1. Introduction

In order to meet more stringent requirements on fuel consumption and pollution emissions [

1,

2], electrification has increasingly attracted attention across the aeronautical industry. In particular, the tremendous success of electric cars has greatly enhanced public confidence in extensive applications of the electrification concept to aviation, which recently led to the advent of massive electric airplanes. The usages of electrified propulsion architectures enable electric aircraft to achieve zero emissions, additionally lowering the operation costs [

3]. On top of that, electrification also allows innovative concepts of airplanes being infeasible due to some intrinsic limitations of conventional propulsion architectures. Needless to say, the move to more electric propulsion systems would ultimately spark a revolution in the aeronautical industry.

Currently, the development of electric aircraft is mainly focused on short-haul flights. In this category, propellers connected to electric motors have been regarded as the most effective propulsion systems, just as turboprop-driven aircraft widely used in regional airliners. Moreover, the rotational motion of propellers to generate thrust is naturally aligned with electric motors to output power. This has further expanded the popularization of propellers for electric aircraft. Consequently, advanced propeller design has become one of the core technologies to be explored for electric aircraft in order to achieve excellent overall performance.

Among various design factors for an advanced propeller, the low-noise requirement is of great importance. Nowadays the expectations of more comfortable travel and low impacts on ground communities are increased for enter-into-service aircraft, particularly future electric airplanes operating at relatively low altitudes. For a propeller-driven electric aircraft, the propeller noise becomes relatively dominant in the absence of the primary perceived noise from turbomachinery, combustion chamber and high-speed jet existing in conventional gas turbo engines. Apparently, the mitigation of the radiated noise from propellers is the premise to design quieter electric aircraft [

4].

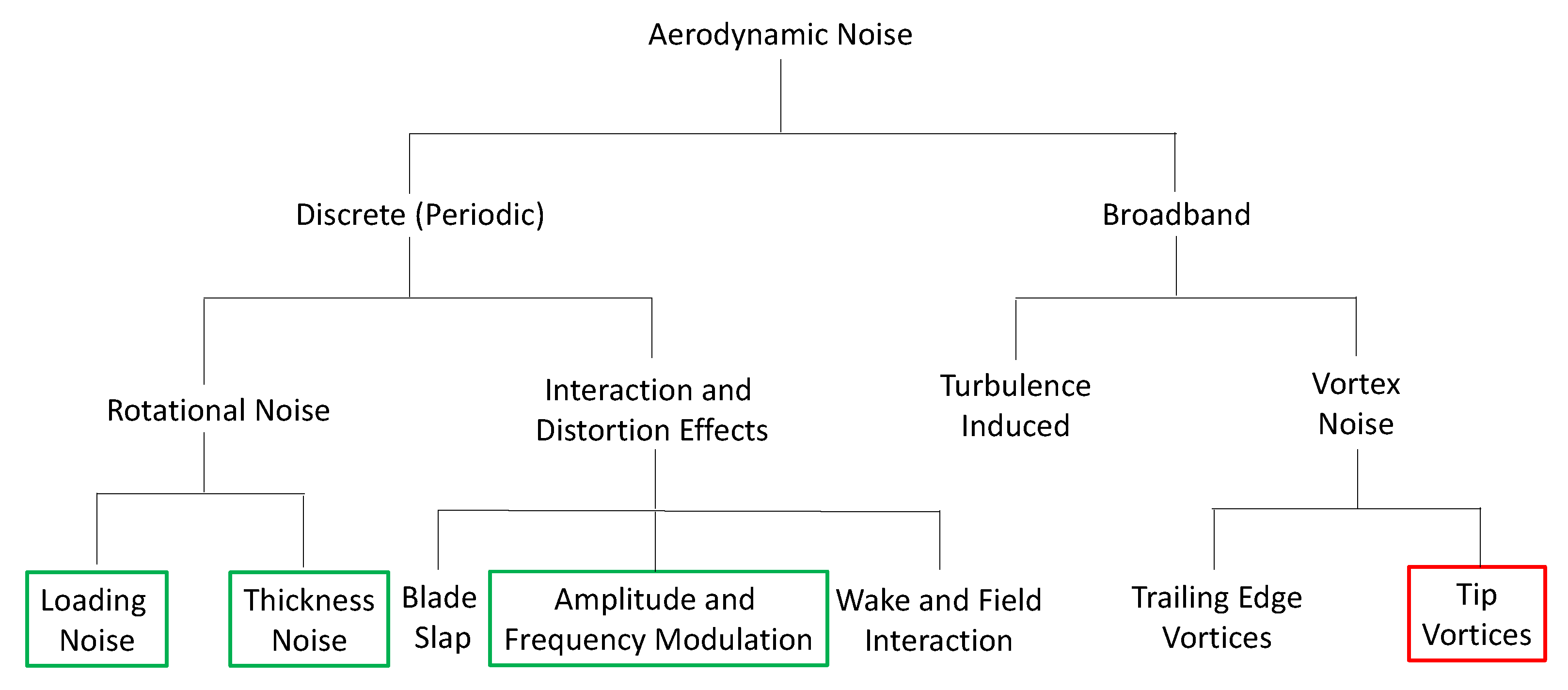

For a classical rotating blade, the associated aerodynamic noise sources can be found in

Figure 1. As can be seen, the overall aerodynamic noise is classified as discrete frequency (tonal) and broadband noise. The tonal noise is mainly associated with periodic aerodynamic loading that is imposed on blade surfaces, whereas the broadband noise is primarily generated from turbulence. The sources of the loading and thickness noise are formulated from surface pressure fluctuations and surface normal velocity [

5,

6]. Although a noticeable part of the loading and thickness noise is tonal, another part is broadband noise, the sources of which are flow separation and turbulence near the blade surface [

4]. Moreover, tip vortices can also generate tonal noise at specific conditions, for example, blade–vortex interaction (BVI) [

7] or gap turbulence and blade interaction [

8]. A dual-blade concept, termed Boxprop was proposed by Richard and Lundbladh [

9] and has recently been studied in terms of its aerodynamics and noise generation [

4]. The dual-blade is designed by joining the tips of two sub-blades. The blade tip of this concept is apparently different from classical single blade tips. On the other hand, the effects of the new tip geometry on the noise generation have not yet been clear in terms of possible differences compared to classical propellers.

The noise generation caused by tip vortices was also found for counter-rotating propellers [

11]. The mechanisms are that tip vortices shed from the blades of the upstream propeller interact with the blades of the downstream propeller and the interaction is essentially the source of the tonal noise. In that study, the effects of the spiral tip vortices were modelled in two ways and the direct modelling of the vortices was found more accurate. In the study of Elson [

12], the tip vortex noise is divided into two parts, namely the pure rotor noise and the interaction noise. Different rotor blade geometries were investigated using the Reynolds-Averaged Navier–Stokes equations (RANS) and Particle Image Velocimetry (PIV). The tip vortex effects were parameterized to analyze the effects on the noise generation.

A major contributor to the helicopter BVI noise is blade-tip vortices [

7]. Based on the vorticity computed using RANS, Zhao et al. modelled the spiral tip vortices using a viscous wake model. The vortices were then treated as noise sources and input into the Ffowcs Williams and Hawkings (FW-H) equation [

5] to predict the noise. More specifically, one of the formulations from the family of the FW-H equation, Formulation 1A of Farassat [

13], was used. It was found that the interaction angle is important in determining the noise intensity and propagation direction.

The spiral blade-tip vortex development was studied for a typical multicopter drone propeller subjected to inflow angles from 0

to 180

[

14]. The isolated propeller has two blades and the diameter is 0.46 m. The numerical methods such as a blade element momentum theoretical approach, free wake method and unsteady RANS were compared to evaluate their accuracy in the aerodynamics evaluation. Moreover, PIV measurements were conducted to validate the numerical results. The effects of the non-axial inflow (the angle above 0

) on the aerodynamics were addressed. A DJI Phantom 2 stock propeller with two blades was modified by notching the trailing edge near the blade tips [

15]. Noise measurements in an anechoic chamber showed that the modified propeller produced similar noise levels in the far field, while a tone at 50 Hz was present due to the notch.

Reduction of propeller tonal noise can be achieved by improving the blade geometric parameters (e.g., chord length and pitch angle distribution), tip speed and blade number, as the forces on the blade surface contributing to the noise generation are adjusted [

10,

16]. Spacing blades asymmetrically in the circumferential direction has been shown to reduce the tonal noise over a wide range of frequencies [

17]. This effect has been confirmed, for example, by experiments [

18]. The blade tip speed determines the optimal spacing angle, according to a theoretical approach and experiments by Dobrzynski [

19]. In recent developments for drone propellers, the noise has been reduced with additional bio-inspired micro structures. In the work by Noda et al. [

20], a serrated Gurney flap consisting of an array of small cylinders was attached onto the blade trailing edge. Inspired by owl feathers, a comb-shaped serrated structure was added to the blade leading edge [

21]. A variety of shapes and geometric parameters of the leading edge serration were discussed by Wei et al. [

22].

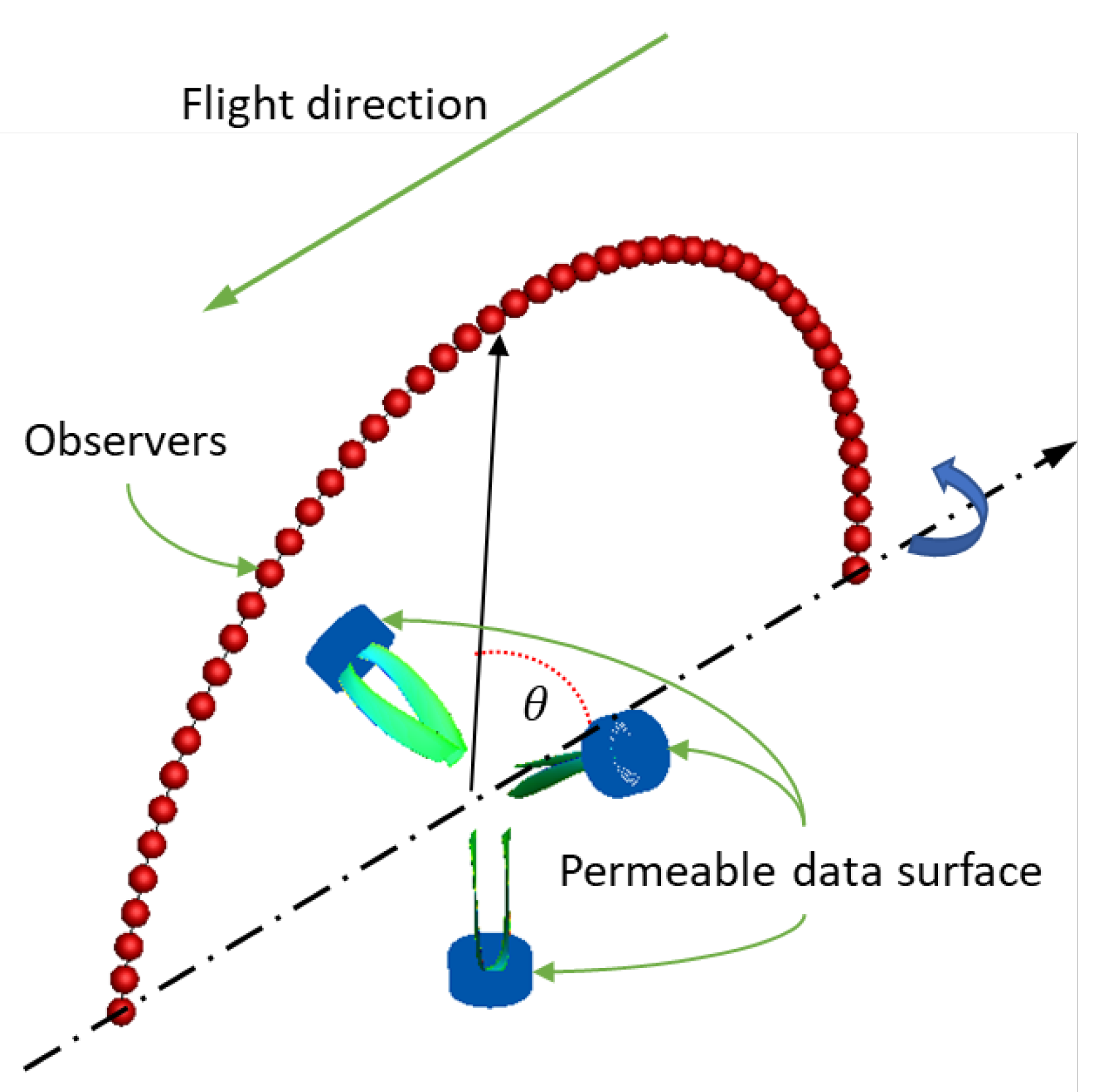

This paper aims at investigating the noise generated from the vortices that are developed at the blade tips of three different propellers for short-range electric aircraft. The analysis will focus on the blade tip geometry and the number of blades, that is, three- and six-blade propellers. The interrelations between tip vortex development and noise generation will be exploited. The aerodynamic performance and noise emission will be addressed with respect to the propeller geometry differences, to understand the trade-off between the aerodynamic benefits and noise mitigation.

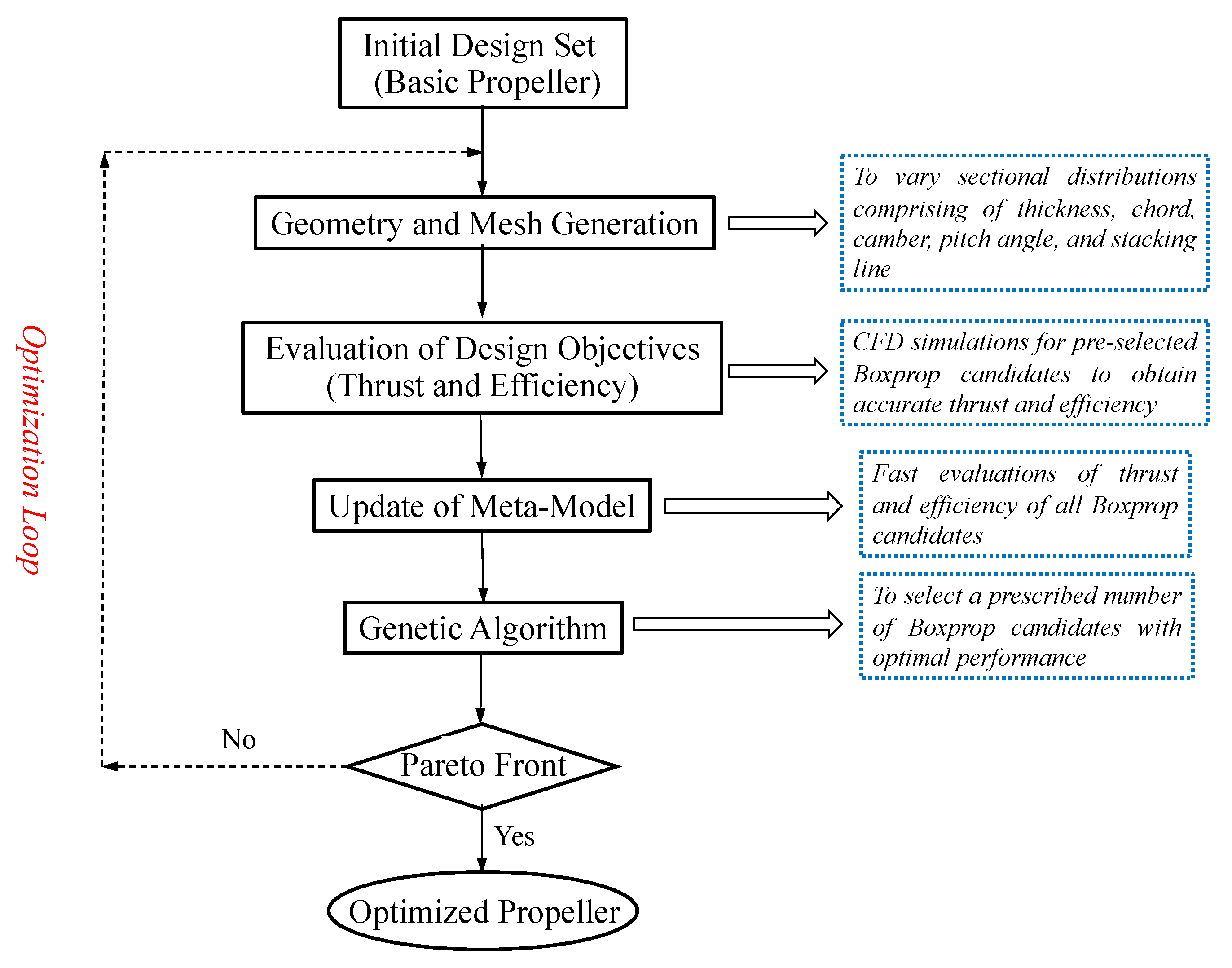

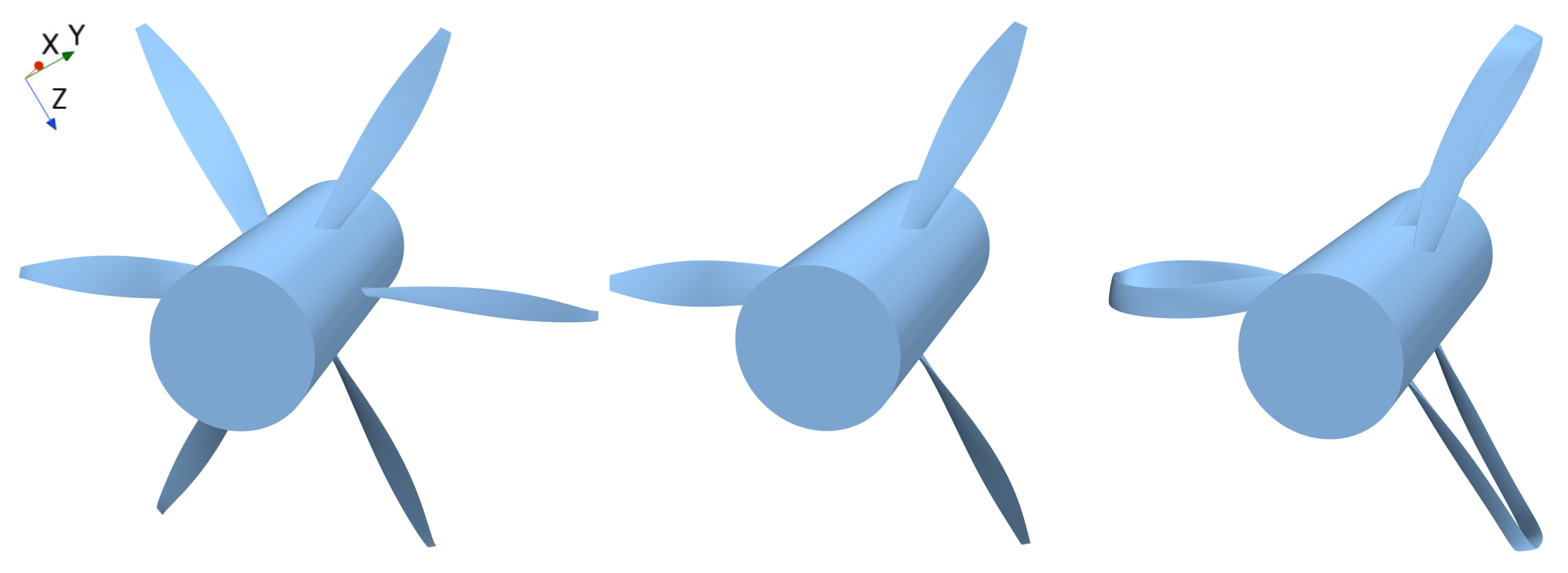

3. Design and Optimization of Propellers

The optimization platform mentioned above is applied to designing the classical propellers with 3 or 6 blades, termed Conprop-3 and Conprop-6 and the conceptual propeller with 3 dual-blades, termed Boxprop. The 3D geometries of these propellers are illustrated in

Figure 3.

Table 1 outlines the primary geometrical and operational parameters that are set to design these propellers. The thrust coefficient is the objective variable of the optimization. To avoid repetition, the elaborate derivation of the thrust coefficient refers to [

4].

To execute the optimization program, the propeller blade geometry needs to be first parameterized. The parameterization is performed in terms of the stacking line and the airfoil geometric parameters.

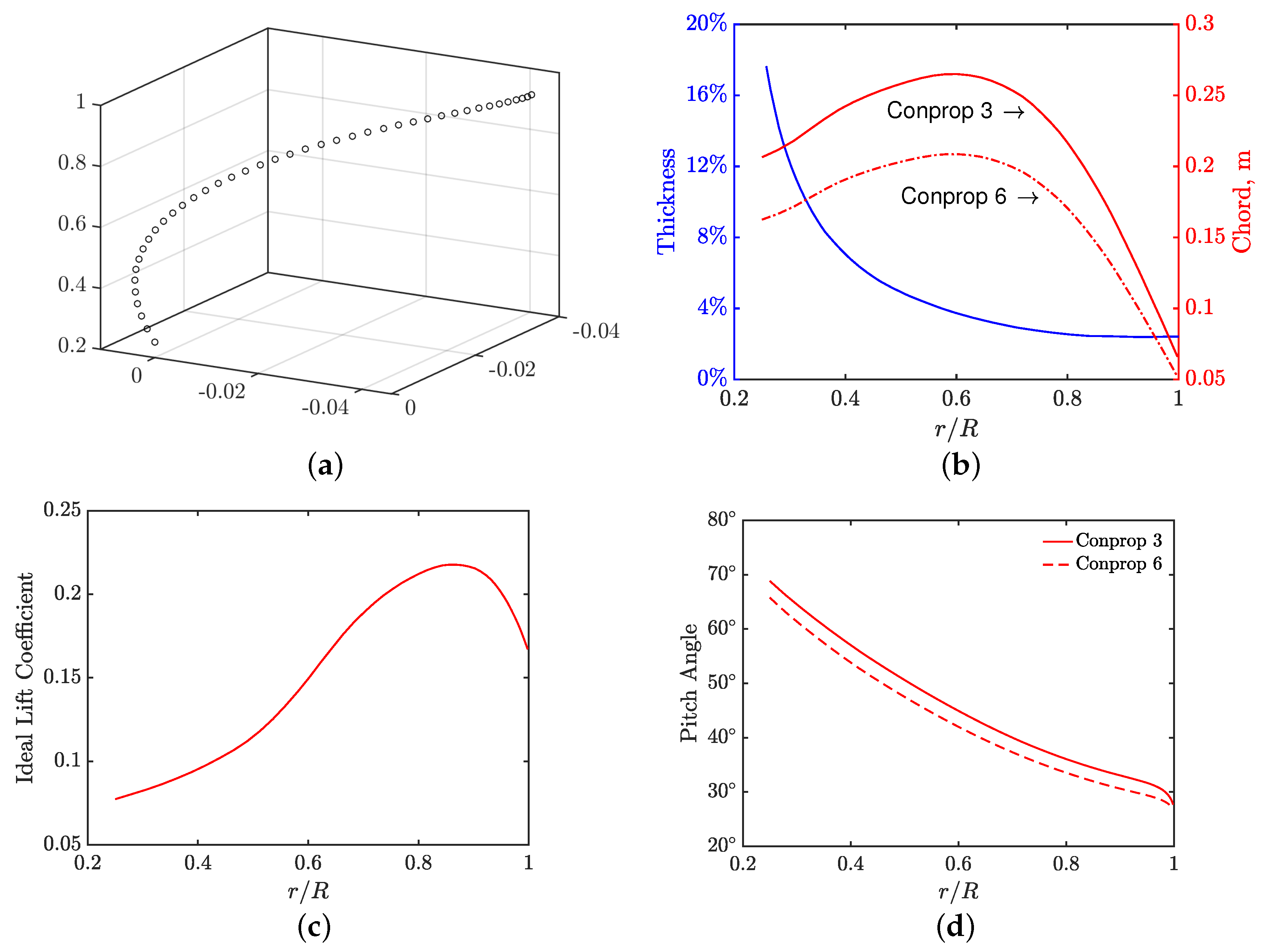

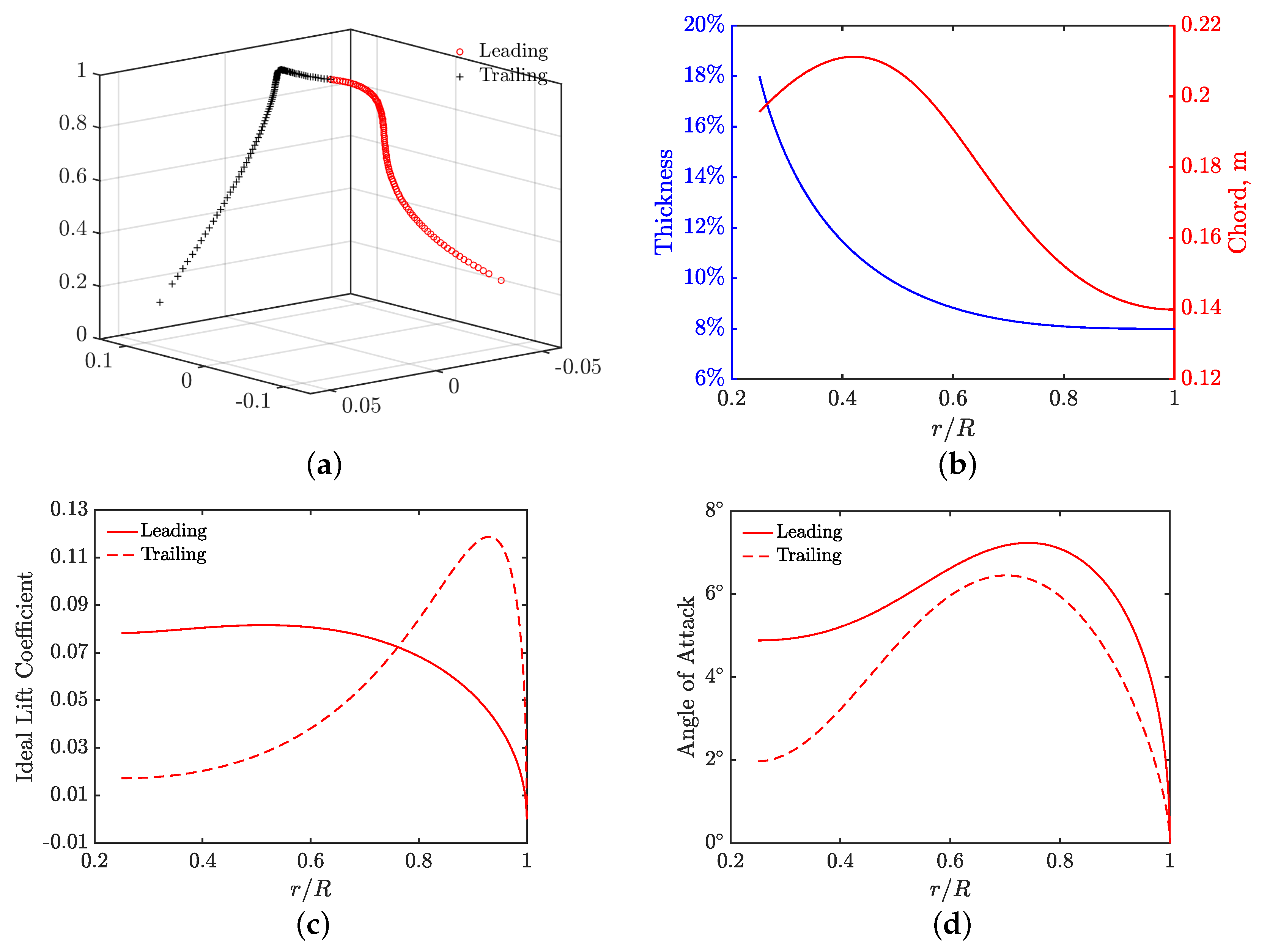

Figure 4 shows the sectional distributions of the parameters for the two classical propellers, Conprop-3 and -6. Here the ideal lift coefficient is defined at the angle of attack with the minimum drag coefficient. The distributions are defined based on Bézier’s curves.

The underlying motivation to choose two classical propellers with 3 and 6 blades is that quantifying the equivalence between the dual-blade and the single blade is not obvious in terms of the number of blades. In fact, a dual-blade is composed of 2 sub-blades with their tips joined. This means that the present Boxprop propeller possessing 3-dual blades contains 6 sub-blades in total. We therefore believe that Boxprop should be assessed in comparison with classical propellers with either 3 or 6 blades. In

Figure 4, the difference of the chord distribution between Conprop-3 and -6 is attributed to the activity factor and mechanical safety. In the initial settings for the propeller generation, the same activity factor is defined for both propellers. However, this leads to a too large chord length distribution for a propeller with 3 blades, which exceeds the limits prescribed to ensure structure mechanical safety. The chord length distribution for the 3-blade propeller is therefore reduced and, meanwhile, the pitch angle distribution is increased to achieve the required thrust (see

Figure 4b). The camber distribution is quantified using the ideal lift coefficient.

Using the same design method for Conprop-3 and -6, the Boxprop blade geometry is also parameterized in terms of the stacking line and sectional airfoil parameters, as shown in

Figure 5. Each dual-blade consists of leading and trailing sub-blades. The stacking lines of the sub-blades are defined with 3D Bézier’s curves. The NACA 16 airfoil is utilized in the sectional geometry. The airfoil parameters are the thickness, chord, camber and angle of attack (AOA). These parameters are represented by 4th-order 2D Bézier curves varying with respect to the radius of the leading or trailing sub-blade. The camber is expressed as the function of the lift coefficient.

Note that in the parameterization of the Boxprop blade, AOA instead of the pitch angle is considered. The pitch angle is the sum of the AOA and helix angle. The helix angle is dependent on the cruise Mach number and rotation speed and presents a linear decrease against the radial distance. Therefore, it is equivalent in the adjustments between the AOA and pitch angle. The parameterization of Conprop-3 and -6 chooses the pitch angle, whereas Boxprop selects the AOA. This difference is inherited from the definition of the initial geometries at the start of the optimization.

It should be added that all the geometrical parameters mentioned above can be chosen as design variables on the optimization platform. However, in the present study, only the pitch angle and AOA have been selected for Conprop-3/6 and Boxprop in consideration of the computational costs and the scope of the present study.

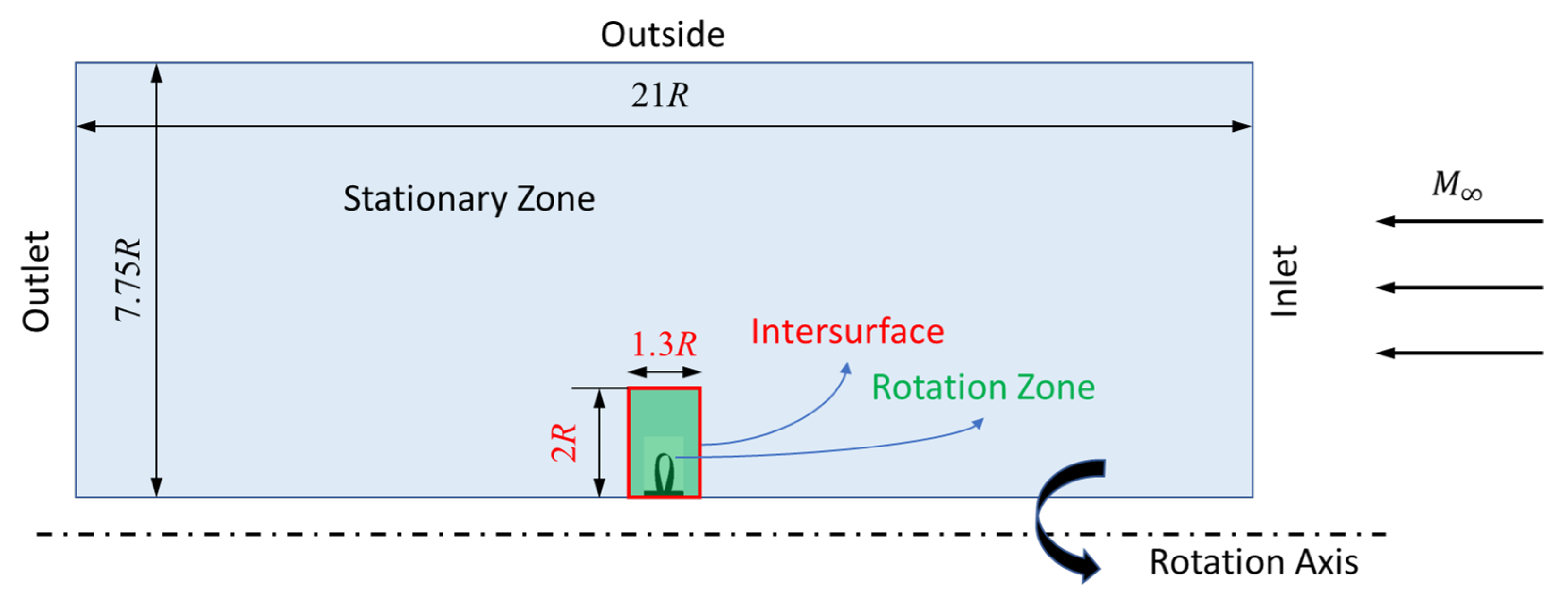

In the process of the optimization, the technique of Multiple Reference Frame (MRF) is employed to perform steady flow simulations using the Reynolds-averaged Navier–Stokes equations (RANS). The

SST turbulence model is applied.

Figure 6 displays the computational domain set for the MRF. The domain consists of two zones, i.e., stationary and rotating. The radius of the propeller is denoted by

R. Only one single passage is considered in the simulation in light of the periodic flow in the circumferential direction.

Regarding the boundary conditions, the total pressure, total temperature, turbulence intensity and the flow speed normal to the boundary are prescribed at the inlet. The static pressure boundary condition is set at the outlet. The free-stream boundary condition is imposed at the side boundary. The no-slip condition is set on the propeller blade surface. The periodic boundary condition is set at the boundaries encasing the flow passage. Between the rotating and stationary zones, an interface is set to communicate flow quantities.

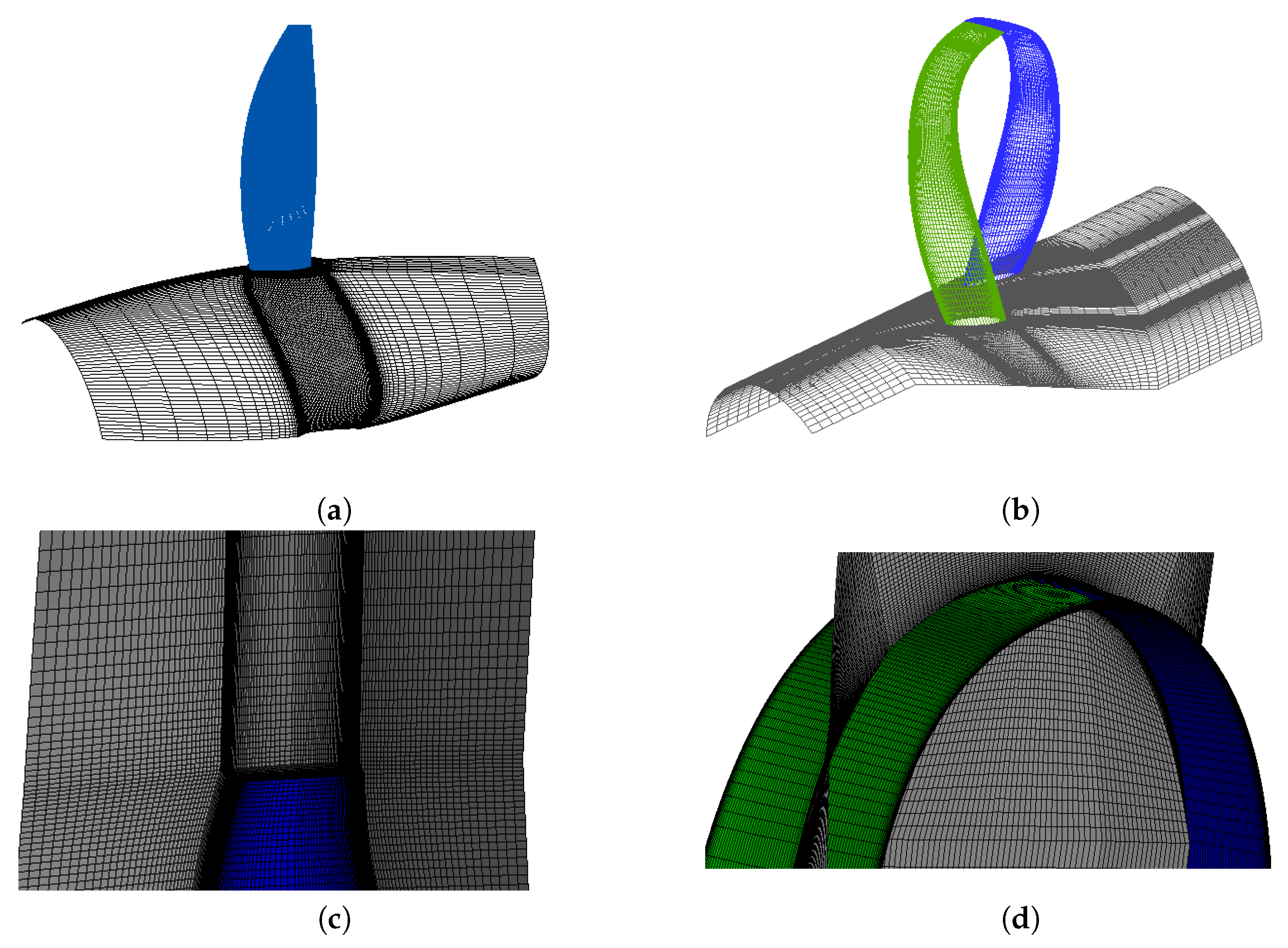

Figure 7 shows surface and volume cells of the meshes generated for Conprop-6 and Boxprop. As the blade geometries of Conprop-3 and -6 are overall similar, the meshes for them are comparable. The mesh for Conprop-3 is not shown for brevity. The mesh generation method and mesh cell parameters are the same as the previous study [

4]. There are

million cells in the meshes for Conprop-3 and Conprop-6 and

million for Boxprop. A specific refinement of cell sizes is made near the blade tip to resolve well vortices developed from the tip, as shown in

Figure 7c,d. A mesh indecency study was conducted to validate the current mesh resolution, which is not presented here for brevity.

As introduced in

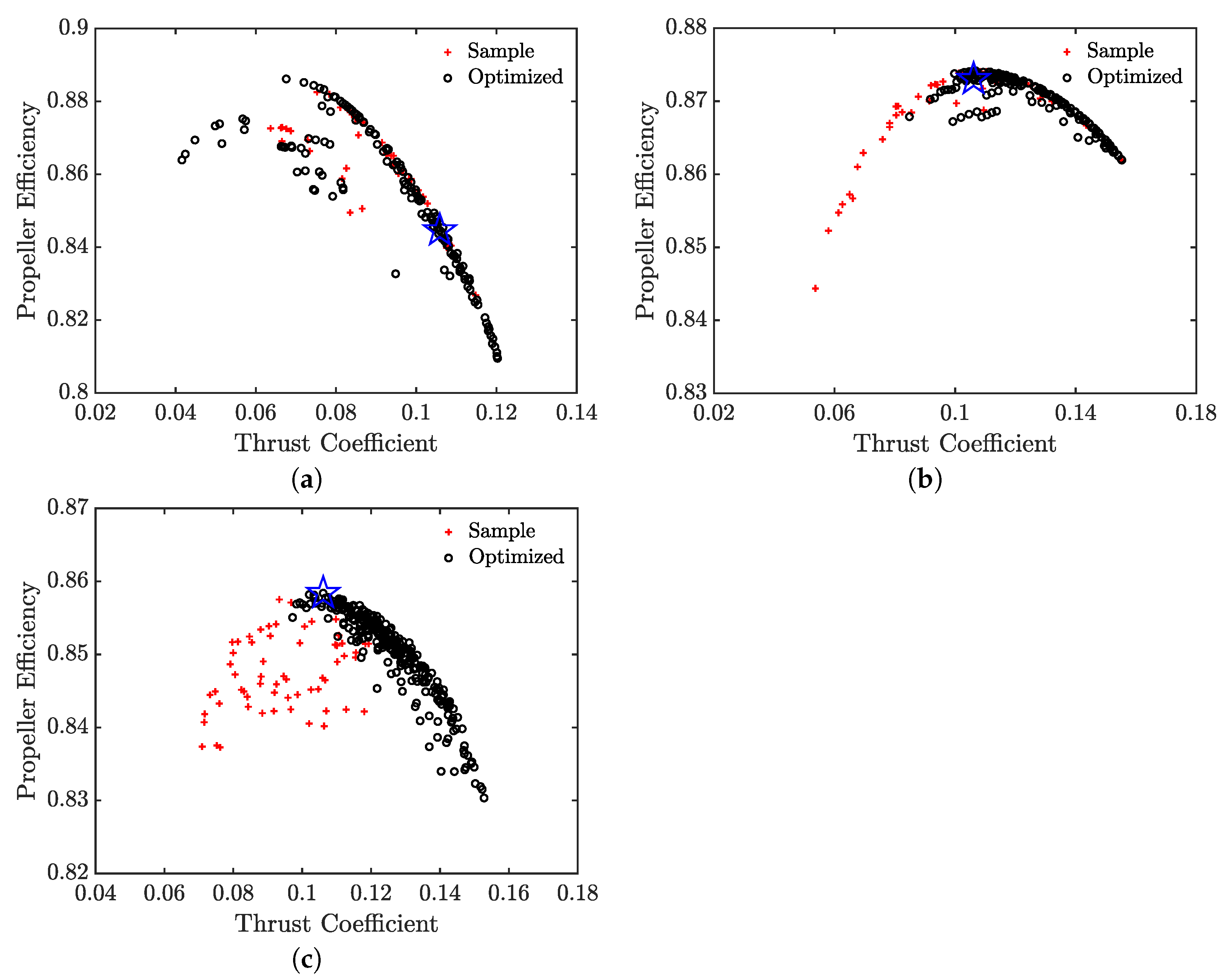

Section 2.1, the Pareto Front is established based on the objective variables, i.e., the thrust coefficient and propeller efficiency that are obtained from the CFD simulations, after executing the optimization platform.

Figure 8 shows the respective Pareto Front of the propellers. Then, the optimized propellers are extracted, corresponding to the optimal efficiencies at the targeted thrust coefficient of

(see the blue stars in the figure).

The aerodynamic performance parameters of the final selected optimal propellers, which are obtained from the RANS simulations during the optimization, are listed in

Table 2. The thrust coefficient of Conprop-3 is

. It is slightly smaller than

of both Conprop-6 and Boxprop. The propeller efficiency of Conprop-3 is

, which is smallest amongst the three optimal propellers. Despite that Conprop-6 and Boxprop possess the same thrust coefficient, the efficiency of Conprop-6 (0.873) is much larger than that of Boxprop (0.858). Nonetheless, these aerodynamic parameters are computed using RANS. It is known that RANS is relatively less accurate in comparison to advanced turbulence-resolved CFD methods such as the improved delayed detached eddy simulation (IDDES) or large eddy simulation. Moreover, accurate noise prediction based on the hybrid CAA methods also requires transient noise source data that need to be resolved in time. IDDES is therefore chosen in the subsequent sections for the further high-fidelity validation of the propeller performance and the prediction of the noise, especially for vortices developed from the blade tip.

6. Conclusions

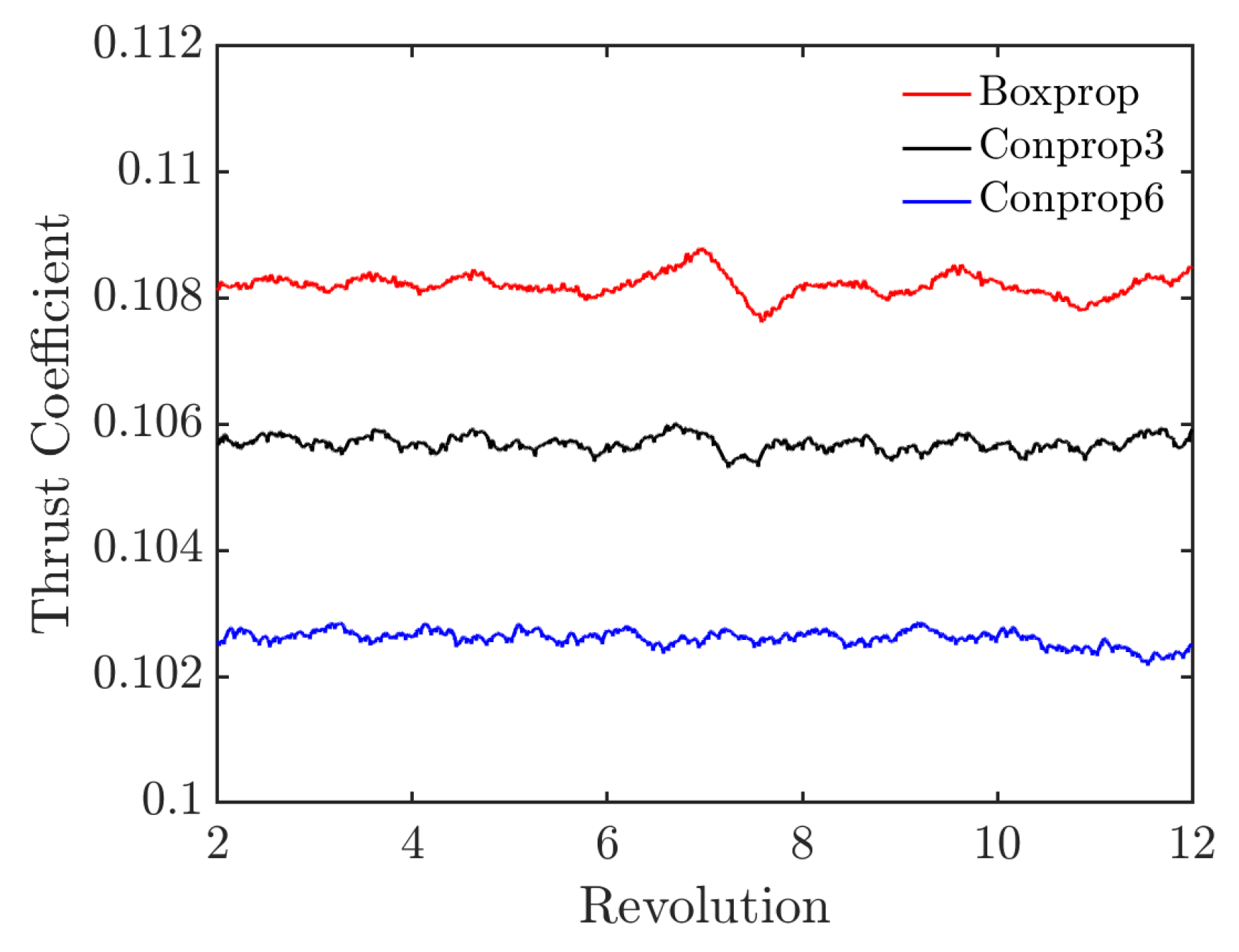

The noise emitted from vortices induced by the blade tip is investigated for three propellers: a classical propeller with three blades (Conprop-3), another classical propeller with six blades (Conprop-6) and a conceptual propeller with three dual-blades (Boxprop). These propellers are designed to target the same diameter, RPM, flight altitude, cruise Mach number of and thrust coefficient. The optimization of the propellers adopts the genetic algorithm and RANS. The IDDES coupled with the FW-H formulation is then used to compute the aerodynamic performance and blade-tip vortex noise of the selected optimal propellers.

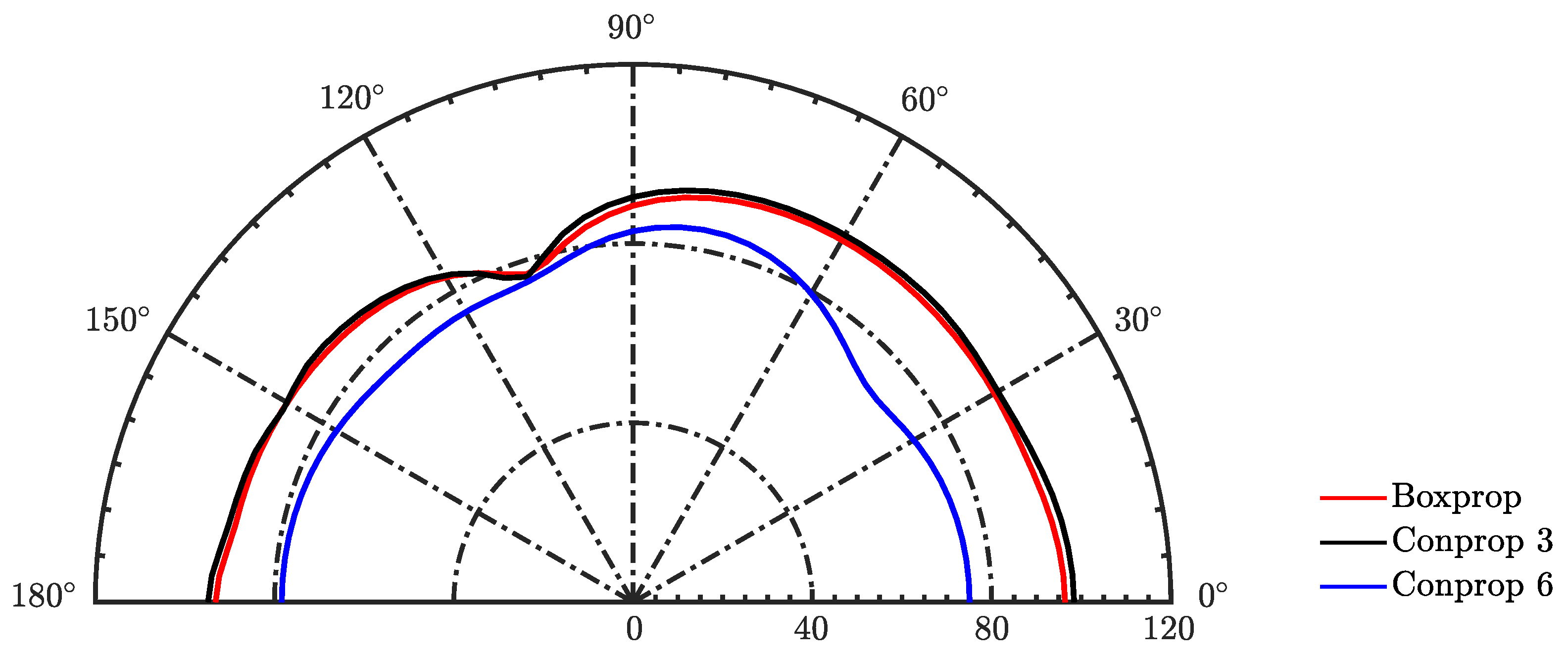

The thrust coefficients of Conprop-6, Conprop-3 and Boxprop are , and . The dual blade consists of two sub-blades whose tips are joined in a round shape. This blade-tip geometry is disparate from the classical ones of Conprop-3 and -6. By means of a sophisticated visualization of the vorticity magnitudes, the joined round blade tip exhibits the vortex development surrounding its surface, with no formation of streamwise vortex tubes that are commonly found for the classical blades. However, the tip vortices shed from the joined blade tip are quickly developed into a dominant spiral vortex in the wake. The spiral vortex is the same as those vortices shed from the classical blade tips, even though there are obvious differences between the joined tip and the classical tip in terms of the initialization of the vortices. In addition, the spiral vortices from Conprop-6 are much weaker than those from the three-blade propellers such as Conprop-3 and Boxprop. Up to this point, it infers that the dual-blade of Boxprop is not equivalent to two single classical blades of Conprop-6. Instead, given the same number of blades (three) in Boxprop and Conprop-3, the aerodynamics of the dual-blade is more similar to the single classical blade.

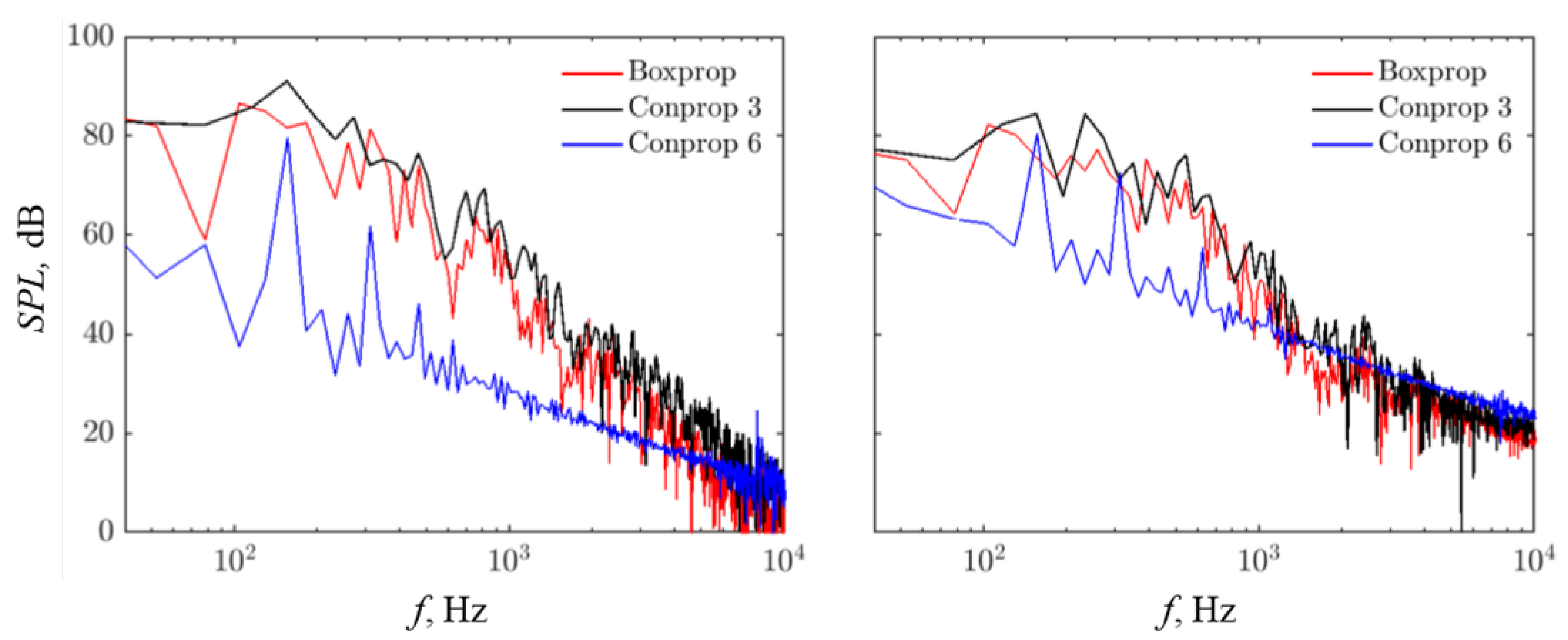

Given there is the same number of blades in the conceptual propeller Boxprop and the classical propeller Conprop-3, the noise from the blade-tip vortices of the dual-blade is only slightly smaller than the classical blade in all directions and the maximum reduction is approximately 1 dB. Conprop-6 with six classical blades produces significantly smaller blade-tip vortex noise than the other propellers. Thus, with the premise of the same propeller parameters such as the diameter, thrust coefficient and RPM, the blade-tip noise is mitigated with the increased blade number.

The blade-tip vortex noise of Conprop-6 features the tones at BPF and the harmonic frequencies, whereas the noise of Conprop-3 and Boxprop is broadband. Two hypotheses are proposed to explain these distinct effects, considering that the blades of the 3-blade propellers have larger pitch angles than that of the 6-blade propeller. The tones might be generated from the periodic mode of coherent vortices and the broadband noise is from turbulence. The first hypothesis assumes that the periodic mode fades and that the turbulence commences due to the flow separation at the large pitch angles. Consequently, the tones are extinct and the broadband noise appears. In the other hypothesis, the periodic mode still exists at the large pitch angle, but its tonal noise is smaller than the broadband noise from the turbulence. The tonal noise is masked by the broadband noise. The data and results of the current study are not sufficient to justify these hypotheses. Instead, the hypotheses are presented to humbly request more systematic studies by the entire community in the future.

Since the propellers are designed by constraining a group of primary geometric and operational parameters, a question is whether aerodynamic performance can be further improved if other constraints are selected, for example, the distribution of the chord length and camber. The broadband noise of the 3-blade propellers infers the important role of the turbulence. It would be interesting to develop modelling methods for the quick prediction of the broadband noise such as the stochastic noise generation and radiation (SNGR) method [

30]. The method has been applied to the optimization of flap side-edge noise [

31].