1. Introduction

One of the significant advantages of gliders is that they do not use engines, thereby considerably reducing takeoff weight compared to other aircraft. This advantage has made gliders become popular with many applications. However, to achieve maximum operational efficiency, gliders must be designed to suit the specific characteristics of each mission. A crucial problem in the design phase is finding the optimal aerodynamic shape for the glider. The optimal glider shape must satisfy certain mission criteria, such as achieving maximum range or maximum flight endurance under given flight conditions.

In practice, aerodynamic optimization problems have been addressed for various types of aircraft. Lyu and Martins [

1] used CFD (computational fluid dynamics) simulations and gradient-based optimization methods for blended wing body aircraft. The CFD method used in Lyu and Martins’ research offers high accuracy as it directly solves the Navier–Stokes equations, but it requires significant computation time and resources.

To overcome this computational bottleneck, the field has increasingly relied on surrogate-based optimization (SBO), which replaces the expensive high-fidelity model with a cheap-to-evaluate approximation. A comprehensive overview of these techniques can be found in several key review articles. Among the most popular surrogate models is Kriging (or Gaussian Process Regression) [

2,

3,

4], which is highly valued for its ability to provide not only a prediction but also a measure of prediction uncertainty, enabling intelligent and efficient global optimization strategies. Other prominent methods include Radial Basis Functions (RBFs) [

5,

6,

7], valued for their conceptual simplicity and effectiveness, and Polynomial Response Surfaces [

8,

9,

10]. More recently, machine learning techniques have gained significant traction. Artificial neural networks (ANNs) [

11,

12,

13], particularly deep neural networks, excel at capturing complex, highly non-linear relationships in high-dimensional design spaces. The choice of optimization algorithm is equally crucial. Gradient-based algorithms are highly efficient for problems with smooth, convex design spaces, but are susceptible to converging to the nearest local minimum in the multi-modal landscapes typical of aerodynamics. In contrast, global, population-based methods such as genetic algorithms (GAs) [

14,

15,

16] and Particle Swarm Optimization (PSO) [

16,

17,

18] are exceptionally robust at exploring the entire design space. They are particularly adept at handling multi-objective problems.

Despite the maturity of these individual components, a significant research gap exists in their integrated application to complex problems like flying wing design, where aerodynamic efficiency and longitudinal static stability are fundamentally conflicting objectives. The necessity of this study, therefore, arises from the need for an efficient computational framework that can navigate this trade-off effectively. The novelty of our work lies in the specific combination of a fast-evaluating ANN surrogate, trained on VLM data, with a robust GA optimizer to efficiently solve a multi-objective design problem for flying wings, explicitly considering this crucial stability–performance conflict. Within the scope of this paper, we investigate the aerodynamic shape optimization problem for flying wing gliders using GAs and ANN. Training data for the ANNs are obtained from simulation results based on the VLM. The use of ANN can significantly reduce the program’s computation time. In this paper, we assume that the glider is released from a predetermined altitude and gradually descends to the ground. The glider’s aerodynamic shape is optimized for two scenarios: requiring maximum flight endurance and requiring maximum range.

4. Discussion and Conclusions

This paper has presented a comprehensive aerodynamic shape optimization methodology for flying wing gliders, leveraging a combination of genetic algorithms and artificial neural networks. The study systematically pursued two distinct objectives—maximum flight range and maximum flight endurance; it uncovered and ultimately resolved a fundamental conflict in tailless aircraft design.

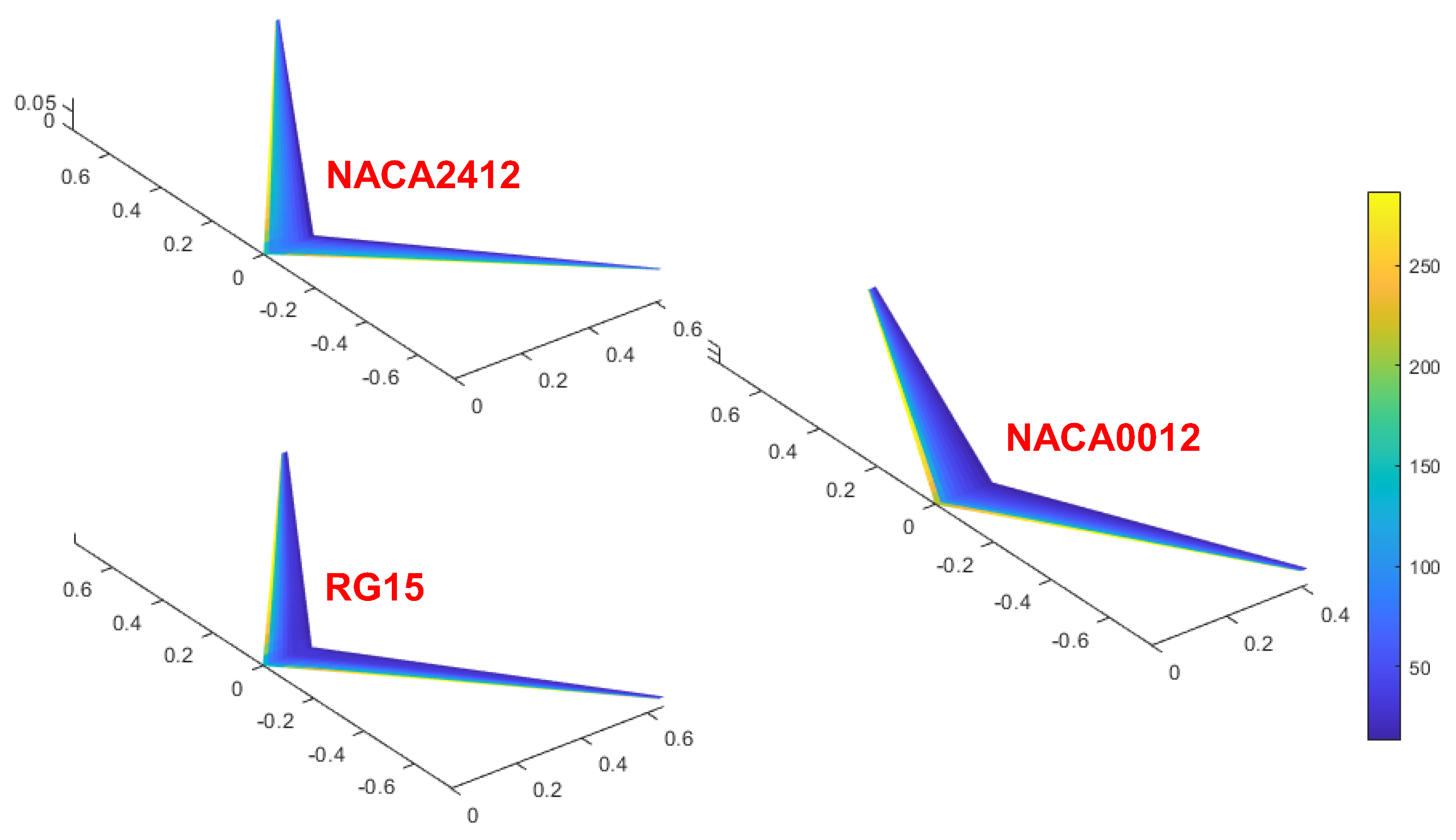

The initial investigation confirmed that the optimal glider shape is intrinsically linked to its mission. Configurations optimized for maximum range are characterized by higher aspect ratios and flight speeds to achieve the best lift-to-drag ratio. Conversely, designs optimized for maximum endurance feature larger wing areas and lower flight speeds to minimize the power required for flight. A comparison of various airfoils, including the NACA0012, NACA2412, RG15, MH78, and GOE765, revealed that while cambered airfoils consistently outperformed symmetric ones, a critical issue of static stability was observed.

The core finding of the unconstrained optimization was the conflict between aerodynamic performance and longitudinal static stability. The analysis of the center of pressure and neutral point locations revealed that the airfoils delivering the highest performance, such as the RG15 and NACA2412, consistently resulted in statically unstable configurations. Conversely, airfoils with reflex, such as the MH78 and GOE765, were the only ones to produce stable designs, but this stability came at a significant cost to their aerodynamic efficiency. This presented an engineering problem: the best-performing designs were unstable, and the most flyable designs were underperforming.

To bridge this gap, the research progressed to a more sophisticated optimization method. A stability constraint, implemented as a Heaviside penalty function, was integrated into the objective function to enforce a positive static margin. The primary mechanism for achieving this was the introduction of wing twist as a design variable. This refined approach proved successful, changing the previously unstable, high-performance designs into robustly stable configurations. A key insight from this result is that applying a geometric twist to a conventional airfoil functionally mimics the effect of a reflexed airfoil, effectively creating a “stable wing” from an “unstable wing section.”

However, this stability was achieved at an aerodynamic cost. The stable designs exhibited a performance decrease of approximately 11.5% in maximum range and a more substantial 25% in maximum endurance compared to their unstable theoretical counterparts. Furthermore, the optimizer found that stability was most efficiently achieved through a combination of high wing sweep and twist, leading to dramatic changes in the final wing planforms.

While the aerodynamic modeling approach has been validated against experimental data for a fundamental case, it is important to acknowledge that the final, optimized designs presented in this paper represent theoretical optima based on this model. Consequently, the performance of these specific configurations must be verified using higher-fidelity methods before any practical application. Future work should therefore focus on validating these promising designs through Reynolds-Averaged Navier–Stokes (RANS) computational fluid dynamics simulations and, ultimately, wind tunnel experiments. Such steps are essential to confirm the predicted performance gains and ensure that the flight characteristics are accurately captured before proceeding to a physical prototype.

Beyond the aerodynamic focus of this study, it is vital to recognize that the optimized geometric parameters have significant structural implications. Designs that converge toward a high aspect ratio and large sweep angle, while aerodynamically efficient, will experience higher bending moments at the wing root and are more susceptible to aeroelastic issues such as divergence and flutter. For instance, the designs in

Table 8, which feature high sweep angles to achieve static stability, would require significant structural reinforcement to maintain stiffness, thereby increasing the overall weight and potentially offsetting some of the aerodynamic gains.

Our design philosophy follows a sequential optimization approach, which is common in conceptual aircraft design. The core of this approach is the observation that for a given flight condition (altitude and velocity), the optimal aerodynamic shape for metrics like the lift-to-drag ratio is largely independent of the aircraft’s mass. Therefore, the structural problem can be effectively decoupled and addressed after the aerodynamic shape has been optimized. In this framework, the optimal aerodynamic shapes found in this study serve as a high-quality baseline. The subsequent structural design phase would then focus on realizing this shape with the minimum possible mass while satisfying all strength, stiffness, and aeroelastic constraints.

This highlights a key limitation of single-discipline optimization. A logical and necessary extension of this research is the development of a Multidisciplinary Design Optimization (MDO) framework. Such a framework would integrate a structural model (e.g., a finite element model) into the optimization loop, allowing for the simultaneous consideration of aerodynamic efficiency and structural constraints like weight, stress, and aeroelastic stability. This would lead to designs that are not only high-performing but also structurally robust and feasible.

In conclusion, this research went from identifying a fundamental design conflict to implementing and analyzing a more practical engineering solution. It has been demonstrated that, through advanced optimization techniques that incorporate aerodynamic mechanisms, such as wing twist and well-posed stability constraints, it is possible to develop high-performance flying wing designs that are both aerodynamically efficient and inherently stable. Future work should build upon these stable baselines to explore aero-structural optimization, the integration of control surfaces for maneuverability, and experimental validation of these promising designs.