Transient Dynamic System Behavior of Pressure Actuated Cellular Structures in a Morphing Wing

Abstract

1. Introduction

2. Methods and Tools

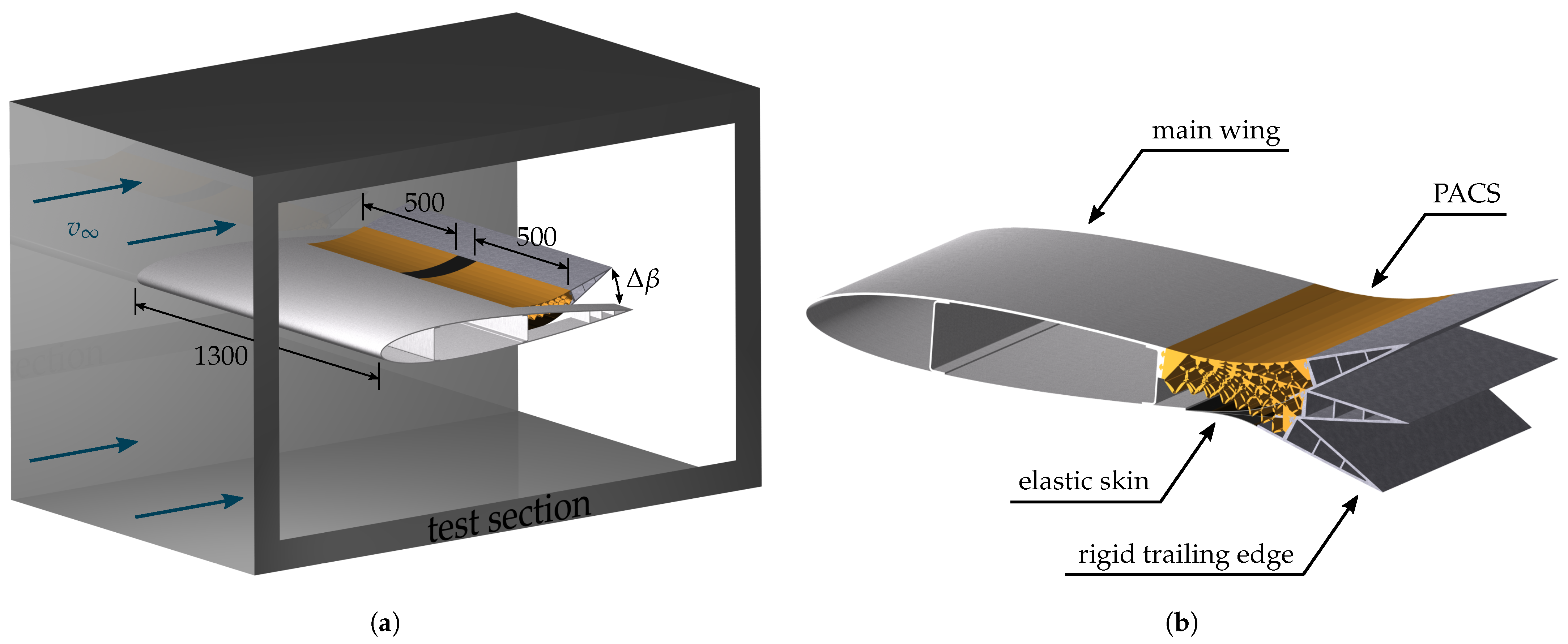

2.1. PACS—Concept and Approach

2.2. Design of a Morphing PACS-Driven Aileron

2.2.1. Operating Conditions and Design Constraints

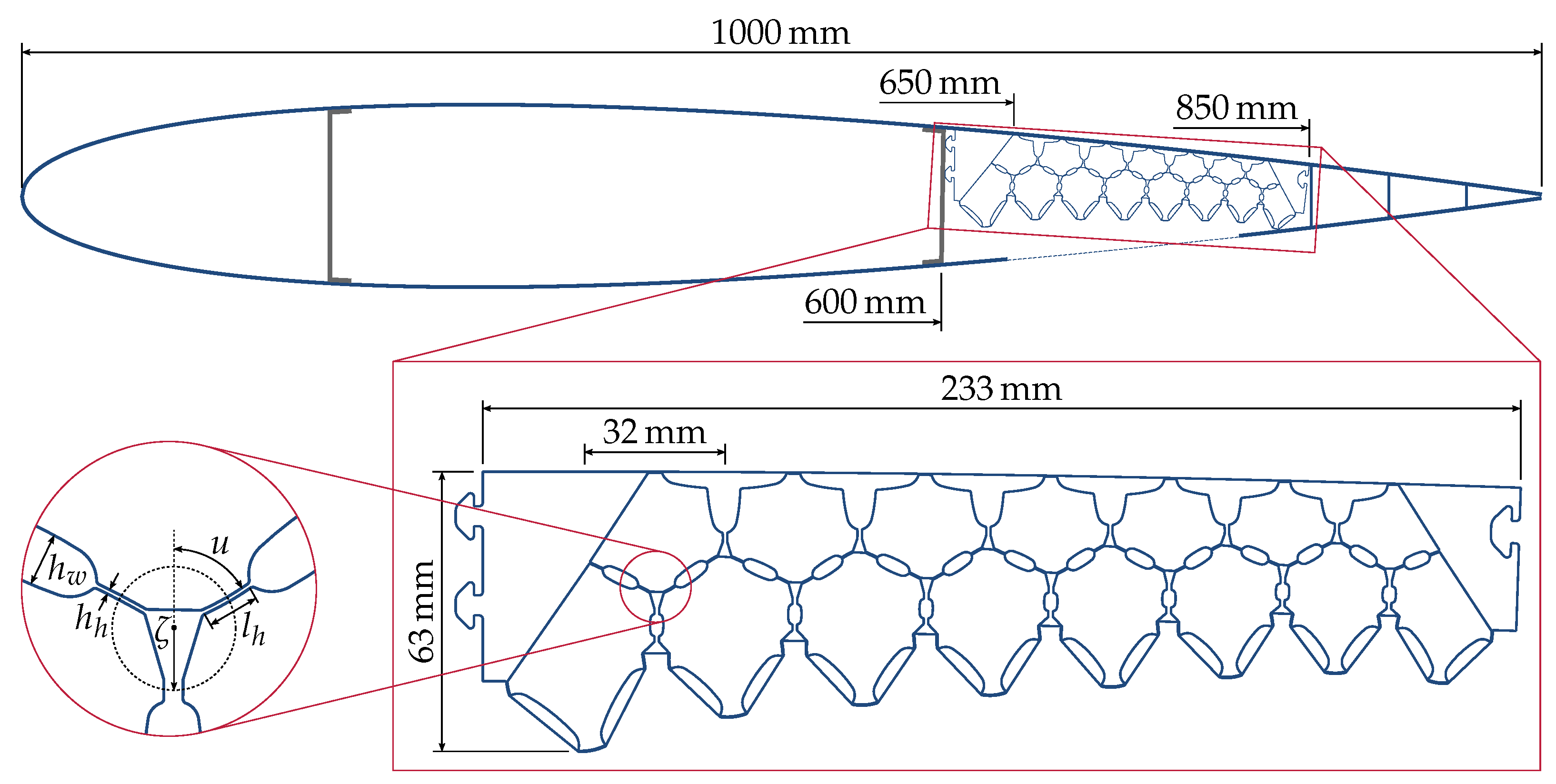

2.2.2. PACS Topology and Initial Shape

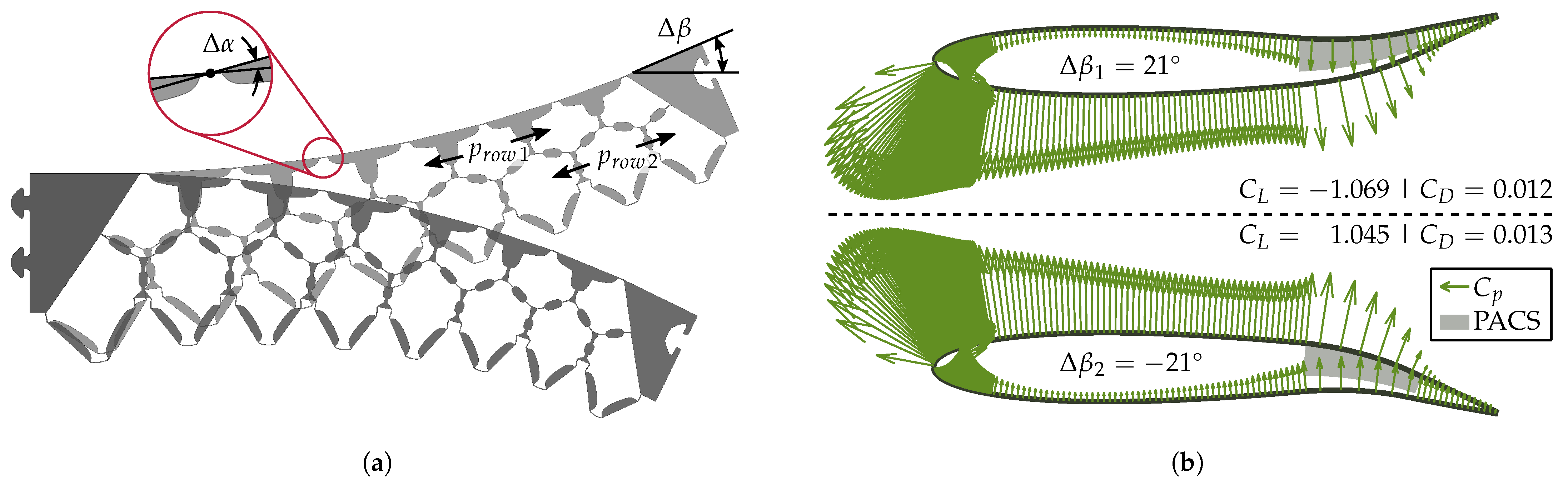

2.2.3. Target Shapes

2.2.4. Loads and Boundary Conditions

2.2.5. Material Selection

2.2.6. Hinge and Cell Wall Sizing

2.2.7. Numerical Model for Verification by FEA

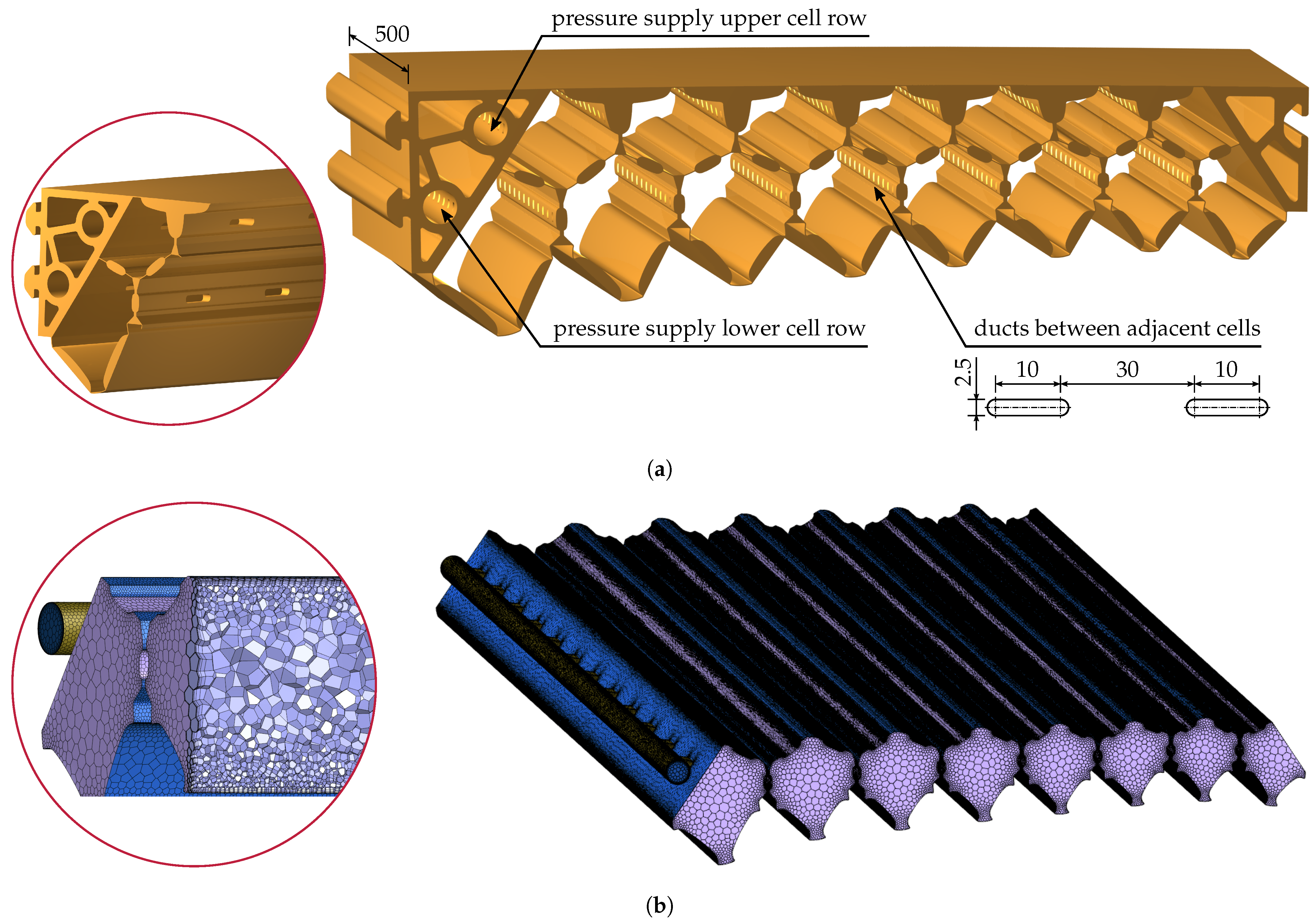

2.3. Pressurization and Internal Flow Behavior of a PACS

2.3.1. Numerical Simulation of the Flow inside a PACS Cell Row Using CFD

2.3.2. PACS-Driven Aileron as a Reduced-Order Model by Pseudo Bond Graph Approach

3. Results

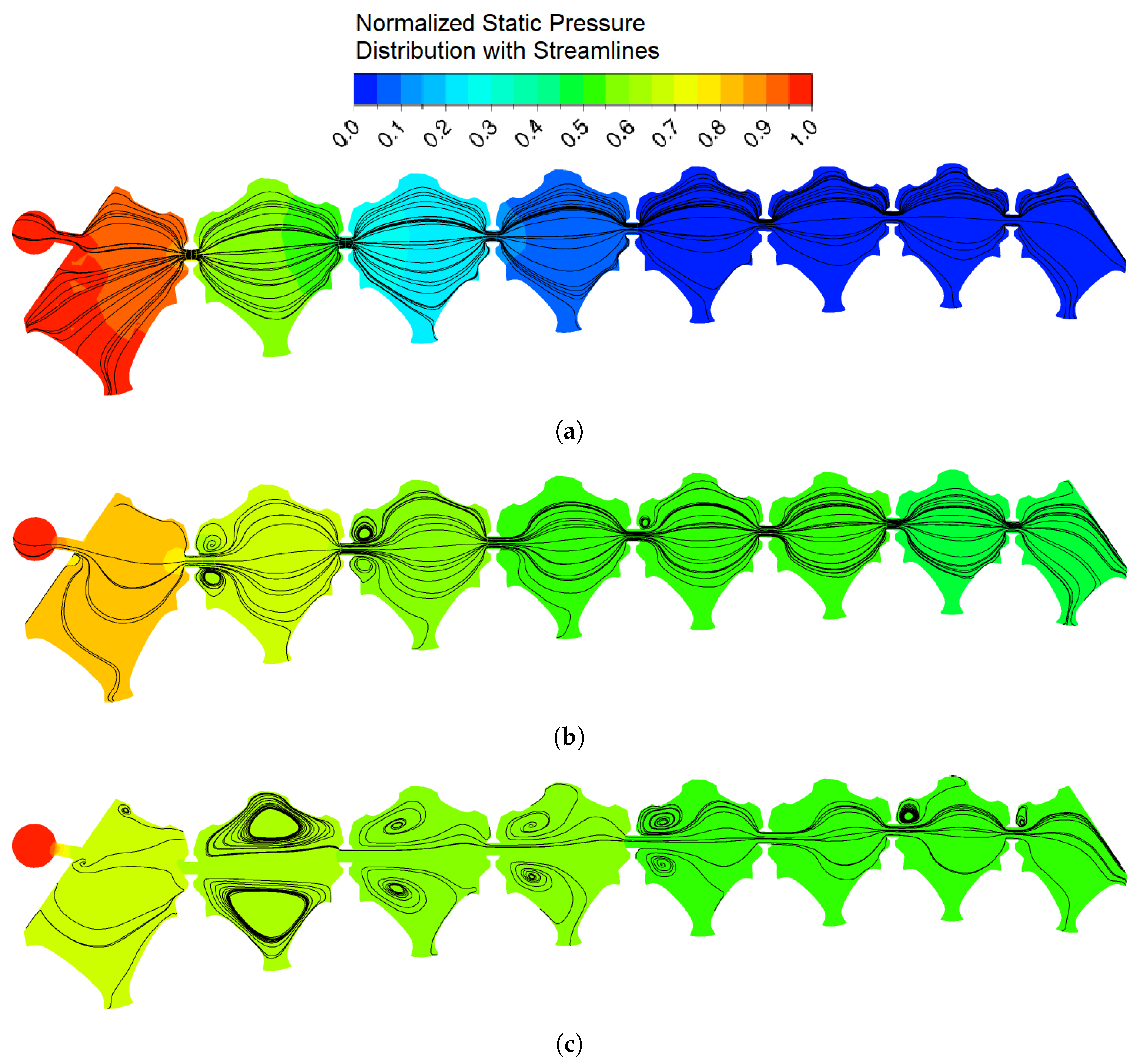

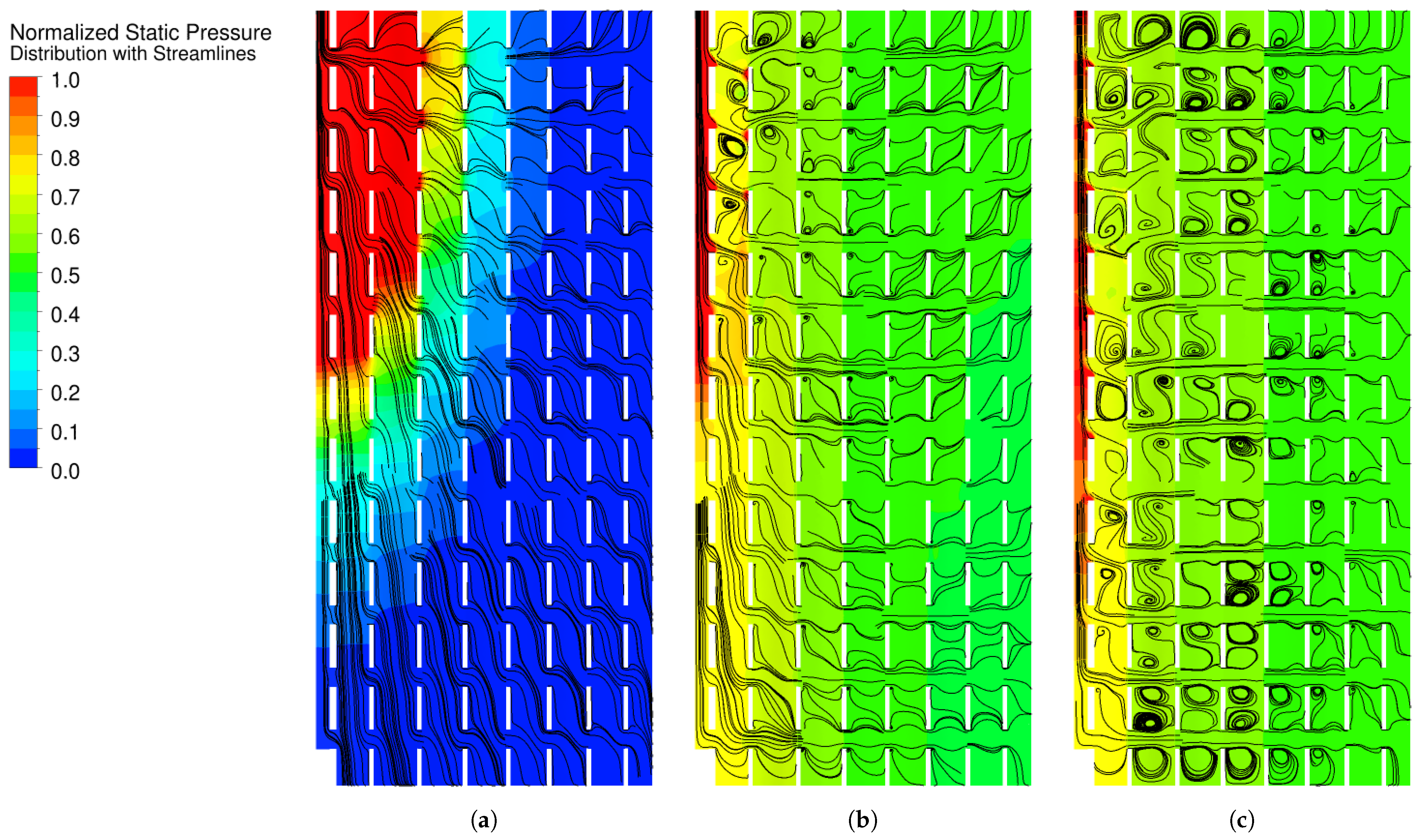

3.1. Studies on the Transient Internal Flow

3.1.1. Flow Behavior Through Ducts and Cells

3.1.2. Variation of Pressurization Time

3.1.3. Pseudo Bond Graph Methodology vs. CFD

3.1.4. Comparison of Duct Cross-Section Geometries

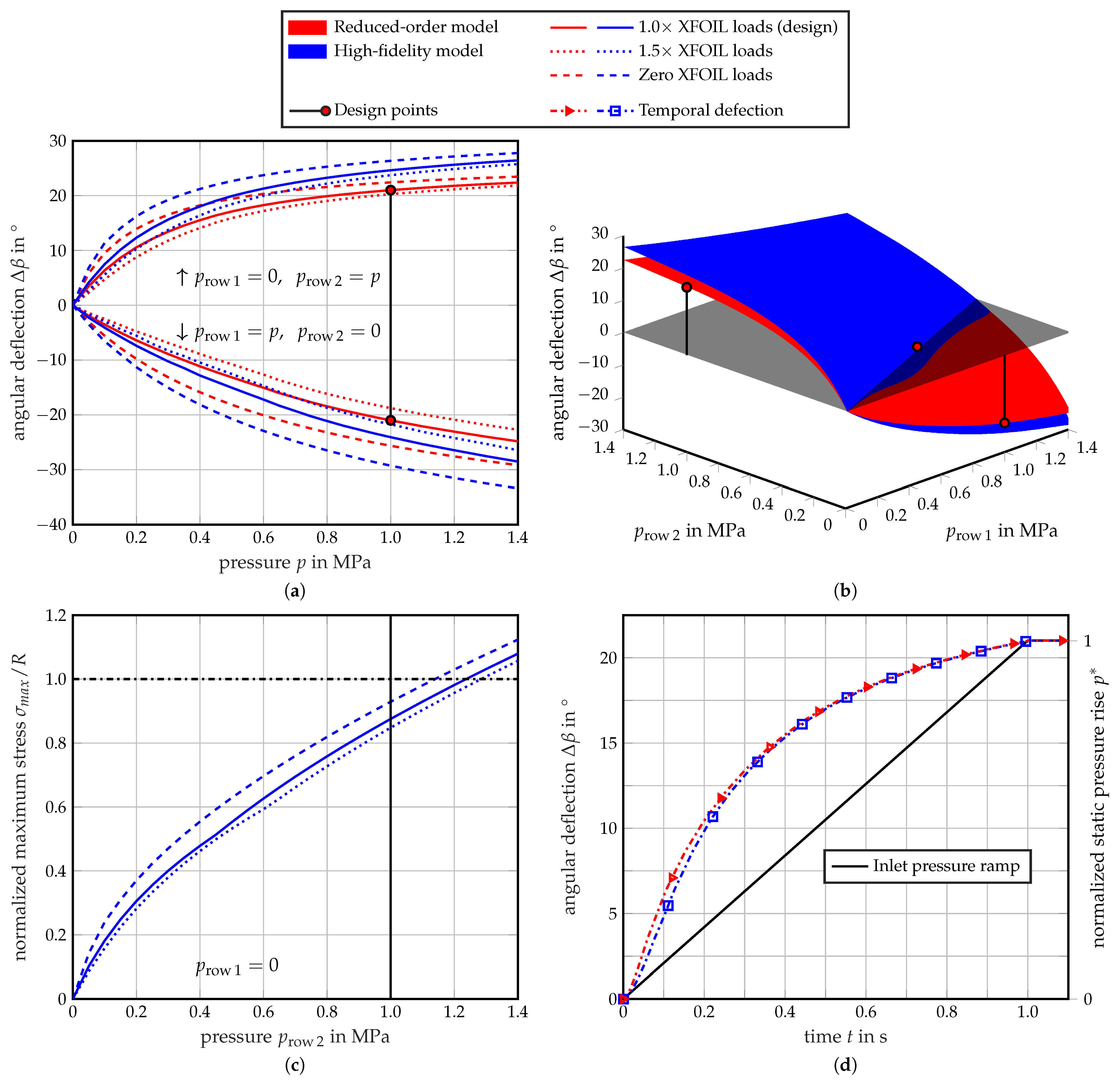

3.2. Studies on Structural Behavior

3.2.1. Reduced-Order Truss Model vs. FEA

3.2.2. Pseudo Bond Graph Methodology vs. CFD

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ASTOR | Aircraft engine simulation for transient operation research |

| CFD | Computational fluid dynamics |

| FEA | Finite element analysis |

| FRP | Fiber reinforced plastic |

| FWT | Folding wingtip |

| GFRP | Glass-fiber reinforced plastic |

| HAR | High aspect ratio |

| PACS | Pressure-actuated cellular structure |

| ROM | Reduced-order model |

Nomenclature

| A | Cross-sectional area |

| Angle of attack | |

| C, | Capacitive or thermal storage |

| Specific heat capacity | |

| E | Young’s modulus |

| Energy flow | |

| e | Effort |

| Flexural stiffness | |

| f | Flow |

| , | Hinge or cell wall thickness |

| I | Inertia storage |

| i, o | Incoming or outgoing |

| l | Hinge length |

| Mass flow | |

| Mach number | |

| n | Number of cells |

| p, | Static or total pressure |

| Heat flow | |

| R | Resistor |

| R | Tensile strength |

| Reynolds number | |

| , | Upper or lower cell row |

| T, | Static or total temperature |

| Turbulence intensity | |

| t | Time |

| u | Hinge angle |

| V | Volume |

| Volume flow | |

| v | Velocity |

| Wall distance | |

| Deflection rate | |

| , | Total pressure or total temperature rise |

| Hinge deflection | |

| Angular deflection per cell | |

| Total angular deflection | |

| Hinge eccentricity | |

| Poisson’s ratio | |

| Density | |

| Maximum equivalent stress |

References

- Afonso, F.; Vale, J.; Oliveira, É.; Lau, F.; Suleman, A. A review on non-linear aeroelasticity of high aspect-ratio wings. Prog. Aerosp. Sci. 2017, 89, 40–57. [Google Scholar] [CrossRef]

- Cheung, R.C.M.; Rezgui, D.; Cooper, J.E.; Wilson, T. Testing of Folding Wingtip for Gust Load Alleviation of Flexible High-Aspect-Ratio Wing. J. Aircr. 2020, 57, 876–888. [Google Scholar] [CrossRef]

- Pattinson, J.; Wilson, T.; Herring, M. High Fidelity Simulation of the Folding Wing Tip for Loads Alleviaton. In Proceedings of the International Forum on Aeroelasticity and Structural Dynamics (IFASD 2015), Petersburg, Russia, 28 June–2 July 2015; IFASD, Ed.; Curran Associates: Red Hook, NY, USA, 2015; pp. 805–820. [Google Scholar]

- Airbus, S.A.S. Wing of the Future: No Winging It Here. 2017. Available online: https://www.airbus.com/newsroom/news/en/2017/01/Wings-of-the-future.html (accessed on 16 February 2021).

- Sanders, B.; Eastep, F.E.; Forster, E. Aerodynamic and Aeroelastic Characteristics of Wings with Conformal Control Surfaces for Morphing Aircraft. J. Aircr. 2003, 40, 94–99. [Google Scholar] [CrossRef]

- Thill, C.; Etches, J.; Bond, I.; Potter, K.; Weaver, P.M. Morphing skins. Aeronaut. J. 2008, 112, 117–139. [Google Scholar] [CrossRef]

- Sinapius, M.; Monner, H.P.; Kintscher, M.; Riemenschneider, J. DLR’s Morphing Wing Activities within the European Network. Procedia IUTAM 2014, 10, 416–426. [Google Scholar] [CrossRef]

- Kintscher, M.; Wiedemann, M.; Monner, H.P.; Heintze, O.; Kühn, T. Design of a smart leading edge device for low speed wind tunnel tests in the European project SADE. Int. J. Struct. Integr. 2011, 2, 383–405. [Google Scholar] [CrossRef]

- Kota, S.; Flick, P.; Collier, F.S. Flight Testing of FlexFloil™Adaptive Compliant Trailing Edge. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2016. [Google Scholar] [CrossRef]

- Barrett, R.M. Active aeroelastic tailoring of an adaptive Flexspar stabilator. Smart Mater. Struct. 1996, 5, 723–730. [Google Scholar] [CrossRef]

- Elzey, D.M.; Sofla, A.Y.N.; Wadley, H.N.G. A bio-inspired, high-authority actuator for shape morphing structures. In Proceedings of the Smart Structures and Materials 2003: Active Materials: Behavior and Mechanics, San Diego, CA, USA, 3–6 March 2003; Lagoudas, D.C., Ed.; SPIE: Bellingham, WA, USA, 2003; pp. 92–100. [Google Scholar] [CrossRef]

- Barbarino, S.; Bilgen, O.; Ajaj, R.M.; Friswell, M.I.; Inman, D.J. A Review of Morphing Aircraft. J. Intell. Mater. Syst. Struct. 2011, 22, 823–877. [Google Scholar] [CrossRef]

- Li, S.; Wang, K.W. Plant-inspired adaptive structures and materials for morphing and actuation: A review. Bioinspir. Biomimet. 2017, 12, 011001:1–011001:17. [Google Scholar] [CrossRef]

- Huber, J.E.; Fleck, N.A.; Ashby, M.F. The selection of mechanical actuators based on performance indices. Proc. R. Soc. A Math. Phys. Eng. Sci. 1997, 453, 2185–2205. [Google Scholar] [CrossRef]

- Barrett, R.M.; Barrett, C.M. Biomimetic FAA-certifiable, artificial muscle structures for commercial aircraft wings. Smart Mater. Struct. 2014, 23, 074011:1–074011:15. [Google Scholar] [CrossRef]

- Dittrich, K. Cellular Actuator Device and Methods of Making and Using Same. U.S. Patent US7055782B2, 6 June 2006. [Google Scholar]

- Vos, R.; Barrett, R.M. Mechanics of pressure-adaptive honeycomb and its application to wing morphing. Smart Mater. Struct. 2011, 20, 094010. [Google Scholar] [CrossRef]

- Vasista, S.; Tong, L. Topology-Optimized Design and Testing of a Pressure-Driven Morphing-Aerofoil Trailing-Edge Structure. AIAA J. 2013, 51, 1898–1907. [Google Scholar] [CrossRef]

- Luo, Q.; Tong, L. Adaptive pressure-controlled cellular structures for shape morphing I: Design and analysis. Smart Mater. Struct. 2013, 22, 055014:1–055014:16. [Google Scholar] [CrossRef]

- Lv, J.; Ren, X.; Song, C.; Zhang, H. Two-Scale Topology Optimization of the 3D Plant-Inspired Adaptive Cellular Structures for Morphing Applications. J. Aerosp. Eng. 2020, 33, 04020032. [Google Scholar] [CrossRef]

- Vasista, S.; Riemenschneider, J.; Mendrock, T.; Monner, H.P. Pressure-Driven Morphing Devices for 3D Shape Changes with Multiple Degrees-of-Freedom. In Proceedings of the ASME 2018 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, San Antonio, TX, USA, 10–12 September 2018; American Society of Mechanical Engineers: Fairfield, NY, USA, 2018; pp. 1–11. [Google Scholar]

- Boyraz, P.; Runge, G.; Raatz, A. An Overview of Novel Actuators for Soft Robotics. Actuators 2018, 7, 48. [Google Scholar] [CrossRef]

- Hühne, C.; Boblenz, J.; Meyer, P. Cellular Structures Actuated by Internal Pressure and Variable in Shape. In Adaptronics—Smart Structures and Materials; Sinapius, M., Ed.; Springer: Berlin, Germany, 2021; pp. 189–204. [Google Scholar]

- Pagitz, M.; Lamacchia, E.; Hol, J.M.A.M. Pressure-actuated cellular structures. Bioinspir. Biomimet. 2012, 7, 016007:1–016007:19. [Google Scholar] [CrossRef]

- Gramüller, B.; Boblenz, J.; Hühne, C. PACS—Realization of an adaptive concept using pressure actuated cellular structures. Smart Mater. Struct. 2014, 23, 115006:1–115006:17. [Google Scholar] [CrossRef]

- Gramüller, B.; Köke, H.; Hühne, C. Holistic design and implementation of pressure actuated cellular structures. Smart Mater. Struct. 2015, 24, 125027:1–125027:28. [Google Scholar] [CrossRef]

- Gramüller, B.; Tempel, A.; Hühne, C. Shape-variable seals for pressure actuated cellular structures. Smart Mater. Struct. 2015, 24, 095005:1–095005:20. [Google Scholar] [CrossRef]

- Adami, M.; Seibel, A. On-Board Pneumatic Pressure Generation Methods for Soft Robotics Applications. Actuators 2019, 8, 2. [Google Scholar] [CrossRef]

- Vasista, S.; Titze, M.; Schäfer, M.; Bertram, O.; Riemenschneider, J.; Monner, H.P. Structural and Systems Modelling of a Fluid-driven Morphing Winglet Trailing Edge. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2020; pp. 1–19. [Google Scholar] [CrossRef]

- Gramüller, B.; Hühne, C. Enhanced design methods for pressure actuated cellular structures and evaluation. In Proceedings of the SAMPE Long Beach 2016, Long Beach, CA, USA, 23–26 May 2016. [Google Scholar]

- Vechtel, D.; Hauber, B.; Looye, G. Analysis of a multi-functional high-lift system driven by an active differential gear box. CEAS Aeronaut. J. 2014, 5, 227–238. [Google Scholar] [CrossRef]

- Xu, J.; Kroo, I. Aircraft Design with Active Load Alleviation and Natural Laminar Flow. J. Aircr. 2014, 51, 1532–1545. [Google Scholar] [CrossRef]

- Gern, F.H.; Inman, D.J.; Kapania, R.K. Computation of Actuation Power Requirements for Smart Wings with Morphing Airfoils. AIAA J. 2005, 43, 2481–2486. [Google Scholar] [CrossRef]

- Meyer, P.; Boblenz, J.; Sennewald, C.; Vorhof, M.; Hühne, C.; Cherif, C.; Sinapius, M. Development and Testing of Woven FRP Flexure Hinges for Pressure-Actuated Cellular Structures with Regard to Morphing Wing Applications. Aerospace 2019, 6, 116. [Google Scholar] [CrossRef]

- Göing, J.; Kellersmann, A.; Bode, C.; Friedrichs, J. Jet Propulsion Engine Modelling Using Pseudo Bond Graph Approach. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019; American Society of Mechanical Engineers: Fairfield, NY, USA, 2019; pp. 1–11. [Google Scholar] [CrossRef]

- Lück, S.; Göing, J.; Bode, C.; Friedrichs, J. Pseudo Bond Graph System Modelling of Electric Air Compressors With Energy Recovery for Fuel Cell Applications. In Proceedings of the ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, London, UK, 22–26 June 2020; American Society of Mechanical Engineers: Fairfield, NY, USA, 2020; pp. 1–12. [Google Scholar] [CrossRef]

- Margolis, D.L. Bond Graph Fluid Line Models for Inclusion with Dynamic Svstems Simulations. J. Frankl. Inst. 1979, 308, 255–268. [Google Scholar] [CrossRef]

- Karnopp, D.; Margolis, D.L.; Rosenberg, R.C. System Dynamics: Modeling, Simulation, and Control of Mechatronic Systems, 5th ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Pagitz, M.; Leine, R.I. Shape optimization of compliant pressure actuated cellular structures. Int. J. Non Linear Mech. 2017, 94, 268–280. [Google Scholar] [CrossRef]

| Category | Parameter | Value |

|---|---|---|

| Geometry | Number of cells n | upper row: 7, lower row: 8 |

| Size of the first cell | 32 mm | |

| Taper factor | 0.75 | |

| Cell wall thickness | ||

| Hinge thickness | ||

| Hinge length | ||

| Hinge eccentricity | ||

| Performance | Maximum cell pressure | |

| Angular deflection per cell | ±3° | |

| Total angular deflection | ±21° | |

| Material | Young’s modulus E | 42,000 MPa |

| Tensile strength R | 1200 MPa | |

| Poisson’s ratio | 0.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meyer, P.; Lück, S.; Spuhler, T.; Bode, C.; Hühne, C.; Friedrichs, J.; Sinapius, M. Transient Dynamic System Behavior of Pressure Actuated Cellular Structures in a Morphing Wing. Aerospace 2021, 8, 89. https://doi.org/10.3390/aerospace8030089

Meyer P, Lück S, Spuhler T, Bode C, Hühne C, Friedrichs J, Sinapius M. Transient Dynamic System Behavior of Pressure Actuated Cellular Structures in a Morphing Wing. Aerospace. 2021; 8(3):89. https://doi.org/10.3390/aerospace8030089

Chicago/Turabian StyleMeyer, Patrick, Sebastian Lück, Tobias Spuhler, Christoph Bode, Christian Hühne, Jens Friedrichs, and Michael Sinapius. 2021. "Transient Dynamic System Behavior of Pressure Actuated Cellular Structures in a Morphing Wing" Aerospace 8, no. 3: 89. https://doi.org/10.3390/aerospace8030089

APA StyleMeyer, P., Lück, S., Spuhler, T., Bode, C., Hühne, C., Friedrichs, J., & Sinapius, M. (2021). Transient Dynamic System Behavior of Pressure Actuated Cellular Structures in a Morphing Wing. Aerospace, 8(3), 89. https://doi.org/10.3390/aerospace8030089