Numerical Simulation of Temperature Distribution in CCD Detector Irradiated by Nanosecond Pulsed Laser

Abstract

1. Introduction

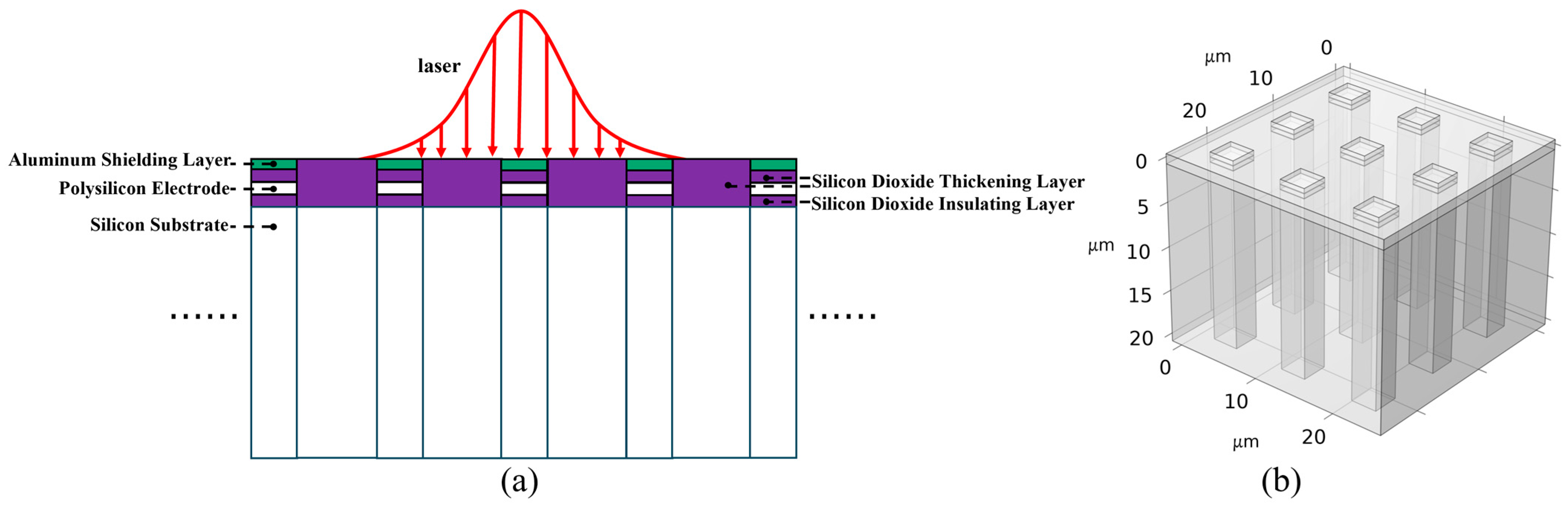

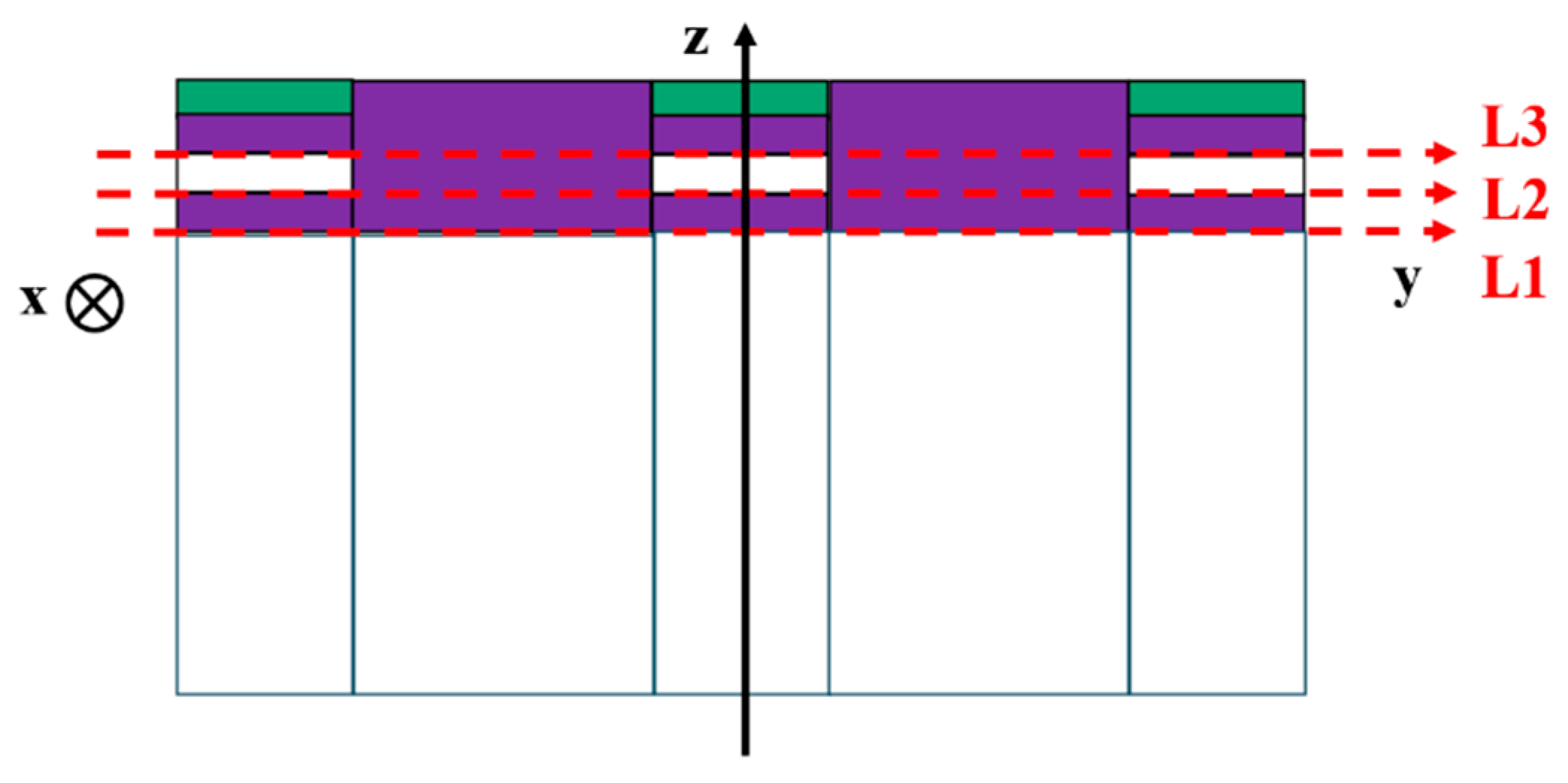

2. Physical Model

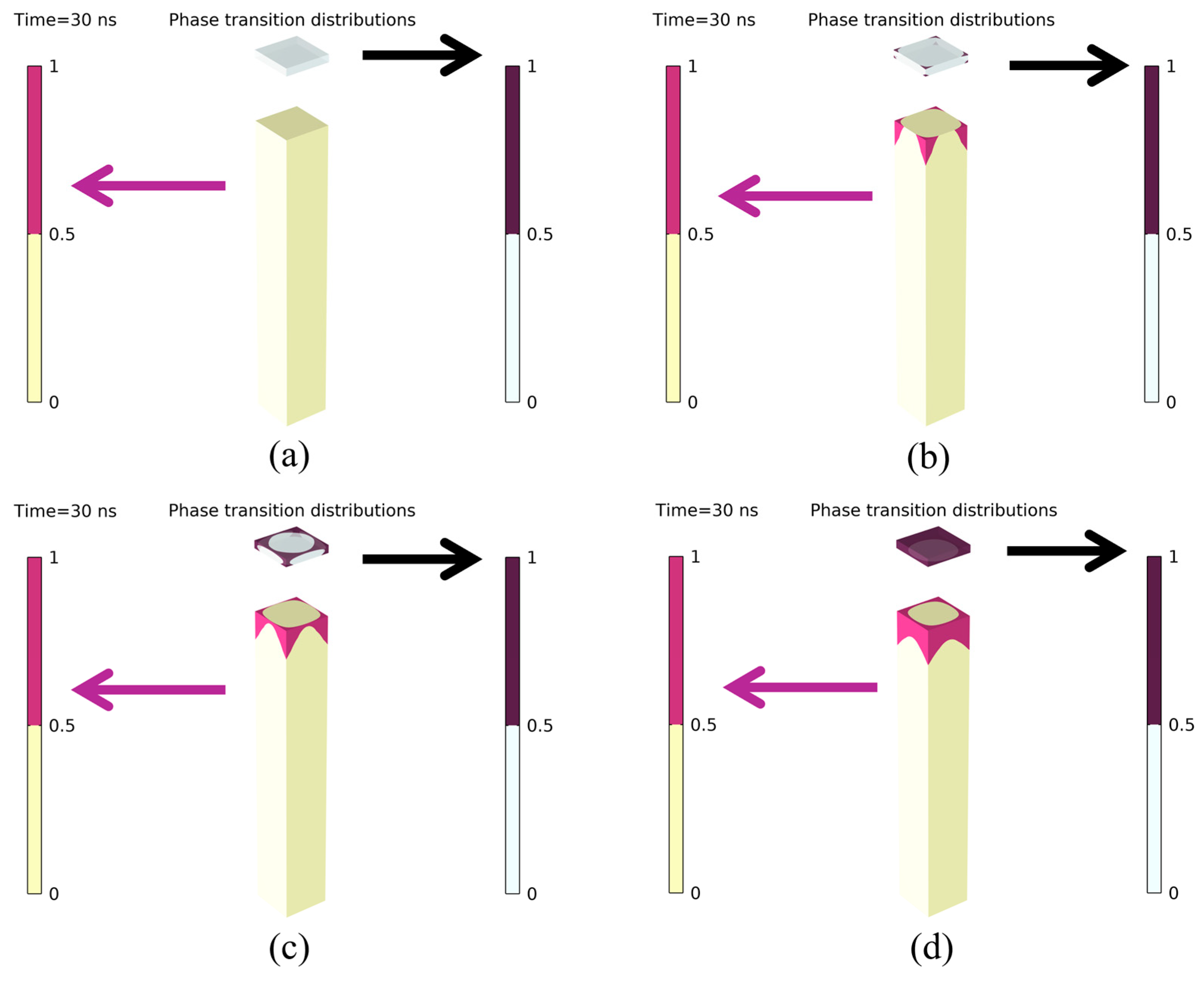

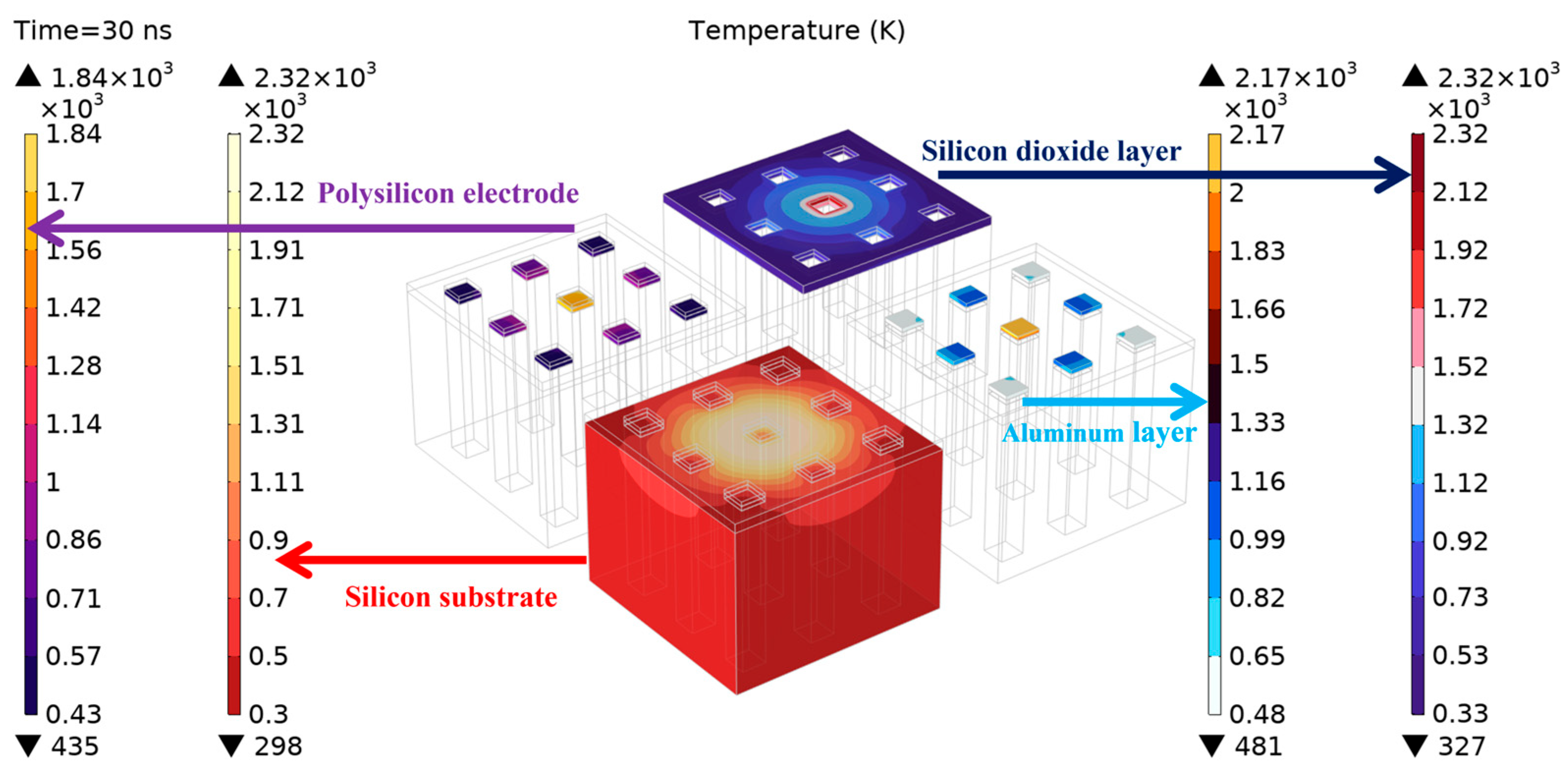

3. Results and Discussion

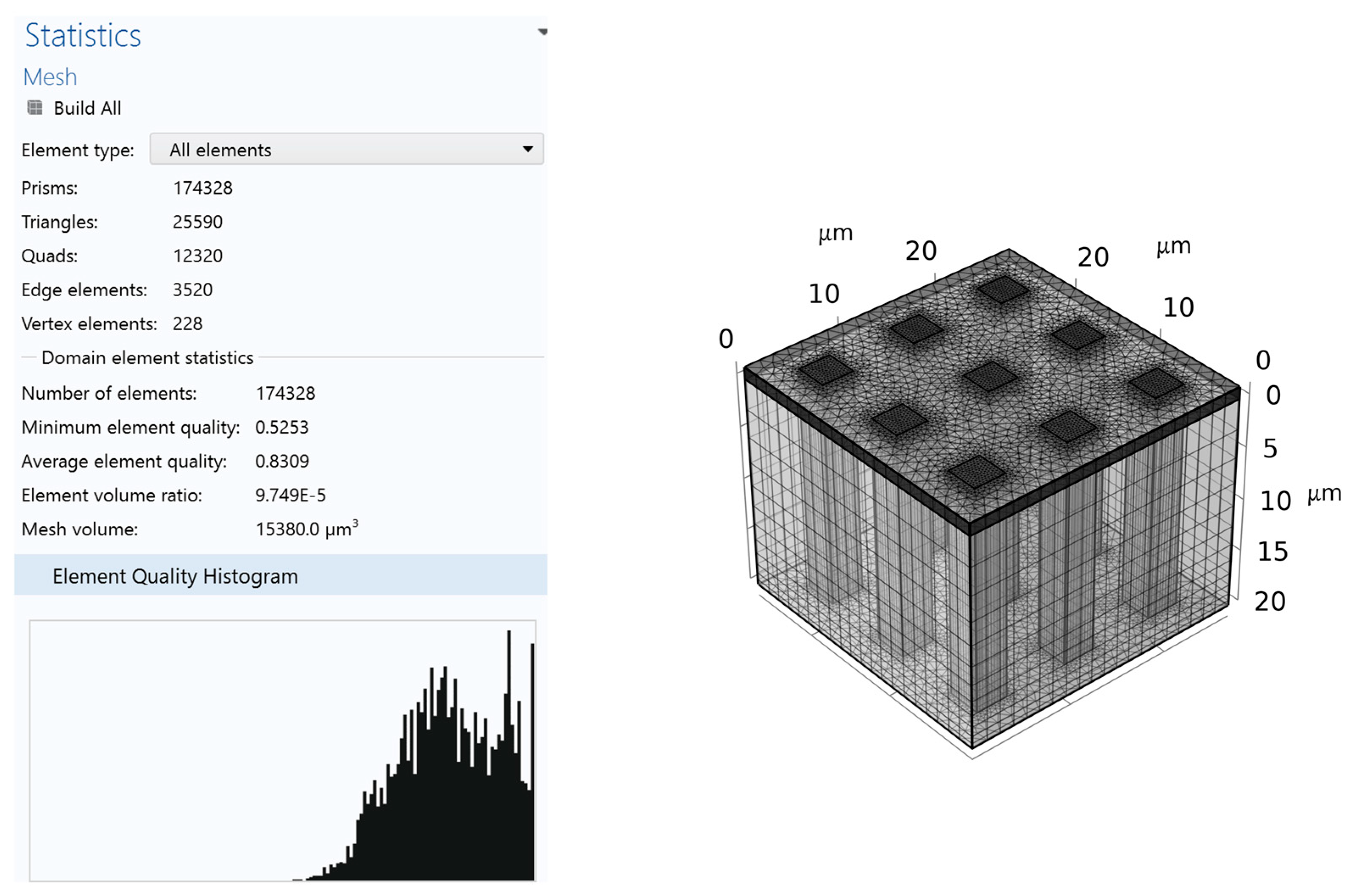

3.1. Validation of the Model

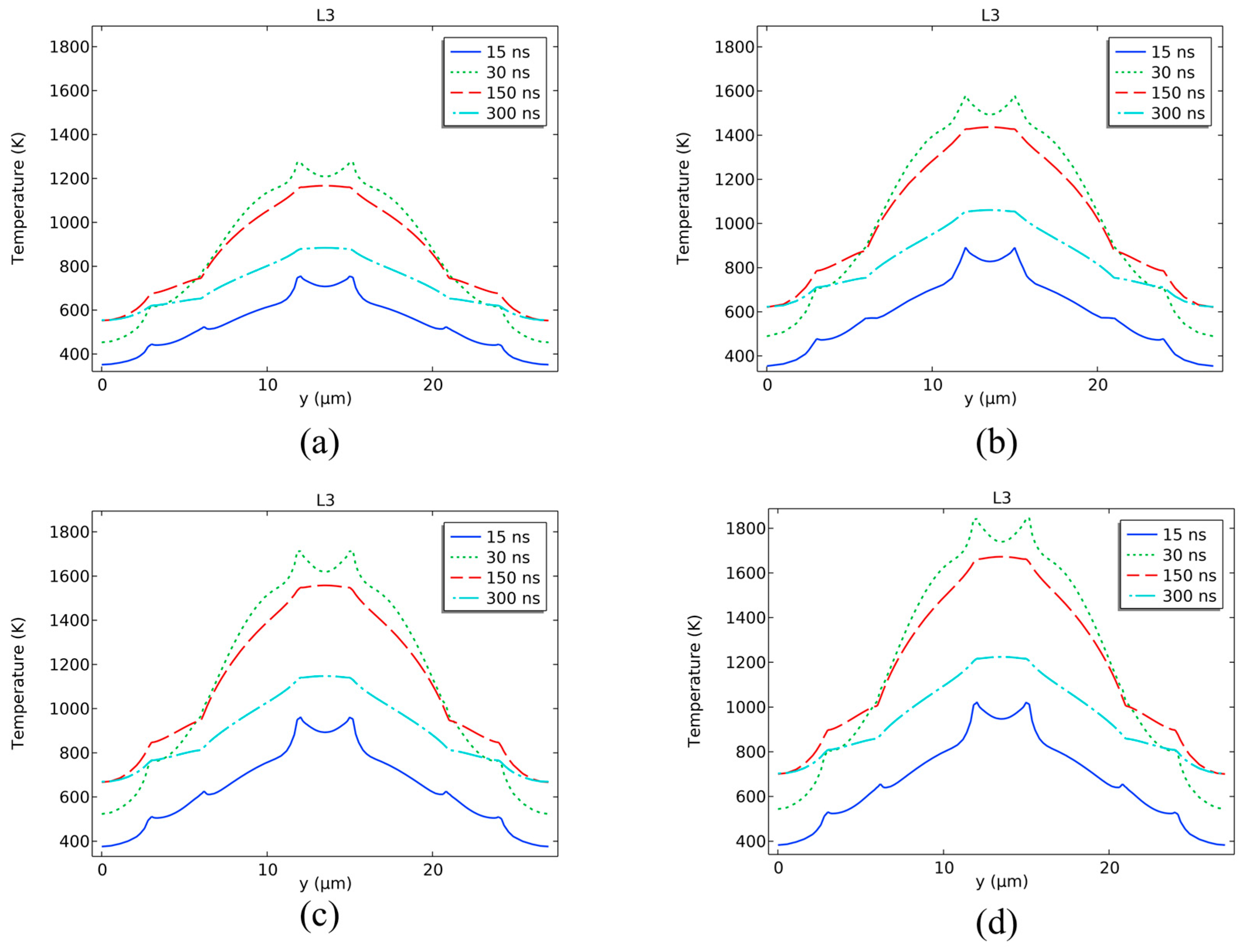

3.2. Influence of Laser Fluence on Thermal Damage

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Towaranonte, B.; Gao, Y. Application of Charge-Coupled Device (CCD) Cameras in Electrochemiluminescence: A Minireview. Anal. Lett. 2022, 55, 186–202. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Wang, J.; Feng, Q.; Guo, Y.-F.; Zhang, J.; Wang, Z.-Y.; Geng, Z.; Gao, J.; Liu, H.; et al. Development and performance test of a scientific CCD camera prototype for the Earth 2.0 mission. J. Astron. Telesc. Instrum. Syst. 2024, 10, 016002. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, R.; Zeng, C.; Liu, L.; Li, X.; Wang, X.; He, B.; Ehret, G.; Chen, B.; Han, S. A fast and precise autofocus method using linear array CCD. In Optical Metrology and Inspection for Industrial Applications XI; SPIE: Cergy, France, 2024; Volume 13241. [Google Scholar]

- Baranov, M. Image Processing of Biological Liquids Films for Medical Diagnostics. J. Electron. Sci. Technol. 2020, 18, 100027. [Google Scholar] [CrossRef]

- Jamaludin, J.; Rahim, R.A.; Rahim, H.A.; Rahiman, H.F.; Muji, S.Z.M.; Fadzil, N.S.M.; Ling, L.P.; Jumaah, F.; Ahmad, A.; Ayob, N.M.N.; et al. Introducing an application of a charged coupled device (CCD) in an optical tomography system. J. Teknol. (Sci. Eng.) 2015, 73. [Google Scholar] [CrossRef][Green Version]

- Yu, Y.; Zhao, X.-F.; Luo, H.; Mao, Y.-D.; Tang, Z.-H. Application of CCD drift-scan photoelectric technique on monitoring GEO satellites. Adv. Space Res. 2018, 61, 2320–2327. [Google Scholar] [CrossRef]

- Mori, S.; Enokuchi, A.; Konoue, K. Time delay integration using COTS IT-CCD for remote sensing and other applications. In Sensors and Systems for Space Applications XIII; SPIE: Cergy, France, 2020; Volume 11422. [Google Scholar][Green Version]

- Schwarz, B.; Ritt, G.; Koerber, M.; Eberle, B. Laser-induced damage threshold of camera sensors and micro-optoelectromechanical systems. Opt. Eng. 2017, 56, 034108. [Google Scholar]

- Schwarz, B.; Ritt, G.; Koerber, M.; Eberle, B. Impact of threshold assessment methods in laser-induced damage measurements using the examples of CCD, CMOS, and DMD. Appl. Opt. 2021, 60, F39–F49. [Google Scholar] [CrossRef] [PubMed]

- Han, M.; Nie, J.S.; Sun, K.; Wang, X.; Dou, X.A. Experiment on the temporal evolution characteristics of a CCD multilayer structure irradiated by a 1.06-µm continuous laser. Appl. Opt. 2018, 57, 4415–4420. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.N.; Niu, C.H.; Zhao, S.; Lv, Y. Investigation of interference on photodetector CCD by lasers with different wavelengths. Optik 2020, 202, 9. [Google Scholar] [CrossRef]

- Cheng, X.Z.; Shao, M.; Qu, W.D.; Shao, J.F.; LI, W.Z.; Fan, Y. Research on high-power laser damage to CCD detectors. Laser Infrared 2023, 53, 1743–1749. [Google Scholar]

- Cao, H.; Xie, X.; Chang, H.; Li, Y.; Yue, J.; Yu, Y.; Wang, G.; Tang, Z.; Li, L.; Wang, Y.; et al. Laser-induced damages to charge coupled devices with combined nanosecond/picosecond short-pulse lasers. Front. Phys. 2024, 12, 1345859. [Google Scholar] [CrossRef]

- Nie, J.S.; Wang, X.; Li, H.; Bian, J.T.; Hao, X.N. Thermal and mechanical damage in CCD detector induced by 1.06 μm laser. Infrared Laser Eng. 2013, 42 (Suppl. S2), 380–386. [Google Scholar]

- Li, G.; Shen, H.B.; Li, L.; Zhang, C.; Mao, S.J.; Wang, Y.B. Laser-induced damages to charge coupled device detector using a high-repetition-rate and high-peak-power laser. Opt. Laser Technol. 2013, 47, 221–227. [Google Scholar]

- Li, Z.; Wang, X.; Shen, Z.; Lu, J.; Ni, X. Mechanisms for the millisecond laser-induced functional damage to silicon charge-coupled imaging sensors. Appl. Opt. 2015, 54, 378–388. [Google Scholar] [CrossRef]

- Zhang, F.; Niu, Y.X.; Liu, N.; Liang, Z.J.; Liu, S. Research of temperature field and thermal stress field of CCD under laser irradiation. Laser Technol. 2017, 41, 433–437. [Google Scholar]

- Li, M.X.; Jin, G.Y.; Tan, Y. Simulation of the Si-CCD irradiated by millisecond pulse laser. Optik 2017, 131, 67–71. [Google Scholar]

- Ren, X.D.; Lei, W.H.; Wang, Y. Study on thermodynamic effect of CCD detector irradiated by laser. Optik 2019, 185, 497–504. [Google Scholar] [CrossRef]

- Kou, Z.; Li, Y.; Wang, G.; Li, K.; Hou, Y.; Xie, X.; Yu, Y.; Wang, Y.; Lu, Z. Temporal evolution characteristics and mechanism analysis of CCD breakdown induced by nanosecond and picosecond pulse lasers. Optik 2022, 262, 169313. [Google Scholar] [CrossRef]

- Cao, X.; Kang, H.; Yu, H.; Zhang, Y.; Gao, X. Liquid-solid phase transition time characteristics of CCD aluminum layer metal induced by nanosecond pulse laser. J. Appl. Opt. 2023, 44, 898–903. [Google Scholar] [CrossRef]

- Luštica, A. CCD and CMOS image sensors in new HD cameras. In Proceedings of the ELMAR-2011, IEEE, Zadar, Croatia, 14–16 September 2011. [Google Scholar]

- Peng, B. Study on the Thermal Stress of Millisecond Pulsed Laser Irradiation CCD Image Detectors. Master’s thesis, Changchun University of Science and Technology, Changchun, China, 2014. [Google Scholar]

- Li, Y.; Kou, Z.; Wang, G.; Hou, Y.; Xie, X.; Yu, Y.; Wang, Y.; Lu, Z. Recent advances of short-pulse laser–induced breakdown effect on charge-coupled device detectors. Opt. Laser Technol. 2022, 156, 108533. [Google Scholar] [CrossRef]

- Shao, J.F.; Liu, Y.; Wang, T.F.; Guo, J. Damage effect of charged coupled device with multiple-pulse picosecond laser. Acta Armament. 2014, 35, 1408–1413. [Google Scholar]

| Parameters | PI | Al | SiO2 | Si |

|---|---|---|---|---|

| Density/(kg/m3) | 1530 | 2709 | 2640 | 2330 |

| Thermal conductivity/(W/m·K) | 0.12 | 254 | 1.3 | 27 |

| Specific heat/(J/kg·K) | 1090 | 1050 | 787 | 1009 |

| Melting point/K | 710 | 932 | 1880 | 1685 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, H.; Zhou, W.; Jian, Z.; Ma, Y.; Quan, X.; Wang, Z. Numerical Simulation of Temperature Distribution in CCD Detector Irradiated by Nanosecond Pulsed Laser. Aerospace 2025, 12, 791. https://doi.org/10.3390/aerospace12090791

Chang H, Zhou W, Jian Z, Ma Y, Quan X, Wang Z. Numerical Simulation of Temperature Distribution in CCD Detector Irradiated by Nanosecond Pulsed Laser. Aerospace. 2025; 12(9):791. https://doi.org/10.3390/aerospace12090791

Chicago/Turabian StyleChang, Hao, Weijing Zhou, Zhilong Jian, Yingjie Ma, Xiaoyuan Quan, and Zikang Wang. 2025. "Numerical Simulation of Temperature Distribution in CCD Detector Irradiated by Nanosecond Pulsed Laser" Aerospace 12, no. 9: 791. https://doi.org/10.3390/aerospace12090791

APA StyleChang, H., Zhou, W., Jian, Z., Ma, Y., Quan, X., & Wang, Z. (2025). Numerical Simulation of Temperature Distribution in CCD Detector Irradiated by Nanosecond Pulsed Laser. Aerospace, 12(9), 791. https://doi.org/10.3390/aerospace12090791