Several types of spectroscopies are available, such as photoluminescence, Raman, electroluminescence, impedance, Fourier transform infrared, and fluorescence spectroscopy.

Raman spectroscopy is capable of identifying stress, stain and several other defects on PV modules by using inelastic scattering of photons that provides information about the molecular and structural composition of materials. When laser light interacts with the molecules in the material’s structure, mainly it scatters elastically, while a small part scatters inelastically, namely the Raman scattering light. The latter results in a shift in the light’s energy which is analogous to the vibrational modes of the molecules, thus, it can characterize the material’s composition. The Raman scattering light is collected and analyzed using a spectrometer. A hyper Raman head measure is employed to measure the spectrometry maps and detect defects PV modules [73]. To map snail trails, point measurements are taken using Raman spectroscopy, and then converted into Raman maps, which visually represent the spatial distribution of different materials and defects across the PV module. At this step, florescence images can also be produced to provide complementary information to Raman maps. To enhance the quality of maps, Gaussian fiters can be employed to smooth the image and reduce noise effects. Such a measurement setup is shown in Figure 11 [73]. Raman spectroscopy also measures thermomechanical stresses in PV modules during manufacturing [74]. A confocal Raman spectrometer is used to measure stress in solar cells, caused by metallization, lamination, etc., during manufacturing, by detecting shifts in the Raman peaks, associated to changes in the vibrational modes of materials [74].

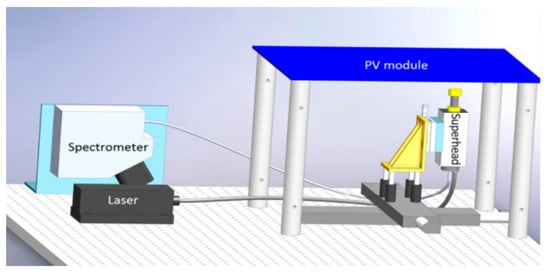

Figure 11.

Measurement setup using a Raman spectrometer and Raman superhead [73].

Fluorescence spectroscopy is used in [71] to study modules exposed to ageing. The module is illuminated by a light source, that excites the electrons in the material of the PV modules, making them move to higher energy states. Returning to their initial state causes them to emit light of different wavelengths, i.e., fluorescence. Fluorescence light is detected and measured using a spectrometer. The properties of the detected light such as the intensity and wavelength can provide insight regarding the properties of the module.

Fourier transform infrared spectroscopy (FTIR) is used to acquire and analyze the molecular structure of PV materials [71]. The interaction between mid-infrared radiation and the material can excite molecular vibrations corresponding to specific absorption wavelengths which appear in the infrared spectra, revealing detailed information about the molecular structure of the material.

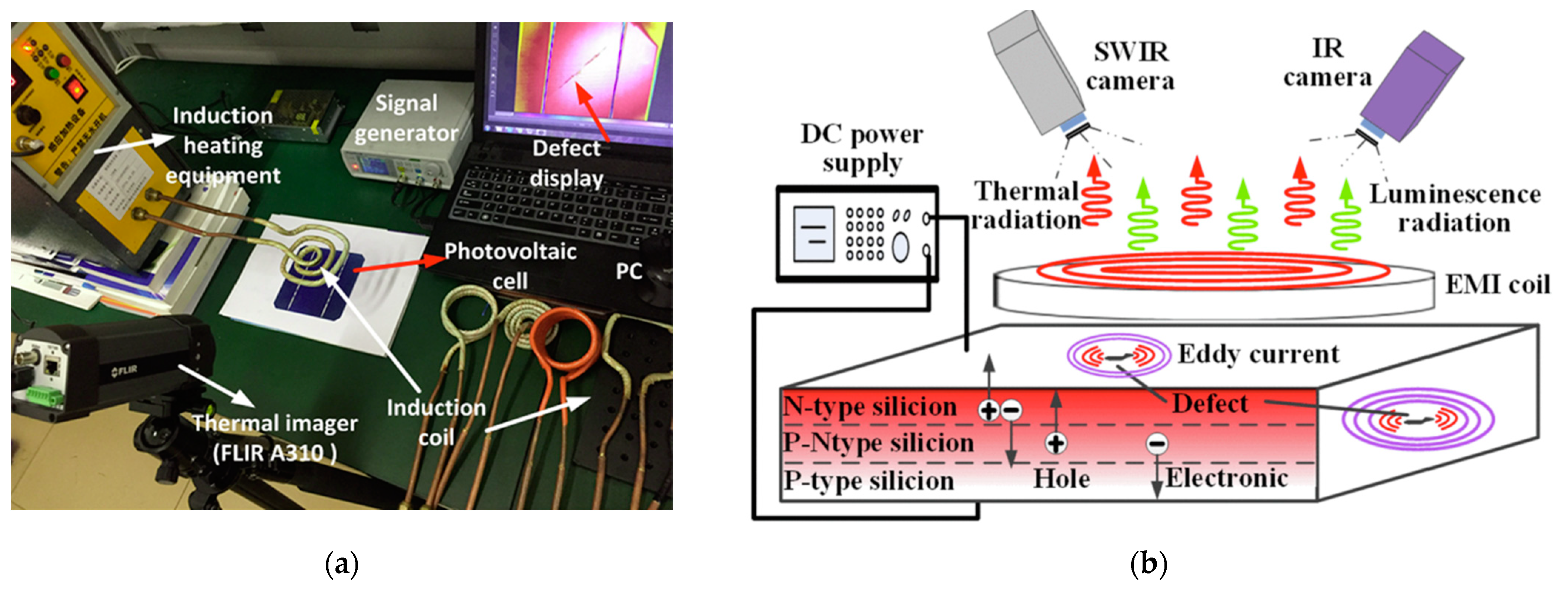

5.1.9. Electromagnetic Induction-Based Measurements

Electromagnetic (EM) radiation induction for PV fault detection uses electromagnetic waves to identify faults in the modules. Usually, it is combined with IR thermography and EL to provide more comprehensive assessments since they provide complementary type of information; EM analyzes changes in the electrical properties of a PV module exposed to electromagnetic waves and can detect electrical faults, thermography measures the thermal profile of modules with an IR camera and can detect thermal anomalies, while EL measures emitted light by the modules when electric current is applied and can detect structural defects.

The combination of IR thermography with EM induction can effectively detect defects in PV modules. An electromagnetic wave is applied to the PV module to heat the electrical resistant materials, inducing currents within the module. The induced currents heat the defected areas that disrupt the flow of current, revealing impurities. An IR camera captures the thermal properties of the module, aiming to indicate faults in the module. Figure 12a illustrates an active electromagnetic induction infrared thermography system for PV cells from the literature [75].

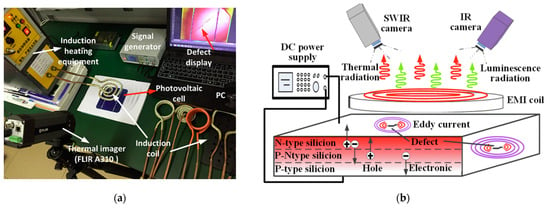

Figure 12.

(a) Experimental setup of an EIIT thermography system for PV cells [75]; (b) thermography and EL imaging setup based on electromagnetic induction [76].

Similarly, the combination of EL imaging with EM induction can provide the accuracy of PV fault detection. First, EM induction is employed, while applied electric current causes electroluminescence captured by an IR camera that provides the EL image with highlighted the defected areas.

In general, the combination of different techniques can provide a more complete picture of the module’s health status. Towards this direction, Yang et al. [76] in their work compare the fusion results of a set of techniques, evaluating PV performance based on well-known metrics. The used EM induction-based thermography and EL imaging setup of Yang et al. is shown in Figure 12b.

5.1.10. Capabilities and Limitations

After reviewing the key detection technologies individually, this section aims to identify their capabilities and limitations by examining fault detection technologies in combination, aiming to answer RQ2. To achieve this, we utilize two comprehensive tables (Table 2 and Table 3) that detail the strengths and limitations of the different basic detection technologies and ultimately how they relate to various faults in photovoltaic systems, based on an extensive literature analysis.

Table 2.

Cumulative table of limitations and capabilities of basic PV fault detection technologies. CV based fault detection technologies are marked in bold.

Table 3.

Comparative table of limitations and capabilities of basic CV-based PV fault detection technologies.

Besides the individual application of each basic detection technology, various studies examine the comparative application of multiple CV-based technologies on PV modules. The findings of these comparative applications are summarized in Table 3.

5.2. Fault Detection Using AI-Based Computer Vision

Computer vision is rapidly gaining traction as a groundbreaking technology aiming to replace conventional monitoring systems in the PV sector, satisfying escalating global energy demands driven by the exponential growth of population. The integration of AI into PV energy systems is becoming a topic of interest, since AI is foreseen to play a pivotal role in addressing future energy requirements.

Computer vision systems in the PV sector comprise high-resolution camera, sophisticated imaging devices, such as RGB, EL, IR cameras or Light Detection and Ranging (LiDARs) devices, drones for aerial inspections, edge computing devices for on-site processing, and corresponding machine/deep learning algorithms to analyze the captured images and identify underlying issues. Thus, computer vision systems aim to make the latter components work together, to endow devices with adequate intelligence, so as to enhance the real-time monitoring, maintenance, and efficiency of PV systems based on image data analysis. The extracted information is then used by control systems for efficient decision making, leading to automated alerts, predictive maintenance and optimization actions, performance reports, and more, to ensure high efficiency and extended lifespan of PV systems. The computer vision-based inspection process is implemented similarly as experienced human workers perform visual inspections, yet they enhance the process with their energy and labor savings, risk reduction, speed, accuracy, and advanced analytical capabilities.

Essentially, the monitoring and fault detection in PV systems are automated through machine learning and deep learning algorithms and image processing techniques, as extensively acknowledged in the literature. Deep learning, in particular, has demonstrated exceptional performance in this domain. For instance, automated image classification and detection systems can replace EL image analysis of PV cells or modules, while automatic edge detection in IR imaging, defects detection and localization in RGB imaging, quality assessment of silicon wafer in PL images, and cracks segmentation tasks in EL imaging are also notable examples.

In these examples, computers or machines exhibit human intelligence, referred to as automated or AI-based methods, regardless the used data [87], and are utilized for several tasks, including predictions, modeling, and predictive maintenance analyses [88,89,90]. Specific types of algorithms are selected depending on the task; SVMs, ANNs, CNNs, etc., for both classification and regression. Regarding the most commonly used image processing techniques, Canny edge detection, color quantification, filtering, morphological operations, and data augmentation are reported. Moreover, in classification tasks, a preprocessing step includes usually features extraction and features selection methodologies. At present, AI-based methods are minimally utilized in PV monitoring. Yet, rising energy demands and the ongoing establishment of large PV farms, foretell the indispensable adoption of automated methods.

5.2.1. Machine Learning and Other Pattern Recognition Methods

Automatic classification of PV images as either normal or defective, is implemented by using machine learning algorithms. Demant et al. [91] classified cracked and normal photoluminescence images using the SVM algorithm. In [92], crack patterns were defined using the gradient location and orientation histogram (GLOH). A limitation of the method is that it is sensitive to region errors, which can be corrected, but will result in a very time-consuming algorithm implementation.

In order to classify a module as defective or not, image feature extraction methods can be employed, along with a classifier to assess the panels’ status. In [93], Kato extracted features, using HOG [94] and SURF [95] algorithms, from PV image sequences resulting from a captured video, and employed an SVM classifier to assess faults resulted by the collision of PV cells with metal conductors in varying forces.

Pattern recognition methods can also be used. Demant et al. [96] in their work used an SVM classifier with radial basis function kernel to automatically detect cracks in photoluminescence and IR images, by utilizing pattern recognition methods based on the extraction of local descriptors.

Other approaches, such as the one presented in [63], use Fourier image reconstruction techniques towards detecting defects on PV panels. In the latter approach, faults were visible in images like bar or line-shaped objects, and the authors concluded in an effective approach, yet with some limitations; faults with more complex shapes could not be detected, and the implementation was relatively slow, reporting inference of 0.29 s for testing one cell.

Pre-processing tasks are also reported in the literature, such as filtering, towards extracting crack saliency maps [97]. In [97], crack saliency maps were created by employing evidence filtering in EL images. The map was then processed with a local threshold process to detect cracks based on segmentation. Then, the minimum spanning tree connected crack fragments, and finally, cracks were detected by skeleton extraction. A drawback of the method was that the segmented crack may miss a part when morphological operations were applied to remove non-crack pixels, affecting the performance of the detection algorithm especially when curvilinear crystal grains were in the background.

Another reported technique included independent component analysis (ICA) [98]. ICA reconstruction procedure was initiated by selecting a normal image for training after being preprocessed to be centered and whitened. Then the ICA algorithm was used to compute the independent components, that were sorted in downward order and rearranged so as to select a number of them, and the unmixing matrix, that was reshaped. Thus, the image was reconstructed and binarized. As a reported disadvantage of this method, was the fact that finger interruptions in cells were handled identically to small and deep cracks.

In general, the limitations of machine learning algorithms, as already mentioned in Section 4, are due to the need for representative features for each fault type. The latter process can be time-consuming and could prove insufficient to capture the characteristics of each fault. Traditional machine learning methods fail to generalize well in case of new unseen data, which is a limitation in case of PV faults, where input images can be under various and different environmental conditions. Moreover, large datasets and high-resolution images are hard to feasibly handle and process in real-time.

Referenced methods of this section are further comparatively evaluated in Section 7, based on preset performance criteria.

5.2.2. Image Processing Techniques

Several image processing methods are also utilized for PV defects detection, based on the literature [99]. Alsafasfeh et al. [100] captured IR images of a PV farm using a drone. The captured images were subjected to grayscale conversion and segmentation, and morphological operations were applied, along with Canny edge detection. A reported disadvantage of the proposed approach was the appearance of shadowing in images, seriously obstructing hot spots detection.

Li et al. [101], aiming to detect visible faults like snake trails and dust, implemented other image processing techniques to the captured RGB images of PV systems from a drone. Image conversion to single-channel model (red, green, blue) was first implemented to make the processing more efficient and reduce complex computations, followed by image filtering by using the first derivative of the Gaussian function (FODG) towards noise reduction. Finally, to determine the faults, an edge detection algorithm was used. A disadvantage of this approach was the limitation of the drone’s flight height, restricted sun-angles and flights conducted only in ideal weather conditions, so as to provide efficient results.

Canny edge detection method was used as a preprocessing step for segmentation tasks towards the identification of hot spots in IR images [102,103]. Both works reported as limitation the fact that Canny edge, in case of any specular object present in the background, caused grey-level variations that were false assumed as hot spots. Segmentation is also used to detect defects in infrared module images [104], yet was not efficiently performing in case of whole modules with several defects. Dotenco et al. [105] employed statistical methods and other image processing methodologies to evaluate PV faults from UAV IR images. In [106], the authors used a combination of segmentation and morphological methods to detect hot spots in PV panels. However, the proposed method could not detect other types of faults.

Segmentation was also combined with filtering operations for PV fault detection [99,107]. In [47], preprocessing included filtering, color quantization, and Canny edge detection towards faults detection of different severities (normal, slight defected, severe defected) in IR images.

Finally, the vesselness-based algorithm for segmentation can also be used for the automatic fault detection scheme. This method was used in [108] for EL images. It has some limitations, such as only considering cracks longer than 20 mm, and disregarding other defect types and cracks shorter than 20 mm.

Same as in traditional machine learning algorithms for PV fault detection, the limitations of image processing methods, as already mentioned in Section 4, are due to the need for exhausting manual feature extraction. Such methods are sensitive to noise and environmental variations, leading to poor adaptability, requiring fine-tuning for each specific case, and subsequently resulting in poor detection performances. Scalability for covering large PV farms, and complexity of large datasets, are also evident.

Referenced methods of this section are further comparatively evaluated in Section 7, based on preset performance criteria.

5.2.3. Deep Learning Methods

Deep learning methods are also used for PV defects detection, as reported in the literature [109,110,111,112]. For example, Demant et al. [113] engaged a CNNs in the production of solar cells, to perform quality control and monitor the process. Their method, however, was constrained by the used low-resolution camera.

Mehta and Azad, in [114], used a Mask FCNN model to predict defects and localize them in PV modules, also aiming to predict power losses. All methodologies mentioned refer to the detection of visible faults. Yet, there are also works that use deep learning methods to both EL and IR images. In [114], the authors utilize EL images, features extraction methods including KAZE, SIFT, HOG, and SURF, and an SVM model.

It should be noted that optimal performances were reported by utilizing CNNs and transfer learning. In both works [115,116], the researchers proposed CNN architectures, and an open EL image dataset of PV cells, and applied transfer learning utilizing the VGG model. Evaluation results indicated deterioration in the detection performance due to labelling errors, particularly at the edges of cracks.

Akram et al. [11] used a lightweight CNN model and generalization approaches to detect faults in EL images of various defects. Data augmentation was employed to balance the dataset and deal with limited original image data. The authors reported efficient performance by utilizing simple hardware; however, all results were from in-lab testing.

In another work, the same authors Akram et al. [49], employ standalone deep learning and transfer learning, to detect faults in IR imaging. Regarding standalone learning, the authors utilized a lightweight CNN trained from scratch. Regarding transfer learning, the authors utilized a base pre-trained model on another EL image dataset. The second approach with transfer learning returned better performance results, while classification errors were mainly noticed for defects with small number of images in the dataset.

Greco et al. [117] employed a YOLO model to detect hot spots in IR images. The proposed method conducted features fusion using bypass connections, and image segmentation for hot spots detection. Results implied a robust method with high efficiency, that could run in real-time without vast resources.

In [118,119], the authors use VGG and MobileNet models towards faults detection and classification from IR imaging. The captured images were subjected to feature extraction, by using SIFT and dense SIFT algorithm, and were classified with an SVM model as normal and defective. Both polynomial and radial basis function kernels were tested for the SVM, with the first one reporting optimal performance. Reported disadvantages include model complexities, and computational burden, that need to be further considered.

Wei et al. [12] employed a Faster R-CNN towards detecting hot spots in thermal IR images. For the latter implementation, the weights of the pre-trained model were adjusted based on the used dataset. Moreover, preprocessing steps included Hough line transform and Canny edge detection. The used deep model reported efficient results, yet with high computational demands, posing a challenge for UAV-based implementations considering their limited capabilities in memory and GPU for processing. Transfer learning was also used by Buratti et al. [120]. The authors conducted features extraction from EL images and classification of faults, reaching 96% of accuracy. The used dataset comprised monocrystalline silicon cell EL images (busbar-free, with 3 busbars, and with 5 busbars), and their matching I-V parameters.

These methods and applications highlight the potential of deep learning in detecting and classifying defects in PV systems, emphasizing their effectiveness and significance in the field.

In general, the limitations of deep learning algorithms, as already mentioned in Section 4, are due to the need for large amounts of labeled and diverse input data. Data acquisition and annotation could be exhausting. Moreover, deep models require powerful GPUs especially for real-time applications. Explainability of deep models is an additional challenge, closely related to the trust on their outputs, especially for stakeholders who want to invest in this technology.

Referenced methods of this section are further comparatively evaluated in Section 7, based on preset performance criteria.

6. CV Detectable Faults and Related Performance of PV Systems

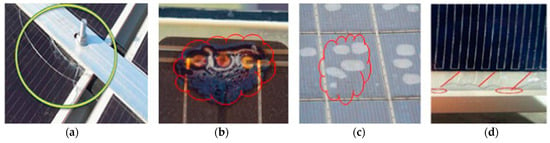

Photovoltaic modules (PVMs) can experience various types of failures, often covered by the system’s warranty if they happen under normal operating conditions [93]. When these systems fail, it can lead to safety risks, reduced efficiency, decreased power availability and compromised system reliability. Common issues found in PVMs include discoloration, cracks, snail trails, damage to the reflective coating, bubbles, pollution, oxidation of distribution bars, corrosion and breakdown of encapsulation on cells and interconnections. Additionally, problems like loss of adhesion of the back sheet are also noted [28,121,122,123,124,125,126,127,128].

There are various strategies to detect these failures, focusing on issues like encapsulation, unit corrosion, cell cracks and problems with the photovoltaic inverter [128]. Failures in PVMs are generally categorized into two types: permanent and temporary. Permanent issues include delamination, bubbles, yellowing, scratches and burned cells, typically requiring the replacement of the defective modules. Temporary problems, like partial shading, dust accumulation, dirt and snow on the PVM, can usually be resolved by the users without needing to replace the modules. Failures can arise from both external and internal causes, both of which can decrease the system’s output power, efficiency and reliability.

The main types of failures that can occur in a PVM are summarized in Table 4. Moreover, their effects on the systems’ performance are also included in the table, along with the affected elements and the causes, based on the examined literature (RQ3). More details regarding failures and their relation to performance can be found in the following subsections.

Table 4.

Summary of fault types, effected elements, causes and effects on system performance.

6.1. Hot Spot Faults

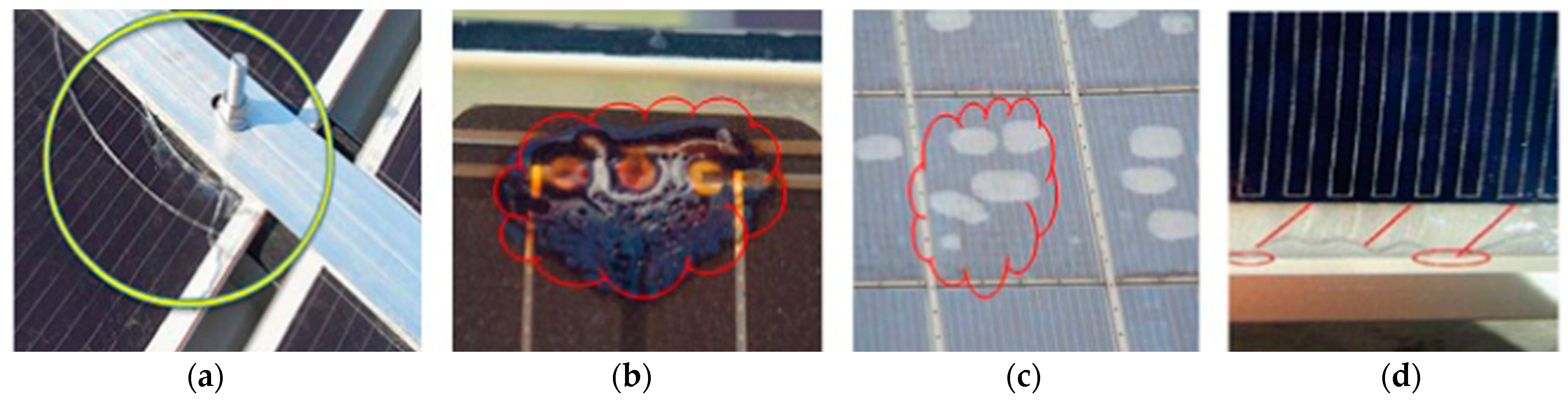

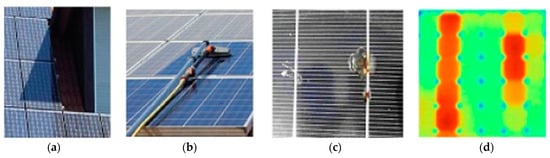

Hot spot (HS) faults can happen when some cells in a photovoltaic (PV) panel have differing current–voltage (I–V) characteristics [125]. This typically occurs due to inconsistencies in manufacturing, which lead to high-resistance points or poor solder joints [125]. Dust and dirt buildup on the panels [129,130,147,148] (Figure 13b), aging of the cells, incomplete insulation at the edges with transparent materials, manufacturing tolerances and uneven sunlight exposure can also contribute to these issues. Partial shading of the panels (Figure 13a) is a common example of such imbalances. HS issues (Figure 13c) arise when the bypass diodes of shaded cells fail or become isolated. This results in a drop in current and a negative voltage, causing the shaded cells to consume energy from the non-shaded cells instead of generating it. If this condition persists, it can damage the affected solar cells [133] (Figure 13d). Detection methods for HS faults are discussed in [36], with many quick detection techniques relying on infrared measurements to identify the problematic areas.

Figure 13.

HS faults: (a) shading; (b) soiling and dust accumulation; (c) HS damaged on solar cells; (d) detected HS phenomena on a PVM using infrared equipment [87].

6.2. Diode Faults

Bypass and blocking diodes are vital components in PV systems, ensuring their efficient and safe operation. Bypass diodes (BpD) help protect the system from reverse voltage while blocking diodes (BkD) prevent reverse current. Common issues with these diodes include short circuits and open circuits, which can occur if a PV string is partially shaded for long periods [134]. The bypass diode is critical for the system’s safe operation [93], but the blocking diode, which is connected in series with the PV module, can sometimes interfere with the proper functioning of Overcurrent Protection Devices (OCPD) [136]. If the reverse current drops below a certain level, known as the Negative Loading Point (LLF), the blocking diode will cut off the current, causing the system to fail. To avoid these types of faults, it is important to carefully choose and thoroughly test both bypass and blocking diodes.

6.3. Junction Box Faults

The junction box (JB) is a critical component for the reliability of photovoltaic (PV) panels during their operation in the field [137]. Corrosion over time can cause the resistance in the JB to increase rapidly [138]. This can lead to electrical arcing between connections, resulting in overheating and melting of the junction box. Such incidents can damage the PV modules and the entire string, leading to significant energy production losses for the system owner. To avoid these issues, several actions and recommendations have been proposed. Regular inspections and maintenance can help detect early signs of wear and corrosion. Ensuring proper installation and using high-quality materials can also reduce the risk of faults. Implementing these strategies can significantly enhance the reliability and lifespan of the junction box, thereby improving the overall performance of the PV system [137].

6.4. PV Module Faults

PV module faults can happen for a variety of reasons, such as corrosion, aging components, internal current leaks, or manufacturing defects. These issues can cause disconnections or internal short circuits within the modules [28,123,124]. When such faults occur, they can pose serious risks like electric shocks or fires. For example, Figure 14 shows various types of defects in PV modules; Figure 14a illustrates a broken glass panel, Figure 14b–d show common problems like oxidation, delamination and bubbles, respectively. These kinds of defects are often seen in PV modules and can affect both the safety and performance of the system. To prevent these issues from escalating, regular inspections and maintenance are crucial. Identifying and addressing these problems early can help maintain the system’s efficiency and longevity.

Figure 14.

Module defects: (a) broken glass; (b) oxidation and discoloration; (c) delamination; (d) bubbles [87].

6.5. Ground Faults

Ground faults in photovoltaic systems (PVSs) happen when there’s an unintended electrical short circuit between the ground and one or more of the system’s energized wires [141]. These faults are a major safety concern because they can create DC electrical arcs at the fault location, which, if left unaddressed, can lead to fires [140]. Detecting ground faults is especially challenging in ungrounded PV systems, as these faults don’t produce enough fault current to be easily detected during normal operations [142]. Ground faults are the most common type of fault in PVSs and can arise from various causes. These include accidental short circuits between wires and the ground, insulation failure of cables and internal ground faults within PV modules (PVMs). A common outcome of ground faults is Potential Induced Degradation (PID), which happens when there’s a significant voltage difference between the cells and the ground. These faults not only pose a fire risk but also affect the overall performance of the system. To mitigate these risks, it’s recommended to use Ground Fault Detectors to monitor insulation in both residential and large-scale PV systems, enhancing safety and reliability [143]. Regular maintenance and timely detection are key to preventing ground faults and ensuring the longevity of PV systems.

6.6. Arc Faults

An arc fault happens when electricity jumps across a gap through the air or another insulating material. These faults come in two main types: (1) Series Arc Faults (AFa), when there is a break or gap in a single electrical wire, and (2) Parallel Arc Faults (AFa), between two wires with potential difference [144]. It is essential for every electrical system to have an Arc Fault Detector to identify these faults.

There are two primary methods for detection [145]:

- DC Method: This method involves monitoring the DC in a wire. By adding a small resistance in series with the circuit, the voltage across the resistor can be measured to detect any anomalies.

- AC Method: this method uses the AC flowing through a wire, with a current transformer acting as a sensor to detect changes caused by an arc fault.

To prevent fires and protect the photovoltaic system (PVS), these detectors need to activate safety circuits when an arc fault is detected. Arc faults pose a significant fire hazard, so detecting and preventing them is critical for the safety and reliability of PV systems. By implementing these detection methods, we can ensure that the system runs safely and efficiently.

6.7. Line-to-Line Faults

Line-to-line faults (LLFs) happen when there is an unintended low-resistance connection between two points with potential different in an electrical system. In PV system, this usually means a short circuit between the cables of different PVMs or arrays with different voltages [146]. These faults in PV arrays can be caused by:

- Cable Insulation Failure: when the insulation around cables deteriorates or fails, it can lead to accidental short circuits between wires.

- Poor Insulation and Mechanical Stress: if the insulation between string connectors is inadequate or if the cables are subjected to mechanical stress, it can result in LLFs.

To prevent these faults, many companies have developed specialized protective devices. These devices detect and mitigate LLFs, ensuring the system remains safe and functional. Along with using these protective devices, regular maintenance and careful installation are key to prevent LLFs and ensure the reliability and safety of photovoltaic systems.

6.8. Relationship of Faults-Performance of PV Systems

The study [149] explores how different environmental factors impact the performance of PV systems. It specifically looks at four factors: (1) dust accumulation, (2) water droplets, (3) bird droppings and (4) partial shading. The key findings from the study are:

- Dust, Shading and Bird Droppings: these factors significantly reduce the current and voltage in PV systems, leading to lower energy production.

- Shading: This has the most significant impact on PV efficiency. When shading covers a quarter, half and three-quarters of the panel surface, the power output drops by 33.7%, 45.1% and 92.6%, respectively.

- Water Droplets: inlike the other factors, water droplets can actually help by cooling the panels, which increases the voltage difference and boosts power output by at least 5.6%.

- Dust: accumulation of dust on panels reduces power output by 8.80% and efficiency by 11.86%.

- Bird Droppings: these decrease system performance by about 7.4%.

These findings emphasize the need for regular cleaning and maintenance of PV panels to ensure they perform at their best. By keeping the panels clean, we can minimize the negative effects of environmental factors and maintain optimal energy production.

In general, environmental factors such as extreme weather conditions, can also severely impact the effectiveness of PV fault detection technologies. Extreme heat can affect thermal cameras to misinterpret overheated areas, while extreme cold may reduce the operational time of drones and cameras by affecting their battery. Rain and humidity can cause obstructions and blur to camera lenses, posing obstacles for accurate faults detection. Strong wind conditions can cause blurry images due to stabilization issues of cameras, while drones could not be able to operate in case of strong winds. Snow and ice may cover the panels, obstructing detection or ever damaging drones and cameras. Finally, direct sunlight may also affect the quality of images due to sun glaring.

7. Evaluation of CV-Based PV Fault Detection Methodologies

Having outlined the fundamental detection and imaging technologies concerning key faults in photovoltaic systems, we now aim to evaluate the effectiveness of the detection methodologies identified in the literature, as imposed by RQ4. For this purpose, a comprehensive table, Table 5, has been structured, linking all the primary automated detection technologies with the use of computational intelligence algorithms, for detecting each specific set of anomalies in PV systems in the literature. The table records the performance of each methodology achieved in each study, in relation to (1) the ability to identify photovoltaic panels and (2), the performance of each methodology in detecting a corresponding set of anomalies.

Table 5.

Evaluation summary of PV fault detection methodologies.

However, since Table 5 is extensive and conclusions cannot easily draw, a color-coded evaluation table (Table 6) was also created. More specifically, the information from the cumulative Table 5 which connects the performance of each identified technique with the corresponding faults, has been coded by using four color levels: red for performances 0–30%, yellow for 30–70%, green for 70–100%, gray when no numerical performance is reported. UAV-based applications were also considered. Next, three evaluation criteria were selected:

Table 6.

Evaluation summary of PV fault detection methodologies (Performance color code: red for performances 0–30%, yellow for 30–70%, green for 70–100%, gray for no numerical performance reported). Shading anomalies are marked in blue font.

- The total number of green indicators, showing the range of faults that the methodology effectively addressed (degree of satisfactory for anomaly coverage).

- Whether it satisfactorily detects shading anomalies (dust, snail trails, bird droppings and snow deposits), which significantly affect cell performance, as already discussed.

- The degree of automation provided by the methodology, consisting of two sub-questions:

- a.

- Does the methodology in this study detected photovoltaic units? (Column: “Panel Detection”)

- b.

- Was the automated image acquisition in this study via UAV technology? (Column: “UAV Inspection”)

By applying these criteria to each row of Table 6, we rank the top five optimal methods from our literature findings in the final column. The latter approach aims to identify and evaluate the best performing approaches of the literature according to preset criteria.

It should be noted that cost-effectiveness and economic viability of each proposed PV fault detection method is crucial, especially towards their large-scale adaption in the solar industry. Yet, the comparison of the various methods could not include such cost information since the latter was not reported within the articles and therefore was not available. Moreover, the cost-effectiveness of camera-based PV panel inspection systems is not easily comparable since the viability of each method depends on several factors, such as the type of the used cameras, and the size of the solar installation that will be applied to. Low cost RGB cameras can be used, however hotspots and other defects can be better detected by thermal cameras which are most cost effective. For cameras mounted on drones, high resolution is essential, which are more pricey. Combined systems integrating both thermal and high-resolution cameras are more advanced and expensive options that may offer enhanced detection capabilities. Yet costs are closely related to the size of the solar installation. Ground based inspection systems can be more affordable, yet they are not feasible solutions for large scale PV farms. Drone-based systems on the contrary, can be affordable for large scale PV installations regardless costly mounted high-resolution cameras and thermal imaging equipment, while the latter would not be economically beneficial to use it in small PV installations. Therefore, in order to compare and choose the most cost-effective method, all the above aspects should be carefully considered according to each application case.

8. Discussion

In this holistic literature review, we analyzed existing methodologies for fault detection in photovoltaic systems using computer vision, machine learning and deep learning techniques. The main observations and conclusions of the study are summarized as follows:

- Evolution of Detection Technologies: The advancement of computer vision algorithms in recent years has significantly improved the accuracy and effectiveness of fault detection. In particular, DL techniques, especially CNNs, have proven to be highly efficient in detecting anomalies in photovoltaic units.

- Shading Anomalies: Fault detection and regular maintenance of photovoltaic panels are critical for maintaining optimal performance. Environmental factors that increase panel shading, such as various types of dust and bird droppings, can significantly impact system performance, making continuous monitoring and cleaning essential.

- Methodology Evaluation: From the evaluation of various methodologies, the CNN variant Resnet 50 shows a very promising future among the other literature findings. It is also evident that DL techniques, such as YOLO variants and combinations of CNN with SVM classifiers, provide high detection accuracy and cover a wide range of faults. However, traditional methods, such as thresholding techniques, while satisfactory in some cases, have limitations in covering different types of anomalies.

To further improve fault detection in photovoltaic systems and develop more efficient and economically viable solutions, the following directions are proposed:

- Scalability and Economic Viability: The development of scalable deep learning models that can incorporate economic analyses will be important. This will enable the application of these technologies on a large scale and ensure the viability of solutions in large photovoltaic parks.

- Real-Time Detection: Adapting and improving real-time detection techniques is crucial. Developing algorithms that can operate effectively under various environmental conditions and provide immediate feedback will enhance maintenance efficiency and the performance of photovoltaic systems.

- Integration of Multiple Technologies: Integrating technologies such as infrared imaging, electroluminescence imaging and RGB imaging, combined with deep learning algorithms, will allow for better fault detection and diagnosis. Hybrid models that could combine different AI techniques could also be investigated to improve the accuracy of PV fault detection, as well as the integration of IoT and edge computing devices for continuous real-time data collection. All the above could lead to more comprehensive and reliable detection solutions.

- Data augmentation and synthetic data generation: data collection can be also enhanced through augmentation techniques and the generation of synthetic data, towards creating balanced benchmark datasets of all kinds of faults to effectively train AI models.

With ongoing research and development in these areas, fault detection in photovoltaic systems is expected to improve significantly, offering higher performance and longer lifespan for photovoltaic systems. Therefore, practical implications of vision-based PV systems that could be translated into actionable insights for PV industry stakeholders, include the following:

- Cost management due to the early detection of faults, preventing minor faults to expand and ruin the entire system, therefore reducing repairing and replacement costs for PV farms. Data analysis could also aim towards preventing faults before occurring through the identification of patterns, resulting in PV installations performance optimization. In general, data-based insights can overall improve predictive maintenance strategies of PV installations, due to the ability to prevent, plan and act.

- Efficiency of operations for large PV installations, since automated monitoring solutions can reduce inspection time, as well as both human labor and human error.

- By reducing human involvement, safety is provided for PV installation personnel, since inspections in the field involve hazards due to the nature of the PV structures that require the worker to climb ladders or high places in order to properly inspect, as well as their exposure to potentially adverse environmental conditions.

- Safety is also a requirement for PV system operations. Fault detection aims towards compliance with regulations, i.e., standards and requirements for PV installations, to ensure their operation safety as predefined by corresponding guidelines.

- Computer-vision PV fault detection strategies may lead to more consistent, reliable and efficient PV inspection, making PV installations that adapt such technologies more competitive in the market.

More analytically, regarding the color-coded evaluation of Table 6, we observe that the detection methodology from the study [152] ranks first. This methodology was based on infrared thermography with UAVs, using Mask FCNNs for detecting photovoltaic units, and employed the DL network Resnet 50 to detect and classify seven out of the total seventeen anomalies. Of these, six were detected with satisfactory accuracy and one with average (less than 70%) accuracy.

The second highest performance according to our criteria, goes to the methodology presented in [155], which utilizes RGB imaging via UAVs, CNN for feature extraction and SVM for anomaly classification. This method also satisfactorily covers six out of seventeen faults. However, it lacks an integrated algorithm for detecting photovoltaic units, which reduces its level of automation compared to the top-ranked method. It is worth noting that of the six faults detected with satisfactory accuracy, two are shading anomalies (dust accumulation and snail trails). Given our observations on our second research finding—shading anomalies significantly impact the performance and output of PV units—this could potentially place the methodology in the first rank depending on the priorities of each specific implementation (e.g., resource allocation relative to desired PV unit performance). Accordingly, we could continue to rank all other methodologies based on the overall degree of satisfactory anomaly coverage, anomaly detection capability and the level of automation included in each specific study.

Another significant observation from the evaluation results is that the top five methodologies all involve DL techniques, with the top three including CNNs or their variations and two using YOLO variations. In contrast, segmentation methodologies with thresholding, while providing satisfactory accuracy, are able to detect a narrow range of different anomaly types. It is also noteworthy that the SVM classifier was found in the second position. This shows that even when combined with a CNN for feature extraction, SVM remains a highly competitive ML method for effective anomaly detection in photovoltaic units, despite the current trend towards using DL algorithms in computer vision tasks.

Practical applications and real-world implementations of vision-based PV fault detection can be found solely for large scale PV installations. The most well-known PV power station is that of Kamuthi in Tamil Nadu region in India. The latter is the largest PV farm, spreading across an area of 10 km2. The farm employes drones equipped with high-resolution cameras and thermal sensors to overall monitor the status of all PV modules. Drones fly over the PV farm to collect images, and data analysis is performed afterwards to detect anomalies and various types of faults. Challenges in real-world implementations include as already mentioned in Section 6.8, mainly the effects of environmental conditions that influence the accuracy of cameras, and the demanding processing of the vast number of generated data

9. Conclusions