1. Introduction

Aircraft structures are designed based on the damage-tolerance concept, where flaws can exist in any structure and such flaws propagate with usage. A maintenance program will result in the detection and repair of damage, corrosion and fatigue cracking before such damage threatens the safety of the system. Structural maintenance of aircraft is currently based on scheduled maintenance, which accounts for more than 27% of the lifecycle cost of an aircraft [

1]. There are ongoing research efforts to reduce the maintenance cost by utilizing condition-based maintenance where the health status of the system is continuously monitored, and maintenance is requested when the safety of the system is threatened [

2].

Structural health monitoring (SHM) [

3,

4,

5] is the process of identifying damage and evaluating the safety of a system based on online and/or offline data. It uses an array of sensors to obtain measurement data that are directly or indirectly related to damage. The statistical analysis of these measurements can help predict the future state of the system and thus improve the safety of the system. SHM can be found in a wide variety of applications such as bridges and dams [

6], buildings [

7], stadiums, platforms, airframes [

8], power plants [

9], etc. Prognostics is an extension of SHM, which is the process of estimating the time beyond which a system can no longer function to meet desired performances [

10]. The time, in terms of cycles/hours, remaining to run the system before failure is called the remaining useful life (RUL).

There are two types of prognostics methods: data-driven and physics-based approaches [

11]. The data-driven approaches [

12] are advantageous when many training data are available for a complex system, while the physics-based approaches [

13,

14] are good when a physical model of damage degradation is available. In this paper, the physics-based approach is used for prognostics, where a well-defined physics model is assumed to be available to represent the progression of degradation, and measurement data are used to estimate the model parameters, from which the RUL can be predicted.

Identifying model parameters is the key step in the prognostics using physics-based approaches [

15] because, with the identified parameters, the RUL can easily be calculated by propagating the degradation model to the future. In addition to operating conditions and model-form errors, it is critically important to identify uncertainty in the parameters, as they are directly related to the uncertainty in the RUL. In addition, when multiple parameters are involved, it is important to identify the correlation between them. Correlation occurs when the combinations of more than one parameter can represent the same physical phenomenon. For example, in Paris crack growth model, different combinations of two model parameters can yield the same crack growth rate [

16]. This often happened because a single physical quantity is measured, while multiple parameters influence the quantity.

Model parameter identification is equivalent to a curve-fitting process where the errors between model predictions and measured data are minimized using linear/nonlinear regression [

10]. Recently, statistical estimation methods have become popular to consider the uncertainty in future degradation [

17]. Many of the statistical approaches have their theoretical foundation on the Bayesian inference, where the observed data can improve the information on the current model parameters. In the case of statistical approaches, the maximum likelihood estimation is often used to identify the probability distribution of model parameters [

18]. In Bayesian inference, the joint probability density function (PDF) of model parameters is updated from its prior PDF to the posterior PDF. The posterior PDF shows the level of knowledge in the unknown parameters based on the observed data.

In general, correlation in statistics measures the similarity in trend between two or more random variables. In the regime of epistemic uncertainty of model parameters, two parameters are considered to be correlated when multiple combinations of them can predict the same degradation state. Since the predicted value is the same, it is inherently difficult to identify individual values of parameters. Instead, a relationship between them can be obtained. If the marginal PDF of individual parameters is used, the RUL prediction can significantly be different from the true one. Therefore, it is important to identify the correlation structure between degradation parameters. Li and Vu [

19] presented non-identifiability problems of biology model parameters in nonlinear dynamic models due to correlations between parameters. Santos and Pinto [

20] showed that when a variable correlation is unknown, the simultaneous estimation of model parameters and variable correlation may lead to meaningless parameter estimates and parameter uncertainties. In statistical approaches, Matzke et al. [

21] used Bayesian inference to quantify the correlation uncertainty in the presence of measurement error. Most literature on correlation focuses on identifying the correlation structure, not the value of parameters.

An important contribution of the present work is related to the fact that the number of unknown model parameters is normally larger than that of the measurement data types. Normally a single type of degradation data is measured while multiple model parameters need to be estimated. In addition, these parameters are often strongly correlated. In such a situation, it is difficult, if not impossible, to identify the accurate model parameters. An et al. [

16] showed that even if the accurate model parameters may not be identified, the correlation relationship can still be used to predict the RUL accurately. However, it is often necessary to identify accurate model parameters in order to use them under different operating conditions or to use them in different systems.

The objective of this paper is to present various types of correlations that occur during model parameter estimation and then introduce two ways of identifying degradation parameters even if the correlation between them is strong. The idea is that it is possible to identify the accurate degradation parameters when the correlation structure changes over time or when different operating conditions are used. The proposed methods of identifying degradation parameters are demonstrated using a crack growth model with synthetic data. In particular, it is shown that the proposed method is robust even if relatively a large level of noise is present in the data.

The remaining sections are organized as follows. In

Section 2, it is shown that different types of correlations can occur in the model parameter estimation process. In

Section 3, Bayesian inference is introduced to obtain the distribution of model parameters. In

Section 4, two methods of identifying accurate model parameters are introduced using the Paris model of fatigue crack growth, followed by conclusions in

Section 5.

2. Correlations in the Identification Process

Crack growth is an important phenomenon related to structural failure [

22]. In this section, the Paris–Erdogan crack growth model is used to explain the fundamental nature of correlation. The fatigue crack growth rate of the Paris–Erdogan model is given as:

where

is the half crack size,

is the cycle of fatigue loading,

is the range of Mode I stress intensity factor,

is the range of applied stress, and

and

are the two model parameters that need to be estimated. Equation (1) is nonlinear because the stress intensity factor

depends on the crack size

. Although the loading cycle,

, is an integer, it is considered as a continuous variable in the above differential equation. Since the degradation model requires the crack size as a function of time and model parameters, Equation (1) can be integrated to obtain the following degradation model:

where

is the initial size of the crack when

. It is assumed that the crack sizes are measured using an SHM system, where the measured data include random noise and a constant bias. It is assumed that the random noise follows a normal distribution as

where

is the standard deviation (STD) of the noise. The deterministic bias represents the error in the model form or the calibration error of SHM sensors.

In the following sub-sections, three types of correlations that occur during model parameter estimation will be discussed.

2.1. Correlation between Model Parameters

In statistics, correlation is defined as the degree to which a pair of random variables are linearly related. This commonly happens when two variables are not statistically independent. The degree of correlation is often measured using correlation coefficients such as Pearson correlation coefficient or Spearman’s rank correlation [

23]. The former can be applied for a linear relationship, while the latter is robust for a nonlinear relationship. In this section, the concept of correlation is utilized to describe statistical dependency between model parameters, which is represented in the form of the posterior joint PDF using Bayesian inference.

Correlation in estimating model parameters can be shown using a simple example of where is the measured output, while model parameters, and , need to be identified. For example, when is measured, there are infinite combinations of and to yield ; i.e., . Although it is impossible to identify the true values of and , the sum of the two variables always shows a consistent outcome; i.e., .

It turned out that the correlation between the two parameters,

and

, was strong, which means that it would be difficult to identify individual values. Instead, the correlation relationship can be identifiable [

16].

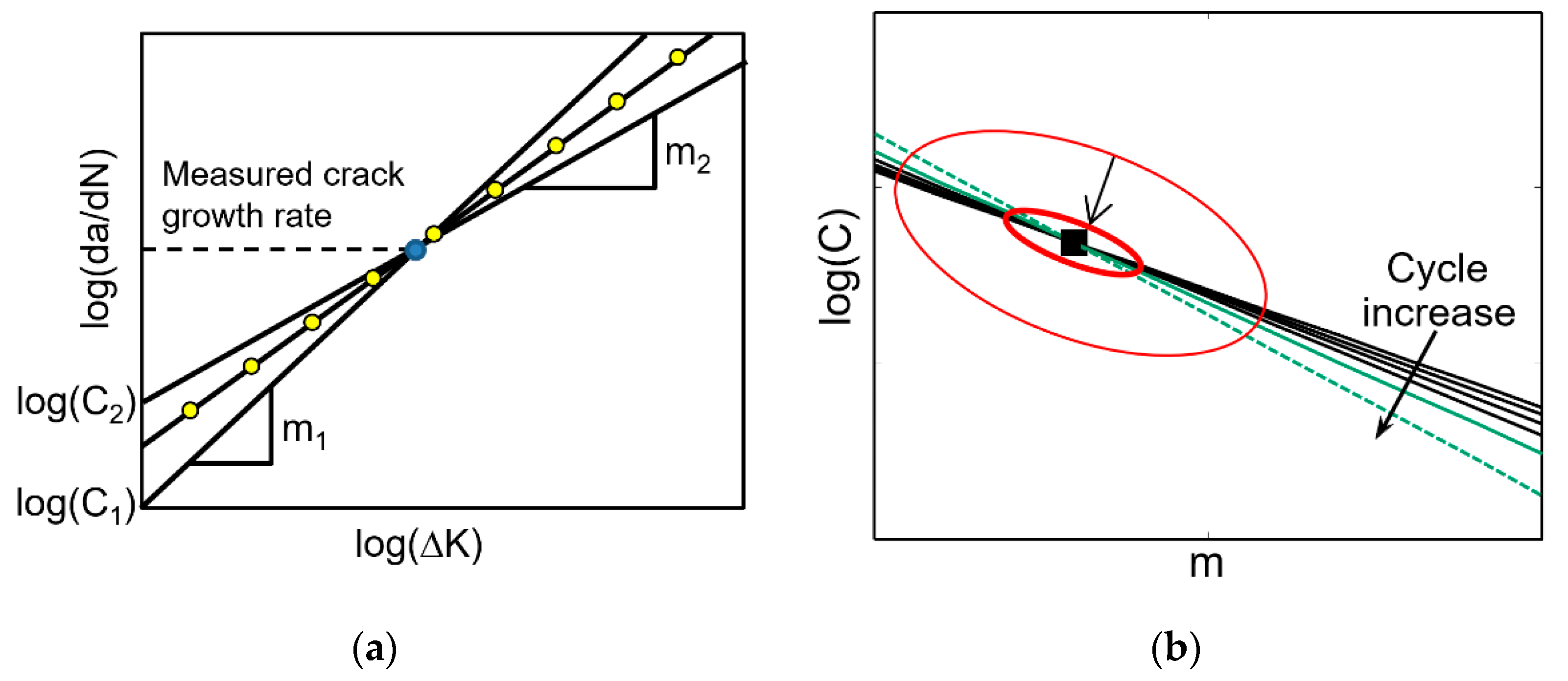

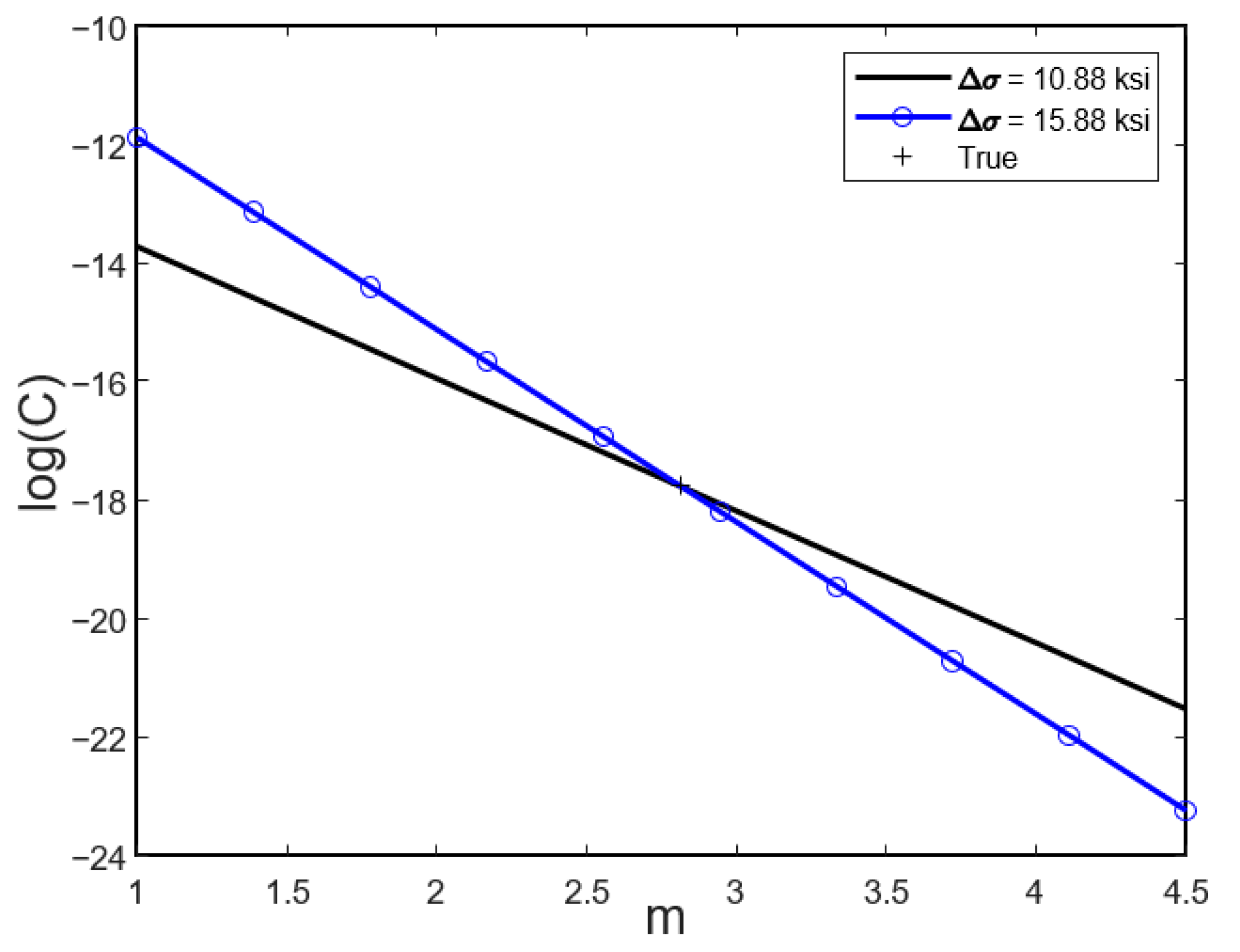

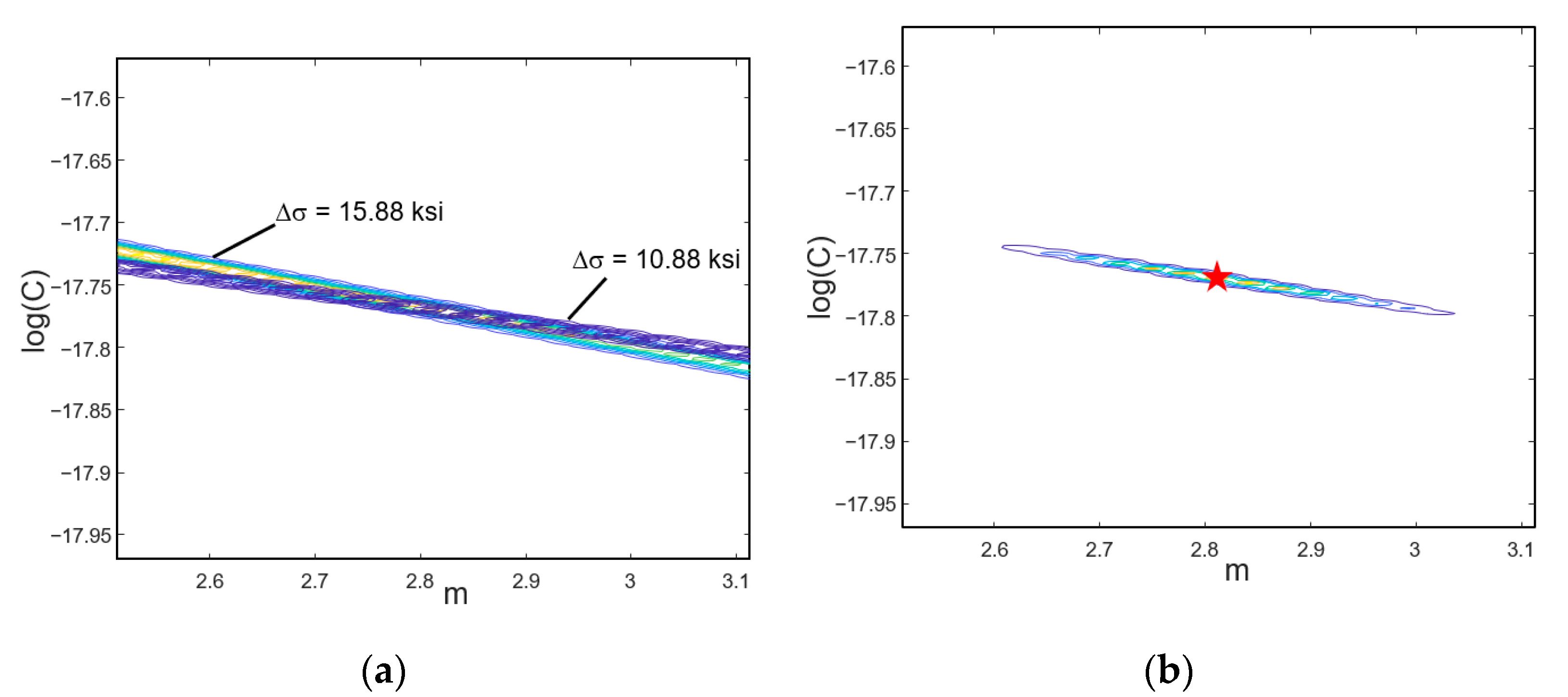

Figure 1a shows a log-log scale graph of the crack growth rate versus the range of stress intensity factor. When the crack growth is in a stable stage, the crack growth rate shows a linear trend, which can be determined using the slope

and y-intercept

.

As shown in

Figure 1a, for a given

, the measured crack growth rate

can be obtained by infinitely many combinations of

and

. That is, different combinations of

and

can represent the same crack growth. This is the basic nature of correlation that this paper addresses. Indeed, a functional relation between them can be obtained as:

where

and

are the true model parameters that we want to identify. The above equation can be considered as a linear relationship between

and

. Considering Equation (3) as a linear curve, the slope

will change as the crack grows.

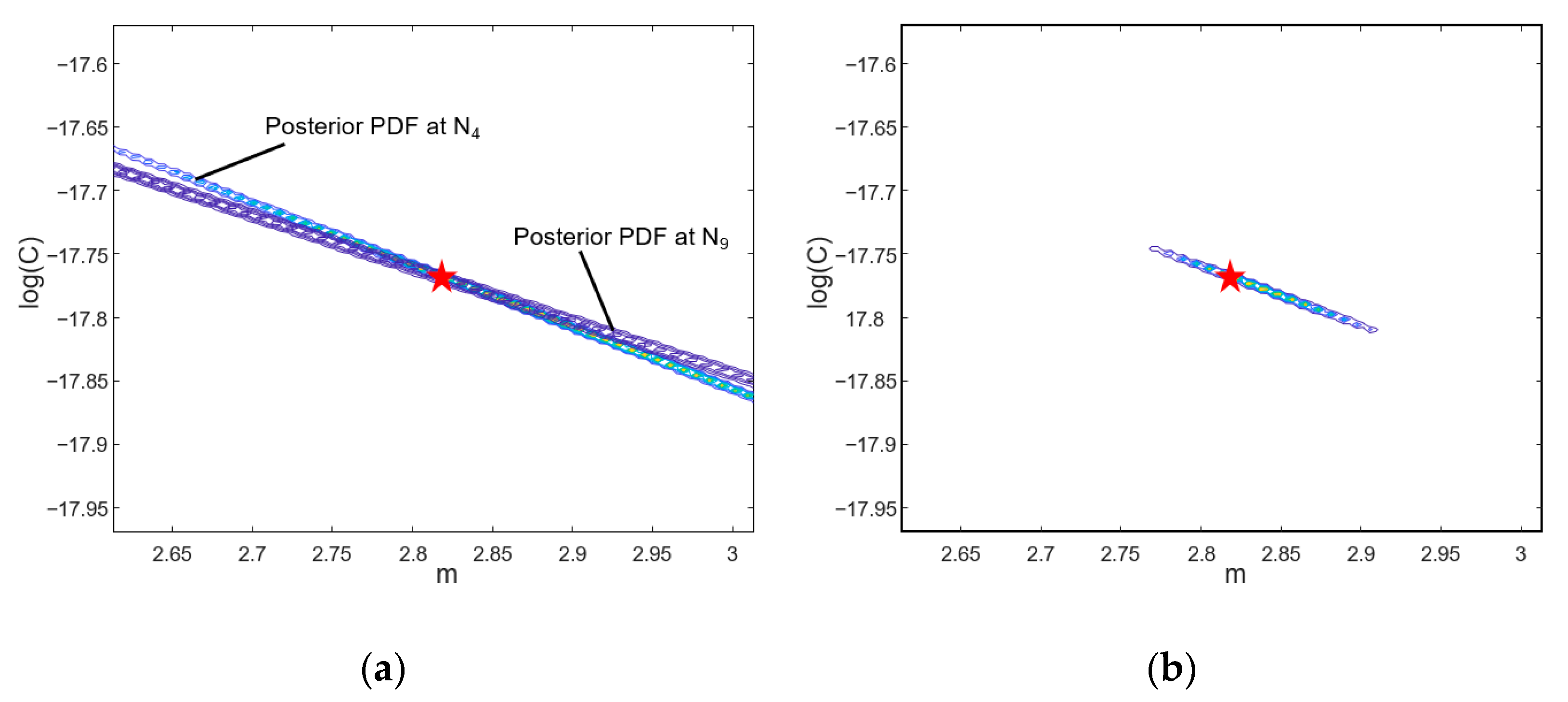

As the crack grows and the stress intensity factor increases, the correlation line between the two parameters gradually rotates with the true values at the center, which makes the correlation shape to be identified as a narrow-banded ellipse as shown in

Figure 1b. If the slopes of two lines are significantly different, the intersection of two lines can be used to identify the true values of model parameters. This characteristic will be used in

Section 4 to identify individual model parameters under correlation.

2.2. Correlation between Load Condition and Model Parameters

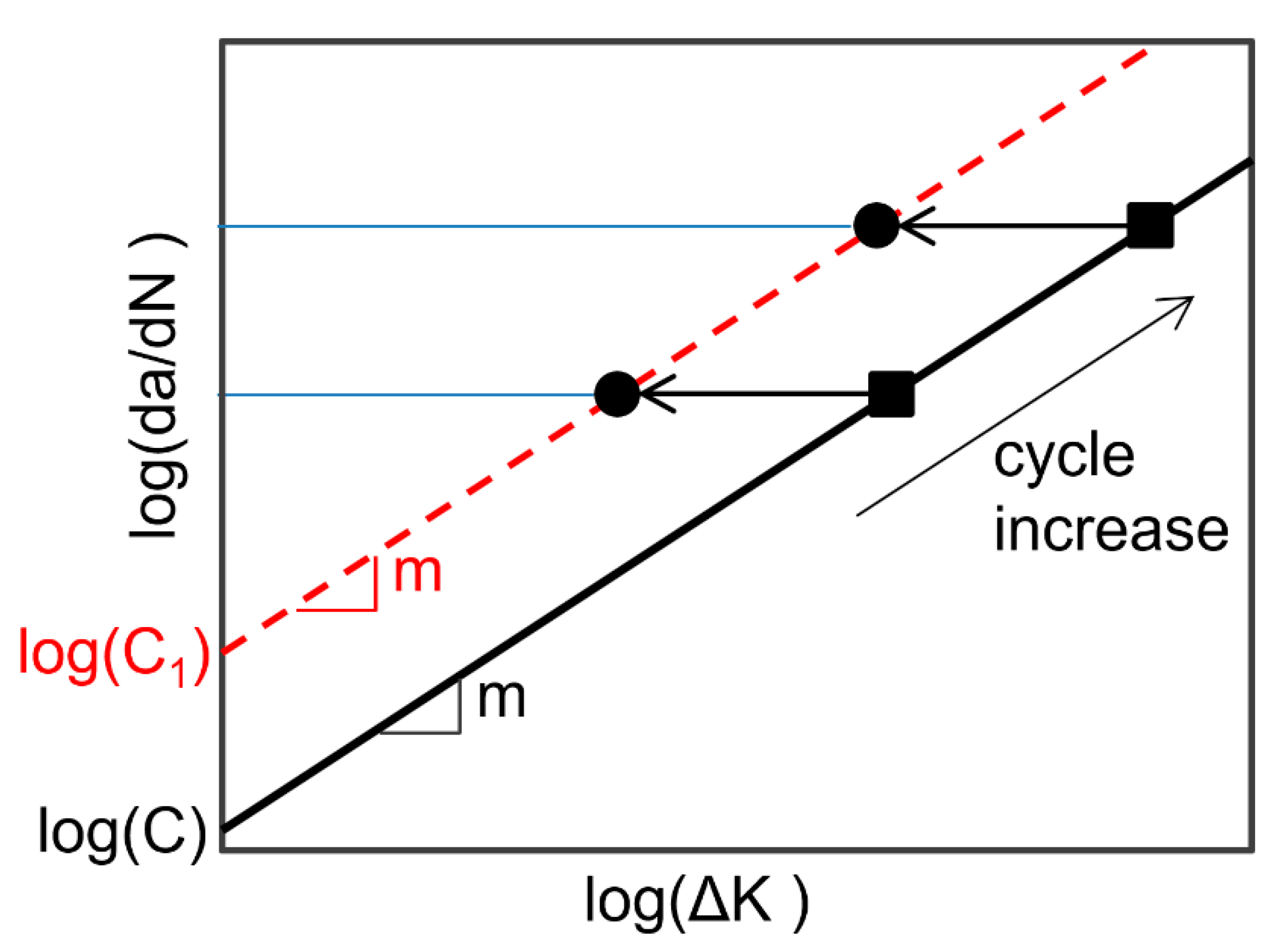

In addition to the correlation between two parameters, another interesting correlation in physics-based models occurs between the applied loadings (operating conditions) and degradation parameters. The black solid line in

Figure 2 represents the true crack growth when both applied loadings and degradation parameters are correct. In fatigue crack growth, the range of stress intensity factor,

, corresponds to the loading condition. Since

depends on the local stress, it is possible that an incorrect stress can be used due to the error in stress calculation. When engineers assume a lower value of

, the same observed crack growth can be obtained by increasing the y-intercept from

to

. That is, the same crack growth can be obtained by decreasing

and increasing y-intercept, which is another case of correlation. This linear relationship between

and

can also be seen from Equation (3) with a fixed

.

This kind of correlation is different from that of degradation parameters. The conclusion in the correlation between degradation parameters in the previous section was that even if the true values cannot be identifiable, the correlation allows predicting the RUL properly. Different from the fact that degradation parameters need to be identified, loading conditions are not a part of identification. Rather, they are input conditions. Therefore, this case happens when the information on the applied loading is wrong. If a lower

than the actual one is used, the crack growth in the black line moves to the dashed red line in

Figure 2. Therefore, a new combination of parameters,

and

, will be identified as equivalent parameters with a lower stress intensity factor. When the loading remains constant, it is equivalent to correlated parameter identification. Therefore, the equivalent parameters,

and

, would predict the RUL properly.

In order to show the relationship clearly, let us assume that the exponent is fixed to

. Then by taking the logarithm of Equation (1) at two different loading conditions, the following equation can be derived as:

where

and

are the correct model parameters under

.

For practical applications, this correlation and equivalent degradation parameters are in favor of prognostics. It has been mentioned that the model–form error is an important issue in physics-based prognostics. Since most models include assumptions and simplifications, the actual degradation behavior is different from that of the model. Such a model-form error often appears in the form of loading conditions. As an example, it is well-known that the Paris–Erdogan model is designed for an infinite flat plate with a loading direction being perpendicular to the crack. In practice, all plates have a finite size under various boundary conditions. Therefore, the model needs to be modified/corrected to compensate for the effect of geometry, crack shape and location, and boundary conditions. In order to compensate for these effects, the stress intensity factor is modified by:

where

is the correction factor, given as the ratio of the true stress intensity factor to the value predicted by

. The correction factor depends on the geometry ratio of the crack and plate and the loading conditions. Therefore, the apparent stress intensity factor

is different from the correct stress intensity factor

. However, the process of identifying model parameters can compensate for this error by identifying equivalent model parameters that can yield the same RUL.

2.3. Correlation between Measurement Bias and Initial Crack Size

When damage is measured using sensors, the signals may have calibration error or the conversion model may have model form error, which leads to bias error. In particular, when a crack is measured using SHM, the exact location of the crack is often unknown. Since the crack size is estimated using the signal strength and since the signal strength depends on the crack location, the estimated crack size may include bias error [

24]. In prognostics algorithms, bias can significantly affect predictions. While estimating the crack size, for example, if the estimated crack size is larger than the actual one, this is referred to as a positive bias. Such a positive bias leads to overestimating

because the crack size

is larger than the true one. When the crack size is large, but the crack growth is the same, the exponent

will be underestimated. In the case of a negative bias, it will be overestimated [

25].

For simplicity, it is assumed that the bias is a constant, and it needs to be included as an unknown parameter. It is possible that the bias may change as a function of the stress intensity factor, but it would require a more complicated bias function with more unknown parameters. With the physics model for the crack size given in Equation (2) and a constant bias, the relationship between the measured and actual crack sizes can be written as:

where

is the unknown bias, and

is the actual crack size at loading cycle

. When the measurement process has a systematic bias, the stress intensity factor should be calculated using the actual crack size; i.e.,

.

A new type of correlation occurs between the initial crack size and systematic bias, which will influence the results of the prognostic. In order to show the correlation, let the initial measure crack size be

. Under the assumption that the measurement system does not have any noise, the relationship between measured size and the true size can be written as:

Since infinitely many combinations of and can produce the same , linear correlation exists between the two.

3. Model Parameter Estimation Using Bayesian Inference

As previously mentioned, the noise in data makes the identification process difficult. In addition, all three correlations may present simultaneously, which may cause the process more challenging. Although there are many parameter identification methods, such as the least-squares method, the Bayesian method is used in this paper.

In the following explanation,

represents the uncertain variable of unknown model parameter, and

represents the uncertain variable of the degradation feature. A variable with an upper case denotes an uncertain variable, while a variable with a lower case denotes a realization of the uncertain variable. Bayesian inference estimates the degree of belief in a hypothesis based on collected evidence. Bayes [

26] formulated the degree of belief using the following identity in conditional probability:

where

is the conditional probability of

given

. In the case of estimating the model parameter using measured data, the conditional probability of

when the probability of measured data

is available can be written as:

where

is the posterior probability of parameter

for given measurement data

, and

is called the likelihood function or the probability of obtaining data

for a given parameter

. In Bayesian inference,

is called the prior probability, and

is the marginal probability of

and acts as a normalizing constant. The above equation can be used to improve the knowledge of

when additional information

is available.

Bayes’ theorem in Equation (9) can be extended to the continuous probability distribution with a probability density function (PDF), which is more appropriate for the purpose of the present paper [

27]. Let

be a PDF of model parameter

. When there are more than one model parameters,

can be a joint PDF of multiple parameters. If SHM measures a degradation feature

Y, it is also a random variable, whose PDF is denoted by

. Then, the joint PDF of

and

can be written in terms of

and

, as:

When

and

are independent, the joint PDF can be written as

and Bayesian inference cannot be used to improve the probabilistic distribution of

. Using the above identity, the original Bayes’ theorem can be extended to the PDF as [

28]:

Since the denominator is a constant and since the integral of is one from the property of PDF, the denominator in Equation (11) can be considered as a normalizing constant. By comparing Equation (11) with Equation (9), is the posterior PDF of parameter given measured data , and is the likelihood function or the PDF value of measured data given model parameter . The process of updating the posterior distribution of model parameter using the measured data is called Bayesian inference.

When multiple, independent data are available, Bayesian inference can be applied for all data at once. When

number of measurements are available; i.e.,

, the Bayes’ theorem in Equation (11) can be modified to:

where

is a normalizing constant to make the integral of the posterior PDF equal to one. In the above expression, it is possible that the likelihood functions of individual data are multiplied together to build the total likelihood function, which is then multiplied by the prior PDF followed by normalization to yield the posterior PDF.

An important advantage of Bayes’ theorem over other parameter identification methods, such as the least-squares method and maximum likelihood estimate, is its capability to estimate the uncertainty structure of the identified parameters. These uncertainty structures depend on the prior distribution and likelihood function. Accordingly, the accuracy of the posterior distribution is directly related to that of the likelihood and the prior distribution. Thus, the uncertainty in the posterior distribution must be interpreted in that context.

In the Bayesian method, it is assumed that the users know the prior distribution of model parameters and the distribution type of measurement noise. In this paper, it is assumed that the prior distribution is given as a uniform distribution with a lower- and upper-bound. It is also assumed that the measurement noise has a Gaussian distribution; that is

, where

s is the standard deviation of the noise. In most cases, since the standard deviation of the noise is unknown, it should be a part of unknown model parameters. In the case of crack growth, the vector of unknown model parameters is defined as

. It is also possible that the initial crack size and measurement bias can be included in the unknown model parameters. For the correlation caused by the initial crack size and bias can be found in An et al. [

16]. The prior distribution of each parameter is assumed as a uniform distribution. By assuming that all model parameters are statistically independent, the prior joint PDF of the parameters can be defined as:

The posterior distribution can be obtained by multiplying the prior distribution with the likelihood function.

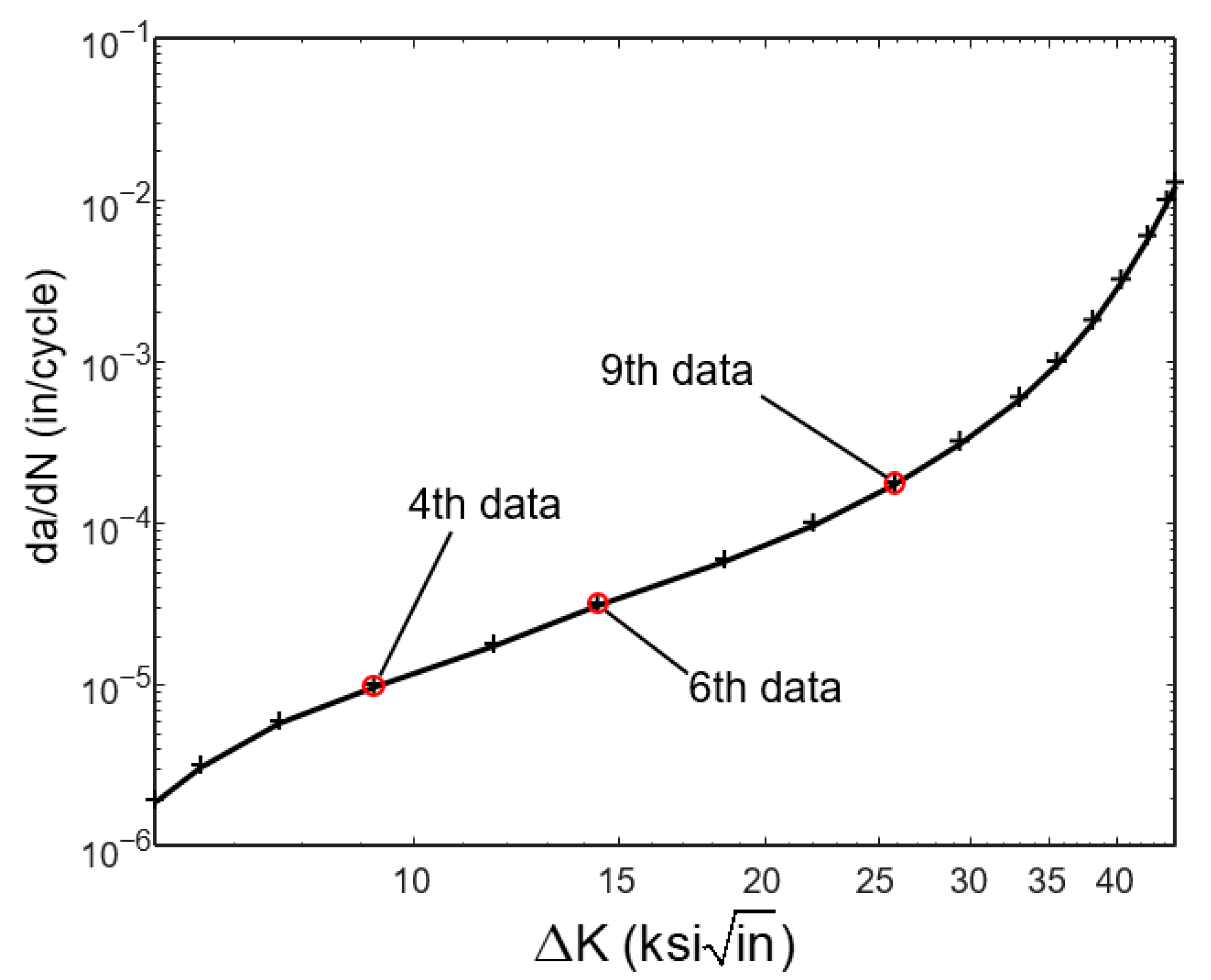

With the given prior distribution, the next step is to calculate the likelihood function using the measured data, as shown in Equation (12). The definition of the likelihood function is the probability (in this case the value of PDF) of obtaining the measured data

for given model parameters

. Since the measured data are fixed, the likelihood function is a function of model parameters. If the model prediction is close to the measured data, then the likelihood is large, while the likelihood is small when the two values are significantly different. To build the likelihood, it is necessary to compare the measured degradation with the predicted one from the model. Since the measured degradation data

are given at discrete times, the degradation model is also evaluated at the same discrete times as

. It is noted that since the degradation model is evaluated at discrete times

tk,

is only a function of model parameters

and

. The measured data

include the random noise that is governed by

, while the model prediction

depends on

and

. Then, the likelihood function of the

k-th measured data can be defined as:

When multiple measured data are present, the likelihood of individual data are multiplied together as shown in Equation (12). With

Ndata data,

, the posterior joint PDF can be calculated by multiplying all likelihood functions with the prior PDF as:

where

is a normalizing constant.

The posterior distribution in Equation (15) can be estimated using a sampling method, such as the Markov-chain Monte-Carlo simulation. However, since the goal is to identify accurate model parameters, a grid method is used to show the posterior PDF. In order to present the results in 2D graph, the third parameter, s, is integrated over its range. The posterior joint PDF is calculated at a 100 × 100 grid. The marginal distribution is calculated by integrating each variable using the grid values.