Planning of Aircraft Fleet Maintenance Teams

Abstract

1. Introduction

2. Aircraft Maintenance

3. Framework Setting

4. Problem Formulation

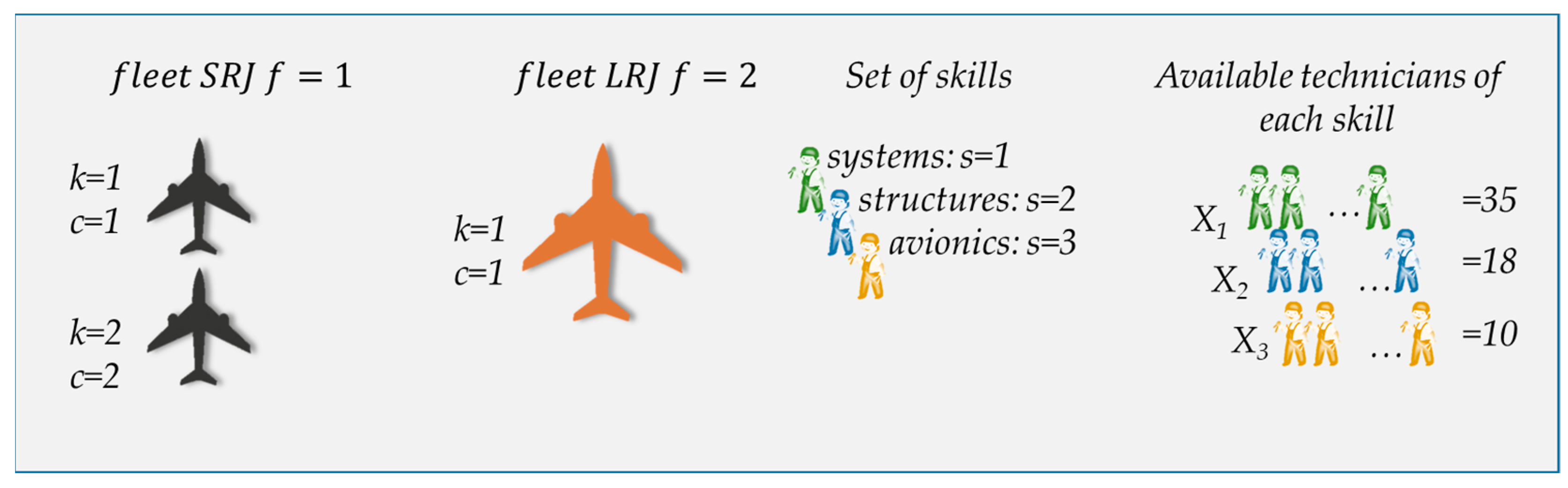

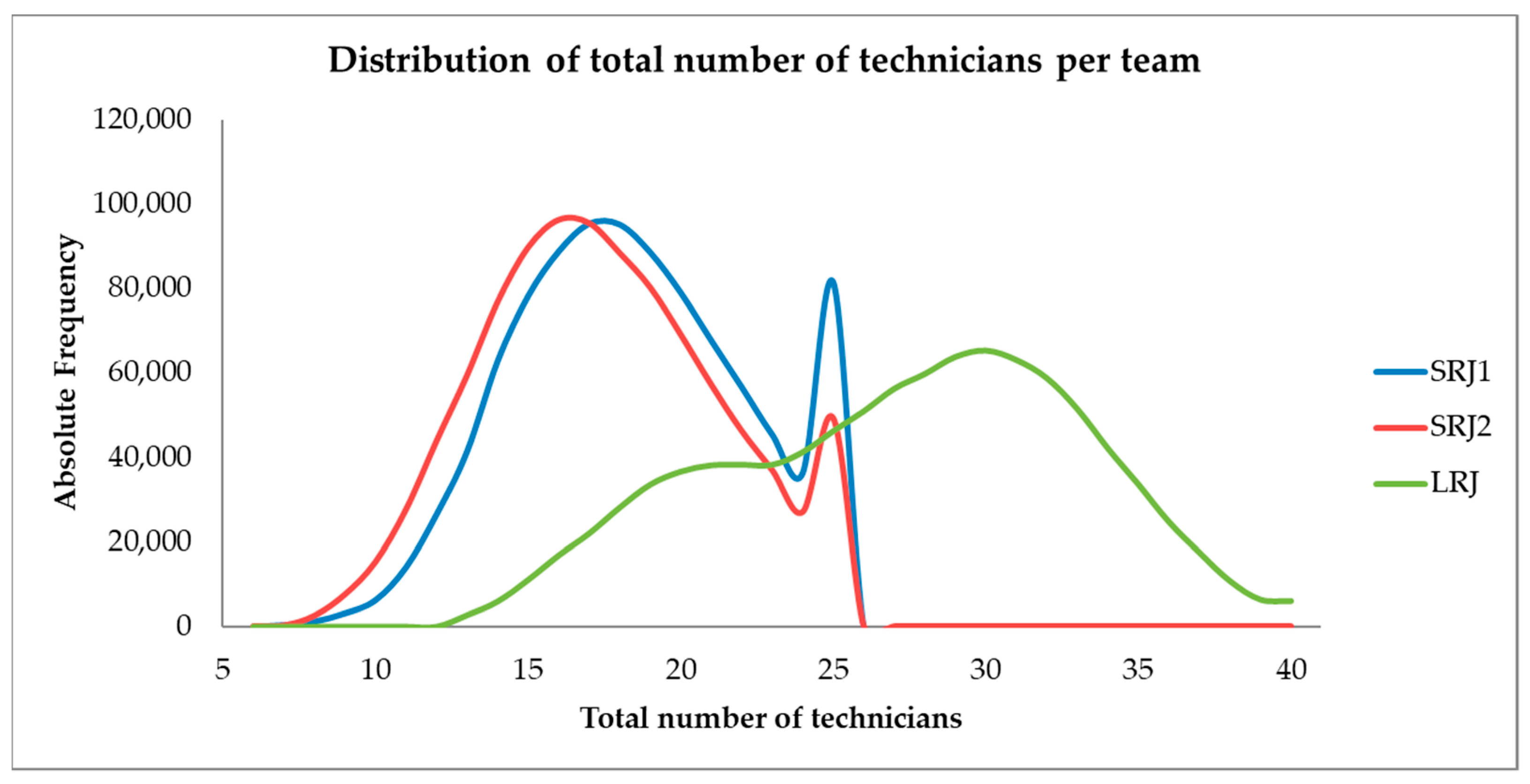

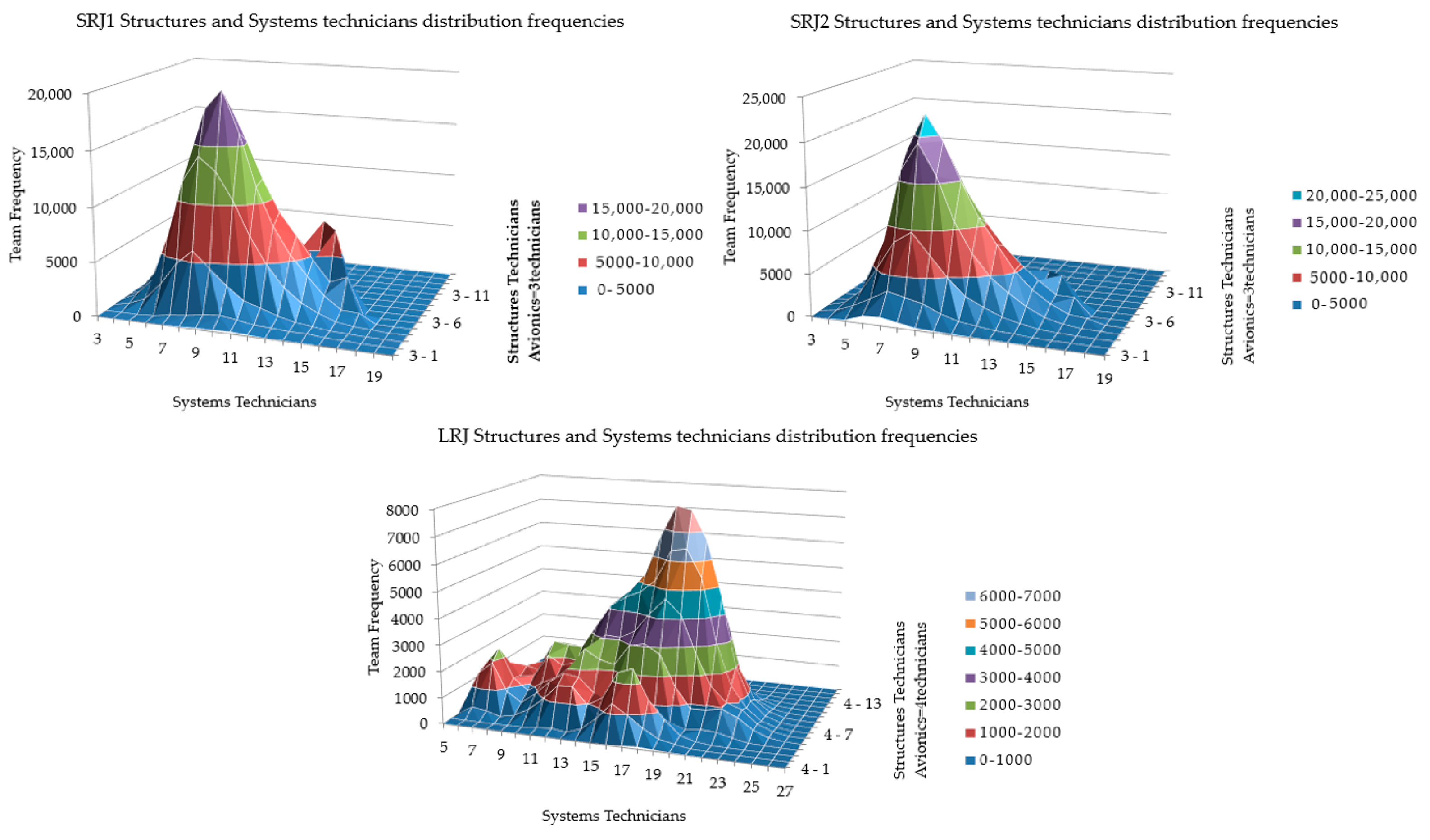

5. Case Study

6. Discussion

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Indexes | |

| f | index of fleet |

| index of aircraft | |

| index of maintenance check | |

| index of skills | |

| index and number of technicians assign in a skill | |

| Sets | |

| set of fleet | |

| set of aircraft of fleet f | |

| set of checks for aircraft k | |

| set of all technicians | |

| Parameters | |

| ratio of labor hours for fleet f aircraft k check c at work skill s | |

| specific cost of the technicians for skill s | |

| workload for fleet f aircraft k check c at work skill s | |

| number of technicians of skill s available to be assigned to the checks | |

| maximum number of technicians allowed to work simultaneously for fleet f aircraft k check c | |

| labor hours for fleet f aircraft k check c | |

| cost related to labor for fleet f aircraft k check c | |

| cost related to materials, subcontracts, and services for fleet f aircraft k check c | |

| cost per day of facilities imputed to fleet f aircraft k check c | |

| daily revenue loss due to not flying fleet f aircraft k | |

| Objective function | |

| cost incurred by the airline to perform the checks on the fleets | |

| Dependent variables | |

| duration in days for the maintenance of fleet f aircraft k during check c | |

| cost of maintenance-task-related for fleet f aircraft k check c | |

| the opportunity cost due to not flying fleet f aircraft k during check c | |

| normalized maintenance cost for fleet f aircraft k check c relative to the reference cost of fleet 1 aircraft 1 check 1, i.e., the value normalized for is 1 | |

| cost of facilities imputed for fleet f aircraft k during check c | |

| Independent variables | |

| number of technicians assigned to fleet f aircraft k check c at work skill s | |

| Binary variables | |

| 0/1 variables for skill s; assign of technician j: 1, assign; 0, no assignment | |

References

- Eurocontrol Comprehensive Assessment COVID 19 European Impact on Aviation. Available online: https://www.eurocontrol.int/publication/eurocontrol-comprehensive-assessment-covid-19s-impact-european-air-traffic (accessed on 13 March 2021).

- Arjomandi, A.; Seufert, J.H. An evaluation of the world’s major airlines’ technical and environmental performance. Econ. Model. 2014, 41, 133–144. [Google Scholar] [CrossRef]

- Alamdari, F.E.; Morrell, P. Airline labour cost reduction: Post-liberalization experience in the USA and Europe. J. Air Transp. Manag. 1997, 3, 53–66. [Google Scholar] [CrossRef]

- Yang, T.-H.; Yan, S.; Chen, H.-H. An airline maintenance manpower planning model with flexible strategies. J. Air Transp. Manag. 2003, 9, 233–239. [Google Scholar] [CrossRef]

- Dhanisetty, V.S.V.; Verhagen, W.J.C.; Curran, R. Multi-criteria weighted decision making for operational maintenance processes. J. Air Transp. Manag. 2018, 68, 152–164. [Google Scholar] [CrossRef]

- Santos, L.F.F.M.; Melicio, R. Stress, pressure and fatigue on aircraft maintenance personal. Int. Rev. Aerosp. Eng. 2019, 12, 35–45. [Google Scholar] [CrossRef]

- Madeira, T.; Melicio, R.; Valério, D.; Santos, L.F.F.M. Machine learning and natural language processing for prediction of human factors in aviation incident reports. Aerospace 2021, 847, 1–18. [Google Scholar]

- Kulkarni, A.; Yadav, D.K.; Nikraz, H. Aircraft maintenance checks using critical chain project path. Aircr. Eng. Aerosp. Technol. 2017, 89, 879–892. [Google Scholar] [CrossRef]

- Zhong, L.; Youchao, S.; Gabriel, O.E.O.; Haiqiao, W. Disassembly sequence planning for maintenance based on metaheuristic method. Aircr. Eng. Aerosp. Technol. 2011, 83, 138–145. [Google Scholar] [CrossRef]

- Pereira, D.P.; Melicio, R.; Mendes, V.M.F. A team allocation decision for aircraft fleet maintenance. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1024, 1–9. [Google Scholar] [CrossRef]

- Wu, H.; Liu, Y.; Ding, Y.; Liu, J. Methods to reduce direct maintenance costs for commercial aircraft. Aircr. Eng. Aerosp. Technol. 2004, 76, 15–18. [Google Scholar] [CrossRef]

- Bozoudis, M.; Lappas, I.; Kottas, A. Use of Cost-adjusted importance measures for aircraft system maintenance optimization. Aerospace 2018, 5, 68. [Google Scholar] [CrossRef]

- Gu, J.; Zhang, G.; Li, K.W. Efficient aircraft spare parts inventory management under demand uncertainty. J. Air Transp. Manag. 2014, 42, 101–109. [Google Scholar] [CrossRef]

- Hart, W.E.; Watson, J.P.; Woodruff, D.L. Pyomo: Modeling and solving mathematical programs in Python. Math. Program. Comput. 2011, 3, 219–260. [Google Scholar] [CrossRef]

- Meindl, B.; Templ, M. Analysis of commercial and free and open source solvers for linear optimization problems. Inst. Stat. Wahrscheinlichkeitstheorie 2012, 20, 1–13. [Google Scholar]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental algorithms for scientific computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef] [PubMed]

- Fioriti, M.; Vercella, V.; Viola, N. Cost-estimating model for aircraft maintenance. J. Aircr. 2018, 55, 1564–1575. [Google Scholar] [CrossRef]

- Saranga, H. Opportunistic maintenance using genetic algorithms. J. Qual. Maint. Eng. 2004, 10, 66–74. [Google Scholar] [CrossRef]

- IATA Maintenance Cost Technical Group. Airline Maintenance Cost Executive Commentary; 2019. Available online: https://www.iata.org/contentassets/bf8ca67c8bcd4358b3d004b0d6d0916f/mctg-fy2018-report-public.pdf (accessed on 25 April 2021).

- Saltoglu, R.; Humaira, N.; Inalhan, G. Scheduled maintenance and downtime cost in aircraft maintenance management. Int. J. Aerosp. Mech. Eng. 2016, 10, 602–607. [Google Scholar]

| Aircraft | Systems (%) | Structures (%) | Avionics (%) |

|---|---|---|---|

| Small regional aircraft (SRJ) | 61% | 25% | 14% |

| Large regional aircraft (LRJ) | 72% | 18% | 11% |

| Facilities | LRJ (%) | SRJ (%) |

|---|---|---|

| Daily cost | 17.5 | 10 |

| Technicians | Systems | Structures | Avionics | LRJ | SRJ |

|---|---|---|---|---|---|

| Number | 35 | 18 | 10 | 40 | 25 |

| #Techn. | SYS | SRJ1 STR | AVI | SYS | SRJ2 STR | AVI | SYS | LRJ STR | AVI |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0% | 0% | 3% | 0% | 1% | 4% | 0% | 1% | 3% |

| 2 | 0% | 1% | 27% | 0% | 5% | 29% | 0% | 2% | 13% |

| 3 | 0% | 9% | 74% | 0% | 17% | 74% | 0% | 7% | 30% |

| 4 | 1% | 26% | 95% | 1% | 38% | 95% | 0% | 13% | 64% |

| 5 | 4% | 49% | 99% | 4% | 61% | 99% | 0% | 22% | 91% |

| 6 | 10% | 71% | 100% | 12% | 80% | 100% | 1% | 35% | 99% |

| 7 | 20% | 87% | - | 25% | 92% | - | 3% | 51% | 100% |

| 8 | 35% | 95% | - | 42% | 97% | - | 6% | 69% | - |

| 9 | 50% | 98% | - | 57% | 99% | - | 9% | 83% | - |

| 10 | 64% | 99% | - | 70% | 100% | - | 13% | 93% | - |

| 11 | 75% | 100% | - | 80% | - | - | 17% | 98% | - |

| 12 | 84% | - | - | 88% | - | - | 22% | 100% | - |

| 13 | 91% | - | - | 93% | - | - | 28% | - | - |

| 14 | 96% | - | - | 97% | - | - | 34% | - | - |

| 15 | 99% | - | - | 99% | - | - | 41% | - | - |

| 16 | 100% | - | - | 100% | - | - | 49% | - | - |

| 17 | - | - | - | - | - | - | 58% | - | - |

| 18 | - | - | - | - | - | - | 68% | - | - |

| 19 | - | - | - | - | - | - | 78% | - | - |

| 20 | - | - | - | - | - | - | 87% | - | - |

| 21 | - | - | - | - | - | - | 93% | - | - |

| 22 | - | - | - | - | - | - | 97% | - | - |

| 23 | - | - | - | - | - | - | 99% | - | - |

| 24 | - | - | - | - | - | - | 100% | - | - |

| Aircraft | Number of Teams | Team Mode | Team Skills | ||

|---|---|---|---|---|---|

| Systems | Structures | Avionics | |||

| SRJ1 | 848 | 19,840 | 9 | 5 | 3 |

| SRJ2 | 854 | 22,381 | 8 | 5 | 3 |

| LRJ | 1682 | 7897 | 18 | 8 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, D.P.; Gomes, I.L.R.; Melicio, R.; Mendes, V.M.F. Planning of Aircraft Fleet Maintenance Teams. Aerospace 2021, 8, 140. https://doi.org/10.3390/aerospace8050140

Pereira DP, Gomes ILR, Melicio R, Mendes VMF. Planning of Aircraft Fleet Maintenance Teams. Aerospace. 2021; 8(5):140. https://doi.org/10.3390/aerospace8050140

Chicago/Turabian StylePereira, Duarte P., Isaias L. R. Gomes, Rui Melicio, and Victor M. F. Mendes. 2021. "Planning of Aircraft Fleet Maintenance Teams" Aerospace 8, no. 5: 140. https://doi.org/10.3390/aerospace8050140

APA StylePereira, D. P., Gomes, I. L. R., Melicio, R., & Mendes, V. M. F. (2021). Planning of Aircraft Fleet Maintenance Teams. Aerospace, 8(5), 140. https://doi.org/10.3390/aerospace8050140