Shape Optimization of Labyrinth Seals to Improve Sealing Performance

Abstract

:1. Introduction

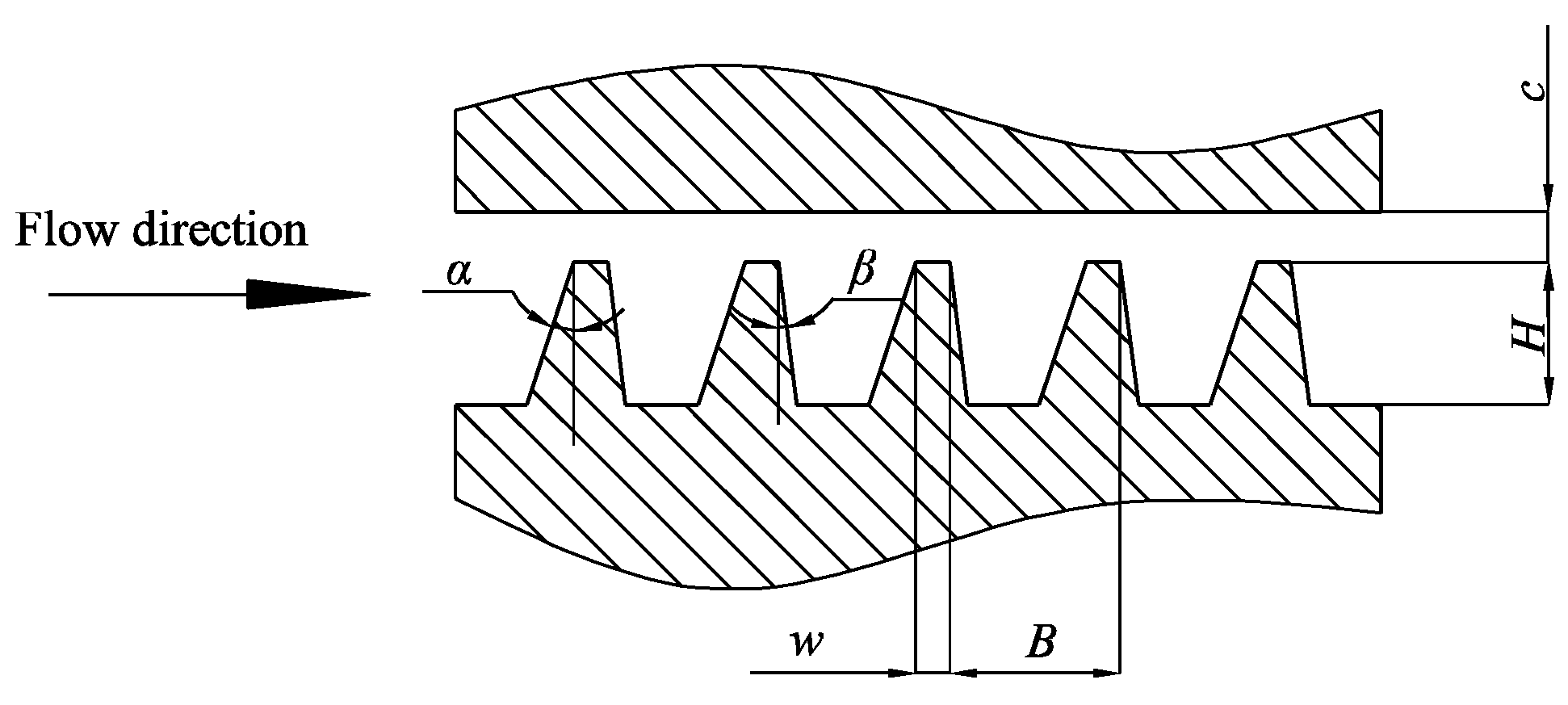

2. Objective Function and Design Variables

3. Optimization Method

3.1. CFD Method

3.2. Surrogate Model Based on LS-SVM

3.3. Chaotic Optimization Algorithm

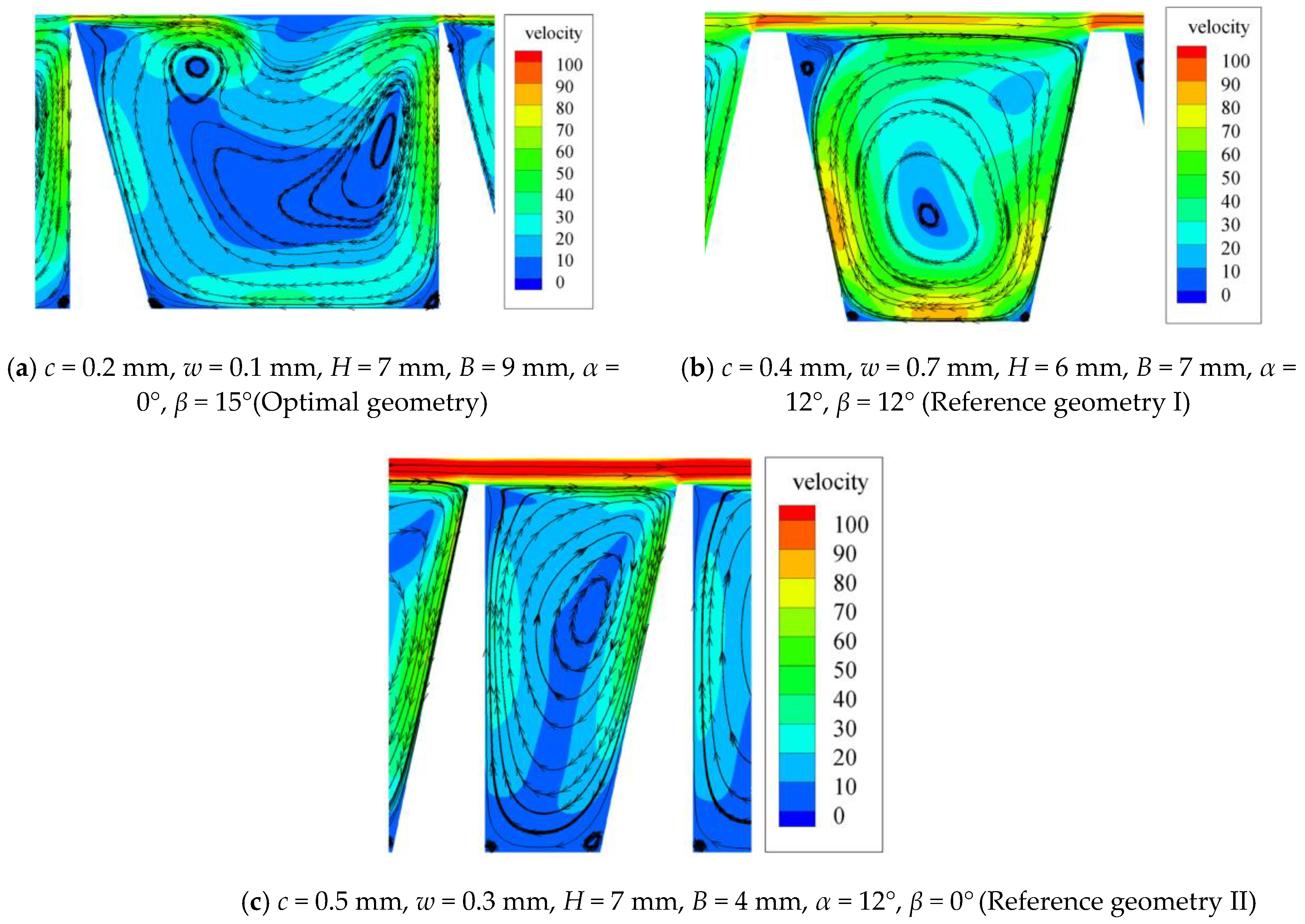

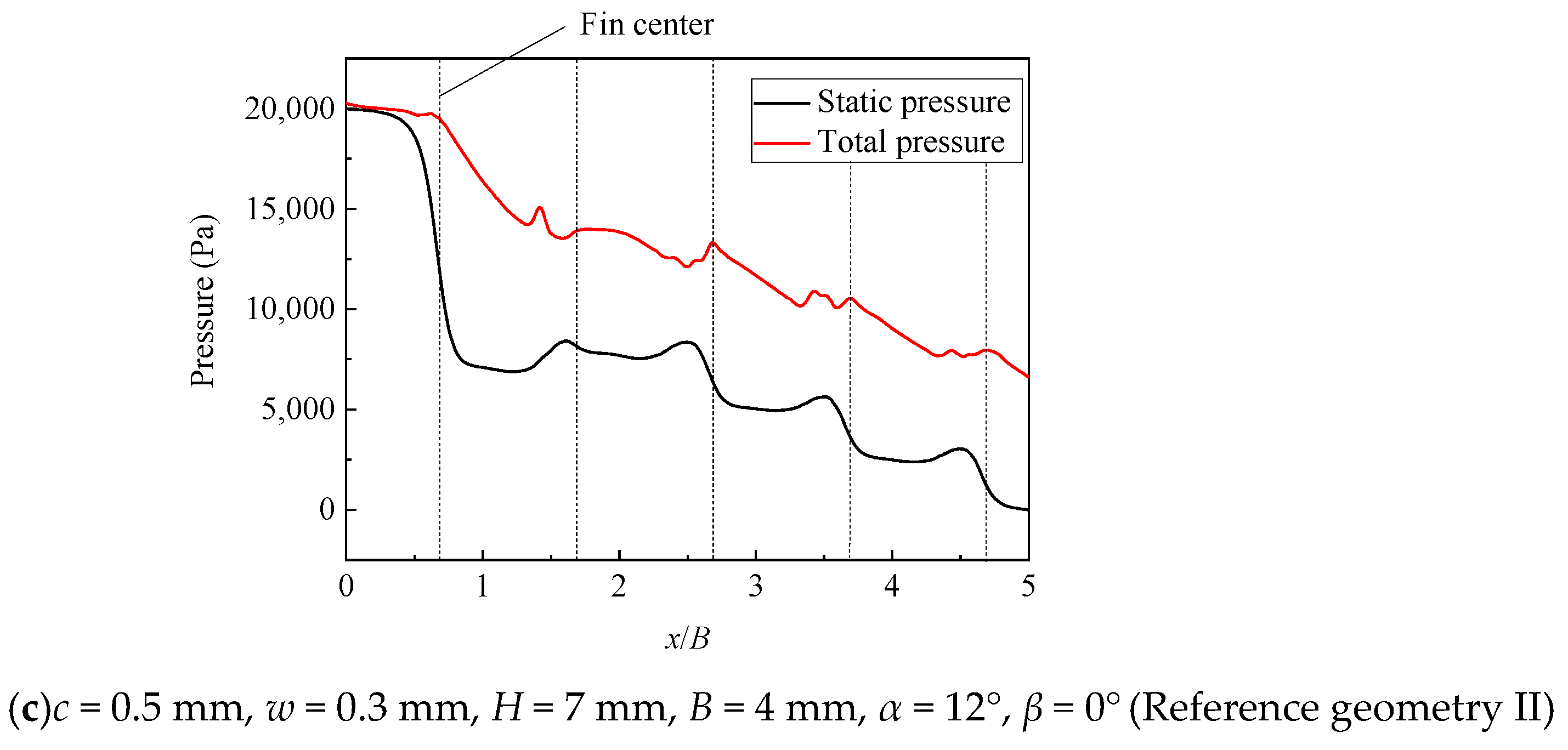

4. Analysis of Results

4.1. CFD Model Validation

4.2. Surrogate Model Validation

4.3. Analysis of Calculation Results from LS-SVM

4.4. Optimization Processes

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nayaka, C. Effect of rotation on leakage and windage heating in labyrinth seals with honeycomb lands. J. Eng. Gas Turbines Power Trans. ASME 2020, 142, 081001. [Google Scholar] [CrossRef]

- Suryanarayanan, S.; Morrison, G.L. Labyrinth seal discharge coefficient for rectangular cavities. In Proceedings of the ASME 2009 Fluids Engineering Division Summer Meeting, Vail, CO, USA, 2–6 August 2009. FEDSM2009-78152. [Google Scholar]

- Witting, S.; Schelling, U.; Kim, S.; Jacobsen, K. Numerical predictions and measurements of discharge coefficient in labyrinth seals. In Proceedings of the ASME International Gas Turbine Conference & Exhibition, Anaheim, CA, USA, 31 May–4 June 1987; The American Society of Mechanical Engineerings: Farifield, NY, USA, 1987. 87-GT-188. [Google Scholar]

- Du, F.Q.; Ji, H.F.; Shuai, H.S.; Zhang, B.; Wang, D.; Lu, H.Y.; Deng, M.C. Orthogonal experiment of effect of fin geometrical parameters on leakage of straight-labyrinth seals. J. Aerosp. Power 2013, 28, 825–831. [Google Scholar]

- Anker, J.E.; Mayer, J.F. Simulation of the interaction of labyrinth seal leakage flow and main flow in an axial turbine. In ASME Turbo Expo 2002: Power for Land, Sea and Air; The American Society of Mechanical Engineerings: Farifield, NY, USA, 2002; GT2002-30348. [Google Scholar]

- Pychynski, T.; Dullenkopf, K.; Bauer, H.J.; Mikut, R. Modeling the labyrinth seal discharge coefficient using data mining methods. In ASME Turbo Expo 2010: Power for Land, Sea, and Air; The American Society of Mechanical Engineerings: Farifield, NY, USA, 2010; GT2010-2266. [Google Scholar]

- Asok, S.P.; Sankaranarayanasamy, K.; Sundararajan, T.; Rajesh, K.; Ganeshan, S.G. Neural network and CFD-based optimisation of square cavity and curved cavity static labyrinth seals. Tribol. Int. 2007, 40, 1204–1216. [Google Scholar] [CrossRef]

- Kim, T.S.; Cha, K.S. Comparative analysis of the influence of labyrinth seal configuration on leakage behavior. J. Mech. Sci. Technol. 2009, 23, 2830–2838. [Google Scholar] [CrossRef]

- Schramm, V.; Denecke, J.; Kim, S.; Witting, S. Shape optimization of a labyrinth seal applying the simulated annealing method. Int. J. Rotating Mach. 2004, 10, 365–371. [Google Scholar] [CrossRef]

- Wang, Z.H.; Xu, L.Q.; Xi, G. Numerical investigation of the labyrinth seal design for a low flow coefficient centrifugal compressor. In ASME Turbo Expo 2010, Power for Land, Sea and Air; The American Society of Mechanical Engineerings: Farifield, NY, USA, 2010; GT2010-23096. [Google Scholar]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Wang, C.H.; Zhang, J.Z.; Zhou, J.H. Prediction of film-cooling effectiveness based on support vector machine. Appl. Therm. Eng. 2015, 83, 82–93. [Google Scholar] [CrossRef]

- Shayeghi, H.; Shayanfar, H.A.; Jalizadeh, S.; Safari, A. Multi-machine power system stabilizers design using chaotic optimization algorithm. Energy Convers. Manag. 2010, 51, 1572–1580. [Google Scholar] [CrossRef]

- Santos, C.L. Turning of PID controller for an automatic regulator voltage system using chaotic optimization approach. ChaosSolitons Fractals 2009, 39, 1504–1514. [Google Scholar] [CrossRef]

- Willenborg, K.; Kim, S.; Witting, S. Effects of Reynolds number and pressure ratio on leakage loss and heat transfer in a stepped labyrinth seal. ASME J. Turbomach. 2011, 123, 815–822. [Google Scholar] [CrossRef]

- Morrison, G.L.; Adnan, A.G. Experimental and computational analysis of a gas compressor windback seal. In ASME Turbo Expo 2007: Power for Land, Sea, and Air; The American Society of Mechanical Engineerings: Farifield, NY, USA, 2007; GT2007-27986. [Google Scholar]

- Suykens, J.A.K.; Vandewalle, J. Least squares support vector machine classifiers. Neural Process. Lett. 1999, 9, 293–300. [Google Scholar] [CrossRef]

- Wang, H.C.; Fang, H.R.; Meng, L.; Xu, F.X. A pre-warning system of abnormal energy consumption in lead smelting based on LSSVR-RP-CI. J. Cent. South Univ. 2019, 26, 2175–2184. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Wang, C.H.; Gong, J.K.; Wang, Y.N. A new adaptive mutative scale chaos optimization algorithm and its application. Control Theory Appl. 2008, 6, 141–145. [Google Scholar]

- Qin, H.Q.; Lu, D.G.; Zhong, D.W.; Wang, Y.; Song, Y. Experimental and numerical investigation for the geometrical parameters effect on the labyrinth-seal flow characteristics of fast reactor fuel assembly. Ann. Nucl. Energy 2020, 135, 106964. [Google Scholar] [CrossRef]

- Ji, G.J.; Ji, H.H. Numerical and experimental investigation of pressure loss and critical sealing characteristics of straight-through labyrinth seals. J. Aerosp. Power 2008, 23, 415–420. [Google Scholar]

| Design Variable | Symbol | Unit | Lower Bound | Upper Bound |

|---|---|---|---|---|

| Fin clearance | c | mm | 0.2 | 0.6 |

| Fin width | w | mm | 0.1 | 0.7 |

| Fin height | H | mm | 3 | 7 |

| Fin pitch | B | mm | 3 | 9 |

| Fin backward expansion angle | α | ° | 0 | 15 |

| Fin forward expansion angle | β | ° | 0 | 15 |

| Number | c (mm) | w (mm) | H (mm) | B (mm) | α(°) | Β(°) | Cd,cal | Cd,exp |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.2 | 0.7 | 3 | 3 | 0 | 0 | 0.438 | 0.450 |

| 2 | 0.3 | 0.7 | 4 | 4 | 5 | 5 | 0.491 | 0.500 |

| 3 | 0.5 | 0.7 | 5 | 6 | 8 | 8 | 0.530 | 0.581 |

| 4 | 0.4 | 0.7 | 6 | 7 | 12 | 12 | 0.403 | 0.389 |

| 5 | 0.6 | 0.7 | 7 | 9 | 15 | 15 | 0.500 | 0.449 |

| 6 | 0.2 | 0.5 | 4 | 6 | 12 | 15 | 0.322 | 0.361 |

| 7 | 0.3 | 0.5 | 5 | 7 | 15 | 0 | 0.365 | 0.426 |

| 8 | 0.5 | 0.5 | 6 | 9 | 0 | 5 | 0.409 | 0.440 |

| 9 | 0.4 | 0.5 | 7 | 3 | 5 | 8 | 0.573 | 0.641 |

| 10 | 0.6 | 0.5 | 3 | 4 | 8 | 12 | 0.608 | 0.551 |

| 11 | 0.2 | 0.3 | 5 | 9 | 5 | 12 | 0.340 | 0.357 |

| 12 | 0.3 | 0.3 | 6 | 3 | 8 | 15 | 0.472 | 0.427 |

| 13 | 0.5 | 0.3 | 7 | 4 | 12 | 0 | 0.609 | 0.595 |

| 14 | 0.4 | 0.3 | 3 | 6 | 15 | 5 | 0.514 | 0.476 |

| 15 | 0.6 | 0.3 | 4 | 7 | 0 | 8 | 0.511 | 0.494 |

| 16 | 0.2 | 0.2 | 6 | 4 | 15 | 8 | 0.460 | 0.516 |

| 17 | 0.3 | 0.2 | 7 | 6 | 0 | 12 | 0.409 | 0.386 |

| 18 | 0.5 | 0.2 | 3 | 7 | 5 | 15 | 0.342 | 0.36 |

| 19 | 0.4 | 0.2 | 4 | 9 | 8 | 0 | 0.412 | 0.369 |

| 20 | 0.6 | 0.2 | 5 | 3 | 12 | 5 | 0.652 | 0.587 |

| 21 | 0.2 | 0.1 | 7 | 7 | 8 | 5 | 0.363 | 0.331 |

| 22 | 0.3 | 0.1 | 3 | 9 | 12 | 8 | 0.292 | 0.274 |

| 23 | 0.5 | 0.1 | 4 | 3 | 15 | 12 | 0.557 | 0.509 |

| 24 | 0.4 | 0.1 | 5 | 4 | 0 | 15 | 0.373 | 0.344 |

| 25 | 0.6 | 0.1 | 6 | 6 | 5 | 0 | 0.539 | 0.497 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Wang, C. Shape Optimization of Labyrinth Seals to Improve Sealing Performance. Aerospace 2021, 8, 92. https://doi.org/10.3390/aerospace8040092

Zhao Y, Wang C. Shape Optimization of Labyrinth Seals to Improve Sealing Performance. Aerospace. 2021; 8(4):92. https://doi.org/10.3390/aerospace8040092

Chicago/Turabian StyleZhao, Yizhen, and Chunhua Wang. 2021. "Shape Optimization of Labyrinth Seals to Improve Sealing Performance" Aerospace 8, no. 4: 92. https://doi.org/10.3390/aerospace8040092

APA StyleZhao, Y., & Wang, C. (2021). Shape Optimization of Labyrinth Seals to Improve Sealing Performance. Aerospace, 8(4), 92. https://doi.org/10.3390/aerospace8040092