A Review on Gas Turbine Gas-Path Diagnostics: State-of-the-Art Methods, Challenges and Opportunities

Abstract

1. Introduction

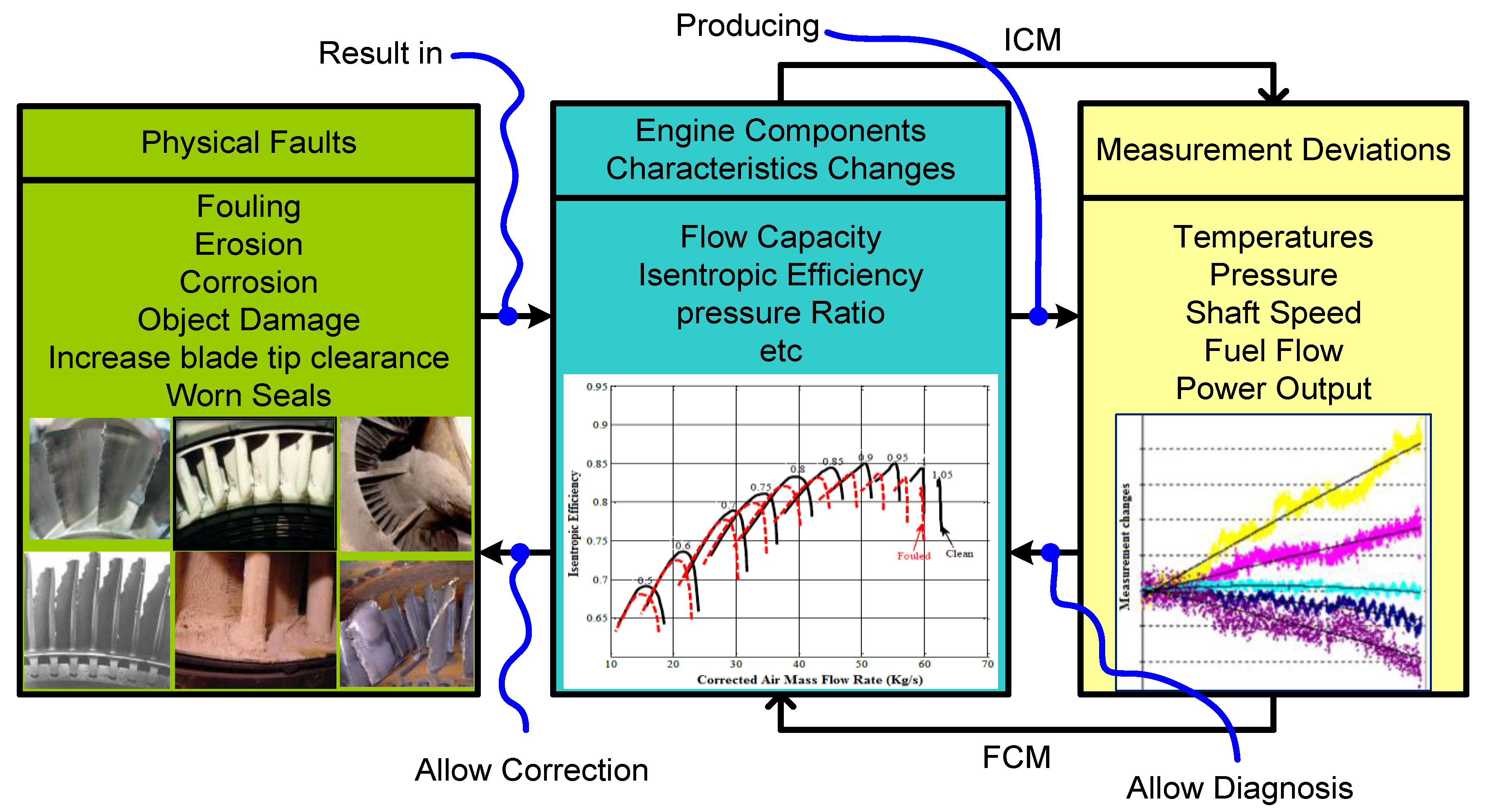

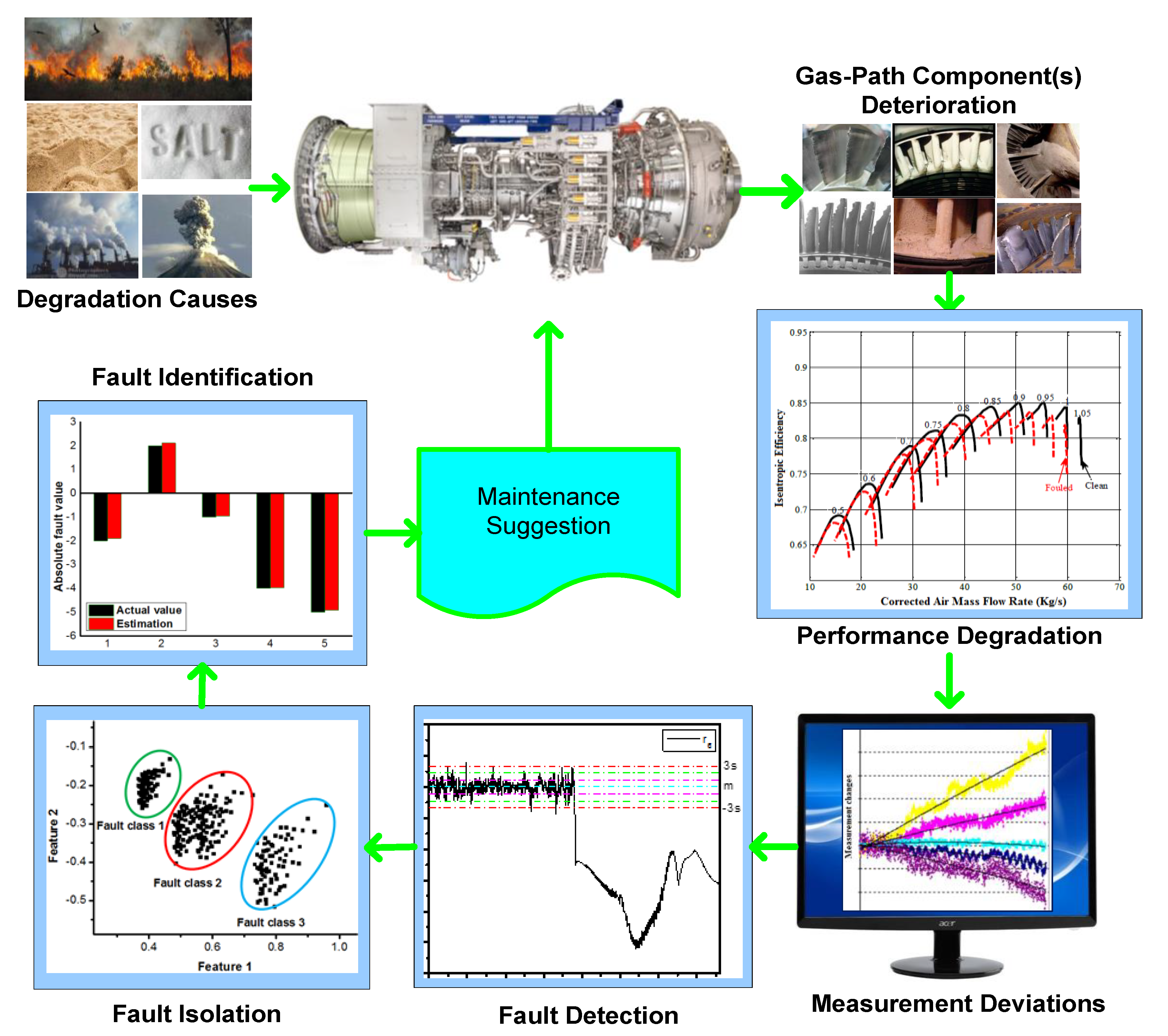

2. Gas Turbine Performance Degradation

2.1. Fouling

2.2. Erosion

2.3. Corrosion

2.4. Foreign Object Damage (FOD)/Domestic Object Damage (DOD)

2.5. Increase in Blade Tip Clearance

3. Fault Diagnostics

- Fault detection: Detecting the presence of an abnormal behavior, which may gradually lead to the failure of the system or part of it.

- Fault isolation: Determining the type and location of the fault(s).

- Fault identification: Estimating the magnitude of the fault(s).

3.1. Challenges of Successful GT Fault Diagnostics

- Nonlinearity of the diagnostic problem. The relationship between dependent parameters (measurements) and independent parameters (performance parameters) is highly non-linear. The complexity of the nonlinearity of the diagnostics problem increases as two or more components are affected simultaneously and/or sensor and component faults exist together. The diagnostic system to be proposed should thus be capable of dealing with the non-linear nature of the engine behavior.

- Measurement uncertainty. In reality, the data obtained from real engine operation cannot be error-free [78]. This error may come from the sensor itself (due to improper installation, miscalibration or malfunctioning), the operating environment, or the operator itself. Measurement uncertainties provide incorrect information about the nature of the fault signatures, thereby causing misinterpretation during engine health assessment. Noise and bias are the two categories of measurement uncertainty [79]. Noise is a measurement’s non-repeatability due to the engine harsh operating environments. Whereas bias refers to a sensor fault which is the difference between the average measurement and the actual value defined by the National Bureau of Standards (NBS) [78]. It is a fixed error (can be higher or lower than the actual value) that usually occurs as a result of a flaw in the sensor itself. Sometimes, the values of these uncertainties may reach a level often comparable to the actual measurement deviations caused by component deterioration. If this effect is ignored during the diagnostic method development, the solution will be unrealistic. Conversely, engine fault diagnosis using uncertain measurements may give an erroneous result, particularly, in MB methods. Therefore, either the sensor problem should be treated and corrected prior to the component fault diagnosis or the component fault diagnostic technique should tolerate these effects.

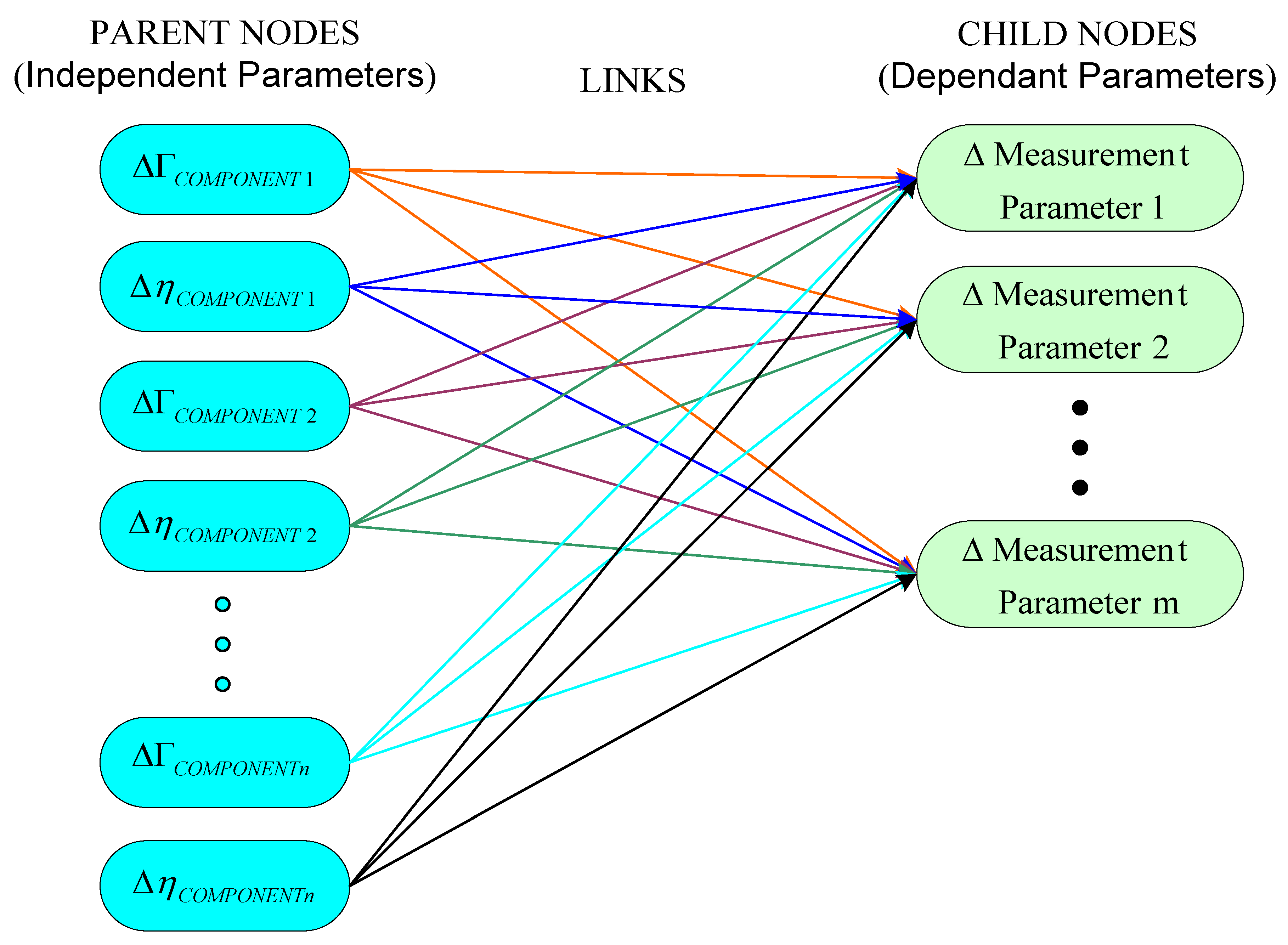

- Availability of limited sensors. GT engines are packed with different sensors for different purposes such as process control, health monitoring, and diagnostics. Measurement parameters which are essential for engine performance analysis are known as standard measurements [80]. For instance, these include pressure, temperature, fuel flow rate, and spool speed. The deviations of these measurements provide relevant information about the nature and severity of components’ performance deterioration. A careful measurement selection is crucial for effective fault diagnostics, especially in the case of MB methods. On the one hand, an accurate gas-path analysis requires a large number of measurements since the engine model is developed based on several instrumentation suites. In order to satisfy the requirement for a determinate equation, the number of measurements (the dependent parameters) has to be at least equal to the number of performance parameters (the independent parameters). On the contrary, in real engine service, the number of instruments available are limited due to weight and bulk issues (particularly in aircraft and marine applications), sensor noise and bias problems, the need of a reduced sensors’ installation and maintenance cost, and the absence of the gas generator turbine inlet sensors (since they cannot withstand the very high operating temperature) [81,82]. It is also impractical to measure the air flow rate due to the absence of the technology. Therefore, the diagnostic system is accountable to give the required solution using the available limited information obtained from the minimum sets of measurements.

- Occurrence of multiple faults simultaneously: In harsh engine operating conditions, the occurrence of multiple component/sensor faults is a likelihood. Hence, a single fault assumption can result in an untrustworthy fault diagnosis in the presence of multiple faults. The probability of the number of possible fault combinations grows exponentially depending on the available number of engine components/sensors and as a result the complexity of the diagnostic problem increases. The performance of a gas-path fault diagnostics scheme is highly influenced by the number of simultaneous faults [83]. This is because, when two or more components/sensors are affected together, there is a chance of producing similar or obscure fault signatures, thereby masking or compensating for each other’s effects. For example, in the case of double component faults (DCFs), when one of the components is lightly affected, the combined effect may result a confusing pattern with that of a single component fault (SCF). Likewise, if both components are severely affected, they may produce similar patterns with that of a triple component fault (TCF), and as a result, the DCFs may wrongly be classified as TCF or vice versa [83]. In general, as a multiple fault scenario, concurrent component faults, concurrent sensor faults, or concurrent sensor and component faults possibly exist during the engine lifetime.

- Operating condition variations. Due to load and/or ambient condition variations, the engine operating point may not be fixed. Therefore, operating point changes should be taken into account for practicability. A common way to avoid the influence of operating conditions variations is to form a “baseline” model, compute measurement deviations, and use them as network inputs instead of measurements themselves. Usually, this requires the model of the normal state to figure out the “baseline” [74,84]. Different GTs have different baselines based on their configuration and application environment. Hence, for a reliable fault diagnosis, an accurate baseline establishment is critical.

- Lack of standards in defining and representing fault diagnostic problems [85]. In the literature there is no consistency in defining and representing GT fault diagnostic problems. The majority of the available methods in the open domain are considered to be different platforms with different levels of complexity and applied different performance evaluation metrics. This inconsistency causes difficulties in exchanging diagnostic ideas, information fusion between fault diagnostic results of different engine systems, and a one-to-one comparison of different techniques.

- Unavailability of data in the required type, quality and quantity. Fault diagnostic method developers require relevant and reliable operational data, which can sufficiently represent the healthy and unhealthy engine conditions, to demonstrate and verify new algorithms. However, because of the very limited access to engine operational data (owing to proprietary and liability issues) and lack of deteriorated engine data due to the frequent washing actions, it is difficult to obtain the required data [81]. Performance data can be generated by either intentionally ingesting different physical fault causes/contaminants into the operating GT or implanting artificial fault patterns to the engine performance model [86]. The former alternative is not recommended since it is not technically and economically feasible. Whereas the latter, which is the most widely used alternative in this field, requires an accurate model.

- Absence of Diagnostic Methods Validation Techniques: GT users need a practical tool to evaluate the performance and effectiveness of a newly proposed algorithm in order to incorporate to their plant. Up to now, there are no standards to effectively evaluate the technical and economic feasibility of new algorithms [81]. The general procedures used by the research community so far will be presented later in this paper.

3.2. Desirable Attributes of a Fault Diagnostic System

- Fault diagnostic accuracy: For a correct maintenance decision, the fault diagnostics technique should able to detect, isolate and identify gas-path faults successfully. A fault detection task commits two types of errors: false alarms and missed detections. Both detection errors are equally harmful. A false detection leads to an increased maintenance cost, which is the opposite of the aim of fault diagnostics. Conversely, a missed detection may cause a significant performance loss or even system/component failure. Hence, in the detection step, the so-called normal class has to be distinguished from the abnormal class with reasonably acceptable accuracy. This is very important to avoid unnecessary or unexpected downtimes and enhance reliability. As well as fault detection, the diagnostic system should successfully determine the fault type and location. In particular, a GT fault isolation algorithm is accountable to separate sensor faults from actual engine component faults followed by classification of different component faults. All the possible single and multiple sensor and/or component fault cases are required to be isolated correctly using the minimum instrumentation suite. For a final maintenance decision, an accurate fault-level estimation is highly desirable so that the operator can make a strategic maintenance schedule of possible maintenance actions.

- Robustness: For a practical implementation, diagnostic systems are highly required to be robust/tolerant against measurement uncertainties.

- Explanation facility: To support engine users in the maintenance decision process, the fault diagnostic tool is required to be able to explain the nature of the faults (i.e., their root cause, current situation, and propagation) and justification of the recommendations.

- Simplicity/user-friendliness: The method should be simple to use and easy to understand by the operators so that an urgent decision can be made without the presence of any expert. It should thus be capable of providing a user-friendly interface.

- Adaptability: GT performance is sensitive to ambient condition changes or load variations. Therefore, a performance-based GT fault diagnosis system should be able to adapt to those variations so as to maintain its performance.

- Memory and computational requirements: The storage capacity and computational requirements (computational speed, time, and complexity) are the two basic features of a GT fault diagnosis algorithm, particularly for online applications.

- Reliability. Concerns about the practicability of the method for an engine with limited numbers of sensors and measurement errors. It should also be simple and cost-effective with minimum downtime for repair and maintenance.

- Comprehensiveness. This is the measure of the ability of the method to incorporate improvements when it is necessary and to be interfaced with other engine health management systems through data fusion in order to obtain a complete condition-based maintenance framework.

- Flexibility. It measures the degree of capability of the method, optimizing its configuration and adapting/extending the system to work on different engines or on the same engine running at different operating conditions. A low set-up time is desirable to implement this feature.

4. State-of-the-Art: GT Gas-Path Diagnostic Methods

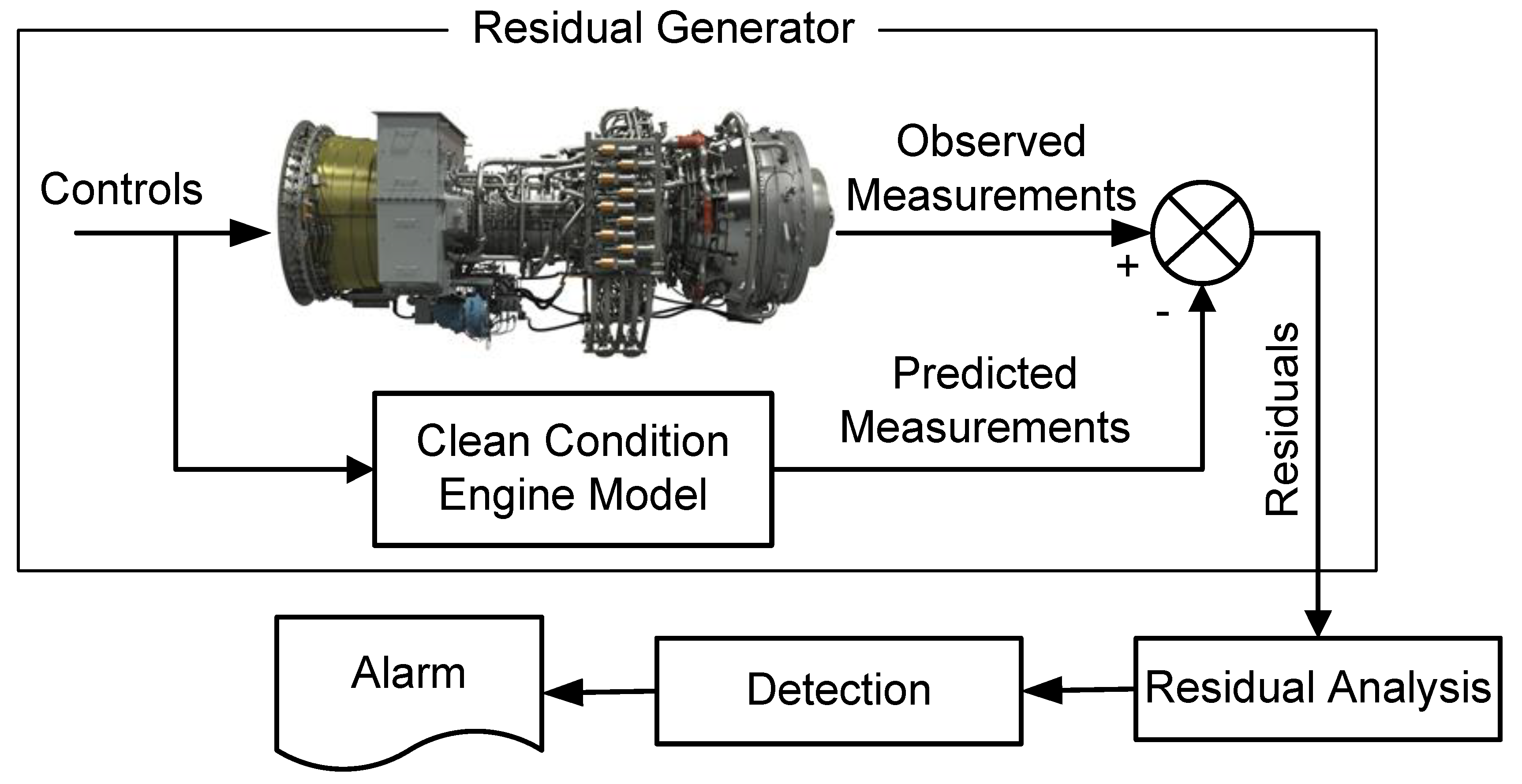

4.1. Model-Based Diagnostic Methods

4.1.1. Gas-Path Analysis

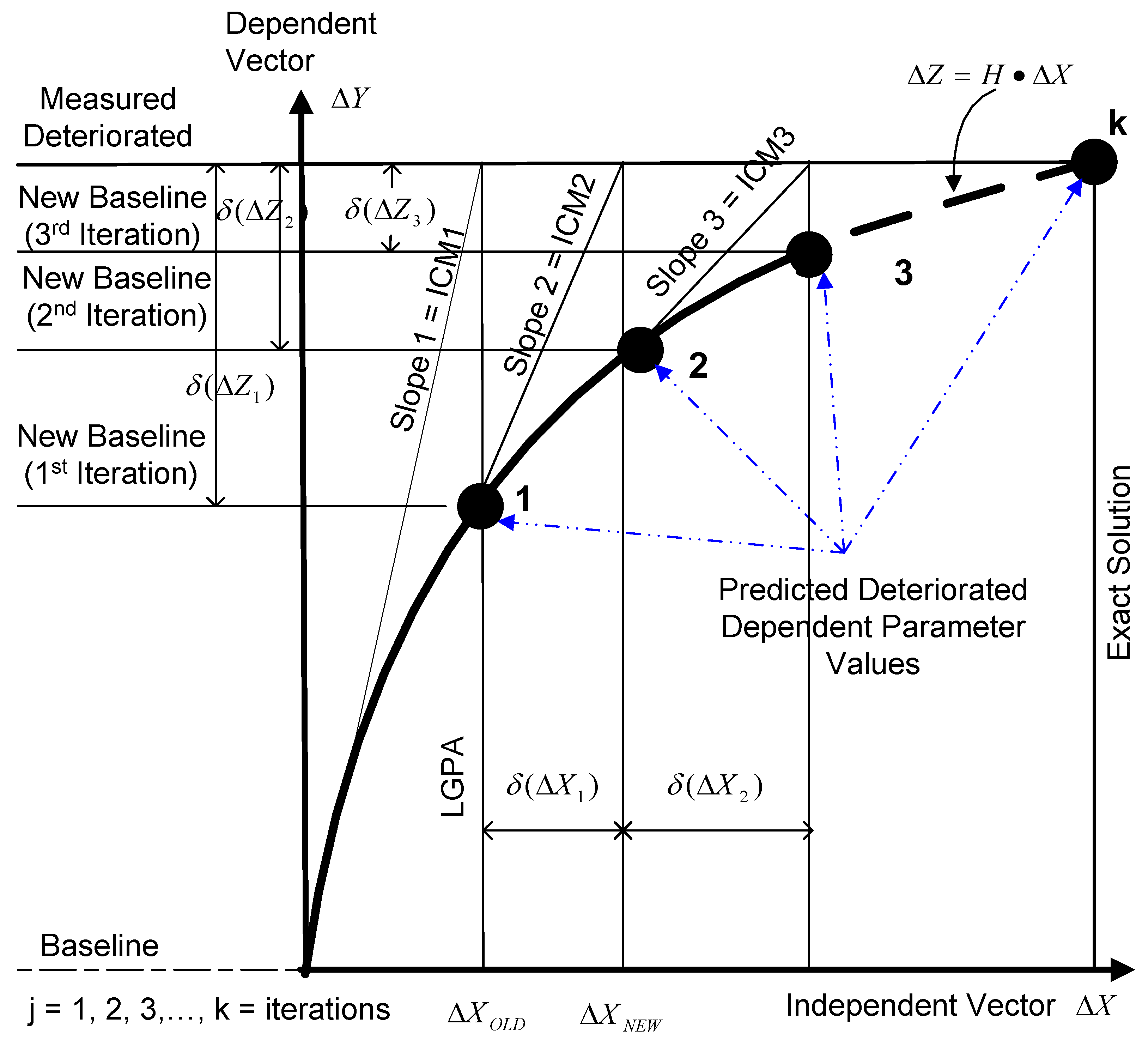

Linear GPA (LGPA)

- Case 1. (When M = N): When the number of measurements and performance parameters are equal, the number of unknowns and equations will be equal, and thereby the problem will be determinable. In this case, the ICM is a square matrix and invertible.

- Case 2. (When M > N): When the number of measurements is greater than the number of performance parameters to be estimated, the problem will be over-determined. In this case, the solution can be found applying the least square estimation method by replacing H−1 with the so-called pseudo-inverse.

- Case 3. (When M < N): In the real situation of a GT operation neglecting the effect of sensor noise and bias leads to an unrealistic solution. Conversely, considering all these issues including model uncertainty would result in an undetermined set of equations. The suitable solution for this problem scenario is given by Volponi [81].

Non-Linear GPA (NLGPA)

- is vector of measurement delta and can be expressed as:

- is performance parameter delta vector and can be expressed as:for example

- H is the ICM, which determines the relationship between and . It is the percentage delta in each measurement parameter for the corresponding percentage change in each performance parameter. For an infinitesimal change in the independent parameters, the corresponding ICM is the Jacobian.

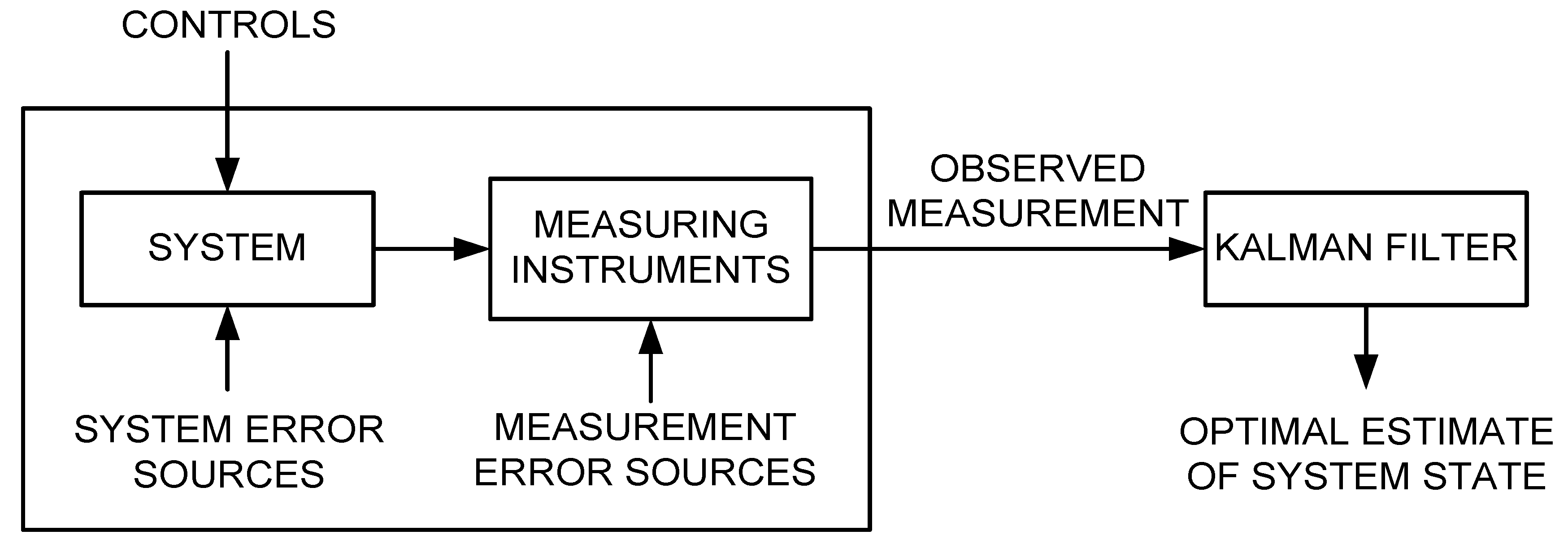

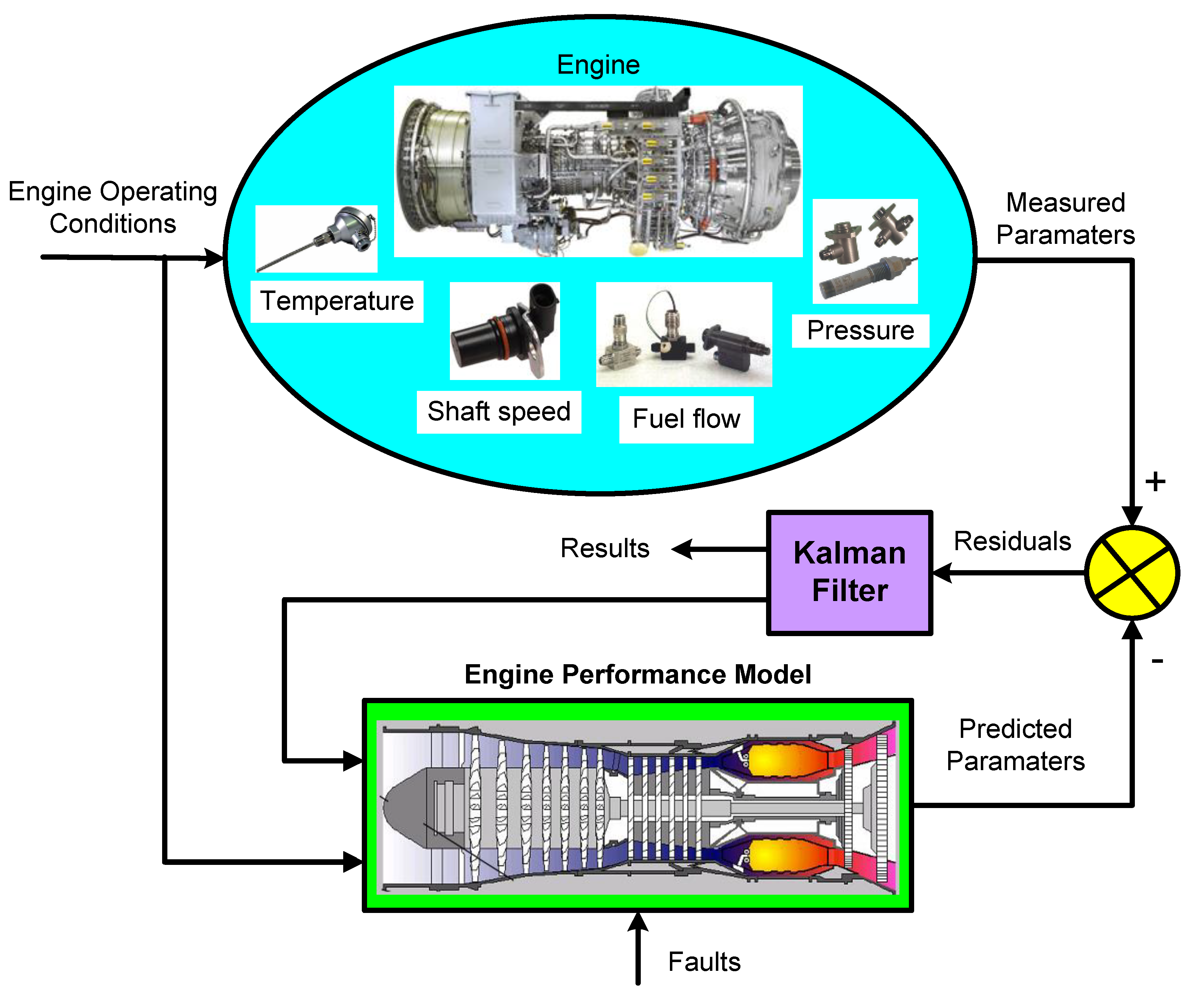

4.1.2. The Kalman Filter

- ○

- Initial conditionwhere represents the expectation operator.

- ○

- The initial system state, system noise, and measurement noise are uncorrelated

- ○

- The system noise and measurement noise are white, independent, and Gaussian distributed with known covariance matrices.

- State estimate extrapolation:

- Covariance of the estimation error (State Covariance Extrapolation):

- Kalman Gain (KG) Computation:

- State Estimate Update

- Error Covariance Updatewhere:

- -

- X(k/k−1): An estimate of X at a time k based on data up to sample time k − 1

- -

- : System state vector at time k + 1 based on time k

- -

- : System state vector at time k

- -

- : Transition matrix at time k + 1 based on time k

- -

- : System state vector at time k + 1 based on data up to sample time k

- -

- : Kalman gain matrix at time k + 1 based on time k

- -

- : Prediction covariance at time k + 1

- -

- : System sate vector at time k + 1 based on time k

- -

- : System error covariance at time k

- -

- : Measurement noise matrix at time k + 1

- -

- : Estimation error at time k

4.1.3. Advantages and Limitations of MB Methods

4.2. AI based Methods

4.2.1. Artificial Neural Networks

Multilayer Perceptron

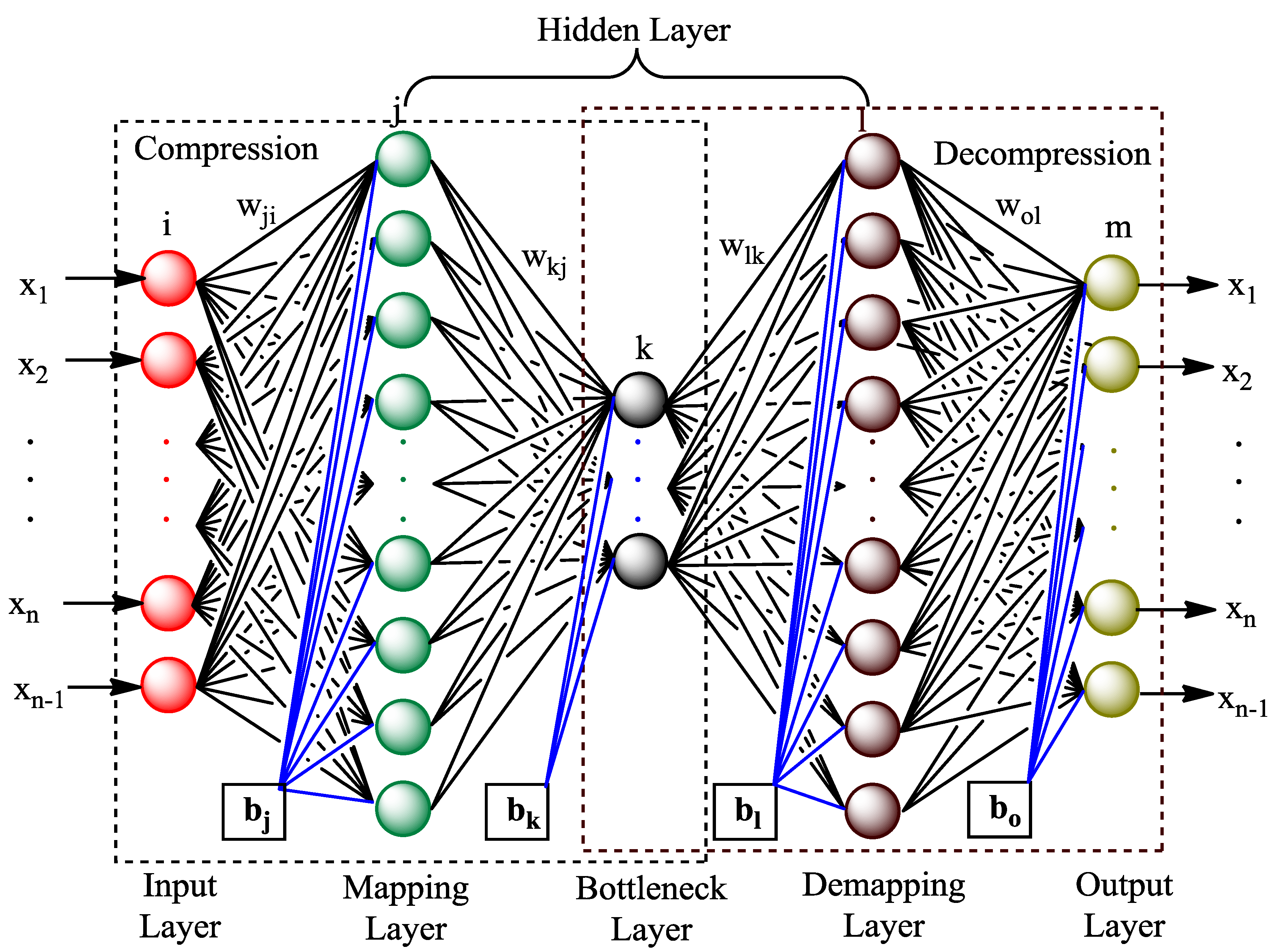

Autoassociative Neural Networks

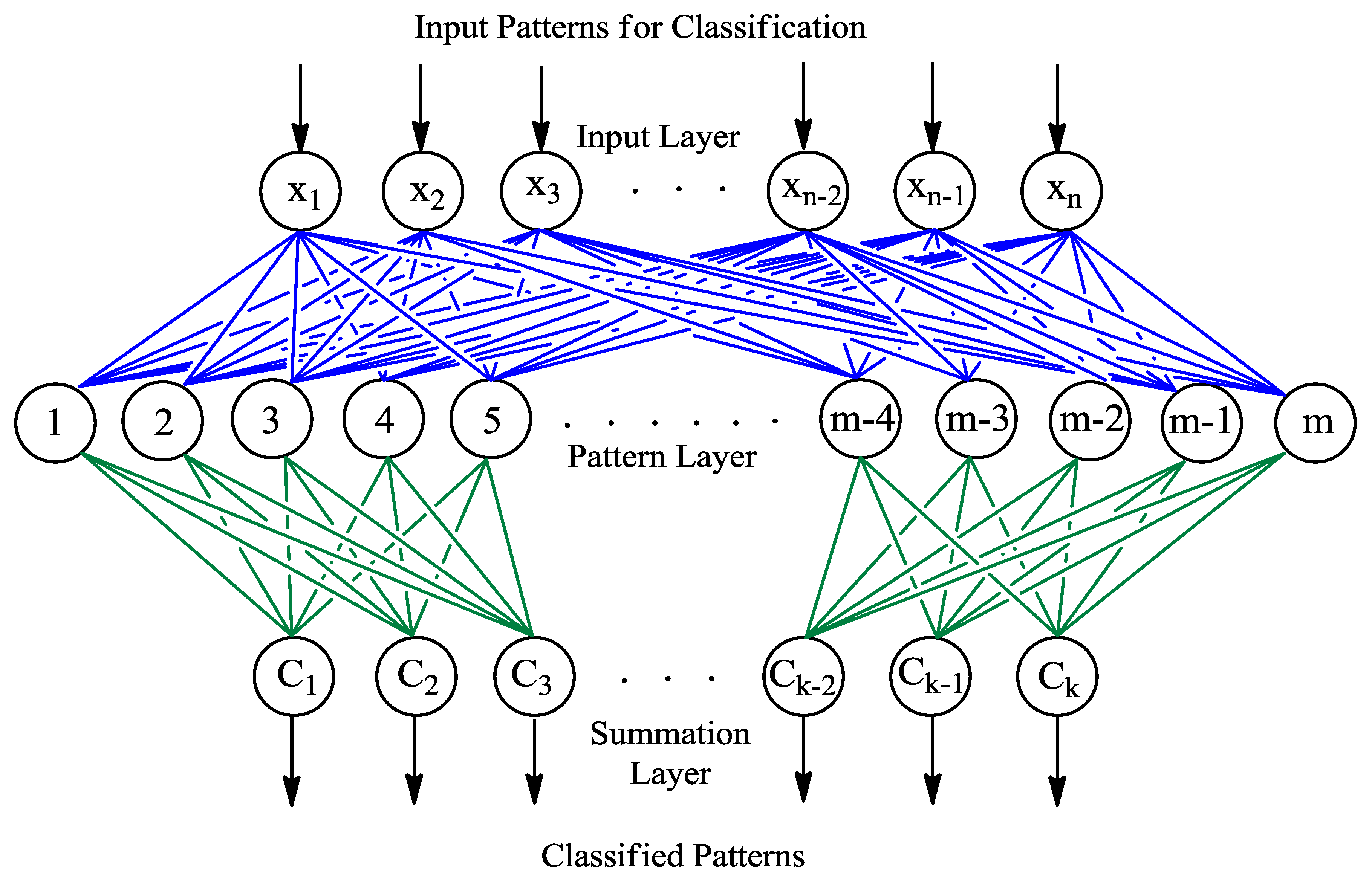

Probabilistic Neural Network

Radial Basis Function Networks

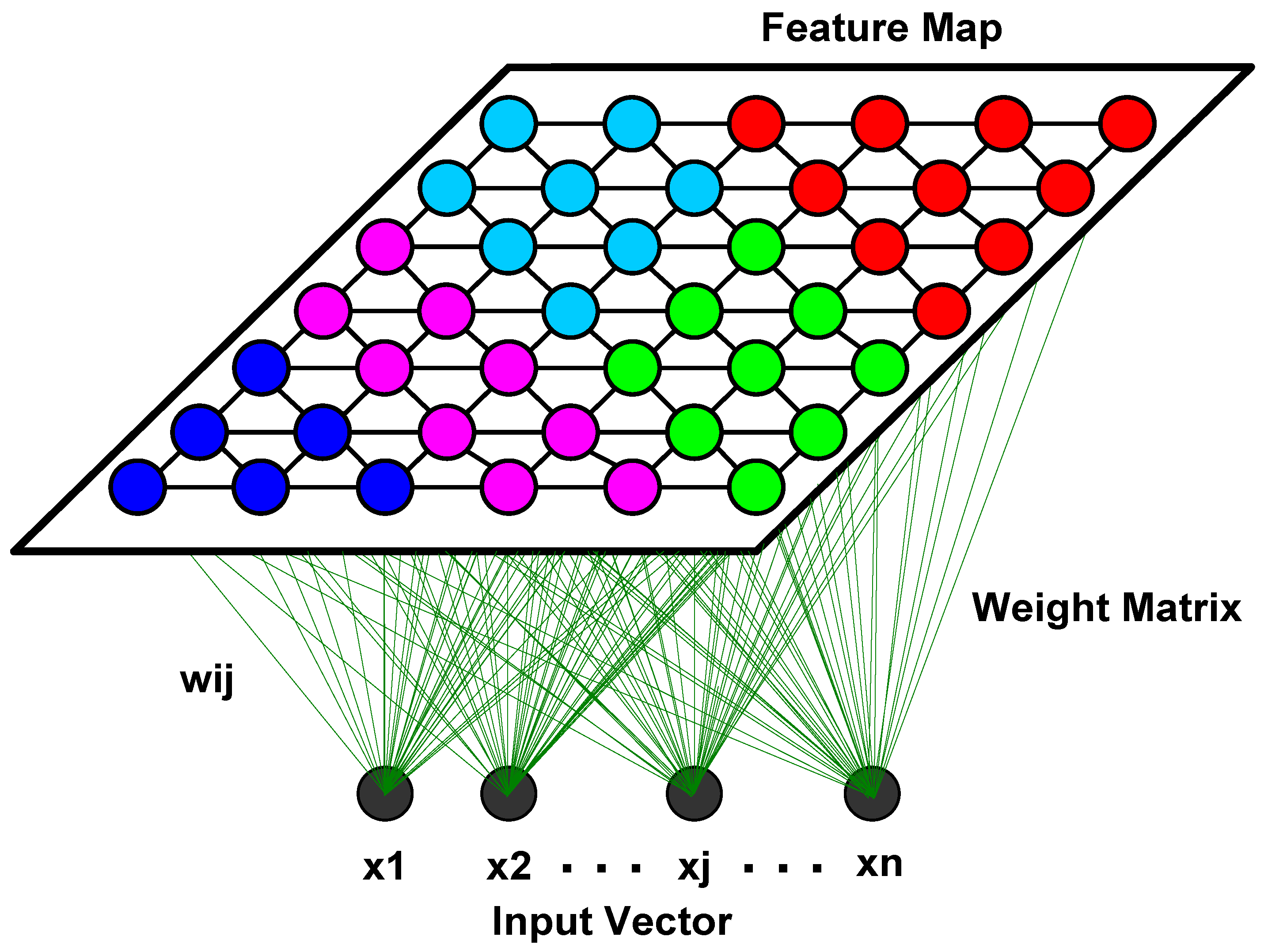

Self-Organizing Map

4.2.2. Deep Learning

4.2.3. Bayesian Belief Network

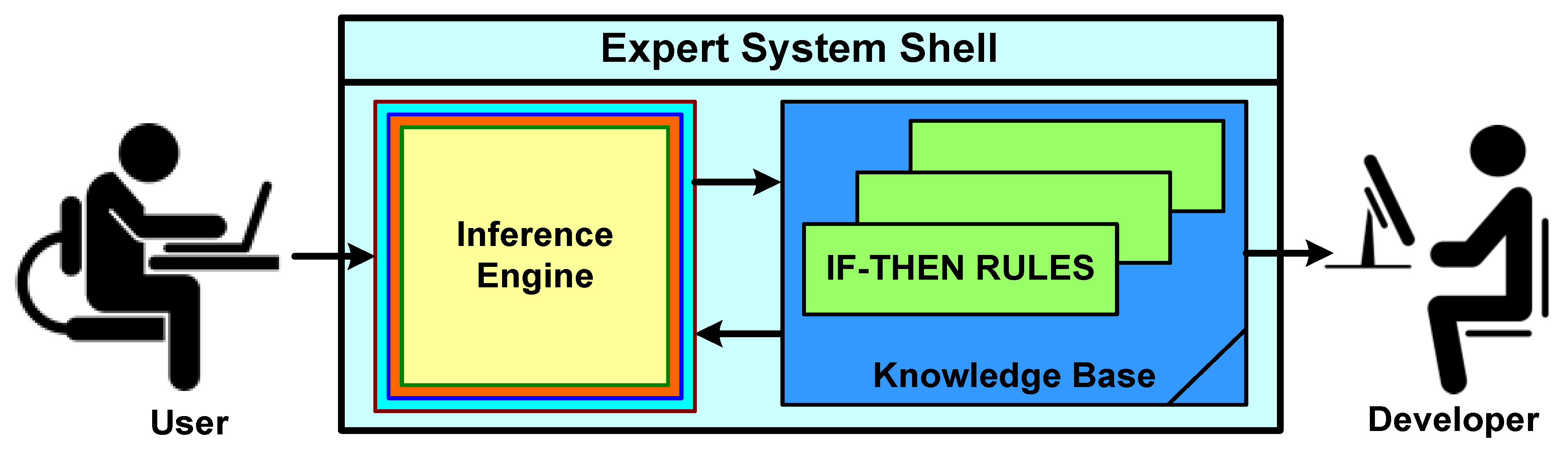

4.2.4. Expert Systems

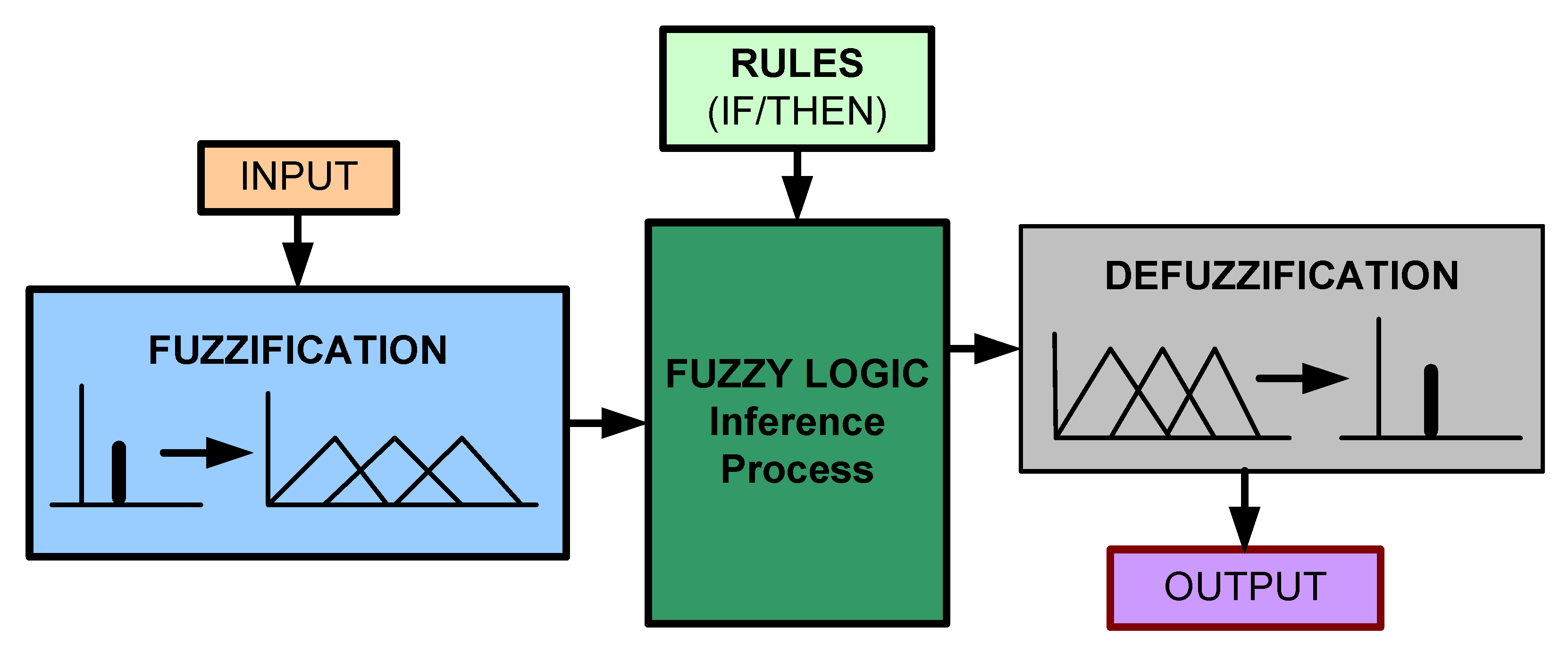

4.2.5. Fuzzy Logic Methods

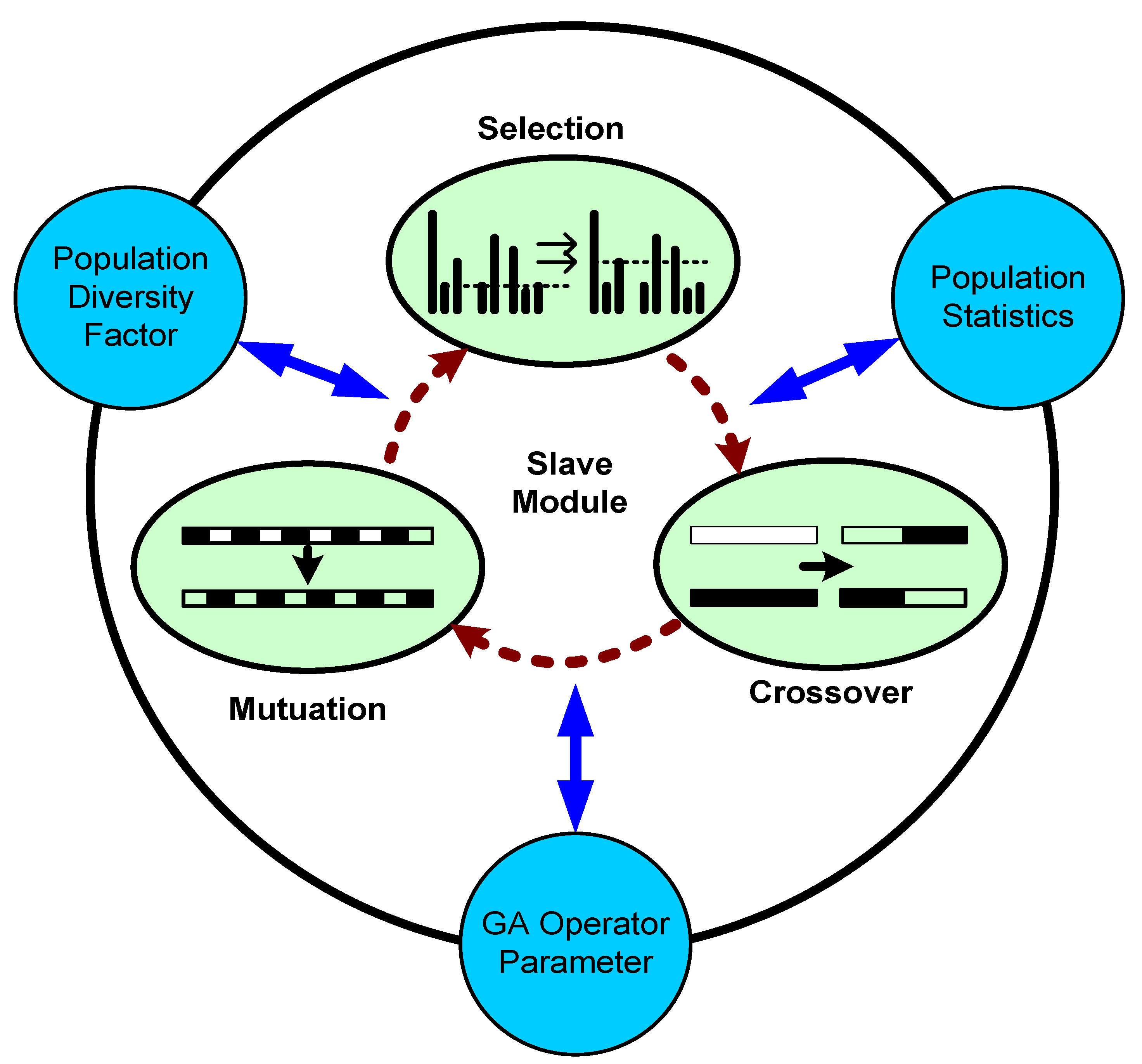

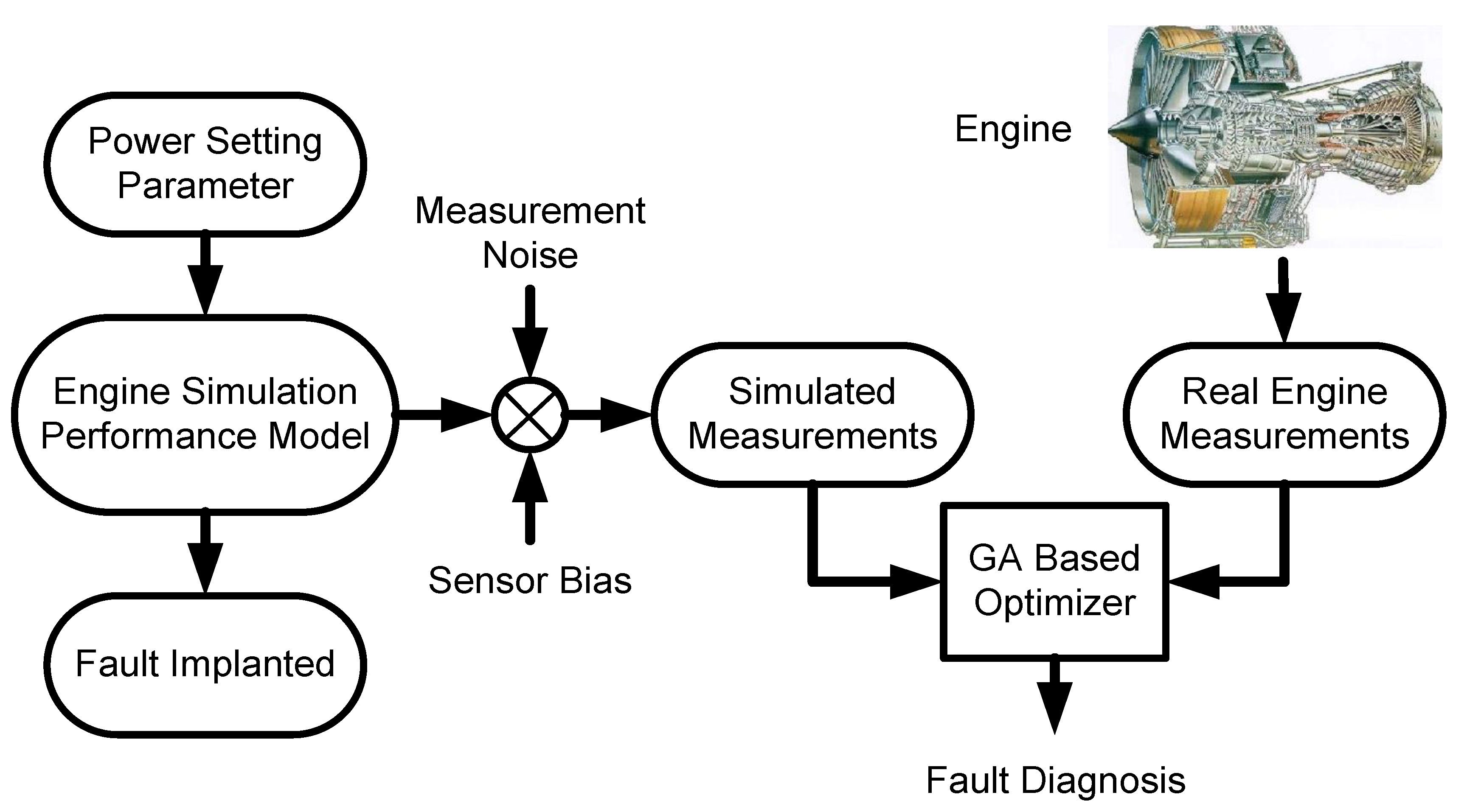

4.2.6. Genetic Algorithm

4.2.7. Hybrid AI Methods

4.2.8. Advantages and Limitation of AI Methods

4.3. Strengths and Weaknesses of the Gas-Path Diagnostic Methods

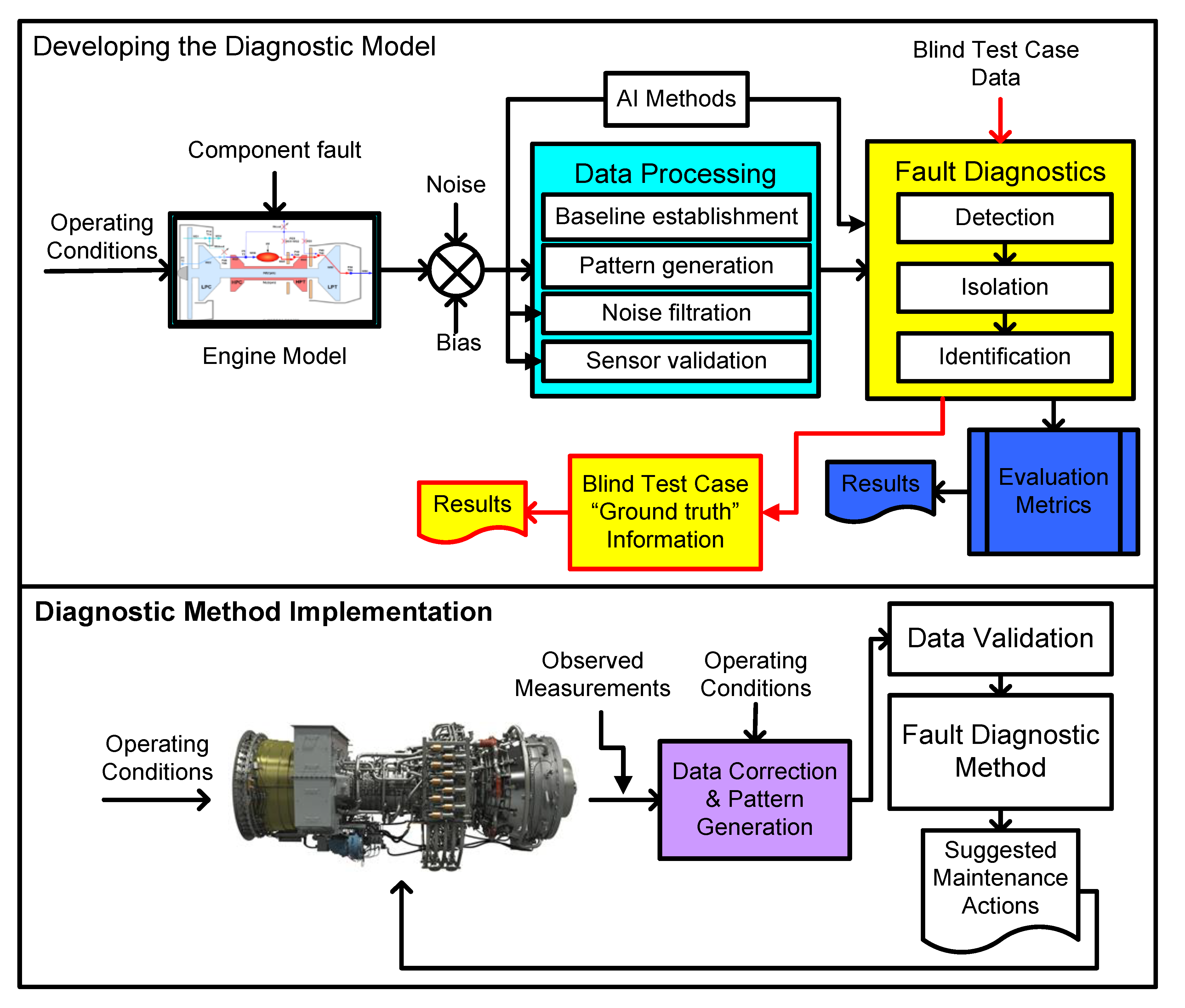

5. GT Diagnostic Methods Validation Techniques

- Performance Metrics Approach: Performance metrics can be used to measure the detection, isolation, and identification performance of a fault diagnostics algorithm [218]. The detection metric measures how accurately the detection algorithm detects abnormal operating conditions. The isolation metrics evaluates how successfully the isolation part of the diagnostic framework distinguishes the fault types and their locations. Also, the identification metrics measures how accurately the diagnostics system estimates the magnitude of the faults. A more detailed description about this concern together with sample performance metrics is available in [219]. The majority of the fault diagnostic methods available in the open domain are evaluated based on this approach. A fault diagnostics performance metric associated with the fault detection and isolation reliability of four different methods for aircraft engines is presented by Simon et al. [220].

- Benchmark Fault Cases Approach: The generally accepted and implemented solution to obtain the required performance data for diagnostic method development and validation is implanting fault cases corresponding to the possibly existing faults into the GT performance model [113,221]. However, there exists some inconsistencies concerning the range of the performance parameter losses that different gas-path faults are represented by [222]. The issue of using benchmark fault cases has also been thoroughly studied by the OBIDICOTE (On Board Identification, Diagnosis and Control of GT Engines) Project conducted by the European research community [223]. The project identified a set of benchmark fault cases, which have been used by several researchers so far to evaluate their engine fault diagnostic methods [191,211,224]. The effectiveness of using some sets of benchmark fault cases to evaluate the performance of a diagnostic system is further investigated by the engine health management industry review (EHMIR) established under The Technical Cooperation Program (TTCP) [224]. TTCP is a collaboration forum for defense science and technology (DST) between five nations, namely, UK, USA, Canada, Australia and New Zealand. The effort of this forum resulted in a reference engine problem, together with a recommendation of an evaluation environment for different diagnostics algorithms. Based on the recommendation of the aircraft engine health monitoring community, recently, NASA’s research team developed a public benchmark gas-path fault diagnostics techniques’ performance evaluation software referred to as the Propulsion Diagnostic Method Evaluation Strategy (ProDiMES), applicable to aircraft engines [220]. In this software, four different methods are included; Weighted Least Squares, PNN, Performance Analysis Tool, and Generalized Observer/Estimator. Moreover, the field GT condition monitoring and diagnostics has been studied for many years by the research team of the Laboratory of Thermal Turbomachines of the National Technical University of Athens (LTT/NTUA) [12] and Cranfield University (CU) [1] and proposed many different techniques. These groups showed the effectiveness of using benchmark fault cases to develop and evaluate the performance of diagnostic algorithms.

- Comparison of Methods Approach: As a third alternative, there are also some self-conducted comparative evaluation (a one-to-one comparison of methods) based research works to assess the diagnostic performance of different themes [113,221]. In this category, previously published papers are used as benchmark methods to compare the performance of the newly developed algorithm. However, this approach has limitations due to the reason that most of the available GT diagnostic methods targeted different engine problems and degree of complexity under variety of diagnostic conditions (i.e., operating modes, measurement system, deterioration profile etc.) [224].

6. Conclusions and Future Research Directions

- The need for a standardized gas-path diagnostic problem definition. According to this survey, there is no consensus between researchers in defining and representing gas-path diagnostic problems (terminologies, component fault representation, ranges of sensor/component faults, and the number and type of faults corresponding to different engine configurations that possibly exist in the engines lifetime). This inconsistency may confuse young researchers of the field, create barriers in exchanging gas-path diagnostic related ideas/solutions and performing a one-to-one comparison of different algorithms.

- The review on GT performance deterioration revealed that the degradation profile corresponding to each gas-path’s faults is not consistent. This may lead to an incorrect representation of components deterioration, and thereby unreliable fault diagnostic results. Hence, there should be more investigations in this regard.

- Most of the devised techniques for simultaneous fault analysis were restricted to qualitative solutions (i.e., detecting and isolating without estimating the level of the fault, which is a very important step in the maintenance decision). Moreover, the accuracy of the available limited quantitative approaches requires improvement for multiple fault scenarios. Development of an effective gas-path diagnostic system that can perform both qualitative and quantitative diagnostics of both single and multiple fault scenarios thus needs further investigation.

- Development of efficient hybrid methods. Most of the available gas-path diagnostic methods are single-technique-based and it is difficult to find single-technique which can address all gas-path diagnostic related challenges along with providing accurate diagnostic results. It is recommended to combine two or more methods based on their merits.

- Development of integrated platforms. Although a large number of diagnostic methods have been devised so far, the majority of those methods considered different platforms with different levels of complexity and applied for different engine system monitoring (such as sensor, component, vibration, controller, and fuel and oil systems). Integration of verity of methods into a diagnostic tool being capable of addressing the entire GT system problems is required.

- Establishment of a practical approach to verification and validation. Engine users need practical tools to objectively assess the effectiveness (i.e., the technical and economic feasibility) of newly proposed solutions and determine its advantages over the existing maintenance practices before incorporating into their plants. However, there are no internationally accepted standards or unified frameworks that can be applied for this purpose. Hence, the establishment of practical verification and validation approaches requires attention in this field.

- Development of user-friendly gas-path diagnostic software. Regarding engine performance simulation, there are some powerful commercial software available. Conversely, other than the traditional techniques, there are no advanced software tools based on AI methods. Therefore, user-friendly gas-path diagnostic software that can acquire, preprocess and validate performance data, assess the condition of engines and suggest the appropriate maintenance actions is required.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature and Abbreviations

| AANN | Auto-associative neural network |

| AI | Artificial intelligence |

| ANN | Artificial neural network |

| BBN | Bayesian belief network |

| CBM | Condition-based maintenance |

| CCPP | Combined cycle power plant |

| CPT | Conditional probability table |

| DB | Data based |

| DCF | Double component fault |

| DD | Data driven |

| DL | Deep learning |

| DNN | Dynamic neural network |

| DOD | Domestic object damage |

| DST | Defense science and technology |

| EGT | Exhaust gas temperature |

| EHM | Engine health monitoring |

| EHMIR | Engine health management industry review |

| EKF | Extended Kalman filter |

| ELM | Extreme learning machine |

| ES | Expert system |

| FCM | Fault coefficient matrix |

| FDD | Fault detection and diagnostics |

| FDI | Fault detection and isolation |

| FDIA | Fault detection, isolation and accommodation |

| FDII | Fault detection, isolation and identification |

| FDIR | Fault detection, isolation and recovery |

| FL | Fuzzy logic |

| FOD | Foreign object damage |

| GA | Genetic algorithm |

| GLR | Generalized likelihood ratio |

| GPA | Gas-path analysis |

| GT | Gas turbine |

| HC | Hierarchical clustering |

| HELIX | HELicopter Integrated eXpert |

| HPC | High pressure compressor |

| HPT | High pressure turbine |

| IATA | International air transport association |

| ICM | Influence coefficient matrix |

| IEKF | Iterated extended Kalman filter |

| IFDIS | Interactive Fault Diagnosis and Isolation System |

| KF | Kalman filter |

| LCC | Life cycle cost |

| ICR | Intercooled recuperated |

| LGPA | Linear gas-path analysis |

| LKF | Linear Kalman filter |

| LPT | Low pressure turbine |

| MAP | Maximum a posterior |

| MB | Model based |

| MF | Membership function |

| ML | Machine learning |

| MLP | Multiple layer perceptron |

| MLPNN | Multiple layer perceptron neural network |

| MRO | Maintenance repair and overhaul |

| MSE | Mean square error |

| NBS | National bureau of standards |

| NLGPA | Nonlinear gas-path analysis |

| NLKF | Nonlinear Kalman filter |

| NTUA | National technical university Athens |

| OBDICOTE | On board identification, diagnosis and control of gas turbine |

| OEM | Original equipment manufacturer |

| OF | Object function |

| PCA | Principal component analysis |

| PNN | Probabilistic neural network |

| PR | Pressure ratio |

| PWL | Piecewise linear |

| RBF | Radial basis function |

| RBFN | Radial basis function network |

| RMS | Root mean square |

| RRAP | Rolles-Royce aerothermal performance |

| SCF | Single component fault |

| SDAE | Stacked denoising autoencoder |

| SOM | Self-organizing map |

| STORM | Self-tuning onboard real-time model |

| SVM | State variable engine model |

| TCF | Triple component fault |

| TEXMAS | Turbine Engine EXpert Maintenance Advisor System |

| TIGER | Testability Insertion Guidance Expert System |

| TTCP | The technical cooperation program |

| XMAN | A Tool for Automated Jet Engine Diagnostics |

| Γ | Flow capacity |

| η | Isentropic Efficiency |

References

- Singh, R. Advances and opportunities in gas path diagnostics. In Proceedings of the 15th ISABE, Bangalore, India, 2–7 September 2003. Paper No. ISABE-2003-1008. [Google Scholar]

- Bechini, G. Performance Diagnostics and Measurement Selection for On-Line Monitoring of Gas Turbine Engines. Ph.D. Thesis, Cranfield University, Bedford, UK, 2007. [Google Scholar]

- Association, I.A.T. Airline Maintenance Cost: Executive Commentary. 2011. Available online: http://www.iata.org/workgroups/Documents/MCTF/AMC_ExecComment_FY09.pdf (accessed on 10 April 2019).

- McFadden, M.; Worrells, D.S. Global outsourcing of aircraft maintenance. J. Aviat. Technol. Eng. 2012, 1, 4. [Google Scholar] [CrossRef]

- Ogaji, S.O.T.-O. Advanced Gas-path Fault Diagnostics for Stationary Gas Turbines. Ph.D. Thesis, Cranfield University, Bedford, UK, 2003. [Google Scholar]

- Boyce, M.P. Gas Turbine Engineering Handbook; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Factbook, C. The World Factbook. 2010. Available online: https://www.cia.gov/library/publications/the-world-factbook (accessed on 15 April 2019).

- Lengyel, G.J. Department of Defense Energy Strategy: Teaching an Old Dog New Tricks; DTIC Document; DTIC: Fort Belvoir, VA, USA, 2007.

- Marinai, L.; Probert, D.; Singh, R. Prospects for aero gas-turbine diagnostics: A review. Appl. Energy 2004, 79, 109–126. [Google Scholar] [CrossRef]

- Stamatis, A.G. Engine condition monitoring and diagnostics. In Progress in Gas Turbine Performance; Benini, E., Ed.; InTech: Rijeka, Croatia, 2013; pp. 187–212. [Google Scholar] [CrossRef]

- Tahan, M.; Tsoutsanis, E.; Muhammad, M.; Karim, Z.A. Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: A review. Appl. Energy 2017, 198, 122–144. [Google Scholar] [CrossRef]

- Romesis, C.; Aretakis, N.; Roumeliotis, I.; Alexiou, A.; Tsalavoutas, A.; Stamatis, A.; Mathioudakis, K. Experiance with condition-based maintenance related methods and tools for gas turbines. In Proceedings of the Future of Gas Turbine Technology, 7th International Gas Turbine Conference, Brussels, Belgium, 14–15 October 2014. [Google Scholar]

- Meher-Homji, C.B.; Chaker, M.; Motiwalla, H. Gas turbine performance deterioration. In Proceedings of the 30th Turbomachinery Symposium, Houston, TX, USA, 17–20 September 2001; pp. 17–20. [Google Scholar]

- Meher-Homji, C.B.; Matthews, T.; Pelagotti, A.; Weyermann, H. Gas Turbines and Turbocompressors for LNG service. In Proceedings of the 36th Turbomachinery symposium, Houston, TX, USA, 11–13 September 2007. [Google Scholar]

- Marinai, L.; Singh, R.; Curnock, B.; Probert, D. Detection and prediction of the performance deterioration of a turbofan engine. In Proceedings of the International Gas Turbine Congress, Tokyo, Japan, 2–7 November 2003; pp. 2–7. [Google Scholar]

- Urban, L.A. Parameter selection for multiple fault diagnostics of gas turbine engines. ASME J. Eng. Power 1975, 97, 225–230. [Google Scholar] [CrossRef]

- Meher-Homji, C.B.; Chaker, M.; Bromley, A.F. The fouling of axial flow compressors: Causes, effects, susceptibility, and sensitivity. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009; pp. 571–590. [Google Scholar]

- Diakunchak, I.S. Performance deterioration in industrial gas turbines. J. Eng. Gas Turbines Power 1992, 114, 161–168. [Google Scholar] [CrossRef]

- Morini, M.; Pinelli, M.; Spina, P.; Venturini, M. Influence of blade deterioration on compressor and turbine performance. J. Eng. Gas Turbines Power 2010, 132, 032401. [Google Scholar] [CrossRef]

- Melino, F.; Morini, M.; Peretto, A.; Pinelli, M.; Spina, P.R. Compressor fouling modeling: Relationship between computational roughness and gas turbine operation time. J. Eng. Gas Turbines Power 2012, 134, 052401. [Google Scholar] [CrossRef]

- Saravanamuttoo, H.I.H.; Lakshminarasimha, A.N. A Preliminary Assessment of Compressor Fouling; ASME: New York, NY, USA, 1985. [Google Scholar]

- Aretakis, N.; Roumeliotis, I.; Mathioudakis, K. Performance model “zooming” for in-depth component fault diagnosis. J. Eng. Gas Turbines Power 2011, 133, 031602. [Google Scholar] [CrossRef]

- Lakshminarasimha, A.N.; Boyce, M.P.; Meher-Homji, C.B. Modelling and analysis of gas turbine performance deterioration. In Proceedings of the ASME 1992 International Gas Turbine and Aeroengine Congress and Exposition, Cologne, Germany, 1–4 June 1992; p. V004T010A022. [Google Scholar]

- Meher-Homji, C.B.; Bromley, A. Gas turbine axial compressor fouling and washing. In Proceedings of the 33rd Turbomachinery Symposium, Houston, TX, USA, 21–23 September 2004; pp. 20–23. [Google Scholar]

- Zwebek, A.; Pilidis, P. Degradation effects on combined cycle power plant performance - Part I: Gas turbine cycle component degradation effects. J. Eng. Gas Turbines Power 2003, 125, 651–657. [Google Scholar] [CrossRef]

- Kurz, R.; Brun, K. Gas Turbine Performance—What Makes the Map. In Proceedings of the 29th Texas A&M Turbomachinery Symposium, Houston, TX, USA, 18–21 September 2000; pp. 18–21. [Google Scholar]

- Tarabrin, A.P.; Schurovsky, V.A.; Bodrov, A.I.; Stalder, J.P. An analysis of axial compressor fouling and a blade cleaning method. J. Turbomach. 1998, 120, 256–261. [Google Scholar] [CrossRef]

- Ogiriki, E.A.; Li, Y.G.; Nikolaidis, T.; Isaiah, T.E.; Sule, G. Effect of fouling, thermal barrier coating degradation and film cooling holes blockage on gas turbine engine creep life. Procedia CIRP 2015, 38, 228–233. [Google Scholar] [CrossRef]

- Aker, G.F.; Saravanamuttoo, H.I.H. Predicting gas turbine performance degradation due to compressor fouling using computer simulation techniques. J. Eng. Gas Turbines Power 1989, 111, 343–350. [Google Scholar] [CrossRef]

- Yang, H.; Xu, H. The new performance calculation method of fouled axial flow compressor. Sci. World J. 2014, 2014, 906151. [Google Scholar] [CrossRef] [PubMed]

- Tarabrin, A.; Schurovsky, V.; Bodrov, A.; Stalder, J.-P. Influence of Axial Compressor Fouling on Gas Turbine Unit Perfomance Based on Different Schemes and With Different Initial Parameters. In Proceedings of the ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition, Stockholm, Sweden, 2–5 June 1998; p. V004T011A006. [Google Scholar]

- Mezheritsky, A.D.; Sudarev, A.V. The Mechanism of Fouling and the Cleaning Technique in Application to Flow Parts of the Power Generation Plant Compressors. In Proceedings of the ASME 1990 International Gas Turbine and Aeroengine Congress and Exposition, Brussels, Belgium, 11–14 June 1990; p. V004T011A003. [Google Scholar]

- Seddigh, F.; Saravanamuttoo, H. A proposed method for assessing the susceptibility of axial compressors to fouling. In Proceedings of the ASME 1990 International Gas Turbine and Aeroengine Congress and Exposition, Brussels, Belgium, 11–14 June 1990; p. V003T007A012. [Google Scholar]

- Boyce, M.P.; Gonzalez, F. A study of on-line and off-line turbine washing to optimize the operation of a gas turbine. J. Eng. Gas Turbines Power 2007, 129, 114–122. [Google Scholar] [CrossRef]

- Stalder, J.P. Gas Turbine Compressor Washing State of the Art: Field Experiences. J. Eng. Gas Turbines Power 2001, 123, 363. [Google Scholar] [CrossRef]

- Casari, N.; Pinelli, M.; Suman, A.; di Mare, L.; Montomoli, F. An Energy-Based Fouling Model for Gas Turbines: EBFOG. J. Turbomach. 2017, 139, 021002. [Google Scholar] [CrossRef]

- Maiwada, B.; Mu’az, N.I.; Ibrahim, S.; Musa, S.M. Impacts of Compressor Fouling on the Performance of Gas Turbine. Int. J. Eng. Sci. 2016, 2118–2125. [Google Scholar] [CrossRef]

- Aretakis, N.; Roumeliotis, I.; Doumouras, G.; Mathioudakis, K. Compressor washing economic analysis and optimization for power generation. Appl. Energy 2012, 95, 77–86. [Google Scholar] [CrossRef]

- Diakunchak, I.S. Performance Improvement in Industrial Gas Turbines. In Proceedings of the Joint ASME/IEEE Power Generation Conference, Kansas City, KS, USA, 17–22 October 1993. [Google Scholar] [CrossRef]

- Wilcox, M.; Baldwin, R.; Garcia-Hernandez, A.; Brun, K. Guideline for Gas Turbine Inlet Air Filtration Systems; Gas Machinery Research Council: Dallas, TX, USA, 2010. [Google Scholar]

- Singh Grewal, M. Gas Turbine Engine Performance Deterioration Modelling and Analysis. Ph.D. Thesis, Cranfield University, Bedford, UK, 1988. [Google Scholar]

- Salar, A.; Hosseini, S.M.; Zangmolk, B.R.; Sedigh, A.K. Improving model-based gas turbine fault diagnosis using multi-operating point method. In Proceedings of the 2010 Fourth UKSim European Symposium on Computer Modeling and Simulation (EMS), Pisa, Italy, 17–19 November 2010; pp. 240–247. [Google Scholar]

- Qingcai, Y.; Li, S.; Cao, Y.; Zhao, N. Full and Part-Load Performance Deterioration Analysis of Industrial Three-Shaft Gas Turbine Based on Genetic Algorithm. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Harbin, China, 13–17 June 2016; p. V006T005A016. [Google Scholar]

- Kurz, R.; Brun, K. Degradation in Gas Turbine Systems. J. Eng. Gas Turbines Power 2000, 123, 70–77. [Google Scholar] [CrossRef]

- Kurz, R.; Brun, K. Gas turbine tutorial—maintenance and operating practices effects on degradation and life. In Proceedings of the 36th Turbomachinery Symposium, Houston, TX, USA, 11–13 September 2007; pp. 10–13. [Google Scholar]

- Gannan, A. Cascade Testing and CFD Applied to Gas Turbine Performance Improvement with Compressor Cleaning. Ph.D. Thesis, Cranfield University, Bedford, UK, 2010. [Google Scholar]

- Wilcox, M.; Kurz, R.; Brun, K. Successful Selection and Operation of Gas Turbine Inlet Filtration Systems. In Proceedings of the 40th Turbomachinery Symposium, Houston, TX, USA, 12–15 September 2011; pp. 12–15. [Google Scholar]

- Kurz, R.; Brun, K. Degradation of gas turbine performance in natural gas service. J. Nat. Gas Sci. Eng. 2009, 1, 95–102. [Google Scholar] [CrossRef]

- Mishra, R.K. Fouling and Corrosion in an Aero Gas Turbine Compressor. J. Fail. Anal. Prev. 2015, 15, 837–845. [Google Scholar] [CrossRef]

- Varelis, A.G. Technoeconomic Study of Engine Deterioration and Compressor Washing for Military Gas Turbine Engines. Ph.D. Thesis, Cranfield University, Bedford, UK, 2008. [Google Scholar]

- Zwebek, A. Combined Cycle Performance Deterioration Analysis. Ph.D. Thesis, Cranfield University, Bedford, UK, 2002. [Google Scholar]

- Kurz, R.; Brun, K.; Wollie, M. Degradation Effects on Industrial Gas Turbines. J. Eng. Gas Turbines Power 2009, 131, 062401. [Google Scholar] [CrossRef]

- Diakunchak, I.S. Performance deterioration in industrial gas turbines. In Proceedings of the ASME 1991 International Gas Turbine and Aeroengine Congress and Exposition, Orlando, FL, USA, 3–6 June 1991; p. V004T010A012. [Google Scholar]

- Giebmanns, A.; Backhaus, J.; Frey, C.; Schnell, R. Compressor Leading Edge Sensitivities and Analysis With an Adjoint Flow Solver. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar] [CrossRef]

- MacIsaac, B. Engine Performance and Health Monitoring Models Using Steady State and Transient Prediction Methods; DTIC Document; DTIC: Fort Belvoir, VA, USA, 1992.

- Giampaolo, T. The Gas Turbine Handbook: Principles and Practices; The Fairmont Press, Inc.: Lilburn, GA, USA, 2008. [Google Scholar]

- Cruz-Manzo, S.; Maleki, S.; Zhang, Y.; Panov, V.; Latimer, A. Performance analysis of a twin shaft Industrial Gas Turbine at fouling conditions. In Proceedings of the 2017 IEEE International Conference on Prognostics and Health Management (ICPHM), Dallas, TX, USA, 19–21 June 2017; pp. 234–238. [Google Scholar]

- Cruz-Manzo, S.; Panov, V.; Zhang, Y. Gas Path Fault and Degradation Modelling in Twin-Shaft Gas Turbines. Machines 2018, 6, 43. [Google Scholar] [CrossRef]

- Ntantis, E. Capability Expansion of Non-Linear Gas Path Analysis; Cranfield University: Bedford, UK, 2008. [Google Scholar]

- Ying, Y.; Cao, Y.; Li, S.; Li, J.; Guo, J. Study on gas turbine engine fault diagnostic approach with a hybrid of gray relation theory and gas-path analysis. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef]

- Ogaji, S.O.T.; Li, Y.G.; Sampath, S.; Singh, R. Gas Path Fault Diagnosis of a Turbofan Engine From Transient Data Using Artificial Neural Networks. In Proceedings of the ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; pp. 405–414. [Google Scholar] [CrossRef]

- Sadough Vanini, Z.N.; Khorasani, K.; Meskin, N. Fault detection and isolation of a dual spool gas turbine engine using dynamic neural networks and multiple model approach. Inf. Sci. 2014, 259, 234–251. [Google Scholar] [CrossRef]

- Sina Tayarani-Bathaie, S.; Khorasani, K. Fault detection and isolation of gas turbine engines using a bank of neural networks. J. Process Control 2015, 36, 22–41. [Google Scholar] [CrossRef]

- Zhang, Y.; Bingham, C.; Garlick, M.; Gallimore, M. Applied fault detection and diagnosis for industrial gas turbine systems. Int. J. Autom. Comput. 2017, 14, 463–473. [Google Scholar] [CrossRef]

- Wang, W.; Xu, Z.; Tang, R.; Li, S.; Wu, W. Fault detection and diagnosis for gas turbines based on a kernelized information entropy model. Sci. World J. 2014, 2014, 617162. [Google Scholar] [CrossRef]

- Pourbabaee, B.; Meskin, N.; Khorasani, K. Sensor Fault Detection, Isolation, and Identification Using Multiple-Model-Based Hybrid Kalman Filter for Gas Turbine Engines. IEEE Trans. Control Syst. Technol. 2016, 24, 1184–1200. [Google Scholar] [CrossRef]

- Taylor, J.H.; Omana, M. Fault detection, isolation and accommodation using the generalized parity vector technique. IFAC Proc. Vol. 2008, 41, 1914–1921. [Google Scholar] [CrossRef]

- Vural, S.Y.; Hacızade, C. Sensor/actuator fault detection, isolation and accommodation applied to UAV model. J. Aeronaut. Space Technol. 2016, 9, 1–12. [Google Scholar]

- Yang, J.; Chen, Y.; Zhang, L. An Efficient Approach for Fault Detection, Isolation, and Data Recovery of Self-Validating Multifunctional Sensors. IEEE Trans. Instrum. Meas. 2017, 66, 543–558. [Google Scholar] [CrossRef]

- Simani, S. Identification and fault diagnosis of a simulated model of an industrial gas turbine. IEEE Trans. Ind. Inform. 2005, 1, 202–216. [Google Scholar] [CrossRef]

- Vachtsevanos, G.; Lewis, F.; Roemer, M.; Hess, A.; Wu, B. Fault Diagnosis. In Intelligent Fault Diagnosis and Prognosis for Engineering Systems; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; pp. 172–283. [Google Scholar] [CrossRef]

- Simon, D. Challenges in aircraft engine gas path health management. In Proceedings of the Tutorial on Aircraft Engine Control and Gas Path Health Management, Cleveland, OH, USA, 2012. [Google Scholar]

- Khorasgani, H.; Jung, D.E.; Biswas, G.; Frisk, E.; Krysander, M. Robust residual selection for fault detection. In Proceedings of the 2014 IEEE 53rd Annual Conference on Decision and Control (CDC), Los Angeles, CA, USA, 15–17 December 2014; pp. 5764–5769. [Google Scholar]

- Ogaji, S.O.T.; Singh, R.; Probert, S.D. Multiple-sensor fault-diagnoses for a 2-shaft stationary gas-turbine. Appl. Energy 2002, 71, 321–339. [Google Scholar] [CrossRef]

- Sadough Vanini, Z.N.; Meskin, N.; Khorasani, K. Multiple-Model Sensor and Components Fault Diagnosis in Gas Turbine Engines Using Autoassociative Neural Networks. J. Eng. Gas Turbines Power 2014, 136, 091603. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, H.; Weng, S. A new gas path fault diagnostic method of gas turbine based on support vector machine. J. Eng. Gas Turbines Power 2015, 137, 102605. [Google Scholar] [CrossRef]

- Jaw, L.C.; Lee, Y.-J. Engine diagnostics in the eyes of machine learning. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, Düsseldorf, Germany, 16–20 June 2014; p. V006T006A029. [Google Scholar]

- Abernathy, R.; Powell, B.D.; Colbert, D.L.; Sanders, D.G.; Thompson, J., Jr. Handbook, Uncertainty in Gas Turbine Measurements; DTIC Document; DTIC: Fort Belvoir, VA, USA, 1973.

- Abernethy, R.; Thompson, J., Jr. Uncertainty in Gas Turbine Measurements. In Proceedings of the 9th Propulsion Conference, Las Vegas, NV, USA, 5–7 November 1973; p. 1230. [Google Scholar]

- Jasmani, M.S.; Li, Y.-G.; Ariffin, Z. Measurement selections for multicomponent gas path diagnostics using analytical approach and measurement subset concept. J. Eng. Gas Turbines Power 2011, 133, 111701. [Google Scholar] [CrossRef]

- Volponi, A.J. Gas Turbine Engine Health Management: Past, Present, and Future Trends. J. Eng. Gas Turbines Power 2014, 136, 051201. [Google Scholar] [CrossRef]

- Simon, D.L.; Garg, S.; Hunter, G.W.; Guo, T.-H.; Semega, K.J. Sensor Needs for Control and Health Management of Intelligent Aircraft Engines; ASME Paper No. GT2004-54324; ASME: New York, NY, USA, 2004. [Google Scholar]

- Ogaji, S.O.T.; Singh, R. Advanced engine diagnostics using artificial neural networks. Appl. Soft Comput. J. 2003, 3, 259–271. [Google Scholar] [CrossRef]

- Kurzke, J. Model Based Gas Turbine Parameter Corrections. In Proceedings of the ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; pp. 91–99. [Google Scholar]

- Jaw, L.C. Recent advancements in aircraft engine health management (EHM) technologies and recommendations for the next step. In Proceedings of the ASME turbo expo 2005: Power for land, sea, and air, Reno, NV, USA, 6–9 June 2005; pp. 683–695. [Google Scholar]

- Ogaji, S.O.T.; Sampath, S.; Singh, R.; Probert, S.D. Parameter selection for diagnosing a gas-turbine’s performance-deterioration. Appl. Energy 2002, 73, 25–46. [Google Scholar] [CrossRef]

- Dash, S.; Venkatasubramanian, V. Challenges in the industrial applications of fault diagnostic systems. Comput. Chem. Eng. 2000, 24, 785–791. [Google Scholar] [CrossRef]

- Sobhani-Tehrani, E.; Khorasani, K. Fault Diagnosis of Nonlinear Systems Using a Hybrid Approach; Springer US: New York, NY, USA, 2009; Volume 383. [Google Scholar]

- Venkatasubramanian, V.; Rengaswamy, R.; Yin, K.; Kavuri, S.N. A review of process fault detection and diagnosis: Part I: Quantitative model-based methods. Comput. Chem. Eng. 2003, 27, 293–311. [Google Scholar] [CrossRef]

- Fast, M.; Assadi, M.; De, S. Development and multi-utility of an ANN model for an industrial gas turbine. Appl. Energy 2009, 86, 9–17. [Google Scholar] [CrossRef]

- Li, Y.G. Performance-analysis-based gas turbine diagnostics: A review. Proc. Inst. Mech. Eng. Part A 2002, 216, 363–377. [Google Scholar] [CrossRef]

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Kong, C. Review on Advanced Health Monitoring Methods for Aero Gas Turbines using Model Based Methods and Artificial Intelligent Methods. Int. J. Aeronaut. Space Sci. 2014, 15, 123–137. [Google Scholar] [CrossRef]

- Zhao, N.; Wen, X.; Li, S. A Review on Gas Turbine Anomaly Detection for Implementing Health Management. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Harbin, China, 13–17 June 2016; p. V001T022A009. [Google Scholar]

- Zedda, M. Gas Turbine Engine and Sensor Fault Diagnosis. Ph.D. Thesis, Cranfield University, Bedford, UK, 1999. [Google Scholar]

- Urban, L.A. Gas Path Analysis Applied to Turbine Engine Condition Monitoring. J. Airc. 1973, 10, 400–406. [Google Scholar] [CrossRef]

- Volponi, A.J. Sensor error compensation in engine performance diagnostics. In Proceedings of the ASME 1994 International Gas Turbine and Aeroengine Congress and Exposition, Hague, The Netherlands, 13–16 June 1994; p. V005T015A008. [Google Scholar]

- Doel, D.L. TEMPER: A gas-path analysis tool for commercial jet engines. In Proceedings of the ASME 1992 International Gas Turbine and Aeroengine Congress and Exposition, Cologne, Germany, 1–4 June 1992; p. V005T015A013. [Google Scholar]

- Escher, P. Pythia: An Object-Orientated Gas Path Analysis Computer Program for General Applications. Ph.D. Thesis, Cranfield University, Bedford, UK, 1995. [Google Scholar]

- Provost, M. The Use of Optimal Estimation Techniques in the Analysis of Gas Turbines. Ph.D. Thesis, Cranfield University, Bedford, UK, 1994. [Google Scholar]

- Provost, M.; Singh, R. Gas-Path Analysis: Preparing for Success; Rolls-Royce Plc: London, UK, 1995. [Google Scholar]

- Gulati, A. An Optimization Tool for Gas Turbine Engine Diagnostics. Ph.D. Thesis, Cranfield University, Bedford, UK, 2001. [Google Scholar]

- Li, Y.G.; Pilidis, P. GA-based design-point performance adaptation and its comparison with ICM-based approach. Appl. Energy 2010, 87, 340–348. [Google Scholar] [CrossRef]

- Escher, P.C. Gas turbine data validation using gas path analysis. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; pp. 45–51. [Google Scholar]

- Li, Y. Gas turbine performance and health status estimation using adaptive gas path analysis. J. Eng. Gas Turbines Power 2010, 132, 041701. [Google Scholar] [CrossRef]

- Stamatis, A.G. Evaluation of gas path analysis methods for gas turbine diagnosis. J. Mech. Sci. Technol. 2011, 25, 469–477. [Google Scholar] [CrossRef]

- Larsson, E. Model Based Diagnosis and Supervision of Industrial Gas Turbines; Linköping University: Linköping, Sweden, 2014. [Google Scholar]

- Chen, M.; Quan Hu, L.; Tang, H. An Approach for Optimal Measurements Selection on Gas Turbine Engine Fault Diagnosis. J. Eng. Gas Turbines Power 2015, 137, 071203. [Google Scholar] [CrossRef]

- Kalman, R.E. A new approach to linear filtering and prediction problems. J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef]

- Kalman, R.E.; Bucy, R.S. New results in linear filtering and prediction theory. J. Basic Eng. 1961, 83, 95–108. [Google Scholar] [CrossRef]

- Ganguli, R. Gas Turbine Diagnostics: Signal Processing and Fault Isolation; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Bishop, G.; Welch, G. An Introduction to the Kalman Filter. Proc. Siggraph Course 2001, 8, 41. [Google Scholar]

- Volponi, A.J.; DePold, H.; Ganguli, R.; Daguang, C. The Use of Kalman Filter and Neural Network Methodologies in Gas Turbine Performance Diagnostics: A Comparative Study. J. Eng. Gas Turbines Power 2003, 125, 917–924. [Google Scholar] [CrossRef]

- Cooper, W.S. Use of optimal estimation theory, in particular the Kalman filter, in data analysis and signal processing. Rev. Sci. Instrum. 1986, 57, 2862–2869. [Google Scholar] [CrossRef]

- Dewallef, P.; Romessis, C.; Léonard, O.; Mathioudakis, K. Combining Classification Techniques with Kalman Filters for Aircraft Engine Diagnostics. J. Eng. Gas Turbines Power 2006, 128, 281. [Google Scholar] [CrossRef]

- Mzwinski, A. Stochastic Process and Filtering Theory; Academic Press: Cambridge, MA, USA, 1970. [Google Scholar]

- Welch, G.; Bishop, G. An Introduction to the Kalman Filter; UNC: Chapel Hill, NC, USA, 2006. [Google Scholar]

- Zedda, M.; Singh, R. Gas Turbine Engine and Sensor Fault Diagnosis Using Optimization Techniques. J. Propuls. Power 2002, 18, 1019–1025. [Google Scholar] [CrossRef]

- Kobayashi, T.; Simon, D.L. Application of a bank of Kalman filters for aircraft engine fault diagnostics. In Proceedings of the ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; pp. 461–470. [Google Scholar]

- Simon, D.L.; Rinehart, A.W. Sensor Selection for Aircraft Engine Performance Estimation and Gas Path Fault Diagnostics. J. Eng. Gas Turbines Power 2016, 138, 071201. [Google Scholar] [CrossRef]

- Borguet, S.; Dewallef, P.; Léonard, O. A way to deal with model-plant mismatch for a reliable diagnosis in transient operation. J. Eng. Gas Turbines Power 2008, 130, 031601. [Google Scholar] [CrossRef]

- Meskin, N.; Naderi, E.; Khorasani, K. A multiple model-based approach for fault diagnosis of jet engines. IEEE Trans. Control Syst. Technol. 2013, 21, 254–262. [Google Scholar] [CrossRef]

- Lu, F.; Ju, H.; Huang, J. An improved extended Kalman filter with inequality constraints for gas turbine engine health monitoring. Aerosp. Sci. Technol. 2016, 58, 36–47. [Google Scholar] [CrossRef]

- Marinai, L. Gas-Path Diagnostics and Prognostics for Aero-Engines Using Fuzzy Logic and Time Series Analysis. Ph.D. Thesis, Cranfield University, Bedford, UK, 2004. [Google Scholar]

- Sampath, S. Fault Diagnostics for Advanced Cycle Marine Gas Turbine Using Genetic Algorithm. Ph.D. Thesis, Cranfield University, Bedford, UK, 2003. [Google Scholar]

- Yang, Q.; Li, S.; Cao, Y. A strong tracking filter based multiple model approach for gas turbine fault diagnosis. J. Mech. Sci. Technol. 2018, 32, 465–479. [Google Scholar] [CrossRef]

- Konar, A. Artificial Intelligence and Soft Computing: Behavioral and Cognitive Modeling of the Human Brain; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Simon, D.L. Propulsion Diagnostic Method Evaluation Strategy (ProDiMES) User’s Guide; NASA: Washington, DC, USA, 2010.

- Awodele, O.; Jegede, O. Neural networks and its application in engineering. In Proceedings of the Informing Science & IT Education Conference (InSITE), Macon, GA, USA, 12–15 June 2009. [Google Scholar]

- Asgari, H.; Chen, X.; Menhaj, M.B.; Sainudiin, R. Artificial Neural Network–Based System Identification for a Single-Shaft Gas Turbine. J. Eng. Gas Turbines Power 2013, 135, 092601. [Google Scholar] [CrossRef]

- Demuth, H.; Beale, M.; Hagan, M. Neural Network Toolbox for Use with MATLAB—User’s Guide, Version 4.0. 6, Ninth Printing Revised for Version 4.0.6 (Release 14SP3); The Math Works: Natick, MA, USA, 2015. [Google Scholar]

- Kong, C.d.; Ki, J.y.; Kang, M.c.; Kho, S.h. Intelligent performance diagnostics of a gas turbine engine using user-friendly interface neural networks. Airc. Eng. Aerosp. Technol. 2004, 76, 391–397. [Google Scholar] [CrossRef]

- Matuck, G.R.; Barbosa, J.o.R.; Bringhenti, C.; Lima, I. Multiple Faults Detection of Gas Turbine by MLP Neural Network. In Proceedings of the ASME Turbo Expo 2009: Power for Land, Sea, and Air, Orlando, FL, USA, 8–12 June 2009; pp. 697–703. [Google Scholar]

- Patan, K.; Witczak, M.; Korbicz, J. Towards robustness in neural network based fault diagnosis. Int. J. Appl. Math. Comput. Sci. 2008, 18, 443–454. [Google Scholar] [CrossRef]

- Tayarani-Bathaie, S.S.; Vanini, Z.S.; Khorasani, K. Dynamic neural network-based fault diagnosis of gas turbine engines. Neurocomputing 2014, 125, 153–165. [Google Scholar] [CrossRef]

- Mohammadi, R.; Naderi, E.; Khorasani, K.; Hashtrudi-Zad, S. Fault diagnosis of gas turbine engines by using dynamic neural networks. In Proceedings of the 2011 IEEE International Conference on Quality and Reliability, ICQR 2011, Bangkok, Thailand, 14–17 September 2011; pp. 25–30. [Google Scholar]

- Kiakojoori, S.; Khorasani, K. Dynamie neural networks for jet engine degradation prediction and prognosis. In Proceedings of the Neural Networks (IJCNN), 2014 International Joint Conference on, Beijing, China, 6–11 July 2014; pp. 2531–2538. [Google Scholar]

- Amozegar, M.; Khorasani, K. An ensemble of dynamic neural network identifiers for fault detection and isolation of gas turbine engines. Neural Netw. 2016, 76, 106–121. [Google Scholar] [CrossRef] [PubMed]

- Tahan, M.; Muhammad, M.; Karim, Z.A. A multi-nets ANN model for real-time performance-based automatic fault diagnosis of industrial gas turbine engines. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 2865–2876. [Google Scholar] [CrossRef]

- Zin, Z.M. Using auto-associative neural networks to compress and visualize multidimensional data. In Proceedings of the 2014 11th International Conference on Ubiquitous Robots and Ambient Intelligence, URAI 2014, Kuala Lumpur, Malaysia, 12–15 November 2014; pp. 408–412. [Google Scholar]

- Kramer, M.A. Nonlinear Principal Component Analysis Using Autoassociative Neural Networks. AIChE J. 1991, 37, 233. [Google Scholar] [CrossRef]

- Kramer, M.A. Neutral network applications in chemical engineeringAutoassociative neural networks. Comput. Chem. Eng. 1992, 16, 313–328. [Google Scholar] [CrossRef]

- Guo, T.-H.; Saus, J.; Lin, C.-F.; Ge, J.-H. Sensor validation for turbofan engines using an autoassociative neural network. In Proceedings of the Guidance, Navigation, and Control Conference, San Diego, CA, USA, 29–31 July 1996; p. 3926. [Google Scholar]

- Lu, P.J.; Hsu, T.C. Application of autoassociative neural network on gas-path sensor data validation. J. Propuls. Power 2002, 18, 879–888. [Google Scholar] [CrossRef]

- Lu, P.J.; Zhang, M.C.; Hsu, T.C.; Zhang, J. An evaluation of engine faults diagnostics using artificial neural networks. J. Eng. Gas Turbines Power 2001, 123, 340–346. [Google Scholar] [CrossRef]

- Lemma, T.A.; Hashim, F.M. Wavelet analysis and auto-associative neural network based fault detection and diagnosis in an industrial gas turbine. In Proceedings of the 2012 IEEE Business Engineering and Industrial Applications Colloquium (BEIAC), Kuala Lumpur, Malaysia, 7–8 April 2012; pp. 103–108. [Google Scholar]

- Specht, D.F. Probabilistic neural networks. Neural Netw. 1990, 3, 109–118. [Google Scholar] [CrossRef]

- Jain, A.K.; Mao, J.; Mohiuddin, K.M. Artificial neural networks: A tutorial. Computer 1996, 29, 31–44. [Google Scholar] [CrossRef]

- Eustace, R.; Merrington, G. A Probabilistic Neural Network Approach to Jet Engine Fault Diagnosis. In Proceedings of the IEA/AIE, Melbourne, Australia, 5–9 June 1995; pp. 67–76. [Google Scholar]

- Romesis, C.; Mathioudakis, K. Setting Up of a Probabilistic Neural Network for Sensor Fault Detection Including Operation with Component Faults. J. Eng. Gas Turbines Power 2003, 125, 634–641. [Google Scholar] [CrossRef]

- Mathioudakis, K.; Romessis, C. Probabilistic neural networks for validation of on-board jet engine data. Proc. Inst. Mech. Eng. Part G 2004, 218, 59–72. [Google Scholar] [CrossRef]

- Loboda, I.; Feldshteyn, Y.; Ponomaryov, V. Neural networks for gas turbine fault identification: Multilayer perceptron or radial basis network? In Proceedings of the ASME Turbo Expo, Vancouver, BC, Canada, 6–10 June 2011; pp. 465–475. [Google Scholar]

- Loboda, I.; Olivares Robles, M.A. Gas turbine fault diagnosis using probabilistic neural networks. Int. J. Turbo Jet-Engines 2015, 32, 175–191. [Google Scholar] [CrossRef]

- Schaback, R. A practical guide to radial basis functions. Electron. Resour. 2007, 11, 1–12. [Google Scholar]

- Simani, S.; Fantuzzi, C. Fault diagnosis in power plant using neural networks. Inf. Sci. 2000, 127, 125–136. [Google Scholar] [CrossRef]

- Leonard, J.A.; Kramer, M.A.; Ungar, L.H. Using radial basis functions to approximate a function and its error bounds. IEEE Trans. Neural Netw. 1992, 3, 624–627. [Google Scholar] [CrossRef] [PubMed]

- Verma, R.; Roy, N.; Ganguli, R. Gas turbine diagnostics using a soft computing approach. Appl. Math. Comput. 2006, 172, 1342–1363. [Google Scholar] [CrossRef]

- Roy, N.; Ganguli, R. Filter design using radial basis function neural network and genetic algorithm for improved operational health monitoring. Appl. Soft Comput. 2006, 6, 154–169. [Google Scholar] [CrossRef]

- Loboda, I.; Rios, U.E.; Sanchez, C.E. Probabilistic neural networks for gas turbine fault recognition. Aerosp. Tech. Technol. J. Natl. Aerosp. Univ. 2012, 89, 53–58. [Google Scholar]

- Wen, X.; Zhang, X.; Zhu, Y. Design of Fault Detection Observer Based on Hyper Basis Function. Tsinghua Sci. Technol. 2016, 20, 200–204. [Google Scholar] [CrossRef]

- Kohonen, T. Essentials of the self-organizing map. Neural Netw. 2013, 37, 52–65. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.-P.; Li, S.-Y.; Yi, S.; Zhao, N.-B. Fault diagnosis of a gas turbine gas fuel system using a self-organizing network. Adv. Sci. Lett. 2012, 8, 386–392. [Google Scholar] [CrossRef]

- Kohonen, T.; Oja, E.; Simula, O.; Visa, A.; Kangas, J. Engineering applications of the self-organizing map. Proc. IEEE 1996, 84, 1358–1384. [Google Scholar] [CrossRef]

- Yu, J. A hybrid feature selection scheme and self-organizing map model for machine health assessment. Appl. Soft Comput. 2011, 11, 4041–4054. [Google Scholar] [CrossRef]

- Yang, B.-S.; Han, T.; An, J.L. ART–KOHONEN neural network for fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2004, 18, 645–657. [Google Scholar] [CrossRef]

- Germen, E.; Başaran, M.; Fidan, M. Sound based induction motor fault diagnosis using Kohonen self-organizing map. Mech. Syst. Signal Process. 2014, 46, 45–58. [Google Scholar] [CrossRef]

- Zhang, K.; Chai, Y.; Yang, S.X. Self-organizing feature map for cluster analysis in multi-disease diagnosis. Expert Syst. Appl. 2010, 37, 6359–6367. [Google Scholar] [CrossRef]

- Xinyi, C.; Xuefeng, Y. Fault diagnosis in chemical process based on self-organizing map integrated with fisher discriminant analysis. Chin. J. Chem. Eng. 2013, 21, 382–387. [Google Scholar]

- Lu, B.; Stuber, J.; Edgar, T.F. Data-driven adaptive multiple model system utilizing growing self-organizing maps. J. Process Control 2018, 67, 56–68. [Google Scholar] [CrossRef]

- Roemer, M.J.; Atkinson, B. Real-time health monitoring and diagnostics for gas turbine engines. In Proceedings of the ASME 1997 International Gas Turbine and Aeroengine Congress and Exhibition, Orlando, FL, USA, 2–5 June 1997; p. V004T015A007. [Google Scholar]

- Kim, K.; Ball, C.; Nwadiogbu, E. Fault diagnosis in turbine engines using unsupervised neural networks technique. In Proceedings of the Independent Component Analyses, Wavelets, Unsupervised Smart Sensors, and Neural Networks II, Orlando, FL, USA, 14–15 April 2004; pp. 150–159. [Google Scholar]

- Côme, E.; Cottrell, M.; Verleysen, M.; Lacaille, J. Aircraft engine health monitoring using self-organizing maps. In Industrial Conference on Data Mining; Springer: Berlin/Heidelberg, Germany, 2010; pp. 405–417. [Google Scholar]

- Cottrell, M.; Gaubert, P.; Eloy, C.; François, D.; Hallaux, G.; Lacaille, J.; Verleysen, M. Fault prediction in aircraft engines using self-organizing maps. In International Workshop on Self-Organizing Maps; Springer: Berlin/Heidelberg, Germany, 2009; pp. 37–44. [Google Scholar]

- Deng, L.; Yu, D. Deep learning: Methods and applications. Found. Trends.Signal Process. 2014, 7, 197–387. [Google Scholar] [CrossRef]

- Yu, D.; Deng, L. Deep learning and its applications to signal and information processing [exploratory dsp]. IEEE Signal Process. Mag. 2010, 28, 145–154. [Google Scholar] [CrossRef]

- Najafabadi, M.M.; Villanustre, F.; Khoshgoftaar, T.M.; Seliya, N.; Wald, R.; Muharemagic, E. Deep learning applications and challenges in big data analytics. J. Big Data 2015, 2, 1. [Google Scholar] [CrossRef]

- Deng, L.; Hinton, G.; Kingsbury, B. New types of deep neural network learning for speech recognition and related applications: An overview. In Proceedings of the 2013 IEEE International Conference on Acoustics, Speech and Signal Processing, Vancouver, BC, Canada, 26–31 May 2013; pp. 8599–8603. [Google Scholar]

- Ker, J.; Wang, L.; Rao, J.; Lim, T. Deep learning applications in medical image analysis. IEEE Access 2017, 6, 9375–9389. [Google Scholar] [CrossRef]

- Mamoshina, P.; Vieira, A.; Putin, E.; Zhavoronkov, A. Applications of deep learning in biomedicine. Mol. Pharm. 2016, 13, 1445–1454. [Google Scholar] [CrossRef]

- Khan, S.; Yairi, T. A review on the application of deep learning in system health management. Mech. Syst. Signal Process. 2018, 107, 241–265. [Google Scholar] [CrossRef]

- Arel, I.; Rose, D.C.; Karnowski, T.P. Deep machine learning—A new frontier in artificial intelligence research. IEEE Comput. Intell. Mag. 2010, 5, 13–18. [Google Scholar] [CrossRef]

- Luo, H.; Zhong, S. Gas turbine engine gas path anomaly detection using deep learning with Gaussian distribution. In Proceedings of the 2017 Prognostics and System Health Management Conference (PHM-Harbin), Harbin, China, 9–12 July 2017; pp. 1–6. [Google Scholar]

- Yan, W.; Yu, L. On accurate and reliable anomaly detection for gas turbine combustors: A deep learning approach. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, San Diego, CA, USA, 18–24 October 2015. [Google Scholar]

- Vincent, P.; Larochelle, H.; Lajoie, I.; Bengio, Y.; Manzagol, P.-A. Stacked denoising autoencoders: Learning useful representations in a deep network with a local denoising criterion. J. Mach. Learn. Res. 2010, 11, 3371–3408. [Google Scholar]

- Xuyun, F.; Hui, L.; Zhong, S.; Lin, L. Aircraft engine fault detection based on grouped convolutional denoising autoencoders. Chin. J. Aeronaut. 2019, 32, 296–307. [Google Scholar]

- Kadamb, A. Bayesian Belief Network for Aero Gas-Turbine Module and System-Fault Isolation. Ph.D. Thesis, Cranfield University, Bedford, UK, 2003. [Google Scholar]

- Breese, J.S.; Horvitz, E.J.; Peot, M.A.; Gay, R.; Quentin, G.H. Automated decision-analytic diagnosis of thermal performance in gas turbines. In Proceedings of the ASME 1992 International Gas Turbine and Aeroengine Congress and Exposition, Cologne, Germany, 1–4 June 1992; p. V005T015A015. [Google Scholar]

- Palmer, C.A. Combining Bayesian belief networks with gas path analysis for test cell diagnostics and overhaul. In Proceedings of the ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition, Stockholm, Sweden, 2–5 June 1998; p. V005T015A015. [Google Scholar]

- Romessis, C.; Stamatis, A.; Mathioudakis, K. Setting up a belief network for turbofan diagnosis with the aid of an engine performance model. ISABE Pap. 2001, 1032, 19–26. [Google Scholar]

- Mathioudakis, K.; Kamboukos, P.; Stamatis, A. Turbofan Performance Deterioration Tracking Using Nonlinear Models and Optimization Techniques. J. Turbomach. 2002, 124, 580. [Google Scholar] [CrossRef]

- Romessis, C.; Mathioudakis, K. Bayesian network approach for gas path fault diagnosis. J. Eng. Gas Turbines Power 2006, 128, 64–72. [Google Scholar] [CrossRef]

- Lee, Y.K.; Mavris, D.N.; Volovoi, V.V.; Yuan, M.; Fisher, T. A fault diagnosis method for industrial gas turbines using Bayesian data analysis. J. Eng. Gas Turbines Power 2010, 132, 041602. [Google Scholar] [CrossRef]

- Pham, D.T.; Ruz, G.A. Unsupervised training of Bayesian networks for data clustering. Proc. R. Soc. A 2009, 465, 2927–2948. [Google Scholar] [CrossRef]

- Alonso-Barba, J.I.; delaOssa, L.; Gámez, J.A.; Puerta, J.M. Scaling up the Greedy Equivalence Search algorithm by constraining the search space of equivalence classes. Int. J. Approx. Reason. 2013, 54, 429–451. [Google Scholar] [CrossRef]

- Nozari, H.A.; Shoorehdeli, M.A.; Simani, S.; Banadaki, H.D. Model-based robust fault detection and isolation of an industrial gas turbine prototype using soft computing techniques. Neurocomputing 2012, 91, 29–47. [Google Scholar] [CrossRef]

- Zhang, Y.; Jombo, G.; Latimer, A. A Knowledge Transfer Platform for Fault Diagnosis of Industrial Gas Turbines. In Proceedings of the 2018 IEEE 22nd International Conference on Intelligent Engineering Systems (INES), Las Palmas de Gran Canaria, Spain, 21–23 June 2018; pp. 000347–000352. [Google Scholar]

- Ganguli, R. Application of Fuzzy Logic for Fault Isolation of Jet Engines. J. Eng. Gas Turbines Power 2003, 125, 617–623. [Google Scholar] [CrossRef]

- Fuster-Parra, P.; Ligeza, A.; Aguilar-Martin, J. Adductive diagnostic procedure based on an AND/OR/NOT graph for expected behaviour: Application to a gas turbine. In Proceedings of the 10th International Congress and Exhibition on Condition Monitoring and Diagnostic Engineering Management, Espoo, Finland, 9–11 June 1997; pp. 511–520. [Google Scholar]

- Marinai, L.; Singh, R. A fuzzy logic approach to gas path diagnostics in Aero-engines. In Computational Intelligence in Fault Diagnosis; Springer: Berlin/Heidelberg, Germany, 2006; pp. 37–79. [Google Scholar]

- Ganguli, R. Data Rectification and Detection of Trend Shifts in Jet Engine Path Measurements Using Median Filters and Fuzzy Logic. J. Eng. Gas Turbines Power 2002, 124, 809–816. [Google Scholar] [CrossRef]

- Ogaji, S.O.T.; Marinai, L.; Sampath, S.; Singh, R.; Prober, S.D. Gas-turbine fault diagnostics: A fuzzy-logic approach. Appl. Energy 2005, 82, 81–89. [Google Scholar] [CrossRef]

- Kyriazis, A.; Mathioudakis, K. Gas Turbine Fault Diagnosis Using Fuzzy-Based Decision Fusion. J. Propuls. Power 2009, 25, 335–343. [Google Scholar] [CrossRef]

- Sampath, S.; Ogaji, S.; Singh, R.; Probert, D. Engine-fault diagnostics: An optimisation procedure. Appl. Energy 2002, 73, 47–70. [Google Scholar] [CrossRef]

- Golberg, D.E. Genetic Algorithms in Search, Optimization, and Machine Learning; Addion Wesley: Reading, MA, USA, 1989. [Google Scholar]

- Chipperfield, A.; Fleming, P.; Pohlheim, H.; Fonseca, C. Genetic algorithm toolbox for use with MATLAB. 1994. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.16.1178&rep=rep1&type=pdf (accessed on 10 April 2019).

- Gulati, A.; Zedda, M.; Singh, R. Gas turbine engine and sensor multiple operating point analysis using optimization techniques. In Proceedings of the 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000; p. 3716. [Google Scholar]

- Loboda, I.; Yepifanov, S.; Feldshteyn, Y. A Generalized Fault Classification for Gas Turbine Diagnostics at Steady States and Transients. J. Eng. Gas Turbines Power 2007, 129, 977. [Google Scholar] [CrossRef]

- Li, Y.G.; Abdul Ghafir, M.F.; Wang, L.; Singh, R.; Huang, K.; Feng, X.; Zhang, W. Improved Multiple Point Nonlinear Genetic Algorithm Based Performance Adaptation Using Least Square Method. J. Eng. Gas Turbines Power 2012, 134, 031701. [Google Scholar] [CrossRef]

- Kong, C.; Kang, M.; Park, G. Study on Condition Monitoring of 2-Spool Turbofan Engine Using Non-Linear Gas Path Analysis Method and Genetic Algorithms. Int. J. Mater. Mech. Manuf. 2013, 214–220. [Google Scholar] [CrossRef][Green Version]

- Denney, G. F16 jet engine trending and diagnostics with neural networks. In Proceedings of the Optical Engineering and Photonics in Aerospace Sensing, Orlando, FL, USA, 11–16 April 1993; pp. 419–422. [Google Scholar]

- Sampath, S.; Singh, R. An Integrated Fault Diagnostics Model Using Genetic Algorithm and Neural Networks. J. Eng. Gas Turbines Power 2006, 128, 49. [Google Scholar] [CrossRef]

- Green, A.; Allen, D.; Green, A.; Allen, D. Artificial intelligence for real time diagnostics of gas turbine engines. In Proceedings of the 33rd Joint Propulsion Conference and Exhibit, Seattle, WA, USA, 6–9 July 1997; p. 2899. [Google Scholar]

- Kobayashi, T.; Simon, D.L. Hybrid neural-network genetic-algorithm technique for aircraft engine performance diagnostics. J. Propuls. Power 2005, 21, 751–758. [Google Scholar] [CrossRef]

- Bettocchi, R.; Pinelli, M.; Spina, P.R.; Venturini, M. Artificial Intelligence for the Diagnostics of Gas Turbines—Part I: Neural Network Approach. J. Eng. Gas Turbines Power 2006, 129, 711–719. [Google Scholar] [CrossRef]

- Li, Y.G.; Ghafir, M.F.A.; Wang, L.; Singh, R.; Huang, K.; Feng, X. Nonlinear Multiple Points Gas Turbine Off-Design Performance Adaptation Using a Genetic Algorithm. J. Eng. Gas Turbines Power 2011, 133, 071701. [Google Scholar] [CrossRef]

- Pearl, J. Probabilistic Reasoning in Intelligent Systems: Networks of Plausible Inference; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Tsoutsanis, E. Performance Adaptation of Gas Turbines for Power Generation Applications. Ph.D. Thesis, Cranfield University, Bedford, UK, 2010. [Google Scholar]

- Orsagh, R.F.; Roemer, M.J.; Savage, C.J.; Lebold, M. Development of performance and effectiveness metrics for gas turbine diagnostic technologies. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 9–16 March 2002; p. 6. [Google Scholar]

- George, V.; Frank, L.; Michael, R.; Andrew, H.; Biqing, W. Intelligent Fault Diagnosis and Prognosis for Engineering Systems; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Simon, D.L.; Borguet, S.; Léonard, O.; Zhang, X.F. Aircraft engine gas path diagnostic methods: Public benchmarking results. J. Eng. Gas Turbines Power 2014, 136, 041201. [Google Scholar] [CrossRef]

- Kamboukos, P.; Mathioudakis, K. Comparison of Linear and Nonlinear Gas Turbine Performance Diagnostics. J. Eng. Gas Turbines Power 2005, 127, 49. [Google Scholar] [CrossRef]

- Romesis, C.; Li, Y.-G. Condition-based maintenance for gas turbines plants. Available online: https://pdfs.semanticscholar.org/90fb/311a711721a6189f9ed2e88ca349b9fa11d8.pdf (accessed on 10 April 2019).

- Curnock, B. Obidicote Project—Word Package 4: Steady-State Test. Cases; Technical Report DNS62433; Rolls-Royce Plc: London, UK, 2000. [Google Scholar]

- Simon, D.L.; Bird, J.; Davison, C.; Volponi, A.; Iverson, R.E. Benchmarking gas path diagnostic methods: A public approach. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; pp. 325–336. [Google Scholar]

| Compressor Fouling Consequences | Ref. |

|---|---|

| ΓC ↓ by 5%, ηC ↓ by 2.5%, and power output ↓ by 10% | [21,23] |

| ΓC ↓ by 5%, ηC by 1.8 %, power output ↓ by 7%, and heat rate ↑ by 2.5% | [18] |

| A 1% reduction in Γc resulted in a 0.8% ηc reduction | [13] |

| ΓC ↓ by 3.1% and ηC ↓ by 0.906% | [22] |

| Power output reduces between 2% (under favorable conditions) and 15 to 20% (under adverse conditions) | [24] |

| ΓC ↓ by 5%, fuel consumption ↑ by 2.5%, and power output ↓ by 8% | [25] |

| Physical Fault | Contaminant/Cause | Exposed Component(s) | Effect | Performance Change Indication | Results | References |

|---|---|---|---|---|---|---|

| Fouling | Dust, dirt, sand, rust, ash, carbon particles, oil, unburned hydrocarbons, soot, chemicals, fertilizers, herbicides fuel, etc. | Compressor & turbine |

|

|

| [17,19,37,56,57,58] |

| Erosion | Dirt, sand, dust, ash, carbon particles, etc. | Compressor & turbine |

|

|

| [18,19,59] |

| Corrosion | Salts, acids, nitrates, sulfates, etc. | Compressor & Turbine |

|

|

| [18,45,50,59] |

| Blade tip clearance | Rubs between rotor and stator blades caused by thermal expansion, Foreign Object Damage (FOD) and erosion | Compressor & turbine |

|

|

| [39,52] |

| Foreign object damage (FOD)/Domestic object damage (DOD) | Hailstones, runway gravel or birds, large carbon particles | Compressor and turbine |

|

|

| [56,59] |

| Author | Ref. | Year | Classification Categories |

|---|---|---|---|

| Dash et al. | [87] | 2000 | MB and Data-driven (DD) |

| Li | [91] | 2001 | MB, Artificial Intelligence (AI)-based, and Fuzzy logic |

| Venkatasubramanian et al. | [89] | 2003 | Quantitative, Qualitative, and DD |

| Ogaji & Singh | [5] | 2003 | Conventional and Evolving |

| Jew | [85] | 2005 | MB, DD, and Hybrid |

| Jardine et al. | [92] | 2006 | Statistical, MB, and AI-based |

| Stamatis | [10] | 2014 | MB, AI-based, and Hybrid |

| Kong | [93] | 2014 | MB and Soft Computing |

| Zhao et al. | [94] | 2016 | MB, DD, and Knowledge-based |

| Tahan et al. | [11] | 2017 | MB, DD, and Hybrid |

| Method | Advantages | Limitations |

|---|---|---|

| GPA |

|

|

| KF |

|

|

| Method | Advantages | Limitations |

|---|---|---|

| ANN |

|

|

| FL |

|

|

| GA |

|

|

| BBN |

|

|

| Expert System (ES) |

|

|

| Method | Category | Coping with Noise & Bias [9,91] | Ability to Deal with Problem Non-Linearity [9,91] | No. of Sensors Required [9] | Data Fusion Ability [2,9] | Computational Speed [2,91] | SFI Capability [9] | Ability to Provide Quantitative Solutions [2] |

| LGPA | MB | No | Incapable | M ≥ N | L | H | Capable | Capable |

| NLGPA | MB | No | Capable | M ≥ N | L | FH | Capable | Capable |

| LKF | MB | Partial | Incapable | N < M | AA | H | Capable | Capable |

| NLKF | MB | Partial | Capable | N < M | AA | H | Capable | Capable |

| ANN | DD | Yes | Capable | N < M | FH | H | Capable | Capable |

| GA | MB/AI | Yes | Capable | N < M | FH | L | Capable | Capable |

| FL | DD | Yes | Capable | N < M | H | H | Capable | Partial |

| BBN | DD | Yes | Capable | N < M | H | L | Capable | Capable |

| ES | DD | Yes | Capable | N < M | Fairly high | FH | Capable | Capable |

| Method | System Complexity [91] | MFII Capability [9,87] | Explanation Facility [87] | Adaptability [87] | Memory Requirement [9,87] | Online/Offline Application [9] | User Friendly Interface [11] | Flexibility [2] |

| LGPA | L | Capable | - | NF | L | Offline | F | H |

| NLGPA | L | Capable | - | NF | L | Offline | F | H |

| LKF | FL | Capable | NF | NF | L | Both | F | AA |

| NLKF | Mm | Capable | NF | NF | L | Both | F | AA |

| ANN | FH | Partial | NF | F | H | Both | F | L |

| GA | FH | Partial | - | F | H | Offline | NF | AA |

| FL | H | Partial | - | F | H | Both | F | A |

| BBN | H | Partial | NF | F | H | Offline | F | F |

| ES | H | Partial | NF | F | H | Offline | F | A |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fentaye, A.D.; Baheta, A.T.; Gilani, S.I.; Kyprianidis, K.G. A Review on Gas Turbine Gas-Path Diagnostics: State-of-the-Art Methods, Challenges and Opportunities. Aerospace 2019, 6, 83. https://doi.org/10.3390/aerospace6070083

Fentaye AD, Baheta AT, Gilani SI, Kyprianidis KG. A Review on Gas Turbine Gas-Path Diagnostics: State-of-the-Art Methods, Challenges and Opportunities. Aerospace. 2019; 6(7):83. https://doi.org/10.3390/aerospace6070083

Chicago/Turabian StyleFentaye, Amare D., Aklilu T. Baheta, Syed I. Gilani, and Konstantinos G. Kyprianidis. 2019. "A Review on Gas Turbine Gas-Path Diagnostics: State-of-the-Art Methods, Challenges and Opportunities" Aerospace 6, no. 7: 83. https://doi.org/10.3390/aerospace6070083

APA StyleFentaye, A. D., Baheta, A. T., Gilani, S. I., & Kyprianidis, K. G. (2019). A Review on Gas Turbine Gas-Path Diagnostics: State-of-the-Art Methods, Challenges and Opportunities. Aerospace, 6(7), 83. https://doi.org/10.3390/aerospace6070083