Abstract

Since the first successful on-orbit repair mission in 1984 to the Solar Maximum Mission (SMM) satellite, considerable progress has been made in the field of On-orbit Servicing, Assembly, and Manufacturing (OSAM) of spacecraft using either human-guided or autonomous robots. This article aims to provide a review of state-of-the-art efforts in this field and the necessary technologies to achieve the ultimate objective of autonomous spacecraft repairs while in orbit. The article covers the literature relevant to OSAM, including a brief overview of OSAM, inspection technologies, manufacturing and repair technologies, state-of-the-art robotic technologies capable of performing the required tasks, and intelligent path planning of robots. The article also highlights the research’s location, timeframe, and public versus private sector efforts, and outlines future directions in this field. This article aims to foster a community of researchers and public-private partnerships working towards the common objective of autonomous robotic inspection and repair of on-orbit spacecraft.

1. Introduction

Significant progress has been made in the On-orbit Servicing, Assembly, and Manufacturing (OSAM) technologies in the last few decades. However, there is an ever-growing need for continued advancements of OSAM technology with the launch of spacecraft and satellites into space.

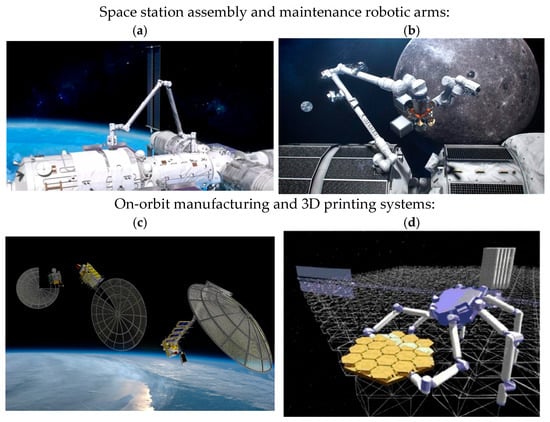

OSAM represents a transformative shift in space operations, encompassing three interconnected components: on-orbit servicing, on-orbit assembly, and on-orbit manufacturing. On-orbit servicing (OOS) includes maintenance, repair, and upgrades performed on spacecraft while they remain in orbit. Activities such as refueling, replacing components, and performing in situ repairs can extend spacecraft lifespans, increase mission flexibility, and correct issues associated with launch failures [1]. On-orbit assembly (OOA) involves the construction of large structures in space which are deemed impractical to launch as single craft. This capability enables the development of complex systems such as modular space habitats, large-scale telescopes, and other advanced infrastructure [2]. On-orbit manufacturing (OOM) leverages in situ resource utilization (ISRU) or in-space resources to fabricate components or an entire spacecraft. By using materials sourced from space such as asteroids, the Moon, or other celestial bodies, OOM can reduce dependence on Earth-based resources which lowers mission costs and offers mission sustainability [3].

Having a working OSAM platform on-orbit could very well be the difference between mission success and a mission failure. The Columbia shuttle tragedy occurred due to heat shield damage, and could illustrate the potential of OSAM technologies [4,5]. A more recent event occurred in the summer of 2024 where a series of critical failures with Boeing’s Starliner kept two astronauts in space until 2025, significantly longer than originally planned. Evaluating the potential of OSAM systems in addressing issues such as those seen in these two events requires the development and deployment of an operational system. Such technologies could be essential for enhancing mission safety and extending spacecraft lifelines.

With the rapid increase in satellite constellations over the past few years, and many more planned for the future, the need for functional OSAM systems in orbit has become increasingly important. For example, SpaceX has launched over seven thousand satellites since 2023, in addition to OneWeb completing its constellation [6]. This growth in the satellite population heightens concerns about a potential Kessler Syndrome scenario, a cascade of orbital collisions that could render space unusable [7,8]. A central challenge in preventing this outcome is managing end-of-life satellites, making deorbit and active debris removal among the most critical servicing functions. In addition, OSAM capability such as life-extension servicing, assembly, and manufacturing offer pathways to reduce unnecessary decommissioning and optimize the use of on-orbit assets. These emerging capabilities address the growing challenges of congestion in Earth orbit and establish new paradigms for sustainable space operations.

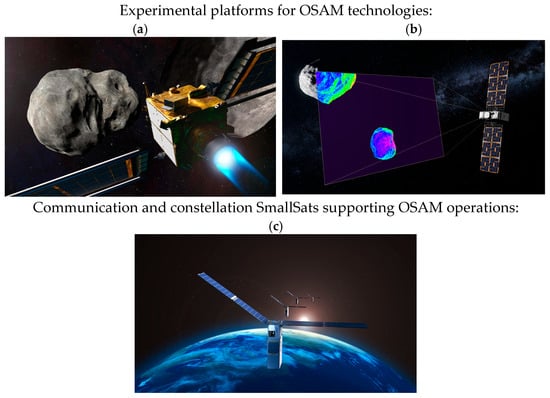

Although OSAM remains an emerging field, it is rapidly growing due to breakthroughs in critical technologies. One of the recent OSAM platforms, Northrop Grumman’s Mission Extension Vehicle (MEV) series, has successfully flown and is designed to extend satellite life using robotic servicing systems [9,10,11]. Recent research highlights various advancements such as the parametric formation control for nanosatellites used to enhance cooperative missions [12], and the optimization of spacecraft flyby inspectors and servicers [13,14]. Similarly, efforts to tackle space debris, like the multi-debris removal missions proposed by [15,16], underline OSAM’s importance for maintaining orbital sustainability. These innovations showcase OSAM’s capacity to deliver efficient, adaptable, and long-term support for spacecraft.

This literature review identifies past and current varying innovations in relation to OSAM. It will investigate inspection and fault detection technologies, highlighting different methods and concepts. Different manufacturing and repair technologies/concepts are then presented which are currently used in space or provide more efficient processes. Finally, current robotic technologies used with OSAM are reviewed and discussed.

This paper is structured in the following order:

- Section 1 introduces OSAM, detailing its background, significance, and future potential.

- Section 2 explores inspection technologies, outlining their contributions to spacecraft maintenance.

- Section 3 examines manufacturing and repair techniques, focusing on their applications for sustainable spacecraft operations.

- Section 4 highlights robotic technological advancements, emphasizing their role in autonomous OSAM operations.

- Section 5 concludes with a summary of OSAM’s current state and proposes directions for future research.

2. Inspection and Fault Detection Technologies

Inspection and fault detection for a spacecraft is one of the first steps required to complete a full OSAM operation. In situ inspection systems can provide real-time monitoring of spacecraft systems and need to be specifically engineered to operate in the demanding environment of space. Equipped with an array of sensors, cameras, and robotic mechanisms, they can conduct thorough inspections of critical systems, including solar panels and propulsion systems. Their primary function is to identify potential faults, wear, missing parts, or damage induced by micrometeoroid impacts and other harsh space conditions. Once a fault has been discovered, it must be analyzed to determine if the fault is mission critical or under what conditional change it will become mission critical.

One of the earliest examples of a spacecraft inspection was conducted in 1973 on the Skylab mission where the Skylab 2 crew conducted a visual inspection of Skylab, identifying specific issues with the space station [17]. Since then, advancements in technology have allowed for a wide array of inspection technologies covering electronic visual imaging methods, 3D scanning, and LIDAR imaging. An integrated approach to inspection combines multiple technologies including in situ inspection systems, visible-light scanning, telemetry, remote monitoring, thermal imaging, and ultrasonic testing to provide a comprehensive view of spacecraft health. Each method contributes uniquely to the evaluation of structural integrity, subsurface faults, and surface anomalies fundamental for safe, reliable space operation.

2.1. Traditional Inspection Systems

Traditional on-orbit inspection methods have long served as the backbone of spacecraft health monitoring and damage detection. They include extravehicular activities (EVAs), telemetry and remote monitoring, usage of onboard cameras, satellite- and Earth-based imaging. These methods have played a pivotal role in diagnosing surface degradation, structural damage, and subsystem failures across a wide range of missions. Due to their extensive operational history and continued relevance in many modern spacecraft designs, these techniques are classified as traditional inspection methods and will be referred to as such. Table 1 briefly summarizes some of the well-known traditional methods.

Table 1.

Summary of traditional inspection technologies and their operational trade-offs.

Extravehicular activity (EVA) remains one of the earliest and most versatile methods of spacecraft inspection, relying on astronauts physically exiting the spacecraft to perform direct visual assessments and manual repairs. A notable example is the Hubble Space telescope servicing missions, STS-61 in 1993 and STS-109 in 2002 [27], where astronauts corrected optical flaws and upgraded hardware. Similarly, STS-120 in 2007 saw crew perform an emergency EVA to repair a torn solar array on the International Space Station (ISS) [28]. Despite the advantages EVAs can provide, they still present significant risks to crew safety [29], are resource-intensive [30], and requires substantial preparation and life support systems [19], making them an option reserved for high-priority mission-critical tasks.

Telemetry systems are fundamental to spacecraft operations, continuously monitoring structural, thermal, and dynamic parameters. One of the earliest examples of telemetry use for spacecraft health monitoring was Sputnik 1, launched in 1957, which transmitted temperature, pressure, and battery status back to Earth, providing critical insight into the spacecraft performance [31]. On modern platforms, such as the ISS, telemetry systems have been used to detect impact events, for example, the 2018 incident where a small air leak in the Soyuz MS-09 module was first indicated by a pressure drop in telemetry data [32]. These embedded systems provide vital early warning capabilities but are limited to sensors installed pre-launch, and their long- term reliability can be affected by sensor drift and calibration degradation over extended missions.

Fixed cameras are a feature in modern spacecraft, offering passive visual inspection capabilities. The Canadarm2 is outfitted with cameras that have been used to visually inspect visiting vehicles and station components [33]. During the STS-114 mission in 2005, cameras onboard the Discovery Shuttle were used to examine potential damage to thermal protection tiles after launch [34]. These tools provide valuable imaging without requiring additional hardware deployments. However, they are limited by field of view and lighting conditions and repositioning them generally requires complex mechanical systems or the maneuvering of spacecraft.

Orbital imaging platforms enable inspection using nearby spacecraft or co-orbiting assets. A compelling example occurred in 2011, when China’s Shenzhou-8 spacecraft performed a flyby of the Tiangong-1 module to visually inspect its docking interface post-separation [35]. Similarly, NASA’s DART spacecraft and Orbital Express in 2007 demonstrated autonomous proximity operations that included inspection functions [36]. Such platforms offer flexible, non-contact inspection options, especially useful when onboard imaging is insufficient. However, successful deployment requires precise navigation and is subject to line-of-sight and resolution limitation, especially at longer ranges.

Ground-based optical, radar, and laser systems have long been used to track and inspect spacecraft from Earth. Agencies like the U.S. Space Force (USSF) Geostationary Space Situational Awareness Program (GSSAP) provide geostationary satellite imagery [37], while laser ranging systems, such as those operated by the International Laser Ranging Service (ILRS), provide precise orbital data [38]. Debris with potential to cause damage to spacecraft are tracked using the ESA’s Space Debris Tracking Network using radar [39]. One high-profile case was NASA’s analysis of Columbia’s potential damage, though their resolution proved insufficient to detect the fatal breach [40]. While valuable for broad tracking and positional verification, these systems cannot resolve fine structural detail and are limited by atmospheric interference and viewing windows.

While traditional inspection methods have formed the backbone of spacecraft health assessment and maintenance for decades, they often involve significant operational constraints, such as limited resolution, line-of-sight dependency, and risks to crew safety. These challenges have driven the development of emerging inspection technologies designed to overcome these limitations by enabling higher autonomy, increased precision, and broader accessibility in dynamic orbital environments. The following section explores these novel approaches, many of which are still under development or in early development and highlights their potential to redefine spacecraft inspection capabilities in the context of modern and future OSAM operations.

2.2. Emerging and Evolving Inspection Systems

Traditional inspection methods use legacy technology that still works very well, but due to recent advancements in imaging, sensing, and miniaturization, new inspection technologies can now be used to augment or upgrade legacy systems. These emerging methods, many of which are adapted from terrestrial industries, show promise to improve autonomy, accuracy, and adaptability in the in-situ inspection of spacecraft. While not all have reached full operational readiness, they represent a critical step towards more robust and scalable inspection systems. Some of these emerging technologies include photoclinometry, 3D scanning, LiDAR, and more and can be seen in Table 2.

Table 2.

Visible light scanning technologies.

Photoclinometry, or shape from shading, is a long-established photometric technique traditionally used in terrestrial and planetary surface mapping, such as generating elevation models of the Moon and Mars from single images captured by orbiters [55]. Recently, the method has been revisited for spacecraft inspection applications, including reconstructing surface geometry for small bodies and potentially spacecraft hulls. For instance, stereo-photoclinometry (SPC) has been successfully employed using imagery from NASA’s Dawn mission to the asteroids Vesta and Ceres [56] and the OSIRIS-REx mission to map the asteroid Bennu [57,58], where it was shown to be effective for autonomous shape mapping. Earth-based laboratory tests further demonstrate its suitability for emulating external inspection from orbiter images. However, photoclinometry remains highly sensitive to lighting geometry and surface reflectivity, making accurate pose estimation and radiometric calibration critical for spacecraft applications. Integrating photoclinometry into spacecraft inspection systems will require overcoming challenges in maintaining consistent lighting conditions and computationally efficient onboard processing. Ongoing efforts to deploy photoclinometry-capable payloads on SmallSat missions or as a part of inspection-focused spacecraft could soon demonstrate its viability for detecting surface defects or topological anomalies during OSAM operations [59].

Three-dimensional scanning technologies, particularly structured light and laser triangulation, are increasingly being explored for spacecraft inspection due to their ability to generate high-resolution surface geometry maps [60]. These systems operate by projecting known light patterns onto surfaces and capturing distortions. Though widely used in terrestrial robotics and manufacturing, their application in microgravity environments has been studied through lab-based simulation and parabolic flights. For instance, a project collaboration between NASA and the Canadian Space Agency, the TriDAR vision system used laser scanning to provide relative real-time pose data. Similarly, NASA’s former OSAM-1 mission was to include the use of 3D vision sensors, based on triangulation, to guide robotic arms in servicing and refueling satellites [61]. Although these systems offer excellent precision and compact form factors, their performance is sensitive to surface reflectivity, lighting conditions, and requires careful calibration. Nevertheless, continued miniaturization and robust algorithm development are making these sensors increasingly viable for autonomous inspection within OSAM missions.

LiDAR is a mature terrestrial technology and shows great promise for spacecraft health monitoring. LiDAR excels in identifying micro-level defects, impact damage, and structural anomalies by creating high-resolution point clouds of spacecraft exteriors. NASA has extensively used LiDAR for proximity operations and navigation, notably in missions like OSIRIS-REx, which utilized the OSIRIS-REx Altimeter (OLA) to construct 3D maps of asteroid Bennu’s surface for landing site selection [62] and in the now canceled OSAM-1 project [63,64]. Additional inspection efforts such as ESA’s Laser Infrared Imaging Sensors (LIRIS) on the ATV-5 mission tested LiDAR-based rendezvous and object tracking technologies, validating the potential for autonomous inspection during close proximity operations [65]. On the commercial side, Northrop Grumman’s Mission Extension Vehicle (MEV) leveraged LiDAR guided rendezvous capabilities for satellite servicing, demonstrating the utility of LiDAR in precision docking and inspection tasks. Despite its high spatial resolution and robustness in low light, LiDAR remains power-intensive, and its performance can be impacted by highly reflective or absorptive surfaces. To overcome these limitations, future LiDAR systems need to be adaptable to different orbital regions, radiation-resistant, and more energy efficient. These advancements, alongside integration with other sensors like thermal imaging, are making it easier to transition this technology from terrestrial to extra-terrestrial at a rapid pace.

Time-of-flight (ToF) cameras have gained attention in spacecraft inspection due to their ability to generate real-time 3D depth maps using light pulse timing. By emitting infrared light and measuring the time it takes for reflections to return, these systems can provide high-speed spatial data in compact and lightweight packages. One of the most notable demonstrations of ToF technology on orbit was NASA’s Astrobee aboard the ISS, which uses specialized ToF sensors for navigation and environmental mapping [66]. Other research efforts have further investigated ToF systems for tasks such as autonomous docking and pose determination [67]. However, ToF cameras remain sensitive to variations in surface reflectivity and may struggle with highly absorptive materials, which can distort depth accuracy. Ongoing research is addressing these challenges by fusing ToF data with traditional RGB or LiDAR inputs, allowing for more robust inspection systems.

Photogrammetry is a widely used remote sensing technique that reconstructs 3D models from overlapping 2D images using triangulation and feature-matching algorithms. For spacecraft inspection, its non-contact and sensor agnostic nature makes it especially appealing for missions with limited payload capacity. Photogrammetry was used by NASA during the Space Shuttle program to assess tile damage after launch, employing cameras on the Orbiter Boom Sensor System and Canadarm2 to gather high-resolution imagery for surface reconstruction [68]. Despite its benefits, photogrammetry is computationally intensive and highly dependent on image quality, lighting, and surface texture.

Terahertz (THz) imaging leverages electromagnetic waves in the THz frequency range to detect subsurface features without causing material damage. This technique has drawn increasing attention for spacecraft inspection due to its ability to reveal hidden defects such as delamination, voids, and microcracks in composite structures. Lab experiments by NASA and ESA have demonstrated that THz imaging can detect impact damage and thermal degradation in carbon fiber reinforced polymers (CFRPs), which are often used in thermal shielding and structural panels. However, THz imaging’s relatively shallow penetration depth and sensitivity to moisture and surface geometry remain limitations. Current research is focused on integrating compact THz sensors into autonomous robotic platforms and exploring hybrid methods that pair THZ imaging with other methods.

Near-Infrared Computed Tomography (NIR-CT) employs near-infrared light to generate tomographic reconstructions of surface and near-surface features, offering non-destructive evaluation capabilities for fine-scale defect detection. While more commonly applied in medical imaging and material sciences, its recent adaptation to aerospace applications has opened new opportunities for detecting delamination, micro-cracks, and porosity in advanced composite materials. Experimental work performed by teams at the ESA has demonstrated the ability of NIR-CT systems to resolve defects as small as a few microns in carbon-fiber panels, with real-time imaging potential for in situ diagnostics [69]. A key strength of NIR-CT is its ability to differentiate materials based on their optical scattering and absorption properties, making it particularly useful for layered composites and bonded joins. However, the technique is generally limited to shallow penetration depths and is sensitive to surface reflectivity and geometric curvature. As NIR-CT systems become more compact and robust, they could serve as a valuable complement to other inspection modalities.

Thermal Imaging is a key technology for spacecraft inspection and fault detection, offering valuable insights into temperature variations and thermal signatures. It excels in identifying hotspots, overheating components, and cold spots that may indicate system malfunctions or insulation issues. Using infrared testing, thermal imaging can detect electrical and thermal anomalies, providing a non-invasive, non-destructive, real-time system to monitor a spacecraft’s health. Technologies such as the Robotic External Leak Locator (RELL) on the ISS which detects ammonia leaks [70], and the Robotic Refueling Mission (RRM) which assists in visualizing thermal signatures during simulated operations, are enhancing the precision of thermal diagnostics [71]. However, limitations include surface-level sensitivity and interference from solar radiation, which can skew readings. Future advancements could focus on AI integration, solar-resistant sensors, and combing thermal imaging with other techniques for deeper insights into spacecraft health.

Ultrasonic testing is a high-precision, non-destructive techniques that uses high-frequency sound waves to detect internal flaws such as cracks, voids, and delamination in spacecraft materials, particularly composites. NASA Langley has demonstrated its utility through in situ monitoring systems capable of detecting porosity defects during composite curing, enabling real-time adjustments to manufacturing parameters [72]. On the ISS, ultrasonic methods are proposed to assess micrometeoroid and orbital debris (MMOD) damage from inside the spacecraft [73] and using shear wave scans and 3D C-scan imaging to map and compare structural defects [74]. While effective, conventional ultrasonic sensors require contact or a medium to transmit waves, posing a challenge in the space environment, which is a vacuum. To address this, research is ongoing into laser-based and remote ultrasonic systems, as well as robotic arms equipped with transducers for inspection purposes.

2.3. Inspection Platforms

In recent decades, the need for persistent, precise, and non-intrusive spacecraft inspection has led to the development of a wide range of dedicated inspection platforms. These systems are designed to operate autonomously or semi-autonomously in the extreme conditions of space and play a critical role in ensuring mission longevity, detecting anomalies, and enabling responsive repair or servicing actions. From robotic arms mounted on the ISS, to free-flying autonomous agents and dedicated servicing missions, each platform embodies a unique combination of mobility, sensing, and data transmission capabilities. Many of these platforms build directly on the robotic systems discussed in Section 4, which provide the manipulators, mobility mechanisms, and autonomous control architectures that make inspection feasible. Table 3 summarizes some major current and past spacecraft inspection platforms, including their operational purpose and the technologies employed to conduct inspections.

Table 3.

Section summary of representative OSAM platforms with inspection technologies.

These platforms showcase a progression from crew-assisted manual inspection to fully robotic autonomous systems capable of high-fidelity assessments. The shift toward autonomy, modularity, and multi-functional systems reflects a broader trend in OSAM, where inspection is no longer a stand-alone activity, but an integration function within servicing and repair workflows. As the space environment becomes more congested and missions grow in complexity and duration, the continued evolution of these platforms, incorporating more advanced sensors and dexterous manipulators, will be essential for achieving operational resilience and sustainability on orbit.

3. Manufacturing and Repair Techniques

After the inspection of a spacecraft and the discovery of damage, the next step is to devise a manufacturing technique to repair or replace the damaged material. Being able to manufacture a repair while in space could increase spacecraft lifespans and prevent premature mission failure, enabling the cost-effective fabrication of larger, more complex structures. This could reduce reliability on Earth resources, reduce space debris, and reduce the financial risks of deploying a satellite. Several analyses suggests that on-orbit refueling can offer substantial cost savings compared to full spacecraft replacement, with estimates ranging from approximately $100 million to over $400 million, depending on satellite type, orbital regime, and servicing architecture [77,78,79]. This spread reflects the sensitivity to satellite class, remaining life, launch-price assumptions, and financing and insurance risk. There are also cases of a significant decrease in experimental capability of a spacecraft due to a fault or technological failure [80].

An innovative approach to mitigating operational risks, such as collision during proximity operations, damage from orbital debris, or failures in servicing hardware, in on-orbit servicing was proposed in a study [81], which introduced the concept of utilizing CubeSat robots. These small robots are equipped with specialized capabilities for repair, mapping, and deorbiting, offering resilience in the face of potential damage from debris. By employing multiple small robots, the mission can continue even if one or two robots are compromised. The study suggests a strategy involving three CubeSats tethered together with a 0.5-m tether to capture and deorbit aging or defunct spacecraft.

Implementing OSAM operations presents several technical and operations challenges. Spacecraft components must be designed with constraints on volume, mass, and cost, while maintaining robustness and durability to withstand the harsh space environment [82]. Additionally, reliance on Earth-based resupply limits the sustainability of long-term operations, motivating the exploration of in situ resource utilization (ISRU) as a potential feedstock for additive manufacturing systems. ISRU involves extracting or processing materials from planetary bodies, such as the Moon, Mars, or asteroids, to produce components or repair materials in space, reducing reliance on terrestrial resources.

For this review, the focus is on in-space manufacturing and selective repair techniques, rather than full on-orbit assembly. While assembly is an integral part of spacecraft manufacturing and repair, it is considered beyond the scope of this paper.

3.1. Additive Manufacturing (AM) Techniques

AM is highly valuable for spacecraft due to its ability to produce complex and lightweight structures that can be manufactured in real time. Recognized AM methods include material extrusion, where a filament, typically polymer, is heated and extruded layer by layer, and vat photopolymerization, which uses ultraviolet UV light to solidify liquid resin. Other methods, such as material jetting, binder jetting, powder bed fusion, and sheet lamination, utilize various techniques from depositing material droplets to employing lasers and ultrasound for construction [83]. Some of the techniques with the potential for space applications can be seen in Table 4.

Table 4.

Overview of representative AM techniques for the purpose of in-space manufacturing.

Practical applications of these techniques have been demonstrated aboard the ISS. Made In Space’s 3D printer, known as the Additive Manufacturing Facility (AMF), has been operational on the ISS since 2015, producing a variety of tools and components on demand. In 2020, the AMF successfully printed a ceramic turbine part, making a significant milestone in space-based manufacturing. Additionally, Tethers Unlimited developed the Refabricator, a system that combines a 3D printer and a recycler to produce new filament from plastic waste. Installed on the ISS in 2018, the Refabricator demonstrated the ability to recycle and print new parts, supporting sustainable manufacturing practices in space [84,85].

Binder Jetting (BJT) involves bonding layers of powdered materials (metal, ceramic, or composites) with a binder to form a model, which is then cured with heat and depowdered to remove excess material. The resulting part may require additional post-processing, such as sintering or infiltration, to achieve desired mechanical properties [86]. BJT technology still needs refinement and maturation to be fully applicable for in-space manufacturing. Part of this refinement was conducted in a 2021 study where the main process parameters were studied and optimized to achieve an increased final density of Invar36 printed parts to 92.7% ± 0.18%. These parts are geared toward applications where temperature fluctuations, in a range of 25–250 °C, interfere with the printing system [87]. Just a year later another study further improved the final part density of Invar36 to 99.8% using HIP thermal treatment and confirming that binder drying time has a significant impact on reducing surface roughness [88]. More recently, in 2024, an international collaboration simulated a novel technology able to mitigate sintering lead shape distortion seen in some BJT models when printed in microgravity conditions. They simulated sintering in a rotating furnace with stainless steel 316L hollow tubes and found that controlling the rotational speed has potential to solve some of the existing problems with sintering under microgravity conditions [89]. Research into using BJT for in-space manufacturing is still relatively new and not quite ready for practical application; its potential to produce complex parts with local materials makes it a promising technology.

Direct Energy Deposition (DED) is the process of melting feedstock such as metal powder or wire using a laser, electron beam, or plasma arc layer by layer [90]. In 2022, a research team from Sweden concluded that DED using a laser and wire feedstock in a controlled atmosphere could be adapted for in-space manufacturing. They suggested that, with appropriate process controls, minor variation caused by the space environment could be mitigated to maintain part quality [91]. The same year a master’s student at the Delft University of Technology conceptualized a platform with a dual DED printer assembly, each one on a robotic arm, that could simultaneously print support structures for a flexible and deployable solar panel. To validate this conceptualization many questions needed to be answered such as what are the required functionalities, subsystems, and power system, what are the manufacturing rate limiting factors, what is the optimal feedstock, geometrical limitations, etc. Once these questions were answered it was concluded that wire-based DED is possible for the in-space manufacturing of solar array structures, but more technology maturation is required [92].

Material Extrusion (MEX) is a technique where a material is extruded through a heated nozzle onto a surface layer by layer [93]. There are many different types of MEX such as Fused Filament Fabrication (FFF) [94], Robocasting [95], and Extrusion-based Direct Ink Writing (DIW) [96]. Of the many AM techniques available, MEX has gained the most interest for in-space manufacturing. In a 2021 study, the effects of a vacuum environment were investigated on fused filament fabrication (FFF) [97]. They examined the dimensional and mechanical properties of 3D prints produced using a commercially available FFF printer with polycarbonate feedstock at pressures of 10 mbar and 1 bar. Their findings revealed that vacuum-printed parts displayed a 5.4% increase in tensile yield strength and a 59% improvement in extension at break, suggesting enhanced strength and ductility, along with an 11.2% boost in compressive strength compared to parts printed at normal pressure. The study attributed these improvements to more effective welding between polymer threads in a vacuum, leading to fewer defects and voids as well as more uniform thread shapes. In addition to studying the effects of vacuum FFF printing with polycarbonate, others have studied vacuum printed polyether ether ketone (PEEK) [98], composites [99], and others [100]. In addition to studying the effects of a vacuum print, one must also study the effects of microgravity [101], radiation [102], and temperature cycling [103]. Similarly, a 2022 study investigated the feasibility of FFF on the moon from the perspective of heat transfer in printed parts [104]. Experimental data and simulations at different resolutions quantified the significance of each heat transfer mechanism that took place during printing. That quantification investigated how the lunar environment affects the cooling of the printed parts. This study predicts that FFF is feasible for Moon manufacturing, but there will be a limited printing window and higher temperature gradients and thermal stresses, meaning moon FFF should be used for precision manufacturing small components.

Material Jetting (MJT) is similar to paper ink jet printing, but, instead of printing with ink, it uses photopolymers, wax, or resins [105]. As layers are deposited, they are cured with either UV light or using heat. MJT is one of the few AM techniques that require gravity to allow the material droplet to fall into place, which would be a problem for ISM. Some studies have opted to simulate the effects of microgravity on droplets [106], while others have designed and executed actual experiments [107]. One study investigated this issue by using an electric field to simulate anti-gravity on metal droplets [108]. They used a horizontal droplet generator with a vertical substrate and found that with the anti-gravity electric field a droplet can be accurately deposited onto the substrate even after traveling long distances. In 2022, scientists developed a novel metal droplet deposition system designed for space environments, leveraging a drop-on-demand method for 3D metal part manufacturing [109]. Using their novel MJT printer they were also able to study the upper and lower limits of parameters needed to acquire the desired droplet properties geared towards in-space manufacturing applications.

Powder Bed Fusion (PBF) printing involves the fusion of powdered material, usually a metal, polymer, or ceramic, layer by layer using a laser or electron beam [110]. In between each layer fusion, the material cools and solidifies allowing for the next layer to be added. While using fusing powder together works well with gravity [111], it is not feasible to complete a PBF print in microgravity. Some studies have suggested that applying artificial gravity using centrifugal acceleration to the PBF process is a viable way to successfully PBF print in-space [112] while some use a gas flow to stabilize a print [113]. One notable case study created a novel PBF process that operates independently of gravity using an enclosed container and powder compression [114]. Validation involved process simulation, followed by testing both on the ground and during parabolic flights. Remarkably, findings indicated that the quality of powder deposition remained consistent regardless of gravity conditions. Moreover, the study suggests that this innovative powder deposition process holds promise for manufacturing parts using regolith-planetary surface materials-which they believe will be crucial for future space exploration missions. PBF is most popular for Lunar and Martian regolith printing rather than on-orbit manufacturing [115] but it is possible that these techniques could translate to asteroidal materials [116].

Vat Photo-polymerization Process (VPP) is a printing technique involving a vat of liquid resin that is selectively cured using UV light [93]. Most research into VPP for ISM has been on what feedstock material is available and what specialized materials can be engineered. A novel ceramic paste was developed for the direct light processing (DLP) AM technique, aimed at microgravity environments [117]. This approach, centered on adjusting the ceramic slurry’s rheological properties, facilitates the fabrication of complex-shaped ceramic components suitable for space. Ceramic pastes are not the only materials to be investigated for ISM VPP printing. Other materials like polycarbonate-like material, ABS-like resin, ceramic composites [118], and metals [119] have also been studied. Not only are materials being investigated, but so are some different types of VPP. One case study investigated the feasibility of Xolography, a type of VPP, as a potential AM for various gravity conditions [120]. Another group proposed applying a light-sensitive resin in microgravity conditions using a drop tower [121]. Over the many tests they ran, it was found that using this method was feasible for microgravity printing.

While in-space manufacturing techniques such as BJT, DED, MEX, MJT, PBF, and VPP are being developed to enable construction and part production on-orbit, their potential extends beyond fabrication alone. These same processes, and the infrastructure supporting them, can be adapted for spacecraft repair applications, allowing damaged components to be rebuilt, reinforced, or replaced in situ. As a result, the boundary between manufacturing and repair is increasingly blurred in space operations, with many technologies serving dual roles. The following section explores the diverse range of repair techniques being studied and demonstrated for restoring functionality to spacecraft systems, from traditional manual repairs to cutting-edge autonomous solutions. Later in Section 4.4, the role of robotics in leveraging these manufacturing methods for large-scale orbital assembly is discussed, highlighting how fabrication and integration are increasingly interdependent.

3.2. Repair and Refurbishment Techniques

As spacecraft age or encounter unexpected anomalies during operation, repair and refurbishment become essential tools for maintaining functionality and extending mission lifespans. Spacecraft repair methods vary widely from replacing faulty components with spare parts or resupply missions [122,123], mending wiring or electrical damage caused by environmental stressors, and even restoring or optimizing solar panels by replacing antennae. Table 5 summarizes the major categories of repair technologies currently under development or demonstration for orbital servicing missions.

Table 5.

Overview of different repair techniques/technologies being researched for OSAM.

Self-healing materials are an emerging class of smart materials designed to autonomously repair damage, offering potential for extending spacecraft service life and reducing the need for manual intervention during on-orbit servicing missions. These materials are engineered to detect microcracks or material degradation and initiate localized healing processes without external input. Several mechanisms are under investigation including micro-encapsulated healing agents [124,125], intrinsic reversible bonding chemistries [126], and shape-memory polymers [127]. Microcapsule-based systems can release repair agents into cracks upon rupture, initiating polymerization and restoring structural integrity, while intrinsic systems rely on dynamic covalent bonds or supramolecular interactions that can reform after damage. Recent developments have focused on radiation-resistance self-healing composites and polymers capable of multiple healing cycles under extreme conditions [128]. Their integration into critical spacecraft components [129], such as solar arrays [130], hull coating [131], or inflatable structures, could enhance resilience, reduce maintenance demands, and support autonomous health management within future OSAM architectures.

Spacecraft refueling is aimed at extending the operational lifespan of satellites and spacecraft. Traditionally, satellites are launched with a fixed supply of propellant, leading to end-of-life disposal once all fuel is exhausted, even if the spacecraft is otherwise fully functional [132]. Recent advances in OSAM have enabled the development of refueling systems that allow for the in-space transfer of propellants. Key challenges include the standardization of refueling interfaces, ensuring leak-tight seals, managing thermal and pressure control during transfer, and refurbishing legacy spacecraft with refueling capabilities [133].

Spacecraft refurbishment and system upgrades involve on-orbit replacement or enhancement of components to extend mission life and improve performance without the need for a full replacement [134]. Unlike refueling, refurbishing may include swapping outdated or degraded subsystems such as power units [135], communication modules [136], sensors [137], or propulsion elements with modernized versions. This capability supports evolving mission requirements, technology refresh, and repair of wear-induced faults. Key challenges include developing standardized modular interfaces [138], ensuring reliable robotic manipulation and component integration in microgravity, and verifying system compatibility across generations.

Space welding has been proposed as a technique for structural repair and assembly during on-orbit servicing operations. In the harsh environment of space, traditional Earth-based welding methods face challenges due to vacuum conditions, microgravity, and thermal extremes [139]. Research has explored multiple welding techniques suitable for space application such as electron beam welding (EBW) [140], laser beam welding (LBW) [141], cold welding [142], and arc welding [143]. Ongoing research continues to adapt these technologies for robotic use, aiming to support autonomous or teleoperated welding during on-orbit manufacturing and repair tasks.

Repairs and replacement parts can be additively manufactured, providing the capability to manufacture on-demand directly in space, and reducing reliance on Earth-based resupply. This capability is valuable for producing replacement parts, structural brackets, or tools that may break or degrade over time. NASA’s Made in Space initiative, which successfully operated polymer-based 3D printers onboard the ISS, demonstrated the feasibility of printing functional tools and components in microgravity [144]. The Refabricator system was designed to recycle plastic waste into new filament for 3D printing, illustrating a closed-loop manufacturing and repair cycle [145]. Ongoing research at ESA and Thales Alenia Space has examined metal AM using techniques like wire-arc AM and laser-based deposition to fabricate structural metal components under vacuum conditions [146,147,148,149]. More recently, NASA’s OSAM-2 (Archinaut One) mission aims to use robotic arms and 3D printing to construct and repair large-scale spacecraft structures on-orbit, including booms and antennae [150]. These studies show that AM is rapidly evolving from a demonstrative technology to a functional solution for creating repair parts and supporting long-duration missions to where supply constraints and unplanned failures are mission critical concerns.

Manual repairs performed by astronauts have played a pivotal role in the history of on-orbit servicing. One of the most notable examples is the Hubble Space Telescope (HST) servicing missions, during which crew conducted multiple EVAs to replace faulty components, install new instruments, and perform critical upgrades [151]. These missions involved the use of highly specialized tools such as the Power Ratchet Tool (PRT), torque limiters, and custom fastener capture devices to accommodate gloved operations in microgravity [152]. During Hubble Space Telescope’s fourth servicing mission, astronauts employed a Fastener Capture Plate (FCP) on one of their spacewalks. The FCP was designed to securely hold any fasteners or washers removed during repairs, preventing them from drifting away and contaminating the spacecraft or the surrounding environment. This innovative tool ensured the crew could perform necessary repairs safely and effectively without risking the introduction. Many of these EVAs were performed with assistance from the Canadarm which provided a stable platform for crew positioning and tool handling. In 2007, during STS-120, crew manually repaired a torn solar array on the ISS using makeshift ‘cufflink’ stabilizers fashioned from wire and pins [153]. Similarly, robotic arms such as Canadarm2 and Dextre have been used in tandem with crew or autonomously to assist with tasks like replacing battery modules, handling large components, or positioning hardware [154].

Advanced Techniques for Repair Optimization

To enhance the optimization of autonomous spacecraft repair strategies, integrating advanced machine learning techniques is essential. A notable approach is the application of reinforcement learning to model the complex relationships within spacecraft systems. Specifically, the Deep Deterministic Policy Gradient (DDPG) algorithm has been adapted to operate within a spacecraft performance fault relationship graph, enabling robots to identify and address faults effectively. This adaptation, known as the Semantic relation and Position DDPG (SPDDPG), combines representation learning and deep reinforcement learning to improve fault diagnosis and repair decision-making. By utilizing a performance fault relationship graph as the training environment, this method enhances prediction speed and accuracy, facilitating real-time autonomous in-space repairs [155].

Implementing Finite Element Analysis (FEA) topology optimization for spacecraft repairs represents a forward-thinking method that could greatly enhance spacecraft durability. This technique mathematically refines material distribution within specified parameters, lightening the load while upholding structural strength. Its application in space repair promises to decrease maintenance frequency, mitigate further damage risks, and elevate mission success rates [156,157]. A topology optimization algorithm was developed to design a composite patch for mending a cracked aluminum plate, using MATLAB for programming the algorithm and Abaqus/Standard for finite element analysis (FEA) [158]. This method leverages the stress field derived from FEA, illustrating a sophisticated approach to structural repairs. A well-known example was the design optimization of the Airbus A380, notably the leading-edge ribs and the fuselage door intercostals, which is a well-documented case of advanced engineering contributing to a substantial weight reduction [159]. The successful implementation of topology optimization in these components achieved significant weight saving, reported to be approximately 1000 kg per aircraft.

Many scholars have conducted studies reviewing the use of topology optimization with AM [160,161]. AM utilizes layer-by-layer construction, provides an appealing approach to produce topologically optimized structures, which otherwise are extremely challenging to make using traditional subtractive manufacturing processes. Due to the manufacturing freedoms of the AM technologies that allow for highly efficient designs with internal components and intricate features, the application of topology optimization becomes more important as AM gains more popularity. For space missions, FEA and topology optimization significantly enhance on-orbit fabrication and repair of spacecraft components. One study explored the potential and challenges of these technologies for spacecraft structures, demonstrating their application in optimizing an AM helium tank support structure using Laser Powder Bed Fusion [162]. Additionally, bonded flush repairs were studied emphasizing optimization, reliability, and durability [163]. These findings suggest that optimization algorithms can effectively identify the most efficient configurations for these applications.

Building on the capabilities provided by manufacturing and repair technologies within OSAM, space robotic technologies are critical for executing these functions in the unique and often hazardous environment of space. Robotics enables the precise manipulation and assembly of components, allowing greater autonomy and robustness in on-orbit operations, which enlarges the scope of what can be achieved in space maintenance, assembly, and manufacturing.

3.3. Material Challenges

Materials in space are subject to radiation, extreme thermal cycling, and unique degradation processes leading to embrittlement, cracking, and even structural failure. Outgassing and material incompatibility with vacuum environments pose a risk to the integrity of components manufactured or repaired on orbit. To mitigate these issues, research in advanced radiation-resistant materials, such as metal-matrix alloys [164] or hydrogen-rich polymers [165], is ongoing. In addition, fluoropolymers and vacuum-compatible 3D printable alloys are being developed to reduce outgassing and enable more reliable in situ manufacturing and repair.

3.3.1. Robotic Control in Microgravity Control

The absence of gravitational forces complicates precision in assembly and repair tasks. Components can drift during manipulation, increasing the complexity of alignment and joining operations. Traditional joining techniques that rely on gravity or atmospheric conditions are often unsuitable for microgravity. To address this, force feedback control and AI-assisted robotic systems are being explored to improve precision and adaptability. Welding techniques compatible with microgravity, such as laser and electron beam welding, are under investigation, as are adhesive bonding methods designed for vacuum environments to enhance structural integrity during OSAM operations.

3.3.2. Thermal and Power Management

Manufacturing and repair operations require consistent power and effective thermal regulation, both of which are constraints in space. Excessive heat can become trapped, threatening the stability of spacecraft systems while loss of power leads to mission failure. Current literature aims at the development of advanced batteries, fuel cells, and high-efficiency solar arrays [166,167]. Radiative cooling systems and thermoelectric generators have emerged as tools for thermal management. Such generators aid with cooling and converting waste heat into usable energy, improving system efficiency.

3.3.3. Autonomy of Repair and Manufacturing Systems

Autonomous repair and manufacturing systems face reliability and adaptability issues. Current systems involved in these processes struggle with accurate fault detection and run into complex decision-making without human intervention. AI driven and machine learning algorithms enhance the predictive nature for autonomous response capabilities. Self-healing materials and smarter robotic systems have been introduced which could allow for self-diagnosing defects and performing autonomous repairs leading to future space systems exhibiting greater autonomy and resilience [168,169].

3.3.4. Resource Management and in Situ Utilization

Dependence on Earth-based resources presents a major barrier to scalable, sustainable on-orbit manufacturing. Resupply missions are costly and time-consuming, limiting the feasibility of large-scale operations. In situ resource utilization (ISRU) and on-orbit recycling are being explored as key enablers for long-term OSAM viability. Recycling systems can transform waste material into feedstock for manufacturing, while ISRU techniques aims to extract resources from lunar or asteroid surfaces, reducing reliance on Earth-based logistics and enabling on-demand material availability in space.

3.3.5. Quality Control and Reliability of Manufactured Parts

Early demonstrations of in-space manufacturing, such as the polymer faceplates and clips produced aboard the ISS in 2014, highlight how small, non-critical components can be manufactured and used with minimal testing requirements. However, extending this capability to structural or safety-critical repairs poses a far greater challenge. Different classes of parts, ranging from tools and covers, to load-bearing brackets and pressure retaining elements, would each demand increasingly stringent quality checks. For example, non-critical replacements may require only basic dimensional verification, whereas load bearing or environmentally exposed components would necessitate nondestructive evaluation, material property validation, and possibly on-orbit stress testing before integration. Future approaches could involve in situ monitoring of the manufacturing process, onboard inspection using methods described in Section 2, or even embedding sensors within printed parts to track performance over time. Until such practices are matured, the role of in-space manufacturing for spacecraft repair is likely to remain limited to non-critical applications, while Earth manufactured spares will continue to be essential for high-reliability functions.

3.4. Integrated Manufacturing and Repair Platforms

As the capabilities of OSAM advance, a growing number of platforms are being developed to integrate both in-space manufacturing and repair functions into cohesive systems. These integrated platforms represent a key step toward autonomous, sustainable space infrastructure by minimizing the need for resupply from Earth and enabling real-time response to structural damage, wear, or mission reconfiguration needs.

Rather than attempting to list every program, Table 6 organizes representative examples into broad categories of platforms. Each entry highlights the primary operational purpose of the system, along with its manufacturing and repair capabilities, to illustrate how different approaches contribute to the evolving OSAM ecosystem.

Table 6.

Section summary of representative OSAM platforms with manufacturing and repair capabilities.

The integration of manufacturing and repair capabilities into unified platforms is essential for reducing logistical dependencies, increasing spacecraft longevity, and enabling scalable in-space infrastructure. The platforms summarized above are not exhaustive but are representative examples drawn from different categories of manufacturing and repair servicing systems.

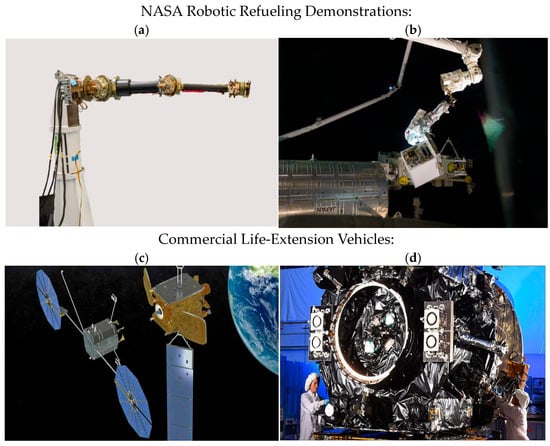

4. Space Robotic Technologies for OSAM

Robotic systems serve as the third pillar in the progression of OSAM technologies, building upon earlier capabilities such as basic satellite servicing and in-orbit assembly. These advanced systems are engineered to execute complex tasks, including servicing existing spacecraft, assembling large structures, and manufacturing new components in space. As electromechanical devices equipped with sophisticated sensors, actuators, and control systems, robotic systems can operate autonomously or under remote guidance to perform tasks with precision and reliability. Their use offers a safer and more efficient alternative to extravehicular activities (EVAs), commonly known as spacewalks, which expose astronauts to significant risks, such as radiation, temperature extremes, and potential space debris collisions. By eliminating the need for human involvement in these high-risk operations, robotic systems ensure safer mission execution while maintaining consistent performance. Space robotics delivers unique advantages in persistence, precision, and risk reduction, but no task is performed in isolation. Every on-orbit activity integrates sensing, GNC, manipulation, comms, flight dynamics, and ground operations; the robot is one element of a holistic system. Moreover, in unstructured or novel situations, human problem-solving can be superior, and some operations are safer with human oversight. Our discussion therefore focuses on the specific OSAM functions where robotics augments or extends human capability and how human-on-the-loop supervision is retained for the safety-critical inflection point.

In addition to safety, robotic systems provide operational advantages by overcoming the limitation of human endurance, enabling continuous work over extended periods and thereby accelerating mission timelines. These technologies are uniquely suited to the challenges of space. Operating in microgravity, which poses significant challenges for traditional tools and human manipulation, robotic systems rely on advanced mobility mechanisms. For example, articulated arms, grappling systems, and thrusters help to navigate and stabilize robots in the vacuum of space for precise task execution. Moreover, their materials and components are specifically engineered to endure extreme temperatures, radiation, and vacuum conditions. For missions in deep space, where communication delays make real-time human intervention impractical, robotic systems can perform tasks autonomously or semi-autonomously, ensuring mission success even in remote environments.

In the context of space operations, robotic systems excel in tasks requiring precision and dexterity. For example, they can refuel satellites, construct and maintain space stations, and capture space debris to reduce the risk of collisions [170]. They are also pivotal in assembling large-scale scientific instruments or habitats that cannot be launched as a single unit due to size constraints. These capabilities not only extend the operational life of space infrastructure but also reduce costs by enabling asset reuse and minimizing the need for replacement missions. The diverse applications of robotic systems in OSAM can be categorized based on their mission objectives, including repair and maintenance robots, refueling robots, space debris capture robots, manufacturing and assembly robots, and CubeSats/SmallSats. Robotic systems are designed to perform intricate tasks such as refueling, enhancing, and repair to prolong the functionality of satellites, space stations, and space assets. Over the recent decades, servicing robots have been employed on spacecraft to refuel, repair, upgrade satellites in orbit for longer usability, and assist with research tasks.

4.1. Repair and Maintenance Robots

Robotic systems dedicated to repairs and maintenance warrant the longevity and sustainability of space operations. These systems perform servicing tasks that reduce astronaut involvement in high-risk activities, maintain spacecraft functionality, and minimize flight risks. As discussed in Section 3.2, repair operations form a critical element of on-orbit servicing, and their effectiveness relies on the ability to deploy robotic platforms capable of executing complex corrective actions. The technologies introduced here represent the practical realization of those repair strategies, enabling tasks such as component replacement, structural maintenance, and system recovery without direct astronaut intervention.

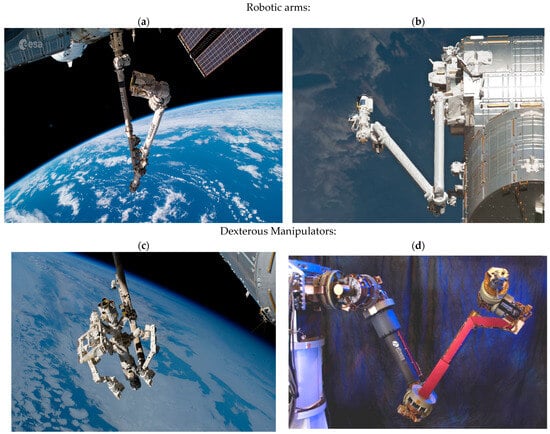

One of the pioneering robotic systems in space is the Shuttle Remote Manipulator System (SRMS), also known as the Canadarm1 (Figure 1a). This robotic arm, equipped with six degrees of freedom (DOF), plays a key role in tasks such as capturing satellites and deploying payloads in LEO [171,172,173]. By reducing the need for astronauts to perform high-risk tasks, SRMS significantly prioritized crew safety and extended mission longevity while lowering flight risks. It was designed for both manual control from the space shuttle’s cockpit and remote operation, showcasing the potential of robotic arms for space servicing. Building on this capability, the Manipulator Flight Demonstration (MFD) further advanced robotic arms in space by incorporating autonomous capabilities for servicing and maintenance tasks. The MFD demonstrated its ability to autonomously attach/detach orbital replacement units (ORUs), critical components used for replacing malfunctioning spacecraft parts [174]. MFD allows for autonomous repairs in orbit, reducing the need for astronauts to conduct EVAs and significantly extending the operational lifespan of spacecraft components.

In addition to these robotic arms, The Japanese Experiment Module Remote Manipulator System (JEMRMS), mounted outside the Japanese Experiment Module (JEM) on the ISS, has been used for precise maintenance tasks, including payload handling and module repairs (Figure 1b) [171,175]. Consisting of two robotic arms with six DOF, JEMRMS performs delicate maintenance tasks such as payload handling, component inspections, component replacement, and astronaut support during EVAs. JEMRMS reduces astronaut exposure to high-risk EVAs and helps ensure spacecraft operational longevity of the ISS. Similarly, Dextre, or the Special Purpose Dexterous Manipulator (SPDM), is a two-armed robot with seven DOF per arm located on the ISS (Figure 1c). Dextre is equipped with tools capable of performing various complex tasks such as replacing batteries, repairing spacecraft components, and servicing equipment [154]. The autonomous capability extends the operational lifespan of the ISS and reduces astronaut risks associated with spacewalks.

To highlight free-flying robots in space, the Synchronized Position Hold Engage and Reorient Experimental Satellites (SPHERES) program, developed by MIT’s Space Systems Laboratory, aimed to test and validate technologies critical for satellite formation flight and autonomy. Deployed aboard the ISS, SPHERES provides a safe, reusable zero-gravity platform to test sensor, control, and autonomy technologies for use in satellites particularly in formation flight [176,177]. Shortly after, the Astrobee project was introduced representing how autonomous robotic systems could assist with servicing operations in space. Astrobee is a free-flying robotic assistant (distinct from satellites), which are also free-flying systems but lack manipulation and servicing functionality (Figure 1e) [66]. The system consists of three cube-shaped robots Bumble, Honey, and Queen [178,179]. Each are equipped with advanced sensors, cameras, and thrusters for autonomous navigation. These robots are designed for inspections, environmental interaction, and experiments while testing robotic technologies for future space operations. Without being tethered to a specific location, free-flying robots offer autonomous inspections, assembly, and repair capabilities. Their ability to navigate and interact with space structures increases mission flexibility, reduces human intervention, and enables more complex operations. More recently, with the rise in artificial intelligence, CIMON-2 was constructed as an AI-driven robotic assistant aboard the ISS by the German Aerospace Center (DLR) (Figure 1h) [180]. CIMON-2 autonomously supports data collection and basic maintenance tasks to increase astronaut productivity and assure smooth spacecraft functionality, even during extended missions. Similarly, JAXA’s Int-Ball (Internal Ball Camera) augments crew efficiency by autonomously navigating the station’s modules to document experiments and daily activities (Figure 1f) [181]. By freeing astronauts from the task of manual photography and videography, Int-Ball allows them to dedicate more time to critical science and operational tasks, further contributing to the ecosystem of assistive robotics that underpins modern space station operations. Building on the success of the first model launched in 2017, the upgraded Int-Ball2 was deployed to the ISS in 2023 with enhanced maneuverability, imaging capabilities, and improved ground operability [182]. This second-generation system further reduces astronaut workload by enabling more autonomous camera operations, strengthening the role of free-flying robotic assistants in supporting crew and mission efficiency. By enabling autonomous and precise servicing, space robots maintain spacecraft functionality, repair damaged components while supporting on-orbit maintenance. Full-system missions only illustrate how robotic elements (e.g., manipulators, sensors, autonomy) are embedded within larger platforms and trace requirements that flow down to the robotics.

A notable satellite servicing program named Orbital Express was proposed by the (Defense Advanced Research Projects Agency) DARPA in 1999 [183,184]. Orbital Express aimed to verify the servicing capabilities of on-orbit satellites through tasks such as capturing, maintenance, and refueling. The program utilized two main satellites: the Autonomous Space Transport Robotic Orbiter (ASTRO) and the NEXT Generation Serviceable Satellite (NEXTSat), which worked together for OOS and refueling (Figure 1i). ASTRO, equipped with advanced video guidance sensors (AVGs), autonomously located and docked with NEXTSat to perform maintenance tasks, inspections, and component replacements.

Following this, DARPA released the Phoenix Spacecraft Servicing Program (PSSP) [185]. PSSP aimed to develop technology for reusing functional components from decommissioned or malfunctioning satellites, reducing the cost of new space equipment. The program utilized a Payload Orbital Delivery System (POD) stored within modular functional components (Satlets) of satellites (Figure 1j). Service satellites captured the PODs and extracted functional components for installation onto new space systems, demonstrating modular satellite replacement and flexible teleoperation capabilities. These programs represent significant advancements in satellite repair and servicing technology, with potential implications for reducing mission costs, extending satellite lifespans, and enabling more complex space missions in the future.

DARPA also developed the RSGS project, which involves the development of robotic systems capable of servicing and repairing satellites in geosynchronous orbit (GEO) [75]. The system includes robotic arms capable of repairing satellite components and extending satellite life by servicing key systems such as propulsion and thermal management. The robotic manipulator part of RSGS is the Front-end Robotics Enabling Near-term Demonstration (FREND). FREND is a robotic manipulator designed for satellite maintenance and servicing, offering precise and autonomous capabilities (Figure 1d). FREND features a 7 DOF robotic arm, allowing for precise and flexible manipulation of objects in space [186,187]. Equipped with advanced vision systems and sensors, FREND can accurately track objects, align, and interact, ensuring the safe handling of satellites and debris. The system can perform repairs, refueling, and deorbiting defunct satellites in orbit [186]. As part of OSAM, FREND helps demonstrate the capabilities of a more sustainable space environment and paves the way for future servicing and refueling capabilities to maintain space assets for long-term viability.

Expanding on the success of previous robotic systems and programs, the development of humanoid robots introduced a new level of dexterity and autonomy, enabling more sophisticated maintenance tasks in space. Robonaut 1 (R1) and Robonaut 2 (R2), NASA’s humanoid robots were designed to assist astronauts in a variety of maintenance and repair tasks during space missions (Figure 1g) [188,189,190]. Containing human-like dexterity, both R1 and R2 can perform precise tasks, handle tools, and support astronauts during EVAs. Their ability to manage repairs autonomously and assist astronauts in complex maintenance scenarios directly contributes to safer and more efficient space operations, allowing for quicker recovery from system failures. Beyond repairs and maintenance, spacecraft functionality hinges on ensuring a steady supply of fuel for propulsion, altitude control, and thermal regulation. Robotic refueling systems, equipped with advanced nozzles, and precision alignment mechanisms are engineered to autonomously access fuel ports, transfer cryogenic or hypergolic propellants, and verify proper seals. These capabilities address one of the most significant challenges in long-duration missions–fuel depletion, enabling spacecraft to extend their operational lifespans and support deeper space exploration missions.

Figure 1.

Representative examples of robotic systems for repair and maintenance in space, organized by functional category. (a) Shuttle Remote Manipulator System (Canadarm1) capturing a satellite (Courtesy of NASA/CSA). (b) Japanese Experiment Module Remote Manipulator System (JEMRMS) mounted on the ISS for payload handling (Courtesy of JAXA). (c) Special Purpose Dexterous Manipulator (SPDM, “Dextre”) conducting component replacement on the ISS (Courtesy of NASA/CSA). (d) FREND robotic arm developed under DARPA’s Robotic Servicing of Geosynchronous Satellites (RSGS) program (Courtesy of DARPA/Northrop Grumman) [187]. (e) Astrobee free-flying robotic assistant “Bumble” operating on the ISS (Courtesy of NASA). (f) JAXA’s Int-Ball (Internal Ball Camera) performing autonomous documentation tasks on the ISS (Courtesy of JAXA). (g) Robonaut, a humanoid robot designed to assist astronauts with maintenance tasks on the ISS (Courtesy of NASA). (h) CIMON-2, an AI-driven robotic assistant supporting astronauts aboard the ISS (Courtesy of DLR/Airbus). (i) DARPA’s Orbital Express mission showing ASTRO and NEXTSat docking for autonomous servicing [183,184]. (j) Concept rendering of modular Satlets developed under the DARPA Phoenix program for satellite servicing (Courtesy of DARPA). These examples illustrate the progression from traditional robotic arms to dexterous manipulators, free-flying assistants, humanoids, and autonomous satellite servicing systems that collectively extend spacecraft functionality, reduce astronaut risk, and enhance mission sustainability.

4.2. Refueling and Life-Extension Servicing with Robots

Refueling spacecraft in orbit addresses critical economic and operational challenges in space exploration and operation. Satellites and spacecraft are traditionally launched with a finite supply of fuel, limiting their lifespan and maneuverability. Without refueling, these assets eventually decommission, often resulting in the costly launch of replacements and contributing to the growing issue of space debris. Refueling servicers with robotics are designed to extend spacecraft lifetimes by transferring propellant in orbit or through autonomous docking. On-orbit refueling extends the operational life of spacecraft, reduces mission costs, and supports the more sustainable management of space assets. Several pioneering missions have demonstrated the feasibility and benefits of on-orbit refueling.

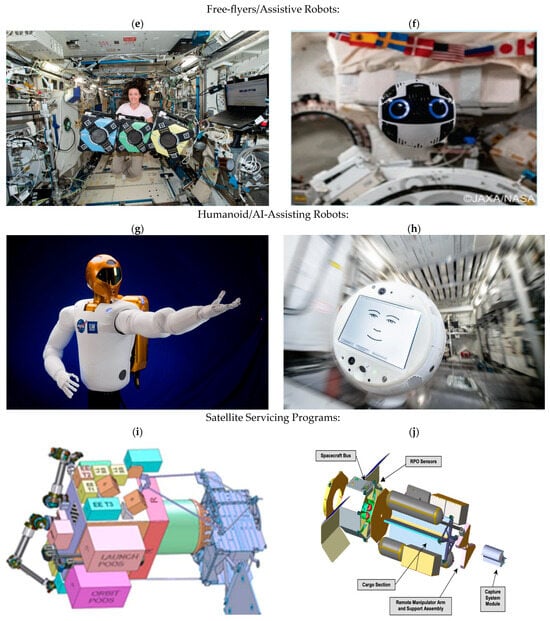

NASA’s Robotic Refueling Mission (RRM), conducted on the ISS, showcased a suite of robotic tools and techniques used for servicing satellites not originally designed for servicing [71,191]. The mission used the ISS’s robotic arm, Dextre, equipped with specialized robotic tools such as the Remote Manipulator System (RMS) and tools for cap unscrewing, blanket cutting, and transferring simulated fuel (Figure 2b) [192]. The RRM system involved complex tasks such as precise docking and transfer of cryogenic and non-cryogenic fluids, using a sophisticated robotic setup that mimicked an actual fuel transfer. This demonstration proved that autonomous robots could handle fueling tasks along with complex servicing operations in space, eliminating the need for human EVAs. A key achievement of Orbital Express was the first fully autonomous demonstration of satellite-to-satellite refueling in orbit [183,184]. During the mission, ASTRO successfully transferred hydrazine propellant to NEXTSat, validating the feasibility of extending spacecraft lifetimes through on-orbit refueling. This DARPA-led milestone directly paved the way for later commercial servicing initiatives, most notably Northrop Grumman’s Mission Extension Vehicle (MEV), which operationalized life-extension services for satellites. Taking a step further into the commercial sector, Northrup Grumman’s Mission Extension Vehicle-1 (MEV-1) marked a significant milestone in satellite life extension. Unlike RRM, MEV-1 involved a custom-built servicer spacecraft that docked precisely with the target satellite’s liquid apogee engine nozzle [11,193]. The mission required high-precision alignment and stabilization to ensure that satellite transfer propellant effectively or in this case extend space assets’ life. After docking, MEV-1 took control of the satellite’s propulsion and altitude systems, significantly extending the lifespan of Intelsat 901 (Figure 2c). MEV-1 proved that commercial missions could autonomously dock successfully, a necessary action in refueling services, reducing the need for costly satellite replacements and showcasing the feasibility of autonomous system systems in a commercial context (Figure 2b).

Figure 2.

Examples of robotic refueling and life-extension servicer missions organized by functional category: (a) The Restore-L concept featuring the SPIDER robotic arm, designed to perform autonomous propellant transfer and satellite servicing tasks in low Earth orbit). (b) NASA’s Robotic Refueling Mission (RRM) conducted on the ISS using the Dextre manipulator to demonstrate valve access, cap removal, and simulated propellant transfer. (c) Northrop Grumman’s MEV-1 docked with Intelsat 901, providing propulsion and attitude control to extend the satellite’s lifespan. (d) MEV-2 servicing Intelsat 10-02 in GEO, continuing the demonstration of commercial life-extension services through attached propulsion systems. Together, these missions illustrate the transition from government-led technology demonstrations to operational commercial servicing vehicles, underscoring the growing role of robotic refueling in enabling sustainable space operations.

Following this, Northrup Grumman released MEV-2 designed to extend the life of aging satellites through OOS. Launched in 2020, MEV-2 successfully docked with Intelsat 10-02 in 2021 and provided propulsion and station-keeping services extending its operational life [194]. The mission marked a milestone to demonstrate the feasibility of satellite life extension through autonomous docking and maintenance servicing (Figure 2d). Similarly, Orbit Fab’s Tanker-001 aims at a commercial solution for on-orbit refueling by being the first operational refueling satellite in GEO. The Tanker-001 mission is designed to dock with satellites in need of fuel, using a fully automated refueling process [195,196,197]. Equipped with a precise docking system, the Tanker-001 aims for the transfer of hydrazine or other propellants to target satellites. This mission demonstrates that the commercial refueling infrastructure can be implemented in orbit to offer a sustainable alternative to traditional satellite replacement. Building on these advancements, the Restore-L mission, which is now canceled, aimed to demonstrate autonomous refueling and servicing capabilities for satellites in LEO (Figure 2a). SPIDER, a robotic arm with seven DOF contains a precision end effector to interact with satellite fuel ports, enabling the transfer of propellants such as hydrazine [198,199]. The system is capable of docking with target satellites, performing intricate tasks such as unscrewing caps and connecting fuel lines, ensuring a controlled and safe refueling process. Robotic refueling technologies extend operational lifespans of spacecraft, enhance mission efficiency, and reduce the economic and environmental impact of space operations. These innovations offer the potential to revolutionize satellite/spacecraft servicing by enabling autonomous refueling suited for long-duration missions and mitigating risks associated with fuel depletion in space.

While robotic technologies address critical aspects of spacecraft longevity, another pressing challenge in space operations is the growing issue of space debris. To ensure space sustainability, specialized robots have been developed to capture and de-orbit space debris, preventing collisions and reducing the accumulation of defunct satellites and other hazardous objects in Earth’s orbit.

4.3. Space Debris Capture Robots

Space debris refers to non-functional objects or fragments resulting from human activity in Earth’s orbit, including defunct satellites, spent rocket stages, and discarded fragments from collisions or accidents [200]. As the number of satellites and space missions increases, so does the accumulation of debris, creating a significant risk for operational spacecraft, space stations, and future missions [201,202]. The growing congestion in orbit poses a threat to both the safety of space assets and the sustainability of space activities. This has led to space debris becoming a primary target for space servicing technologies, with active debris removal (ADR) emerging as a critical area of focus to mitigate risks, reduce collisions, and preserve valuable orbital space for future space missions [203].