In this section the experimental results of the test campaign are presented and discussed.

4.2. Experimental Regression Rate Considerations

The main measured quantities, for the different firing tests, are summarized in

Table 3.

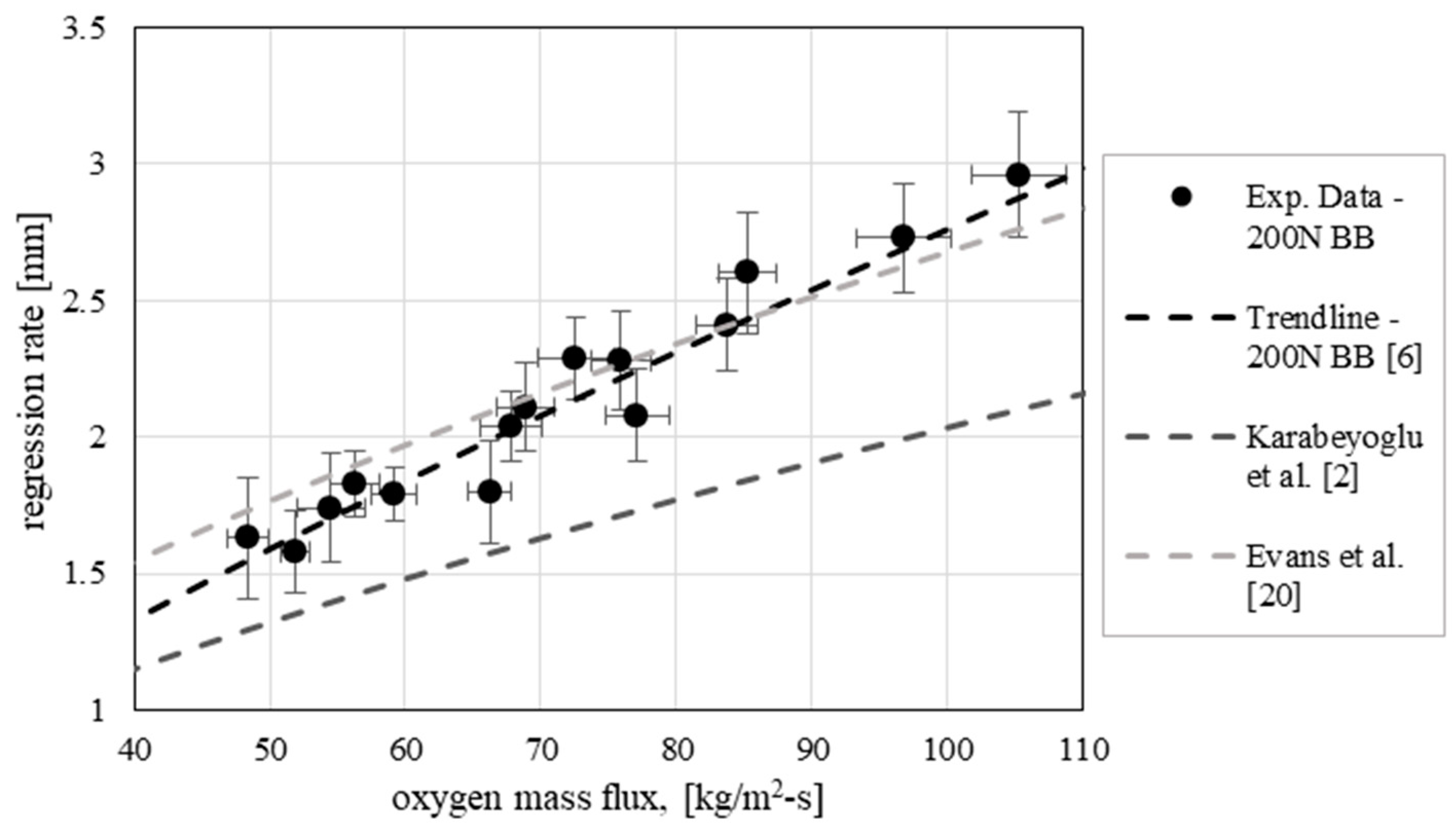

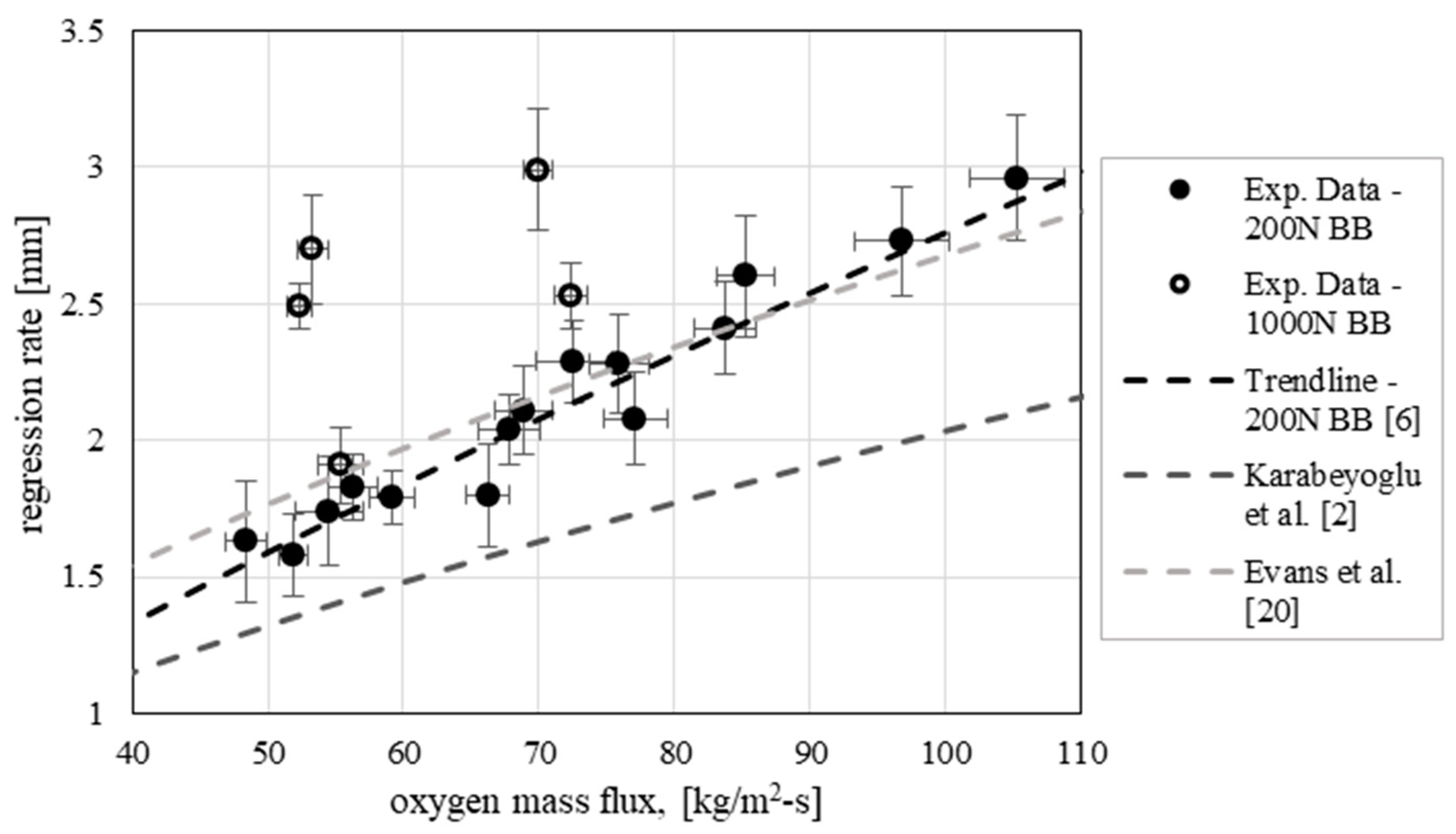

The experimental data point in terms of fuel regression rate as function of the oxidizer mass flux are reported in

Figure 10 along with the data point measured on the subscale 200 N-class breadboard. Also, trends from relevant literature are reported for comparison. It is quite evident that, although the fuel grain formulation was the same, the regression rates experienced with the 1000 N breadboard, which range between about 1.9 mm/s (test L1) and 3 mm/s (test L5), are significantly higher with respect to the values obtained with the subscale breadboard at equal oxidizer mass flux. In fact,

Table 4 reports the relative deviations between the expected values of the regression rate on the basis of the regression rate law as function of the oxidizer mass flux only (Equation (2)) and the corresponding measured data, which range between around 10% and 40% in module.

The above discussed results show that, while Equation (2) represents a sufficiently good fit of experimental data obtained with the 200 N breadboard, it leads to a non-negligible underestimation of the regression rate in the case of the larger scale engine. Consequently, in the scale-up of hybrid rockets it should be taken into account that the oxidizer mass flux is not the only quantity affecting the fuel regression rate. This is also confirmed by the fact that the experimental data for the 1000 N breadboard themselves do not show a clear trend of regression rate with oxygen mass flux. Therefore, other significant operating parameters must play a significant role, which should be properly investigated and assessed. In particular, the possible effect of two main parameters, i.e., the grain port diameter and the mixture ratio, on the fuel consumption behavior is discussed in the following and will be the subject of the future experimental investigations.

Recalling the main idea of previous authors’ work [

6], the grain port diameter is a first quantity which could have an effect on the regression rate, as a consequence of the oxidizer injection flow pattern. In the case of axially injected oxidizer, a flow recirculation is created in the entrance region of the grain port where the oxidizer jet spreads up to the impingement point on the grain surface, enhancing the heat transfer to the wall. The extension of the vortex increases with the port diameter and, therefore, macroscopic result is that the fuel regression rate could be influenced by the port diameter other than by the mass flux [

18]. For this reason, in Ref. [

6] a correlation of the fuel regression rate with the oxidizer mass flux and the time-space averaged port diameter has been obtained which is expressed by

where the regression rate is expressed in mm/s, mass flux in kg/m

2s and the port diameter is in mm.

Although it should be taken into account that the different injector and pre-chamber design limit the application of the above described correlation, the law of Equation (3) has been applied to calculate new values of the expected fuel regression rate and the results are reported in

Table 5.

Although the deviations are reduced in almost all cases with respect to the basic formulation, the errors are still relatively high, so it can be concluded that combustion chamber conditions (i.e., MR, p

c) directly affect the regression rate. In particular, as reported in [

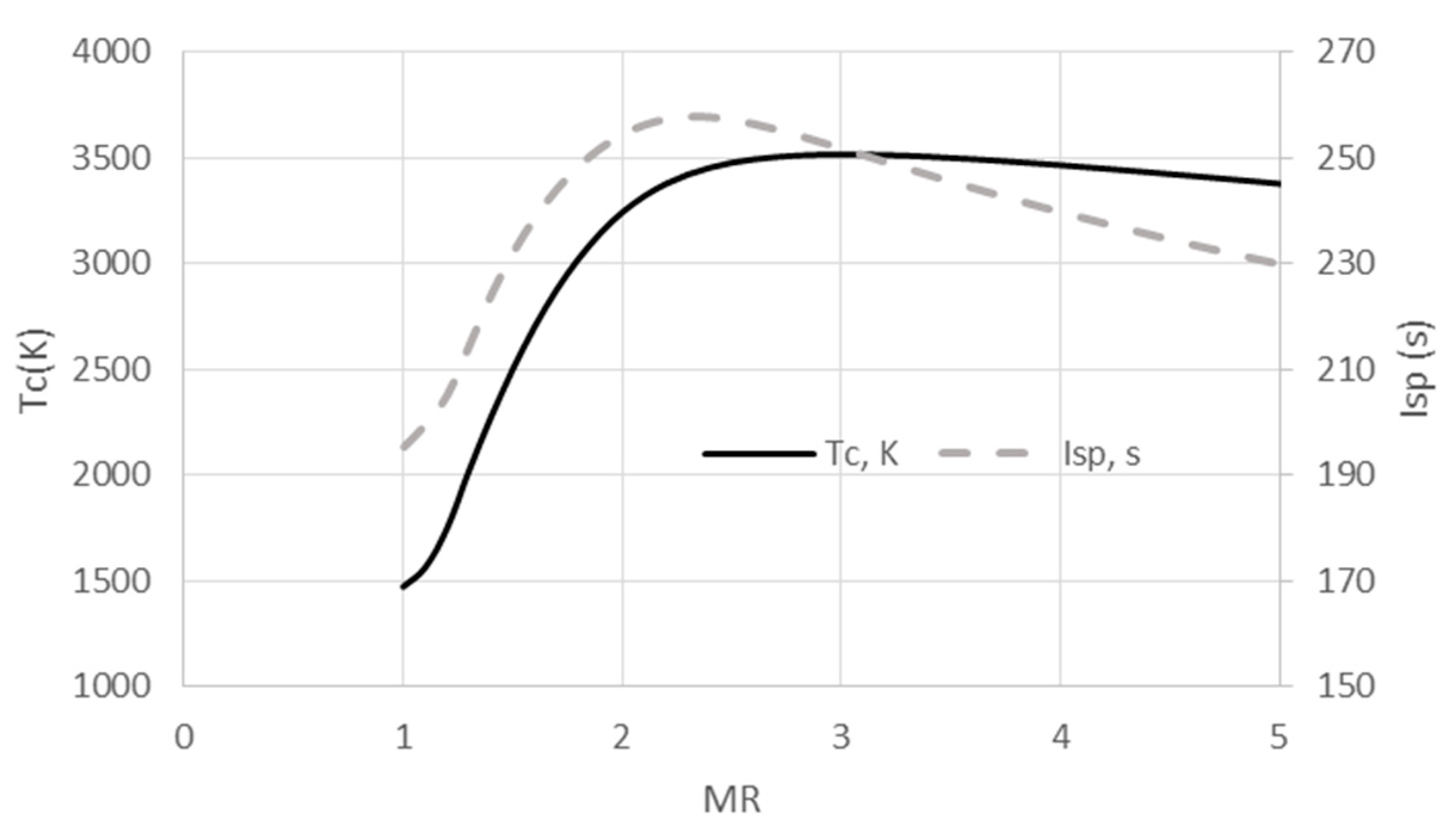

2], the regression rate could be significantly affected by the oxidizer-to-fuel ratio. In fact, from

Figure 11, which shows the adiabatic flame temperature variation with mixture ratio at fixed chamber pressure (

), it can be observed that in the mixture ratio range between 1 and 2 a strong temperature increase of the flame is expected. The temperature increase determines both increase of the heat transfer to the gas-liquid interface and variation of the gas properties, which in turn affect both the vaporization and the entrainment contributions to the fuel regression rate.

In particular, the vaporization contribution is given by the classical hybrid theory, which describes the regression rate of hybrid fuels in the absence of entrainment. The widely accepted formula due to Marxman et al. [

19] shows the dependence of the vaporization regression rate with the gas properties (the gas viscosity in particular) and the radiative to convective heat transfer ratio.

where

is the reference shear stress (generally assumed equal to 0.03) and

is a corrective factor of the surface friction [

5]. It is evident that, once chosen the fuel propellant and fixed the oxidizer mass flux, the evaporation regression rate increases with the flame temperature due to both increase of gas viscosity and radiative to convective heat transfer ratio.

The entrainment contributions, on the two different breadboards, is more complex to define and requires deeper investigations. However, this mechanism is meanly related to the fuel properties, which remain unchanged. According to [

5], the general empirical expression for the entrainment rate, in terms of the relevant properties of the hybrid breadboard, is

where

is approximately 1.5,

is approximately 2 and

and

are approximately 1.

is the dynamic pressure of the gas flow in the port and

has the same formulation of Equation (4), therefore depending on

. Once the mass flux through the port is fixed, a higher flame temperature leads to an increase of both skin friction coefficient (proportional to gas viscosity) and dynamic pressure (

). The melt layer thickness is more difficult to quantify, but if a slight variation is assumed, then it can be asserted that also the entrainment contribution to regression rate is higher for the 1000 N breadboard with respect to the subscale.

Therefore, observing that the tests with the 1000 N breadboard are characterized by higher average mixture ratio if compared to the test performed with the subscale engine at similar oxidizer mass flux, the previous considerations could explain the higher measured values of the regression rate. Moreover, the regression rate in test L3 is higher than that of test L1 although the average oxidizer mass fluxes are similar (and similarly regression rate in test L5 is higher with respect to that of test L2) because the higher oxygen mass flow rate determines higher initial value of the mixture ratio which, as said before, is the cause of an enhanced fuel consumption.

The above discussed considerations lead to the conclusion that the regression rate law derived with subscale testing (Equation (2)) is not suitable when the motor operating parameters move away from those associated with the 200 N campaign. In fact, considering Test L1 of the 1000 N breadboard the Equation (2) remains still applicable, but for the other tests its application leads to a regression rate underestimation (since Test L2 to L5 are characterized by higher value of the oxidizer to fuel mixture ratio). A general expression of the fuel regression rate should include other operating parameters, beyond the oxidizer mass-flux, as for instance, mixture ratio. Dedicated experimental test campaign will be addressed to further investigate this question and, once more data would be available, an upgraded formulation of the Equations (2) and (3) for the regression rate will be derived.

4.3. Data Assessment and Performances Considerations

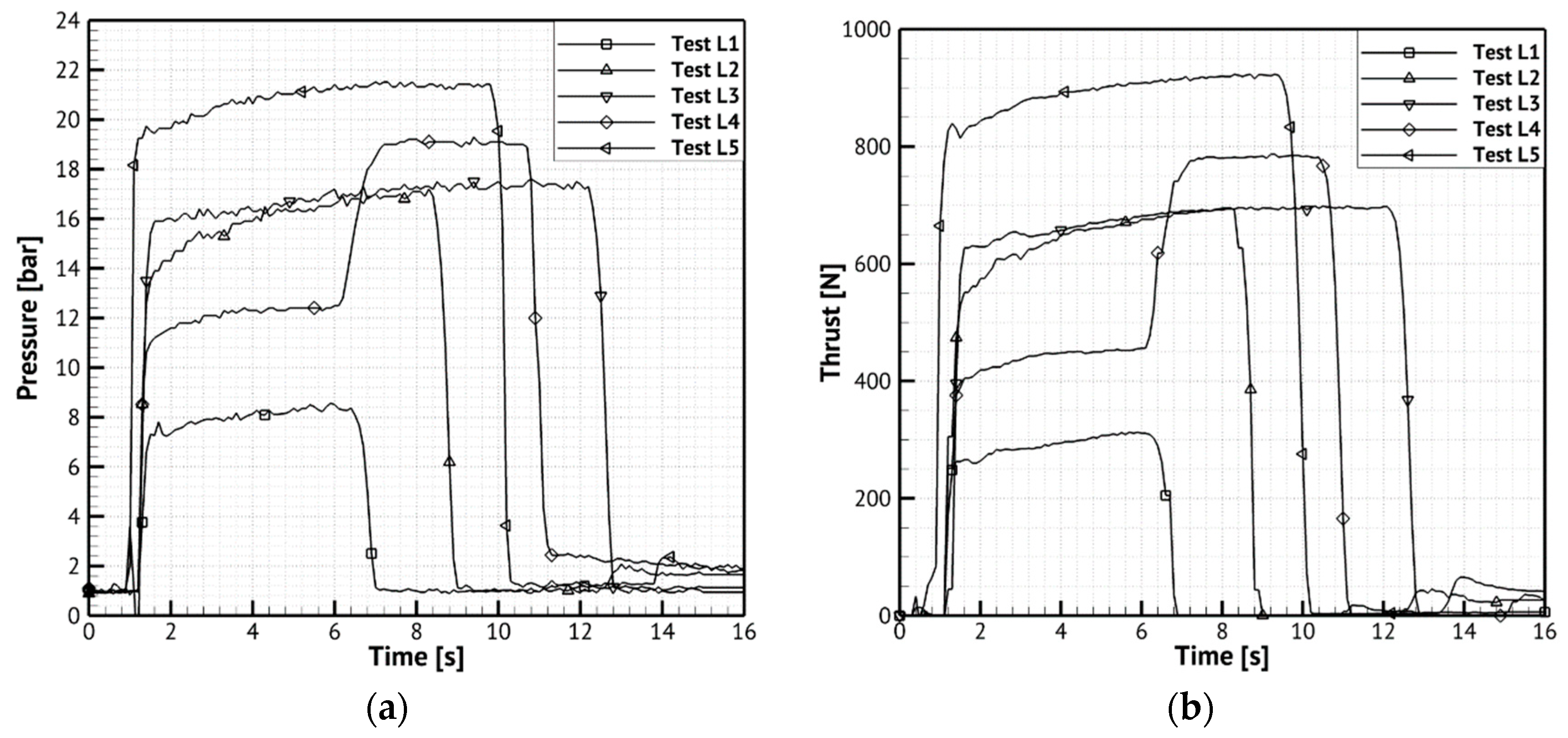

This section presents main data recorded by the experimental test campaign along with their preliminary assessment with consideration about general performance parameters.

Figure 12 provides the temporal evolution of chamber pressure (a) and thrust (b) acquired for the different firing tests. Chamber pressure was not affected by throat diameter increase, since negligible ablation was measured after the firing tests. It is interesting noticing that pressure slightly increases and tends to a constant value during firing time; this behavior is opposite with respect to the previsions by HDC, since they were based on the regression rate law of the small-scale breadboard (Equation (2)). Due to higher measured regression rates with respect to the law presented in [

6], even if on one side the temperature decreases in time due to decrease of MR from the optimum (see

Figure 11), the higher paraffin mass-flow rate compensates this effect and the result is a nearly constant chamber pressure.

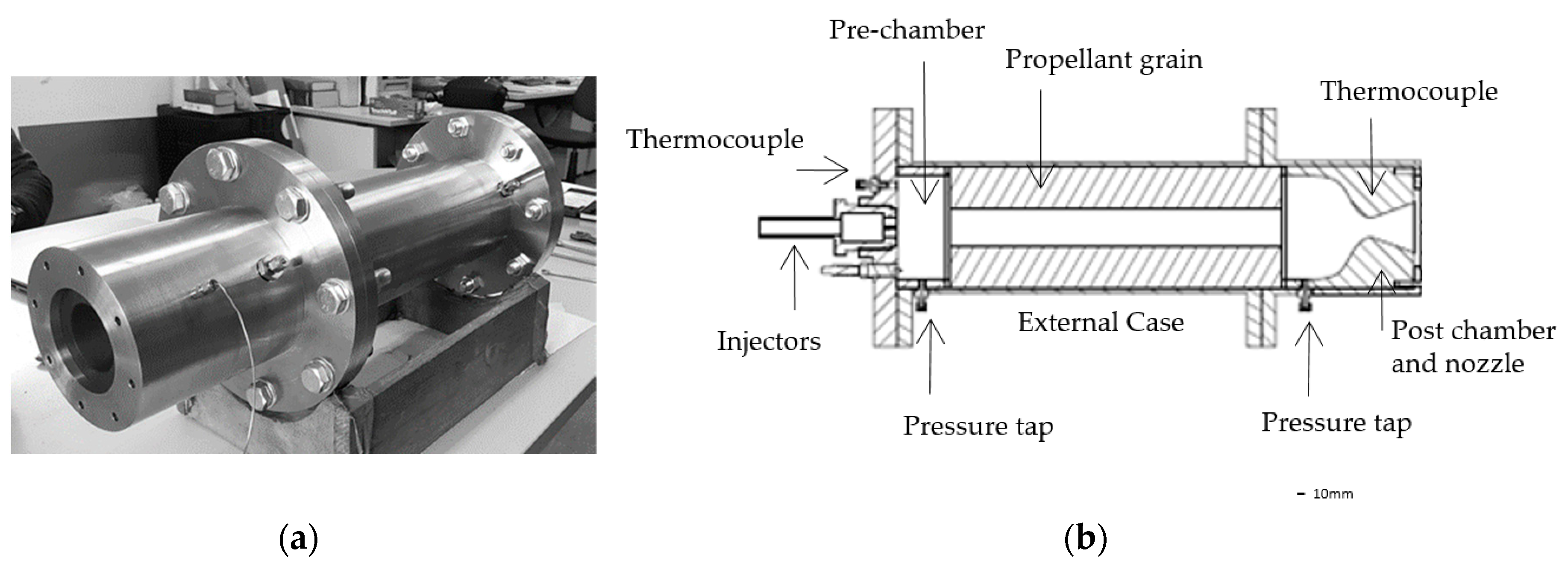

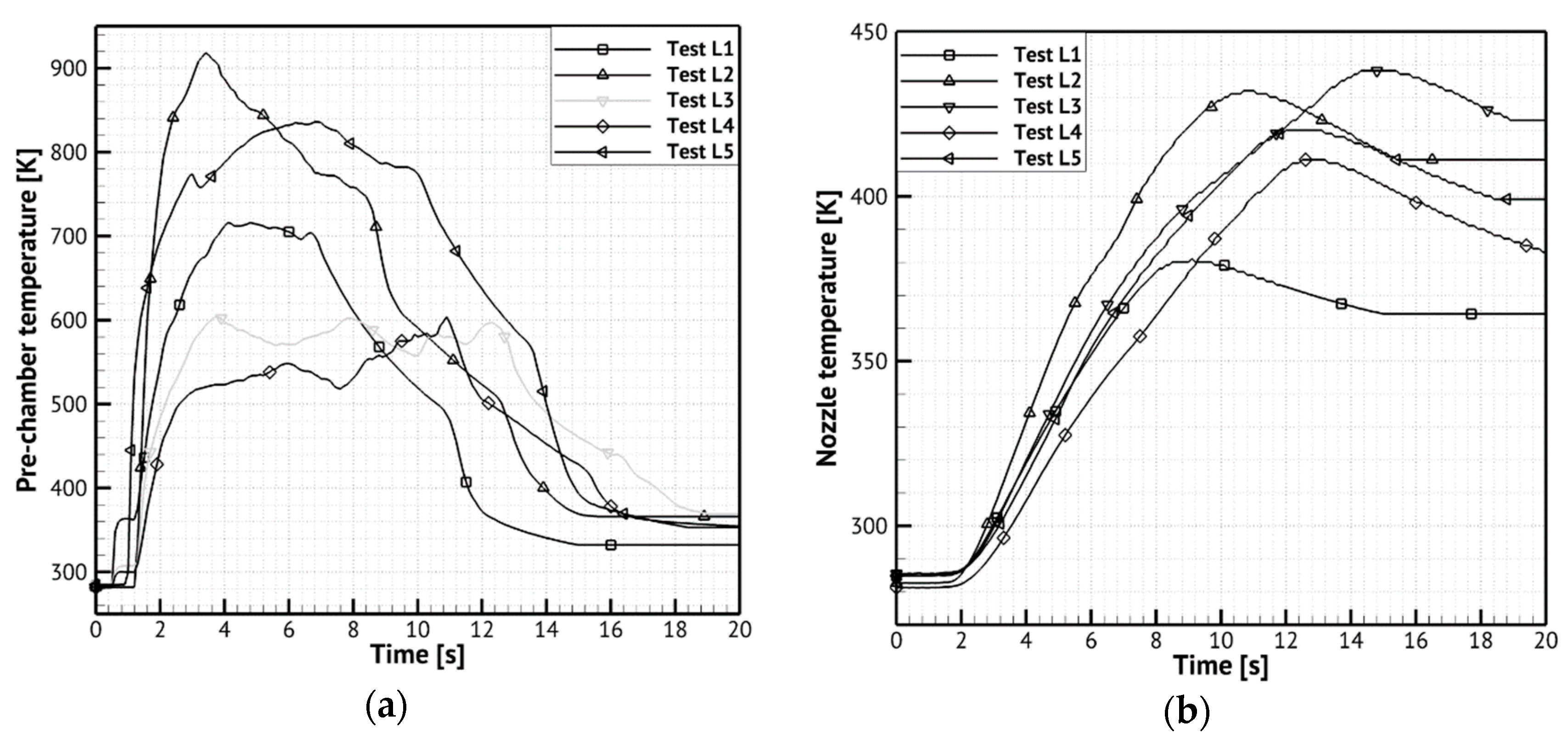

Figure 13 shows temperature acquisitions by a thermocouple located in the breadboard pre-chamber (a) and an embedded thermocouple in proximity of the nozzle throat (b)—(for details see

Figure 7). For test L3, the pre-chamber TC did not acquire due to a paraffin occlusion of the hole.

The experimental nozzle material temperature levels recorded during test, in

Figure 13b, justify the absence of ablation phenomena.

Table 6 reports the experimental breadboard performances. The time-averaged specific impulse is in line with the prevision made by the equilibrium calculation for each test conditions and thrust level is almost coherent with design predictions. It is important pointing out the behavior of the breadboard in the throttling test L4 (

Figure 12), where thrust and pressure levels are steady for both the operating conditions and the transition appears stable without spikes and oscillations.

The combustion efficiency has been highlighted only for test L5, being, this operative point very close to the nominal one in terms of oxidizer mass flow. The estimation is based on the mean mixture ratio and has been calculated as the ratio between real and ideal values: