Active Fault-Tolerant Control for Quadrotor UAV against Sensor Fault Diagnosed by the Auto Sequential Random Forest

Abstract

:1. Introduction

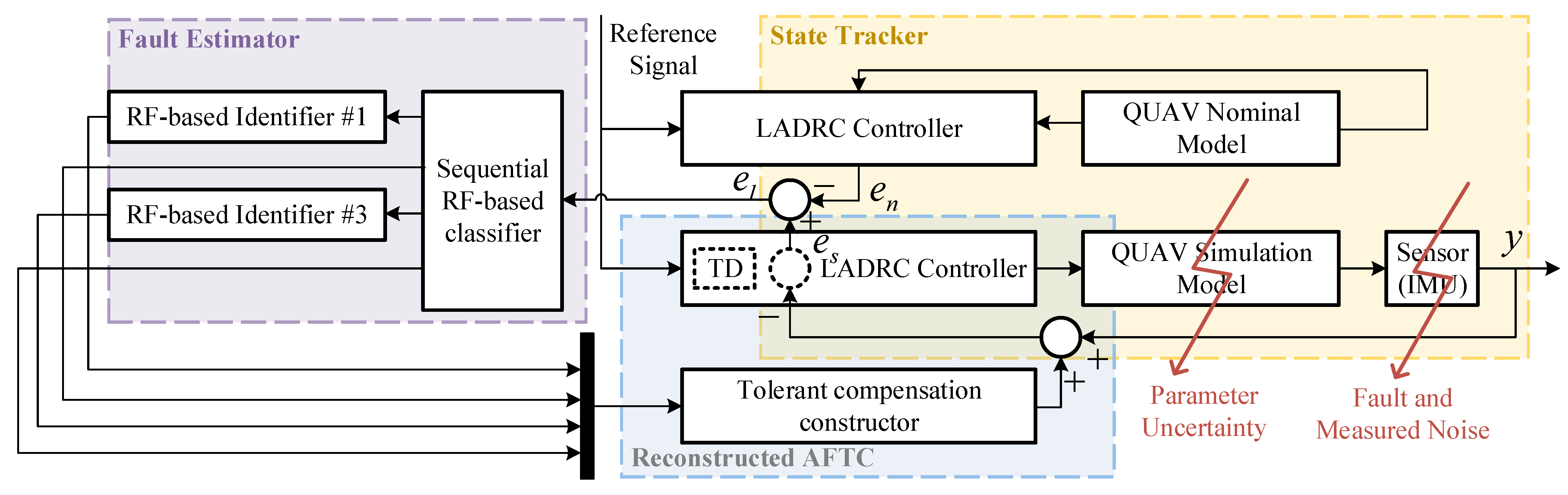

- A precise state tracker based on the linear extended state observer (LESO) and reference model is proposed, which can avoid the influence of maneuver changes, where the LESO ensures that the observed residual is within the noise level (under no-fault condition). The reference model makes the residual follow the transient changes, so as to eliminate the LESO delay effect caused by slow tracking.

- Trained simply by a small amount of data, an precise fault estimator is designed. The auto sequential RF algorithm is proposed to realize real-time adaptive sensor fault diagnosis based on multi-sample, and the improved sparrow search algorithm (LSSA) is used for performing autonomous hyperparameter optimization.

- A high-performance AFTC approach combines the active compensation control strategy and the ADRC-based PFTC strategy is proposed for fault-tolerant control. Among them, the novel fault diagnosis algorithm provides the necessary fault information for the active compensation control strategy.

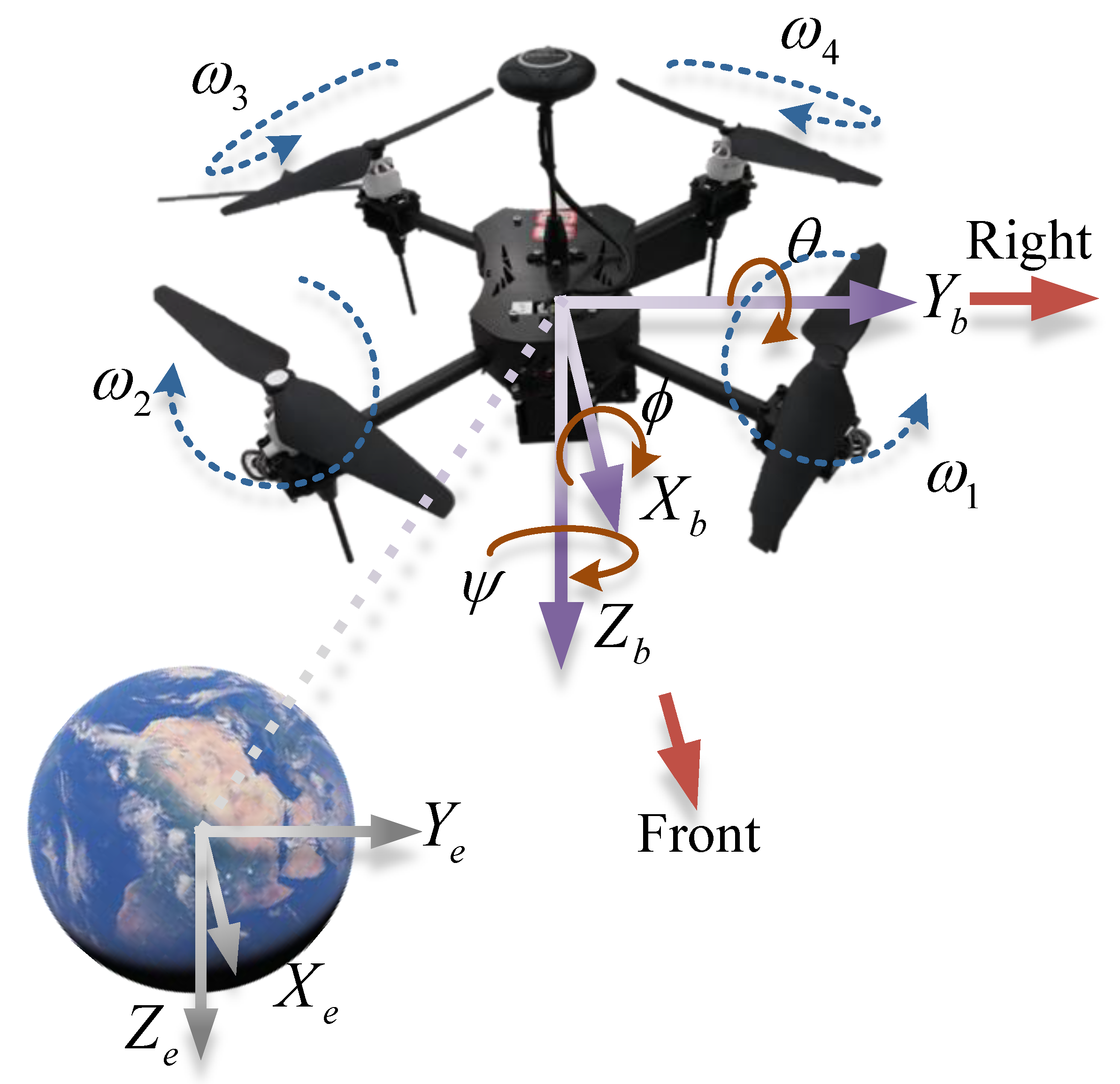

2. Mathematical Modeling of QUAV with Sensor Fault

2.1. Modeling of the QUAV System

2.2. Problem Formulation

2.2.1. Quadrotor Attitude Passive Controller Modeling

2.2.2. Sensor Fault Description

Hard-Over Fault

Stuck Fault

Slow-Varying Fault

Outlier-Data Fault

3. LADRC-Based Active-Tolerant Control Strategy

3.1. Semi-Model-Dependent LESO State Tracker

3.2. Model-Free Intelligent Fault Estimator

3.2.1. Data Acquisition

3.2.2. Parameter Optimization Based on the Improved Sparrow Search Algorithm

3.2.3. Fault Isolation and Identification Based on the Auto Sequential RF

- If , the test is terminated and the system is ruled normal, where and are the false negative rate and false positive rate, respectively.

- If , the test is terminated and the k-th fault is justified to occur the system.

- If , then the system is determined of the same state as the previous, and next sampling sample is waited to test.

| Algorithm 1 The auto sequential RF-based online fault isolation procedure |

Obtain the online test set after the feature extraction; Given the sampling time , intercept gap , false negative rate , false positive rate ; Input: The online test set Output: Fault type Initialization: The sequential probability ratio statistic , final type , justified result .

|

3.3. Reconfigurable Tolerant Compensation Constructor

4. Simulation Results

4.1. State Tracking Tests

4.2. Performance Metrics

4.3. Fault Estimation Tests

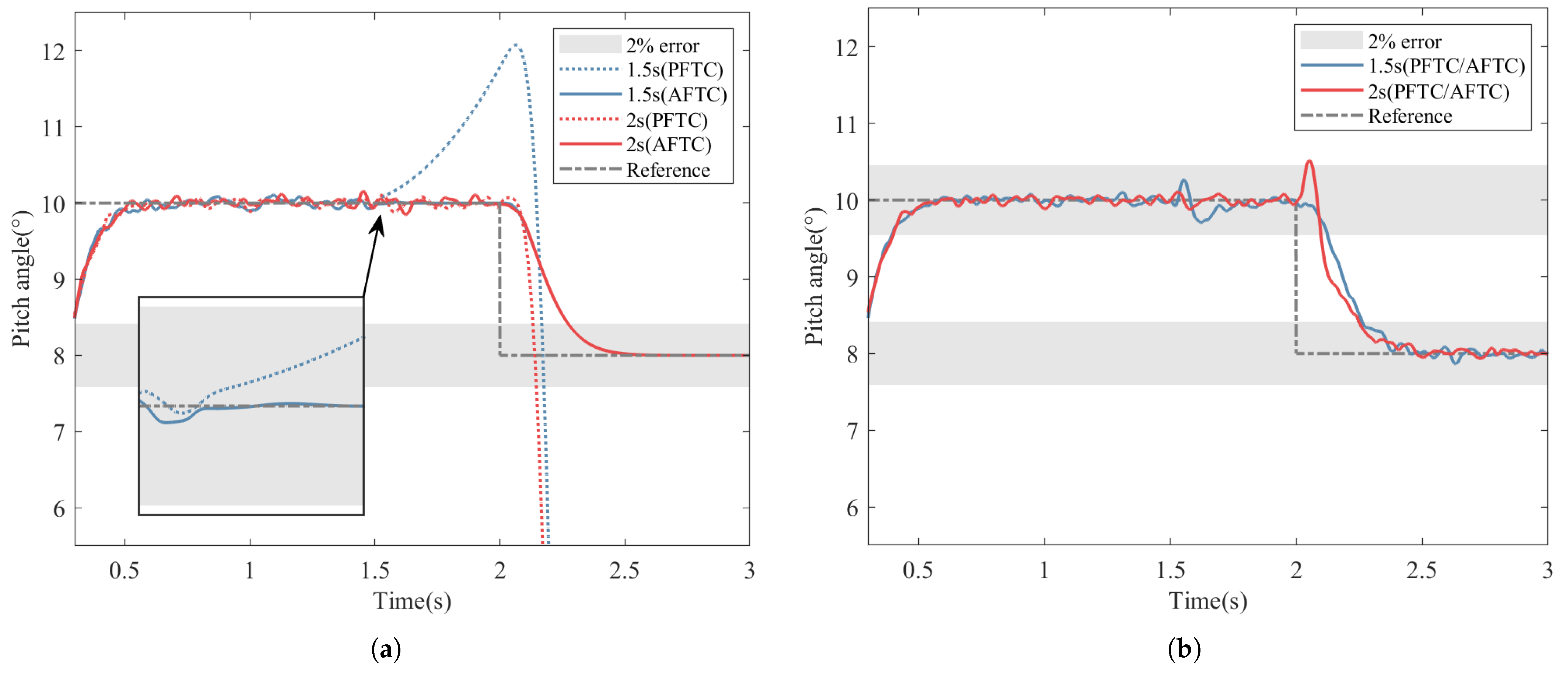

4.4. Fault-Tolerant Control Tests

5. Conclusions

- A semi-model-dependent state tracker is obtained by innovatively combining the LESO with reference model. The slow-tracking problem is solved, that residual signal changes are easily confounded when faults occur and reference signal changes.

- Based on the accurate classification and prediction of the RF, an adaptive real-time fault diagnosis for the multi-sample data is achieved. To autonomously construct the fault estimator, the LSSA optimization achieves high speed and accuracy.

- The control effect is verified by experiments using the high fidelity simulation model. The results show that the proposed ADRC-based AFTC method can track the desired attitude signal precisely and quickly, and that performance requirements are met.

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Walter, C.A.; Braun, A.; Fotopoulos, G. Impact of three-dimensional attitude variations of an unmanned aerial vehicle magnetometry system on magnetic data quality. Geophys. Prospect. 2019, 67, 465–479. [Google Scholar] [CrossRef]

- Wang, Z.X.; Zhao, J.; Cai, Z.H.; Wang, Y.X.; Liu, N.J. Onboard actuator model-based Incremental Nonlinear Dyn.amic Inversion for quadrotor attitude control: Method and application. Chin. J. Aeronaut. 2021, 34, 216–227. [Google Scholar] [CrossRef]

- Yu, Z.Q.; Zhang, Y.M.; Jiang, B.; Fu, J.; Jin, Y. A review on fault-tolerant cooperative control of multiple unmanned aerial vehicles. Chin. J. Aeronaut. 2021, 35, 1–18. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, H.; Jiang, B. Fault-tolerant control for a class of linear interconnected hyperbolic systems by boundary feedback. J. Frankl. Inst. 2019, 356, 5630–5651. [Google Scholar] [CrossRef]

- Nguyen, N.P.; Xuan Mung, N.; Ha, L.N.N.T.; Hong, S.K. Fault-Tolerant Control for Hexacopter UAV Using Adaptive Algorithm with Severe Faults. Aerospace 2022, 9, 304. [Google Scholar] [CrossRef]

- Zou, Y.; Xia, K. Robust Fault-Tolerant Control for Underactuated Takeoff and Landing UAVs. IEEE Trans. Aerosp. Electron. Syst. 2020, 56, 3545–3555. [Google Scholar] [CrossRef]

- Rudin, K.; Ducard, G.J.; Siegwart, R.Y. Active fault-tolerant control with imperfect fault detection information: Applications to UAVs. IEEE Trans. Aerosp. Electron. Syst. 2019, 56, 2792–2805. [Google Scholar] [CrossRef]

- Abbaspour, A.; Yen, K.K.; Forouzannezhad, P.; Sargolzaei, A. A Neural Adaptive Approach for Active Fault-Tolerant Control Design in UAV. IEEE Trans. Syst. Man Cybern. Syst. 2020, 50, 3401–3411. [Google Scholar] [CrossRef]

- Zeghlache, S.; Mekki, H.; Bouguerra, A.; Djerioui, A. Actuator fault tolerant control using adaptive RBFNN fuzzy sliding mode controller for coaxial octorotor UAV. ISA Trans. 2018, 80, 267–278. [Google Scholar] [CrossRef]

- Nguyen, N.P.; Hong, S.K. Fault diagnosis and fault-tolerant control scheme for quadcopter UAVs with a total loss of actuator. Energies 2019, 12, 1139. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.Q.; Dong, C.Y.; Ran, M.P.; Liu, Y. Fully distributed time-varying formation tracking control for multiple quadrotor vehicles via finite-time convergent extended state observer. Chin. J. Aeronaut. 2020, 33, 2907–2920. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Rizzoni, G.; Cordoba-Arenas, A.; Amodio, A.; Aksun-Guvenc, B. Model-based diagnosis and fault tolerant control for ensuring torque functional safety of pedal-by-wire systems. Control Eng. Pract. 2017, 61, 255–269. [Google Scholar] [CrossRef]

- Kang, J.; Xiong, Z.; Wang, R.; Zhang, L. Multi-Layer Fault-Tolerant Robust Filter for Integrated Navigation in Launch Inertial Coordinate System. Aerospace 2022, 9, 282. [Google Scholar] [CrossRef]

- Yu, P.; Cao, J.; Jegatheesan, V.; Shu, L. Activated sludge process faults diagnosis based on an improved particle filter algorithm. Process Saf. Environ. Protect. 2019, 127, 66–72. [Google Scholar] [CrossRef]

- Yan, K.; Chen, M.; Jiang, B.; Wu, Q.X. Robust adaptive active fault-tolerant control of UAH with unknown disturbances and actuator faults. Int. J. Adapt. Control Signal Process. 2019, 33, 684–711. [Google Scholar] [CrossRef]

- Zhu, Q.Y.; Li, Z.Y.; Tan, X.T.; Xie, D.B.; Dai, W. Sensors fault diagnosis and active fault-tolerant control for PMSM drive systems based on a composite sliding mode observer. Energies 2019, 12, 1695. [Google Scholar] [CrossRef]

- Shao, X.L.; Liu, J.; Cao, H.L.; Shen, C.; Wang, H.L. Robust dynamic surface trajectory tracking control for a quadrotor UAV via extended state observer. Int. J. Robust Nonlinear Control 2018, 28, 2700–2719. [Google Scholar] [CrossRef]

- Meng, Q.; Hou, Z.S. Active Disturbance Rejection Based Repetitive Learning Control With Applications in Power Inverters. IEEE Trans. Control Syst. Technol. 2020, 29, 2038–2048. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Cao, D.; Yang, J.; Wang, H.M. High-order sliding mode observer-based trajectory tracking control for a quadrotor UAV with uncertain dynamics. Nonlinear Dyn. 2020, 102, 2583–2596. [Google Scholar] [CrossRef]

- Xu, Q.Z.; Wang, Z.S.; Zhen, Z.Y. Information fusion estimation-based path following control of quadrotor UAVs subjected to Gaussian random disturbance. ISA Trans. 2020, 99, 84–94. [Google Scholar] [CrossRef]

- Zhou, L.S.; Ma, L.L.; Wang, J.Z. Fault tolerant control for a class of nonlinear system based on active disturbance rejection control and rbf neural networks. In Proceedings of the 36th Chinese Control Conference, Dalian, China, 26–28 July 2017; pp. 7321–7326. [Google Scholar]

- Amin, A.A.; Mahmood-ul Hasan, K. Robust active fault-tolerant control for internal combustion gas engine for air–fuel ratio control with statistical regression-based observer model. Meas. Control 2019, 52, 1179–1194. [Google Scholar] [CrossRef]

- Ijaz, S.; Yan, L.; Hamayun, M.T.; Shi, C. Active fault tolerant control scheme for aircraft with dissimilar redundant actuation system subject to hydraulic failure. J. Frankl. Inst. 2019, 356, 1302–1332. [Google Scholar] [CrossRef]

- Al Younes, Y.; Noura, H.; Rabhi, A.; El Hajjaji, A. Actuator fault-diagnosis and fault-tolerant-control using intelligent-output-estimator applied on quadrotor uav. In Proceedings of the 2019 International Conference on Unmanned Aircraft Systems, Atlanta, GA, USA, 11–14 June 2019; pp. 413–420. [Google Scholar]

- Zhong, Y.J.; Liu, Z.X.; Zhang, Y.M.; Zhang, W.; Zuo, J.Y. Active fault-tolerant tracking control of a quadrotor with model uncertainties and actuator faults. Front. Inform. Technol. Elect. Eng. 2019, 20, 95–106. [Google Scholar] [CrossRef]

- Wang, B.; Shen, Y.Y.; Zhang, Y.M. Active fault-tolerant control for a quadrotor helicopter against actuator faults and model uncertainties. Aerosp. Sci. Technol. 2020, 99, 105745. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, K.; Wang, Y.; Luo, K.J.L.; Fu, H.Y.; Si, L. Online condition diagnosis for a two-stage gearbox machinery of an aerospace utilization system using an ensemble multi-fault features indexing approach. Chin. J. Aeronaut. 2019, 32, 1100–1110. [Google Scholar] [CrossRef]

- Gao, K.; Song, J.; Wang, X.; Li, H. Fractional-order proportional-integral-derivative linear active disturbance rejection control design and parameter optimization for hypersonic vehicles with actuator faults. Tsinghua Sci. Technol. 2020, 26, 9–23. [Google Scholar] [CrossRef]

- Liu, C.Q.; Luo, G.Z.; Chen, Z.; Tu, W.C.; Qiu, C. A linear ADRC-based robust high-dynamic double-loop servo system for aircraft electro-mechanical actuators. Chin. J. Aeronaut. 2019, 32, 2174–2187. [Google Scholar] [CrossRef]

- Gao, K.; Song, J.; Yang, E. Stability analysis of the high-order nonlinear extended state observers for a class of nonlinear control systems. Trans. Inst. Meas. Control 2019, 41, 4370–4379. [Google Scholar] [CrossRef]

- Zhao, K.; Song, J.; Hu, Y.; Xu, X.; Liu, Y. Deep Deterministic Policy Gradient-Based Active Disturbance Rejection Controller for Quad-Rotor UAVs. Mathematics 2022, 10, 2686. [Google Scholar] [CrossRef]

- Tan, J.; Fan, Y.; Yan, P.; Wang, C.; Feng, H. Sliding mode fault tolerant control for unmanned aerial vehicle with sensor and actuator faults. Sensors 2019, 19, 643. [Google Scholar] [CrossRef] [Green Version]

- Ai, S.J.; Song, J.; Cai, G.B. Diagnosis of Sensor Faults in Hypersonic Vehicles Using Wavelet Packet Translation Based Support Vector Regressive Classifier. IEEE Trans. Reliab. 2021, 70, 901–915. [Google Scholar] [CrossRef]

- Xue, J.K.; Shen, B. A novel swarm intelligence optimization approach: sparrow search algorithm. Syst. Sci. Control Eng. 2020, 8, 22–34. [Google Scholar] [CrossRef]

- Li, X.Q.; Jiang, H.K.; Niu, M.G.; Wang, R.X. An enhanced selective ensemble deep learning method for rolling bearing fault diagnosis with beetle antennae search algorithm. Mech. Syst. Signal Process. 2020, 142, 106752. [Google Scholar] [CrossRef]

- Pathak, Y.; Arya, K.; Tiwari, S. Feature selection for image steganalysis using levy flight-based grey wolf optimization. Multimed. Tools Appl. 2019, 78, 1473–1494. [Google Scholar] [CrossRef]

- Guo, P.; Infield, D. Wind Turbine Power Curve Modeling and Monitoring With Gaussian Process and SPRT. IEEE Trans. Sustain. Energy 2020, 11, 107–115. [Google Scholar] [CrossRef]

- Asadi, D. Model-based Fault Detection and Identification of a Quadrotor with Rotor Fault. Int. J. Aeronaut. Space Sci. 2022, 1–13. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Mass (kg) | m | 1.44 |

| Inertia tensor (kg m2) | ||

| Propeller moment of inertia (kg m2) |

| Model | Fault Size | Data per Class 1 | Parameter Search Space | Attention Coefficient | Optimal Parameters | Error | |||

|---|---|---|---|---|---|---|---|---|---|

| n | m | n | m | ||||||

| The RF classifier | ,, , | 500 | 1 | 0 | 500 | 8 | 0 (OOB error) | ||

| The RF identifier for hard-over fault | 9 | 1 | 136 | 12 | 0.0068 (MSE error) | ||||

| The RF identifier for slow-varying fault | 9 | 1 | 92 | 12 | 0.0004 (MSE error) | ||||

| Fault Type | Fault Size | Accuracy (%) | Hybrid Accuracy (%) |

|---|---|---|---|

| Hard-over fault | 1.275 | 100 | 100 |

| 2 | 100 | ||

| 3 | 100 | ||

| 4 | 100 | ||

| 5 | 100 | ||

| Slow-varying fault | 1.10 | 86.20 | 88.0516 |

| 1.06 | 100 | ||

| 1.04 | 89.20 | ||

| 0.97 | 89.60 | ||

| 0.94 | 100 | ||

| 0.90 | 53.40 |

| Performance Metric | Auto Sequential RF | Contrast | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Normal | Hard-Over | Stuck | Slow-Varying | Outlier-Data | Normal | Hard-Over | Stuck | Slow-Varying | Outlier-Data | |

| FPR(%) | 4.52 | 0 | 0 | 1.87 | 0 | 0.40 | 0 | 6.75 | 4.43 | 0.36 |

| Precision(%) | 84.70 | 100 | 100 | 91.63 | 100 | 98.43 | 100 | 78.73 | 83.37 | 98.44 |

| Recall(%) | 100 | 92.52 | 100 | 81.93 | 100 | 100 | 72.36 | 100 | 88.87 | 91 |

| FNR(%) | 0 | 7.48 | 0 | 18.07 | 0 | 0 | 27.64 | 0 | 11.13 | 9 |

| Method | Fault Size (%) | Accuracy (%) | Time Delay (s) | Fault Probability (%) | Hybrid Accuracy (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Hard-Over | Stuck | Slow-Varying | Outlier-Data | Normal | |||||

| Auto Sequential RF | 1.275 | 62.6 | 0.04 | 62.6 | 0 | 37.4 | 0 | 0 | 99.6 |

| 2 | 100 | 0.02 | 100 | 0 | 0 | 0 | 0 | ||

| 3 | 100 | 0.02 | 100 | 0 | 0 | 0 | 0 | ||

| 4 | 100 | 0.02 | 100 | 0 | 0 | 0 | 0 | ||

| 5 | 100 | 0.02 | 100 | 0 | 0 | 0 | 0 | ||

| Contrast | 1.275 | 0 | 0.1 | 0 | 11.4 | 88.6 | 0 | 0 | 91.8 |

| 2 | 92.8 | 0.1 | 92.8 | 0 | 0 | 7.2 | 0 | ||

| 3 | 86.4 | 0.1 | 86.4 | 13.6 | 0 | 0 | 0 | ||

| 4 | 92.6 | 0.1 | 92.6 | 7.4 | 0 | 0 | 0 | ||

| 5 | 90 | 0.1 | 90 | 10 | 0 | 0 | 0 | ||

| Method | Fault Size | Accuracy (%) | Time Delay (s) | Fault Probability (%) | Hybrid Accuracy (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Hard-Over | Stuck | Slow-Varying | Outlier-Data | Normal | |||||

| Auto Sequential RF | 1.10 | 100 | 0.02 | 0 | 0 | 100 | 0 | 0 | 86.05 |

| 1.06 | 100 | 0.02 | 0 | 0 | 100 | 0 | 0 | ||

| 1.04 | 53.6 | 0.02 | 0 | 0 | 53.6 | 0 | 46.4 | ||

| 0.97 | 38.0 | 0.02 | 0 | 0 | 38.0 | 0 | 62.0 | ||

| 0.94 | 100 | 0.02 | 0 | 0 | 100 | 0 | 0 | ||

| 0.90 | 100 | 0.02 | 0 | 0 | 100 | 0 | 0 | ||

| Contrast | 1.10 | 90.6 | 0.1 | 0 | 9.4 | 90.6 | 0 | 0 | 81.95 |

| 1.06 | 91.4 | 0.1 | 0 | 8.6 | 91.4 | 0 | 0 | ||

| 1.04 | 86.2 | 0.1 | 0 | 7.6 | 86.2 | 0 | 6.2 | ||

| 0.97 | 84.6 | 0.1 | 0 | 12.0 | 84.6 | 0 | 3.4 | ||

| 0.94 | 89.4 | 0.1 | 0 | 10.6 | 89.4 | 0 | 0 | ||

| 0.90 | 91.0 | 0.1 | 0 | 9.0 | 91.0 | 0 | 0 | ||

| Fault Type | Method 1 | Accuracy (%) | Fault Probability (%) | Early Diagnosis (%) | Time Delay (s) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Hard-Over | Stuck | Slow-Varying | Outlier-Data | Normal | |||||

| Stuck | A | 100 | 0 | 100 | 0 | 0 | 0 | 0 | 0.04 |

| B | 94.6 | 0 | 100 | 0 | 0 | 0 | 5.4 | 0.1 | |

| Outlier-data | A | 100 | 0 | 0 | 0 | 100 | 0 | 0 | 0.02 |

| B | 91.0 | 0 | 9.0 | 0 | 91.0 | 0 | 9.0 | 0.1 | |

| Fault Type | Occurrence Time (s) | Fault Size | |

|---|---|---|---|

| Scenario 1 (S1) | Slow-varying | 1.5 | 0.94 |

| Hard-over | 2 | 2 | |

| Scenario 2 (S2) | Slow-varying | 1.5 | 1.06 |

| Hard-over | 2 | 4 | |

| Scenario 3 (S3) | Hard-over | 1.5 | 2 |

| Hard-over | 2 | 4 | |

| Scenario 4 (S4) | Slow-varying | 1.5 | 0.94 |

| Slow-varying | 2 | 0.90 | |

| Scenario 5 (S5) | Hard-over | 1.5 | 4 |

| Stuck | 2 | ||

| Scenario 6 (S6) | Slow-varying | 1.5 | 0.94 |

| Stuck | 2 | ||

| Scenario 7 (S7) | Outlier-data | 1.5 | 40 |

| Stuck | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ai, S.; Song, J.; Cai, G.; Zhao, K. Active Fault-Tolerant Control for Quadrotor UAV against Sensor Fault Diagnosed by the Auto Sequential Random Forest. Aerospace 2022, 9, 518. https://doi.org/10.3390/aerospace9090518

Ai S, Song J, Cai G, Zhao K. Active Fault-Tolerant Control for Quadrotor UAV against Sensor Fault Diagnosed by the Auto Sequential Random Forest. Aerospace. 2022; 9(9):518. https://doi.org/10.3390/aerospace9090518

Chicago/Turabian StyleAi, Shaojie, Jia Song, Guobiao Cai, and Kai Zhao. 2022. "Active Fault-Tolerant Control for Quadrotor UAV against Sensor Fault Diagnosed by the Auto Sequential Random Forest" Aerospace 9, no. 9: 518. https://doi.org/10.3390/aerospace9090518

APA StyleAi, S., Song, J., Cai, G., & Zhao, K. (2022). Active Fault-Tolerant Control for Quadrotor UAV against Sensor Fault Diagnosed by the Auto Sequential Random Forest. Aerospace, 9(9), 518. https://doi.org/10.3390/aerospace9090518