1. Introduction

The structure of an aero-engine is complex, and its response characteristics are affected by various factors such as intake conditions, flight status, and load variations, rendering it a typical system characterized by strong coupling, fast time-varying, nonlinearity, and uncertainty. Modeling such a system with large-scale and high precision within the flight envelope presents significant challenges [

1,

2,

3]. Additionally, data are often sparse and incomplete due to physical limitations or faults of the data sampling system, external disturbances, and packet loss during transmission in practical operations. This sparsity caused by data loss further increases the difficulty of modeling [

4,

5]. However, effective modeling technology is essential for precise monitoring, fault diagnosis, control optimization, and performance prediction of aero-engines [

6,

7,

8,

9]. Therefore, conducting relevant research to address the special challenges in the aero-engine modeling methods has fundamental significance. An increasing number of researchers have focused on consensus protocols with specific convergence requirements.

Researchers have conducted a considerable amount of work in this field. Existing studies can generally be categorized into three types: “white- box” model, “gray- box” model, and “black- box” model. The basic principle of the “white- box” model involves establishing a gas turbine mathematical model based on the Brayton cycle principles. This is achieved by solving three types of nonlinear equilibrium equations: flow continuity equations, pressure balance equations, and power balance equations, according to the work characteristics of each component. Noteworthy works in this domain include [

10,

11,

12]. The primary challenges of the white-box model include (1) model convergence issues, real-time performance concerns arising from multiple iterative computations, and precision dependency of model accuracy on component characteristics; (2) degradation in engine component performance or actual installation errors can easily lead to model mismatch; and (3) models obtained through this method are challenging to apply in control design directly. The “gray-box” model often employs a data- and model-collaborative-driven architecture, where the model structure is derived based on the mechanistic approach [

13,

14,

15], and the specific parameters of the architecture are identified through data-driven methods. This approach combines the advantages of both white-box and black-box models. In [

16], a jet propulsion engine model was derived using a sparse identification method, and both batch least squares and recursive extended Kalman Filter were utilized for “gray-box” estimation. Wei et al. [

17] presented an onboard modeling method for gas turbine aero-engines based on a Hybrid Wiener Model (HWM) that utilized engine monitoring data. However, similar to the white box model, the mechanistic approach demands a considerable level of professional technical expertise from researchers, and the inaccuracy of component characteristics obtained by data-driven methods will seriously affect the model’s accuracy.

To tackle the challenges mentioned above, researchers have developed “black-box” models, with typical instances encompassing fuzzy system models [

18,

19,

20,

21] and artificial neural network models [

22,

23], among others. Although these models have demonstrated excellent performance in applications of aero-engines, especially when dealing with intricate nonlinear and time-varying characteristics, past applications have been restricted by constraints imposed by hardware and software systems. Recent technological advancements have significantly enhanced the data acquisition, computing, storage, and communication capabilities of aero-engine control systems, providing a solid foundation for new methods. In particular, innovations in artificial intelligence and Big Data offer fresh perspectives for developing “black-box” model [

24,

25,

26]. In [

27,

28], the data-driven “black-box” model is proposed, which does not depend on the physical mechanisms or fundamental equations of the system but learns the behavior of the system through input-output data. For example, Study [

29] proposes a framework combining Autoencoders and Gaussian Mixture Models (GMMs). It focuses on fault early warning in unsupervised scenarios. Study [

30] presents a comprehensive and valuable comparison of advanced modeling techniques, including Autoencoders, LSTMs, and Gaussian processes, for predictive maintenance. This work provides significant insights into uncertainty quantification, successfully demonstrating the capabilities of complex deep learning architectures. Another study [

31] offers a innovative approach by integrating Automated Feature Engineering (AFE) with Artificial Neural Networks to significantly improve the reliability of health status predictions. This method effectively addresses feature selection challenges and enhances model performance. The primary objective of the frameworks in [

29,

30,

31] is to achieve accurate predictions over long horizons. In comparison, control applications have different needs, placing with a particular emphasis on model interpretability, minimal latency, and the ability to precisely capture transient dynamics for immediate feedback.

The NARX model structure is derived from dynamic system theory, making it more suitable for formulating control-oriented models that must interact with a controller in real-time, as required in our study. De Giorgi and Quarta [

22] developed and validated a hybrid method combining the multigene genetic programming (GP) algorithm with artificial neural networks based on the NARX model, utilizing real flight data to simulate the transient behavior of the Viper 632-43 military turbojet engine, achieving promising results. In [

23], a method in which two NARX models collaborate was proposed for predicting the specific fuel consumption of a turboshaft engine during instantaneous flight maneuvers, which demonstrates its adaptability to “sudden operating condition changes”. Xu et al. [

32] introduced a digital twin model (DTM) based on NARX, which can accurately predict engine gas path parameters, and further verifies the reliability of NARX in predicting core performance parameters.The above works demonstrate that modeling engines using the NARX model is feasible and yields good results. Therefore, we adopt a data-driven NARX “black- box” model to construct a high-precision model of the entire operation process of a specific aero-engine in this paper.

However, existing “black- box” modeling methods face two main issues: (1) Due to physical limitations of the data sampling system, system faults, or data packet loss during transmission, the data are often sparse and incomplete. This missing data leads to sparsity, which reduces model accuracy and prevents effective generalization, sometimes even causing the model to fail to converge [

33,

34,

35]. (2) Although the NARX model theoretically has the potential to achieve a high-performance model, the actual performance is often highly sensitive to hyperparameters. Traditional approaches typically involve manual tuning of hyperparameters, such as the number of neurons in the hidden layers, transfer functions, delay orders, training functions, and output layer transfer functions. These methods are inefficient and do not guarantee optimal results, lacking theoretical or experimental guidelines, making it difficult to obtain a convergent NARX model [

36,

37,

38]. To address the above issues, we propose an ANAS-based ensemble modeling method for aero-engines using sparse data, tackling the challenge of high-precision modeling throughout the entire engine operation range, from the idle state to the full throttle state. The main contributions of this paper are summarized as follows:

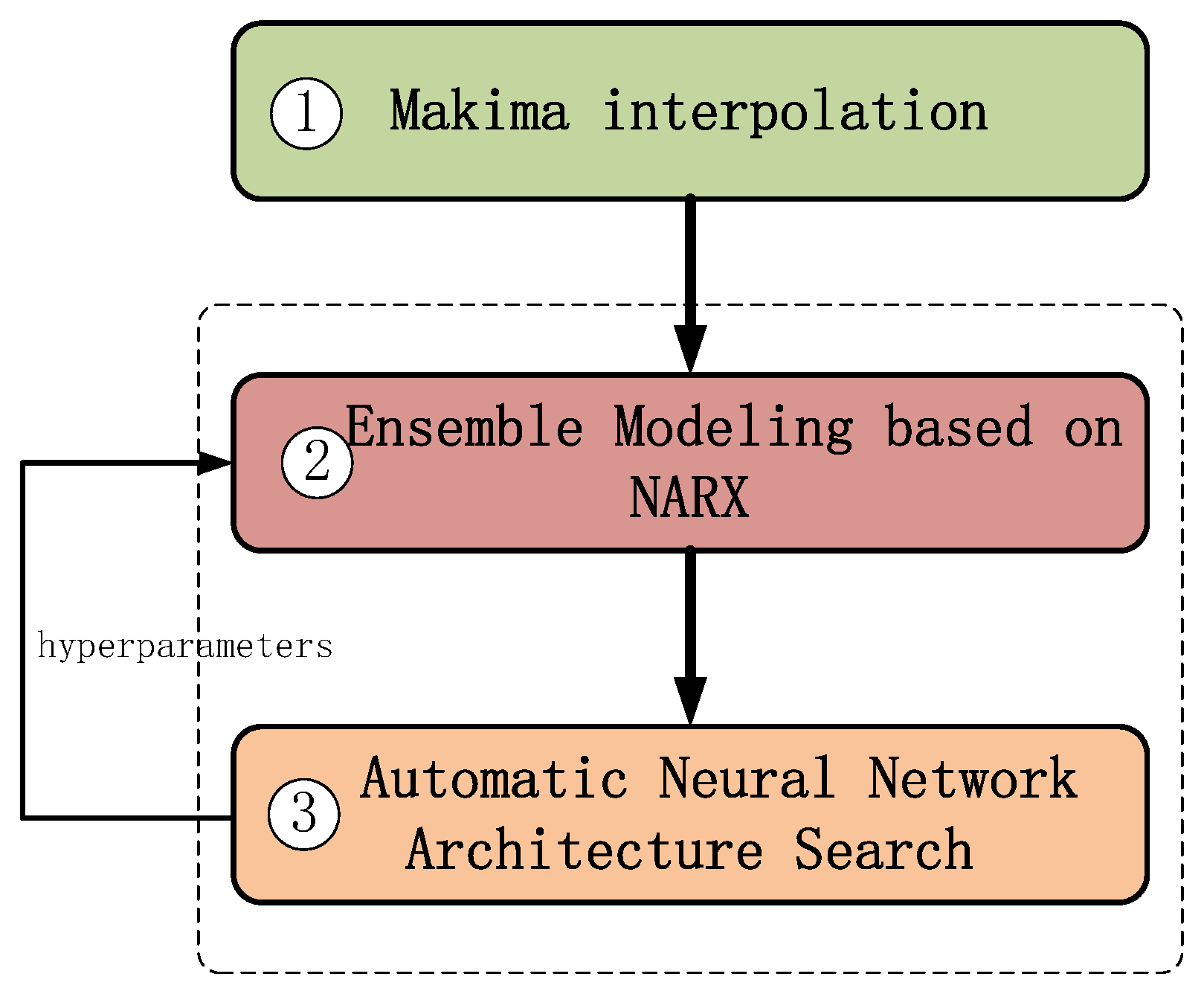

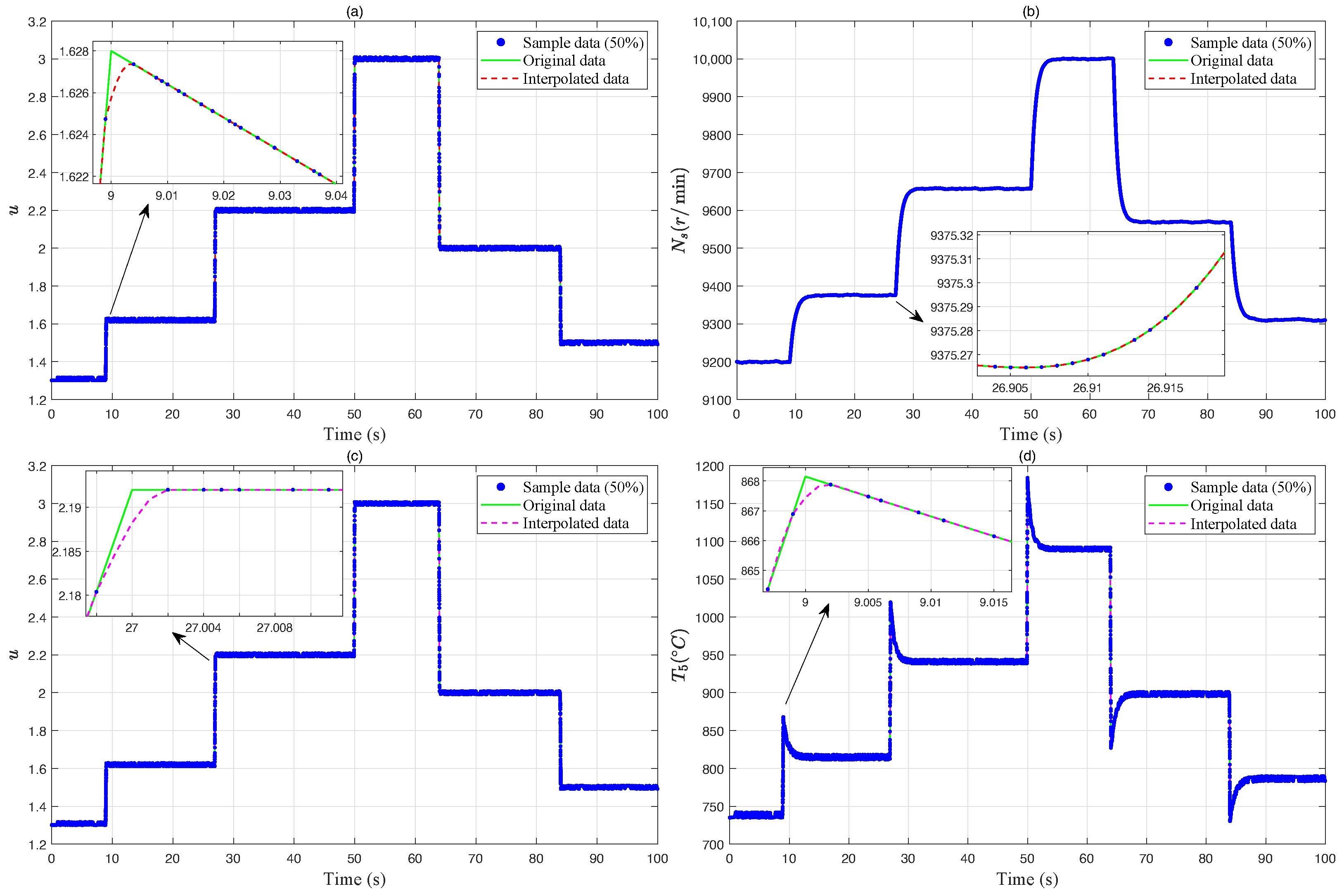

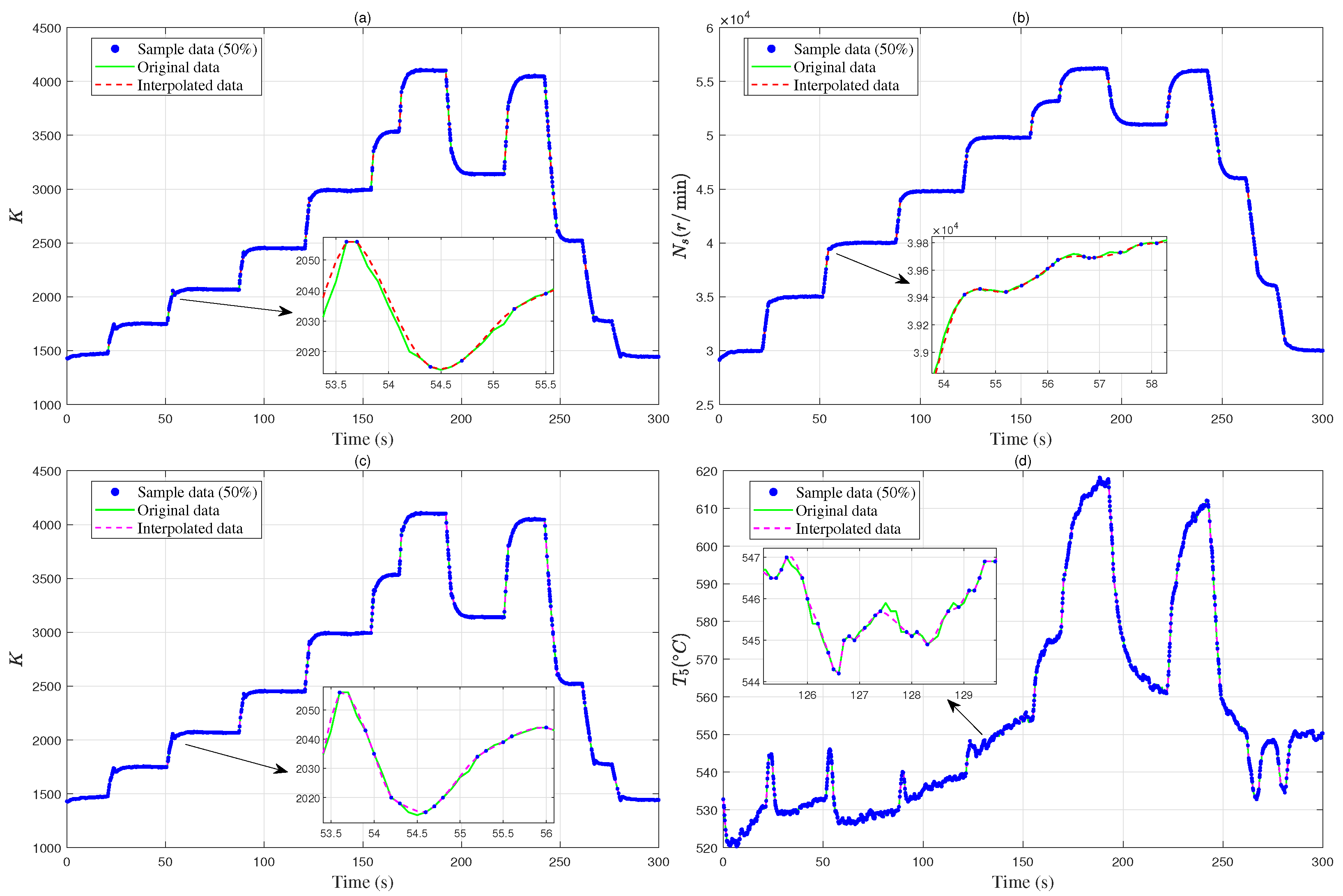

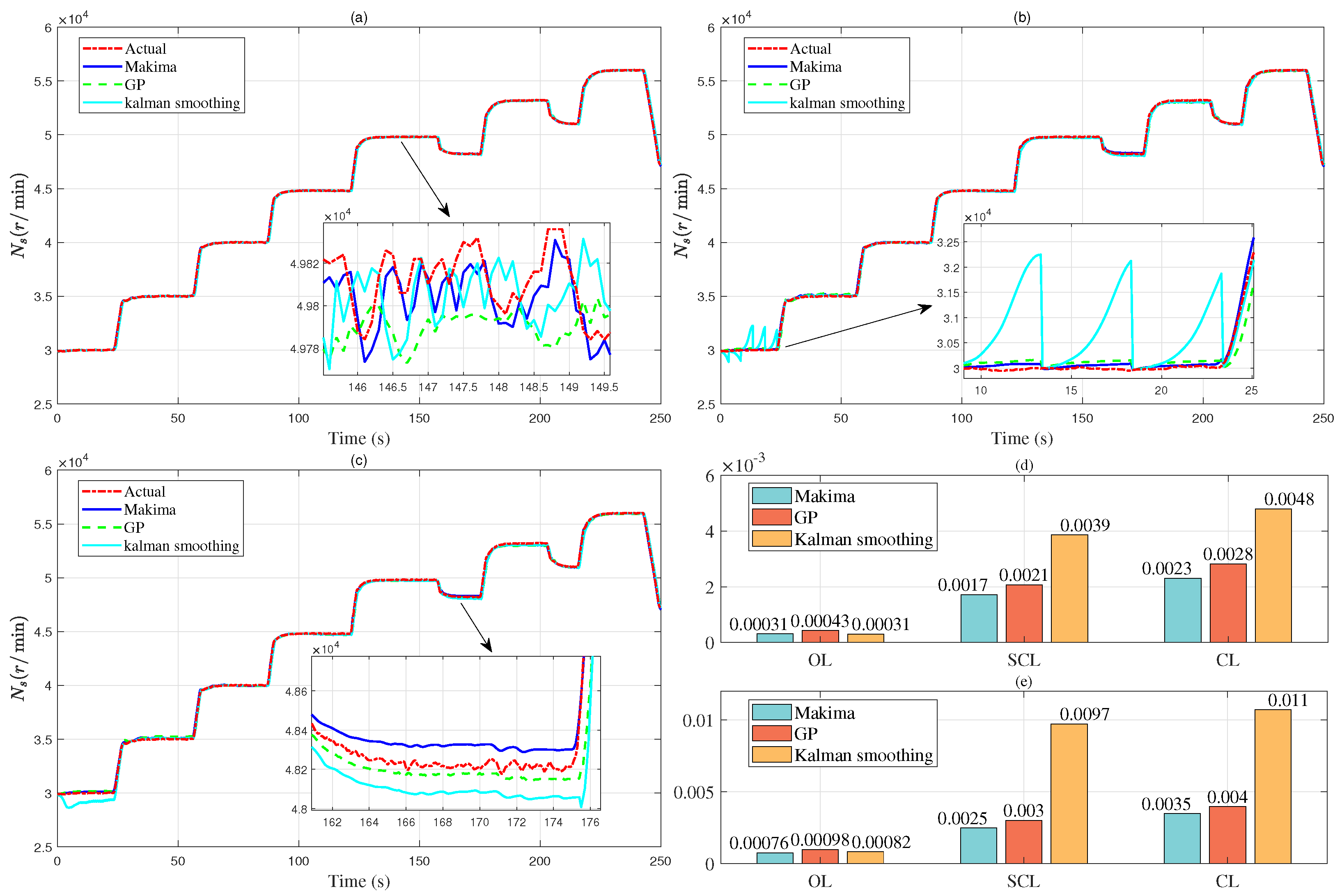

To address issues of incomplete and poor-quality data caused by sensor faults, system limitations, external disturbances, and data packet loss, we employ the Makima method to interpolate and complete sparse data. Based on the local geometric structure and trend information of the data, this method constructs a highly smooth and reasonable interpolation function to generate new data containing information on the input-output mapping of the aero-engine, thereby effectively enhancing the continuity and completeness of the data. The dataset obtained through this method can reflect the actual operational states of the engine more comprehensively and accurately, effectively avoiding problems such as poor model accuracy and non-convergence caused by data sparsity.

Based on actual operational data of the aero-engine and a new dataset obtained by the Makima method, we fully adopt the core principle of data-driven modeling and introduce a NARX neural network model. Considering the specificity of the data, we utilize an ANAS method to search for the hyperparameters [

39,

40]. In this way, we enhance the proposed method’s search efficiency and model accuracy.

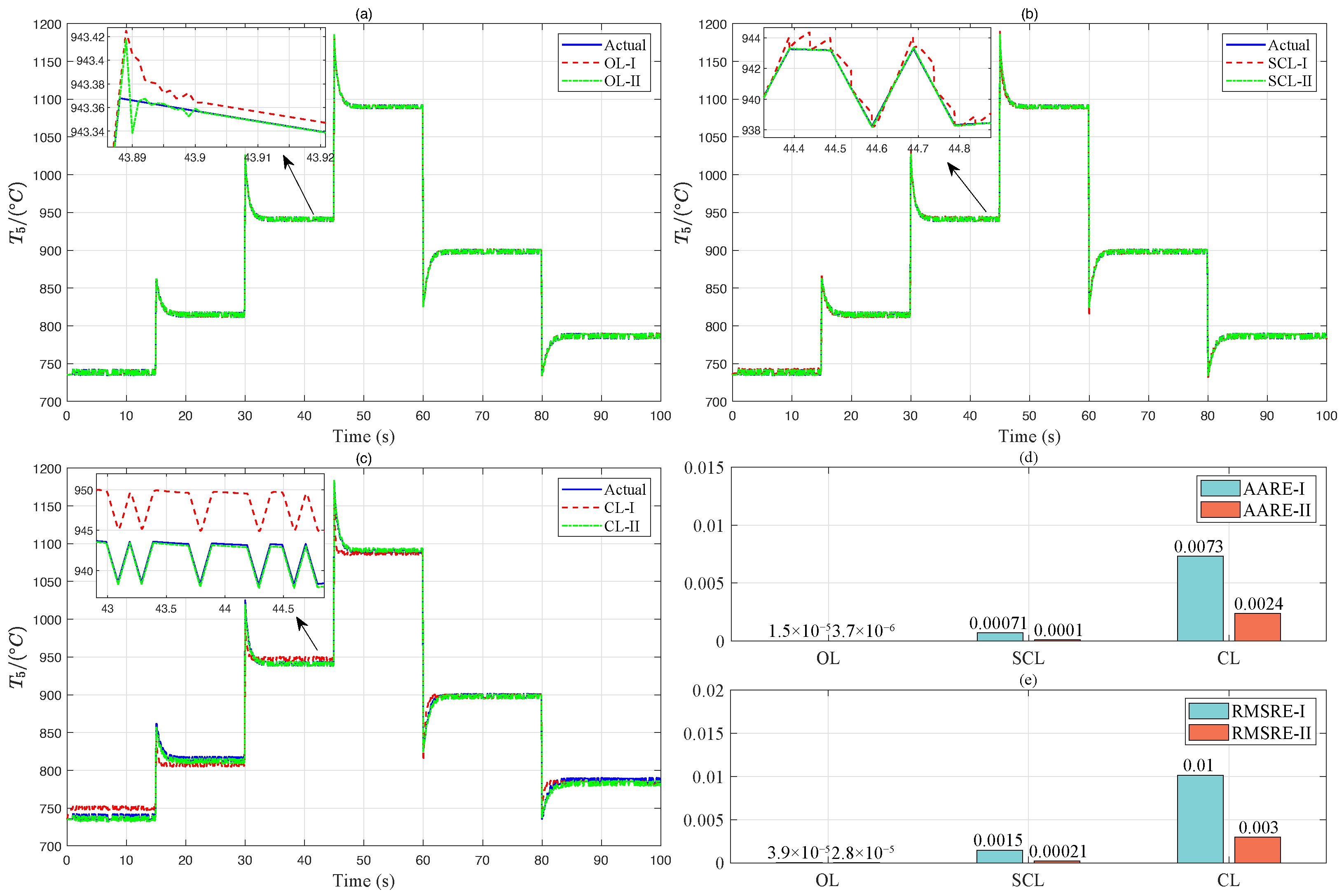

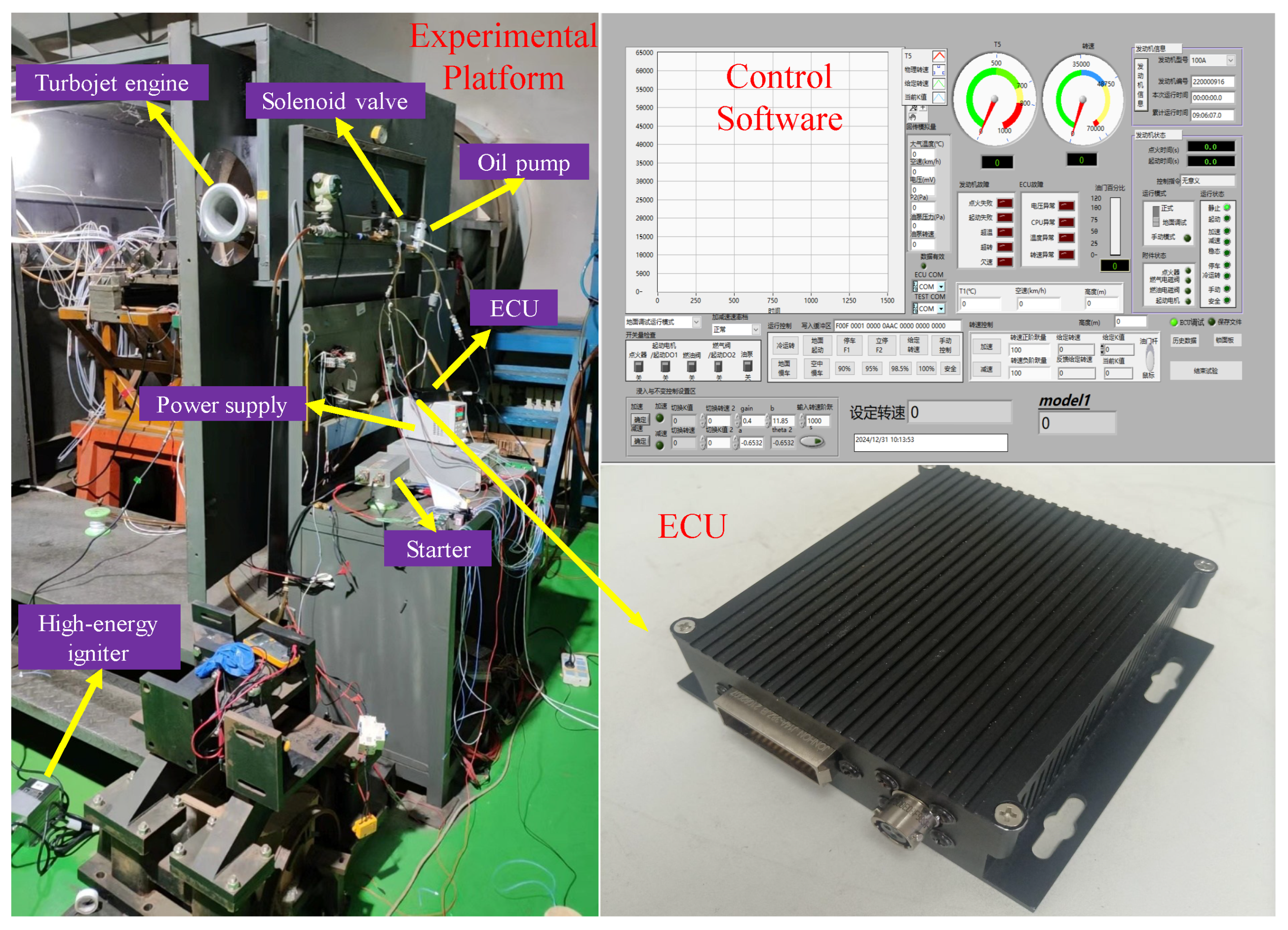

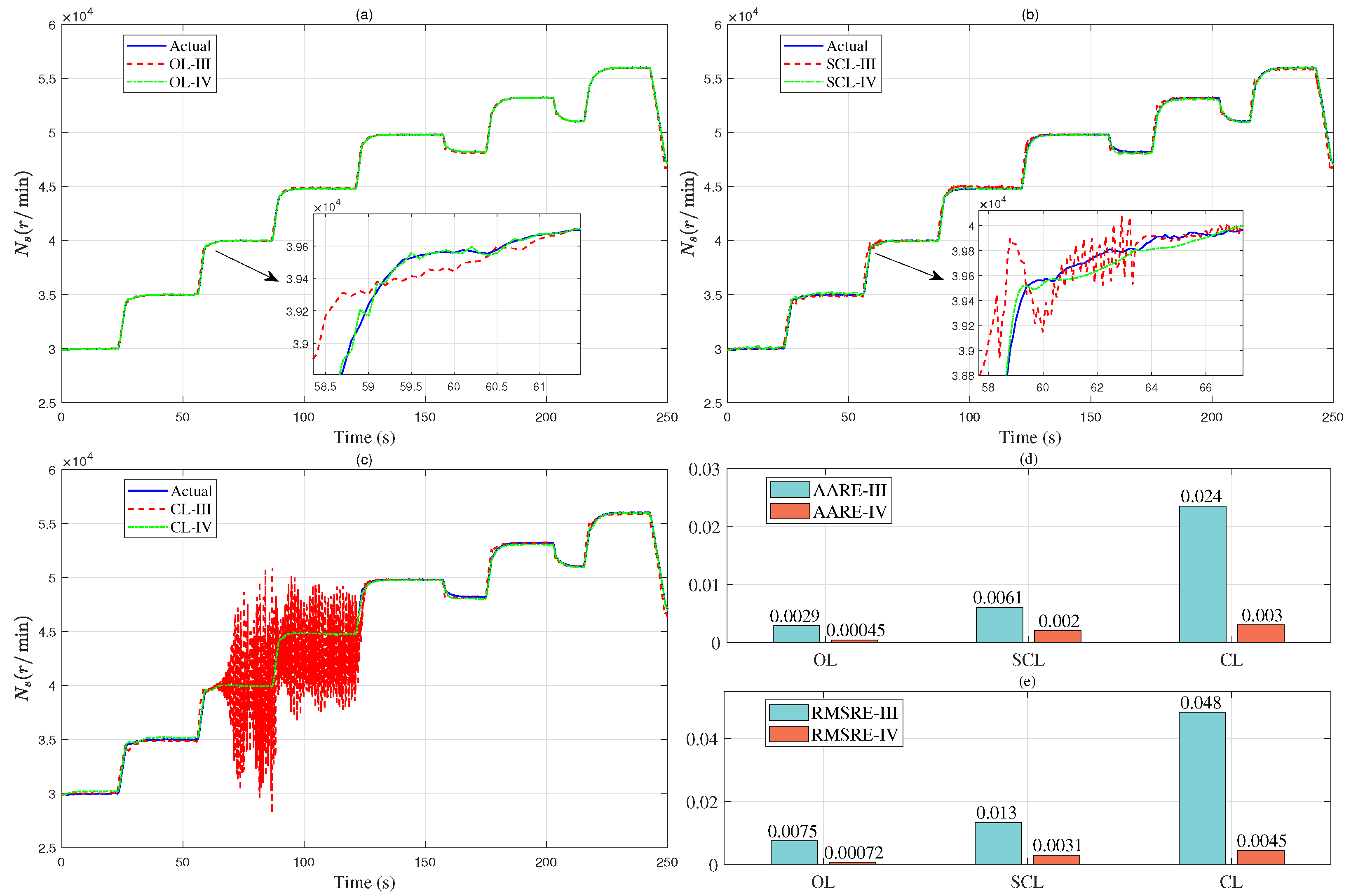

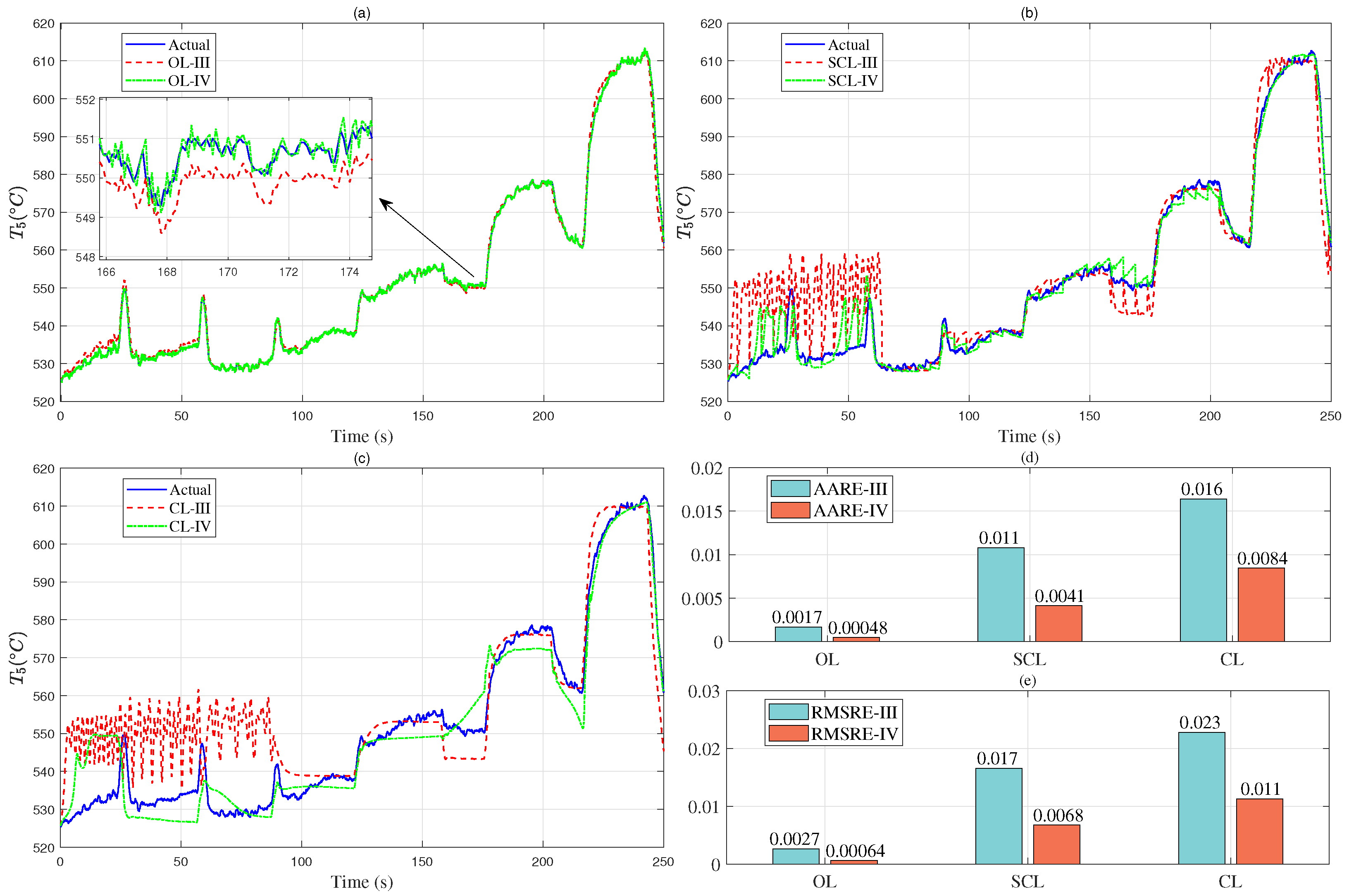

A novel ensemble modeling method for aero-engines is developed based on the Makima method, the NARX model, and the ANAS method. An experimental verification platform is designed, and the approach is validated through ground tests, achieving high-precision modeling of the entire operation process from the idle state to the full-throttle state. The results show that the aero-engine model obtained by the proposed ensemble modeling method demonstrates high performance in terms of convergence, accuracy, generalization ability, and real-time capability.

The subsequent sections of the paper are structured as follows:

Section 2 provides a detailed description of the ensemble modeling problem for aero-engines under sparse data, along with relevant background knowledge.

Section 3 presents the ensemble modeling method under sparse data, including modeling planning, the implementation of the NARX model, and the search process of the ANAS method.

Section 4 involves simulations, experiments, and analysis, primarily delineating the experimental validation platform and methodology, followed by an analysis of the experimental results. Finally, some conclusions are given in

Section 5.

2. Problem Formulation and Model Evaluation Indexes

The main objective of this paper is to find the following nonlinear mapping, which can be expressed as a difference equation as follows:

where

is the input and

is the output vector of the model,

and

are the delay orders of the input and output, respectively, which represent the order of the model. Specifically, for the experimental verification platform (a 100-kg thrust turbojet engine) in this paper, its input

is the control parameter

K value of the voltage to the oil pump motor, the output

represents the aero-engine rotational speed

, and the output

is the exhaust gas temperature

. According to the actual circuit design of the Engine Control Unit (ECU), the input voltage of the oil pump motor is determined by the following formula:

where

is the input voltage to the oil pump motor, and it positively correlates with the aero-engine’s steady-state fuel flow.

is the ECU supply voltage.

The NARX model, with its strong nonlinear mapping ability and autoregressive dynamic characteristics, is well-suited for representing the difference equations mentioned above. It is widely applied in time series modeling and forecasting [

41,

42,

43,

44], and is particularly effective for solving the modeling challenge presented in this paper. Therefore, the NARX model is employed to construct a comprehensive model of the entire operating process of an aero-engine. The evaluation indexes of the model adopt Average Absolute Relative Error (AARE) and Root Mean Squared Relative Error (RMSRE), which are calculated as follows:

where

is the model estimate value,

is the actual measurement value, and

n is the number of samples.

In time series prediction and system modeling, the selection of the Average Absolute Relative Error (AARE) and Root Mean Square Relative Error (RMSRE) as evaluation indices—instead of common indices like MAE, RMSE, or MAPE—is based on the following scientific considerations:

Scale Invariance: Unlike absolute error indexs (e.g., MAE, RMSE), AARE and RMSRE use relative errors (i.e., the ratio of error to the true value), making them insensitive to data scale variations. In engineering applications, data may span multiple orders of magnitude (e.g., variables with different dimensions like temperature, pressure, or flow). AARE and RMSRE enable fair evaluation of model performance across different magnitude data, avoiding evaluation biases caused by varying variable units.

Differentiated Response to Extreme Errors: AARE calculates the mean of absolute relative errors, demonstrating robustness to outliers. It is suitable for scenarios where overall trend evaluation is more critical.RMSRE amplifies the impact of larger relative errors through squaring operations, imposing stricter penalties on significant deviations. This makes it ideal for fields requiring tight control of extreme prediction errors (e.g., fault warnings or safety-critical systems).

Engineering Applicability: In dynamic system modeling (e.g., NARX), the relative magnitude of prediction errors is often more practically meaningful than absolute errors. For example, in process control, a 10 °C deviation might be catastrophic for a low-temperature reaction (e.g., 50 °C) but acceptable for a high-temperature reaction (e.g., 500 °C). AARE and RMSRE directly reflect the relative impact of errors, aligning more closely with the needs of engineering decision-making.

In summary, AARE and RMSRE are chosen for their scale robustness, sensitivity to critical errors, and engineering interpretability, making them particularly suitable for performance evaluation in multi-scale and nonlinear systems.