The Technical Hypothesis of a Missile Engine Conversion and Upgrade for More Sustainable Orbital Deployments

Abstract

1. Introduction

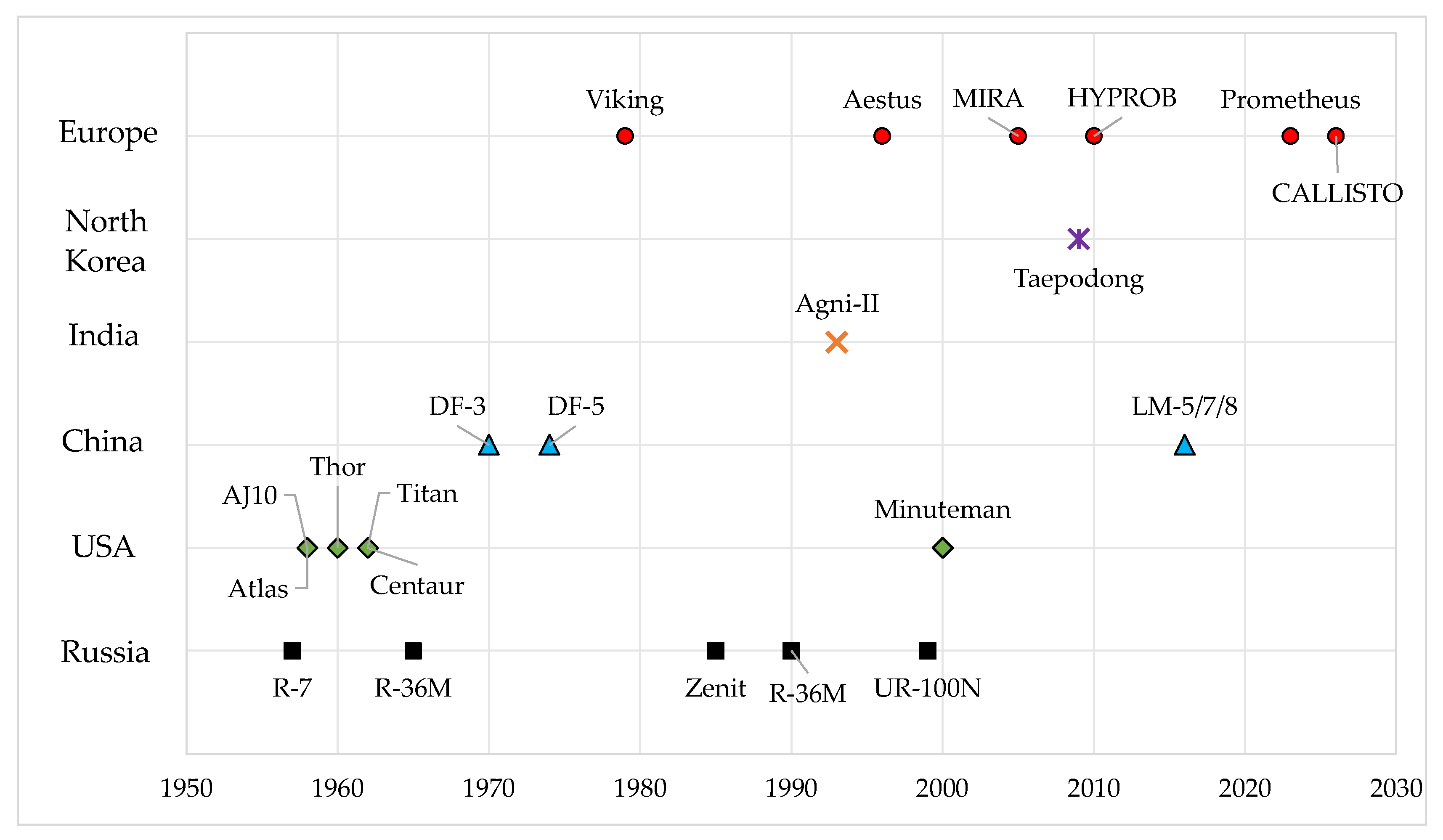

2. Historical Precedents

2.1. Russia and the Former Soviet Union

2.2. USA

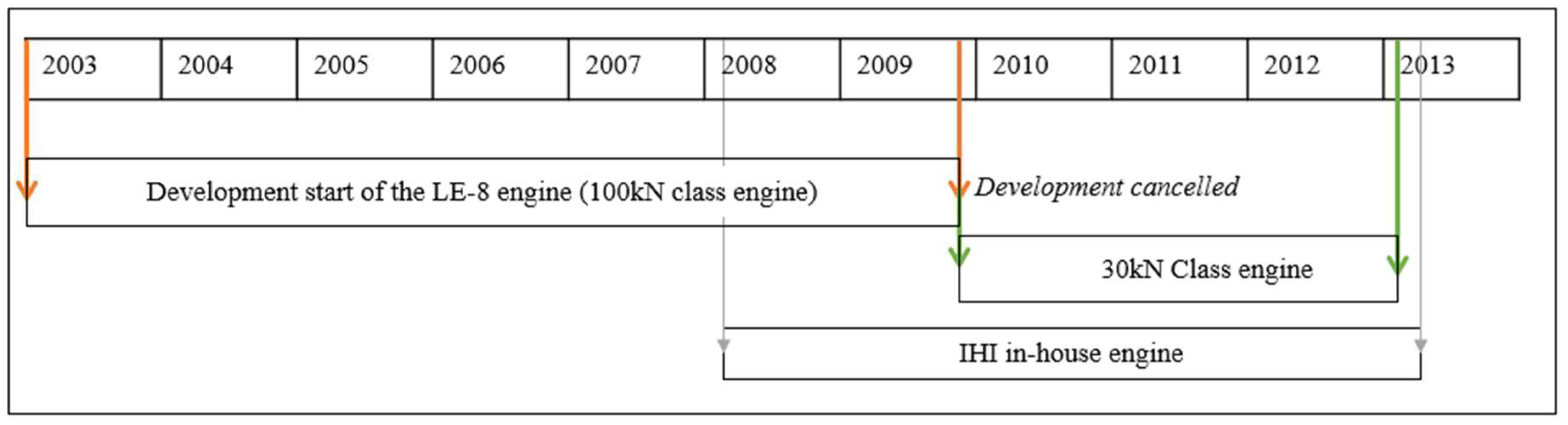

2.3. Asia

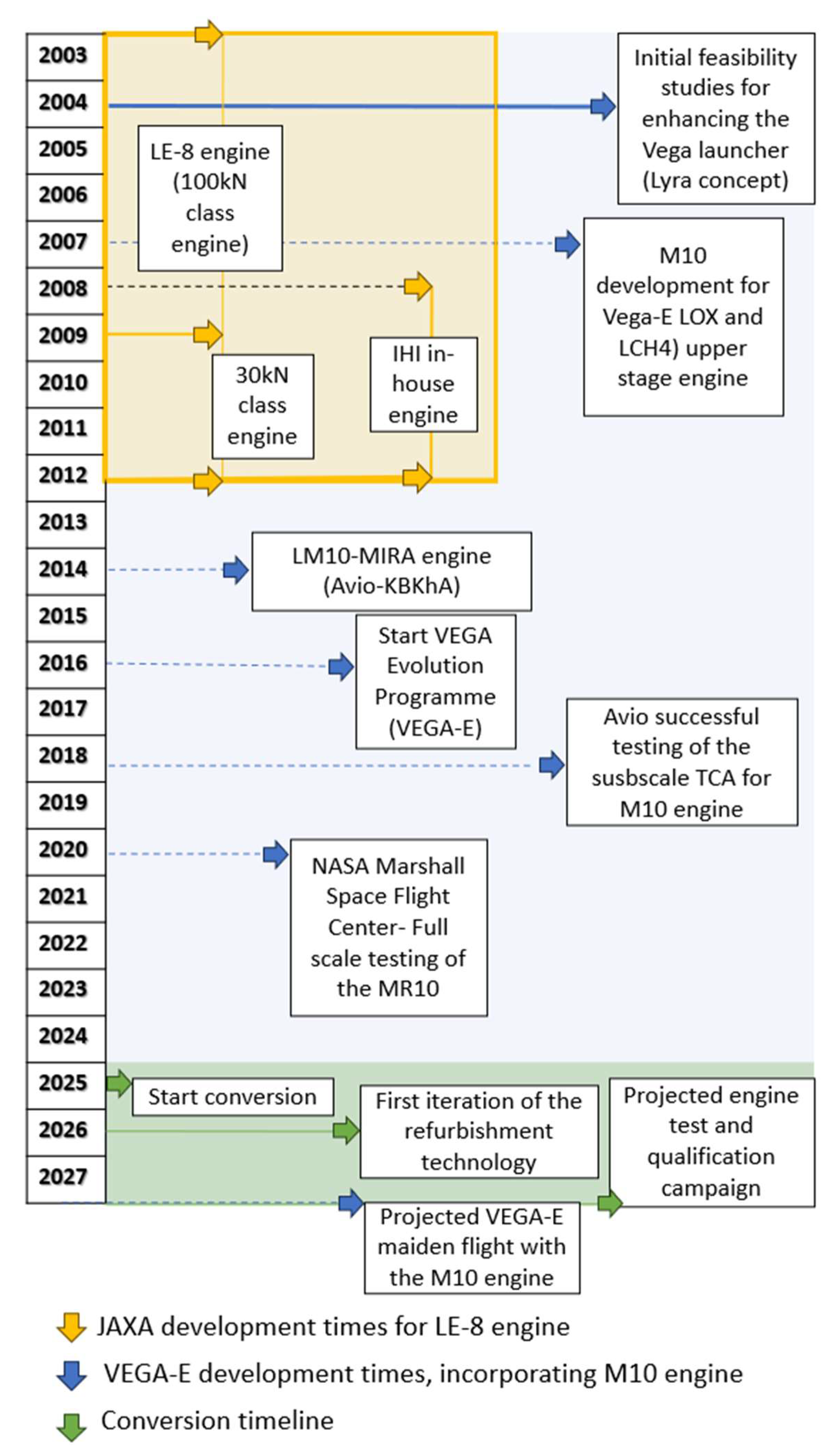

2.4. Europe

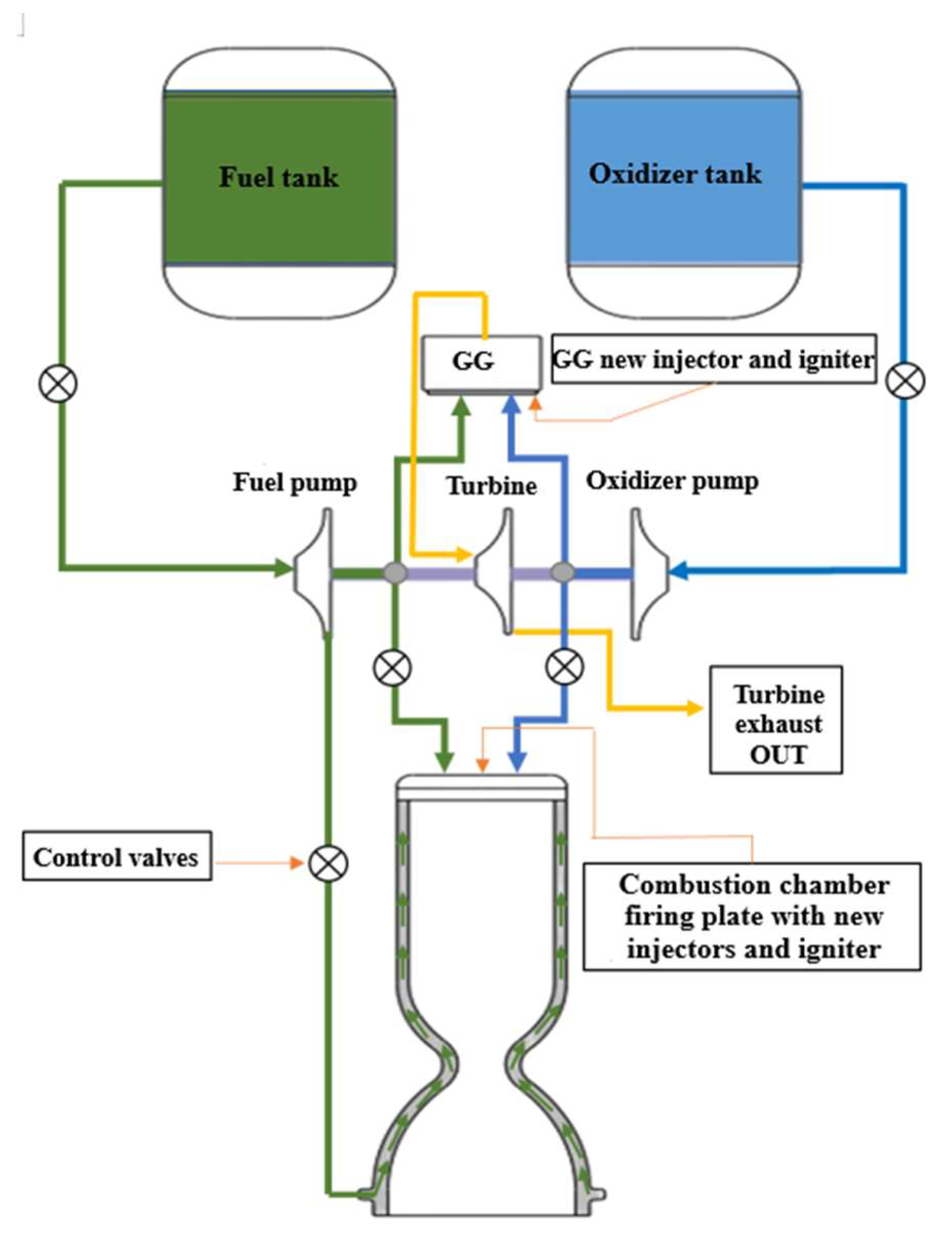

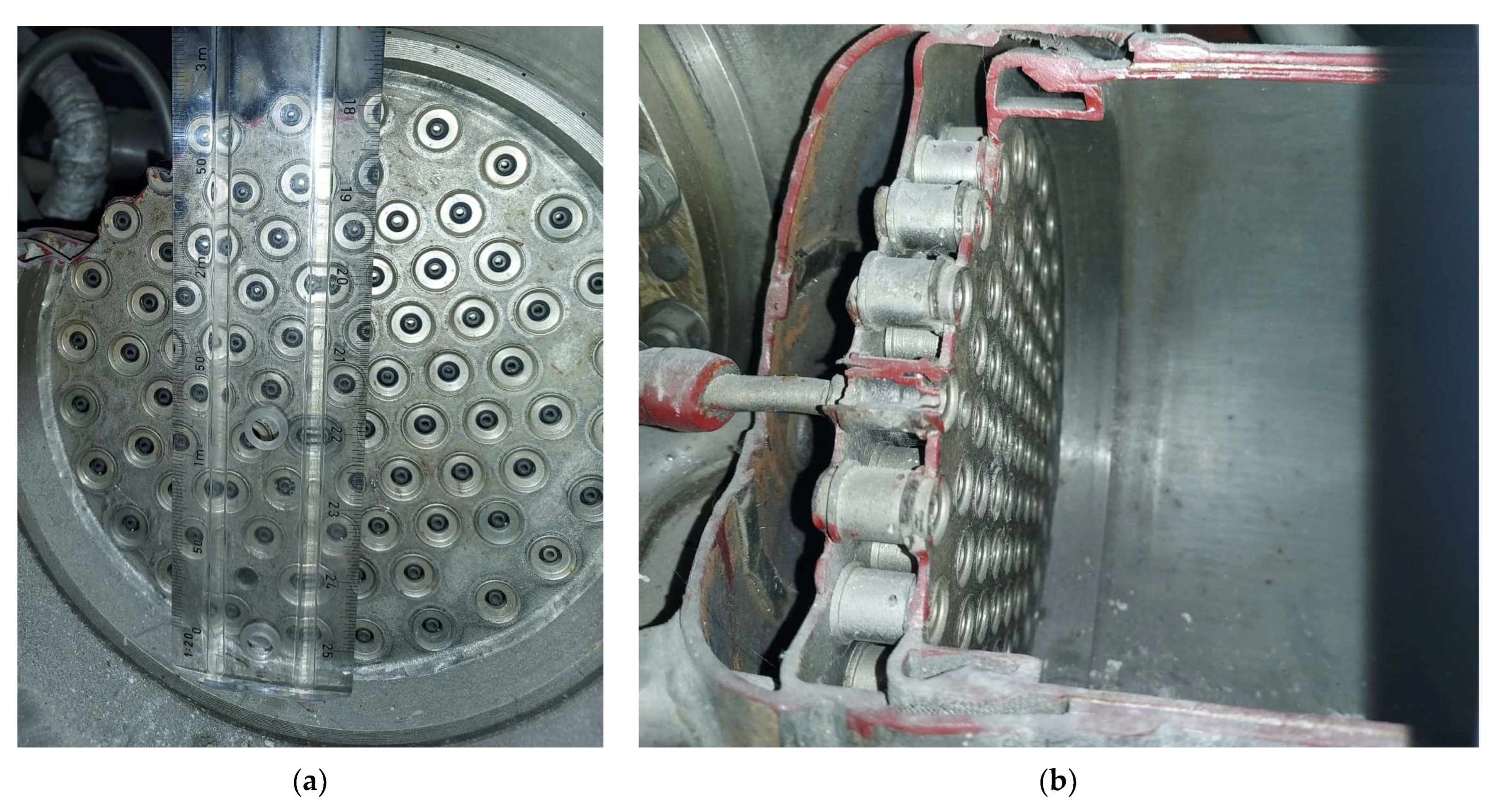

3. Technical Feasibility of the Conversion of the Isayev S2.720

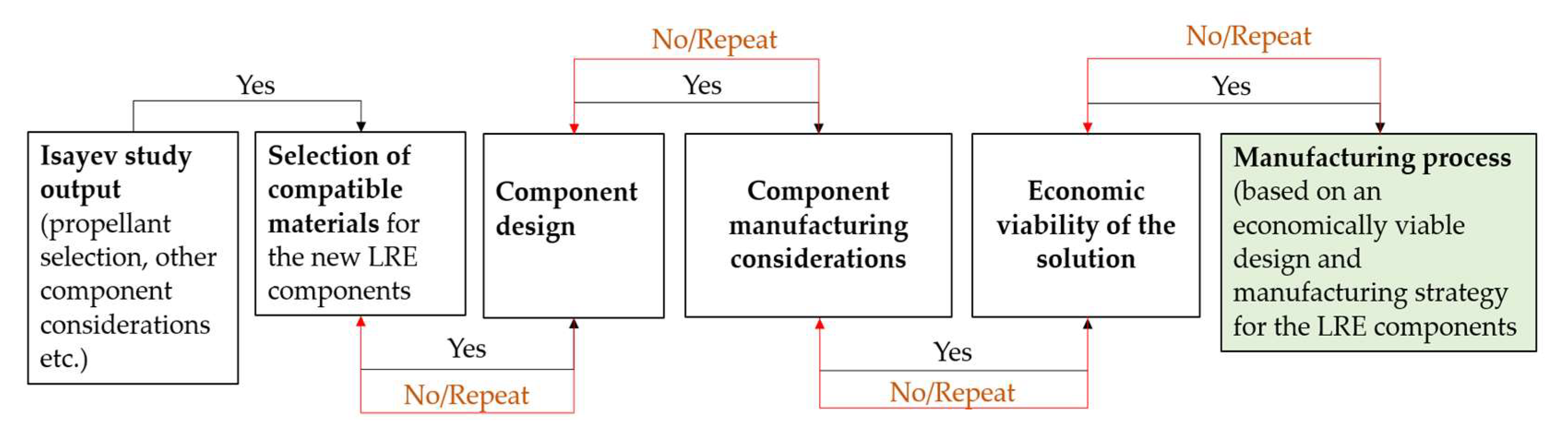

3.1. Proposed Approach for the Conversion Methodology

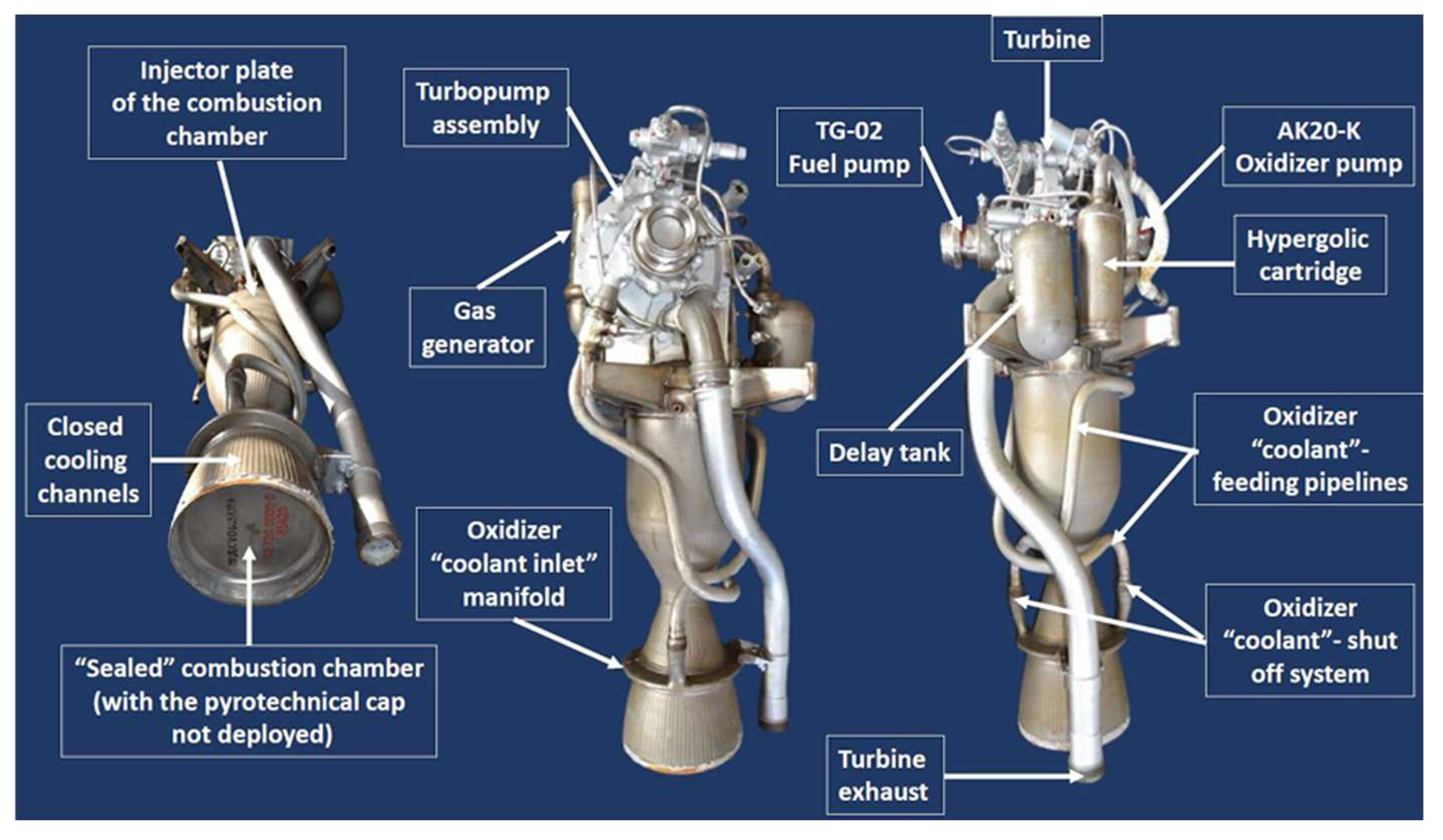

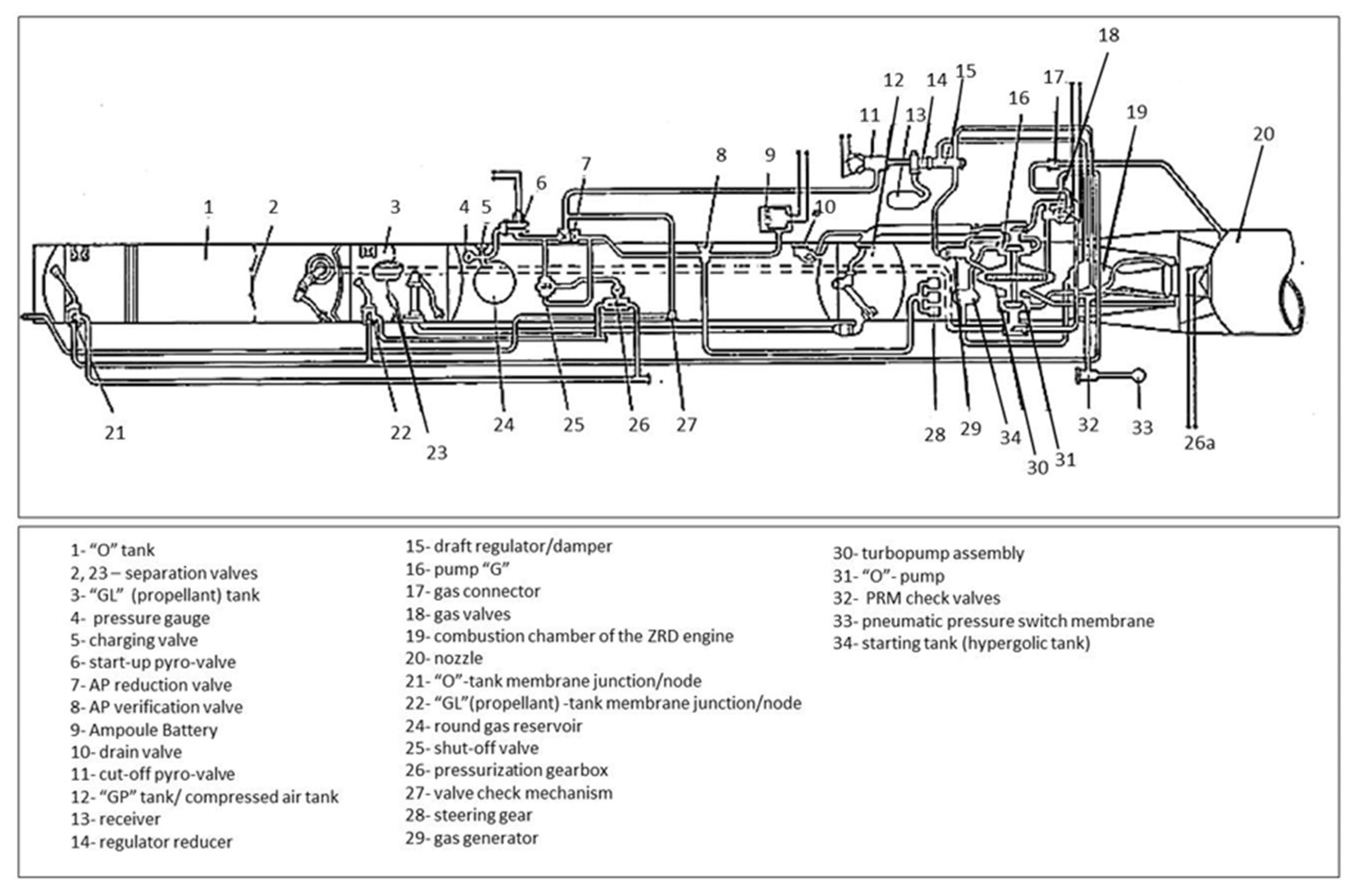

3.2. The Hypothetical Test Case: Isayev S2.720

3.3. Missile Operation Considerations

- (a)

- The start-up sequence

- (b)

- First operating mode (T = 34.32 kN)

- (c)

- Second operating mode (T = 19.61 kN)

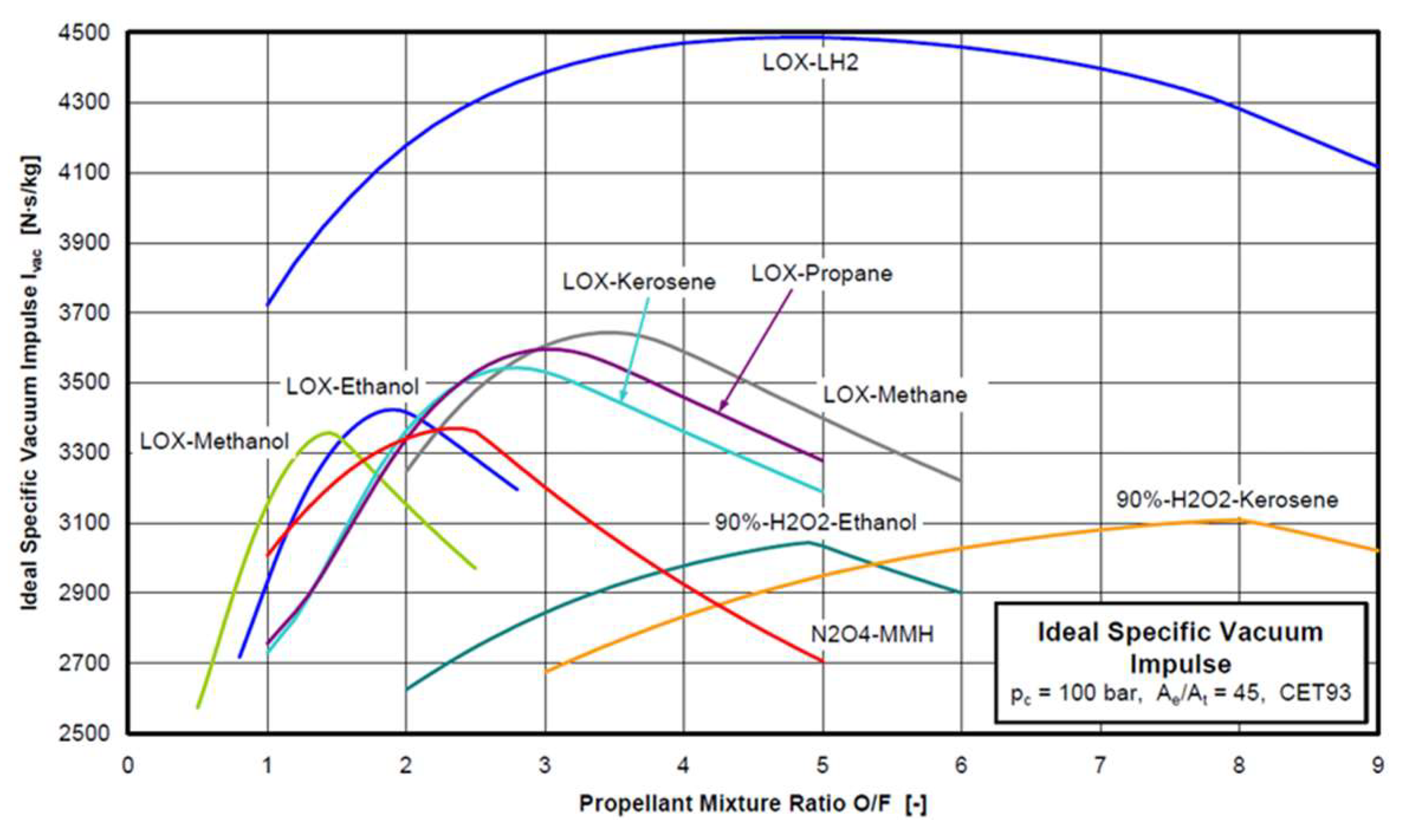

4. Pillar I—Adoption of Cryogenic Propellants for Sustainable Conversion

4.1. Propellant Choice

4.2. Environmental and Operational Conditions

- LOX-Kerosene produces soot and CO2 emissions, contributing to air pollution and carbon buildup;

- LOX-LCH4 burns cleaner and emits only water (H2O) and carbon dioxide (CO2), with significantly less unburnt hydrocarbons and particles;

- A methane-based engine is less prone to carbon fouling, meaning less downtime and lower refurbishment costs;

- Unlike kerosene, methane is non-toxic and does not require complex cleaning procedures, making ground handling safer and easier.

- Hydrogen requires much larger tanks due to its low density, increasing vehicle size and drag;

- Methane’s higher density allows for more compact tankage, improving mass efficiency and structural integrity;

- Methane is more thermally stable than hydrogen, reducing boil-off risks and making it easier to integrate into long-duration missions;

- Kerosene, though dense, requires separate pressurization systems, while methane is more compatible with autogenous pressurization (using its own vapor for pressurization), simplifying vehicle design.

- LOX-LH2 requires extremely high insulation costs and suffers from rapid boil-off, making long-term storage expensive;

- LOX-Kerosene engines require frequent maintenance and cleaning, increasing turnaround times and operational costs;

- Methane is widely available, inexpensive, and can be produced synthetically, making it economically attractive for large-scale space operations.

4.3. Economic Aspects and the Possibility of a Drastic Timeframe Reduction

5. Pillar II—Remanufacturing of Key Components

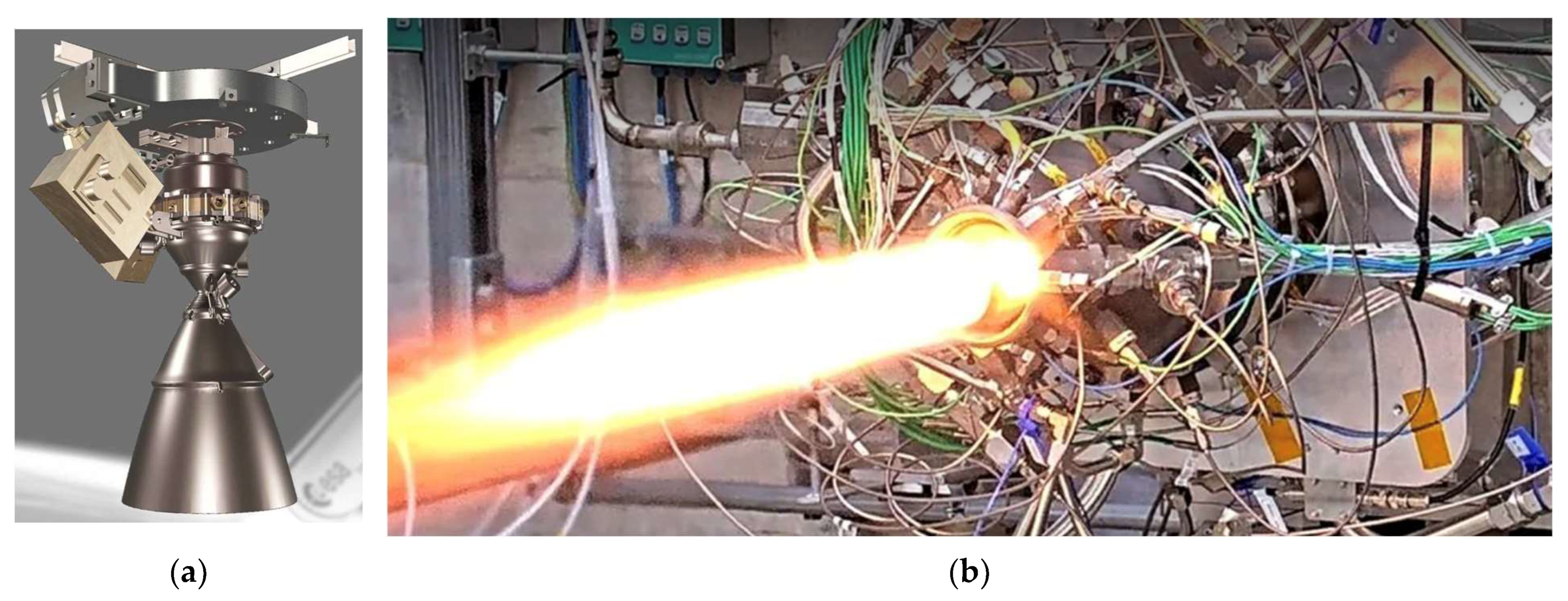

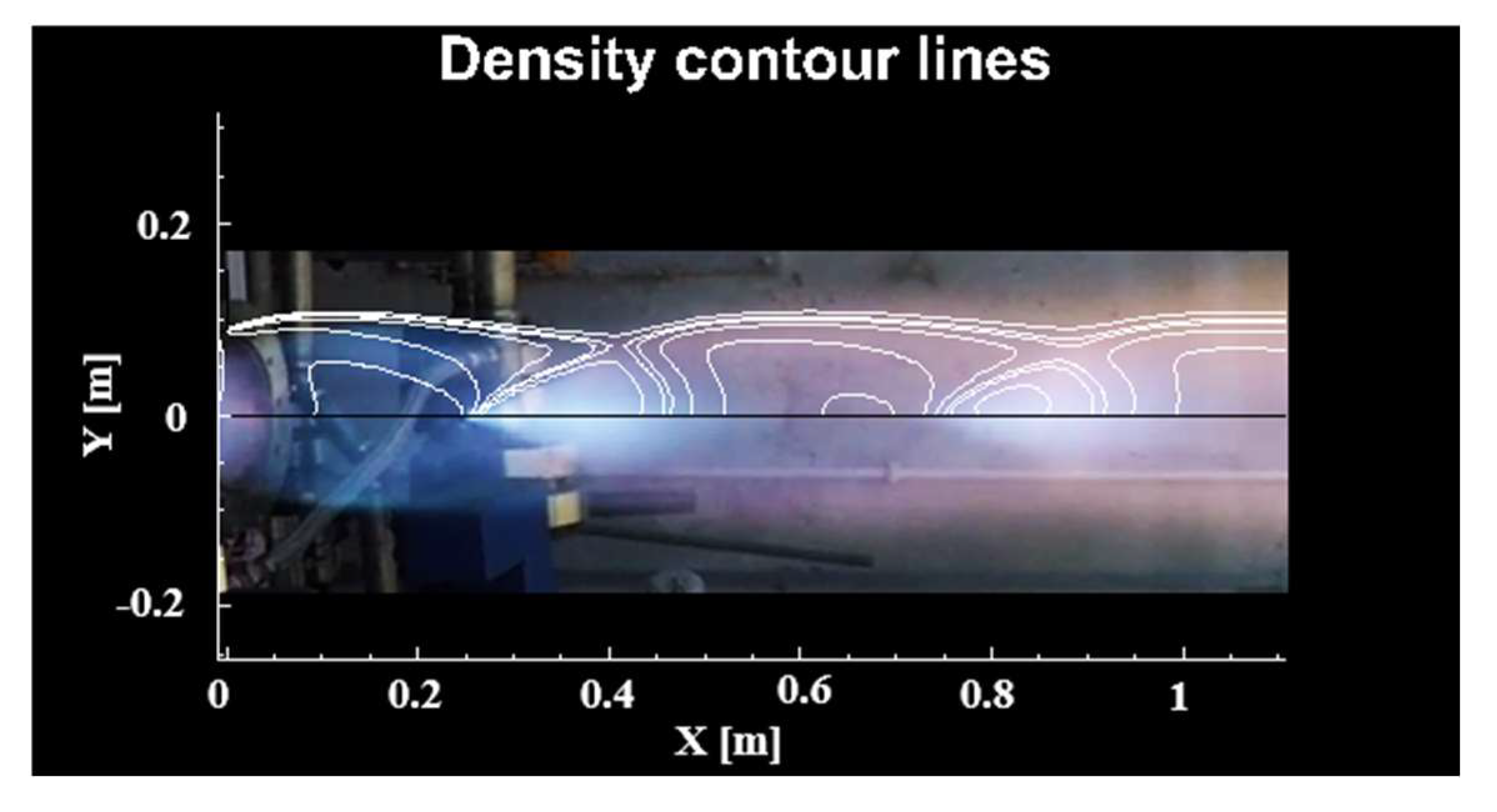

6. Pilar III—Testing

7. Potential European Missiles for Reconversion into Space Propulsion Systems

8. Policy, Security, and Ethical Dimensions

8.1. Policy Framework

8.2. Security Implications

8.3. Ethical Dimensions

9. Conclusions

10. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADN | Ammonium Dinitramide |

| AI | Artificial Intelligence |

| AM | Additive Manufacturing |

| Al2O3 | Aluminum Oxide |

| CALLISTO | Cooperative Action Leading To Launcher Innovation For Stage Toss-Back Operations |

| CCDCOE | Cooperative Cyber Defense Centre Of Excellence |

| CNES | Centre National D’études Spatiales |

| CMG | Control Moment Gyroscopes |

| CO2 | Carbon Dioxide |

| DED | Directed Energy Deposition |

| EIL | Energetic Ionic Liquids |

| ESA | European Space Agency |

| GEO | Geostationary Orbit |

| GG | Gas Generator |

| H2O | Water |

| HAN | Hydroxylammonium Nitrate |

| HC | Hydrocarbons |

| HCl | Hydrogen Chloride |

| HPAS | Hydrogen-Peroxide Aqueous Solutions |

| HTP | High-Test Peroxide |

| HYPROB | Hydrocarbon Propulsion Bench |

| ICBM | Intercontinental Ballistic Missile |

| ISS | International Space Station |

| ISRU | In-Situ Resource Utilization |

| kp | Kilopond (Also Known As A Kilogram-Force, Older Unit Of Force) |

| LCA | Life Cycle Assessment |

| LCC | Life Cycle Costing |

| LEO | Low Earth Orbit |

| LH2 | Liquid Hydrogen |

| LOX | Liquid Oxygen |

| LOX–CH4 | Liquid Oxygen–Methane |

| LPBF | Laser Powder Bed Fusion |

| LRE | Liquid Rocket Engine |

| LUMEN | Liquid Upper Stage Demonstrator Engine |

| MMH | Monomethyl Hydrazine |

| MPGE | Multipurpose Green Engine |

| MTCR | Missile Technology Control Regime |

| N2O4 | Nitrogen Tetroxide |

| NDE | Non-Destructive Evaluation |

| NTO | Nitrogen Tetroxide |

| OMS | Orbital Maneuvering System |

| PSLV | Polar Satellite Launch Vehicle |

| R&D | Research and Development |

| RCS | Reaction Control Systems |

| RP-1 | Kerosene |

| SLBMs | Submarine-Launched Ballistic Missiles |

| SLV | Space Launch Vehicles |

| SoC | System-On-Chip |

| SPS | Service Propulsion System |

| SPTF | Space Propulsion Test Facility |

| SRB | Solid Rocket Boosters |

| THA | Turbopump Assembly |

| UDMH | Unsymmetrical Dimethylhydrazine |

| VTVL | Vertical Take-Off/Vertical Landing |

| mos | Months |

References

- European Space Agency (ESA). Agenda 2025. Available online: https://www.esa.int/About_Us/ESA_Publications/Agenda_2025 (accessed on 3 July 2025).

- European Space Agency (ESA). ESA Strategy 2040. Available online: https://www.esa.int/About_Us/ESA_Strategy_2040 (accessed on 23 June 2025).

- United Nations Framework Convention on Climate Change (UNFCCC). The Paris Agreement. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 23 June 2025).

- European Commission. European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 23 June 2025).

- EU Agency for the Space Programme (EUSPA). Galileo: The EU Global Navigation Satellite System. Available online: https://www.euspa.europa.eu/eu-space-programme/galileo (accessed on 23 June 2025).

- Copernicus. The European Earth Observation Programme. Available online: https://www.copernicus.eu/en (accessed on 24 June 2025).

- European Space Agency (ESA). Ariane 5 Overview. Available online: https://www.esa.int/Enabling_Support/Space_Transportation/Launch_vehicles/Ariane_5 (accessed on 24 June 2025).

- European Space Agency (ESA). Ariane 6 Overview. Available online: https://www.esa.int/Enabling_Support/Space_Transportation/Launch_vehicles/Ariane_6_overview (accessed on 24 June 2025).

- European Space Agency (ESA). The Russian Soyuz Spacecraft. Available online: https://www.esa.int/Enabling_Support/Space_Transportation/Launch_vehicles/The_Russian_Soyuz_spacecraft (accessed on 25 June 2025).

- AeroEnginesAZ. Isayev Engine Brand Overview. Available online: https://aeroenginesaz.com/en/brand_isayev (accessed on 25 June 2025).

- Encyclopaedia Britannica. R-7 Intercontinental Ballistic Missile. Available online: https://www.britannica.com/technology/R-7 (accessed on 25 June 2025).

- National Aeronautics and Space Administration (NASA). Sputnik and the Dawn of the Space Age. Available online: https://www.nasa.gov/history/sputnik/index.html (accessed on 25 June 2025).

- Nikischenko, I.N.; Wright, R.D.; Marchan, R.A. Improving the performance of LOX/kerosene upper stage rocket engines. Propuls. Power Res. 2017, 6, 157–176. [Google Scholar] [CrossRef]

- Center for Strategic and International Studies (CSIS). SS-18 Satan. Available online: https://missilethreat.csis.org/missile/ss-18/ (accessed on 25 June 2025).

- NextSpaceflight. Rokot Launch Vehicle Overview. Available online: https://nextspaceflight.com/rockets/192 (accessed on 26 June 2025).

- European Space Agency (ESA). Dnepr Launch Vehicle Image and Description. Available online: https://www.esa.int/ESA_Multimedia/Images/2004/08/Dnepr_Launch_Vehicle (accessed on 26 June 2025).

- Forecast International. Space Systems Forecast—Launch Vehicles & Manned Platforms: Dnepr (Archived Report DACH_RECNO 1287); Forecast International: Newtown, CT, USA, 2017.

- National Academies of Sciences, Engineering, and Medicine. Launching Science: Science Opportunities Provided by NASA’s Constellation System; The National Academies Press: Washington, DC, USA, 2006; Available online: https://nap.nationalacademies.org/read/11780/chapter/6 (accessed on 26 June 2025).

- Center for Strategic and International Studies (CSIS). SS-19 Stiletto. Available online: https://missilethreat.csis.org/missile/ss-19/ (accessed on 26 June 2025).

- Federation of American Scientists (FAS). UR-100N/SS-19 ‘Stiletto’ ICBM Technical Profile. Available online: https://fas.org/nuke/guide/russia/icbm/ur-100n.htm (accessed on 26 June 2025).

- Spaceflight Now. Russia Launches Rockot Booster with Trio of Satellites. Available online: https://spaceflightnow.com/news/n1309/12rockot/ (accessed on 27 June 2025).

- NASASpaceflight.com. Rokot Retires After Final Launch with Three Gonets-M Satellites. Available online: https://www.nasaspaceflight.com/2019/12/rokot-final-launch-three-gonets-m-satellites (accessed on 30 June 2025).

- Zak, A. Zenit Flight History. Available online: https://www.russianspaceweb.com/zenit_flights.html (accessed on 30 June 2025).

- Missilery.info. R-27 Submarine-Launched Ballistic Missile. Available online: https://en.missilery.info/missile/r27 (accessed on 30 June 2025).

- NASA Safety Center. Proton Launch Vehicle Overview. Available online: https://sma.nasa.gov/LaunchVehicle/proton.html (accessed on 2 July 2025).

- The Editors of Encyclopaedia Britannica. Proton: Russian Heavy-Lift Launch Vehicle. Available online: https://www.britannica.com/technology/Proton-Russian-launch-vehicle (accessed on 30 June 2025).

- Air Force Nuclear Weapons Center. LGM-30G Minuteman III. Available online: https://www.afnwc.af.mil/Weapon-Systems/Minuteman-III-LGM-30G/ (accessed on 30 June 2025).

- U.S. National Park Service. MX Peacekeeper ICBM. Available online: https://www.nps.gov/articles/mx-peacekeeper-icbm.htm (accessed on 2 July 2025).

- NASA. Minotaur V Fact Sheet. Available online: https://www.nasa.gov/wp-content/uploads/2015/12/734208main_minotaur_v_fact.pdf?emrc=29d372 (accessed on 2 July 2025).

- Northrop Grumman. Minotaur Launch Vehicle Family. Available online: https://www.northropgrumman.com/what-we-do/space/launch-vehicles/minotaur (accessed on 2 July 2025).

- Green, C.M.; LoMask, M. Vanguard: A History; National Aeronautics and Space Administration: Washington, DC, USA, 1970.

- This Day in Aviation. Three-Stage Rocket Archives. Available online: https://www.thisdayinaviation.com/tag/three-stage-rocket/ (accessed on 2 July 2025).

- Harland, D.M.; Lorenz, R.D. The Missiles. In Space Systems Failures; Springer Praxis Books, Praxis; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

- Harland, D.M.; Lorenz, R.D. Space Systems Failures: Disasters and Rescues of Satellites, Rockets and Space Probes; Springer: Chichester, UK; Praxis Publishing Ltd.: Chichester, UK, 2005; ISBN 0-387-21519-0. [Google Scholar]

- NASA Marshall Space Flight Center. Historical Programs Overview. Available online: https://ssfl.msfc.nasa.gov/history/programs (accessed on 3 July 2025).

- San Diego Air & Space Museum. Titan ICBM Exhibit. Available online: https://sandiegoairandspace.org/exhibits/online-exhibit-page/titan-icbm (accessed on 3 July 2025).

- National Museum of the U.S. Air Force. USAF Satellite Launch Vehicles. Available online: https://www.nationalmuseum.af.mil/Visit/Museum-Exhibits/Fact-Sheets/Display/Article/197691/usaf-satellite-launch-vehicles/ (accessed on 3 July 2025).

- Center for Strategic and International Studies (CSIS). Atlas. Available online: https://missilethreat.csis.org/missile/atlas (accessed on 3 July 2025).

- U.S. Air Force Global Strike Command. Air Force History of ICBM Development. Available online: https://www.afgsc.af.mil/News/Features/Display/Article/455710/air-force-history-of-icbm-development-safeguarding-america/ (accessed on 2 July 2025).

- NASA. Mercury Atlas 6—Friendship 7 Mission Overview. Available online: https://www.nasa.gov/mission/mercury-atlas-6-friendship-7/ (accessed on 27 June 2025).

- NASA. Basics of Space Flight: Chapter 14.1—Atlas Launch Vehicle. Available online: https://science.nasa.gov/learn/basics-of-space-flight/chapter14-1/ (accessed on 2 July 2025).

- Encyclopædia Britannica. Atlas (American Launch Vehicle). Available online: https://www.britannica.com/technology/Atlas-American-launch-vehicles (accessed on 3 July 2025).

- Association of Air Force Missileers. Atlas Missile History. Available online: https://www.afmissileers.org/Atlas (accessed on 3 July 2025).

- NASA. This New Ocean: A History of Project Mercury, Chapter 3A. Available online: https://www.nasa.gov/history/SP-4001/p3a.htm (accessed on 2 July 2025).

- Dawson, V.P.; Bowles, M.D. Taming Liquid Hydrogen: The Centaur Upper Stage and Atlas Centaur Launch System; NASA SP-4230; NASA: Washington, DC, USA, 2004; pp. 9–11.

- NASA. Agena D Mission Capabilities and Restraints Catalog, Volume II; NASA Technical Memorandum TM X 52146 (Document ID 19660009137); NASA STI: Washington, DC, USA, 1965.

- NASA. Pioneer 10 Mission Overview. Available online: https://science.nasa.gov/mission/pioneer-10/ (accessed on 2 July 2025).

- NASA. Mariner Program Overview. Available online: https://science.nasa.gov/mission/mariner-program/ (accessed on 3 July 2025).

- NASA. Project Mercury Overview. Available online: https://www.nasa.gov/project-mercury/ (accessed on 26 June 2025).

- Harland, D.M. How NASA Learned to Fly in Space: An Exciting Account of the Gemini Missions; Apogee Books: Burlington, ON, Canada, 2004; p. 152. [Google Scholar]

- Spires, D.N. A History of the United States Air Force Space Launch Enterprise, 1945–2020; Air University Press: Montgomery, AL, USA, 2022. [Google Scholar]

- ULA. The Industry Workhorse. Available online: https://www.ulalaunch.com/about/heritage-rockets/delta-ii (accessed on 12 September 2025).

- LethBridge, C. Delta B Fact Sheet. Available online: https://www.spaceline.org/cape-canaveral-rocket-missile-program/delta-b/ (accessed on 12 September 2025).

- NASA. Centaur: America’s Workhorse in Space; NASA History Office: Washington, DC, USA, 2012.

- Air Force Ballistic Missile Division. Chapter IV: Launch Vehicles—Thor and Atlas Derivatives; U.S. Space Systems Division Publication AFD 060912 024; Los Angeles Air Force Base: Los Angeles, CA, USA, 2006. [Google Scholar]

- Congressional Research Service. Space Launch Vehicles: Government Activities, Commercial Competition, and Satellite Exports. Available online: https://www.everycrsreport.com/reports/98-485F.html (accessed on 15 July 2025).

- Erickson, A.S. China’s space development history: A comparison of the rocket and satellite sectors. Acta Astronaut. 2014, 103, 142–167. [Google Scholar] [CrossRef]

- Cliff, R.; Ohlandt, C.J.R.; Yang, D. China’s Space Capabilities. In Ready for Takeoff: China’s Advancing Aerospace Industry; RAND Corporation: Santa Monica, CA, USA, 2011; pp. 89–114. Available online: http://www.jstor.org/stable/10.7249/mg1100ucesrc.13 (accessed on 15 July 2025).

- Wade, M. CZ 2A (Chang Zheng 2) First Launch: 5 November 1974 Failure Due to Pitch Gyro–Guidance Cable Disconnection. Encyclopedia Astronautica. Available online: http://www.astronautix.com/c/cz-2a.html (accessed on 15 July 2025).

- Chang Zheng 2D Launch Vehicle. Available online: https://nextspaceflight.com/rockets/111 (accessed on 15 July 2025).

- Chang Zheng 2 Overview. Available online: https://www.deagel.com/Aerospace%20Forces/ChangZheng%202/a002554 (accessed on 23 June 2025).

- China National Space Administration (CNSA): Overview of Launch Vehicle Development. Available online: https://www.cnsa.gov.cn/english/n6465715/n6465718/c6476925/content.html (accessed on 23 June 2025).

- Song, Z.; Xie, Z.; Qiu, L.; Xiang, D.; Li, J. Prospects of sea launches for Chinese cryogenic liquid-fueled medium lift launch vehicles. Chin. J. Aeronaut. 2021, 34, 424–437. [Google Scholar] [CrossRef]

- Gordon, K.E. Analysis of Chinese Cryogenic Long March Launch Vehicles and YF-100 Liquid Rocket Engine. Master’s Thesis, Ohio State University, Columbus, OH, USA, 2018. Available online: http://rave.ohiolink.edu/etdc/view (accessed on 23 June 2025).

- Jones, A. China to Debut Large Reusable Rockets in 2025 and 2026. SpaceNews, 2023. Available online: https://spacenews.com/china-to-debut-large-reusable-rockets-in-2025-and-2026/ (accessed on 15 July 2025).

- China Space Industry Development Report. Available online: https://opsjournal.org/DocumentLibrary/Uploads/China.pdf (accessed on 2 July 2025).

- SpaceX. Falcon 9 Overview. Available online: https://www.spacex.com/vehicles/falcon-9 (accessed on 2 July 2025).

- ISRO GSLV Development Presentation by Somnath. Available online: https://web.archive.org/web/20101122032654/http://www.bsxindia.com/SomnathProjectDirector.pdf (accessed on 16 July 2025).

- Agni-V Long Range Ballistic Missile (LRBM). Available online: https://www.army-technology.com/projects/agni-v-long-range-ballistic-missile-lrbm/ (accessed on 12 September 2025).

- Unha Launch Vehicle (North Korea). Gunter’s Space Page. Available online: https://space.skyrocket.de/doc_lau/unha.htm (accessed on 16 July 2025).

- Bermudez, J.S., Jr. A History of Ballistic Missile Development in the DPRK; Occasional Paper No. 2; Center for Nonproliferation Studies Monterey, Institute of International Studies: Monterey, CA, USA, 1999. [Google Scholar]

- CORDIS Project ID 218819: Final Reporting Summary. Available online: https://cordis.europa.eu/project/id/218819/reporting (accessed on 24 June 2025).

- Enhanced Ariane 5 Demonstrates Heavy-Lift Capability. ESA. Available online: https://www.esa.int/Enabling_Support/Space_Transportation/Enhanced_Ariane_5_demonstrates_heavy-lift_capability (accessed on 20 July 2025).

- ArianeGroup Completes Key Prometheus Rocket Engine Tests. European Spaceflight. Available online: https://europeanspaceflight.com/arianegroup-completes-key-prometheus-rocket-engine-tests/ (accessed on 20 July 2025).

- Illig, M.; Ishimoto, S.; Dumon, E. CALLISTO, a demonstrator for reusable launchers. In Proceedings of the 9th European Conference for Aeronautics and Space Sciences (EUCASS), Lille, France, 27 June–1 July 2022. [Google Scholar]

- CALLISTO Project Overview. CNES. Available online: https://cnes.fr/projets/callisto (accessed on 20 July 2025).

- Space Transportation and Nuclear Propulsion. ESA Commercialisation Gateway. Available online: https://commercialisation.esa.int/2022/09/space-transportation-and-nuclear-propulsion/ (accessed on 20 June 2025).

- ESA Study Outlines 2035 Launch of Nuclear Propulsion Demonstrator. European Spaceflight. Available online: https://europeanspaceflight.com/esa-study-outlines-2035-launch-of-nuclear-propulsion-demonstrator/ (accessed on 27 June 2025).

- Successful Hot-Fire Test of the Russian-Italian LM10 MIRA Engine. Available online: https://missilery.info/news/uspeshnoe-ognevoe-ispytanie-rossiysko-italyanskogo-zhrd-lm10-mira (accessed on 22 June 2025).

- Bellomi, P.; Rudnykh, M.; Carapellese, S.; Liuzzi, D.; Caggiano, G.; Arione, L.; Gurtovoy, A.A.; Lobov, S.D.; Rachuk, V.S.; D’Aversa, E.; et al. Development of LM10-MIRA LOX–LNG Expander Cycle Demonstrator Engine. Progress in Propulsion Physics. In Proceedings of the 6th European Conference for Aeronautics and Space Sciences (EUCASS), Krakow, Poland, 29 June–3 July 2015; Volume 11, pp. 447–466. Available online: https://www.eucass-proceedings.eu/ (accessed on 23 July 2025).

- Rudnykh, M.; Carapellese, S.; Liuzzi, D.; Arione, L.; Caggiano, G.; Bellomi, P.; D’Aversa, E.; Pellegrini, R.; Lobov, S.D.; Gurtovoy, A.A.; et al. Development of LM10-MIRA LOX/LNG expander cycle demonstrator engine. Acta Astronaut. 2016, 126, 364–374. [Google Scholar] [CrossRef]

- Avio S.p.A. 2014 Annual Report. Available online: https://avio-data.teleborsa.it/2017%2FAvio_Group-2014_Annual_Report_20170518_111531.pdf (accessed on 12 September 2025).

- EngineeringRussia. Russian and Italian Designers Successfully Tested New Rocket Engine. 10 June 2014. Available online: https://engineeringrussia.wordpress.com/2014/06/10/russian-and-italian-engineers-successfully-test-new-engine-for-carrier-rocket/ (accessed on 12 September 2025).

- SpaceNews. Avio Has Successfully Tested the New M10 Liquid Methane and Oxygen Engine. July 2019. Available online: https://www.avio.com/news-events/m10-liquid-oxygen-and-methane-succesfully-completed-long-duration-and-throttling-test (accessed on 12 September 2025).

- Kajon, D.; Liuzzi, D.; Boffa, C.; Rudnykh, M.; Drigo, D.; Arione, L.; Ierardo, N.; Sirbi, A. Development of the Liquid Oxygen and Methane M10 Rocket Engine for the Vega-E Upper Stage. In Proceedings of the 8th European Conference for Aeronautics and Space Sciences (EUCASS), Madrid, Spain, 1–4 July 2019. [Google Scholar]

- de Matteis, P. The HYPROB Program: Mastering Key Technologies, Design and Testing Capabilities for Space Transportation Rocket Propulsion Evolution. In Proceedings of the 63rd International Astronautical Congress, Naples, Italy, 1–5 October 2012. [Google Scholar]

- Ricci, D.; Battista, F.; Fragiacomo, M.; French, A. Thermal Behaviour of the Cooling Jacket Belonging to a Liquid Oxygen/Liquid Methane Rocket Engine Demonstrator in the Operation Box. Aerospace 2023, 10, 607. [Google Scholar] [CrossRef]

- Battista, F.; Cardillo, D.; Fragiacomo, M.; Di Martino, G.D.; Mungiguerra, S.; Savino, R. Design and Testing of a Paraffin-Based 1000 N HRE Breadboard. Aerospace 2019, 6, 89. [Google Scholar] [CrossRef]

- S-75 Surface-to-Air Missile. Encyclopedia Astronautica. Available online: http://www.astronautix.com/s/s-75.html (accessed on 23 June 2025).

- Ministry of Defense of the USSR. Training Manual: S 75M Surface-to-Air Missile System; Military Publishing House of the Ministry of Defense of the USSR: Moscow, Russia, 1965; Available online: https://ww2aircraft.net/forum/threads/public-available-1970s-soviet-sa2-or-s75-dvina-missile-operator-and-maintenance-manuals.59191/ (accessed on 12 August 2025). (In Russian)

- François Gissy. Isayev S2.720 Rocket Engine. YouTube; published 8 years ago. Available online: https://www.youtube.com/watch?v=pyiJHIF2mvQ (accessed on 12 September 2025).

- Deterrence—Defence Systems. ArianeGroup. Available online: https://ariane.group/en/defence-systems/deterrence/ (accessed on 24 June 2025).

- Ross, M.N.; Toohey, D.W.; Peinemann, M.; Ross, P.N. Global stratospheric effects of the alumina emissions by solid-fueled rocket motors. J. Geophys. Res. Atmos. 1997, 102, 13227–13238. [Google Scholar]

- Salla, D.; Venkatramanan, V.; Venkatesh, G.; Srigengan, V.; Nguyen, T.S.; Praveen, B.S. Environmental footprint of space missions—A review of emissions from rocket launches. Sci. Total Environ. 2023. [Google Scholar]

- Proton-K 17S40. Encyclopedia Astronautica. Available online: http://www.astronautix.com/p/proton-k17s40.html (accessed on 23 June 2025).

- Gent, E. The Black Carbon Cost of Rocket Launches. WIRED. Available online: https://www.wired.com/story/the-black-carbon-cost-of-rocket-launches/ (accessed on 15 July 2025).

- Kokkinakis, I.W.; Drikakis, D. Atmospheric Pollution from Rockets. Phys. Fluids 2022, 34, 056107. [Google Scholar] [CrossRef]

- Dobbins, T.A.; Wiley, D.B. Hypergolic Hydrocarbon Fuels. U.S. Patent No. US8894782B2, 25 November 2014. Available online: https://patentimages.storage.googleapis.com/0d/58/83/47935b6aca4804/US8894782.pdf (accessed on 15 July 2025).

- NASA. Dawn End-of-Mission Toolkit. Available online: https://science.nasa.gov/mission/dawn/toolkit/end-of-mission/ (accessed on 15 July 2025).

- National Aeronautics and Space Administration. Service Life Extension of the ISS Propulsion System Elements; NASA Technical Memorandum NTRS 20150012224; NASA: Greenbelt, MD, USA, 2015.

- NASA/Space Technology Laboratories. Apollo Lunar Module Propulsion Systems Overview; Aerozine-50 fuel and N2O4 oxidizer used throughout RCS and main engines; NASA Technical Report; NASA: Washington, DC, USA, 1966.

- Stephens, D.B.; Belair, M.L.; Quinn, F.D. A Heat and Mass Transfer Model of the Orion European Service Module Propulsion Sub-System; Propulsion Division, NASA Glenn Research Center, Supported by the European Service Module Propellant Integration Team Project; NASA: Washington, DC, USA, 2020.

- Rarata, G.G.; Florczuk, W. The Handling Hazards of Propellants Hypergolic with Hydrogen Peroxide. In Proceedings of the XIV International Scientific Conference IPOEX 2017, Ustroń, Poland, 5–7 June 2017. [Google Scholar]

- Garcia, H.D.; James, J.T.; Limero, T.F. Atmospheric Contaminants and Their Impact on Space Operations: A Summary of Air Quality Monitoring Results. In Proceedings of the 5th Annual Workshop on Space Operations Applications and Research (SOAR 1991), Houston, TX, USA, 9–11 July 1991; NASA: Washington, DC, USA, 1992; Volume 2. [Google Scholar]

- Ju, Y.; Song, C.; Lee, B.J. Guidelines for the Safe Handling of Hypergolic Propellants in Development of Space Propulsion Systems. J. Propuls. Energy 2024, 4, 42–57. [Google Scholar] [CrossRef]

- Black, A.T.; Drolet, M.P.; Pourpoint, T.L. Early Liquid and Gas Phase Hypergolic Reactions between Monomethylhydrazine and Nitrogen Tetroxide or Red Fuming Nitric Acid. Combust. Sci. Technol. 2018, 191, 1990–2005. [Google Scholar] [CrossRef]

- Kim, K.S.; Jung, S.; Kwon, S. Photographic investigation of impinging combustion for the hydrogen peroxide and amine-based hypergolic propellant. In Proceedings of the International Astronautical Congress, IAC, Online, 12–14 October 2020. [Google Scholar]

- Lemmer, K. Propulsion for CubeSats. Acta Astronaut. 2017, 134, 231–243. [Google Scholar] [CrossRef]

- Liu, X.; Shen, Y.; Fu, T.; Zhang, W.; Long, J. A High Energy and Green Monopropellant Propulsion Module for CubeSats; iCubeSat Workshop: Cambridge, UK, 2017. [Google Scholar]

- Hörger, T.; Merz, F.; Steelant, J.; Werling, L.; Kirchberger, C. Result of ESA-Greenraim Test Activities Part 2: Experimental Investigation of a 1 Newton Nitrous Oxide Monopropellant Research Thruster. In Proceedings of the Space Propulsion 2024—9th Edition, Glasgow, Scotland, 20–24 May 2024. [Google Scholar]

- Krejci, D.; Woschnak, A.; Scharlemann, C.; Ponweiser, K. Structural Impact of Honeycomb Catalysts on Hydrogen Peroxide Decomposition for Micro Propulsion. Chem. Eng. Res. Des. 2012, 90, 2302–2315. [Google Scholar] [CrossRef]

- Nosseir, A.E.S.; Cervone, A.; Pasini, A. Review of State-of-the-Art Green Monopropellants: For Propulsion Systems Analysts and Designers. Aerospace 2021, 8, 20. [Google Scholar] [CrossRef]

- Kasbi, Y.; Remissa, I.; Toshtay, K.; Mabrouk, A.; Bachar, A.; Azat, S.; Nosseir, A.E.S.; Tiwari, A.; Sabbar, E.M.; Amrousse, R. H2O2 and HAN Green Monopropellants—A State-of-the-Art Review on Their Recent Development, Corresponding Synthesized Catalysts, and Their Possible Use as Thrusters. Catalysts 2025, 15, 183. [Google Scholar] [CrossRef]

- Chathoth, R.M.; Oommen, C.; Gozin, M.; Dharavath, S.; Jujam, M.; Chowdhury, D.; Das, J. Biomass-derived sustainable hypergolic rocket propellants with hydrogen peroxide. Green Chem. 2025, 27, 6105–6122. [Google Scholar] [CrossRef]

- Lauck, F.; Balkenhohl, J.; Negri, M.; Freudenmann, D.; Schlechtriem, S. Green bipropellant development—A study on the hypergolicity of imidazole thiocyanate ionic liquids with hydrogen peroxide in an automated drop test setup. Combust. Flame 2021, 226, 87–97. [Google Scholar] [CrossRef]

- Sippel, M.; Wilken, J. Selection of propulsion characteristics for systematic assessment of future European RLV-options. CEAS Space J. 2025, 17, 89–111. [Google Scholar] [CrossRef]

- Sriram, K.; Graham, I. Feasibility of Integrating Cryogenic Propulsion for Next Generation Missiles for Enhanced Range, Stealth and Strategic Capabilities. Acceleron Aerosp. J. 2024, 3, 764–784. [Google Scholar] [CrossRef]

- NASA. Apollo 14 Flight Journal—Mission Overview and Technical Summary. Available online: https://www.nasa.gov/history/afj/ap14fj/info.html (accessed on 23 June 2025).

- NASA. Space Launch System (SLS) RS-25 Core Stage Engine Overview. Available online: https://www.nasa.gov/reference/space-launch-system-rs-25-core-stage-engine/ (accessed on 23 June 2025).

- Available online: https://www.esa.int/Enabling_Support/Space_Transportation/Launch_vehicles/Ariane_5_Vulcain_engine (accessed on 24 June 2025).

- Matsuyama, K.; Ohigashi, H.; Ito, T.; Yasui, M.; Manako, H. H-IIA Rocket Engine Development; Technical Review; Mitsubishi Heavy Industries, Ltd.: Tokyo, Japan, 2002; Volume 39. [Google Scholar]

- Rapp, D.; Inglezakis, V.J. Mars In Situ Resource Utilization (ISRU) with Focus on Atmospheric Processing for Near-Term Application—A Historical Review and Appraisal. Appl. Sci. 2024, 14, 653. [Google Scholar] [CrossRef]

- Jin, Y.; Zhang, W.; Zhou, Z.; Liu, T.; Xia, H.; Huang, S.; Zhang, Q. Recent advances in hypergolic ionic liquids with broad potential for propellant applications. FirePhysChem 2022, 2, 236–252. [Google Scholar] [CrossRef]

- Naseem, M.; Botchu, J.; Baek, S.; Lee, H.; Cho, S. Hypergolic Studies of Ethanol Based Gelled Bi-Propellant System for Propulsion Application. Propellants Explos. Pyrotech. 2017, 42, 676–682. [Google Scholar] [CrossRef]

- NASA. Green Propellant Infusion Mission (GPIM) Overview. Available online: https://www.nasa.gov/missions/tech-demonstration/green-propellant-infusion-mission-gpim-overview (accessed on 24 June 2025).

- NASA. NASA Spacecraft to Test Green Propellant Passes Major Pre-Flight Milestone. Available online: https://www.nasa.gov/missions/tech-demonstration/nasa-spacecraft-to-test-green-propellant-passes-major-pre-flight-milestone (accessed on 25 June 2025).

- NASA Technology Experiments Hitching a Ride on SpaceX’s Falcon Heavy Rocket. Spaceflight Now, 24 June 2019. Available online: https://spaceflightnow.com/2019/06/24/nasa-technology-experiments-hitching-a-ride-on-spacexs-falcon-heavy-rocket (accessed on 25 June 2025).

- Rachuk, V.S.; Goncharov, N.S.; Martynyenko, Y.A.; Barinshtein, B.M.; Sciorelli, F.A. Design, Development, and History of the OXYGENrnDROGEN Engine RD-012. In Proceedings of the 31st AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, SanDiego, CA, USA, 10–12 July 1995. [Google Scholar]

- Ha, D.; Roh, T.-S.; Huh, H.; Lee, H.J. Development Trend of Liquid Hydrogen-Fueled Rocket Engines (Part 1: Performance and Operation). Int. J. Aeronaut. Space Sci. 2023, 24, 131–145. [Google Scholar] [CrossRef]

- Vajiram & Ravi. Cryogenic Engine Overview for UPSC Exam. Available online: https://vajiramandravi.com/upsc-exam/cryogenic-engine/ (accessed on 25 June 2025).

- China Space Report. Chang Zheng 5 (CZ-5) Launch Vehicle Overview. Available online: https://chinaspacereport.wordpress.com/launch-vehicles/cz5/ (accessed on 25 June 2025).

- Burkhardt, H.; Herbertz, A.; Sippel, M.; Woschnak, A.; Riccius, J. Evaluation of Green Propellants for Space Applications, DLR-IB 647-2004/03; SART TN-003/2004. 2004. Available online: https://elib.dlr.de/1716/1/SART-TN3-2004.pdf (accessed on 31 July 2025).

- Nosseir, A.E.S.; Cervone, A.; Pasini, A. Modular Impulsive Green Monopropellant Propulsion System (MIMPS-G): For CubeSats in LEO and to the Moon. Aerospace 2021, 8, 169. [Google Scholar] [CrossRef]

- Galfetti, L. Overall Analysis of Hydrogen, Kerosene and Methane in LRE Technology. Master’s Thesis, Scuola di Ingegneria Industriale e dell’Informazione, L’Aquila, Italy, 2021. [Google Scholar]

- Alnaqbi, S.; Darfilal, D.; Swei, S. Propulsion Technologies for CubeSats: Review. Aerospace 2024, 11, 502. [Google Scholar] [CrossRef]

- Leomanni, M.; Garulli, A.; Giannitrapani, A.; Scortecci, F. Propulsion options for very low Earth orbit microsatellites. Acta Astronaut. 2017, 133, 444–454. [Google Scholar] [CrossRef]

- NASA. In-Space Propulsion Overview—Small Satellite Institute. Available online: https://www.nasa.gov/smallsat-institute/sst-soa/in-space_propulsion (accessed on 25 June 2025).

- Haidn, O. Advanced rocket engines. In Advances on Propulsion Technology for High-Speed Aircraft; Von Kármán Institute for Fluid Dynamics (VKI): Sint-Genesius-Rode, Belgium, 2015; pp. 6-1–6-40. [Google Scholar]

- Tomsik, T.M. Performance Tests of a Liquid Hydrogen Propellant Densification Ground System for the X33/RLV. NASA Technical Memorandum 107469, AIAA–97–2976. In Proceedings of the 33rd Joint Propulsion Conference & Exhibit, Seattle, WA, USA, 6–9 July 1997. [Google Scholar]

- Hernandez, I.; Orozco, S.; Hossain, M.A.; Choudhuri, A. Thermal Performance Analysis of LOX/LCH4 Engine Feed Systems Using CFD Modeling. Fluids 2025, 10, 62. [Google Scholar] [CrossRef]

- Soller, S.; Maeding, C.; Rackemann, N. Characterisation of a LOX–LCH4 Gas Generator. In Proceedings of the Space Propulsion Conference 2014, Cologne, Germany, 19–22 May 2014. [Google Scholar]

- Asakawa, H.; Nanri, H.; Aoki, K.; Kubota, I.; Mori, H.; Ishikawa, Y.; Kimoto, K.; Ishihara, S. The Status of the Research and Development of LNG Rocket Engines in Japan. In Chemical Rocket Propulsion; Springer: Cham, Switzerland, 2016; pp. 463–487. [Google Scholar]

- Morehart, J. A Survey of LNG-Fueled Rocket Engine Development Activity—Non U.S. In Proceedings of the AIAA Propulsion and Energy 2021 Forum, Virtual Event, 9–11 August 2021. AIAA 2021-3581. [Google Scholar] [CrossRef]

- Vega M10 Engine Test Success Marks Key Step toward Vega-E. European Space Agency (ESA). Available online: https://www.esa.int/Enabling_Support/Space_Transportation/Vega/M10_engine_test_success_marks_key_step_toward_Vega-E (accessed on 26 June 2025).

- NASA. Space Launch System Overview. Available online: https://www.nasa.gov/reference/space-launch-system/ (accessed on 15 July 2025).

- NASA Office of Inspector General. NASA’s Management of the Space Launch System Booster and Engine Contracts; NASA: Washington, DC, USA, 2023; Report No. IG-23-015.

- NASA. The Space Shuttle Reference. Available online: https://www.nasa.gov/reference/the-space-shuttle/ (accessed on 26 June 2025).

- SpaceX. Starship Launch Vehicle Overview. Available online: https://www.spacex.com/vehicles/starship/ (accessed on 17 July 2025).

- SpaceX. Falcon Heavy Overview. Available online: https://www.spacex.com/vehicles/falcon-heavy (accessed on 12 September 2025).

- Reliability Assessment Using Physics-of-Failure Principles, Modeling and Simulation. Available online: https://sma.nasa.gov/news/articles/newsitem/2017/05/22/reliability-assessment-using-physics-of-failure-principles-modeling-and-simulation (accessed on 1 September 2025).

- Lindsey, N.J.; Dawsona, J.; Sheldonb, D.; Sindjui, L.-N.; DiVenti, A. NASA Physics of Failure (PoF) for Reliability, 370-Cross-Cutting-PAP-0004. In Proceedings of the Probabilistic Safety Assessment and Management PSAM 16, Honolulu, HI, USA, 26 June–1 July 2022; Available online: https://www.iapsam.org/PSAM16/papers/NA280-PSAM16.pdf (accessed on 18 July 2025).

- Kerstens, F.; Cervone, A.; Gradl, P. End to End Process Evaluation for Additively Manufactured Liquid Rocket Engine Thrust Chambers. Acta Astronaut. 2021, 182, 454–465. [Google Scholar] [CrossRef]

- ScienceDirect. Directed Energy Deposition—Materials Science Topics. Available online: https://www.sciencedirect.com/topics/materials-science/directed-energy-deposition (accessed on 18 July 2025).

- Gradl, P.R.; Protz, C.S.; Greene, S.E.; Stanley, C.C.; Laub, B.; Whitmore, M. Additive Manufacturing and Hot-Fire Testing of Bimetallic GRCop-84 and C-18150 Channel-Cooled Combustion Chambers Using Powder Bed Fusion and Inconel 625 Hybrid Directed Energy Deposition. In Proceedings of the 55th AIAA/SAE/ASEE Joint Propulsion Conference, Indianapolis, IN, USA, 19–22 August 2019; Available online: https://ntrs.nasa.gov/api/citations/20190030435/downloads/20190030435.pdf (accessed on 12 August 2025).

- Air Force Research Laboratory (AFRL). AFRL Researchers 3D Print and Test Rocket Engine Thrust Chamber. Air Force Tech Connect. 2024. Available online: https://airforcetechconnect.org/news/afrl-researchers-3d-print-and-test-rocket-engine-thrust-chamber (accessed on 4 August 2025).

- Launcher Inc. Launcher’s Additively Manufactured E-2 Rocket Engine Successfully Tested at NASA Stennis Space Center. Metal Additive Manufacturing. 2022. Available online: https://www.metal-am.com/launchers-additively-manufactured-e-2-rocket-engine-successfully-tested-at-nasa-stennis-space-center (accessed on 4 August 2025).

- 3D-Printed Storable-Propellant Rocket Engine Design Tested. European Space Agency (ESA). Available online: https://www.esa.int/Enabling_Support/Space_Transportation/3D-printed_storable-propellant_rocket_engine_design_tested (accessed on 18 July 2025).

- ArianeGroup Successfully Tests First Combustion Chamber Produced Entirely by 3D Printing. ArianeGroup. Available online: https://ariane.group/en/news/arianegroup-successfully-tests-first-combustion-chamber-produced-entirely-by-3d-printing/ (accessed on 18 July 2025).

- Bee, A.; Cruz, T.; Crachi, M.; Strixner, M.; Armbruster, W.; Börner, M.; Hardi, J.; Mabboux, R.; Vinet, P.; Reichstadt, S. Design, Development and Testing of the Injector for a 3D-Printed Throttleable and Reusable LOX/Methane Rocket Engine. In Proceedings of the 9th Edition of the 3AF International Conference on Space Propulsion, Glasgow, Scotland, 20–23 May 2024. [Google Scholar]

- Peichl, J.; Munk, J.; Selzer, M. Development and Characterization of Additively Manufactured Metallic Porous Structures for Transpiration Cooling Applications. In Proceedings of the 11th European Conference for Aeronautics and Aerospace Sciences (EUCASS), Rome, Italy, 3–4 July 2025. [Google Scholar]

- Sòphia High Tech. MPGE Engine: Success on Firing Test. Sòphia High Tech News & Events. Available online: https://www.sophiahightech.com/mpge-firingtest/ (accessed on 18 July 2025).

- Natale, P.; Saccone, G.; Battista, F. CFD Kinetic Scheme Validation for Liquid Rocket Engine Fuelled by Oxygen/Methane. In Proceedings of the 8th European Conference for Aeronautics and Space Sciences (EUCASS), Madrid, Spain, 1–4 July 2019; CIRA S.C.P.A.: Capua, Italy, 2019. Available online: https://www.researchgate.net/publication/334812121_CFD_KINETIC_SCHEME_VALIDATION_FOR_LIQUID_ROCKET_ENGINE_FUELLED_BY_OXYGENMETHANE (accessed on 4 August 2025).

- Aliberti, M.; Tugnoli, M. The European Launchers Between Commerce and Geopolitics; ESPI Report 56; European Space Policy Institute: Vienna, Austria, 2016; Available online: https://www.espi.or.at/wp-content/uploads/espidocs/Public%20ESPI%20Reports/Rep56_online_160321-2142.pdf (accessed on 4 August 2025).

- The Engines of Ariane 6. European Space Agency (ESA). Available online: https://www.esa.int/Enabling_Support/Space_Transportation/Ariane/The_engines_of_Ariane_6 (accessed on 15 July 2025).

- Propulsion Systems for Launchers. ArianeGroup. Available online: https://ariane.group/en/equipment-services/for-launchers/propulsion-systems-for-launchers/ (accessed on 16 July 2025).

- Prometheus Project. Centre National d’Études Spatiales (CNES). Available online: https://cnes.fr/en/projects/prometheus (accessed on 16 July 2025).

- Signing Secures Next Steps for Reusable Rocket Demonstrations. ESA. Available online: https://www.esa.int/Enabling_Support/Space_Transportation/Future_space_transportation/Signing_secures_next_steps_for_reusable_rocket_demonstrations (accessed on 15 July 2025).

- ASTER Family—Area Protection. MBDA Systems. Available online: https://www.mbda-systems.com/products/area-protection/aster-family (accessed on 16 July 2025).

- ASTER Product Datasheet. MBDA Systems. 2018. Available online: https://www.mbda-systems.com/sites/mbda/files/2024-06/2018%20ASTER%20datasheet.pdf (accessed on 16 July 2025).

- Storm Shadow/SCALP—Deep Strike Weapon. MBDA Systems. Available online: https://www.mbda-systems.com/products/deep-strike/storm-shadow-scalp (accessed on 16 July 2025).

- M51 Missile. Missile Threat, Center for Strategic and International Studies. Available online: https://missilethreat.csis.org/missile/m51/ (accessed on 16 July 2025).

- Council Regulation (EC) No 428/2009. Official Journal of the European Union. Available online: https://eur-lex.europa.eu/eli/reg/2009/428/oj/eng (accessed on 22 July 2025).

- Council Common Position 2008/944/CFSP. Official Journal of the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32008E0944 (accessed on 23 July 2025).

- Arms Control and Disarmament. North Atlantic Treaty Organization (NATO). Available online: https://www.nato.int/cps/en/natohq/topics_88745.htm (accessed on 23 July 2025).

- Cooperative Cyber Defence Centre of Excellence. NATO CCDCOE. Available online: https://ccdcoe.org/ (accessed on 22 July 2025).

- Missile Technology Control Regime (MTCR). Available online: https://www.mtcr.info/en (accessed on 23 July 2025).

- MTCR Frequently Asked Questions. U.S. Department of State. Available online: https://www.state.gov/bureau-of-international-security-and-nonproliferation/releases/2025/01/missile-technology-control-regime-mtcr-frequently-asked-questions (accessed on 23 July 2025).

- The Wassenaar Arrangement. Available online: https://www.wassenaar.org/ (accessed on 22 July 2025).

- Export Control. Federal Office for Economic Affairs and Export Control (BAFA), Germany. Available online: https://www.bafa.de/EN/Foreign_Trade/Export_Control/export_control_node.html (accessed on 22 July 2025).

- Direction Générale de l’Armement (DGA). French Ministry of the Armed Forces. Available online: https://www.defense.gouv.fr/dga (accessed on 22 July 2025).

| Program | Technical Characteristics | Shortcomings in Reusable Technology | Green Propulsion Solutions | Cost Engine Development | Historical Significance |

|---|---|---|---|---|---|

| Russia and the Former Soviet Union | |||||

| Soyuz (R-7) | LOX + RP-1, highly reliable, stage-and-a-half derived from R-7 ICBM. | Fully expendable; no recovery systems. | LOX/RP-1 cleaner than hypergols, but kerosene produces soot. | RD-107/108 engines mass-produced, keeping costs low. | Longest-serving orbital launcher; launched Sputnik 1 and all ISS crew missions until Crew Dragon. |

| Dnepr (R-36M/SS-18) | Converted ICBM; 4.5 t to LEO; first stage UDMH/N2O4, upper stage RP-1/LOX. | No reusability; toxic hypergols. | Requires full replacement with LOX/methane or LOX/LH2. | Conversion reduced costs but no new tech. | Symbol of missile-to-commercial repurposing; multi-satellite launches. |

| Rokot (UR-100N/SS-19) | 2 t to LEO; UDMH/N2O4 first two stages; Breeze-KM upper stage with restart. | Expendable; toxic hypergols. | Would need methane-based redesign. | Low cost (~$15 M) from stockpile conversion. | Affordable smallsat launcher during 1990s–2000s. |

| Zenit (R-27 heritage) | Medium-heavy lift, LOX + RP-1, modular RD-170 engine family. | Expendable only. | Cleaner than hypergols but kerosene still polluting. | Modular, cost-efficient RD-170 engines. | Basis for Energia boosters, Sea Launch. |

| Proton (UR-500) | Heavy-lift to GEO, LOX + RP-1 first stage, hypergolic upper stages. | Toxic hypergols; no reuse. | Needs full LOX/methane or LOX/LH2 transition. | Robust but costly hypergolic engines. | Soviet heavy-lift backbone; GEO sats, ISS modules, interplanetary probes. |

| USA | |||||

| Minotaur (Minuteman/Peacekeeper) | Retired ICBM stages + commercial upper stages; 0.6–1.7 t LEO. | Expendable; solid propellants not reusable. | Solid propellants environmentally harmful; hybrids or LOX/methane better. | Very low cost from missile stockpiles. | Enabled low-cost smallsat launches for U.S. gov. |

| AJ10 Engine Family | From nitric acid/UDMH to MMH/N2O4. Variants powered Vanguard, Apollo SPS, Shuttle OMS. Restartable, reliable. | Hypergols toxic; reusable only on Shuttle OMS with high maintenance. | Replacement by LOX/methane or LH2 needed. | Long lifecycle lowered costs via reuse of design. | One of longest-serving rocket engines; powered Apollo lunar return. |

| Thor (Delta) | Thor IRBM adapted; LOX + RP-1, incremental upgrades. | Fully expendable. | Kerosene moderately polluting; methane future option. | Incremental upgrades kept cost low. | Foundation of Delta family; NASA’s early satellites. |

| Atlas (SM-65) | Stage-and-a-half LOX + RP-1; later Agena/Centaur upper stages. | No reusability; needed redesign for longer burns. | LOX/RP-1 clean vs. hypergols; methane upgrade possible. | Incremental upgrades reduced costs. | First American orbital astronaut (John Glenn, 1962); GPS and planetary probes. |

| Titan II/III/IV | Titan II: hypergols; Titan III/IV added solid boosters. | Hypergols toxic; no reuse. | Future cryogenics or methane needed. | Reused ICBM cores kept costs lower. | Carried Gemini astronauts, defense payloads, planetary probes. |

| Centaur | First cryogenic upper stage; LOX + LH2 RL10 engines. | Expendable; complex cryogenics. | Already green (water exhaust). | High cost due to precision RL10 engines. | Pioneered cryogenics; enabled Surveyor, planetary missions. |

| Asia | |||||

| CZ-1 (DF-3 based) | First SLV (1970). Two DF-3 stages + solid third stage. | Fully expendable. | Early use of polluting propellants. | Conversion kept costs down. | Launched China’s first satellite. |

| CZ-2/3/4 (DF-5 based) | 2.5 t LEO; crewed and satellite launches; later CZ-3B to GEO. | No reusability; early failures. | Still uses UDMH/N2O4 in many stages. | Incremental upgrades = low R&D cost. | Established China’s orbital presence; Shenzhou, satellites. |

| Long March 5/7/8 | New LOX/LH2 and LOX/methane designs; LM-8 reusable 1st stage in dev. | Reusability in progress. | Green cryogenics (LOX/LH2, LOX/CH4). | YF-100, YF-77 advanced engines, costly to develop. | China’s heavy-lift, reusable future. |

| PSLV (Agni-II tech + Viking engine heritage) | Derived from Agni-II solid motors + Vikas (Viking). Precise, reliable 4-stage. | Expendable. | Uses solids + hypergols; methane alternatives under study. | Low cost (~$15–20 M) from missile/foreign engine synergy. | Workhorse of ISRO; Chandrayaan, Mangalyaan. |

| Unha (Taepodong) | Taepodong-derived; UDMH/N2O4 first stage, RP-1/LOX upper. | No reusability. | Hypergols toxic; only partial shift to kerosene/LOX. | Adapted from missile stockpiles. | Symbolic orbital access; strategic display. |

| Europe | |||||

| Aestus (Ariane 5 upper stage) | Ariane 5 hypergolic upper stage (MMH/N2O4). | Expendable; toxic hypergols. | Future replacement with methane/LOX. | Simple design reduced cost. | Supported reliable Ariane 5 orbits. |

| Viking (Ariane 1–4 main stage) | Ariane 1–4 hypergolic stages. | Toxic, expendable. | Basis for future methane engines. | Scaled production reduced costs. | Established Europe’s launcher autonomy. |

| Prometheus (ESA/ArianeGroup) | LOX–methane reusable engine (1000 kN). 3D-printed. | Still in development. | Clean methane–oxygen. | Designed to be 10× cheaper than Vulcain. | Europe’s move toward reusability and sustainability. |

| CALLISTO (CNES–DLR–JAXA) | VTVL demo with LOX–LH2. Reusable first-stage recovery. | First flight planned 2026. | Cryogenic = green. | Aims at reusability to lower costs. | European Falcon 9–style demo. |

| MIRA (Avio–Isayev) | LOX–CH4 upper-stage demo; additive manufacturing. | Cancelled, no ops reuse. | Methane = green. | Additive manufacturing lowered cost. | Tech success; legacy in Vega E, MR-10. |

| HYPROB (CIRA, Italy) | Italian LOX–CH4 and hybrid propulsion program; demo engines 10–30 kN. | Still experimental | Green propulsion explicit focus | Uses AM for cost efficiency | Builds Europe’s hydrocarbon propulsion expertise. |

| Oxidizer | Fuel | Propellant Type | Isp (Vacuum) | Isp (Sea Level) | O/F Ratio | Fuel Density (kg/m3) | Toxicity/Environmental Impact |

|---|---|---|---|---|---|---|---|

| LOX | LH2 | Cryogenic | ~450 s | ~380 s | ~6:1 | ~71 | Clean (water vapor only) |

| LOX | LCH4 | Cryogenic | ~370 s | ~320 s | ~3.5:1 | ~420 | Cleaner than RP-1, some CO2 |

| LOX | RP-1 (Kerosene) | Semi-cryogenic | ~330 s | ~295 s | ~2.7:1 | ~820 | CO2 and soot production |

| N2O4 | UDMH/MMH | Hypergolic | ~320 s | ~285 s | ~2.0:1 | ~793 | Highly toxic, carcinogenic |

| MON-3 | MMH | Hypergolic | ~315 s | ~280 s | ~1.9:1 | ~880 | Toxic, used in spacecraft propulsion |

| HAN (AF-M315E) | Ionic Liquid | Green monopropellant | ~255–265 s | - | - | ~1350 | Low toxicity, safer handling |

| ADN (LMP-103S) | Ionic Liquid | Green monopropellant | ~265–270 s | - | - | ~1450 | Low toxicity, low environmental impact |

| H2O2 (90%+) | RP-1 or Alcohol | Green (if highly pure) | ~250–300 s | ~200–260 s | ~7:1 (varies) | ~800 (RP-1) | Biodegradable, low-toxicity in dilute form |

| Aspect | Missile Engine Conversion | Ground-Up Development (Cryogenic Space Propulsion) |

|---|---|---|

| Initial Cost | Lower (leverage existing technology) | Higher (full design, materials, R&D) |

| Time to Develop | ~Shorter (3–6 years) | Longer (5–10 years) |

| Testing and Validation | Extensive (cryogenic testing, safety, reliability) | Extensive (cryogenic conditions, space-specific testing) |

| Performance | Medium (limited by missile design, not optimized for space) | High (fully optimized for space conditions, Isp, efficiency) |

| Technological Risk | Medium to High (unproven adaptation) | High (new systems and technologies) |

| Reliability | Medium (dependent on successful conversion) | High (designed for space missions) |

| Mission Suitability | Limited (best for smaller, short-duration missions) | High (optimized for long-term space missions) |

| Long-Term Sustainability | Medium (limited by aging missile tech) | High (designed for space with long operational life) |

| Subsystem | Expected Modification Level | Notes |

|---|---|---|

| Feed system (tanks, pressurization, lines, valves) | Minor to moderate adaptation | Material compatibility checks; sizing/pressure-drop verification. |

| Turbo-pump unit | Testing first; redesign only if required | Differences in propellant density/viscosity may necessitate re-tuning or partial redesign, to be confirmed experimentally. |

| Gas generator | Testing first; redesign only if required | New injectors may be needed; chamber volume and stability to be assessed in test campaigns. |

| Combustion chamber | Moderate adaptation | Injector and cooling approaches may need updating for cryogenics. |

| Ignition system | New concept required | Hypergolic start cannot be retained; alternative ignition to be introduced. |

| Aspect | Missile Engine Conversion | Ground-Up Development (Cryogenic Space Propulsion) |

|---|---|---|

| Initial Cost | Lower (leverage existing technology) | Higher (full design, materials, R&D) |

| Time to Develop | ~Shorter (3–6 years) | Longer (5–10 years) |

| Testing and Validation | Extensive (cryogenic testing, safety, reliability) | Extensive (cryogenic conditions, space-specific testing) |

| Performance | Medium (limited by missile design, not optimized for space) | High (fully optimized for space conditions, Isp, efficiency) |

| Technological Risk | Medium to High (unproven adaptation) | High (new systems and technologies) |

| Reliability | Medium (dependent on successful conversion) | High (designed for space missions) |

| Mission Suitability | Limited (best for smaller, short-duration missions) | High (optimized for long-term space missions) |

| Long-Term Sustainability | Medium (limited by aging missile tech) | High (designed for space with long operational life) |

| System | Missile Purpose | Space Purpose |

|---|---|---|

| Cryogenic engines | High-thrust launch of warheads | High-impulse space launch |

| Guidance control | Target acquisition | Precise orbital insertion |

| Airframe and structure | Reentry durability | Payload fairing for satellites |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prisăcariu, E.-G.; Dumitrescu, O.; Battista, F.; Maligno, A.; Munk, J.; Ricci, D.; Haubrich, J.; Cardillo, D. The Technical Hypothesis of a Missile Engine Conversion and Upgrade for More Sustainable Orbital Deployments. Aerospace 2025, 12, 833. https://doi.org/10.3390/aerospace12090833

Prisăcariu E-G, Dumitrescu O, Battista F, Maligno A, Munk J, Ricci D, Haubrich J, Cardillo D. The Technical Hypothesis of a Missile Engine Conversion and Upgrade for More Sustainable Orbital Deployments. Aerospace. 2025; 12(9):833. https://doi.org/10.3390/aerospace12090833

Chicago/Turabian StylePrisăcariu, Emilia-Georgiana, Oana Dumitrescu, Francesco Battista, Angelo Maligno, Juri Munk, Daniele Ricci, Jan Haubrich, and Daniele Cardillo. 2025. "The Technical Hypothesis of a Missile Engine Conversion and Upgrade for More Sustainable Orbital Deployments" Aerospace 12, no. 9: 833. https://doi.org/10.3390/aerospace12090833

APA StylePrisăcariu, E.-G., Dumitrescu, O., Battista, F., Maligno, A., Munk, J., Ricci, D., Haubrich, J., & Cardillo, D. (2025). The Technical Hypothesis of a Missile Engine Conversion and Upgrade for More Sustainable Orbital Deployments. Aerospace, 12(9), 833. https://doi.org/10.3390/aerospace12090833