Failure Analysis of Composite Curved Beam with Initial Delamination Damage

Abstract

1. Introduction

2. Numerical Modeling of Curved Beams

2.1. Progressive Damage Model

2.1.1. Damage Initiation

2.1.2. Damage Evolution

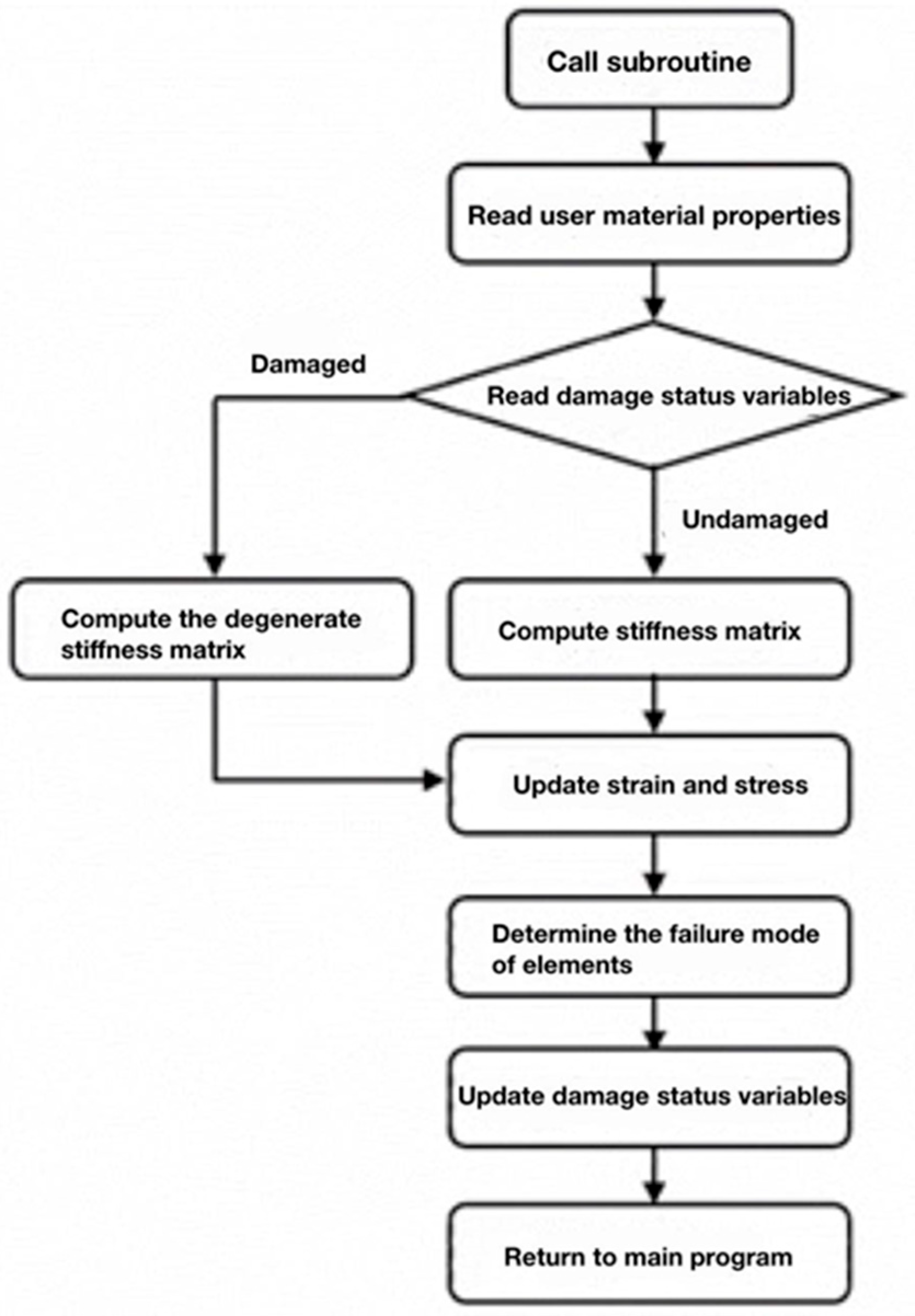

2.1.3. Numerical Implementation of Hashin Damage Model

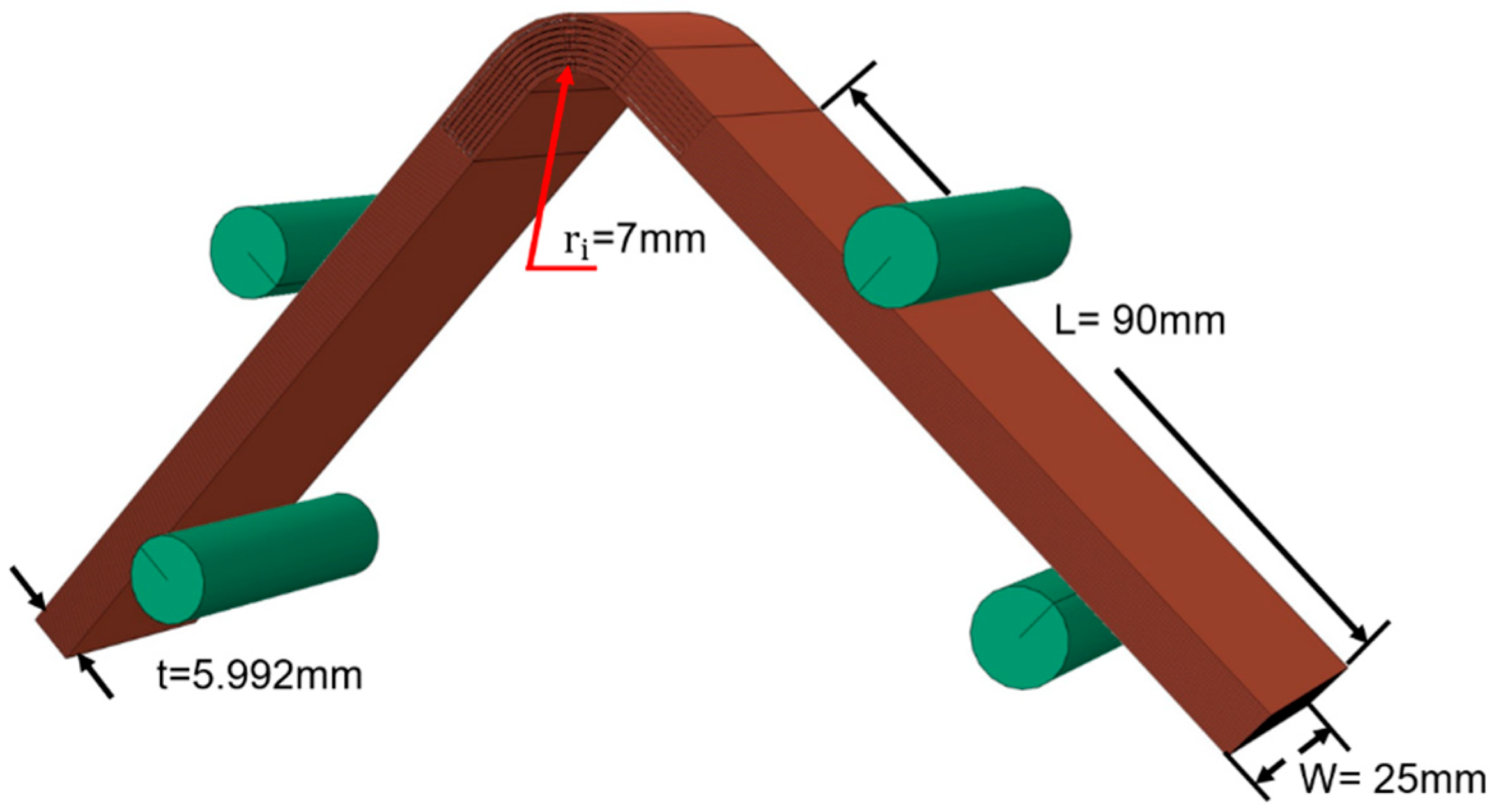

2.2. FE Modeling

- Model the composite curved beams using solid elements.

- Use the “Mesh Editing Tools—Offset Solid Layer” command to create a solid layer with a thickness of 0.01 mm.

- Remove partial elements to simulate pre-delamination zones.

3. Results and Discussion

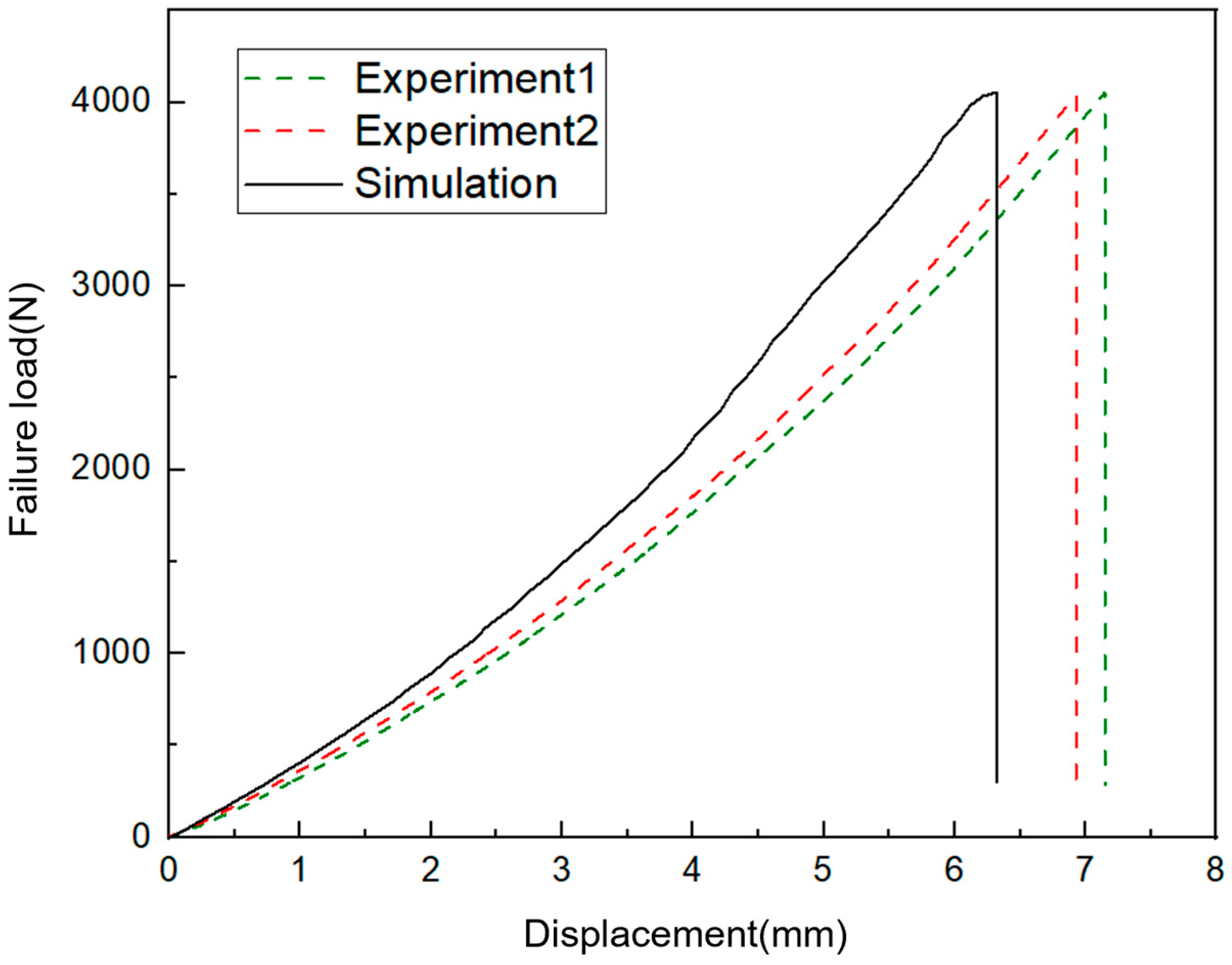

3.1. Validation of the FEM Model

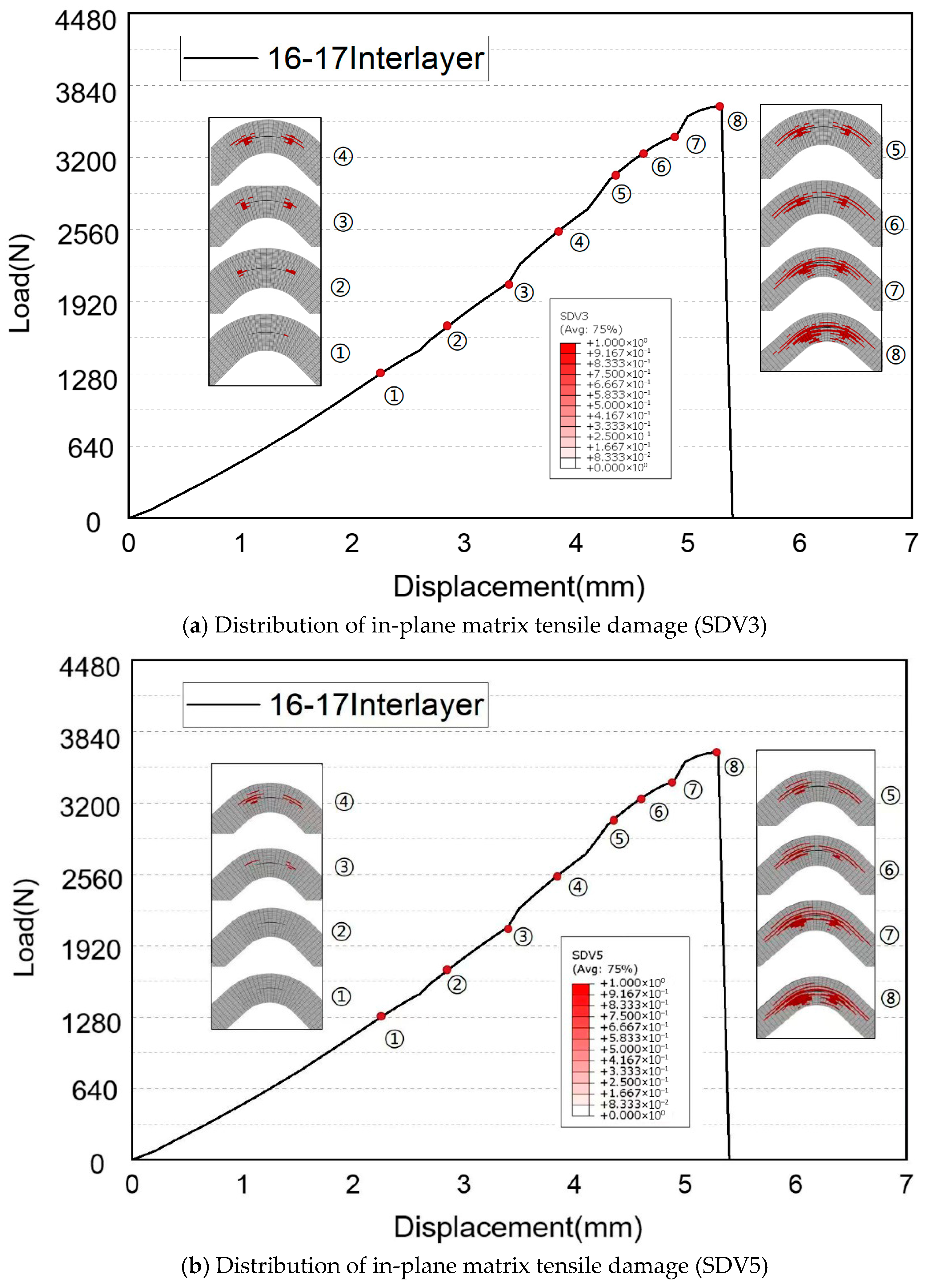

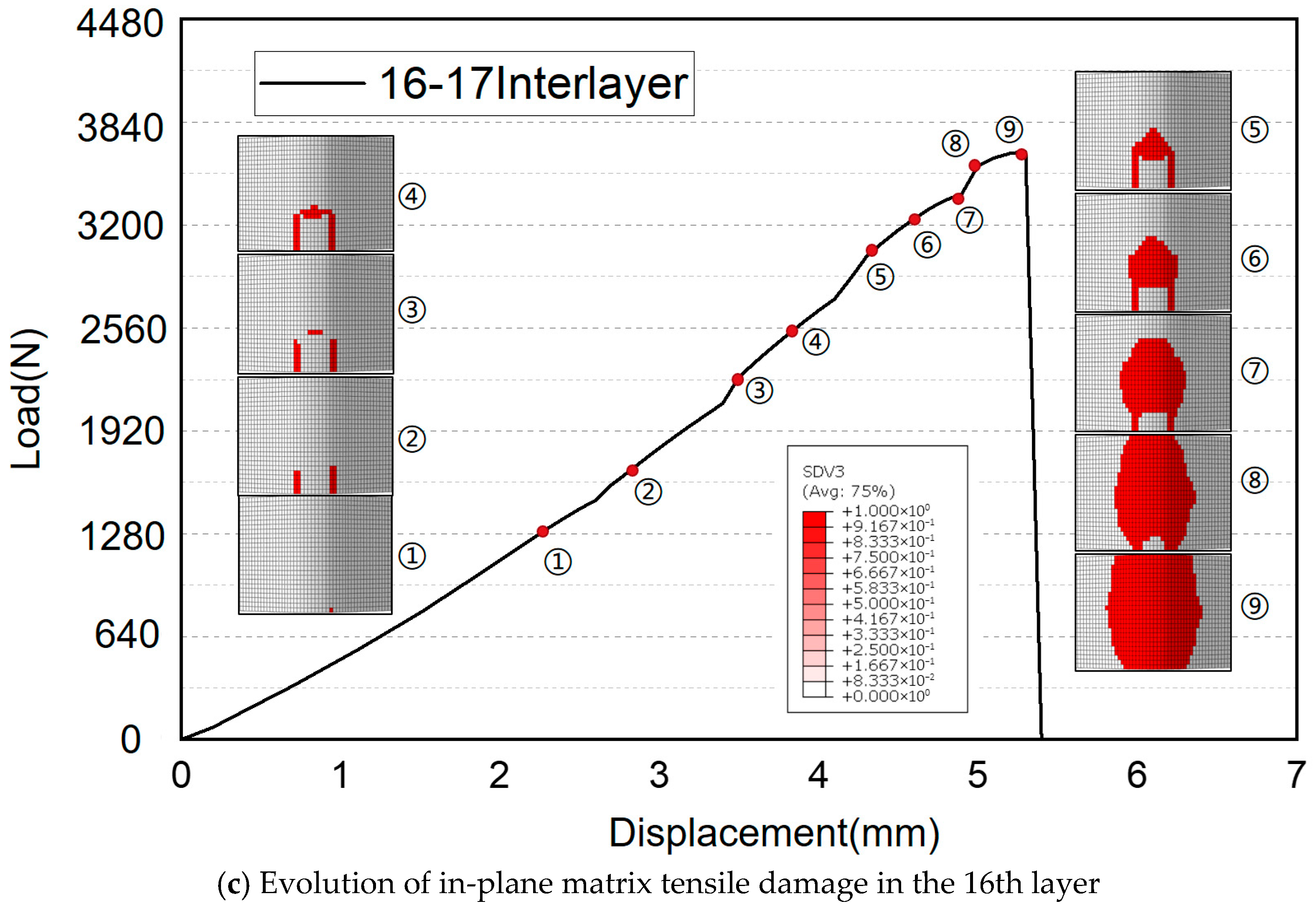

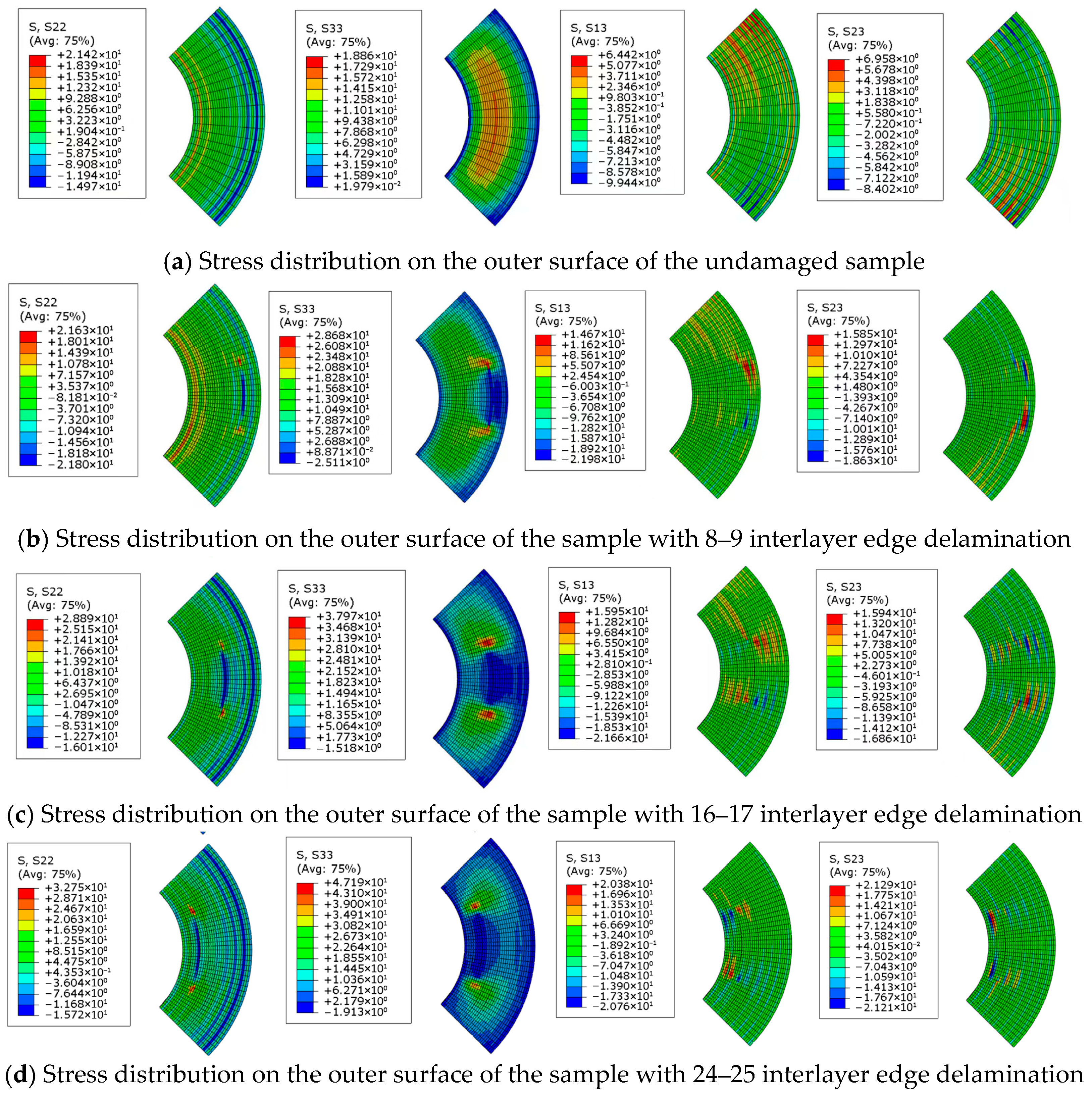

3.2. Simulation of Curved Beams with Initial Delamination Damage

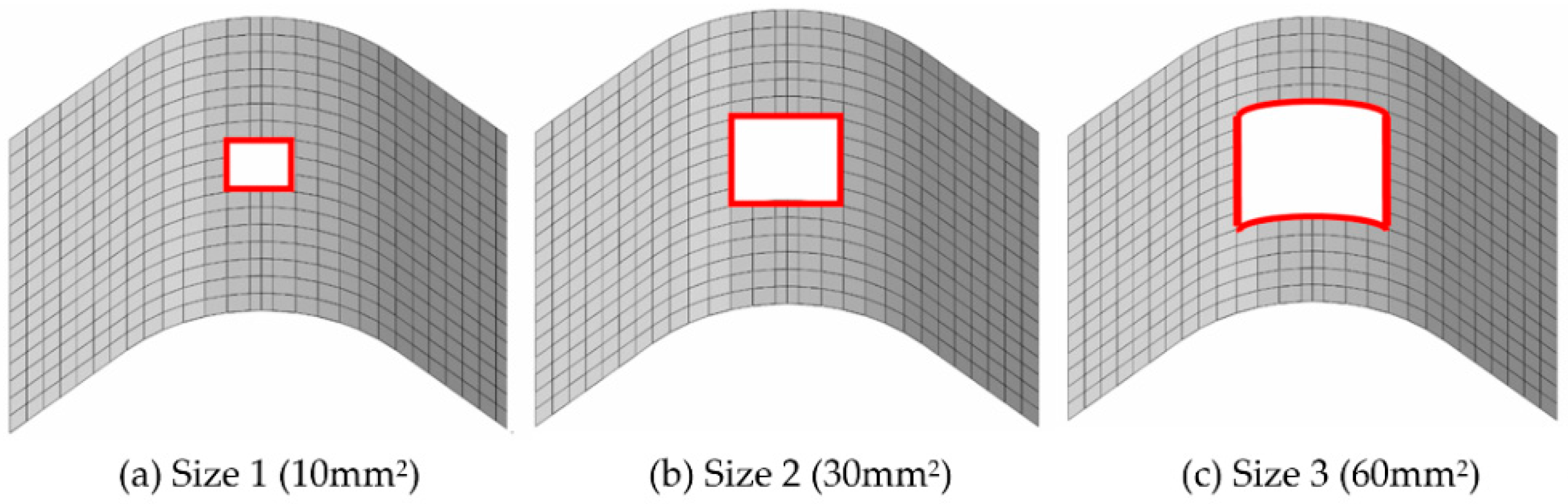

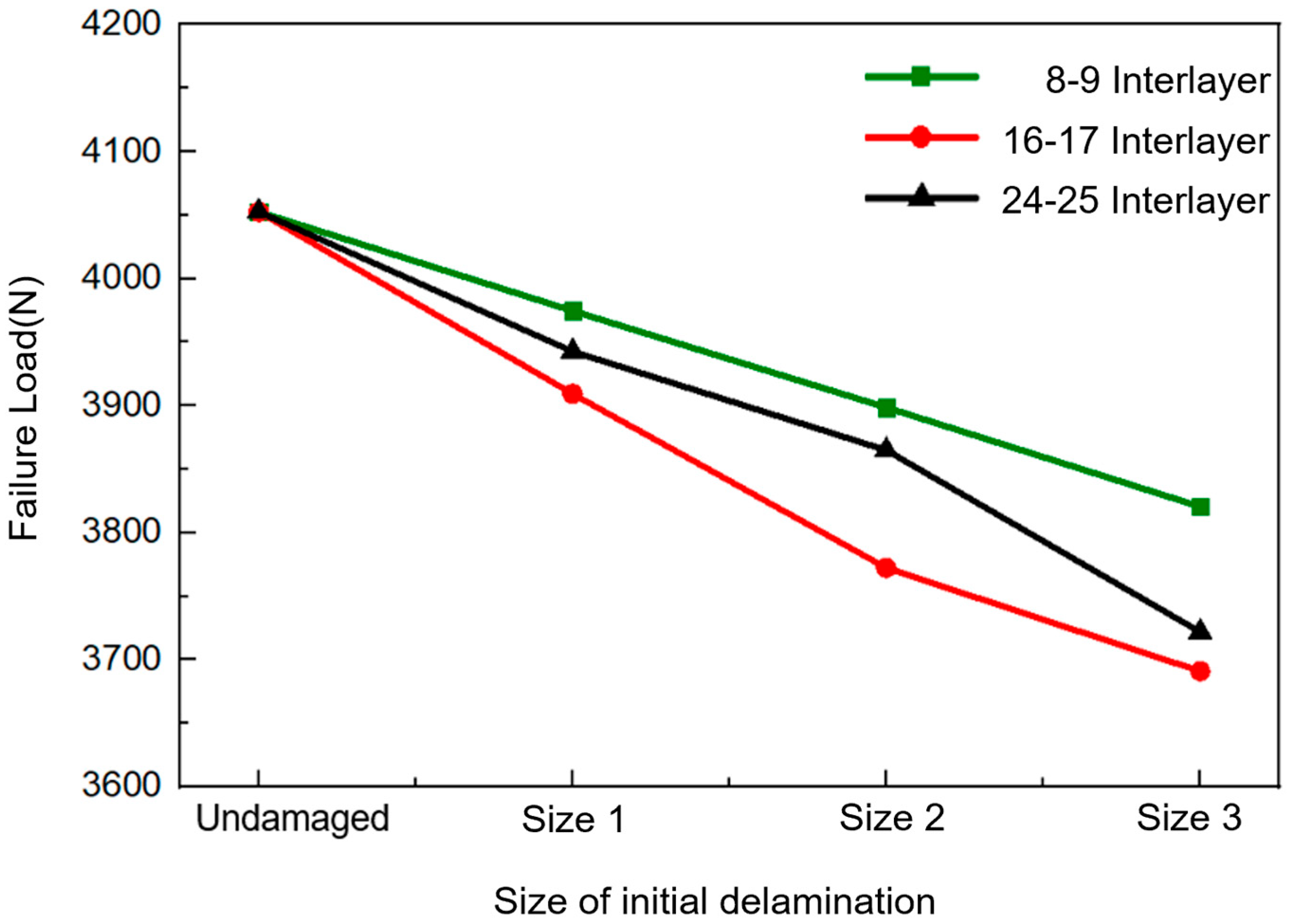

3.2.1. Influence of In-Plane Delamination Size

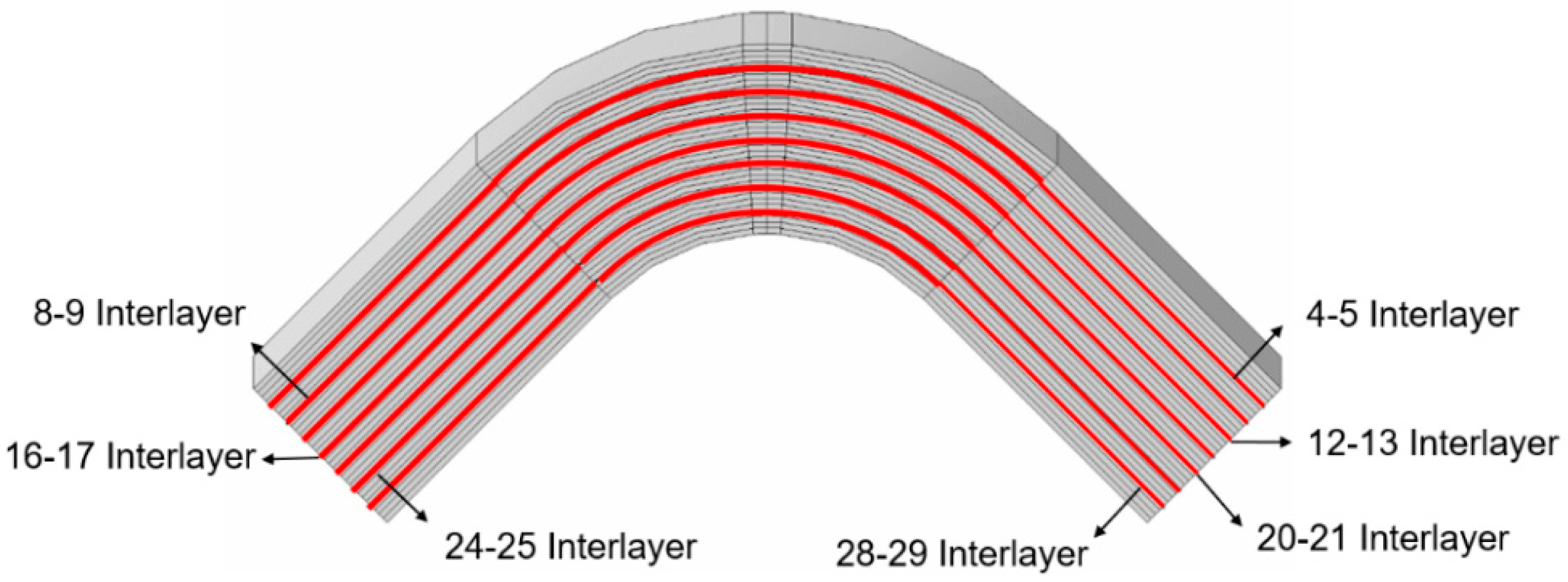

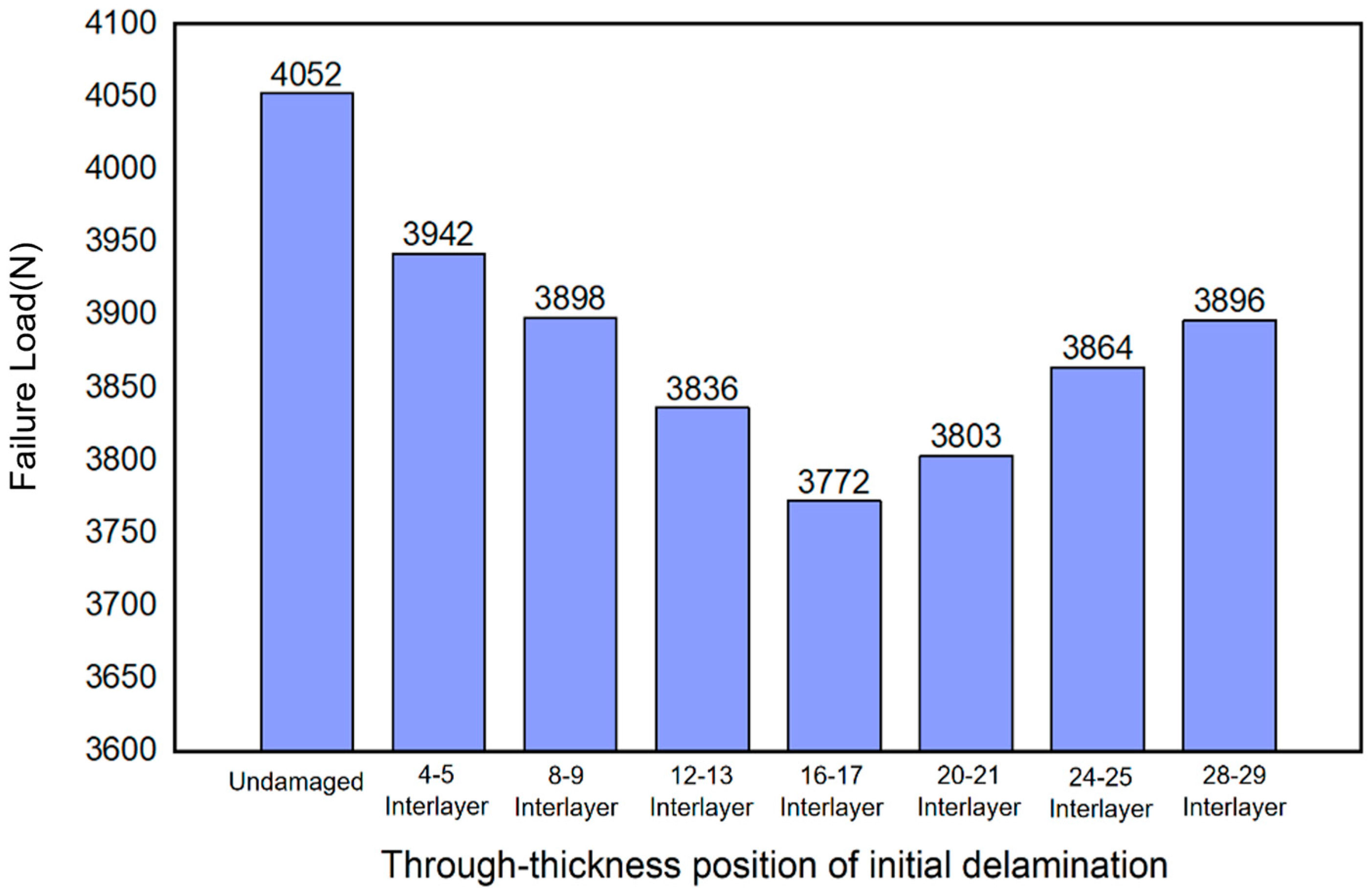

3.2.2. Different Through-Thickness Position of the Initial Delamination

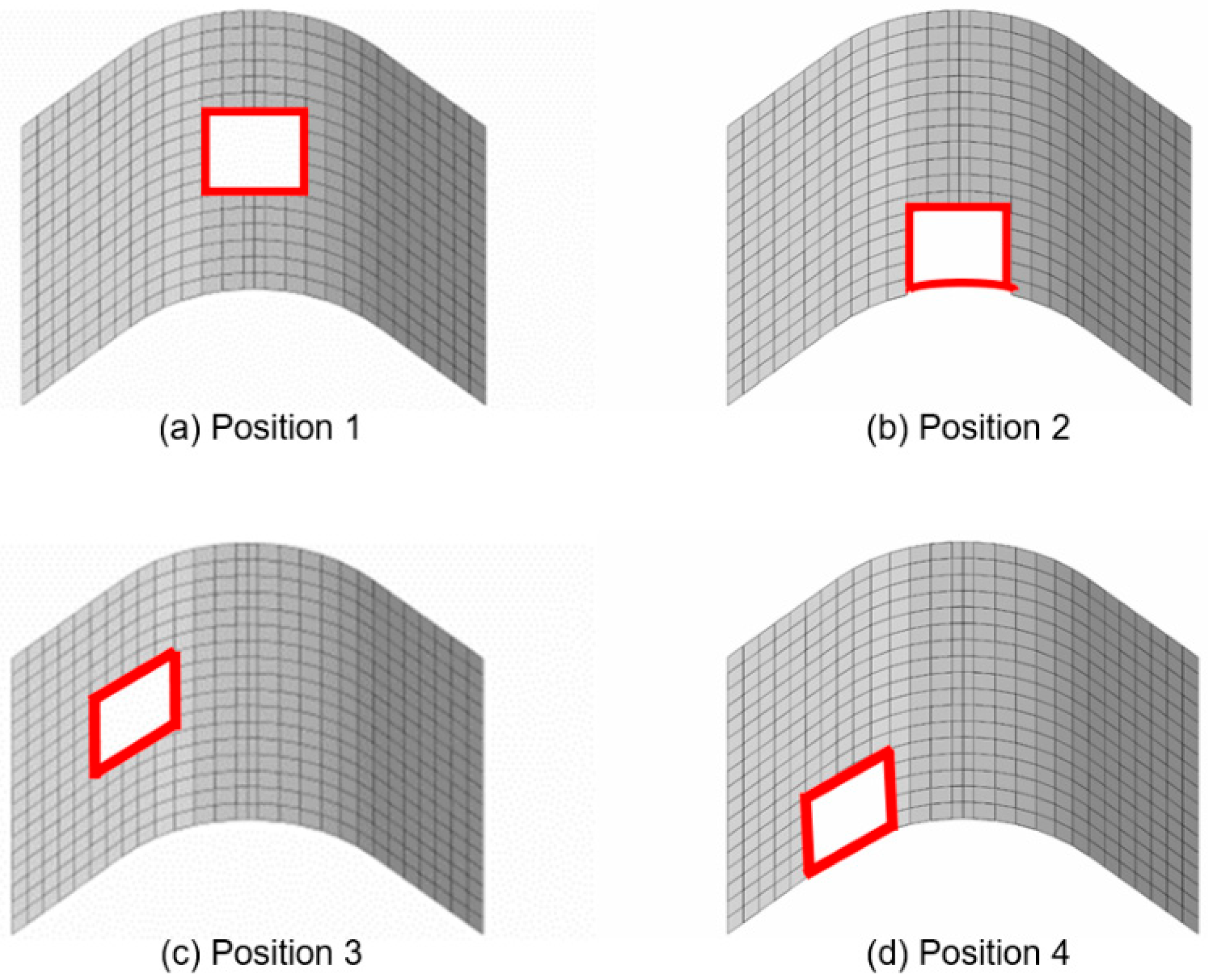

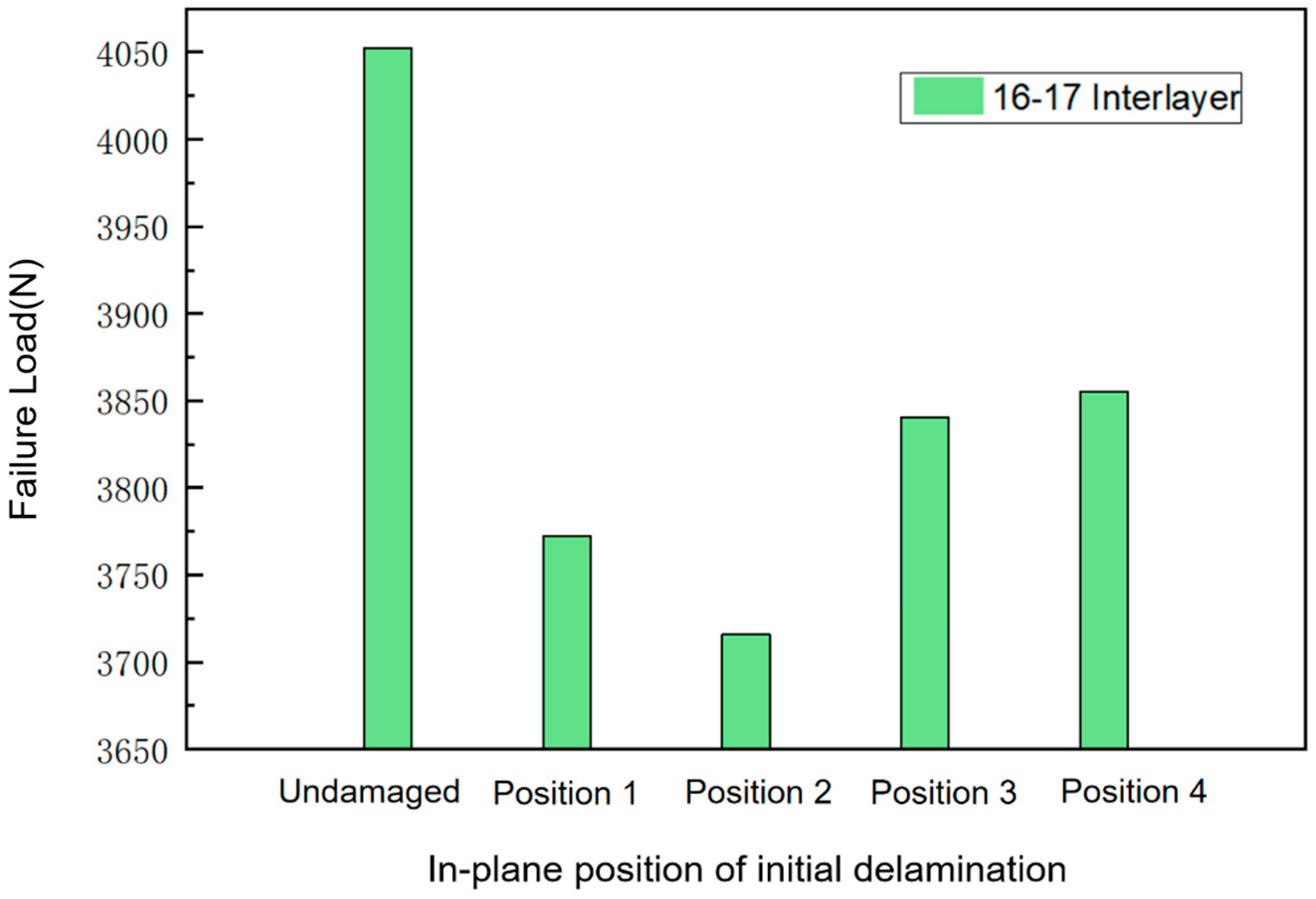

3.2.3. Different In-Plane Position of the Initial Delamination

4. Conclusions

- (a)

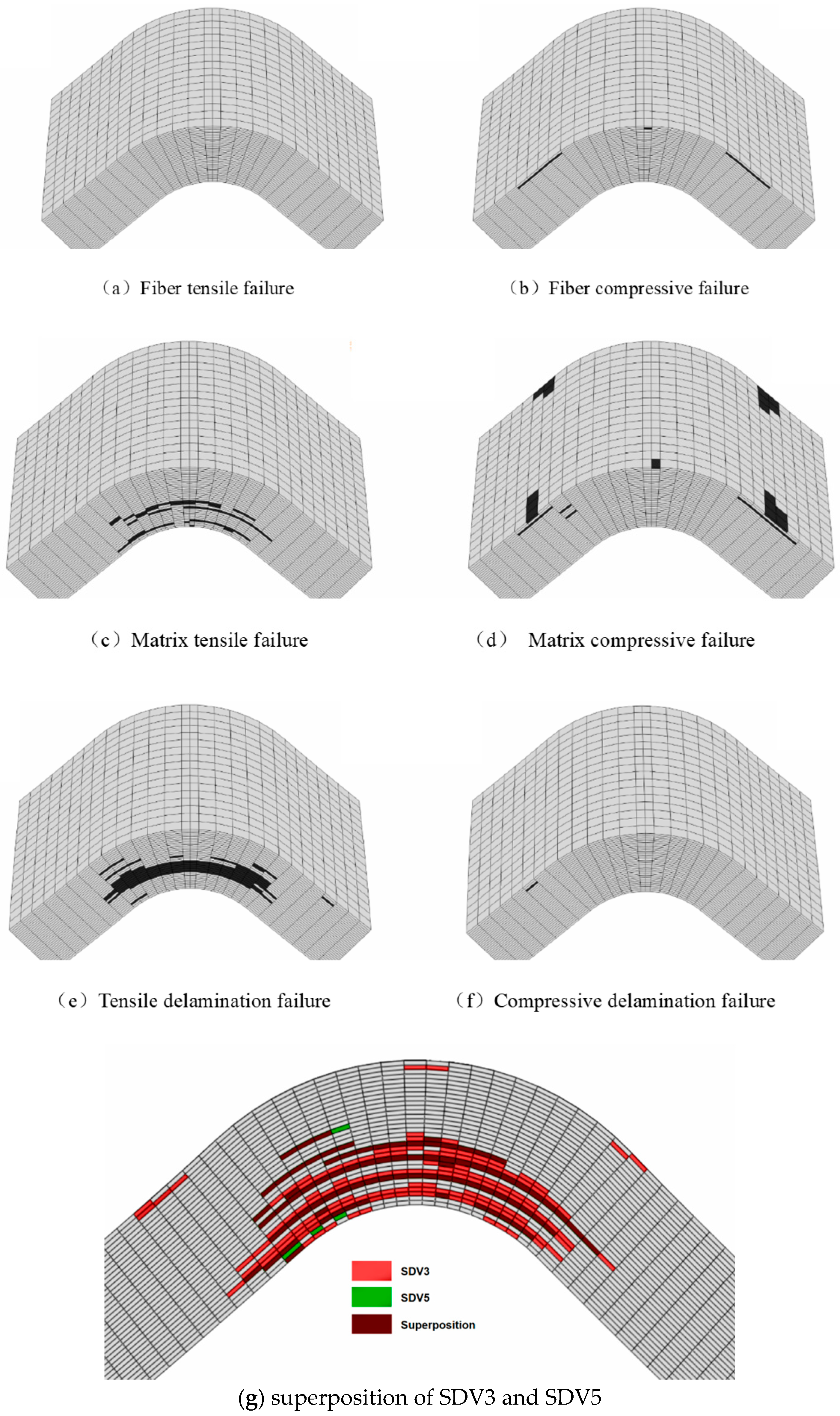

- The failure modes of curved beams with delamination damage are consistent with those of undamaged composite curved beams. Matrix tensile failure occurs initially, followed by tensile delamination. The combined effect of these failures leads to the progressive degradation of the curved beam.

- (b)

- For a quasi-isotropic laminated curved beam, delamination damage at the midplane of the specimen has the most significant impact on the load-bearing capacity of the curved beam. Delamination at the bottom of the curved beam affects its load-bearing capacity more severely than delamination at the top.

- (c)

- Delamination damage at the side edge of the midplane (Position 2) results in the greatest reduction in the load-bearing capacity of the curved beam. This observation is attributed to the manufacturing process, where cutting operations are likely to induce delamination damage at the side edges, thereby weakening the structural integrity of the curved beam.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hubert, P.; Poursartip, A. Aspects of the compaction of composite angle laminates: An experimental investigation. J. Compos. Mater. 2001, 35, 2–26. [Google Scholar] [CrossRef]

- Albert, C.; Fernlund, G. Spring-in and warpage of angled composite laminates. Compos. Sci. Technol. 2002, 62, 1895–1912. [Google Scholar] [CrossRef]

- Li, Y.; Li, M.; Gu, Y.; Zhang, Z. Numerical and Experimental Study on the Effect of Lay-Up Type and Structural Elements on Thickness Uniformity of L-Shaped Laminates. Appl. Compos. Mater. 2009, 16, 101–115. [Google Scholar] [CrossRef]

- Tamagawa, T.; Mori, Y.; Minakuchi, S. Consolidation mechanism of composite corners cured on convex and concave tools. Compos. Part A Appl. Sci. Manuf. 2023, 169, 107500. [Google Scholar] [CrossRef]

- Naji, M.I.; Hoa, S.V. Curing of Thick Angle-Bend Thermoset Composite Part: Curing Cycle Effect on Thickness Variation and Fiber Volume Fraction. J. Reinf. Plast. Compos. 1999, 18, 702–723. [Google Scholar] [CrossRef]

- Naji, M.I.; Hoa, S.V. Curing of Thick Angle-Bend Thermoset Composite Part: Curing Process Modification for Uniform Thickness and Uniform Fiber Volume Fraction Distribution. J. Compos. Mater. 2000, 34, 1710–1760. [Google Scholar] [CrossRef]

- Fernlund, G.; Griffith, J.; Courdji, R.; Poursartip, A. Experimental and numerical study of the effect of caul-sheets on corner thinning of composite laminates. Compos. Part A-Appl. Sci. Manuf. 2002, 33, 411–426. [Google Scholar] [CrossRef]

- Huoying, D.; Zuoguarng, Z.; Yizhuo, G.U.; Min, L.I. Experimental research on defects of L-shape laminates in vacuum-bag process. Acta Mater. Compos. Sin. 2007, 24, 34–39. [Google Scholar]

- Wang, X.; Xie, F.; Li, M.; Zhang, Z. Influence of Tool Assembly Schemes and Integral Molding Technologies on Compaction of T-stiffened Skins in Autoclave Process. J. Reinf. Plast. Compos. 2010, 29, 1311–1322. [Google Scholar] [CrossRef]

- Wang, X.; Xie, F.; Li, M.; Zhang, Z. Influence of core fillers on resin flow and fiber compaction of cocured skin-to-stiffener structures. Polym. Compos. 2010, 31, 1360–1368. [Google Scholar] [CrossRef]

- Xin, C.B.; Gu, Y.Z.; Li, M.; Luo, J.; Li, Y.X.; Zhang, Z.G. Experimental and numerical study on the effect of rubber mold configuration on the compaction of composite angle laminates during autoclave processing. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1353–1360. [Google Scholar] [CrossRef]

- Wang, X.; Li, S.; Xie, F. Influence of curvature radius on manufacturing defect of composite component formed by autoclave. J. Aeronaut. Mater. 2020, 40, 90–96. [Google Scholar] [CrossRef]

- Wang, M.; Liu, Y. Elasticity solutions for orthotropic functionally graded curved beams. Eur. J. Mech.—A/Solids 2013, 37, 8–16. [Google Scholar] [CrossRef]

- Lekhnitskii, S. Anisotropic Plates, Gordon and Breach; Science Publishers: New York, NY, USA, 1968; pp. 95–101. [Google Scholar]

- Bai, J.; Meng, Q.; Zhang, X. Analytical method of solution on delamination in symmetrical orthogonal composite laminated curved beams. Fuhe Cailiao Xuebao/Acta Mater. Compos. Sin. 2003, 20, 142–146. [Google Scholar]

- Shenoi, R.A.; Wang, W. Through-thickness stresses in curved composite laminates and sandwich beams. Compos. Sci. Technol. 2001, 61, 1501–1512. [Google Scholar] [CrossRef]

- Lin, K.C.; Hsieh, C.M. The closed form general solutions of 2-D curved laminated beams of variable curvatures. Compos. Struct. 2007, 79, 606–618. [Google Scholar] [CrossRef]

- Lin, K.C.; Lin, C.W. Finite deformation of 2-D laminated curved beams with variable curvatures. Int. J. Non-Linear Mech. 2011, 46, 1293–1304. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, H.; Xu, Y.; Chang, Y. Calculation of residual compressive strength of composite laminates with initial delamination. Aeroengine 2019, 45, 44–50. [Google Scholar] [CrossRef]

- Martulli, L.M.; Bernasconi, A. An efficient and versatile use of the VCCT for composites delamination growth under fatigue loadings in 3D numerical analysis: The Sequential Static Fatigue algorithm. Int. J. Fatigue 2023, 170, 107493. [Google Scholar] [CrossRef]

- Andraju, L.B.; Raju, G. Continuum and cohesive zone damage models to study intra/inter-laminar failure of curved composite laminates under four-point bending. Compos. Struct. 2020, 253, 112768. [Google Scholar] [CrossRef]

- Ranz, D.; Cuartero, J.; Castejón, L.; Miralbes, R.; Valladares, D. Enhanced cohesive zone model to predict delamination behavior of carbon/epoxy laminated curved beams. Mech. Adv. Mater. Struct. 2022, 29, 331–341. [Google Scholar] [CrossRef]

- Roach, J.; Zhang, D. Progressive failure simulation of angled composite beams subject to flexural loading. Compos. Struct. 2024, 340, 118111. [Google Scholar] [CrossRef]

- Hashin, Z. Failure Criteria for Unidirectional Fiber Composites. J. Appl. Mech. 1980, 47, 329–334. [Google Scholar] [CrossRef]

- Pinho, S.; Iannucci, L.; Robinson, P. Formulation and implementation of decohesion elements in an explicit finite element code. Compos. Part A Appl. Sci. Manuf. 2006, 37, 778–789. [Google Scholar] [CrossRef]

- McCarthy, C.T.; McCarthy, M.A.; Stanley, W.F.; Lawlor, V.P. Experiences with Modeling Friction in Composite Bolted Joints. J. Compos. Mater. 2005, 39, 1881–1908. [Google Scholar] [CrossRef]

- Lin, Y.C. Research on Static and Fatigue Performance of Composite Curved Beams. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2022. [Google Scholar]

- ASTM D6415/D6415M-06a; Standard Test Method for Measuring the Curved Beam Strength of a Fiber-Reinforced Polymer-Matrix Composite. ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- Bian, J.; Zhou, B.; Zheng, Z.; Fan, Y. Analysis of ablation and residual strength for lightning strike on carbon fiber reinforced polymer laminates. Aero Weapon. 2024, 31, 115–122. [Google Scholar] [CrossRef]

- Songhan Plastic Technology Co., Ltd. Hexcel® HexPly® M21 356°F (180 °C) Curing Epoxy Matrix. Available online: https://www.lookpolymers.com/pdf/Hexcel-HexPly-M21-356F-180C-Curing-Epoxy-Matrix.pdf (accessed on 3 January 2016).

- Yang, Y.; Liu, X.; Wang, Y.; Gao, H.; Li, R.; Bao, Y. A progressive damage model for predicting damage evolution of laminated composites subjected to three-point bending. Compos. Sci. Technol. 2017, 151, 85–93. [Google Scholar] [CrossRef]

- González-Cantero, J.M.; Graciani, E.; López-Romano, B.; París, F. Competing mechanisms in the unfolding failure in composite laminates. Compos. Sci. Technol. 2018, 156, 223–230. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Shao, K.; Niu, X. Failure Analysis of Composite Curved Beam with Initial Delamination Damage. Aerospace 2025, 12, 832. https://doi.org/10.3390/aerospace12090832

Zhang X, Shao K, Niu X. Failure Analysis of Composite Curved Beam with Initial Delamination Damage. Aerospace. 2025; 12(9):832. https://doi.org/10.3390/aerospace12090832

Chicago/Turabian StyleZhang, Xiaojing, Kai Shao, and Xinyu Niu. 2025. "Failure Analysis of Composite Curved Beam with Initial Delamination Damage" Aerospace 12, no. 9: 832. https://doi.org/10.3390/aerospace12090832

APA StyleZhang, X., Shao, K., & Niu, X. (2025). Failure Analysis of Composite Curved Beam with Initial Delamination Damage. Aerospace, 12(9), 832. https://doi.org/10.3390/aerospace12090832