Material Design for Enhancing Properties of 3D Printed Polymer Composites for Target Applications

Abstract

:1. Additive Manufacturing

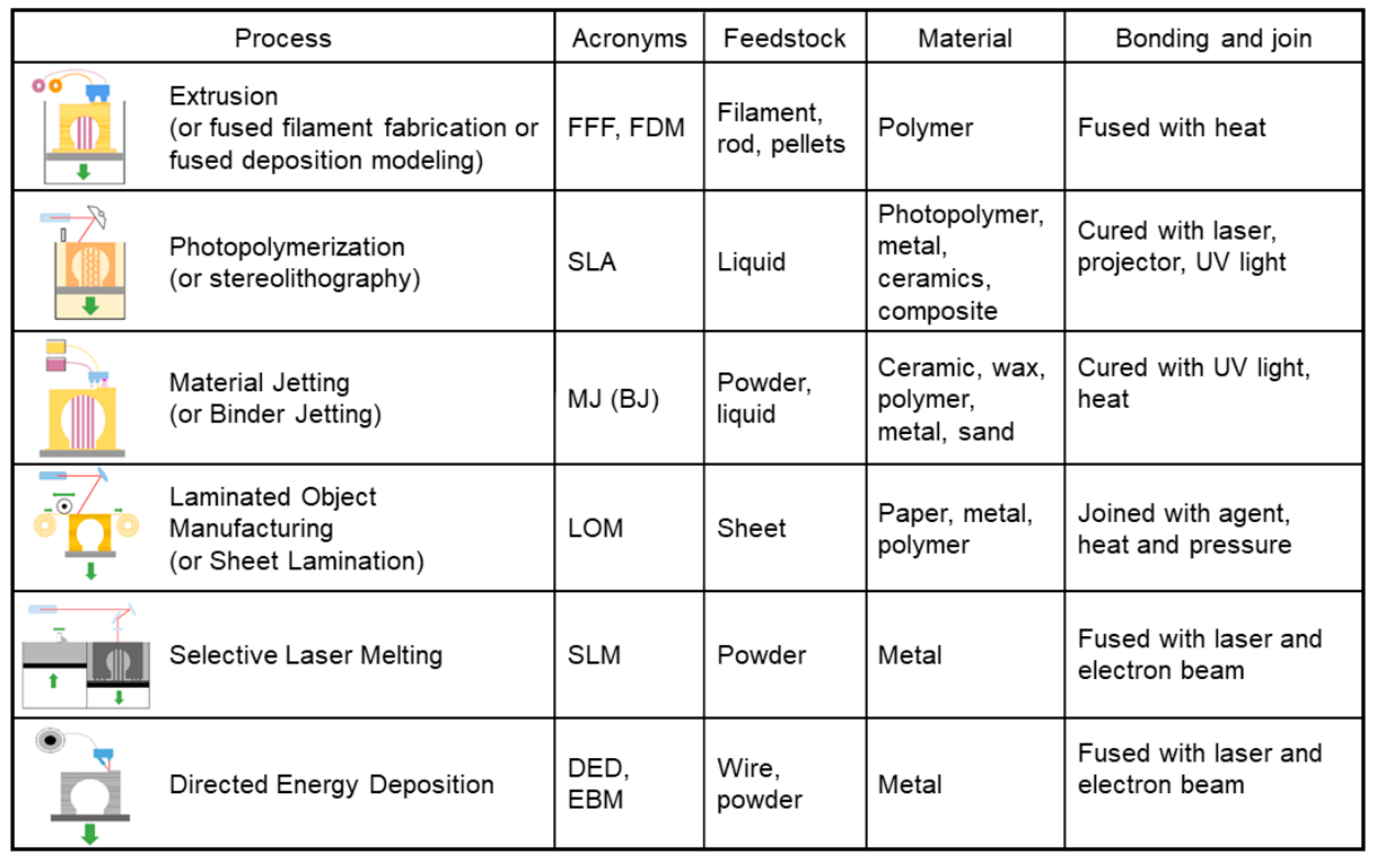

1.1. Types of Additive Manufacturing

2. Materials Design for Inherent Properties

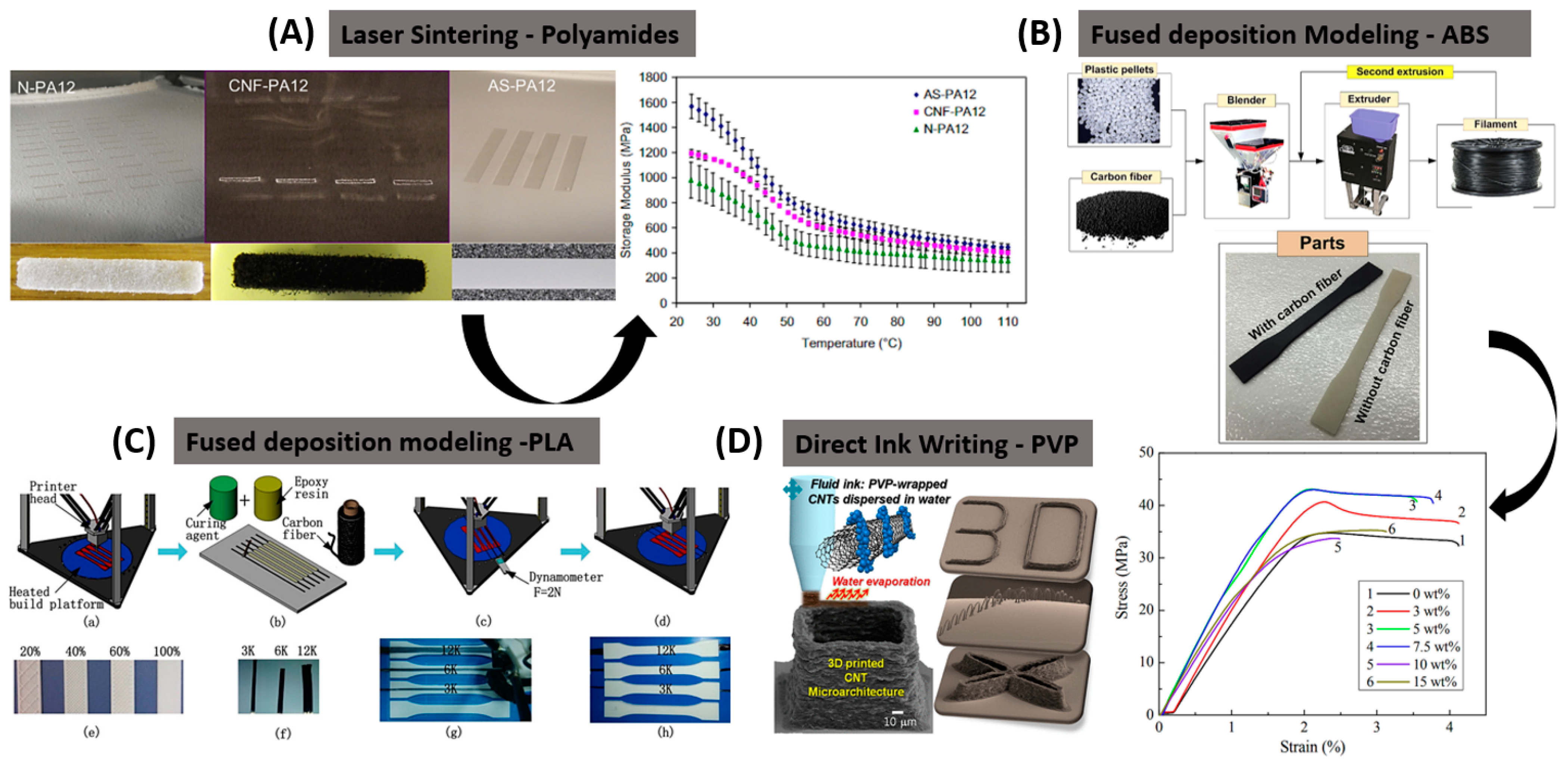

2.1. Carbon Fiber-Reinforced Polymer Composites (CFRP Composites)

2.1.1. Carbon Fiber Filaments

2.1.2. Carbon Fiber Resins

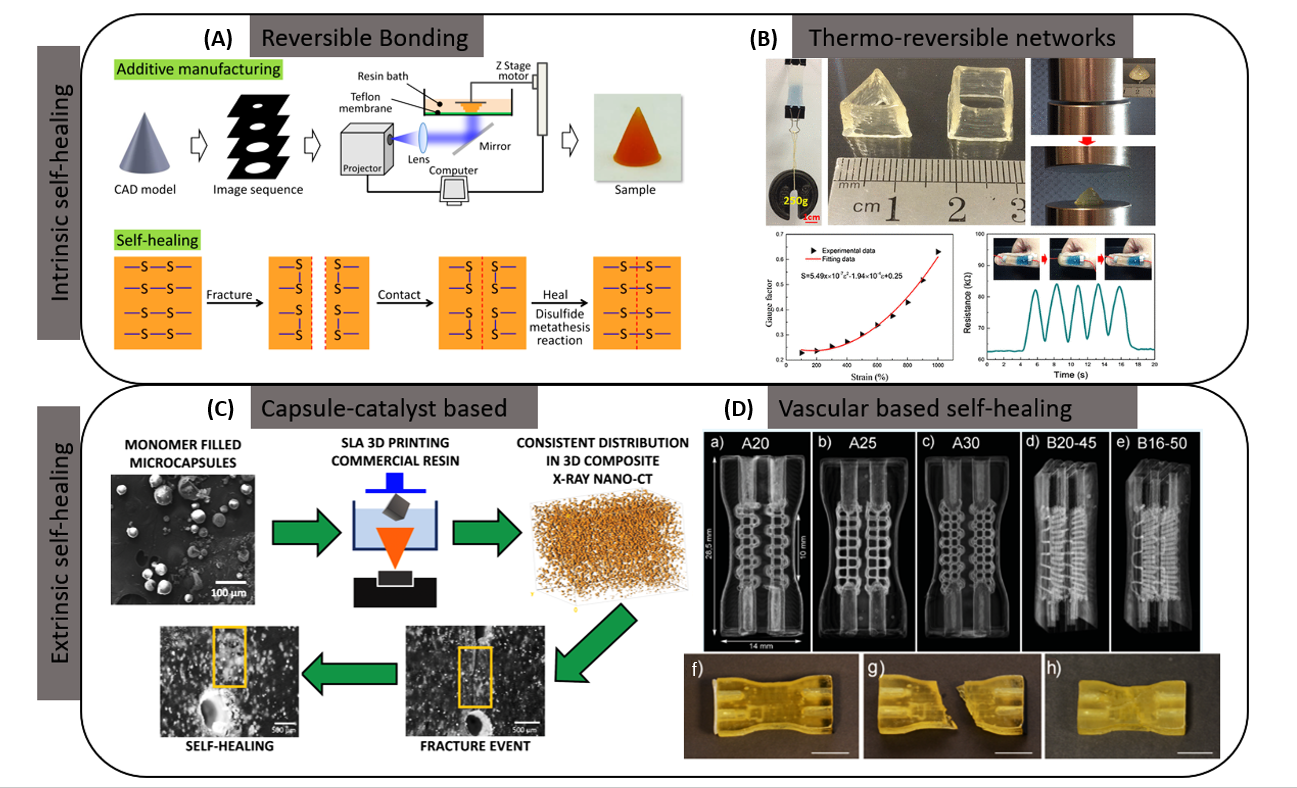

2.2. Self-Healing

2.2.1. Types of Self-Healing

Intrinsic Self-Healing

Extrinsic Self-Healing

2.2.2. Additive Manufacturing of Self-Healing Polymer Composites

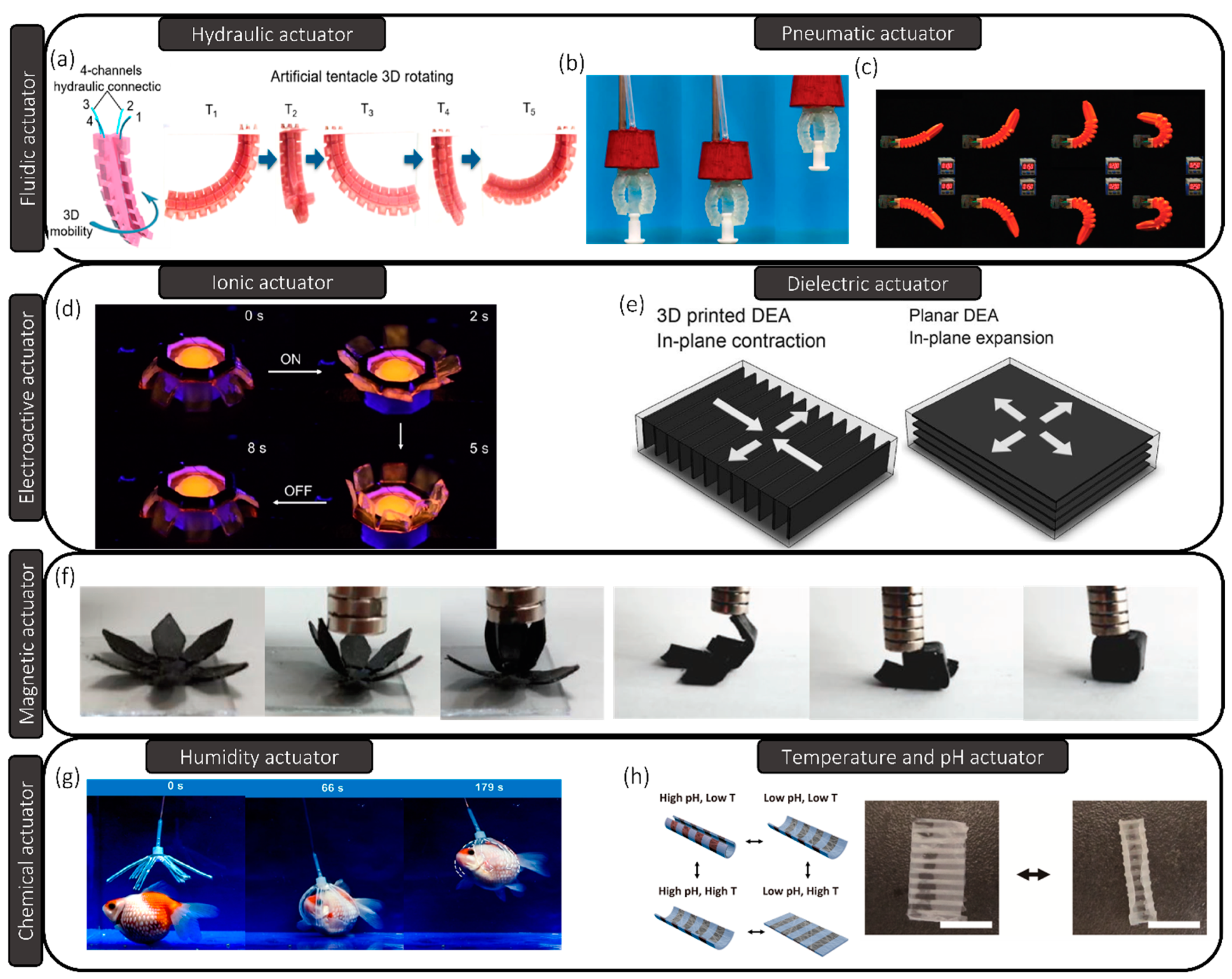

3. Soft Robotics

3.1. Fluidic Actuation

3.1.1. Hydraulic Soft Actuators

3.1.2. Pneumatic Soft Actuators

3.2. Field-Driven Soft Actuators

3.2.1. Electroactive Soft Actuators

Ionic Polymer Actuators

Dielectric Elastomer Actuators

3.2.2. Magnetically Responsive Soft Actuator

3.2.3. Chemically Responsive Soft Actuators

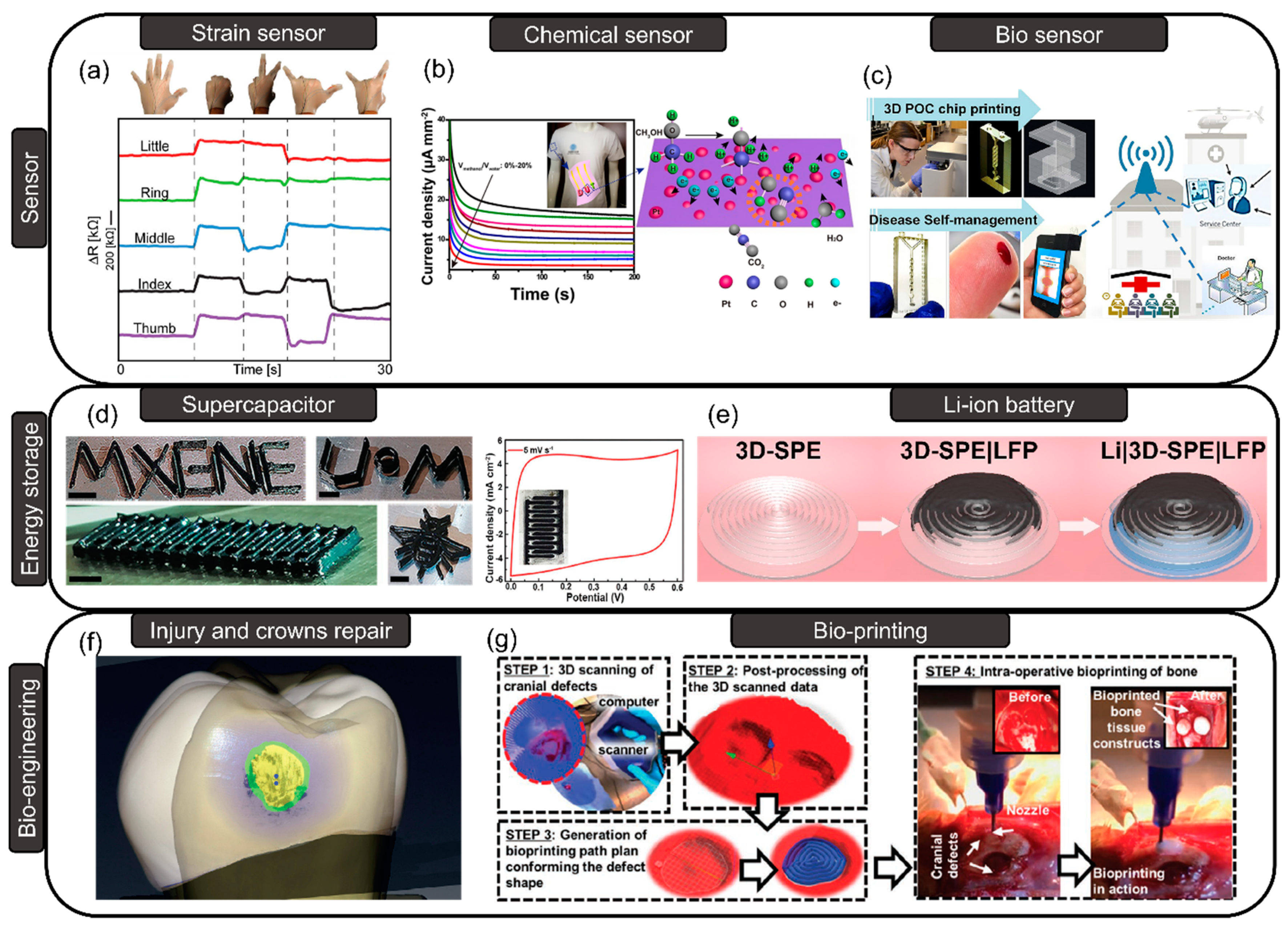

3.3. Flexible Electronics

3.3.1. Sensors

3.3.2. Batteries and Supercapacitors

4. Bioengineering

5. Earth Sciences

6. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zindani, D.; Kumar, K. An insight into additive manufacturing of fiber reinforced polymer composite. Int. J. Lightweight Mater. Manuf. 2019, 2, 267–278. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Mohr, S.; Khan, O. 3D Printing and the Future of Supply Chains. In Proceedings of the Hamburg International Conference of Logistics (HICL); epubli GmbH: Berlin, Germany, 2015; Available online: http://www.dhl.com/content/dam/downloads/g0/about_us/logistics_insights/dhl_trendreport_3dprinting.pdf (accessed on 21 January 2022).

- Kumar, S.; Kruth, J.-P. Composites by rapid prototyping technology. Mater. Des. 2009, 31, 850–856. [Google Scholar] [CrossRef]

- Razavykia, A.; Brusa, E.; Delprete, C.; Yavari, R. An Overview of Additive Manufacturing Technologies—A Review to Technical Synthesis in Numerical Study of Selective Laser Melting. Materials 2020, 13, 3895. [Google Scholar] [CrossRef] [PubMed]

- Goodridge, R.; Shofner, M.; Hague, R.; McClelland, M.; Schlea, M.; Johnson, R.; Tuck, C. Processing of a Polyamide-12/carbon nanofibre composite by laser sintering. Polym. Test. 2011, 30, 94–100. [Google Scholar] [CrossRef]

- Cheah, C.; Fuh, J.; Nee, A.; Lu, L. Mechanical characteristics of fiber-filled photo-polymer used in stereolithography. Rapid Prototyp. J. 1999, 5, 112–119. [Google Scholar] [CrossRef]

- Chiu, S.-H.; Wicaksono, S.T.; Chen, K.-T.; Chen, C.-Y.; Pong, S.-H. Mechanical and thermal properties of photopolymer/CB (carbon black) nanocomposite for rapid prototyping. Rapid Prototyp. J. 2015, 21, 262–269. [Google Scholar] [CrossRef]

- Sakly, A.; Kenzari, S.; Bonina, D.; Corbel, S.; Fournée, V. A novel quasicrystal-resin composite for stereolithography. Mater. Des. 2014, 56, 280–285. [Google Scholar] [CrossRef]

- Gurr, M.; Hofmann, D.; Ehm, M.; Thomann, Y.; Kübler, R.; Mülhaupt, R. Acrylic Nanocomposite Resins for Use in Stereolithography and Structural Light Modulation Based Rapid Prototyping and Rapid Manufacturing Technologies. Adv. Funct. Mater. 2008, 18, 2390–2397. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, S.; Wajahat, M.; Jeong, H.; Chang, W.S.; Jeong, H.J.; Yang, J.-R.; Kim, J.T.; Seol, S.K. Three-Dimensional Printing of Highly Conductive Carbon Nanotube Microarchitectures with Fluid Ink. ACS Nano 2016, 10, 8879–8887. [Google Scholar] [CrossRef]

- El Moumen, A.; Tarfaoui, M.; Lafdi, K. Additive manufacturing of polymer composites: Processing and modeling approaches. Compos. Part B Eng. 2019, 171, 166–182. [Google Scholar] [CrossRef]

- Perelaer, J.; Smith, P.J.; Mager, D.; Soltman, D.; Volkman, S.K.; Subramanian, V.; Korvink, J.G.; Schubert, U.S. Printed electronics: The challenges involved in printing devices, interconnects, and contacts based on inorganic materials. J. Mater. Chem. 2010, 20, 8446–8453. [Google Scholar] [CrossRef]

- Seerden, K.A.M.; Reis, N.; Evans, J.R.G.; Grant, P.S.; Halloran, J.W.; Derby, B. Ink-Jet Printing of Wax-Based Alumina Suspensions. J. Am. Ceram. Soc. 2001, 84, 2514–2520. [Google Scholar] [CrossRef] [Green Version]

- Masood, S.H.; Song, W.Q. Development of new metal/polymer materials for rapid tooling using Fused deposition modelling. Mater. Des. 2004, 25, 587–594. [Google Scholar] [CrossRef]

- Plymill, A.; Minneci, R.; Greeley, D.A. TRACE: Tennessee Research and Creative Graphene and Carbon Nanotube PLA Composite Feedstock Development for Fused Deposition Modeling Graphene and Carbon Nanotube PLA Composite Feedstock Development for Fused Deposition Modeling, 2016. Chancellor’s Honors Program Projects. 1955. Available online: https://trace.tennessee.edu/utk_chanhonoproj/1955 (accessed on 21 January 2022).

- Nikzad, M.; Masood, S.; Sbarski, I. Thermo-mechanical properties of a highly filled polymeric composites for Fused Deposition Modeling. Mater. Des. 2011, 32, 3448–3456. [Google Scholar] [CrossRef]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Milosevic, M.; Stoof, D.; Pickering, K.L. Characterizing the Mechanical Properties of Fused Deposition Modelling Natural Fiber Recycled Polypropylene Composites. J. Compos. Sci. 2017, 1, 7. [Google Scholar] [CrossRef] [Green Version]

- Mwema, F.M.; Akinlabi, E.T. Basics of Fused Deposition Modelling (FDM). In SpringerBriefs in Applied Sciences and Technology; Springer: Berlin, Germany, 2020. [Google Scholar]

- Ahn, D.; Kweon, J.-H.; Kwon, S.; Song, J.; Lee, S. Representation of surface roughness in fused deposition modeling. J. Mater. Process. Technol. 2009, 209, 5593–5600. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Li, L.; Huang, C. Effects of FDM-3D printing parameters on mechanical properties and microstructure of CF/PEEK and GF/PEEK. Chin. J. Aeronaut. 2020, 34, 236–246. [Google Scholar] [CrossRef]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Yao, X.; Luan, C.; Zhang, D.; Lan, L.; Fu, J. Evaluation of carbon fiber-embedded 3D printed structures for strengthening and structural-health monitoring. Mater. Des. 2017, 114, 424–432. [Google Scholar] [CrossRef]

- Ramalingam, P.S.; Mayandi, K.; Balasubramanian, V.; Chandrasekar, K.; Stalany, V.M.; Munaf, A.A. Effect of 3D printing process parameters on the impact strength of onyx—Glass fiber reinforced composites. Mater. Today Proc. 2020, 45, 6154–6159. [Google Scholar] [CrossRef]

- Nuñez, P.; Rivas, A.; García-Plaza, E.; Beamud, E.; Sanz-Lobera, A. Dimensional and Surface Texture Characterization in Fused Deposition Modelling (FDM) with ABS plus. Procedia Eng. 2015, 132, 856–863. [Google Scholar] [CrossRef]

- Yasa, E.; Ersoy, K. Dimensional Accuracy and Mechanical Properties of Chopped Carbon Reinforced Polymers Produced by Material Extrusion Additive Manufacturing. Materials 2019, 12, 3885. [Google Scholar] [CrossRef] [Green Version]

- Rybachuk, M.; Mauger, C.A.; Fiedler, T.; Öchsner, A. Anisotropic mechanical properties of fused deposition modeled parts fabricated by using acrylonitrile butadiene styrene polymer. J. Polym. Eng. 2017, 37, 699–706. [Google Scholar] [CrossRef]

- Yunus, D.E.; He, R.; Shi, W.; Kaya, O.; Liu, Y. Short fiber reinforced 3d printed ceramic composite with shear induced alignment. Ceram. Int. 2017, 43, 11766–11772. [Google Scholar] [CrossRef]

- Bond, I.; Trask, R.; Williams, H.R. Self-Healing Fiber-Reinforced Polymer Composites. MRS Bull. 2008, 33, 770–774. [Google Scholar] [CrossRef]

- Blaiszik, B.; Kramer, S.; Olugebefola, S.; Moore, J.; Sottos, N.; White, S. Self-Healing Polymers and Composites. Annu. Rev. Mater. Sci. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- Xu, H.; Tang, Y.; Liu, Z.; Cai, Y.; Wang, Y. The study of typical failure modes and failure mechanism of polymer materials. IOP Conf. Ser. Mater. Sci. Eng. 2017, 231, 12123. [Google Scholar] [CrossRef] [Green Version]

- Kim, C.; Ejima, H.; Yoshie, N. Polymers with autonomous self-healing ability and remarkable reprocessability under ambient humidity conditions. J. Mater. Chem. A 2018, 6, 19643–19652. [Google Scholar] [CrossRef]

- Terryn, S.; Mathijssen, G.; Brancart, J.; Lefeber, D.; Van Assche, G.; Vanderborght, B. Development of a self-healing soft pneumatic actuator: A first concept. Bioinspir. Biomim. 2015, 10, 046007. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef] [PubMed]

- Zhai, L.; Narkar, A.; Ahn, K. Self-healing polymers with nanomaterials and nanostructures. Nano Today 2019, 30, 100826. [Google Scholar] [CrossRef]

- Chen, X.; Dam, M.A.; Ono, K.; Mal, A.; Shen, H.; Nutt, S.R.; Sheran, K.; Wudl, F. A Thermally Re-mendable Cross-Linked Polymeric Material. Science 2002, 295, 1698–1702. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Wudl, F.; Mal, A.K.; Shen, H.; Nutt, S.R. New Thermally Remendable Highly Cross-Linked Polymeric Materials. Macromolecules 2003, 36, 1802–1807. [Google Scholar] [CrossRef]

- Hong, G.; Zhang, H.; Lin, Y.; Chen, Y.; Xu, Y.; Weng, W.; Xia, H. Mechanoresponsive Healable Metallosupramolecular Polymers. Macromolecules 2013, 46, 8649–8656. [Google Scholar] [CrossRef]

- Peterson, A.M.; Jensen, R.E.; Palmese, G.R. Room-Temperature Healing of a Thermosetting Polymer Using the Diels−Alder Reaction. ACS Appl. Mater. Interfaces 2010, 2, 1141–1149. [Google Scholar] [CrossRef]

- Zeng, C.; Seino, H.; Ren, J.; Hatanaka, K.; Yoshie, N. Bio-Based Furan Polymers with Self-Healing Ability. Macromolecules 2013, 46, 1794–1802. [Google Scholar] [CrossRef]

- Xie, M.; Che, Y.; Liu, K.; Jiang, L.; Xu, L.; Xue, R.; Drechsler, M.; Huang, J.; Tang, B.Z.; Yan, Y. Plastic Supramolecular Films: Caking-Inspired Cold Sintering of Plastic Supramolecular Films as Multifunctional Platforms. Adv. Funct. Mater. 2018, 28, 36. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, B.; Urban, M.W. Self-Repairing Oxetane-Substituted Chitosan Polyurethane Networks. Science 2009, 323, 1458–1460. [Google Scholar] [CrossRef] [PubMed]

- Scheiner, M.; Dickens, T.J.; Okoli, O. Progress towards self-healing polymers for composite structural applications. Polymer 2016, 83, 260–282. [Google Scholar] [CrossRef]

- Kessler, M.; White, S. Self-activated healing of delamination damage in woven composites. Compos. Part A Appl. Sci. Manuf. 2001, 32, 683–699. [Google Scholar] [CrossRef]

- Kessler, M.; Sottos, N.; White, S. Self-healing structural composite materials. Compos. Part A Appl. Sci. Manuf. 2003, 34, 743–753. [Google Scholar] [CrossRef]

- Shinde, V.V.; Celestine, A.-D.; Beckingham, L.E.; Beckingham, B.S. Stereolithography 3D Printing of Microcapsule Catalyst-Based Self-Healing Composites. ACS Appl. Polym. Mater. 2020, 2, 5048–5057. [Google Scholar] [CrossRef]

- Shinde, V.V.; Shelke, S.D.; Celestine, A.N.; Beckingham, B.S. Self-healing in high impact polystyrene ( HIPS ) composites via embedded non-toxic solvent-filled microcapsules. J. Appl. Polym. Sci. 2021, 139, 51463. [Google Scholar] [CrossRef]

- Garcia, S.J.; Fischer, H.R. Self-healing polymer systems: Properties, synthesis and applications. In Smart Polymers and their Applications; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Plaisted, T.A.; Nemat-Nasser, S. Quantitative evaluation of fracture, healing and re-healing of a reversibly cross-linked polymer. Acta Mater. 2007, 55, 5684–5696. [Google Scholar] [CrossRef]

- Fischer, H. Self-repairing material systems—A dream or a reality? Nat. Sci. 2010, 2, 873–901. [Google Scholar] [CrossRef] [Green Version]

- Park, J.S.; Takahashi, K.; Guo, Z.; Wang, Y.; Bolanos, E.; Hamann-Schaffner, C.; Murphy, E.; Wudl, F.; Hahn, H.T. Towards Development of a Self-Healing Composite using a Mendable Polymer and Resistive Heating. J. Compos. Mater. 2008, 42, 2869–2881. [Google Scholar] [CrossRef]

- Park, J.S.; Kim, H.-S.; Hahn, H.T. Healing behavior of a matrix crack on a carbon fiber/mendomer composite. Compos. Sci. Technol. 2009, 69, 1082–1087. [Google Scholar] [CrossRef]

- Murphy, E.B.; Bolanos, E.; Schaffner-Hamann, C.; Wudl, F.; Nutt, S.R.; Auad, M. Synthesis and Characterization of a Single-Component Thermally Remendable Polymer Network: Staudinger and Stille Revisited. Macromolecules 2008, 41, 5203–5209. [Google Scholar] [CrossRef]

- Peterson, A.M.; Jensen, R.E.; Palmese, G.R. Reversibly Cross-Linked Polymer Gels as Healing Agents for Epoxy−Amine Thermosets. ACS Appl. Mater. Interfaces 2009, 1, 992–995. [Google Scholar] [CrossRef] [PubMed]

- Chen, N.; Lee, Y.M. Anion exchange polyelectrolytes for membranes and ionomers. Prog. Polym. Sci. 2020, 113, 101345. [Google Scholar] [CrossRef]

- Tanasi, P.; Santana, M.H.; Carretero-González, J.; Verdejo, R.; López-Manchado, M.A. Thermo-reversible crosslinked natural rubber: A Diels-Alder route for reuse and self-healing properties in elastomers. Polymer 2019, 175, 15–24. [Google Scholar] [CrossRef]

- Eisenberg, A.; Rinaudo, M. Polyelectrolytes and ionomers. Polym. Bull. 1990, 24, 671. [Google Scholar] [CrossRef]

- Cordier, P.; Tournilhac, F.; Soulié-Ziakovic, C.; Leibler, L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature 2008, 451, 977–980. [Google Scholar] [CrossRef] [PubMed]

- Montarnal, D.; Tournilhac, F.; Hidalgo, M.; Couturier, J.-L.; Leibler, L. Versatile One-Pot Synthesis of Supramolecular Plastics and Self-Healing Rubbers. J. Am. Chem. Soc. 2009, 131, 7966–7967. [Google Scholar] [CrossRef] [PubMed]

- An, S.; Lee, M.W.; Yarin, A.L.; Yoon, S.S. A review on corrosion-protective extrinsic self-healing: Comparison of microcapsule-based systems and those based on core-shell vascular networks. Chem. Eng. J. 2018, 344, 206–220. [Google Scholar] [CrossRef]

- Bakry, A.M.; Abbas, S.; Ali, B.; Majeed, H.; Abouelwafa, M.Y.; Mousa, A.; Liang, L. Microencapsulation of Oils: A Comprehensive Review of Benefits, Techniques, and Applications. Compr. Rev. Food Sci. Food Saf. 2015, 15, 143–182. [Google Scholar] [CrossRef]

- Toohey, K.S.; Sottos, N.R.; Lewis, J.A.; Moore, J.; White, S. Self-healing materials with microvascular networks. Nat. Mater. 2007, 6, 581–585. [Google Scholar] [CrossRef] [PubMed]

- Ullah, H.; Azizli, K.A.M.; Man, Z.B.; Ismail, M.B.C.; Khan, M.I. The Potential of Microencapsulated Self-healing Materials for Microcracks Recovery in Self-healing Composite Systems: A Review. Polym. Rev. 2016, 56, 429–485. [Google Scholar] [CrossRef]

- Brown, E.N.; Sottos, N.R.; White, S.R. Fracture Testing of a Self-Healing Polymer Composite. Exp. Mech. 2002, 42, 372–379. [Google Scholar] [CrossRef]

- Brown, E.; White, S.; Sottos, N. Retardation and repair of fatigue cracks in a microcapsule toughened epoxy composite—Part II: In situ self-healing. Compos. Sci. Technol. 2005, 65, 2474–2480. [Google Scholar] [CrossRef] [Green Version]

- Keller, M.W.; White, S.R.; Sottos, N.R. A Self-Healing Poly(Dimethyl Siloxane) Elastomer. Adv. Funct. Mater. 2007, 17, 2399–2404. [Google Scholar] [CrossRef]

- Kumar, A.; Stephenson, L.; Murray, J. Self-healing coatings for steel. Prog. Org. Coat. 2006, 55, 244–253. [Google Scholar] [CrossRef]

- Caruso, M.M.; Delafuente, D.A.; Ho, V.; Sottos, N.R.; Moore, J.S.; White, S.R. Solvent-Promoted Self-Healing Epoxy Materials. Macromolecules 2007, 40, 8830–8832. [Google Scholar] [CrossRef]

- Celestine, A.-D.N.; Sottos, N.R.; White, S.R. Autonomic healing of PMMA via microencapsulated solvent. Polymer 2015, 69, 241–248. [Google Scholar] [CrossRef]

- White, S.R.; Moore, J.S.; Sottos, N.R.; Krull, B.P.; Cruz, W.A.S.; Gergely, R.C.R. Restoration of Large Damage Volumes in Polymers. Science 2014, 344, 620–623. [Google Scholar] [CrossRef]

- Williams, G.; Trask, R.; Bond, I. A self-healing carbon fibre reinforced polymer for aerospace applications. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1525–1532. [Google Scholar] [CrossRef]

- Shields, Y.; De Belie, N.; Jefferson, A.; Van Tittelboom, K. A review of vascular networks for self-healing applications. Smart Mater. Struct. 2021, 30, 063001. [Google Scholar] [CrossRef]

- Calderón-Villajos, R.; López, A.; Peponi, L.; Manzano-Santamaría, J.; Ureña, A. 3D-printed self-healing composite polymer reinforced with carbon nanotubes. Mater. Lett. 2019, 249, 91–94. [Google Scholar] [CrossRef]

- Mondal, S.; Nguyen, T.P.; Pham, V.H.; Hoang, G.; Manivasagan, P.; Kim, M.H.; Nam, S.Y.; Oh, J. Hydroxyapatite nano bioceramics optimized 3D printed poly lactic acid scaffold for bone tissue engineering application. Ceram. Int. 2020, 46, 3443–3455. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Afif, A.; Rahman, S.M.; Azad, A.T.; Zaini, J.; Islam, A.; Azad, A. Advanced materials and technologies for hybrid supercapacitors for energy storage—A review. J. Energy Storage 2019, 25. [Google Scholar] [CrossRef]

- Yu, K.; Xin, A.; Du, H.; Li, Y.; Wang, Q. Additive manufacturing of self-healing elastomers. NPG Asia Mater. 2019, 11, 7. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Li, L. Ultrastretchable and Self-Healing Double-Network Hydrogel for 3D Printing and Strain Sensor. ACS Appl. Mater. Interfaces 2017, 9, 26429–26437. [Google Scholar] [CrossRef] [PubMed]

- Sanders, P.; Young, A.; Qin, Y.; Fancey, K.S.; Reithofer, M.R.; Guillet-Nicolas, R.; Kleitz, F.; Pamme, N.; Chin, J.M. Stereolithographic 3D printing of extrinsically self-healing composites. Sci. Rep. 2019, 9, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Postiglione, G.; Alberini, M.; Leigh, S.; Levi, M.; Turri, S. Effect of 3D-Printed Microvascular Network Design on the Self-Healing Behavior of Cross-Linked Polymers. ACS Appl. Mater. Interfaces 2017, 9, 14371–14378. [Google Scholar] [CrossRef]

- Cheng, Y.; Chan, K.H.; Wang, X.-Q.; Ding, T.; Li, T.; Lu, X.; Ho, G.W. Direct-Ink-Write 3D Printing of Hydrogels into Biomimetic Soft Robots. ACS Nano 2019, 13, 13176–13184. [Google Scholar] [CrossRef] [PubMed]

- Patel, D.; Sakhaei, A.H.; Layani, M.; Zhang, B.; Ge, Q.; Magdassi, S. Highly Stretchable and UV Curable Elastomers for Digital Light Processing Based 3D Printing. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef] [PubMed]

- Yap, H.K.; Ng, H.Y.; Yeow, C.-H. High-Force Soft Printable Pneumatics for Soft Robotic Applications. Soft Robot. 2016, 3, 144–158. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Wang, Z.; He, Q.; Li, C.; Cai, S. 3D Printing of Electrically Responsive PVC Gel Actuators. ACS Appl. Mater. Interfaces 2021, 13, 24164–24172. [Google Scholar] [CrossRef] [PubMed]

- Chortos, A.; Hajiesmaili, E.; Morales, J.; Clarke, D.R.; Lewis, J.A. 3D Printing of Interdigitated Dielectric Elastomer Actuators. Adv. Funct. Mater. 2019, 30. [Google Scholar] [CrossRef]

- Lantean, S.; Barrera, G.; Pirri, C.F.; Tiberto, P.; Sangermano, M.; Roppolo, I.; Rizza, G. 3D Printing of Magnetoresponsive Polymeric Materials with Tunable Mechanical and Magnetic Properties by Digital Light Processing. Adv. Mater. Technol. 2019, 4. [Google Scholar] [CrossRef]

- Yao, Y.; Yin, C.; Hong, S.; Chen, H.; Shi, Q.; Wang, J.; Lu, X.; Zhou, N. Lanthanide-Ion-Coordinated Supramolecular Hydrogel Inks for 3D Printed Full-Color Luminescence and Opacity-Tuning Soft Actuators. Chem. Mater. 2020, 32, 8868–8876. [Google Scholar] [CrossRef]

- Cho, K.; Kang, D.; Lee, H.; Koh, W.-G. Multi-stimuli responsive and reversible soft actuator engineered by layered fibrous matrix and hydrogel micropatterns. Chem. Eng. J. 2021, 427, 130879. [Google Scholar] [CrossRef]

- Kokkinis, D.; Schaffner, M.; Studart, A.R. Multimaterial magnetically assisted 3D printing of composite materials. Nat. Commun. 2015, 6, 8643. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Odent, J.; Vanderstappen, S.; Toncheva, A.; Pichon, E.; Wallin, T.J.; Wang, K.; Shepherd, R.F.; Dubois, P.; Raquez, J.-M. Hierarchical chemomechanical encoding of multi-responsive hydrogel actuators via 3D printing. J. Mater. Chem. A 2019, 7, 15395–15403. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, M.; Cao, X.; Zhang, Z.; Chen, X.; Xiao, Y.; Liang, Y.; Wong, T.-W.; Li, T.; Xu, Z. Fabrication and modeling of dielectric elastomer soft actuator with 3D printed thermoplastic frame. Sens. Actuators A Phys. 2019, 292, 112–120. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, W.; Zhang, Q.; Zheng, K.; Xu, J.; Xu, W.; Shang, E.; Jiang, J.; Zhang, J.; Liu, Y. 3D-Printed Graphene/Polydimethylsiloxane Composites for Stretchable and Strain-Insensitive Temperature Sensors. ACS Appl. Mater. Interfaces 2018, 11, 1344–1352. [Google Scholar] [CrossRef] [PubMed]

- Kalsoom, U.; Waheed, S.; Paull, B. Fabrication of Humidity Sensor Using 3D Printable Polymer Composite Containing Boron-Doped Diamonds and LiCl. ACS Appl. Mater. Interfaces 2020, 12, 4962–4969. [Google Scholar] [CrossRef] [PubMed]

- Mu, Q.; Wang, L.; Dunn, C.K.; Kuang, X.; Duan, F.; Zhang, Z.; Qi, H.J.; Wang, T. Digital light processing 3D printing of conductive complex structures Digital light processing 3D printing of conductive complex structures. Addit. Manuf. 2017, 18, 74–83. [Google Scholar] [CrossRef]

- Shen, K.; Ding, J.; Yang, S. 3D Printing Quasi-Solid-State Asymmetric Micro-Supercapacitors with Ultrahigh Areal Energy Density. Adv. Energy Mater. 2018, 8. [Google Scholar] [CrossRef]

- Park, S.H.; Kaur, M.; Yun, D.; Kim, W.S. Hierarchically Designed Electron Paths in 3D Printed Energy Storage Devices. Langmuir 2018, 34, 10897–10904. [Google Scholar] [CrossRef] [PubMed]

- McOwen, D.W.; Xu, S.; Gong, Y.; Wen, Y.; Godbey, G.L.; Gritton, J.; Hamann, T.R.; Dai, J.; Hitz, G.T.; Hu, L.; et al. 3D-Printing Electrolytes for Solid-State Batteries. Adv. Mater. 2018, 30, e1707132. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Chen, S.; Nie, L.; Sun, Z.; Wu, X.; Liu, W. Stereolithography Three-Dimensional Printing Solid Polymer Electrolytes for All-Solid-State Lithium Metal Batteries. Nano Lett. 2020, 20, 7136–7143. [Google Scholar] [CrossRef] [PubMed]

- Ayan, B.; Heo, D.N.; Zhang, Z.; Dey, M.; Povilianskas, A.; Drapaca, C.; Ozbolat, I.T. Aspiration-assisted bioprinting for precise positioning of biologics. Sci. Adv. 2020, 6, eaaw5111. [Google Scholar] [CrossRef] [Green Version]

- Katzschmann, R.K.; Marchese, A.D.; Rus, D. Hydraulic Autonomous Soft Robotic Fish for 3D Swimming. Exp. Robot. 2015, 405–420. [Google Scholar] [CrossRef]

- Zhu, M.; Do, T.N.; Hawkes, E.; Visell, Y. Fluidic Fabric Muscle Sheets for Wearable and Soft Robotics. Soft Robot. 2020, 7, 179–197. [Google Scholar] [CrossRef] [Green Version]

- MacCurdy, R.; Katzschmann, R.; Kim, Y.; Rus, D. Printable hydraulics: A method for fabricating robots by 3D co-printing solids and liquids. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 3878–3885. [Google Scholar]

- Zatopa, A.; Walker, S.; Menguc, Y. Fully Soft 3D-Printed Electroactive Fluidic Valve for Soft Hydraulic Robots. Soft Robot. 2018, 5, 258–271. [Google Scholar] [CrossRef] [PubMed]

- O’Neill, M.R.; Acome, E.; Bakarich, S.; Mitchell, S.K.; Timko, J.; Keplinger, C.; Shepherd, R.F. Rapid 3D Printing of Electrohydraulic (HASEL) Tentacle Actuators. Adv. Funct. Mater. 2020, 30, 2005244. [Google Scholar] [CrossRef]

- Lee, C.; Kim, M.; Kim, Y.J.; Hong, N.; Ryu, S.; Kim, H.J.; Kim, S. Soft robot review. Int. J. Control. Autom. Syst. 2017, 15, 3–15. [Google Scholar] [CrossRef]

- Peele, B.N.; Wallin, T.J.; Zhao, H.; Shepherd, R. 3D printing antagonistic systems of artificial muscle using projection stereolithography. Bioinspiration Biomimetics 2015, 10, 055003. [Google Scholar] [CrossRef] [PubMed]

- Keong, B.A.W.; Hua, R.Y.C. A Novel Fold-Based Design Approach toward Printable Soft Robotics Using Flexible 3D Printing Materials. Adv. Mater. Technol. 2017, 3. [Google Scholar] [CrossRef]

- Zhang, Y.; Ng, C.J.; Chen, Z.; Zhang, W.; Panjwani, S.; Kowsari, K.; Yang, H.Y.; Ge, Q. Miniature Pneumatic Actuators for Soft Robots by High-Resolution Multimaterial 3D Printing. Adv. Mater. Technol. 2019, 4, 1900427. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, N.; Hingorani, H.; Ding, N.; Wang, D.; Yuan, C.; Zhang, B.; Gu, G.; Ge, Q. Fast-Response, Stiffness-Tunable Soft Actuator by Hybrid Multimaterial 3D Printing. Adv. Funct. Mater. 2019, 29. [Google Scholar] [CrossRef]

- Thrasher, C.J.; Schwartz, J.J.; Boydston, A.J. Modular Elastomer Photoresins for Digital Light Processing Additive Manufacturing. ACS Appl. Mater. Interfaces 2017, 9, 39708–39716. [Google Scholar] [CrossRef]

- Ge, Q.; Chen, Z.; Cheng, J.; Zhang, B.; Zhang, Y.-F.; Li, H.; He, X.; Yuan, C.; Liu, J.; Magdassi, S.; et al. 3D printing of highly stretchable hydrogel with diverse UV curable polymers. Sci. Adv. 2021, 7, eaba4261. [Google Scholar] [CrossRef]

- Sellinger, A.T.; Wang, D.H.; Tan, L.-S.; Vaia, R.A. Electrothermal Polymer Nanocomposite Actuators. Adv. Mater. 2010, 22, 3430–3435. [Google Scholar] [CrossRef]

- Zhang, T.-Y.; Wang, Q.; Deng, N.-Q.; Zhao, H.-M.; Wang, D.-Y.; Yang, Z.; Liu, Y.; Yang, Y.; Ren, T.-L. A large-strain, fast-response, and easy-to-manufacture electrothermal actuator based on laser-reduced graphene oxide. Appl. Phys. Lett. 2017, 111, 121901. [Google Scholar] [CrossRef]

- Sachyani Keneth, E.; Scalet, G.; Layani, M.; Tibi, G.; Degani, A.; Auricchio, F.; Magdassi, S. Pre-Programmed Tri-Layer Electro-Thermal Actuators Composed of Shape Memory Polymer and Carbon Nanotubes. Soft Robot. 2020, 7, 123–129. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Agostini, L.; Moretti, G.; Fontana, M.; Vertechy, R. Dielectric elastomer materials for large-strain actuation and energy harvesting: A comparison between styrenic rubber, natural rubber and acrylic elastomer. Smart Mater. Struct. 2019, 28, 114001. [Google Scholar] [CrossRef]

- Chiba, S. Dielectric elastomers. In Soft Actuators: Materials, Modeling, Applications, and Future Perspectives; Springer: Tokyo, Japan, 2014; Volume 9784431547, pp. 183–195. [Google Scholar]

- Suo, Z. Theory of dielectric elastomers. Acta Mech. Solida Sin. 2010, 23, 549–578. [Google Scholar] [CrossRef]

- Wang, T.; Farajollahi, M.; Choi, Y.S.; Lin, I.-T.; Marshall, J.E.; Thompson, N.M.; Kar-Narayan, S.; Madden, J.D.W.; Smoukov, S.K. Electroactive polymers for sensing. Interface Focus 2016, 6, 20160026. [Google Scholar] [CrossRef] [PubMed]

- Shang, Y.; Wang, J.; Ikeda, T.; Jiang, L. Bio-inspired liquid crystal actuator materials. J. Mater. Chem. C 2019, 7, 3413–3428. [Google Scholar] [CrossRef]

- Hines, L.; Petersen, K.H.; Lum, G.Z.; Sitti, M. Soft Actuators for Small-Scale Robotics. Adv. Mater. 2017, 29, 1603483. [Google Scholar] [CrossRef] [PubMed]

- Terasawa, N.; Ono, N.; Mukai, K.; Koga, T.; Higashi, N.; Asaka, K. A multi-walled carbon nanotube/polymer actuator that surpasses the performance of a single-walled carbon nanotube/polymer actuator. Carbon 2012, 50, 311–320. [Google Scholar] [CrossRef]

- Wang, B.; Hong, L.; Li, Y.; Zhao, L.; Zhao, C.; Na, H. Property Enhancement Effects of Side-Chain-Type Naphthalene-Based Sulfonated Poly(arylene ether ketone) on Nafion Composite Membranes for Direct Methanol Fuel Cells. ACS Appl. Mater. Interfaces 2017, 9, 32227–32236. [Google Scholar] [CrossRef] [PubMed]

- Keneth, E.S.; Kamyshny, A.; Totaro, M.; Beccai, L.; Magdassi, S. 3D Printing Materials for Soft Robotics. Adv. Mater. 2020, 33, e2003387. [Google Scholar] [CrossRef]

- Han, D.; Farino, C.; Yang, C.; Scott, T.; Browe, D.; Choi, W.; Freeman, J.W.; Lee, H. Soft Robotic Manipulation and Locomotion with a 3D Printed Electroactive Hydrogel. ACS Appl. Mater. Interfaces 2018, 10, 17512–17518. [Google Scholar] [CrossRef] [PubMed]

- Shin, Y.; Choi, M.-Y.; Choi, J.; Na, J.-H.; Kim, S.Y. Design of an Electro-Stimulated Hydrogel Actuator System with Fast Flexible Folding Deformation under a Low Electric Field. ACS Appl. Mater. Interfaces 2021, 13, 15633–15646. [Google Scholar] [CrossRef] [PubMed]

- Sommer-Larsen, P.; Kofod, G.; Shridhar, M.H.; Benslimane, M.; Gravesen, P. Performance of dielectric elastomer actuators and materials. SPIE Proc. 2002, 4695, 158–166. [Google Scholar] [CrossRef]

- Gupta, U.; Qin, L.; Wang, Y.; Godaba, H.; Zhu, J. Soft robots based on dielectric elastomer actuators: A review. Smart Mater. Struct. 2019, 28, 103002. [Google Scholar] [CrossRef]

- Zhang, J.; Sheng, J.; O’Neill, C.T.; Walsh, C.J.; Wood, R.J.; Ryu, J.-H.; Desai, J.P.; Yip, M.C. Robotic Artificial Muscles: Current Progress and Future Perspectives. IEEE Trans. Robot. 2019, 35, 761–781. [Google Scholar] [CrossRef]

- Correia, D.; Fernandes, L.; Pereira, N.; Barbosa, J.; Serra, J.; Pinto, R.; Costa, C.; Lanceros-Méndez, S. All printed soft actuators based on ionic liquid/polymer hybrid materials. Appl. Mater. Today 2021, 22, 100928. [Google Scholar] [CrossRef]

- Correia, D.M.; Barbosa, J.C.; Serra, J.P.; Pinto, R.S.; Fernandes, L.C.; Tubio, C.R.; Lanceros-Mendez, S.; Costa, C.M. Comparative Assessment of Ionic Liquid-Based Soft Actuators Prepared by Film Casting Versus Direct Ink Writing. Adv. Eng. Mater. 2021, 23, 2100411. [Google Scholar] [CrossRef]

- Maas, J.; Tepel, D.; Hoffstadt, T. Actuator design and automated manufacturing process for DEAP-based multilayer stack-actuators. Meccanica 2015, 50, 2839–2854. [Google Scholar] [CrossRef]

- Ralchev, M.; Mateev, V.; Marinova, I. Magnetic Properties of FFF/FDM 3D Printed Magnetic Material. In Proceedings of the Conference on Electrical Machines, Drives and Power Systems (ELMA), Sofia, Bulgaria, 1–4 July 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Ji, Z.; Yan, C.; Yu, B.; Wang, X.; Zhou, F. Multimaterials 3D Printing for Free Assembly Manufacturing of Magnetic Driving Soft Actuator. Adv. Mater. Interfaces 2017, 4. [Google Scholar] [CrossRef]

- Richbourg, N.R.; Peppas, N.A. The swollen polymer network hypothesis: Quantitative models of hydrogel swelling, stiffness, and solute transport. Prog. Polym. Sci. 2020, 105, 101243. [Google Scholar] [CrossRef]

- Lopez, C.G.; Lohmeier, T.; Wong, J.E.; Richtering, W. Electrostatic expansion of polyelectrolyte microgels: Effect of solvent quality and added salt. J. Colloid Interface Sci. 2019, 558, 200–210. [Google Scholar] [CrossRef] [PubMed]

- Peppas, N.A.; Reinhart, C.T. Solute diffusion in swollen membranes. Part I. A new theory. J. Membr. Sci. 1983, 15, 275–287. [Google Scholar] [CrossRef]

- Dutta, S.; Cohn, D. Temperature and pH responsive 3D printed scaffolds. J. Mater. Chem. B 2017, 5, 9514–9521. [Google Scholar] [CrossRef] [PubMed]

- Chang, Q.; Darabi, M.A.; Liu, Y.; He, Y.; Zhong, W.; Mequanin, K.; Li, B.; Lu, F.; Xing, M.M.Q. Hydrogels from natural egg white with extraordinary stretchability, direct-writing 3D printability and self-healing for fabrication of electronic sensors and actuators. J. Mater. Chem. A 2019, 7, 24626–24640. [Google Scholar] [CrossRef]

- Bakarich, S.E.; Gorkin, R.; Panhuis, M.I.H.; Spinks, G.M. 4D Printing with Mechanically Robust, Thermally Actuating Hydrogels. Macromol. Rapid Commun. 2015, 36, 1211–1217. [Google Scholar] [CrossRef] [PubMed]

- DI Noto, V.; Lavina, S.; Giffin, G.; Negro, E.; Scrosati, B. Polymer electrolytes: Present, past and future. Electrochim. Acta 2011, 57, 4–13. [Google Scholar] [CrossRef]

- Su, M.; Song, Y. Printable Smart Materials and Devices: Strategies and Applications. Chem. Rev. 2022, 122, 5144–5164. [Google Scholar] [CrossRef] [PubMed]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D Printing of Strain Sensors within Highly Stretchable Elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Ma, J.; Lv, J.; Ma, H.; Xia, H.; Wang, J.; Yang, C.; Xue, M.; Li, G.; Zhu, N. Facile Wearable Vapor/Liquid Amphibious Methanol Sensor. ACS Sens. 2018, 4, 152–160. [Google Scholar] [CrossRef]

- Plevniak, K.; Campbell, M.; Myers, T.; Hodges, A.; He, M. 3D printed auto-mixing chip enables rapid smartphone diagnosis of anemia. Biomicrofluidics 2016, 10, 054113. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Yang, J.; Byun, J.J.; Moissinac, F.P.; Xu, J.; Haigh, S.J.; Domingos, M.; Bissett, M.A.; Dryfe, R.A.W.; Barg, S. 3D Printing of Freestanding MXene Architectures for Current-Collector-Free Supercapacitors. Adv. Mater. 2019, 31, 1902725. [Google Scholar] [CrossRef] [PubMed]

- Mai, H.N.; Lee, K.-B.; Lee, D.-H. Fit of interim crowns fabricated using photopolymer-jetting 3D printing. J. Prosthet. Dent. 2017, 118, 208–215. [Google Scholar] [CrossRef]

- Moncal, K.K.; Gudapati, H.; Godzik, K.P.; Heo, D.N.; Kang, Y.; Rizk, E.; Ravnic, D.J.; Wee, H.; Pepley, D.F.; Ozbolat, V.; et al. Intra-Operative Bioprinting of Hard, Soft, and Hard/Soft Composite Tissues for Craniomaxillofacial Reconstruction. Adv. Funct. Mater. 2021, 31, 2010858. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Yan, X. Progress in achieving high-performance piezoresistive and capacitive flexible pressure sensors: A review. J. Mater. Sci. Technol. 2020, 43, 175–188. [Google Scholar] [CrossRef]

- Zhou, N.; Liu, T.; Wen, B.; Gong, C.; Wei, G.; Su, Z. Recent Advances in the Construction of Flexible Sensors for Biomedical Applications. Biotechnol. J. 2020, 15. [Google Scholar] [CrossRef] [PubMed]

- Trung, T.Q.; Ramasundaram, S.; Hwang, B.-U.; Lee, N.-E. An All-Elastomeric Transparent and Stretchable Temperature Sensor for Body-Attachable Wearable Electronics. Adv. Mater. 2015, 28, 502–509. [Google Scholar] [CrossRef]

- Di, J.; Zhang, X.; Yong, Z.; Zhang, Y.; Li, D.; Li, R.; Li, Q. Carbon-Nanotube Fibers for Wearable Devices and Smart Textiles. Adv. Mater. 2016, 28, 10529–10538. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Liu, X.; Shen, X.; Han, N.M.; Wu, Y.; Zheng, Q.; Jia, J.; Wang, N.; Kim, J. An Ultralight Graphene Honeycomb Sandwich for Stretchable Light-Emitting Displays. Adv. Funct. Mater. 2018, 28. [Google Scholar] [CrossRef]

- Xiao, T.; Qian, C.; Yin, R.; Wang, K.; Gao, Y.; Xuan, F. 3D Printing of Flexible Strain Sensor Array Based on UV-Curable Multiwalled Carbon Nanotube/Elastomer Composite. Adv. Mater. Technol. 2020, 6. [Google Scholar] [CrossRef]

- Wu, T.; Gray, E.; Chen, B. A self-healing, adaptive and conductive polymer composite ink for 3D printing of gas sensors. J. Mater. Chem. C 2018, 6, 6200–6207. [Google Scholar] [CrossRef] [Green Version]

- Han, T.; Kundu, S.; Nag, A.; Xu, Y. 3D Printed Sensors for Biomedical Applications: A Review. Sensors 2019, 19, 1706. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Z.; Liu, J.; Wang, M.; Shen, X.; Qian, T.; Yan, C. Toward safer solid-state lithium metal batteries: A review. Nanoscale Adv. 2020, 2, 1828–1836. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Zhang, S.; Shen, L.; Liu, Q.; Ma, J.; Lv, W.; He, Y.; Yang, Q. Progress and Perspective of Ceramic/Polymer Composite Solid Electrolytes for Lithium Batteries. Adv. Sci. 2020, 7, 1903088. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Li, Q.; Tan, Z. A review of electrospun nanofiber-based separators for rechargeable lithium-ion batteries. J. Power Sources 2019, 443, 227262. [Google Scholar] [CrossRef]

- Wei, T.; Ahn, B.Y.; Grotto, J.; Lewis, J.A. 3D Printing of Customized Li-Ion Batteries with Thick Electrodes. Adv. Mater. 2018, 30, e1703027. [Google Scholar] [CrossRef] [PubMed]

- Shen, W.; Li, K.; Lv, Y.; Xu, T.; Wei, D.; Liu, Z. Highly-Safe and Ultra-Stable All-Flexible Gel Polymer Lithium Ion Batteries Aiming for Scalable Applications. Adv. Energy Mater. 2020, 10. [Google Scholar] [CrossRef]

- Deiner, L.J.; Bezerra, C.A.G.; Howell, T.G.; Powell, A.S. Digital Printing of Solid-State Lithium-Ion Batteries. Adv. Eng. Mater. 2019, 21, 1900737. [Google Scholar] [CrossRef] [Green Version]

- Poly(Ethylene Oxide)−LiTFSI Solid Polymer Electrolyte Filaments. J. Electrochem. Soc. 2020, 167, 7.

- Zhang, Y.; Ji, T.; Hou, S.; Zhang, L.; Shi, Y.; Zhao, J.; Xu, X. All-printed solid-state substrate-versatile and high-performance micro-supercapacitors for in situ fabricated transferable and wearable energy storage via multi-material 3D printing. J. Power Sources 2018, 403, 109–117. [Google Scholar] [CrossRef]

- Areir, M.; Xu, Y.; Harrison, D.; Fyson, J. 3D printing of highly flexible supercapacitor designed for wearable energy storage. Mater. Sci. Eng. B 2017, 226, 29–38. [Google Scholar] [CrossRef]

- Khorsandi, D.; Fahimipour, A.; Abasian, P.; Saber, S.S.; Seyedi, M.; Ghanavati, S.; Ahmad, A.; De Stephanis, A.A.; Taghavinezhaddilami, F.; Leonova, A.; et al. 3D and 4D printing in dentistry and maxillofacial surgery: Printing techniques, materials, and applications. Acta Biomater. 2020, 122, 26–49. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Awad, A.; Robles-Martinez, P.; Gaisford, S.; Goyanes, A.; Basit, A.W. Vat photopolymerization 3D printing for advanced drug delivery and medical device applications. J. Control. Release 2020, 329, 743–757. [Google Scholar] [CrossRef] [PubMed]

- Werz, S.M.; Zeichner, S.J.; Berg, B.-I.; Zeilhofer, H.-F.; Thieringer, F. 3D Printed Surgical Simulation Models as educational tool by maxillofacial surgeons. Eur. J. Dent. Educ. 2018, 22, e500–e505. [Google Scholar] [CrossRef]

- Shon, H.C.; Bang, J.-Y.; Lee, Y.; Koh, K.H.; Kim, J.W. Optimal plate position in minimally invasive plate osteosynthesis for mid-shaft clavicle fractures: Simulation using 3D-printed models of actual clinical cases. Eur. J. Trauma Emerg. Surg. 2020, 47, 1411–1416. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Tawk, C.; Alici, G. A 3D Printed Soft Prosthetic Hand with Embedded Actuation and Soft Sensing Capabilities for Directly and Seamlessly Switching Between Various Hand Gestures. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Delft, The Netherlands, 12–16 July 2021; pp. 75–80. [Google Scholar] [CrossRef]

- Beheshtizadeh, N.; Lotfibakhshaiesh, N.; Pazhouhnia, Z.; Hoseinpour, M.; Nafari, M. A review of 3D bio-printing for bone and skin tissue engineering: A commercial approach. J. Mater. Sci. 2019, 55, 3729–3749. [Google Scholar] [CrossRef]

- Ning, L.; Chen, X.; Ning, L. A brief review of extrusion-based tissue scaffold bio-printing. Biotechnol. J. 2017, 12. [Google Scholar] [CrossRef]

- Mercado-Pagán, E.; Stahl, A.M.; Shanjani, Y.; Yang, Y. Vascularization in Bone Tissue Engineering Constructs. Ann. Biomed. Eng. 2015, 43, 718–729. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guddati, S.; Kiran, A.S.K.; Leavy, M.; Ramakrishna, S. Recent advancements in additive manufacturing technologies for porous material applications. Int. J. Adv. Manuf. Technol. 2019, 105, 193–215. [Google Scholar] [CrossRef]

- Almetwally, A.G.; Jabbari, H. 3D-Printing Replication of Porous Media for Lab-Scale Characterization Research. ACS Omega 2021, 6, 2655–2664. [Google Scholar] [CrossRef]

- Ozelim, L.C.D.S.M.; Cavalcante, A.L.B. Combining Microtomography, 3D Printing, and Numerical Simulations to Study Scale Effects on the Permeability of Porous Media. Int. J. Géoméch. 2019, 19, 04018194. [Google Scholar] [CrossRef]

- Suzuki, A.; Watanabe, N.; Li, K.; Horne, R.N. Fracture network created by 3-D printer and its validation using CT images. Water Resour. Res. 2017, 53, 6330–6339. [Google Scholar] [CrossRef]

- Bacher, M.; Schwen, A.; Koestel, J. Three-Dimensional Printing of Macropore Networks of an Undisturbed Soil Sample. Vadose Zone J. 2015, 14. [Google Scholar] [CrossRef]

- Ferro, N.D.; Morari, F. From Real Soils to 3D-Printed Soils: Reproduction of Complex Pore Network at the Real Size in a Silty-Loam Soil. Soil Sci. Soc. Am. J. 2015, 79, 1008–1017. [Google Scholar] [CrossRef]

- Anjikar, I.S.; Wales, S.; Beckingham, L.E. Fused Filament Fabrication 3-D Printing of Reactive Porous Media. Geophys. Res. Lett. 2020, 47. [Google Scholar] [CrossRef]

- Ishutov, S.; Hasiuk, F.; Harding, C.; Gray, J.N. 3D printing sandstone porosity models. Interpretation 2015, 3, SX49–SX61. [Google Scholar] [CrossRef]

- Goral, J.; Deo, M. Nanofabrication of synthetic nanoporous geomaterials: From nanoscale-resolution 3D imaging to nano-3D-printed digital (shale) rock. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Garum, M.; Glover, P.W.J.; Lorinczi, P.; Scott, G.; Hassanpour, A. Ultrahigh-Resolution 3D Imaging for Quantifying the Pore Nanostructure of Shale and Predicting Gas Transport. Energy Fuels 2020, 35, 702–717. [Google Scholar] [CrossRef]

- Almetwally, A.; Jabbari, H. Experimental investigation of 3D printed rock samples replicas. J. Nat. Gas Sci. Eng. 2020, 76, 103192. [Google Scholar] [CrossRef]

- Ishutov, S.; Hasiuk, F.J.; Jobe, D.; Agar, S. Using Resin-Based 3D Printing to Build Geometrically Accurate Proxies of Porous Sedimentary Rocks. Groundwater 2017, 56, 482–490. [Google Scholar] [CrossRef]

- Song, R.; Wang, Y.; Sun, S.; Liu, J. Characterization and microfabrication of natural porous rocks: From micro-CT imaging and digital rock modelling to micro-3D-printed rock analogs. J. Pet. Sci. Eng. 2021, 205, 108827. [Google Scholar] [CrossRef]

- Kong, L.; Ostadhassan, M.; Hou, X.; Mann, M.; Li, C. Microstructure characteristics and fractal analysis of 3D-printed sandstone using micro-CT and SEM-EDS. J. Pet. Sci. Eng. 2019, 175, 1039–1048. [Google Scholar] [CrossRef]

- Head, D.; Vanorio, T. Effects of changes in rock microstructures on permeability: 3-D printing investigation. Geophys. Res. Lett. 2016, 43, 7494–7502. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.; Zhao, G.-F. A Preliminary Study of 3D Printing on Rock Mechanics. Rock Mech. Rock Eng. 2014, 48, 1041–1050. [Google Scholar] [CrossRef]

- Jiang, Q.; Feng, X.; Song, L.; Gong, Y.; Zheng, H.; Cui, J. Modeling rock specimens through 3D printing: Tentative experiments and prospects. Acta Mech. Sin. 2015, 32, 101–111. [Google Scholar] [CrossRef]

- Hodder, K.J.; Nychka, J.A.; Chalaturnyk, R.J. Process limitations of 3D printing model rock. Prog. Addit. Manuf. 2018, 3, 173–182. [Google Scholar] [CrossRef]

| Paper | Materials | Process | Structure | Parameters | Mechanical Properties | Application | Comments |

|---|---|---|---|---|---|---|---|

| Patel et al., 2017 [85] | Photocurable elastomer resin | DLP | 3-legs gripper | 70 °C bath, 385 nm; 10 s/ layer | E = 4.21 MPa ε = 1100% | Pneumatic actuator | DLP-printed elastomer has good potential in sealed hollow structures |

| Cheng et al., 2019 [84] | Low-viscosity hydrogel | DIW | 4-channel tentacle | η = 50 Pa·S at 0.01 s−1 | E = 59.6 KPa Toughness = 424.6 KJ·m−3 | Hydraulic actuator | Hydrogels with abundant functionalities facilitate the free design of soft robotics |

| Wang et al., 2021 [87] | Dielectric elastomer | DIW | Jellyfish | 216 Pa·S at 0.01 s−1 | E = 26.4 KPa Strength = 235.8 KPa | Electrically responsive gel actuator | 3D-printed dielectric elastomer can actuate rapidly but requires high voltage |

| Kokkinis et al., 2015 [92] | Polymer-alumina composites | MM-3D a | Cuboids | 1.15 Pa·S | E = 7 MPa ε = 150% | Magnetic actuator | MM-3D allows designing composites |

| Odent et al., 2019 [93] | Photocurable hydrogel resin | SLA | Gradient-like structures | 3 s/layer (100 μm); 405 nm | - | Temperature- responsive actuator | 3D-printed gradient structures have various volume expansion properties |

| Zhou et al., 2019 [94] | Dielectric elastomer | FFF | 4-leg soft gripper | 230° nozzle temperature, 100% filling density | Toughness = 440 J/m2 | Dielectric elastomer soft actuator | FFF aids the combination of multi-layer structures without using adhesives |

| Wang et al., 2018 [95] | Graphene/PDMS b composites | DIW | Grid/triangular porous/hexagonal porous structures | η = 10,000 Pa·S at 0.01 s−1 | - | Strain/temperature sensor | 3D printing facilitates the design of complex structures of composites |

| Kalsoom et al., 2020 [96] | Polymer–particles–salt composites | FFF | Filaments | 245 °C extrusion temperature; 0.8 mm nozzle | - | Humidity sensor | FFF facilitates composite sensors without additional electrode layers |

| Mu et al., 2017 [97] | Photocurable resin–carbon source composites | DLP | Hollow structure truss | η = 11.5 Pa·S at 1 s−1; 40 s/layer (19.05 μm) | E = 10 MPa ε = 10% | Strain sensor | DLP optimized electrical performance by printing complex structures |

| Shen et al., 2018 [98] | Metal oxide and quantum dots | DIW | Symmetric arrays | >104 Pa·S at 10 s−1 | - | Micro-supercapacitors | Low-cost and efficient 3D printing optimized the process of building multilayer supercapacitors |

| Park et al., 2018 [99] | Photocurable resin and nanowires | DLP | Porous symmetric arrays | 405 nm; 30 μm per layer; η = 1.3 Pa·S | - | Micro-supercapacitors | DLP helps achieve low electrical resistance by designing structural octet effect |

| McOwen et al., 2018 [100] | Ink (ceramic powder and polymer binder) | DIW | Symmetric arrays | η = 1500 cP | - | Solid-state lithium-ion batteries | Modification of ink formulations optimizes the solid-state electrolyte structure, enhancing electrochemical properties |

| He et al., 2020 [101] | Photocurable resins with ionic liquid | SLA | Growth rings | 355 nm UV (10 W cm−2) | - | Solid-state lithium-metal batteries | 3D-printed growth rings increase the specific area, loading more active materials. |

| Ayan et al., 2020 [102] | Electrocytes with mouse fibroblast cell line | Hybrid bioprinting | Heterogeneous pyramid with spheroids | 250 μm nozzles | - | Precise positioning of biologics | Bioprinting aids study of tissue–tissue, tissue–material interactions and realize bottom-up assembly |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shinde, V.V.; Wang, Y.; Salek, M.F.; Auad, M.L.; Beckingham, L.E.; Beckingham, B.S. Material Design for Enhancing Properties of 3D Printed Polymer Composites for Target Applications. Technologies 2022, 10, 45. https://doi.org/10.3390/technologies10020045

Shinde VV, Wang Y, Salek MF, Auad ML, Beckingham LE, Beckingham BS. Material Design for Enhancing Properties of 3D Printed Polymer Composites for Target Applications. Technologies. 2022; 10(2):45. https://doi.org/10.3390/technologies10020045

Chicago/Turabian StyleShinde, Vinita V., Yuyang Wang, Md Fahim Salek, Maria L. Auad, Lauren E. Beckingham, and Bryan S. Beckingham. 2022. "Material Design for Enhancing Properties of 3D Printed Polymer Composites for Target Applications" Technologies 10, no. 2: 45. https://doi.org/10.3390/technologies10020045

APA StyleShinde, V. V., Wang, Y., Salek, M. F., Auad, M. L., Beckingham, L. E., & Beckingham, B. S. (2022). Material Design for Enhancing Properties of 3D Printed Polymer Composites for Target Applications. Technologies, 10(2), 45. https://doi.org/10.3390/technologies10020045