Design and Test of a Student Hybrid Rocket Engine with an External Carbon Fiber Composite Structure

Abstract

1. Introduction

2. Materials and Methods

2.1. Overview of the Sounding Rocket Educational Project within the STERN Program

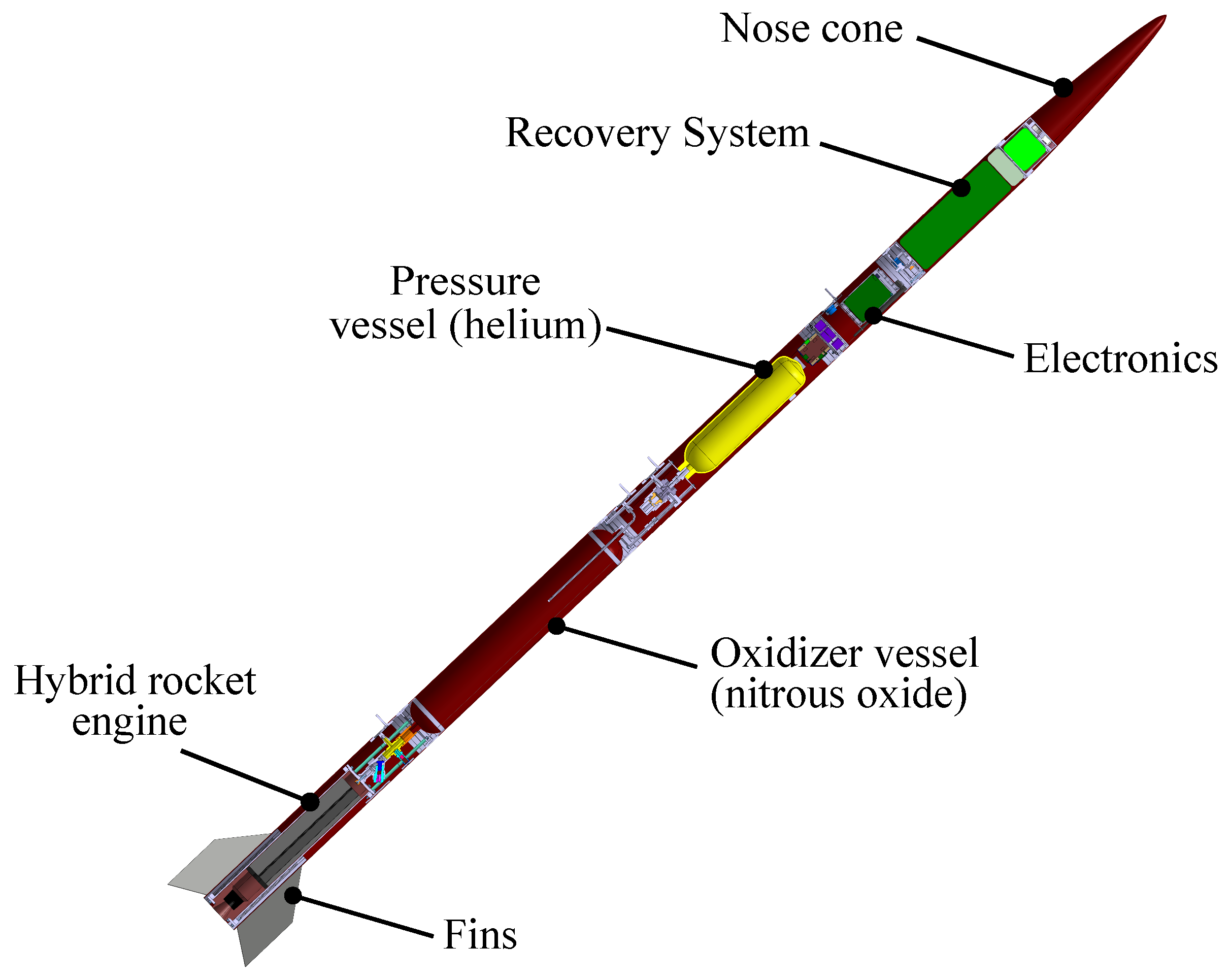

2.2. Design of the Faust Rocket and HYDRA 3X Engine

- Apogee altitude of 10 km;

- Increased engine thrust and total impulse;

- Improved engine power-to-mass ratio;

- Integrated lightweight casing made from CFRP.

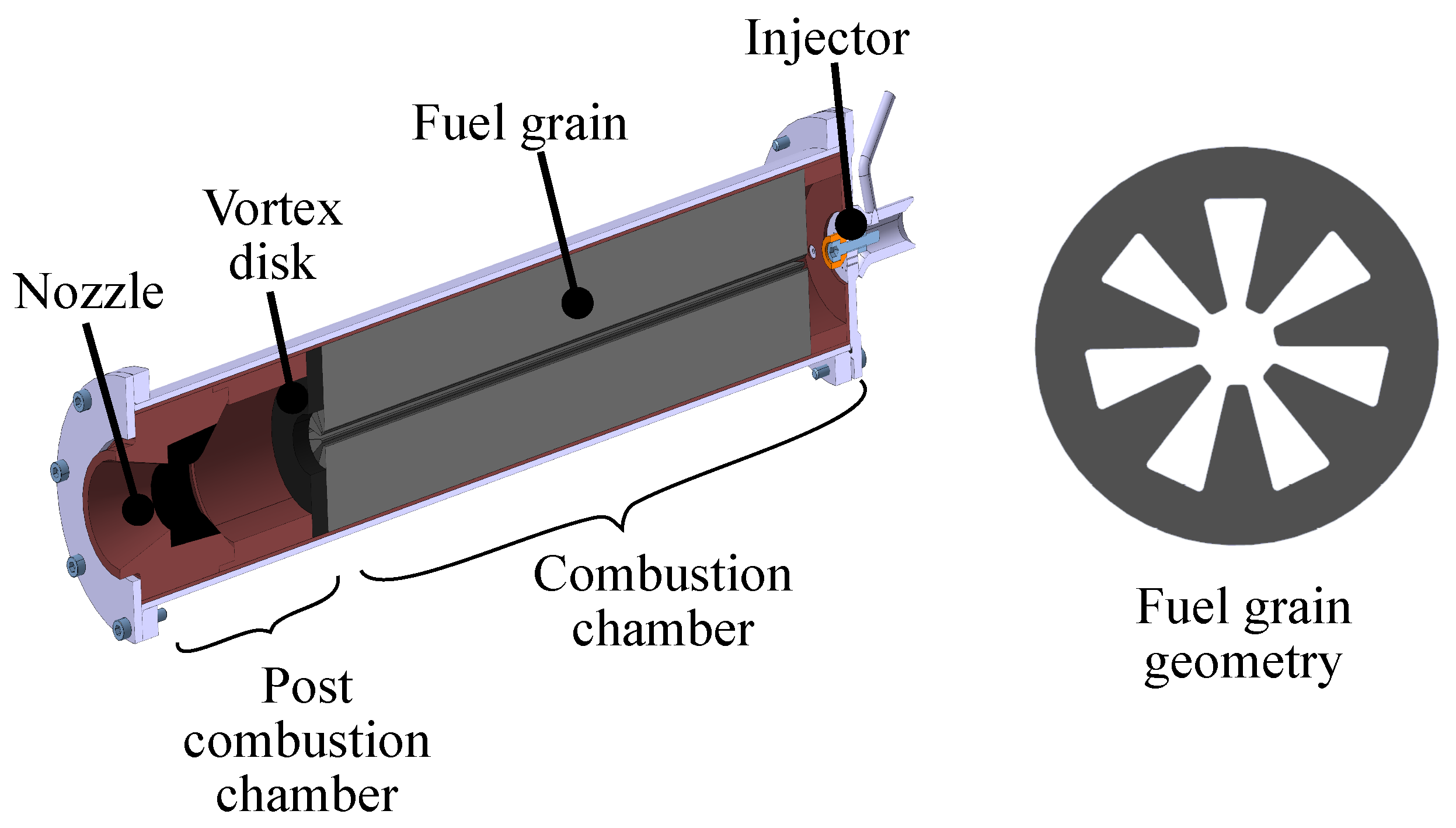

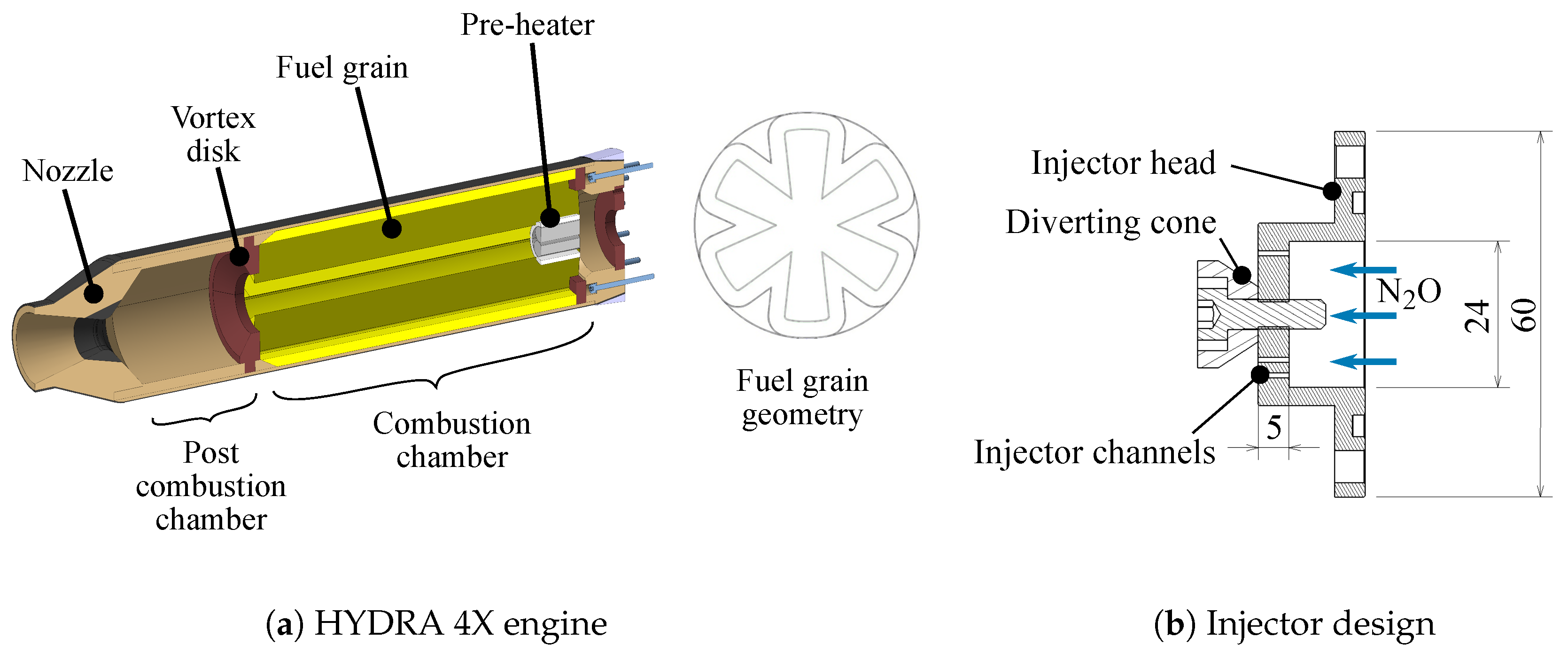

2.3. Design of Hybrid Rocket Engine HYDRA 4X

2.4. Performance Calculations

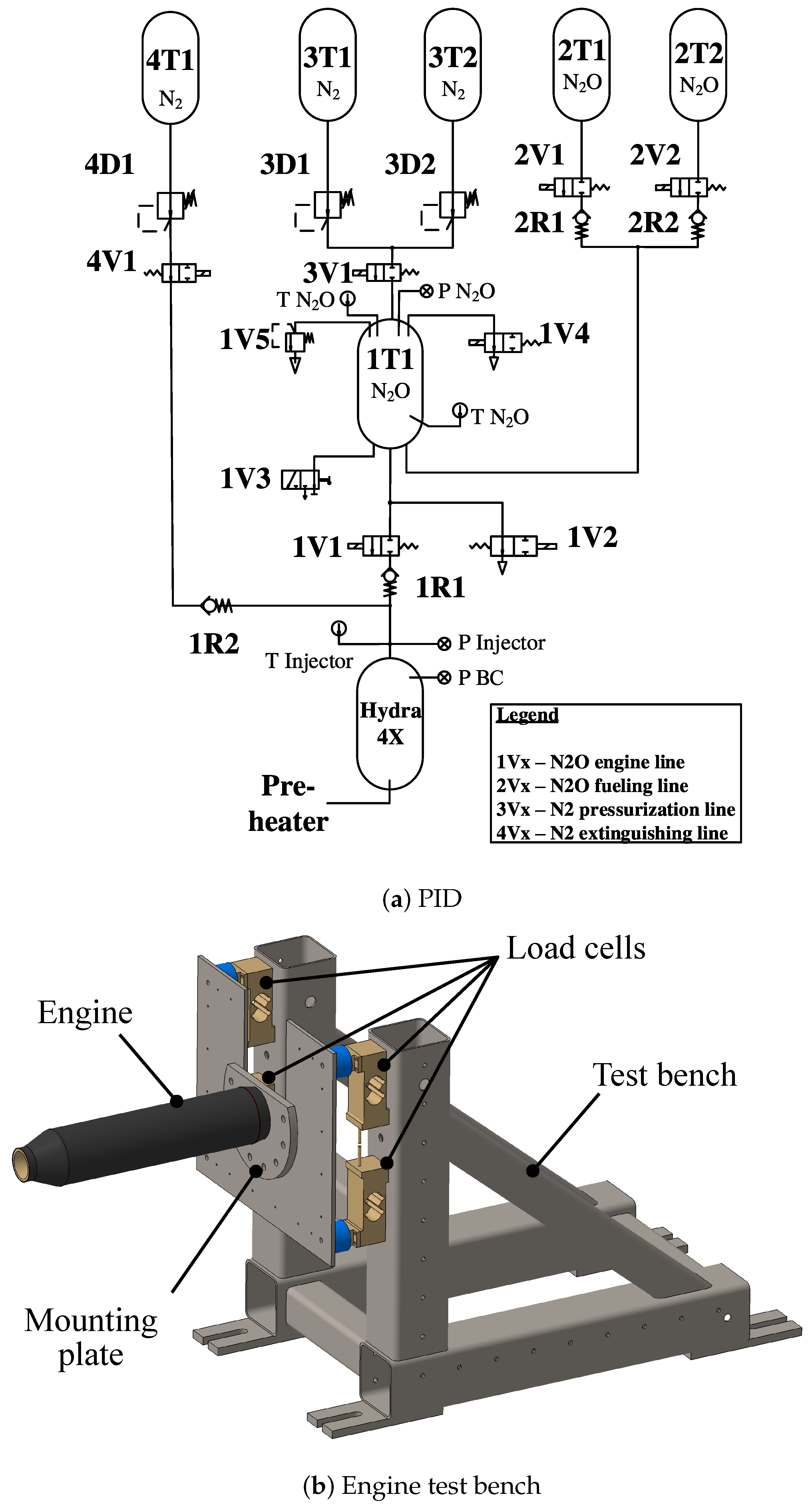

3. Description of the Engine Test Bed

4. Results and Discussion

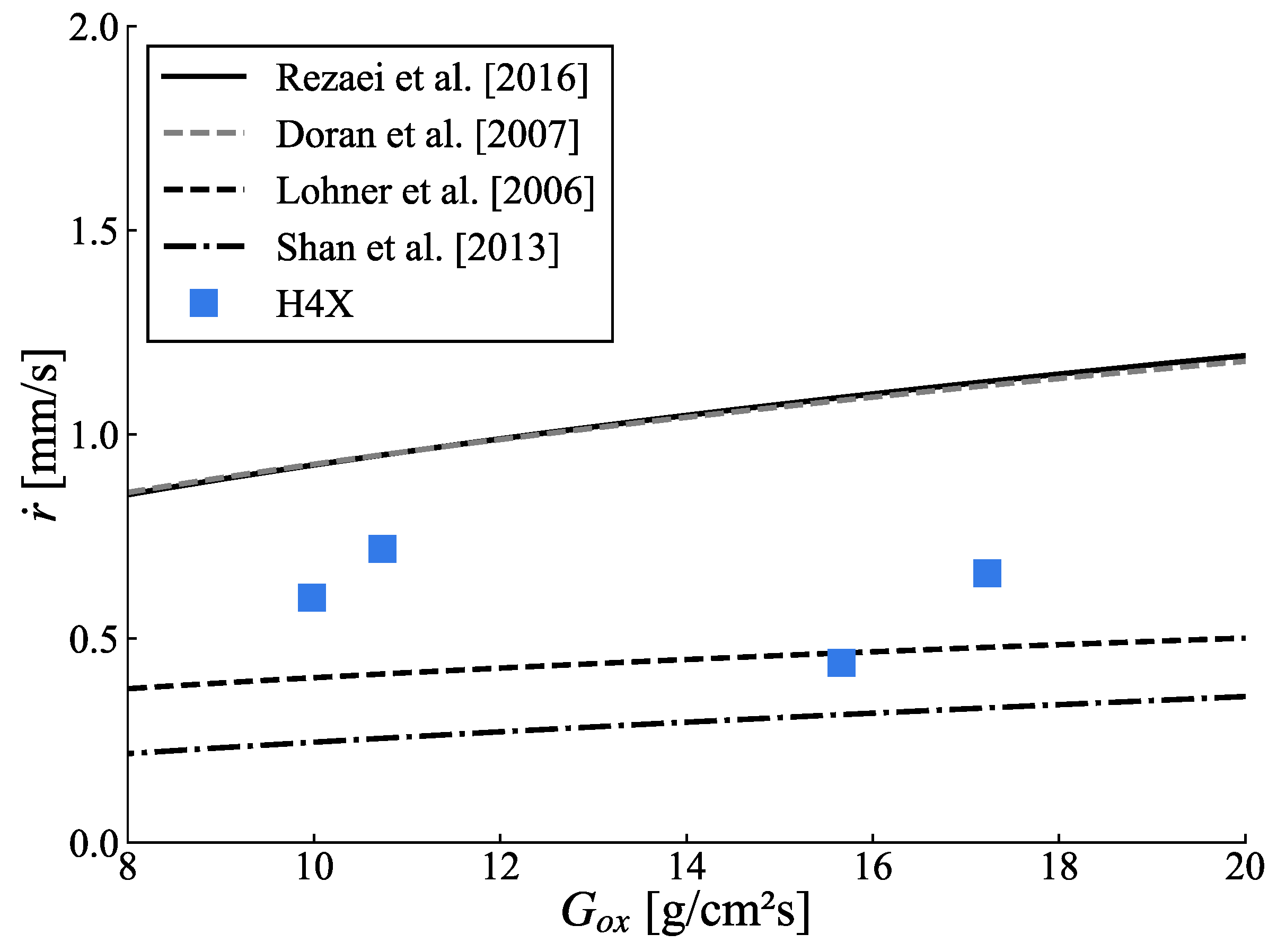

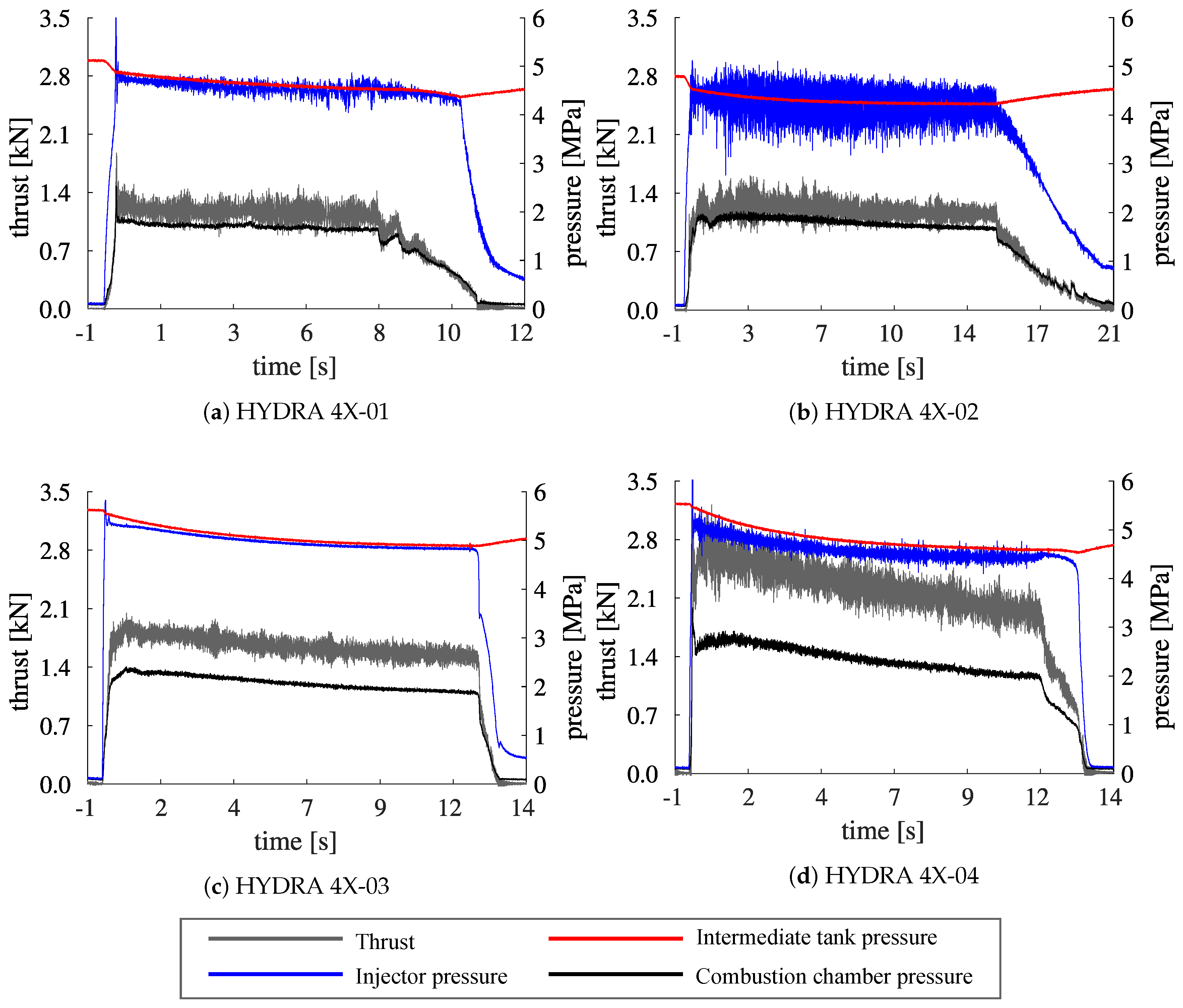

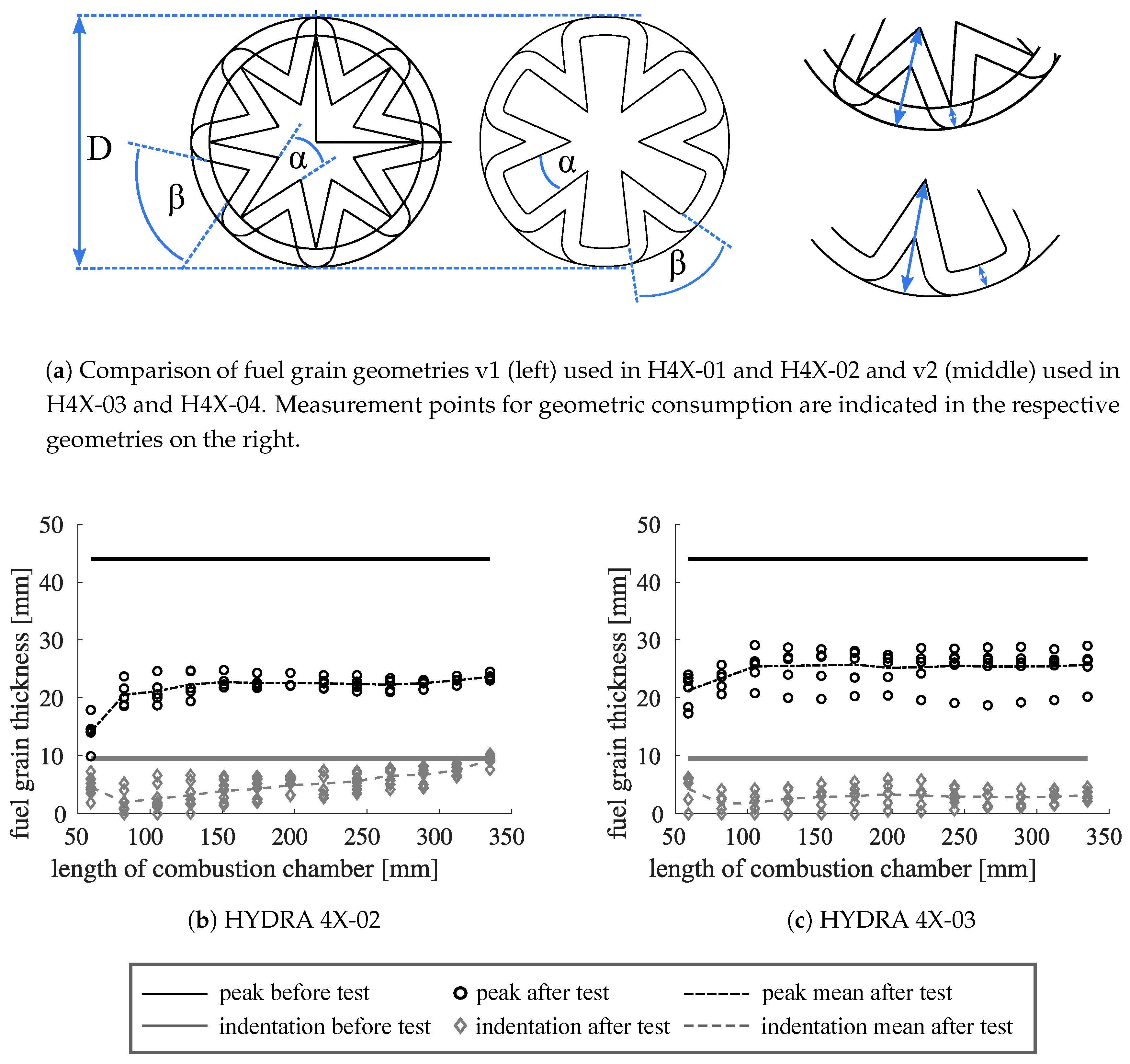

4.1. Hot Fire Tests and Iteration of Design

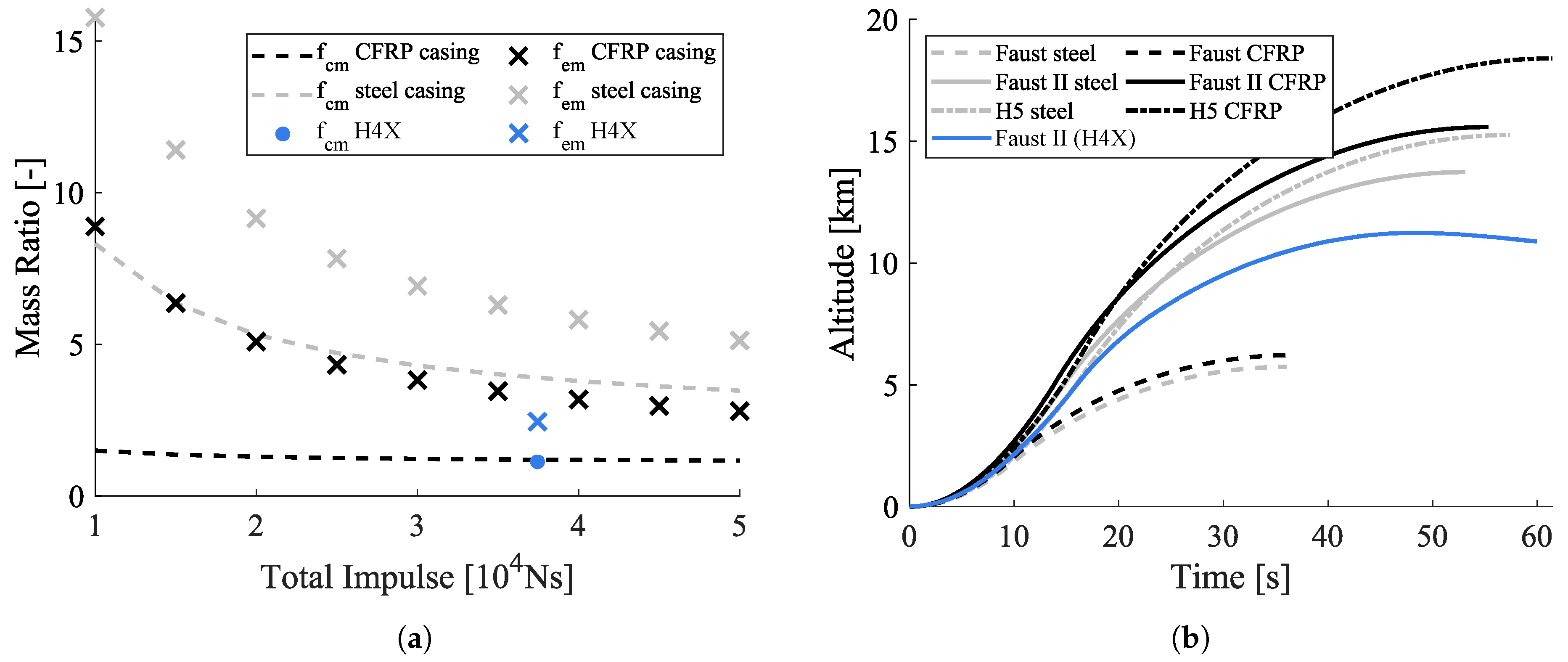

4.2. Impact of Engine Casing Material on Flight Apogee

5. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |

| A | Area (unit: m) |

| a | Regression rate coefficient |

| C | Coefficient (unit: -) |

| d | Diameter (unit: m) |

| F | Thrust (unit: N) |

| G | Oxidizer mass flow-to-free port area ratio (unit: g/cms) |

| f | Relation factor (unit: -) |

| Specific impulse (unit: m/s) | |

| Total impulse (unit: Ns) | |

| M | Molar mass (unit: g/mol) |

| m | Mass (unit: kg) |

| Mass flow (unit: kg/s) | |

| n | Regression rate coefficient, number (unit: -) |

| p | Pressure (unit: Pa) |

| Volume flow (unit: m/s) | |

| Molar gas constant (unit: J/mol·K) | |

| T | Thermodynamic temperature (unit: K) |

| t | Time (unit: s) |

| Greek Symbols | |

| Efficiency (unit: -) | |

| Auxiliary function (unit: -) | |

| Ratio of specific heats (unit: -) | |

| Density (unit: kg/m) | |

| Subscripts | |

| a | Ambient |

| b | Burn |

| cas | Casing |

| c | Chamber |

| D | Discharge |

| e | Engine, exit (nozzle) |

| f | Fuel |

| ox | Oxidizer |

| p | Port |

| str | Structure |

| t | Throat |

| th | Theoretical |

| Abbreviations | |

| TRL | Technical readiness level |

| HRE | Hybrid rocket engine |

| DLR | German Aerospace Center |

| STERN | Studentische Experimental-Raketen |

| MORABA | Mobile Raketenbasis |

| IRAS | Institute of Space Systems |

| ERIG | ExperimentalRaumfahrt-InteressenGemeinschaft |

| BMWi | Federal Ministry of Economic Affairs and Energy |

| HYDRA | Hybrid Demonstrations-RaketenAntrieb |

| HTPB | Hydroxyl-terminated polybutadiene |

| NO | Nitrous oxide |

| HO | Hydrogen peroxide |

| LDPE | Low density polyethylene |

| PE | polyethylene |

| LOX | Liquid oxygen |

| CFRP | Carbon fiber-reinforced plastic |

| O/F | Oxidizer-to-fuel mass ratio |

| NASA | National Aeronautics and Space Administration |

| CEA | Chemical Equilibrium with Applications |

| PID | Piping and instrumentation diagram |

References

- Sutton, G.; Biblarz, O. Rocket Propulsion Elements, 7th ed.; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2001; pp. 27–38, 62–68, 77–82, 580. [Google Scholar]

- Li, X.; Tian, H.; Yu, N.; Cai, G. Experimental investigation of fuel regression rate in a HTPB based lab-scale hybrid rocket motor. Acta Astronaut. 2014, 105, 95–100. [Google Scholar] [CrossRef]

- Mazzetti, A.; Merotto, L.; Pinarello, G. Paraffin-based hybrid rocket engines applications: A review and a market perspective. Acta Astronaut. 2016, 126, 286–297. [Google Scholar] [CrossRef]

- Schmierer, C.; Kobald, M.; Fischer, U.; Tomilin, K.; Petrarolo, A.; Hertel, F. Advancing Europe’s Hybrid Rocket Engine Technology with Paraffin and LOX. In Proceedings of the 8th European Conference for Aeronautics and Aerospace Sciences (EUCASS), Madrid, Spain, 1–4 July 2019. [Google Scholar]

- Schmierer, C. Analysis of a Hybrid Propulsion Lunar Sample Return Mission. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2019. [Google Scholar]

- Schmucker, R.H. Hybridraketenantriebe; Wilhelm Goldmann Verlag GmbH: Munich, Germany, 1972; pp. 22–24, 67–70. [Google Scholar]

- Barrère, M.; Schneider, W.K.; Roy, M.; Von Kármán, T. Raketenantriebe; Elsevier Publishing Co.: New York, NY, USA, 1961; pp. 66–72, 98, 112–114. [Google Scholar]

- Rezaei, H.; Soltani, M.R.; Mohammadi, A.R. Experimental Study of Fuel Regression Rate in a HTPB/N2O Hybrid Rocket Motor. Sci. Iran. 2018, 25, 253–265. [Google Scholar] [CrossRef]

- Chiaverini, M.J.; Kuo, K.K.; Peretz, A.; Harting, G. Regression-Rate and Heat-Transfer Correlations for Hybrid Rocket Combustion. J. Propuls. Power 2001, 17, 99–110. [Google Scholar] [CrossRef]

- Carmicino, C.; Scaramuzzino, F.; Sorge, A.R. Trade-off between paraffin-based and aluminium-loaded HTPB fuels to improve performance of hybrid rocket fed with N2O. Aerosp. Sci. Technol. 2014, 37, 81–92. [Google Scholar] [CrossRef]

- Sun, X.; Tian, H.; Li, Y.; Yu, N.; Cai, G. Regression rate behaviors of HTPB-based propellant combinations for hybrid rocket motor. Acta Astronaut. 2016, 119, 137–146. [Google Scholar] [CrossRef]

- Cheng, P.; Lia, Q.; Chen, H. Flow characteristics of a pintle injector element. Acta Astronaut. 2019, 154, 61–66. [Google Scholar] [CrossRef]

- Di Martino, G.D.; Malgieri, P.; Carmicino, C.; Savino, R. A simplified computational fluid-dynamic approach to the oxidizer injector design in hybrid rockets. Acta Astronaut. 2019, 129, 8–21. [Google Scholar] [CrossRef]

- Greatrix, D.R. Regression rate estimation for standard-flow hybrid rocket engines. Aerosp. Sci. Technol. 2009, 13, 358–363. [Google Scholar] [CrossRef]

- Hui, T.; Yijie, L.; Peng, Z. Transient simulation of regression rate on thrust regulation process in hybrid rocket motor. Chin. J. Aeronaut. 2014, 27, 1343–1351. [Google Scholar]

- Chiba, K.; Kanzaki, M.; Nakamiya, M.; Kitagawa, K.; Shimada, T. Conceptual Design of Single-Stage Launch Vehicle with Hybrid Rocket Engine for Scientific Observation Using Design Informatics. J. Space Eng. 2013, 6, 15–27. [Google Scholar] [CrossRef][Green Version]

- Bozic, O.; Poppe, G.; Porrmann, D. An advanced hybrid rocket engine for an alternative upper stage of the Brazilian VLM 1 LEO-launcher. In Proceedings of the 65th International Aeronautics Congress, Toronto, ON, Canada, 29 September–3 October 2014. [Google Scholar]

- Karp, A.; Benito, J.; Nakazono, B.; Kim, H.; Shotwell, R.; Brandeau, E.; Vaughan, D.; Story, G. A Hybrid Mars Ascent Vehicle Design and FY 2016 Technology Development. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2017. [Google Scholar]

- Tsohas, J.; Appel, B.; Rettenmaier, A.; Walker, M.; Heister, S.D. Development and Launch of the Purdue Hybrid Rocket Technology Demonstrator. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Denver, CO, USA, 2–5 August 2009. [Google Scholar]

- Kawai, H.; Harada, J.; Oguro, J.; Banno, A.; Nakagawa, I. Launches of Hybrid Rockets with Wax Fuel. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, San Jose, CA, USA, 14–17 July 2013. [Google Scholar]

- Werner, R.; Knop, T.; Wink, J.; Ehlen, J.; Huijsman, R.; Powell, S.; Florea, R.; Wieling, W.; Cervone, A.; Zandbergen, B. Development and Performance of the 10 kN Hybrid Rocket Motor for the Stratos II Sounding Rocket. In Proceedings of the Space Propulsion 2016, Rome, Italy, 2–6 May 2016. [Google Scholar]

- DLR-Raumfahrtmanagement. STERN: Studentische Experimental-Raketen. 2012. Available online: https://www.dlr.de/rd/PortalData/28/Resources/dokumente/rl/STERN_Flyer.pdf (accessed on 13 January 2020).

- Becker, J.; Grefen, B.; Stoll, E. Results of the Leonis Project and Launch Campaign within the STERN Program. In Proceedings of the Deutscher Luft- und Raumfahrtkongress, Braunschweig, Germany, 13–15 September 2016. [Google Scholar]

- Schuettauf, K.; Stamminger, A.; Lappoehn, K. The STERN Project—Hand On Rockets Science for University Student. In Proceedings of the 23rd ESA PAC Symposium, Visby, Sweden, 11–15 June 2017. [Google Scholar]

- Rothe, D.; Hink, R. Faust Hybrid Rocket—Current Status. In Proceedings of the Deutscher Luft- und Raumfahrtkongress, Rostock, Germany, 22–24 September 2015. [Google Scholar]

- Dullo, C.M.U.; Hink, R. Experimental Analyses of the HTPB-Aluminum Mixtures for Hybrid Rocket Engines. In Proceedings of the Deutscher Luft- und Raumfahrtkongress, Stuttgart, Germany, 10–12 September 2013. [Google Scholar]

- Gamper, E.; Hink, R. Design and Test of Nitrous Oxide Injectors for a Hybrid Rocket Engine. In Proceedings of the Deutscher Luft- und Raumfahrtkongress, Rostock, Germany, 22–24 September 2015. [Google Scholar]

- Baade, M.; Hink, R. Design of a Nozzle for a Hybrid Rocket Engine Using an Explicit Finite-Volume Based Simulation for Heat Transfer. In Proceedings of the Deutscher Luft- und Raumfahrtkongress, Stuttgart, Germany, 10–12 September 2013. [Google Scholar]

- Hink, R. HYDRA 3 Hybrid Rocket Engine—Flight Version Test Results. In Proceedings of the Deutscher Luft- und Raumfahrtkongress, Rostock, Germany, 22–24 September 2015. [Google Scholar]

- Lemmon, E.W.; McLinden, M.O.; Friend, D.G. NIST Chemistry WebBook, NIST Standard Reference Database Number 69; Chapter Thermophysical Properties of Fluid Systems; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018.

- Lohner, K.; Dyer, J.; Doran, E.; Dunn, Z.; Zilliac, G. Fuel Regression Rate Characterization Using a Laboratory Scale Nitrous Oxide Hybrid Propulsion System. In Proceedings of the 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Sacramento, CA, USA, 9–12 July 2006. [Google Scholar]

- Doran, E.; Dyer, J.; Lohner, K.; Dunn, Z.; Cantwell, B.; Zilliac, G. Nitrous Oxide Hybrid Rocket Motor Fuel Regression Rate Characterization. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cincinnati, OH, USA, 8–11 July 2007. [Google Scholar]

- Shan, F.; Hou, L.; Piao, Y. Combustion performance and scale effect from N2O/HTPB hybrid rocket motor simulations. Acta Astronaut. 2013, 85, 1–11. [Google Scholar] [CrossRef]

- Andrea, L. A Mathematical Perspective on Flight Dynamics and Control; Springer: Berlin, Germany, 2017. [Google Scholar]

| Parameter | Value |

|---|---|

| Diameter | |

| Length | |

| Mass | |

| Altitude | |

| Engine | HYDRA 3X |

| Parameter | Symbol | HYDRA 3X | HYDRA 4X |

|---|---|---|---|

| Overall length | l | ||

| Overall diameter | d | ||

| Fuel grain length | |||

| Post combustion chamber length | |||

| Nozzle throat diameter | |||

| Nozzle area ratio | 5.06 | 4.97 | |

| Mass | m | ||

| Fuel mass | |||

| Casing mass | |||

| Thrust | F | * | |

| Total impulse | * | ||

| Chamber pressure | * |

| Parameter | Symbol | Value |

|---|---|---|

| Input parameter | ||

| Oxidizer to fuel mass ratio (-) | O/F | 7 |

| Combustion chamber pressure (MPa) | 2.5 | |

| Nozzle exit pressure (MPa) | 0.085 | |

| Output parameter | ||

| Temperature (chamber) (K) | 3358.1 | |

| Molar mass of reaction product (chamber) (g/mol) | M | 26.534 |

| Ratio of specific heats (chamber) (-) | ||

| Ratio of specific heats (throat) (-) | ||

| Ratio of specific heats (exit) (-) | ||

| Specific impulse (m/s) | 2391.9 | |

| Parameter | Symbol | Value |

|---|---|---|

| Oxidizer pressure (MPa) | 5 | |

| Combustion chamber pressure (MPa) | 2.5 | |

| Mean density NO (kg/m) | 915.85 | |

| Discharge coefficient (-) | 0.497 | |

| Orifice diameter (mm) | - | 0.8 |

| Orifice length (mm) | - | 5 |

| Mass flow oxidizer (kg/s) | 0.93 | |

| Injector orifices (-) | n | 55 |

| Density HTPB (kg/m) | 936.0 | |

| Regression rate (mm/s) | 0.66 | |

| Mass flow fuel (kg/s) | 0.13 | |

| Outer diameter fuel grain (m) | 0.13 | |

| Length fuel grain (m) | 0.34 | |

| Burn time (s) | 15.8 | |

| Nozzle exit pressure (MPa) | 0.085 | |

| Nozzle area ratio (-) | 4.97 | |

| Momentum thrust coefficient (-) | 1.47 | |

| Characteristic velocity (m/s) | 1607 | |

| Throat diameter (m) | 0.0295 | |

| Divergent nozzle length (m) | 0.07 |

| Design Parameter | H4X-01 | H4X-02 | H4X-03 | H4X-04 |

|---|---|---|---|---|

| Fuel grain geometry | Geometry v1 | Geometry v1 | Geometry v2 | Geometry v2 |

| Injector | 36 orifices | 40 orifices | 40 orifices | 55 orifices |

| Post combustion chamber length | ||||

| Measured parameter as mean over burn time | ||||

| 8 | 15.7 | 12.2 | 12.3 | |

| 1 | 1.2 | 1.6 | 2.3 | |

| 1.5 | 1.8 | 2 | 2.3 | |

| 0.08 | 0.1 | 0.13 | 0.12 | |

| 0.44 | 0.63 | 0.72 | 0.66 | |

| 4.4 | 4.2 | 4.95 | 4.6 | |

| 0.72 | 0.63 | 0.65 | 1.01 | |

| (g/cms) | 15.7 | 10 | 10.7 | 17.2 |

| 8.75 | 6.3 | 5 | 8.4 | |

| H4X-01, 02 | H4X-03, 04 | |

|---|---|---|

| D | 130 mm | |

| n | 8 | 6 |

| 25 | 12 | |

| 70 | 48 | |

| Parameter | Faust | Faust II | H5 Rocket |

|---|---|---|---|

| Cell diameter (m) | |||

| Engine | HYDRA 3X | HYDRA 4X | HYDRA 5 |

| Thrust (kN) | 3 | ||

| Total impulse (kNs) | 50 | ||

| Rocket mass (kg) | Steel: 26.4 (24.1) CFRP: 24.2 | Steel: 44.3 CFRP: 39.6 (46.3) | Steel: 59.0 CFRP: 51.1 |

| Apogee altitude (km) | Steel: 5.73 (5.41) CFRP: 6.22 | Steel: 13.7 CFRP: 15.6 (11.2) | Steel: 15.3 CFRP: 18.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heeg, F.; Kilzer, L.; Seitz, R.; Stoll, E. Design and Test of a Student Hybrid Rocket Engine with an External Carbon Fiber Composite Structure. Aerospace 2020, 7, 57. https://doi.org/10.3390/aerospace7050057

Heeg F, Kilzer L, Seitz R, Stoll E. Design and Test of a Student Hybrid Rocket Engine with an External Carbon Fiber Composite Structure. Aerospace. 2020; 7(5):57. https://doi.org/10.3390/aerospace7050057

Chicago/Turabian StyleHeeg, Francesca, Lukas Kilzer, Robin Seitz, and Enrico Stoll. 2020. "Design and Test of a Student Hybrid Rocket Engine with an External Carbon Fiber Composite Structure" Aerospace 7, no. 5: 57. https://doi.org/10.3390/aerospace7050057

APA StyleHeeg, F., Kilzer, L., Seitz, R., & Stoll, E. (2020). Design and Test of a Student Hybrid Rocket Engine with an External Carbon Fiber Composite Structure. Aerospace, 7(5), 57. https://doi.org/10.3390/aerospace7050057