Small Hall Effect Thruster with 3D Printed Discharge Channel: Design and Thrust Measurements

Abstract

:1. Introduction

2. Materials and Methods

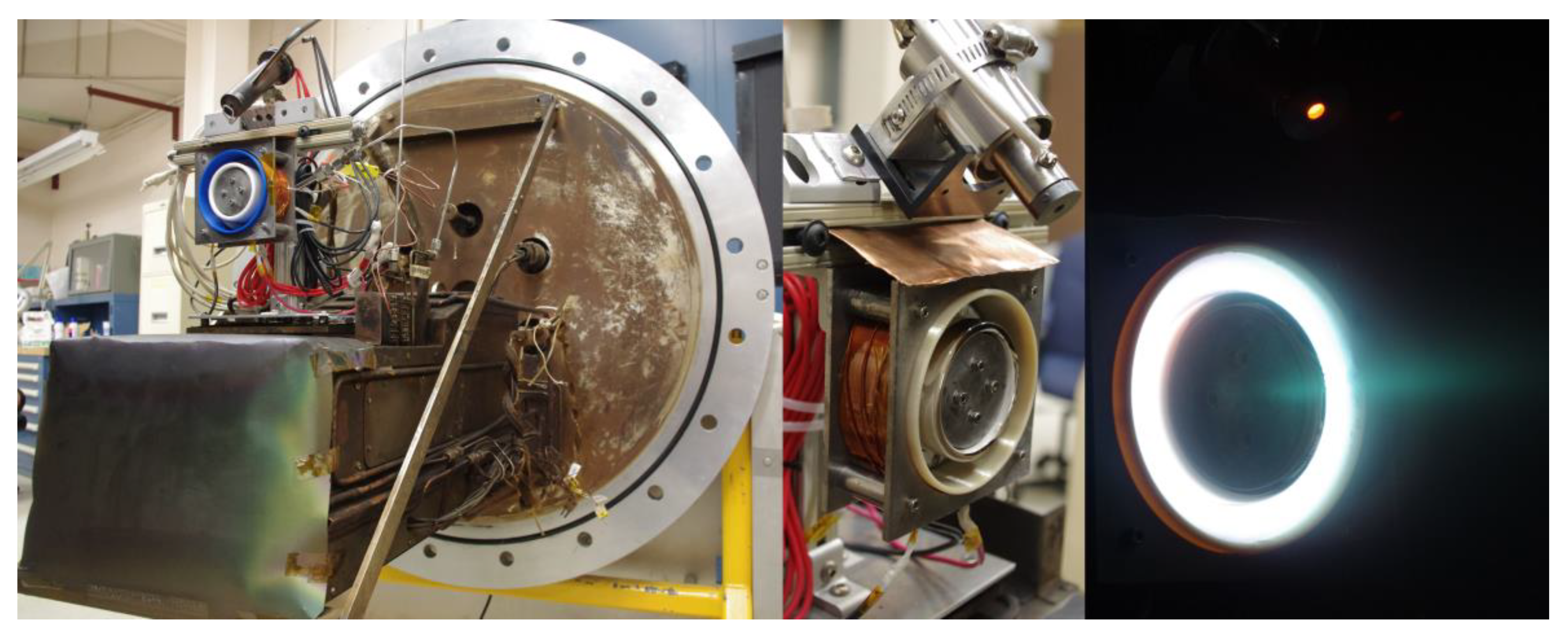

2.1. Thruster Design

2.1.1. 3D Printed Discharge Channel and Materials

2.1.2. Magnetic Field Design

2.1.3. Cost and Turnaround Time

2.2. Test Facility

3. Results and Discussion

3.1. General Characteristics

3.2. Thrust

3.3. Anode Specific Impulse

3.4. Anode Efficiency

3.5. Thrust to Power Ratio

3.6. Repeatability

3.7. Comparison with Other Low-Power Hall Thrusters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hall, S.J.; Florenz, R.E.; Gallimore, A.; Kamhawi, H.; Brown, D.L.; Polk, J.E.; Goebel, D.M.; Hofer, R.R. Implementation and Initial Validation of a 100-kW Class Nested-channel Hall Thruster. In Proceedings of the 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2014. [Google Scholar]

- Ibarzo, J.; Caro, I.; Marcos, J. Alternative manufacture technologies for the manufacture of HET larger ceramic chamber. In Proceedings of the 32nd International Electric Propulsion Conference, Wiesbaden, Germany, 11–15 September 2011; pp. 1–7. [Google Scholar]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Haas, J.M. Low-Perturbation Interrogation of the Internal and Near-Field Plasma Structure of a Hall Thruster Using a High-Speed Probe Positioning System. Ph.D. Dissertation, University of Michigan, Ann Arbor, MI, USA, 2001. [Google Scholar]

- Dunaevsky, A.; Raitses, Y.; Fisch, N.J. Secondary electron emission from dielectric materials of a Hall thruster with segmented electrodes. Phys. Plasmas 2003, 10, 2574. [Google Scholar] [CrossRef] [Green Version]

- Choueiri, E.Y. Fundamental Difference Between the Two Hall Thruster Variants. Phys. Plasmas 2001, 8, 5025–5034. [Google Scholar] [CrossRef] [Green Version]

- Dunaevsky, A.; Raitses, Y.; Fisch, N.J. Yield of Secondary Electron Emission From Ceramic Materials of Hall Thruster With Segmented Electrodes. In Proceedings of the 28th International Electric Prpoulsion Conference, Foulouse, France, 17–21 March 2003; pp. 1–7. [Google Scholar]

- Cazaux, J. A new model of dependence of secondary electron emission yield on primary electron energy for application to polymers. J. Phys. D Appl. Phys. 2005, 38, 2433–2441. [Google Scholar] [CrossRef]

- Goebel, D.M.; Katz, I. Fundamentals of Electric Propulsion: Ion and Hall Thrusters; Jet Propulsion Laboratory: Pasadena, CA, USA, 2008.

- Szabo, J.J.; Pote, B.; Tedrake, R.; Paintal, S.; Byrne, L.; Hruby, V.J.; Kamhawi, H.; Smith, T. High Throughput 600 Watt Hall Effect Thruster for Space Exploration. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2016. [Google Scholar]

- Haag, T.W. Thrust stand for high-power electric propulsion devices. Rev. Sci. Instrum. 1991, 62, 1186–1191. [Google Scholar] [CrossRef]

- Martinez, R.; Dao, H.; Walker, M.; Tech, G. Power Deposition into the Discharge Channel of a Hall Effect Thruster. J. Propuls. Power 2014, 30, 209–220. [Google Scholar] [CrossRef] [Green Version]

- Hruby, V.; Monheiser, J.; Pote, B.; Rostler, P.; Kolencik, J.; Freeman, C. Development of low power Hall thrusters. In Proceedings of the 30th Plasmadynamic and Lasers Conference, Norfolk, VA, USA, 28 June–1 July 1999; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1999. [Google Scholar]

- Santos, R.; Ahedo, E.; Raitses, Y.; Fisch, N.J. Transitional regime in the start-up process of conventional Hall thrusters. In Proceedings of the 32nd International Electric Propulsion Conference, Wiesbaden, Germany, 11–15 September 2011. [Google Scholar]

- Polk, J.E.; Pancotti, A.; Haag, T.; King, S.; Walker, M.; Blakely, J.; Ziemer, J. Recommended practice for thrust measurement in electric propulsion testing. J. Propuls. Power 2017, 33, 539–555. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Prichard, L.; Barwick, V. Preparation of Calibration Curves A Guide to Best Practice Contact Point; LGC Ltd.: Teddington, UK, 2003; pp. 1–27. [Google Scholar] [CrossRef]

- Conversano, R.W.; Goebel, D.M.; Hofer, R.R.; Mikellides, I.G.; Katz, I.; Wirz, R.E. Magnetically Shielded Miniature Hall Thruster: Design Improvement and Performance Analysis. In Proceedings of the 34th International Electric Propulsion Conference, Kobe, Japan, 4–10 July 2015; pp. 1–12. [Google Scholar]

- Manzella, D.; Oleson, S.; Sankovic, J.; Haag, T.; Semenkin, A.; Kim, V. Evaluation of low power hall thruster propulsion. In Proceedings of the 32nd Joint Propulsion Conference and Exhibit, Lake Buena Vista, FL, USA, 1–3 July 1996. [Google Scholar] [CrossRef]

- Hruby, V.; Monheiser, J.; Pote, B.; Freeman, C.; Connolly, W. Low Power, Hall Thruster Propulsion System. In Proceedings of the 26th International Electric Propulsion Conference, Kitakyushu, Japan, 17–21 October 1999; Volume IEPC-99-09. [Google Scholar]

- Apollo Fusion. Available online: https://apollofusion.com/index.html (accessed on 8 August 2021).

- Sommerville, J. Performance of the Aurora Low-Power Hall-Effect Thruster. In Proceedings of the 36th International Electric Propulsion Conference, Vienna, Austria, 15–20 September 2019; pp. 1–7. [Google Scholar]

- Mikellides, I.; Katz, I.; Hofer, R.; Goebel, D. Design of a Laboratory Hall Thruster with Magnetically Shielded Channel Walls, Phase II: Experiments. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Atlanta, Georgia, 30 July–1 August 2012; pp. 1–26. [Google Scholar] [CrossRef] [Green Version]

- Goebel, D.M.; Hofer, R.R.; Mikellides, I.G.; Katz, I.; Polk, J.E.; Dotson, B.N. Conducting wall hall thrusters. IEEE Trans. Plasma Sci. 2015, 43, 118–126. [Google Scholar] [CrossRef]

- Dankanich, J.W.; Polzin, K.A.; Calvert, D.; Kamhawi, H. The iodine satellite (iSAT) Hall thruster demonstration mission concept and development. In Proceedings of the 50th AIAA Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014; pp. 1–13. [Google Scholar]

- Huber, C.; Abert, C.; Bruckner, F.; Groenefeld, M.; Muthsam, O.; Schuschnigg, S.; Sirak, K.; Thanhoffer, R.; Teliban, I.; Windl, R.; et al. 3D Print of Polymer Bonded Rare-Earth Magnets, and 3D Magnetic Field Scanning With an End-User 3D Printer. Appl. Phys. Lett. 2016, 109, 162401. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Nlebedim, I.C.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.R.; Lara-Curzio, E.; Fredette, R.; Ormerod, J.; et al. Big Area Additive Manufacturing of High Performance Bonded NdFeB Magnets. Sci. Rep. 2016, 6, 36212. [Google Scholar] [CrossRef] [PubMed]

- Ma, B.M.; Herchenroeder, J.W.; Smith, B.; Suda, M.; Brown, D.; Chen, Z. Recent development in bonded NdFeB magnets. J. Magn. Magn. Mater. 2002, 239, 418–423. [Google Scholar] [CrossRef]

| Material | Component | Cost | Notes |

|---|---|---|---|

| Carbon Steel | Magnetic Circuit | $57 | |

| Fasteners | Magnetic Circuit | $30 | |

| Magnet Wire | Magnetic Circuit | $30 | |

| Carbon Shim Stock | Magnetic Shields | $15 | |

| Stainless Steel | Anode | $4 | Fabricated from stainless steel washer |

| 3D printed glazed ceramic | Inner Channel | $21 | Quote from manufacturer |

| ULTEM | Outer Channel | $97 | Quote from manufacturer |

| ABS | Inner Channel | $2 | By Volumetric Material Cost |

| Material Total | $256 | ||

| Labor | $560 | 35 $/h for 16 h | |

| Total | $816 | ||

| Material | Component | Cost | Notes |

|---|---|---|---|

| Carbon Steel | Magnetic Circuit | $57 | |

| Fasteners | Magnetic Circuit | $30 | |

| Magnet Wire | Magnetic Circuit | $30 | |

| Carbon Shim Stock | Magnetic Shields | $15 | |

| Stainless Steel | Anode/Propellant Distributor | $50 | Thicker stock material to fabricate the baffled anode for propellant distribution |

| Boron Nitride Channel | Discharge Channel | $1060 | Estimated from prior purchases of boron nitride for larger thrusters |

| Material Total | $1242 | ||

| Labor | $3800 | 35 $/h for 10 days, anode and magnetic circuit fabrication + $1000 for orifice drilling | |

| Total | $5042 | ||

| Thruster | VD (V) | Power (W) | Thrust (mN) | Anode ISP (s) | Anode Efficiency (%) |

|---|---|---|---|---|---|

| MaSMi [17] | 200–250 | 160–747 | 8.8–33 | 775–1321 | 21–29 |

| SPT-50 [18] | 199–282 | 210–389 | 12.9–18.9 | 1160–1524 | 35–41 |

| BHT-200 [19] | 200–275 | 200 | 11.5–12.5 | - | 35–42 |

| ACE [20] | 400 | 18 | 1300 | ||

| Aurora [21] | 300 | 100–300 | 5.7–19 | 1080–1460 | 30–44 |

| UAH-78AM | 180–260 | 280–520 | 17–30 | 870–1450 | 27–42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hopping, E.P.; Huang, W.; Xu, K.G. Small Hall Effect Thruster with 3D Printed Discharge Channel: Design and Thrust Measurements. Aerospace 2021, 8, 227. https://doi.org/10.3390/aerospace8080227

Hopping EP, Huang W, Xu KG. Small Hall Effect Thruster with 3D Printed Discharge Channel: Design and Thrust Measurements. Aerospace. 2021; 8(8):227. https://doi.org/10.3390/aerospace8080227

Chicago/Turabian StyleHopping, Ethan P., Wensheng Huang, and Kunning G. Xu. 2021. "Small Hall Effect Thruster with 3D Printed Discharge Channel: Design and Thrust Measurements" Aerospace 8, no. 8: 227. https://doi.org/10.3390/aerospace8080227

APA StyleHopping, E. P., Huang, W., & Xu, K. G. (2021). Small Hall Effect Thruster with 3D Printed Discharge Channel: Design and Thrust Measurements. Aerospace, 8(8), 227. https://doi.org/10.3390/aerospace8080227