1. Introduction

The deployment of large low-Earth orbit (LEO) satellite constellations became reality in the past couple of years, with hundreds of small satellites being placed on LEO [

1,

2]. It came with no surprise when the mission planners opted for electric propulsion as main propulsive system of their satellites. Proved to offer a drastic reduction in fuel consumption, compared to chemical propulsion systems, and capable of firing for long time intervals with high system fault tolerance, the electric propulsion systems seemed to be ideal for LEO small satellite missions, thus, increasing interest in developing efficient and reliable electric propulsion systems.

The space sector, and mainly the satellite telecom sector, shows an increasing interest in solar electric propulsion as propulsion systems for attitude determination and control systems (ADCS) and even as main propulsion system (orbit control). The rapid expansion of the solar electric propulsion domain came after the recognition of the successful interplanetary missions run by various space agencies which proved the reliability and the excellent versatility of those devices. High power electric propulsion thrusters have been developed in the range of 2–5 kW, such as the PPS1350-E and PPS5000 by Snecma, the T6 by QinetiQ, RIT-22 by ArianeGroup, and the HEMPT3050 (High Efficiency Multistage Plasma Thruster) by Thales Alenia Space. Commercial companies have already launched all-electric satellite platforms on geostationary orbit (GEO), such as Boeing’s 702SP platform [

3], the fist high-power all-electric telecom satellite in the world, EUROSTAR3000EOR platform by Eutelsat and Eurostar NEO by SES [

4,

5]. GSAT-4, an Indian satellite, marks a first for the Asian telecom and navigation market with the first GEO platform equipped with four Hall thrusters [

6], although the satellite failed to reach its orbit due to launch vehicle malfunction. The GSAT-9 mission was a success with the four Hall thrusters being used for station keeping and orbit control [

7]. LEO constellations, like the one proposed by OneWeb and SpaceX’s Starlink, are planned to have hundreds of satellites deployed for internet coverage, all equipped with electric propulsion thrusters [

8]. As of April 2020, Starlink constellation already has 422 satellites equipped with krypton-fed Hall thrusters [

9], while OneWeb’s 76 satellites operate low-power xenon-fed Hall thrusters [

1].

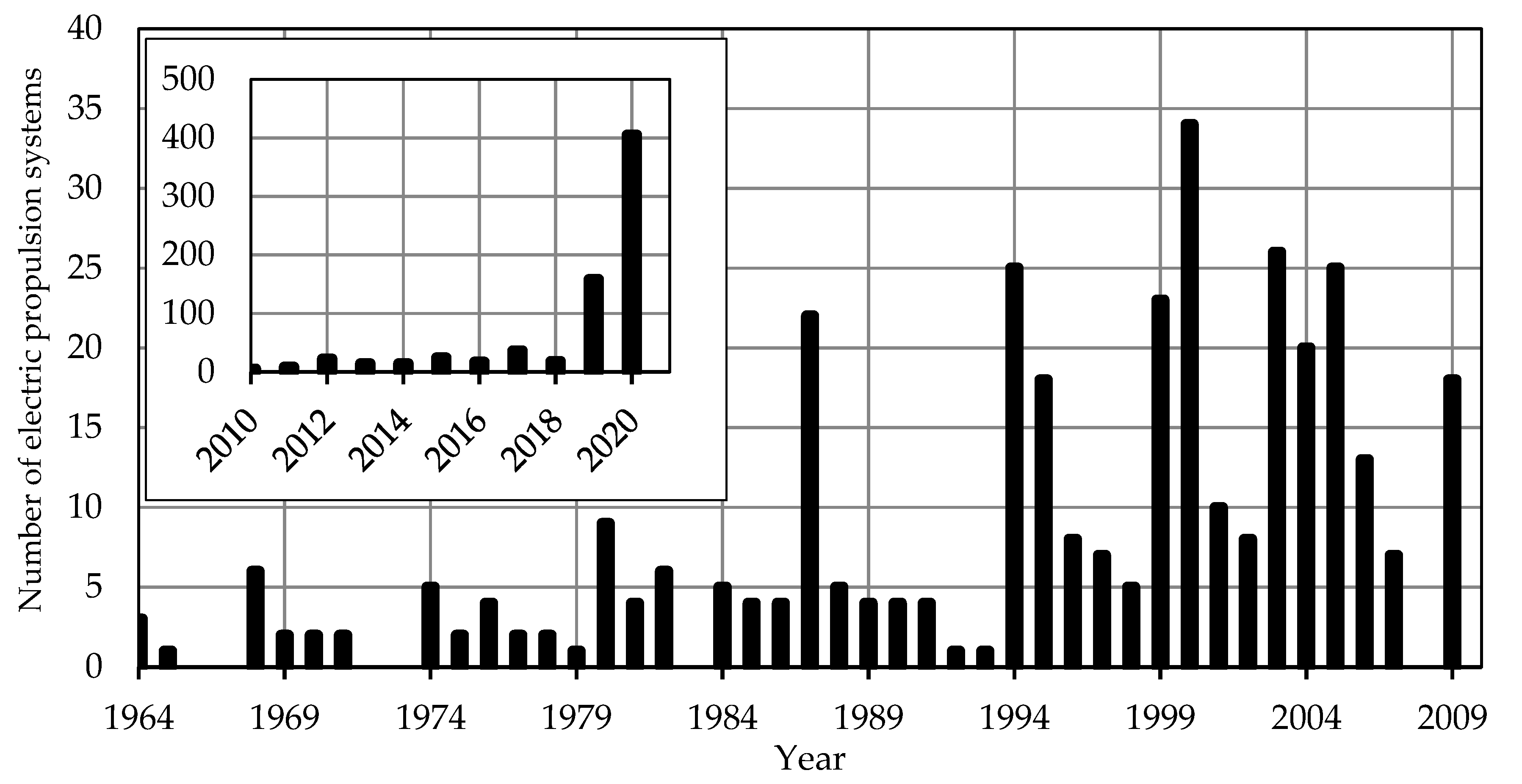

Figure 1 depicts the approximate number of electric propulsion systems that were deployed in space since 1964 until today. It is worth noticing that only in the past 10 years the number of electric propulsion systems more than doubled, compared to the first 45 years, and this can be explained by the large number of satellites with electric propulsion deployed by SpaceX and OneWeb. Furthermore, almost 80% of the total electric propulsion systems launched accounts for Hall thrusters, while 10% for ion engines.

Most of the systems counted in

Figure 1 are high-power systems as they are the best choice for GEO missions, for both station keeping and orbit insertion, and for interplanetary travel. On the other hand, low-power electric propulsion systems can be employed for low orbit missions and small form-factor platforms (of a few units, 1U = 10 cm × 10 cm × 10 cm), 1–500 kg [

11]. Such satellites would need thrusts up to several mN, and since the main tasks for such propulsion systems would be to compensate drag, ADCS and collision avoidance maneuvers, orbital phasing, and formation flying, they will need to produce a high delta-V. Another possible mission that will require a thruster would be the controlled deorbit at the end of life. For ADCS purposes, field emission electric propulsion (FEEP) systems, vacuum arc thrusters (VAT), pulsed plasma thrusters (PPT), or arcjets have been already extensively used. A first successful commercial in-orbit demonstration of a FEEP system for a 3U satellite was achieved in 2016 by Planet Labs’ Flock-3p satellite with IFM Nano from Enpulsion [

12]. However, in the range of 50 W to 100 W the Hall thruster technology can be the perfect candidate for the job of producing relatively high thrusts with high efficiencies, allowing them to be used as a main propulsive system as well as an ADCS, thus, offering both off-orbit and in-orbit autonomy.

Low-power Hall thrusters with classical designs are known to lose thrust efficiency and specific impulse once the input power is lowered. A few innovative designs have been considered to overcome this drawback, including the wall-less technology and the magnetically shielded thrusters. Nevertheless, the cathode remains an instrumental component of a Hall thruster, and as the power level drops, such thermionic emitters would be required to sustain and neutralize a current usually under 1 A. Therefore, the development of low-current cathodes, working in self-sustained mode while consuming external power only during the startup, remains a priority for many electric propulsion research and industrial entities.

At the Plasma Sources and Applications Centre/Space Propulsion Centre Singapore (PSAC/SPC), research on electric propulsion encompasses topics such as low-power Hall thrusters, low-current thermionic cathodes and material processing [

13,

14,

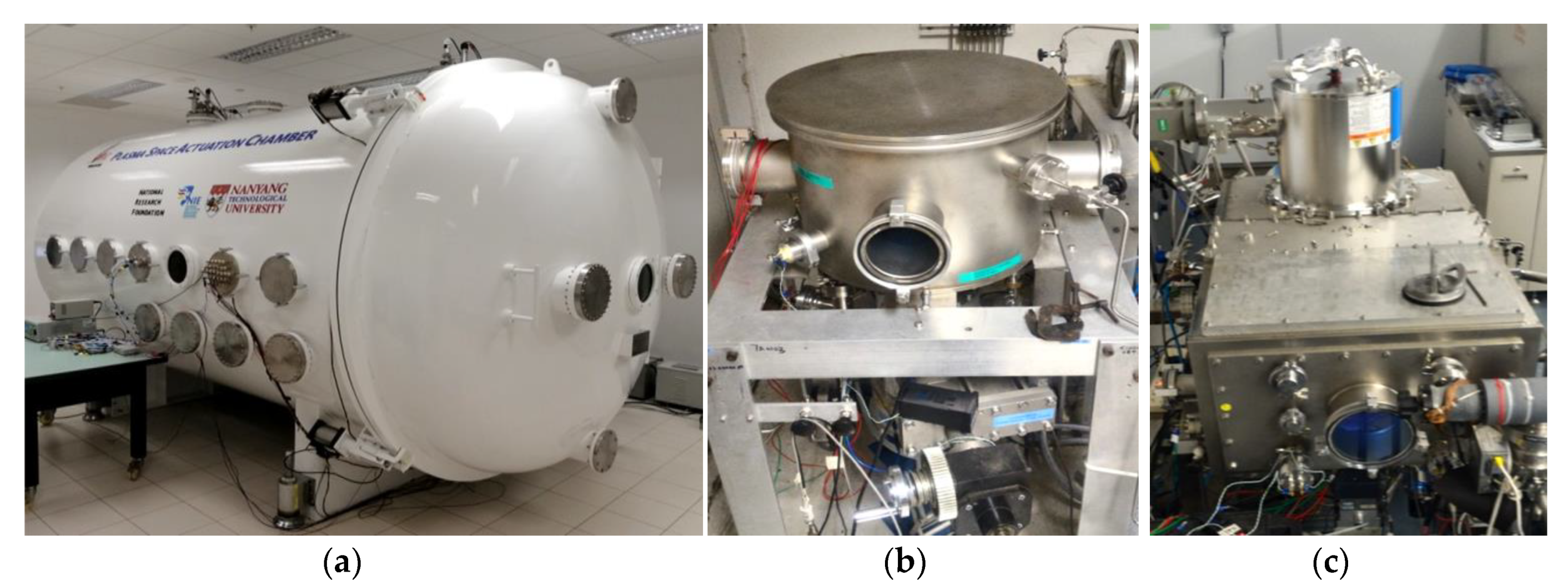

15]. Several classes of Hall thrusters have been designed, manufactured, and operated in the range of 5 to 200 W, while 1 A-class thermionic cathodes were developed to work with the Hall thrusters and have been studied in order to understand the discharge mode transition as well as to construct scaling laws for such devices. Harnessing the knowledge on the rotamak fusion device, at PSAC/SPC, substantial numerical and experimental research is dedicated to the conversion of the rotamak device into an electrodeless plasma thruster. To sustain the research in the field of electric propulsion, several vacuum test facilities of various sizes have been designed and set up, from small (<0.3 m

3) chambers primarily for cathode studies to the Space Environment Simulation Chamber (SESC), a 19.7 m

3, 4.75 m long vacuum test facility used for Hall thruster and cubesat research [

16,

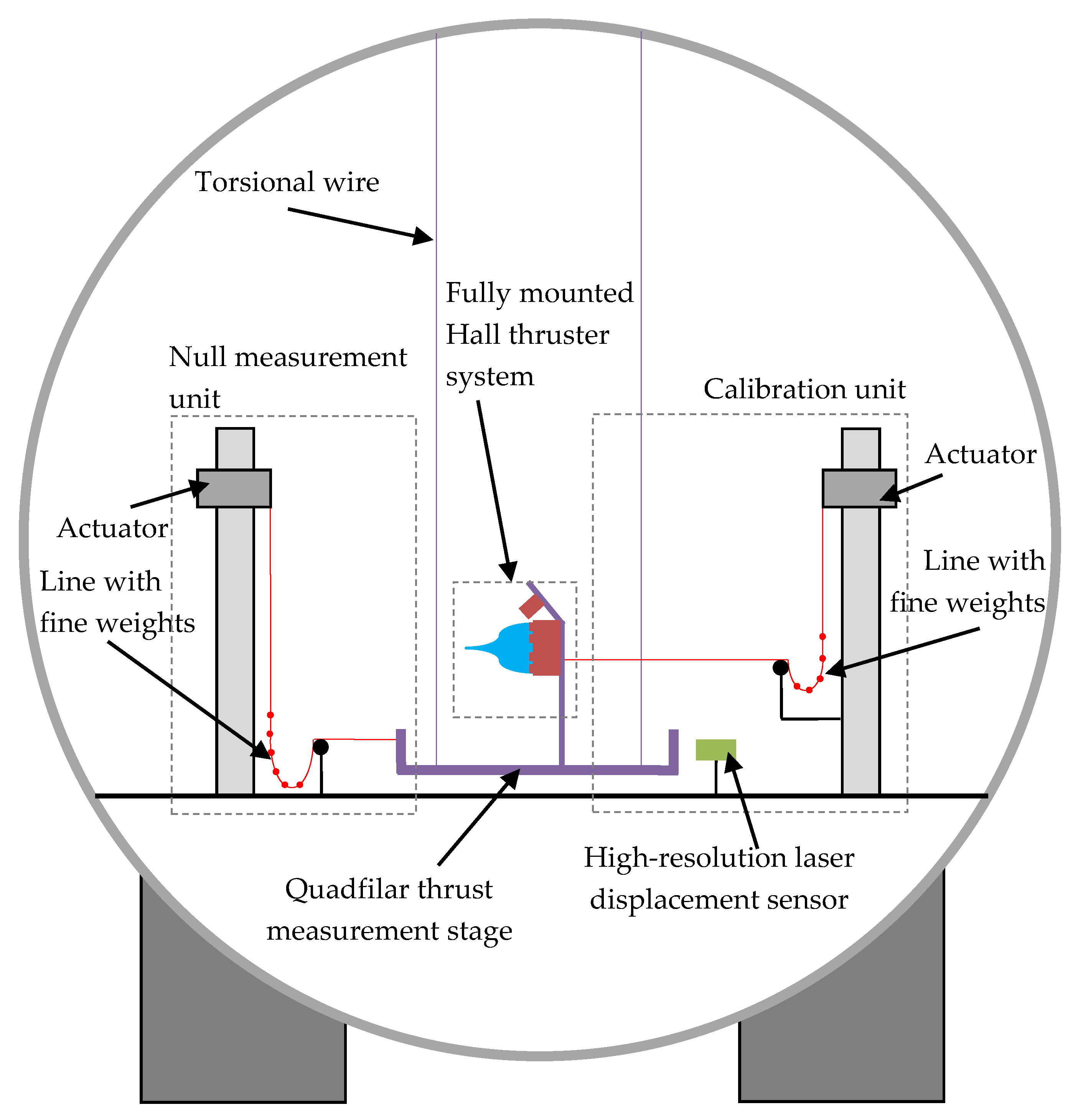

17]. An innovative thrust stand was developed and installed in SESC, while a series of plasma diagnostics, including optical emission spectroscopy (OES), retarding potential analyzers (RPA), Hall probes, Faraday cups, and Langmuir probes were used to characterize plasma properties in the plumes of Hall thrusters, thermionic cathodes, as well as rotamak devices. The following sections introduce and discuss each of the aforementioned facilities, devices, and plasma diagnostics together with selected experimental results.

3. Hall Thrusters: Development and Testing

The primary focus of the research at PSAC/SPC is the development of low-power Hall thrusters that can be used for small satellite platforms. Designing efficient low-power Hall thrusters has been an arduous process and research teams quickly realized that a miniaturized classical geometry of the thruster and the reduction in discharge power comes with a significant drop in thrust efficiency [

40,

41]. At PSAC/SPCS, three classes of Hall thruster have been developed spanning from several watts to hundreds of watts while producing a thrust from μN to mN range. Naturally, the development of Hall thrusters compelled the development of low-current cathodes, which is discussed in

Section 4. The thrusters and cathodes are operated with Ar, Kr, and Xe and their performances are assessed using the diagnostics described in the previous sections. The latest class of Hall thrusters presented in

Section 3.3 is an innovative concept that eliminated the need of an active, external electron emitter, while operating at high discharge voltages.

3.1. 200 W-Class Hall Thrusters

The first class of Hall thrusters developed at PSAC/SPC is a 200 W-class Hall thruster. The thruster has a classical design with a ceramic discharge channel and is operated with an external thermionic electron emitter. The first iteration of the thruster design employed a hybrid magnetic system with internal permanent magnets and external coil. The thruster operating with Xe together with the first design of the PSAC 1 A-class cathode is depicted in

Figure 6a.

The second iteration of the thruster employed electromagnetic coils for both the internal and external magnetic circuit. In general, at low discharge power levels, the magnetic field can be generated only by the internal coil which requires 1 W of power on average. However, at higher discharge power levels, both the internal and external magnetic coils are used with an average power of 3 W. The upgraded thruster with the new generation of the PSAC cathode is presented in

Figure 6b. Moreover, a schematic of the thruster is shown in

Figure 6c.

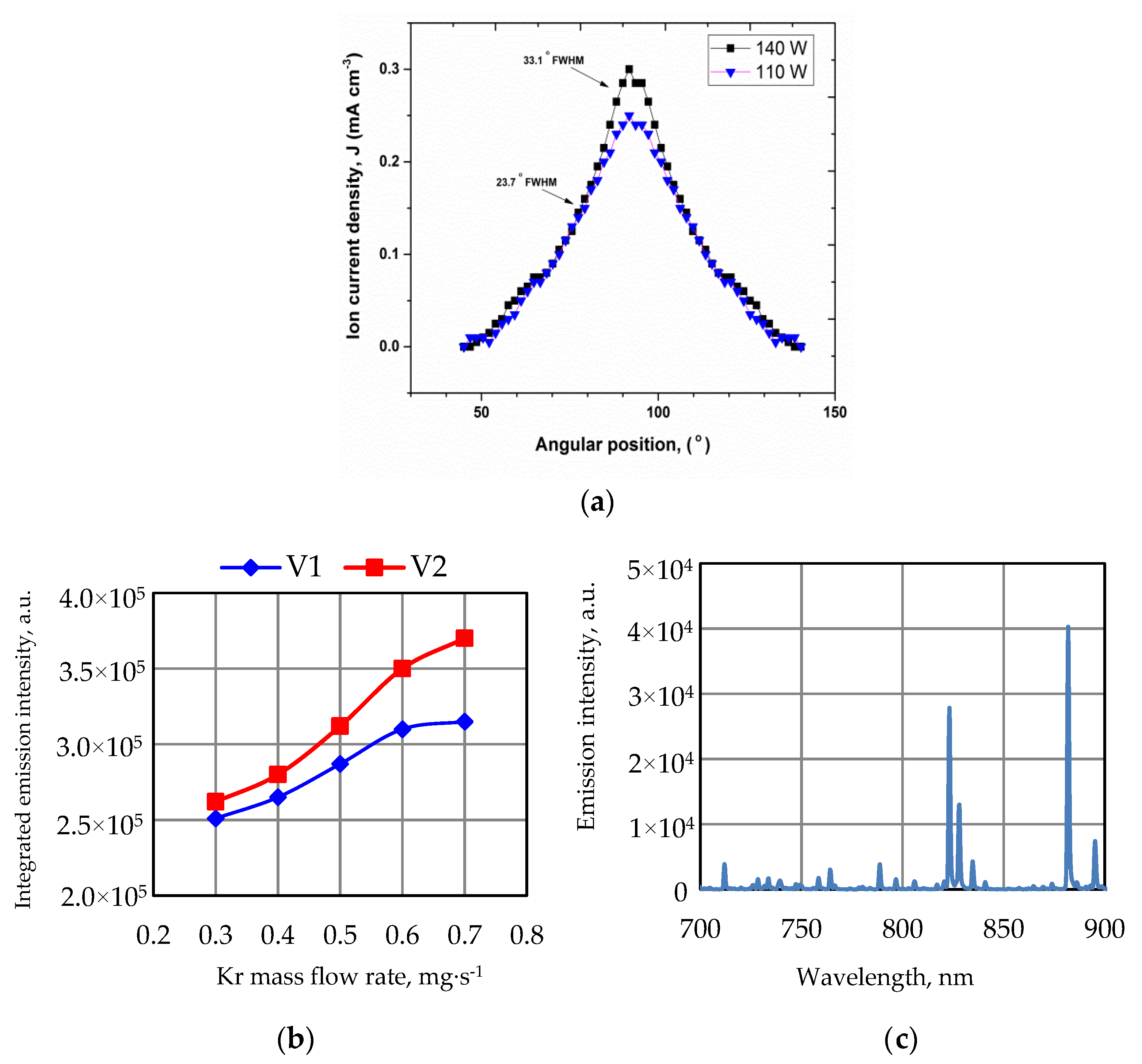

The thruster can stably fire at discharge potentials from 110 to 270 V with mass flow rates ranging from 0.3 to 0.7 mg·s

−1 (3 to 7.1 sccm), leading to an anode power from 50 to 220 W for Xe. Some of the thruster performance results when running with Kr are presented in

Figure 4b–d [

16]. When operating with Xe and at 200 W of discharge power, the thruster can yield a thrust of 9.34 mN and a specific impulse of 1729 s, while the thrust efficiency is 39.3% [

42]. A picture of the thruster plume at this operational point is depicted in

Figure 6d. At 100 W, when operating with Xe, the thruster produces a thrust of 5 mN with a specific impulse of 940 s, at a thrust efficiency of 23.4% [

42].

3.2. 25 and 50 W-Class Hall Thrusters

At PSAC/SPC a continuous effort was dedicated to the development of Hall thrusters with a power consumption level below 100 W and aiming at a thrust level below 5 mN. Such low-power levels can induce a rapid loss in the thrust efficiency, which can be prevented with innovative propellant distribution inside the discharge channel and manipulation of the magnetic field topology.

Two classes of thrusters have been developed and tested: (a) 25 W nominal discharge power—a thruster with an outer discharge channel diameter of 24 mm, depicted in

Figure 7a; (b) 50 W nominal discharge power—a thruster with an outer discharge channel diameter of 30 mm, presented in

Figure 7b. The thrusters were designed employing a classical geometry configuration with ceramic discharge channels, while the significant improvement was made in gas distribution and the outer magnetic field topology in order to improve operation at low mass flow rates in the range of 0.1 to 0.5 mg·s

−1-Xe (1 to 5.1 sccm) and within a high discharge voltage range of 200 to 300 V. The magnetic field is created by two electromagnetic coils, which are connected in series with the discharge power supply to reduce the number of power sources needed to operate the thruster.

Thruster performance evaluation is ongoing, and first in-space tests of the propulsion system based on the thrusters are scheduled in the last quarter of 2020. When operating at ~50 W, the thruster delivers 3 mN of thrust with an efficiency of 25.2%. Both thrusters operate with a BaO impregnated tungsten miniature dispenser cathode to reduce the overall propulsion system power consumption.

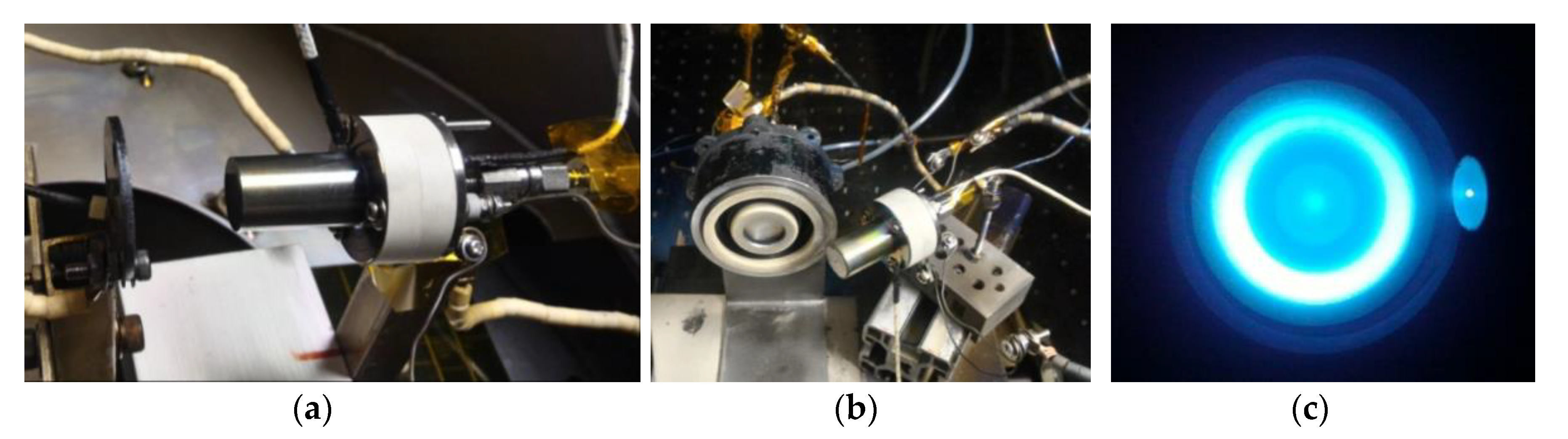

3.3. Cathodeless Hall Thrusters

Cathodeless Hall Effect Microjet Thruster is a flight proven thruster developed in PSAC/SPC and launched on board of a ~200 kg microgravity satellite, Taiji-1 [

43,

44]. Experimental measurements showed that the thruster can provide a wide thrust range of 1 to 100 µN with a resolution of 100 nN and extreme thrust stability in the frequency range of 0.01 to 1 Hz, consuming up to 5 W of power at high discharge voltages (~2000 V). The thruster has a magnetic system formed of permanent magnets and a narrow discharge channel. Plume neutralization is achieved passively using low work function materials placed at some locations on the thruster. A combination of multiple thrusters shall be used for space-based drag-free experiments to compensate the effects of solar radiation, atmosphere drag, tidal, and other non-conservative forces exerted on the spacecraft.

Figure 8a presents the thruster operating with synthesis gas, while

Figure 8b,c depicts the thruster firing in SESC with Xenon during the developmental and qualification campaigns.

4. Thermionic Cathodes for Hall Thrusters

Hall and ion thrusters rely on electron emitters for discharge maintenance as well as plume neutralization. Other electric propulsion systems, such as FEEP, employ electron emitters only for neutralization purposes. Thermionic cathodes are devices that supply the electrons needed for the aforementioned tasks and are a crucial part of the electric propulsion system. The core of a cathode is the emitter, or the insert made of low work function materials. To emit the required electron current, the emitter needs to reach a certain temperature level, dictated by the Richardson–Dushman equation [

45]. This temperature can be reached via active external heating of the emitter, i.e., through a heating element surrounding the emitter, or solely via the emitter region plasma, i.e., electron and mainly ion current heating. The cathode can be started by applying enough heating power to reach a certain level of electron emission, i.e., hot cathode ignition [

46], or through an electrical breakdown between, i.e., cold cathode ignition. The latter cathodes do not employ an external heater and are known as heaterless cathodes [

47].

The main geometrical parameters of a hollow cathode are presented in

Figure 9. The core of a cathode is the emitter which can be shaped as a cylinder or a pallet. In the case of cylindrical emitters, their internal diameter,

, and length,

, define the total emission surface area. The orificed cathodes are characterized by the orifice diameter,

, and length,

, while the orifice aspect ratio,

, is an important parameter that impacts the internal pressure of the device and the internal plasma properties. Some hollow cathodes do not have an orifice plate, and they are known as orifice-less cathodes. The cathode–keeper distance,

, defines the emitter–keeper gap and plays an important role during the cathode startup, when the keeper potential extracts the electrons from the internal plasma out through the cathode orifice at supersonic velocities. The emitter shape, the existence of the cathode orifice, and the cathode–keeper distance are the main parameters that define the potential distribution and the intensity of the electric field inside the cathode. Next, the keeper orifice diameter,

, and length,

, and the aspect ratio,

, are of high importance especially for the orifice-less cathodes, imposing the internal pressure. The electrons that are exiting through the orifice, extracted by the external anode, reach supersonic flow that is large enough to allow for deviations from the equilibrium electron energy distribution function (non-Maxwellian EEDF), leading to the emergence of plasma turbulence and instabilities in the plume [

45,

46,

48].

In the space sector the paradigm changed from the very big satellite platforms to progressively smaller platforms [

1,

10,

49]. A smaller platform means less power available. Therefore, the challenge is in designing electric propulsion systems that can consume increasingly less power, being very efficient at the same time. A quick calculation reveals that a 50 W Hall thruster imposes, ideally, a discharge current of around 0.2 A. Therefore, such a thruster will require a cathode that is capable of emitting a current below 1 A and should not require more than 50 W during the heating time. In order not to impact the thruster performance and efficiency, the cathode should require a very low propellant flow rate and also should operate stably, in a self-sustained mode, namely, after the thruster is ignited and the cathode heating is turned off. For the emitter material, lanthanum hexaboride (LaB

6) remains the preferred choice. However, its relatively high work function [

45] imposes higher operational temperatures and more power consumption. Therefore, the thermal management of such devices is crucial. When it comes to materials for the parts of the hollow cathode, a few choices are available, due to material incompatibility at high temperature [

30,

45,

46]. Refractory metals (tungsten, molybdenum, tantalum, rhenium-tungsten alloys, and tantalum-zirconium-molybdenum alloys) are preferred as well as high temperature ceramics (alumina-Al

2O

3, boron nitride-BN) and graphite [

49].

At PSAC/SPC, low-power thermionic cathodes are developed to work together with the low-power Hall thrusters. Another important aim of the cathode research is to understand the physics that govern their operation which is instrumental and greatly bolster the attempts of device design optimization by testing the cathodes in standalone mode. Although thermionic cathodes present a rather simple geometry, they produce flows that span across a wide range of aspects in plasma physics and fluid mechanics. From a cold propellant flow, through a partially ionized gas, to a compressible viscous flow and supersonic electrons as well as plasma micro-turbulences in the plume, cathodes are the perfect test benches for plasma physics, raising some of the most important challenges in the field of electric propulsion. The cathodes developed at PSAC/SPC are based on LaB

6 hollow cylindrical emitters which are brought to initial thermionic emission via a heated element [

25]. The cathodes are designed to produce emission currents below 1 A, while relying on low heating power [

25,

50]. New emitter designs allowed for a reduction in startup power consumption and self-sustained operation with low-power Hall thrusters.

4.1. PSAC 1 A-Class Cathode

PSAC 1 A-class cathodes are based on a LaB6 hollow cylindrical emitter with an emission surface area of 0.63 cm2. The emitter region continues with the orifice region formed by a 0.55 mm thick LaB6 plate with a 1 mm orifice. The emitter orifice plate has an emission surface area of 0.13 cm2, increasing the total emission surface area of the cathode to 0.76 cm3. A graphite holder contains the emitter and the orifice plate and is further attached to the gas line.

Around the emitter, and fixed to the graphite holder, the two ceramic parts of the heater enclose the tungsten-rhenium filament wire. A thermal shield formed of thin tantalum foils is placed around the heater to reduce the heat loss from the emitter region and improve the heating efficiency of the heater. The graphite keeper is a hollow cylinder with a 1 mm-diameter orifice that surrounds the internal parts, i.e., emitter, heater, and thermal shield. The internal parts are fixed to the stainless steel cathode base by press fitting via the gas line tube. A 3 mm thick complex ceramic insulator (BN-CrO) is placed between the keeper and the base. A schematic depicting the main components of the cathode is shown in

Figure 10a. It is worth adding that several PSAC cathodes have the keeper electrode made of graphite, while others employ a stainless steel keeper with a keeper orifice plate made of graphite or refractory metals, such as tantalum or tungsten, with different thermal characteristics.

Figure 10b,c depicts the various designs of the PSAC cathode.

The cathode was designed to provide a sufficient emission current, typically bellow 1 A, for the low-power Hall thrusters developed at PSAC/SPC. Based on the Richardson–Dushman equation, one can find that the emitter temperature should be around 1623 K for 1 A of the emission current (if the LaB

6 work function is assumed to be 2.7 eV [

45] and no Schottky field enhancement is present). The needed temperature drops to 1586 K if just 0.5 A are needed, while for a startup at 0.1 A the required emitter temperature is 1464 K. Previous tests showed that to startup, the cathode required around 65–70 W of heating power [

25]. Moreover, this type of cathode showed self-sustained operation with xenon at 0.75 A and a mass flow rate as low as 0.028 mg·s

−1 (0.45 sccm) when operating in conjunction with a Hall thruster at 0.4 mg·s

−1 (6.4 sccm) of krypton [

25].

4.1.1. Cathode Thermal Tests and Simulations

The PSAC cathode is intensively employed during the tests with the Hall thruster, running on both Kr and Xe. Apart from this primary purpose, the cathode is used as a test bench for thermionic emitter physics and to better understand the mechanism behind the mode transition in cathodes as well as their thermal behavior. Proper thermal management is instrumental for cathodes with hot emitters. The PSAC cathode consists of a LaB

6 emitter heated by a metallic filament heater, and in order to characterize the thermal aspect of the cathode, temperature measurements for various heating power levels were conducted using K-type thermocouples. Each power level was maintained for 900 s before the measurements were recorded to allow for thermal equilibrium to occur. During the experiments, the background pressure in the CEVAC was

Pa. The positions of the three thermocouples are depicted in

Figure 11a: TC1 was touching the stainless steel base; TC2 was placed on the rim of the keeper orifice plate; TC3 was inserted through the keeper orifice and touched the base of the emitter, around 13 mm inside the cathode.

Finite element steady-state thermal simulations were run in order to compare the simulated results with the experimental data.

Figure 11a contains the main boundary conditions imposed for the thermal simulations. A fixed temperature was imposed at the cathode base and was taken from the thermocouple TC1 data. A simplified geometry of the cathode was used as a finite element model in a 2D axisymmetric steady-state thermal simulation that models heat transfer in solids and implements surface-to-surface radiation. It was observed that when 68 W is applied as heating power, the emitter temperature stabilizes around 1400 °C, as depicted in

Figure 11c. This temperature is enough to allow the startup and steady-state operation of the cathode.

Figure 11b contains the results of the thermocouple measurements and simulations for a PSAC cathode with a stainless steel keeper and a graphite keeper orifice plate. For the thermocouple TC3, the simulation results are on average 130 °C higher than the experimental ones. TC1 measured a temperature of 1258 °C at 68 W, suggesting that at this temperature the cathode is capable of providing 0.27 A of emitted current (due to the emission surface area of 0.76 cm

2). Nevertheless, the cathode was always started at 0.1 A of keeper current. Thermocouple T2 recorded the temperature at the edge of the keeper orifice plate. The experimental data is on average 163 °C lower than the simulated one. The experimental data show temperatures of up to 526 °C at this location at 68 W. Finally, the temperatures recorded by the thermocouple TC1 were used as boundary conditions (fixed temperature) for the thermal simulations. The cathode base temperature (TC1) gradually increases with the heating power but remains under 240 °C throughout the measurement. For the simulation, the finite-element ideal design of the cathode includes a thermal shield that is perfectly concentric. Moreover, the model assumes perfect contact between the different parts of the cathode, i.e., no contact thermal resistance due to surface rugosity and imperfect contact is taken into account. This can explain the differences in temperature between the simulated and experimental results, especially in the case of the temperatures measured by the thermocouple TC2 placed on the keeper edge rim, since here the orifice plate is press-fitted to the stainless steel cylinder.

The temperature measurements suggest that the thermal management of the PSAC cathode would need improvements to reduce the input heating power and keep the cathode self-sustained during steady-state operation. The high temperatures recorded by thermocouple TC1 at the cathode base may suggest high thermal loss from the emitter region. The main loss mechanisms may be conduction through the gas line and radiation inside the keeper electrode.

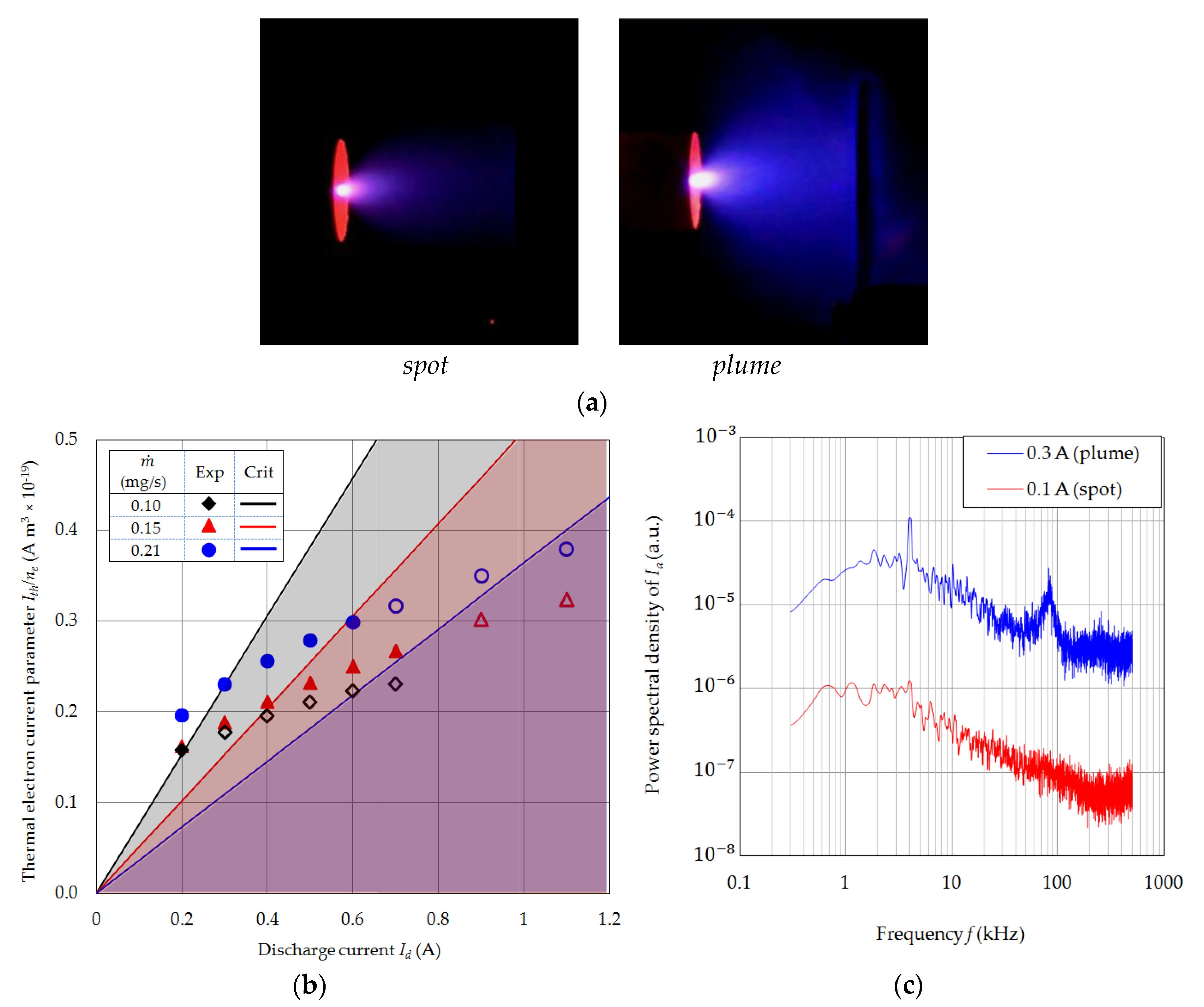

4.1.2. Cathode Discharge Modes and Mode Transition

A thermionic cathode discharge exhibits two main operational modes, spot and plume, with some authors defining also a transition mode [

52,

53,

54,

55]. Spot mode defines a stable cathode operation seen in the low level of anode/keeper current and voltage temporal fluctuations. On the other hand, when in plume mode, the anode/keeper current and voltage fluctuations are high and may induce the formation of energetic ions which in turn can backflow towards the keeper and cathode emitter surfaces inducing high sputtering rates and affecting the cathode lifetime [

56,

57]. To differentiate the modes, a visual inspection of the cathode plasma plume can help, whereas applying mode transition criteria can improve the accuracy of the recognition process [

30].

Figure 12a depicts the PSAC cathode operating with Kr in spot and plume modes. Visually, when in spot mode, the cathode plume is focused in a spot-like structure close to the cathode orifice, displaying a light purple color which suggests a high content of Kr ions. The visual features of the plume in spot mode are induced by the high density of energetic electrons causing ionization and excitation of the propellant neutral only next to the cathode orifice. The remainder of the cathode–anode space is dark, with less ionization and excitation processes happening here. Due to the higher current densities that characterize this discharge mode, the electrical resistance of the plasma is in general lower. On the other hand, when operating in plume mode, visually, the plume of the cathode is less focused with a larger divergence and blue coloring, suggesting high contents of excited Kr atoms instead of ions. In contrast with the spot mode, the ionization and excitation events take place along the entire cathode–anode gap, produced by highly energetic electrons that overcome the sheath potential which usually forms at the cathode exit plane. The mode is characterized also by a lower plasma density, thus, lower collisionality and higher electron temperatures.

Several mode transition criteria were exposed and discussed in a previous publication and applied to identify the mode transition in a Kr-fed PSAC cathode [

30]. Some of the results of the study are presented in

Figure 12b. The cathode was operated over a range of anode current from 0.1 to 1 A, for three mass flow rate values and at a fixed value of keeper current of 0.1 A. One of the criteria used was the anode current oscillations criterion. Developed by Sary et al. and based on plasma simulations and experimental results [

56,

57], this criterion makes use of the time waveforms of the anode current and states the following: spot mode corresponds to the ratio of the anode current standard deviation to anode current mean value,

, being under 9%, while plume mode corresponds to ratios over 9%. This criterion takes into account the weight of ion acoustic turbulences (IAT) that can emerge in the cathode plume and lead to ionization-like instabilities [

28,

29,

30,

48]. It can be observed that the plume mode tends to be more present for low mass flow rates and at higher discharge current, as previously reported in literature [

28,

29,

30,

53,

59,

60,

61,

62,

63]. A more powerful criterion was introduced by Georgin et al. [

60] and was based on the team’s proposed turbulence-driven ionization instability theory.

Figure 12b depicts a simplistic approach on the thermal electron parameter,

, where

is the electron thermal current and

is the electron density, as a function of the cathode discharge current,

, which is a sum of the anode current

and keeper current

. In the figure, both the theoretical expressions and the measurement results are presented for the three different mass flow rates. The experimental expressions were derived based on the discharge potential while assuming a constant electron density across the range of mass flow rates [

30]. It was shown that the criterion succeeds to predict the mode transition under the assumption of an IAT spectrum average frequency of 1.5 MHz.

The power spectral density (PSD) of the anode current is obtained from the time variation of this parameter and can show the main range of frequency peaks and harmonics which are in turn related to the instabilities that appear in the cathode plume. An example of such spectra is depicted in

Figure 12c for the same PSAC cathode operated with Kr at 0.1 A of keeper current and two different anode current levels. As previously presented in literature [

28,

29,

30], plume mode operation is characterized by spectra with high energy and large variations in the energy with the frequency. Moreover, distinct frequency peaks and harmonics can be seen in the range of 10–150 kHz, characteristics of ionization-like instabilities, which may be induced by the emergence of IAT within the cathode plume [

50,

60]. In contrast, spot modes’ PSDs are less energetic with low fluctuations. By employing all those criteria and visual and spectral instruments, mode transition in thermionic cathodes for electric propulsion can be better understood and can be used in the developmental process of miniaturized low-current cathodes.

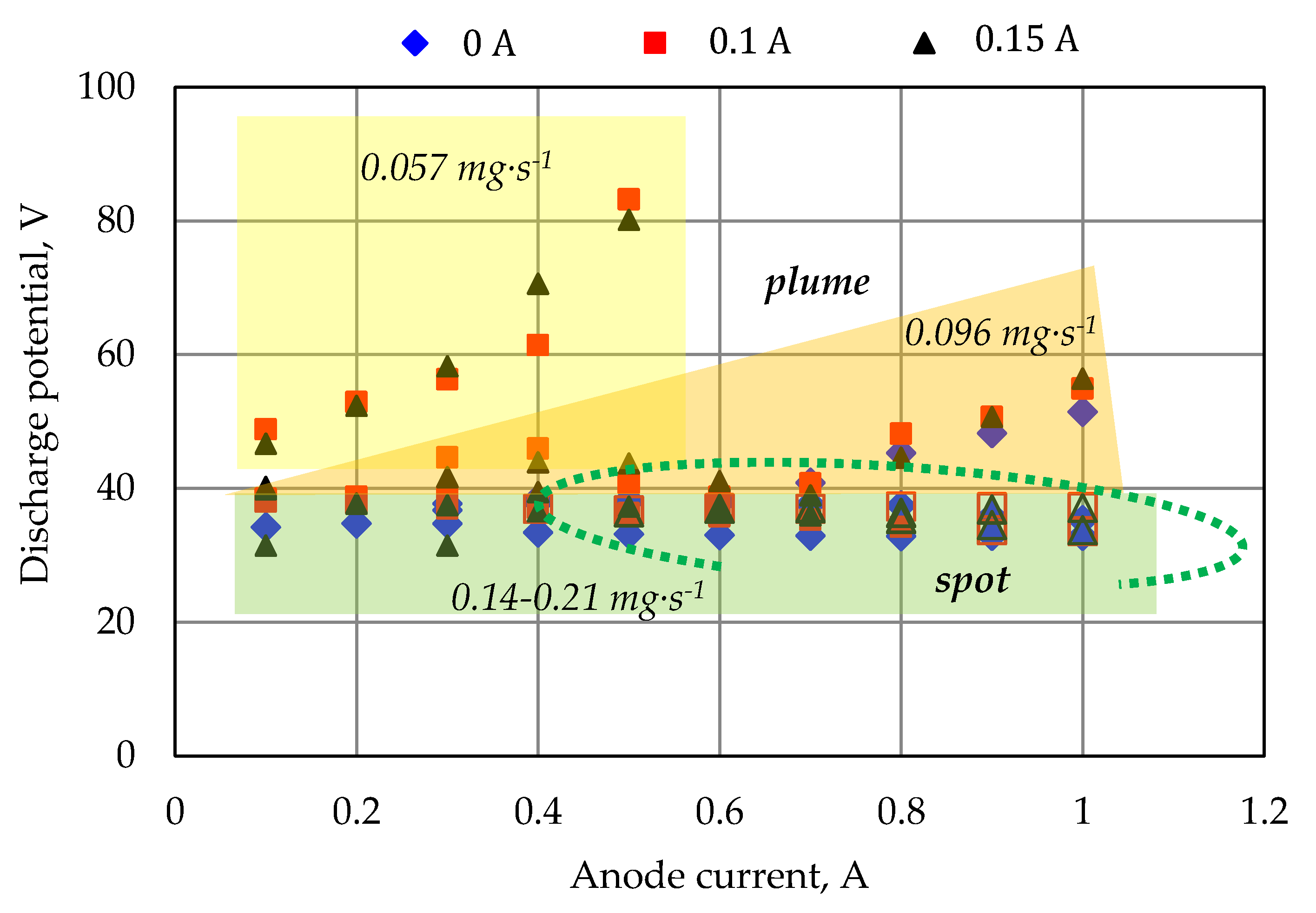

4.2. Knife-Edge Emitter Cathodes

The PSAC cathode proved to be an ideal baseline cathode for the new generation of low-current thermionic emitters developed at PSAC/SPC. The goal of reducing the input heating power leads to changes regarding the thermal management of the cathode, including geometrical modification and different materials for the various parts, as well as a new design of the emitter. Electron production can be favored by higher temperatures of the emitter as well as by a stronger electric field in the emitter region. To achieve the latter, a knife-edge emitter was designed: a hollow cylindrical emitter with a 45° chamfered edge at one of its ends. Electrostatic simulations showed that such geometry can maintain a higher electric field in the emitter exit region than a classical cylindrical shape during startup and steady-state operation with the keeper electrode or anode electrode. The new generation of cathodes kept most of the features that the PSAC cathode has: LaB

6 cylindrical hollow emitter, rhenium-tungsten filament encapsulated in ceramic parts as heater, thermal shield around the heater, and emitter-heater thermal shield subsystem is kept in place by the long and thin gas line to reduce thermal conduction losses to the cathode base. However, to improve the thermal management of the cathode a few modifications were made: the emitter is separated from the heater’s inner ceramic part by a thin pyrolithic graphite sleeve, the keeper is much shorter and is made of stainless steel with a refractory metal keeper orifice plate (tungsten/tantalum), and the ceramic separating the keeper from the cathode base is thicker in order to accommodate a second thermal shield. Preliminary thermal simulations for the new generation of cathodes showed that the cathode emitter can reach temperatures around 1640 K when 30 W of heating power is applied to the heating element. The cathode is presented in

Figure 13.

The knife-edge emitter cathodes were tested in standalone mode with an external disk anode in the CEVAC, see

Figure 13a, and together with a 200 W-class thruster in the TEVAC, see

Figure 13b,c. The startup sequence includes the cathode heating and the ignition of the keeper discharge. Once the keeper discharge ignites, the anode discharge is always established. The average startup heating power was around 34.4 W, up to 34 W lower than the one required by the PSAC cathode [

50]. During tests, the keeper voltage averaged around 415 V with a current limited to 0.1 A, while the cathode mass flow rate was set at 0.21 mg·s

−1 (~2.1 sccm) [

50]. During the 10 ignitions with the thruster in the TEVAC, the cathode mass flow rate was set at 0.1 mg·s

−1 (~1 sccm) while the keeper potential varied between 300 and 900 V, with a current limited to 0.1 A [

50]. The cathode cumulated slightly over 43 h of continuous operation during the tests. Additionally, the cathode was employed in a lifetime test for a Hall thruster, cumulating over 200 h and 50 ignitions.

For standalone testing in diode and triode configuration with an external anode and keeper electrode, the cathode was tested with Xe mass flow rates ranging from 0.057 mg·s−1 to 0.21 mg·s−1 (0.58 to ~2.1 sccm). The anode current was varied from 0.1 A to 1 A, while the keeper current was set at 0.1 A and 0.15 A. When it was stable, the cathode was run with no keeper current, in diode configuration with the external anode only. The cathode showed self-sustained operation only at an anode current of 1 A, while for the rest of the measurements a constant heating power was required for the cathode to operate.

The anode characteristics and discharge mode map for the cathode are presented in

Figure 14. At lower mass flow rates, 0.057 mg·s

−1 and 0.096 mg·s

−1, the anode discharge showed positive discharge impedance. At the lowest mass flow rate, the anode current oscillations averaged 32%, while the anode voltage reached over 83 V. However, the cathode operated stably but exhibited a plume mode discharge. As the mass flow rate was increased, the anode voltage did not exceed 57 V and the anode discharge characteristics showed three main regions: positive impedance for anode current ranging from 0.1 to 0.4 A and 0.7 to 1 A with high levels of fluctuations of this parameter, and a region with negative impedance and fluctuations in the anode current under 20% of the average value, for anode currents ranging from 0.4 to 0.6 A. Nevertheless, the cathode was still operating in plume mode. For higher mass flow rates, 0.14 mg·s

−1 and 0.21 mg·s

−1, spot mode operation was recorded for total discharge current over 0.5 A, with the anode voltage averaging at 35.5 V. At those mass flow rates, the anode characteristics showed negative impedance with the anode voltage ranging from 30 to 40 V. The keeper voltage ranged between 2.9 and 16.7 V, decreasing with the increase in the cathode mass flow rate and anode current. The keeper discharge exhibited positive impedance, as the keeper voltage increases with the keeper current. Therefore, the cathode total power remained almost constant for a specific mass flow rate, disregarding the keeper current, and increasing with the increase in the anode current. The cathode discharge power ranged between 3.5 and 60.3 W, with an average of 20 W for the spot mode operation.

6. Conclusions

Research of low-power electric propulsion systems at PSAC/SPC Singapore started around five years ago, harvesting the expertise the team gathered in the field of applied plasma physics, namely, plasma processing for material research. This paper presents a review of the main activities undertaken at PSAC/SPC in the field of low-power electric propulsion. Besides a description of the main vacuum facilities and plasma diagnostics employed during tests, new devices are introduced for the first time. Based on the lessons learned from the 200 W-class Hall thrusters capable of yielding up to 9 mN, three more classes of thrusters were developed and tested. The 25 W-class and 50 W-class thrusters operated with low-current BaO impregnated tungsten miniature dispenser cathodes and could produce a thrust up to 3 mN. The cathodeless Hall Effect Microjet thruster, an innovative new Hall thruster design, was also introduced in the review. The thruster was run at power levels below 5 W and produced a thrust in the range of 1 to 100 μN with a very low thrust noise level. As the name suggests, the thruster did not require an external electron emitter, while the operation relied on high voltage and low mass flow rates, with plume neutralization achieved by means of passive low work function coatings.

A review of the research on low-current cathodes was also presented. At PSAC/SPC, cathodes in the 0.1–1 A rage were designed and tested, both in standalone mode and together with the thrusters. Mainly hot emitter cathodes with lanthanum hexaboride were designed, while BaO emitters are currently investigated as suitable candidates for the <50 W thrusters. PSAC cathode was used as a benchmark for future cathode developments. The extensive thermal and discharge tests suggested that the thermal management of the cathode remained the most important aspect for future designs. Understanding how different discharge mode transition criteria apply for low-current cathode discharges was another priority, while the results showed that most of the existing criteria developed for high-current cathodes remained valid for emission currents below 1 A. An innovative cathode design was also presented in the review. The knife-edge emitter cathodes are currently under development and are the result of the efforts to reduce the necessary heating power during the LaB6 cathode ignition. Preliminary results showed that a better thermal management of the cathodes together with material selection and higher keeper potentials for the knife-edge emitters allowed for startup powers under 35 W.

PSAC/SPC devoted a large amount of resources on fundamental studies on the rotamak, a device initially developed as a nuclear fusion reactor which can be converted into a plasma thruster. This review introduced for the first time the concept of a rotamak-like electrodeless plasma thruster. Such a thruster will not require an electron emitter for neutralization or discharge sustenance since the device accelerates plasma via an electromagnetic process and not just ions. Moreover, the results of a mathematical code aimed at studying fields and current density distributions in a spherical FRC plasma were presented. The results were in good agreement with previously published experimental data. A modified version of the code is intended to be used in supporting the development of the rotamak-like plasma thruster and the transition from a spherical to a truncated geometry.

The research conducted at PSAC/SPC was primarily focused on the development of low-power, below 200 W, electric propulsion systems. This class of electric propulsion devices remains of high importance for the small satellite markets offering fuel-efficient thrust solutions. The new Hall thruster designs proposed by PSAC/SPC offer decent thrust at power levels below 50 W, while the cathodeless thruster reduced the discharge power to a minimum by eliminating the necessity of a dedicated cathode. Improvements to the knife-edge emitter cathode can lead to a class of highly efficient cathodes that can be ignited at heating power levels under 30 W and may achieve self-sustained operation for emission current under 1 A when run with a Hall thruster. Last but not least, the new concept of the rotamak-like thruster can be a competitive asset for the RF thruster research, allowing for electrodeless configuration and operation at power levels below 100 W. The research presented in this review proves that PSAC/SPC is a devoted and capable player in the field of low-power electric propulsion, being on a constant endeavor of pushing the limits of classical solutions and circumventing their drawbacks with innovative designs.