Validation of PCB Strain-Based Methodology for Structural Design of Spaceborne Electronic Equipment Under Vertical Mounting Conditions in Launch Environments

Abstract

1. Introduction

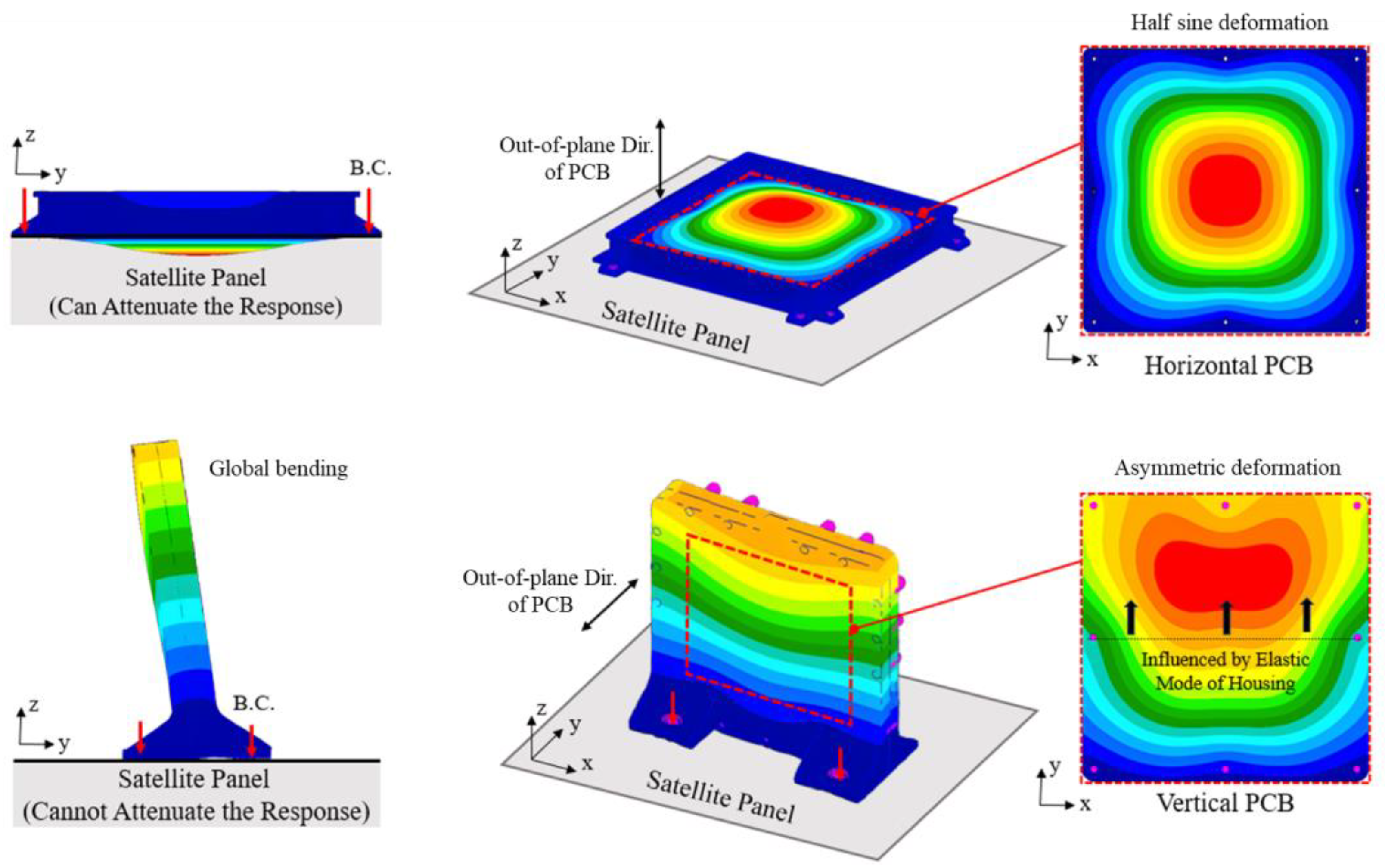

2. Structural Design Methodology

2.1. Steinberg’s Theory

2.2. Oh-Park Methodology

3. Fatigue Life Test of Electronic Equipment Module

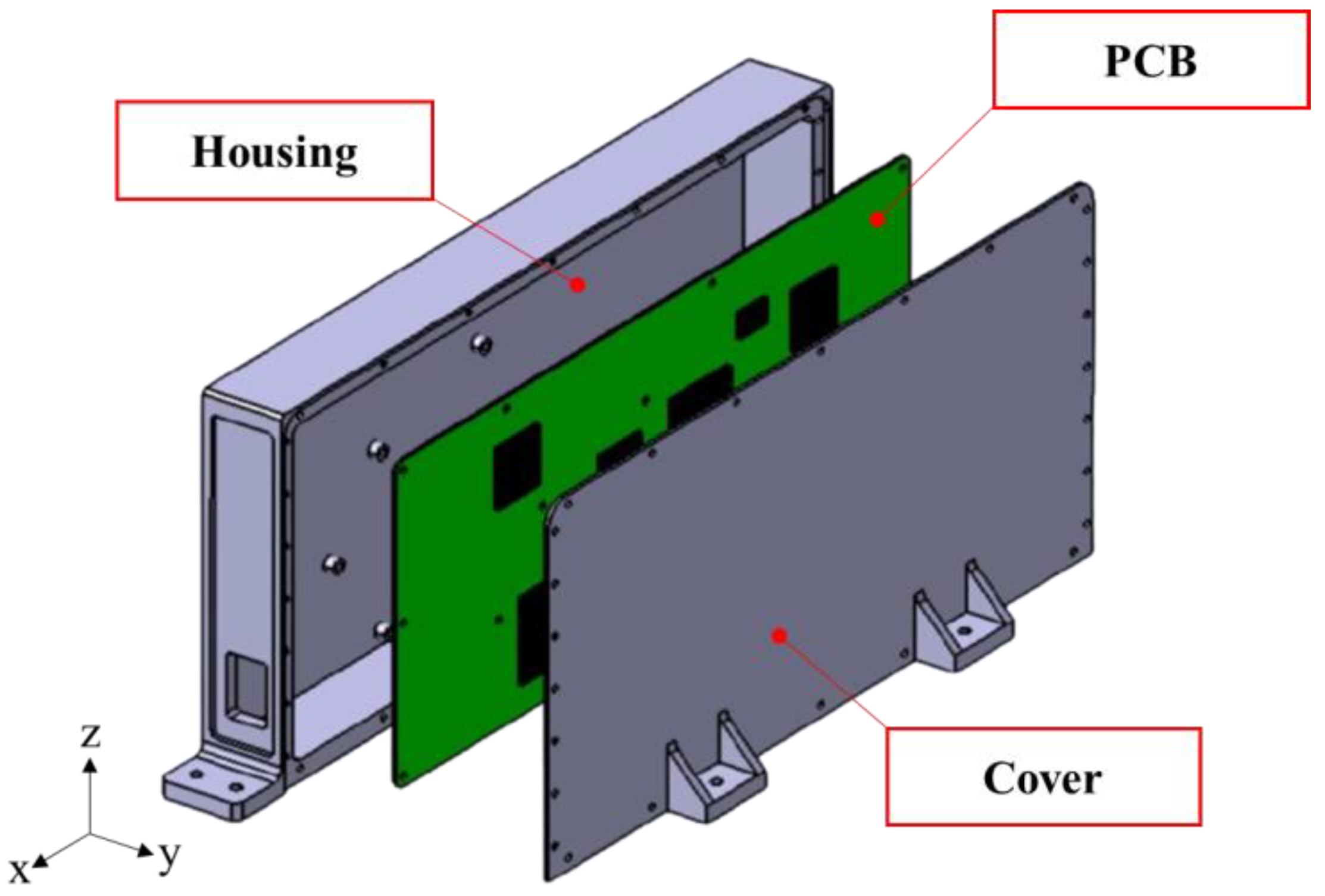

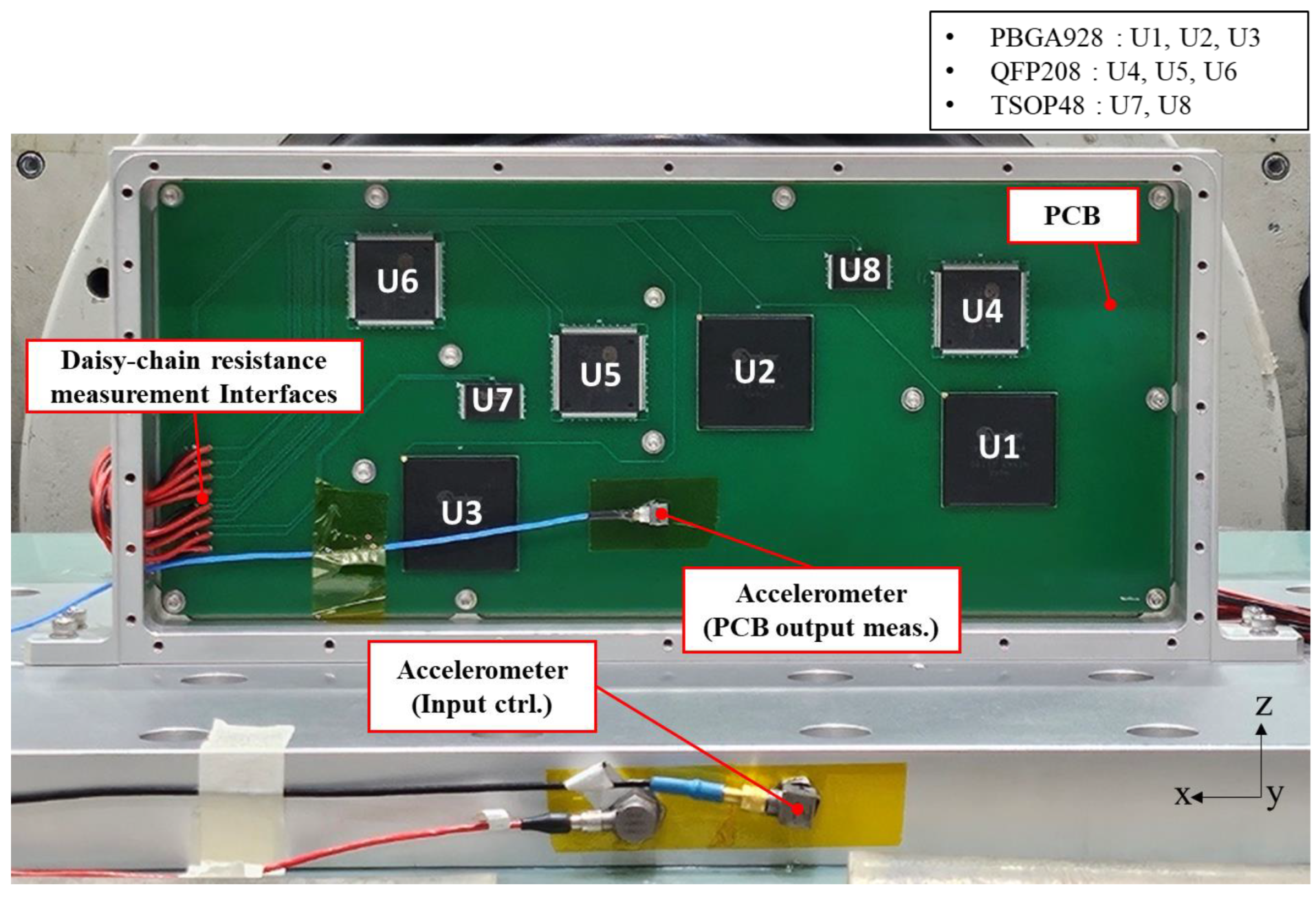

3.1. Description of Electronic Equipment Module

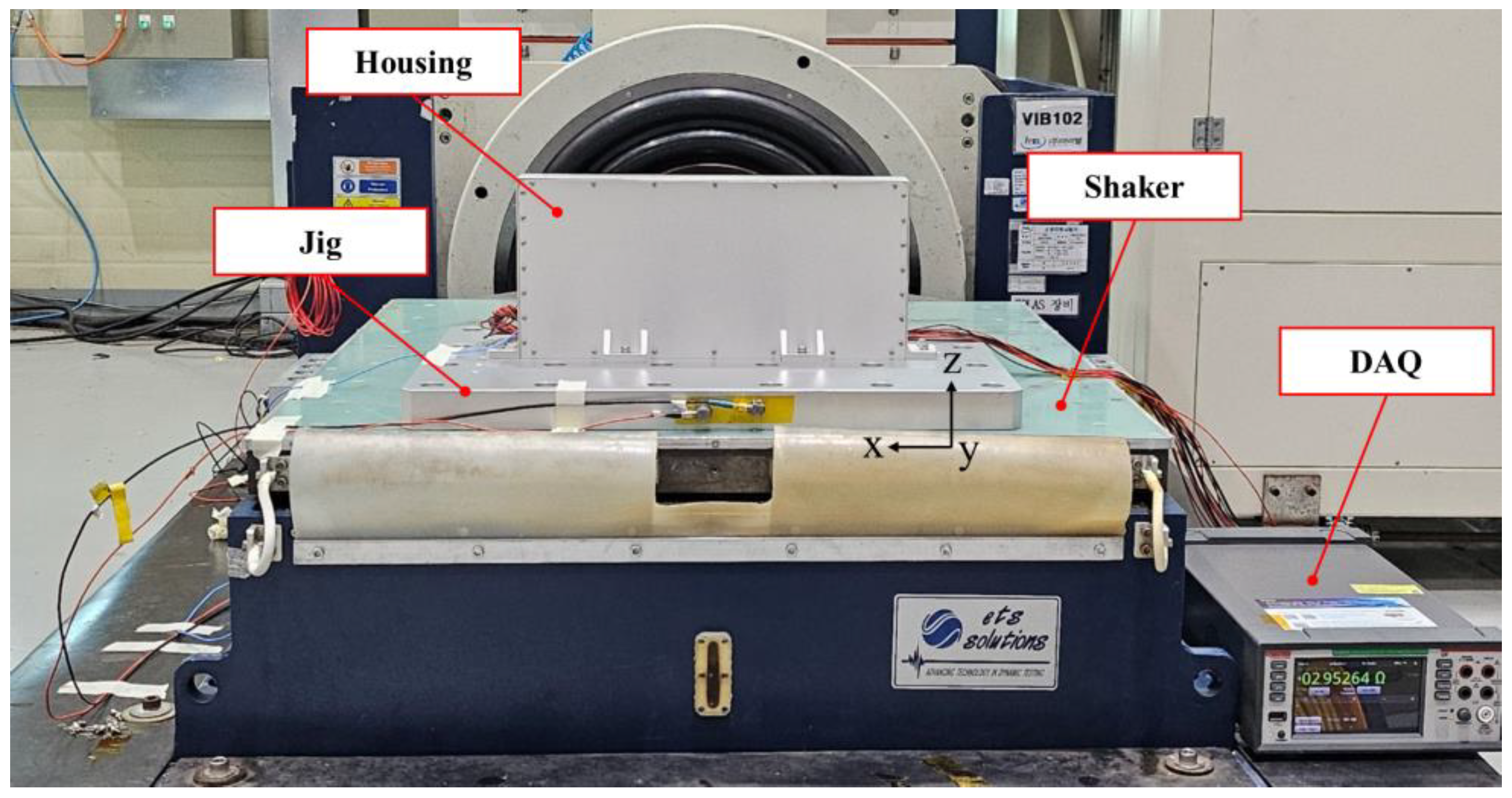

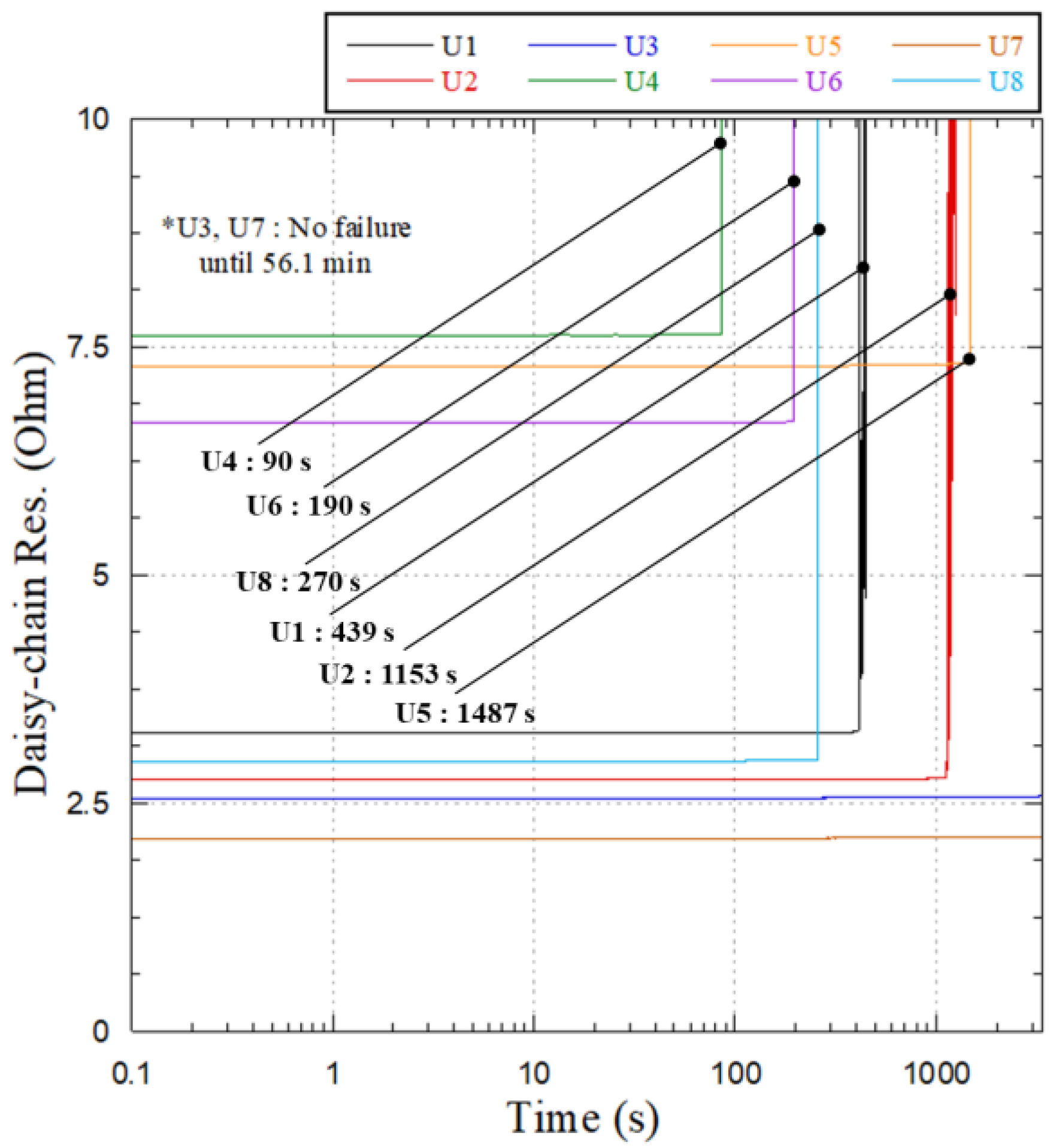

3.2. Random Vibration Fatigue Life Test

4. Verification of the Structural Design Methodology

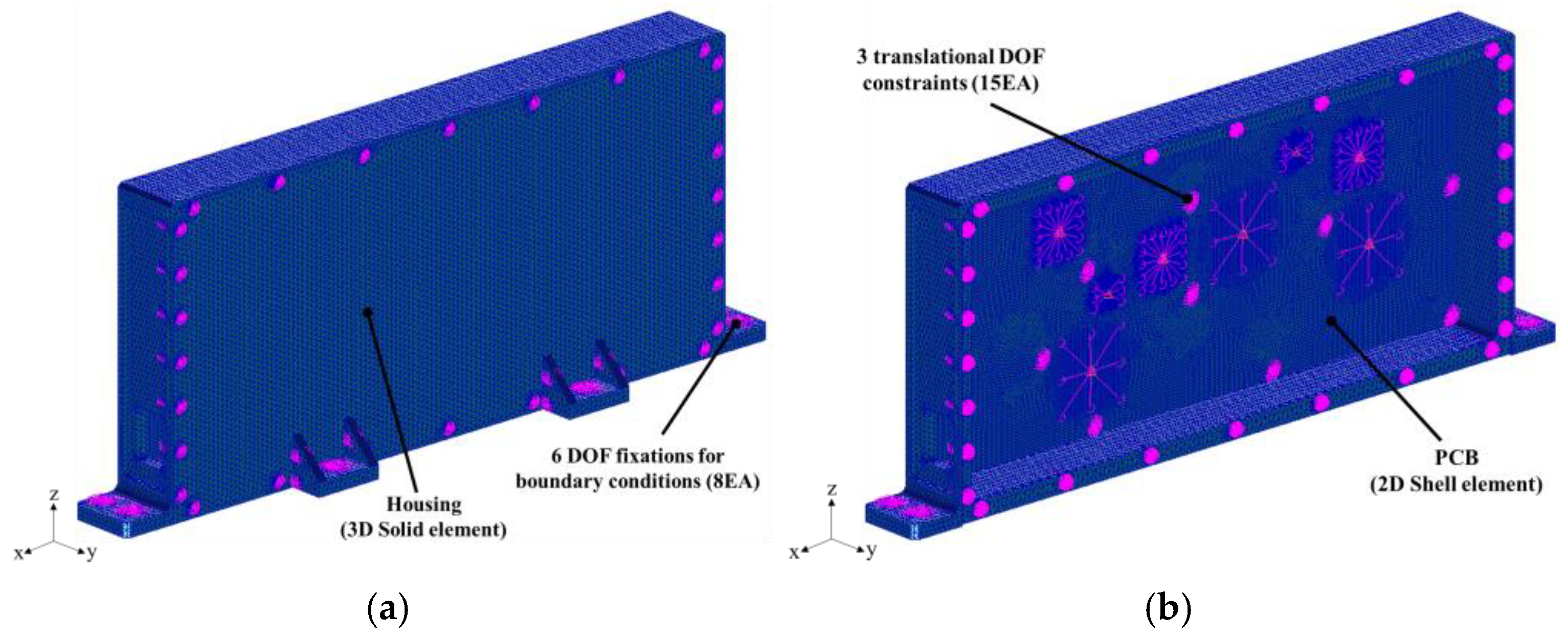

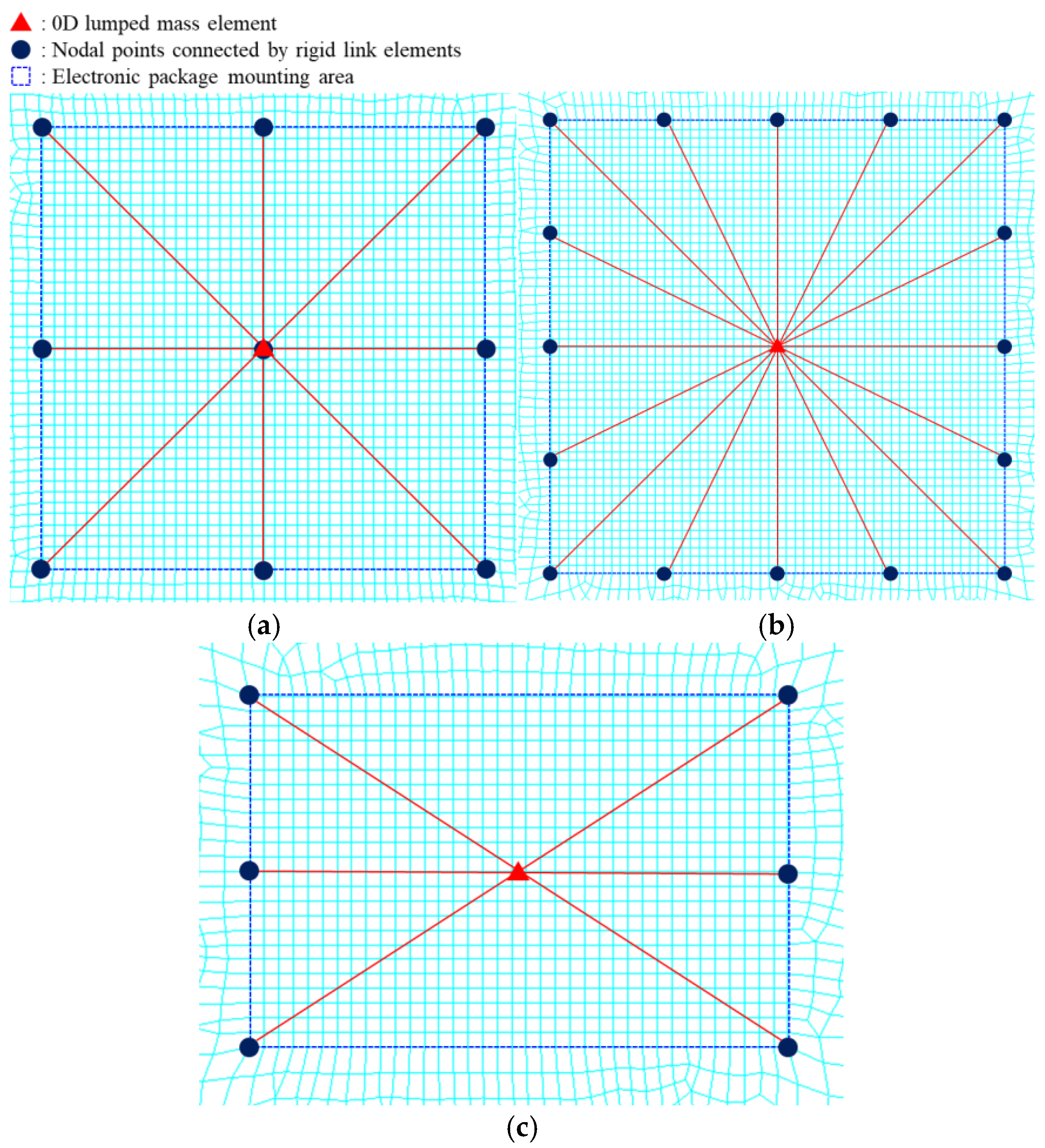

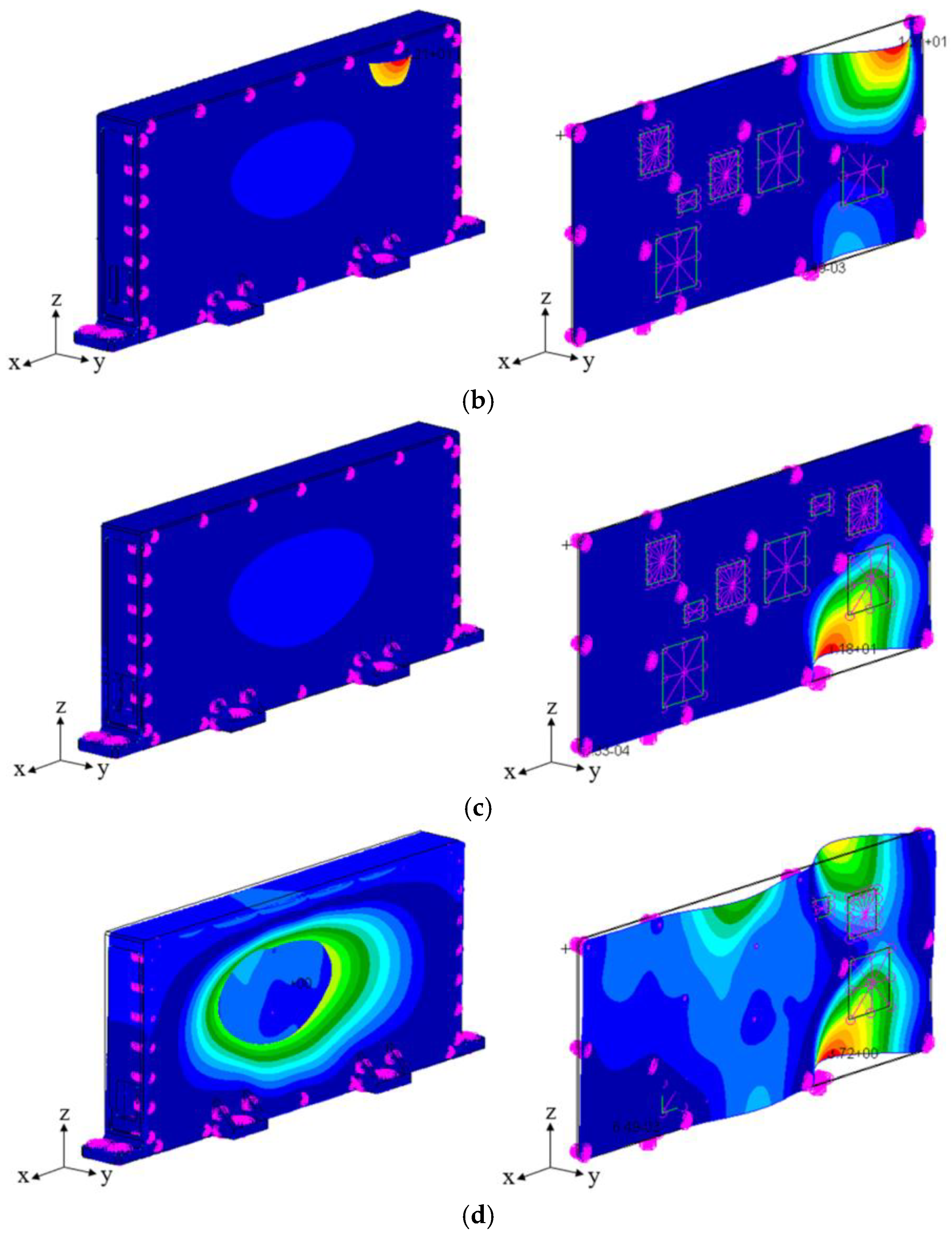

4.1. Structural Analysis Modeling

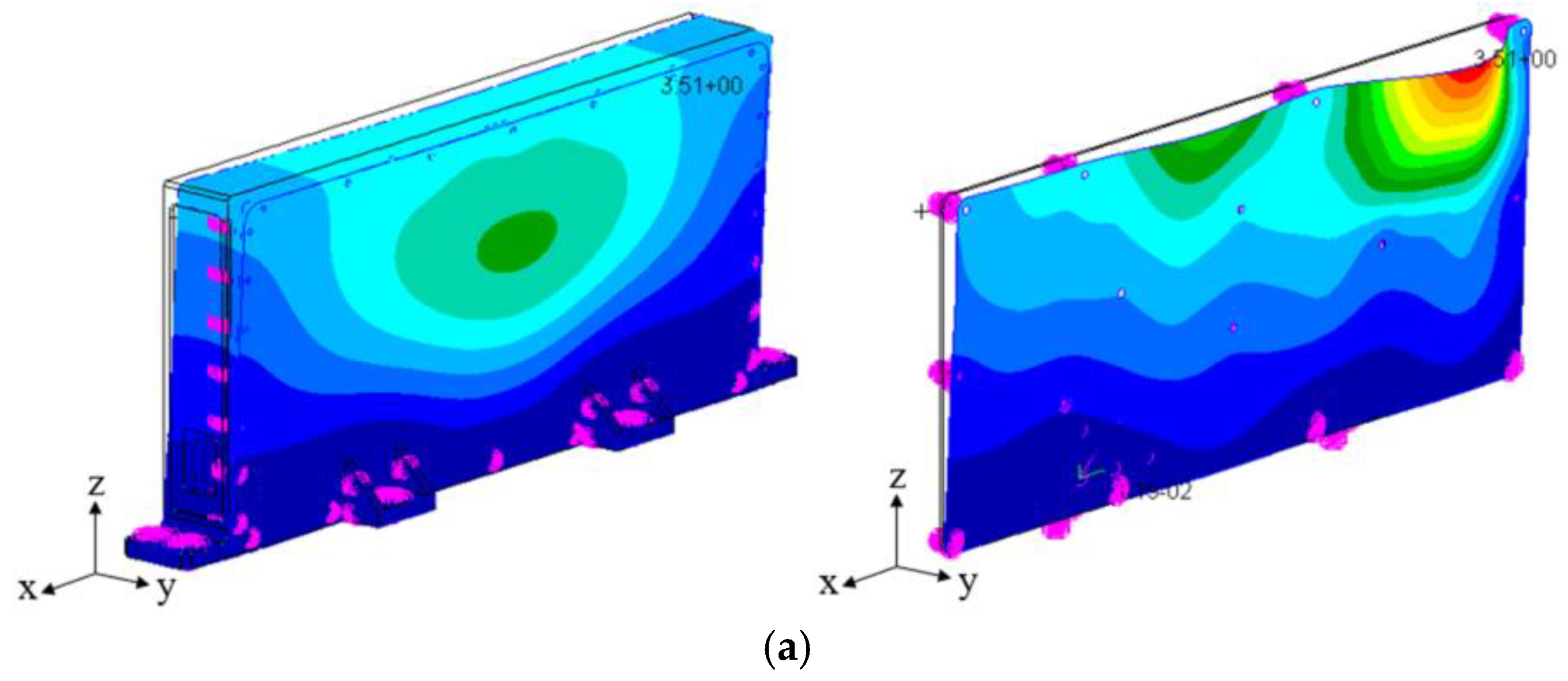

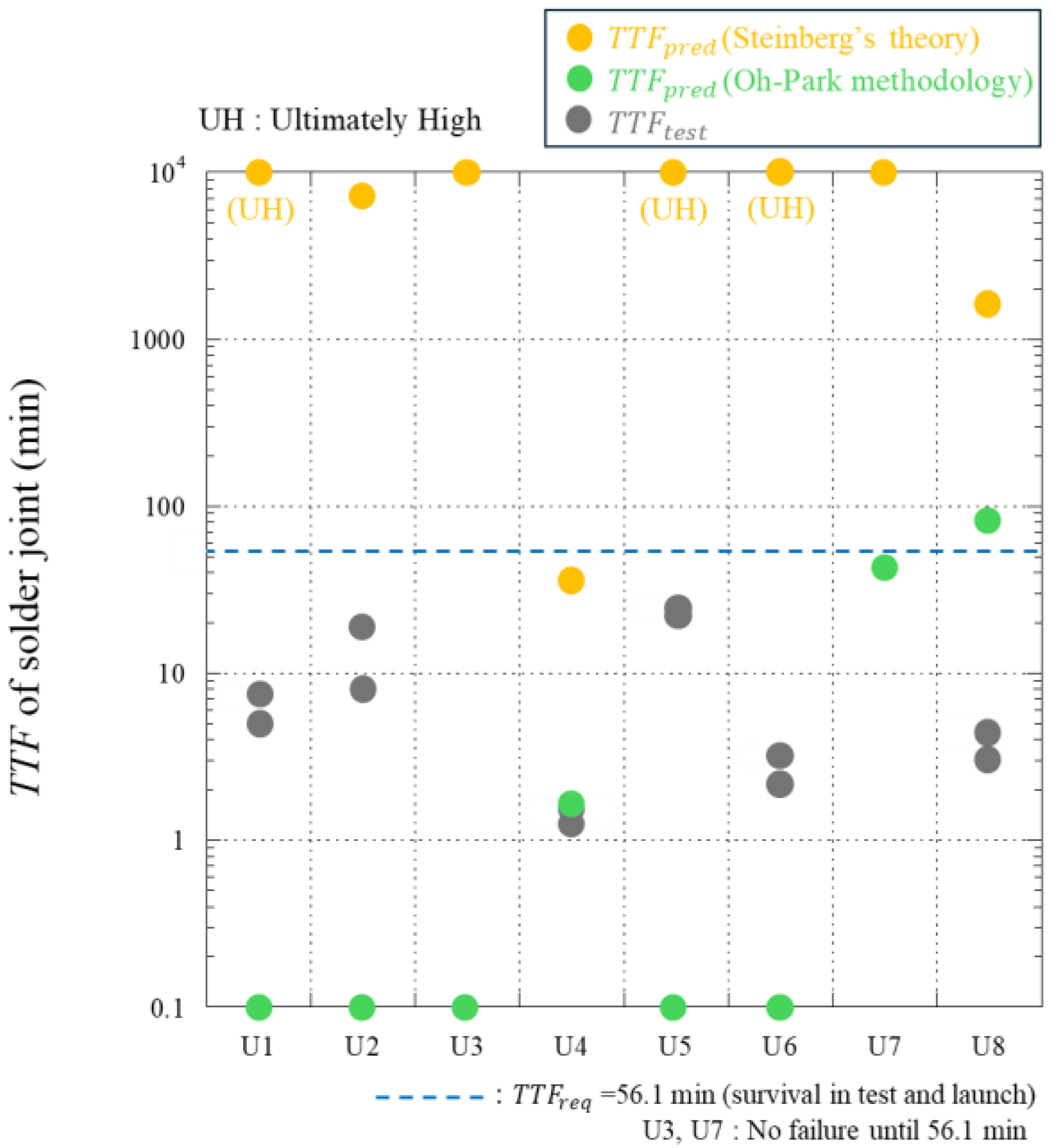

4.2. Analysis and Test Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, Y.K.; Hwang, D.S. PBGA packaging reliability assessments under random vibrations for space applications. Microelectron. Reliab. 2015, 55, 172–179. [Google Scholar] [CrossRef]

- Jang, T.S.; Cho, H.K.; Seo, H.S.; Kim, W.S.; Rhee, J.H. Lightweight composite electronics housing design of modular type for space applications. J. Korean Soc. Aeronaut. Space Sci. 2010, 38, 1209–1216. [Google Scholar] [CrossRef]

- Krumweide, G.C.; Tremblay, G.A. Issues to Address in Use of Composite Materials for Electronic Packaging. In Proceedings of the 17th Digital Avionics Systems Conference, Bellevue, WA, USA, 31 October–7 November 1998; pp. H35-1–H35-8. [Google Scholar]

- Fenske, M.T.; Barth, J.L.; Didion, J.R.; Mul, P. The development of lightweight electronics enclosures for space applications. SAMPE J. 1999, 35, 25–34. [Google Scholar]

- Aglietti, G.S. A Lighter enclosure for electronics for space application. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2002, 216, 131–142. [Google Scholar] [CrossRef]

- Wijker, J.J. Spacecraft Structures; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Lee, W.B.; Kim, G.W. Random vibration analysis for satellite design. Aerosp. Eng. Technol. 2006, 5, 102–107. [Google Scholar]

- Meyyappan, K.; Vujosevic, M.; Wu, Q.; Malatkar, P.; Hill, C.; Parrott, R. Knowledge Based Qualification Process to Evaluate Vibration Induced Failures in Electronic Components. In Proceedings of the ASME 2017 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems Collocated with the ASME 2017 Conference on Information Storage and Processing Systems, San Francisco, CA, USA, 29 August–1 September 2017; p. V001T05A001. [Google Scholar]

- Lee, W.W.; Nguyen, L.T.; Selvaduray, G.S. Solder joint fatigue models: Review and applicability to chip scale packages. Microelectron. Reliab. 2000, 40, 231–244. [Google Scholar] [CrossRef]

- Fan, X.; Ranouta, A.S.; Dhiman, H.S. Effects of package level structure and material propreties on solder joint reliability under impact loading. IEEE Trans. Compon. Packag. Manuf. 2012, 3, 52–60. [Google Scholar] [CrossRef]

- García, A.; Sorribes-Palmer, F.; Alonso, G. Application of Steinberg vibration fatigue model for structural verification of space instruments. AIP Conf. Proc. 2018, 1922, 100003. [Google Scholar] [CrossRef]

- Steinberg, D.S. Vibration Analysis for Electronic Equipment, 3rd ed.; John Wiley & Sons: New York, NY, USA, 2000. [Google Scholar]

- Bèda, M.G. A curvature-based interpretation of the Steinberg criterion for fatigue life of electronic components. Int. Symp. Microelectron. 2015, 2015, 707–712. [Google Scholar] [CrossRef]

- Kavitha, M.; Mahmound, Z.H.; Kishore, K.H.; Petrov, A.M.; Lekomtsev, A.; Iliushin, P.; Zekiy, A.O.; Salmani, M. Application of Steinberg model for vibration lifetime evaluation of Sn-Ag-Cu-based solder joints in power semiconductors. IEEE Trans. Compon. Packag. Manuf. Technol. 2021, 11, 444–450. [Google Scholar] [CrossRef]

- Jeon, Y.-H.; Kim, H.-S.; Lim, I.-O.; Kim, Y.; Oh, H.-U. Mechanical reliability evaluation on solder joint of CCB for compact advanced satellite. J. Korean Soc. Aeronaut. Space Sci. 2017, 45, 498–507. [Google Scholar] [CrossRef]

- Irvine, T. Extending Steinberg’s Fatigue Analysis of Electronics Equipment Methodology to a Full Relative Displacement vs. Cycles Curve. Vibrationdata. 2013. Available online: https://www.vibrationdata.com/tutorials2/electronic_rd_n.pdf (accessed on 1 May 2025).

- Park, T.Y.; Oh, H.U. New PCB strain-based structural design methodology for reliable and rapid evaluation of spaceborne electronics under random vibration. Int. J. Fatigue 2021, 146, 106094. [Google Scholar] [CrossRef]

- Kim, J.K.; Chae, B.G.; Lee, S.H.; Oh, H.U. Structural design of SAR control units for small satellites based on critical strain theory. J. Aerosp. Syst. Eng. 2024, 18, 12–20. [Google Scholar]

- Park, J.H.; Jeong, S.K.; Oh, H.U. Effectiveness of critical-strain-based methodology considering elastic mode vibration of mechanical housing of electronics. Aerospace 2023, 10, 974. [Google Scholar] [CrossRef]

- Kwon, S.C.; Son, J.H.; Song, S.C.; Park, J.H.; Koo, K.R.; Oh, H.U. Innovative mechanical design strategy for actualizing 80 kg-class X-band active SAR small satellite of S-STEP. Aerospace 2021, 8, 149. [Google Scholar] [CrossRef]

- Kang, S.J.; Park, S.W.; Choi, H.Y.; Ryu, G.H.; Kim, J.P.; Jung, S.H.; Kim, S.Y.; Lee, H.I.; Oh, H.U. Thermo-Mechanical Design and Validation of spaceborne High-Speed Digital Receiver Unit for Synthetic Aperture Rader Application. Aerospace 2021, 8, 305. [Google Scholar] [CrossRef]

- Yin, Q.; Xue, F.; Shen, L. Structural design and mechanical analysis for space-borne electronic equipment. J. Phys. Conf. Ser. 2023, 2492, 012009. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, J.; Guo, H.; Wang, S.; Liang, D.; Yu, L. Thermo design technology of spaceborne radar electronic unit. J. Phys. Conf. Ser. 2025, 2955, 012054. [Google Scholar] [CrossRef]

- An, J.H.; Cho, H.K. structural and thermal analyses of image processing units of satellites. J. Korean Soc. Manuf. Technol. Eng. 2020, 29, 42–50. [Google Scholar] [CrossRef]

- Jang, T.S.; Seo, J.K.; Rhee, J.H. A study on fabrication of monolithic lightweight composite electronics housing for space application. J. Korean Soc. Aeronaut. Space Sci. 2013, 41, 975–986. [Google Scholar] [CrossRef]

- Kim, J.K.; Park, T.Y.; Oh, H.U. dynamic response analysis with electronics mounting boundary conditions. J. Aerosp. Syst. Eng. 2024, 18, 9–15. [Google Scholar]

- Kim, K.W.; Park, J.H.; Park, T.Y.; Oh, H.U. Experimental evaluation of the effectiveness of the printed circuit board strain-based methodology in space-borne electronics with vertically mounted printed circuit boards. Aerospace 2024, 11, 562. [Google Scholar] [CrossRef]

- Jung, I.H.; Park, T.W.; Han, S.W.; Seo, J.H.; Kim, S.H. Structural vibration analysis of electronic equipment for satellite under launch environments. J. Korean Soc. Precis. Eng. 2004, 21, 120–128. [Google Scholar] [CrossRef]

- Clerck, J.D.; Epp, D.S. Rotating Machinery, Hybrid Test Methods, Vibro-Acoustics & Laser Vibrometry. In Proceedings of the 34th IMAC, A Conference and Exposition on Structural Dynamics, Orlando, FL, USA, 25–28 January 2016. [Google Scholar]

- ECSS-E-ST-32C; Space Engineering—Structural General Requirements. European Cooperative Space Standards: Noordwijk, The Netherlands, 2008.

- Yunis, I.; Ludwiczak, D. On the use of 3dB qualification margin for structural parts on expendable launch vehicles. In Proceedings of the 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Honolulu, HI, USA, 23–26 April 2007; pp. 1–9. [Google Scholar]

- IPC. IPC-9701A: Performance Test Methods and Qualification Requirements for Surface Mount Solder Attachments; IPC: Bannockburn, IL, USA, 2006. [Google Scholar]

- Jeong, H.S.; Seo, K.W.; Bae, J.S.; Jang, G.H. Effect of boundary conditions on fatigue life of board-level BGA solder joints under random vibration. Microsyst. Technol. 2023, 29, 1651–1658. [Google Scholar] [CrossRef]

- Lee, J.S.; Jeong, H.S.; Jang, G.H. Optimization of the Boundary Conditions of a Board Level Reliability Test Board to Maximize the Fatigue Life of Ball Grid Array Solder Joints under Thermal Cycling and Random Vibration. Materials 2024, 17, 755. [Google Scholar] [CrossRef] [PubMed]

- Park, T.Y.; Park, J.H.; Oh, H.U. Experimental evaluation of vibrational stability of SOPs in aerospace industry using PCB strain effectiveness of a PCB-strain-based design methodology. Aerospace 2023, 10, 516. [Google Scholar] [CrossRef]

- Park, T.Y.; Oh, H.U. Validation of the critical strain-based methodology for evaluating the mechanical safety of ball grid array solder joints in a launch random vibration environment. J. Electron. Packag. 2022, 144, 011006. [Google Scholar] [CrossRef]

| Item | Specifications |

|---|---|

| PBGA928 | Dimension (mm): 40 × 40 × 2.23 |

| Weight (g): 6.7 (Incl. solder balls) |

| No. of solder balls: 928 | |

| Ball pitch (mm): 1.0 | |

| Solder material: Tin/lead | |

| QFP208 | Dimension (mm): 28 × 28 × 3.7 |

| Weight (g): 5.4 |

| Leads: Cu Lead Frame with Lead Finish | |

| Lead pitch (mm): 0.5 | |

| Solder material: Sn-Pb37 | |

| TSOP48 | Dimension (mm): 18.4 × 12 × 1.2 |

| Weight (g): 0.6 |

| Leads: Cu Lead Frame with Lead Finish | |

| Lead pitch (mm): 0.5 | |

| Solder material: Sn-Pb37 |

| Frequency (Hz) | ASD (g2/Hz) |

|---|---|

| 20 | 0.052 |

| 50 | 0.32 |

| 800 | 0.32 |

| 2000 | 0.052 |

| Overall (full level (0 dB)) | 20 grms |

| Package No. | Sample 1 (s) | Sample 2 (s) |

|---|---|---|

| U1 (PBGA928) | 439 | 305 |

| U2 (PBGA928) | 1153 | 502 |

| U3 (PBGA928) | No faliure | No faliure |

| U4 (QFP208) | 90 | 76 |

| U5 (QFP208) | 1487 | 1331 |

| U6 (QFP208) | 190 | 134 |

| U7 (TSOP48) | No faliure | No faliure |

| U8 (TSOP48) | 270 | 183 |

| Material | Elastic Modulus (GPa) | Poisson’s Ratio | Density (kg/m3) |

|---|---|---|---|

| PCB (FR-4) | 18.73 | 0.136 | 1850 |

| Housing Module (A6061-T6) | 68.90 | 0.330 | 2700 |

| Item | Factor | Value | Unit | Remarks |

|---|---|---|---|---|

| No. of vibration tests per each test level | N | 3 | - | Assumption (damage for PCB out-of-plane excitation is accumulated in all test axis) |

| Fatigue exponent for solder joint | B | 6.4 | - | for solder or lead frame material |

| 0 dB-equivalent vibration exposure time for the vibration tests at each test level | T−12dB | 0.00007 | min | Equations (9) and (10) |

| T−9dB | 0.0007 | min | ||

| T−6dB | 0.006 | min | ||

| T−3dB | 0.11 | min | ||

| T0dB | 2.00 | min | ||

| Duration for single test (min) | t1 | 0.50 | min | for low level tests (−12, −9, −6 dB) |

| t2 | 1.00 | min | for accp. test (−3 dB) | |

| tQ | 2.00 | min | for qual. test (0 dB) | |

| 0 dB-equivalent vibration exposure time for qual. test (comp. level) | ΣTC-Q | 6.35 | min | - |

| 0 dB-equivalent vibration exposure time for qual. test (S/S level) | ΣTS/S-Q | 6.35 | min | - |

| Eqv. time for launch (S/S level) | ΣTL | 1.32 | min | Eqv. to AT (ΣD−3dB), 3 axis excitations |

| 0 dB-equivalent vibration exposure time for the launch vibration (min) | tL | 4.00 | min | for launch |

| FoS with respect to. design life (min) | FoSttf | 4 | - | Referred ECSS-E-ST-32C [30] |

| ) for solder joint (min) | TTFreq | 56.1 | min | Equation (7) |

| (a) Steinberg’s Theory | |||||||||

| Package No. | Package Type | Allowable Displacement | Max. Disp. | Structural Safety | Test Results | ||||

| Hz | - | mm | mm | mm | - | - | |||

| U1 | PBGA928 | 298.5 | 0.478 | 150 | 0.397 | 0.156 | 1.60 | 3.07 | Failed |

| U2 | PBGA928 | 298.5 | 0.947 | 150 | 0.200 | 0.150 | 1.60 | 1.14 | Failed |

| U3 | PBGA928 | 298.5 | 0.535 | 150 | 0.354 | 0.034 | 1.60 | 15.73 | Not Failed |

| U4 | QFP208 | 298.5 | 0.452 | 150 | 0.697 | 1.190 | 1.60 | −0.06 | Failed |

| U5 | QFP208 | 298.5 | 0.960 | 150 | 0.328 | 0.116 | 1.60 | 3.52 | Failed |

| U6 | QFP208 | 298.5 | 0.436 | 150 | 0.723 | 0.136 | 1.60 | 7.51 | Failed |

| U7 | TSOP48 | 298.5 | 0.854 | 150 | 0.455 | 0.098 | 1.60 | 6.44 | Not Failed |

| U8 | TSOP48 | 298.5 | 0.503 | 150 | 0.773 | 0.730 | 1.60 | 0.69 | Failed |

| (b) Oh-Park methodology | |||||||||

| Package No. | Package Type | Critical Strain | Max. Strain | Structural Safety | Test Results | ||||

| Hz | - | - | |||||||

| U1 | PBGA928 | 298.5 | 1.08 × 106 | 98.0 | 44.6 | 574.1 | 1.60 | −0.88 | Failed |

| U2 | PBGA928 | 298.5 | 7.60 × 105 | 147.1 | 67.0 | 405.2 | 1.60 | −0.74 | Failed |

| U3 | PBGA928 | 298.5 | 7.92 × 105 | 141.4 | 64.4 | 422.2 | 1.60 | −0.76 | Not Failed |

| U4 | QFP208 | 298.5 | 6.63 × 105 | 166.5 | 125.8 | 353.4 | 1.60 | −0.43 | Failed |

| U5 | QFP208 | 298.5 | 8.17 × 105 | 137.0 | 103.6 | 435.5 | 1.60 | −0.62 | Failed |

| U6 | QFP208 | 298.5 | 1.07 × 106 | 98.5 | 74.4 | 572.1 | 1.60 | −0.79 | Failed |

| U7 | TSOP48 | 298.5 | 5.55 × 106 | 191.5 | 178.5 | 296.1 | 1.60 | −0.04 | Not Failed |

| U8 | TSOP48 | 298.5 | 5.23 × 105 | 200.0 | 186.5 | 278.8 | 1.60 | 0.07 | Failed |

| Package No. | Steinberg’s Theory (min) | Oh-Park Methodology (min) | (min) | |

|---|---|---|---|---|

| Sample 1 | Sample 2 | |||

| U1 | 440,000 | <1 | 7.32 | 5.08 |

| U2 | 7110 | <1 | 19.22 | 8.37 |

| U3 | 3,730,000,000 | <1 | No failure | No failure |

| U4 | 36.5 | 1.5 | 1.50 | 1.27 |

| U5 | 862,000 | <1 | 24.78 | 22.18 |

| U6 | 49,500,000 | <1 | 3.17 | 2.23 |

| U7 | 20,900,000 | 43.8 | No failure | No failure |

| U8 | 1610 | 85 | 4.50 | 3.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, J.-C.; Kim, K.-W.; Oh, H.-U. Validation of PCB Strain-Based Methodology for Structural Design of Spaceborne Electronic Equipment Under Vertical Mounting Conditions in Launch Environments. Aerospace 2025, 12, 770. https://doi.org/10.3390/aerospace12090770

Hwang J-C, Kim K-W, Oh H-U. Validation of PCB Strain-Based Methodology for Structural Design of Spaceborne Electronic Equipment Under Vertical Mounting Conditions in Launch Environments. Aerospace. 2025; 12(9):770. https://doi.org/10.3390/aerospace12090770

Chicago/Turabian StyleHwang, Jae-Cheol, Kwang-Woo Kim, and Hyun-Ung Oh. 2025. "Validation of PCB Strain-Based Methodology for Structural Design of Spaceborne Electronic Equipment Under Vertical Mounting Conditions in Launch Environments" Aerospace 12, no. 9: 770. https://doi.org/10.3390/aerospace12090770

APA StyleHwang, J.-C., Kim, K.-W., & Oh, H.-U. (2025). Validation of PCB Strain-Based Methodology for Structural Design of Spaceborne Electronic Equipment Under Vertical Mounting Conditions in Launch Environments. Aerospace, 12(9), 770. https://doi.org/10.3390/aerospace12090770