On the Structural Design and Additive Construction Process of Martian Habitat Units Using In-Situ Resources on Mars

Abstract

1. Introduction

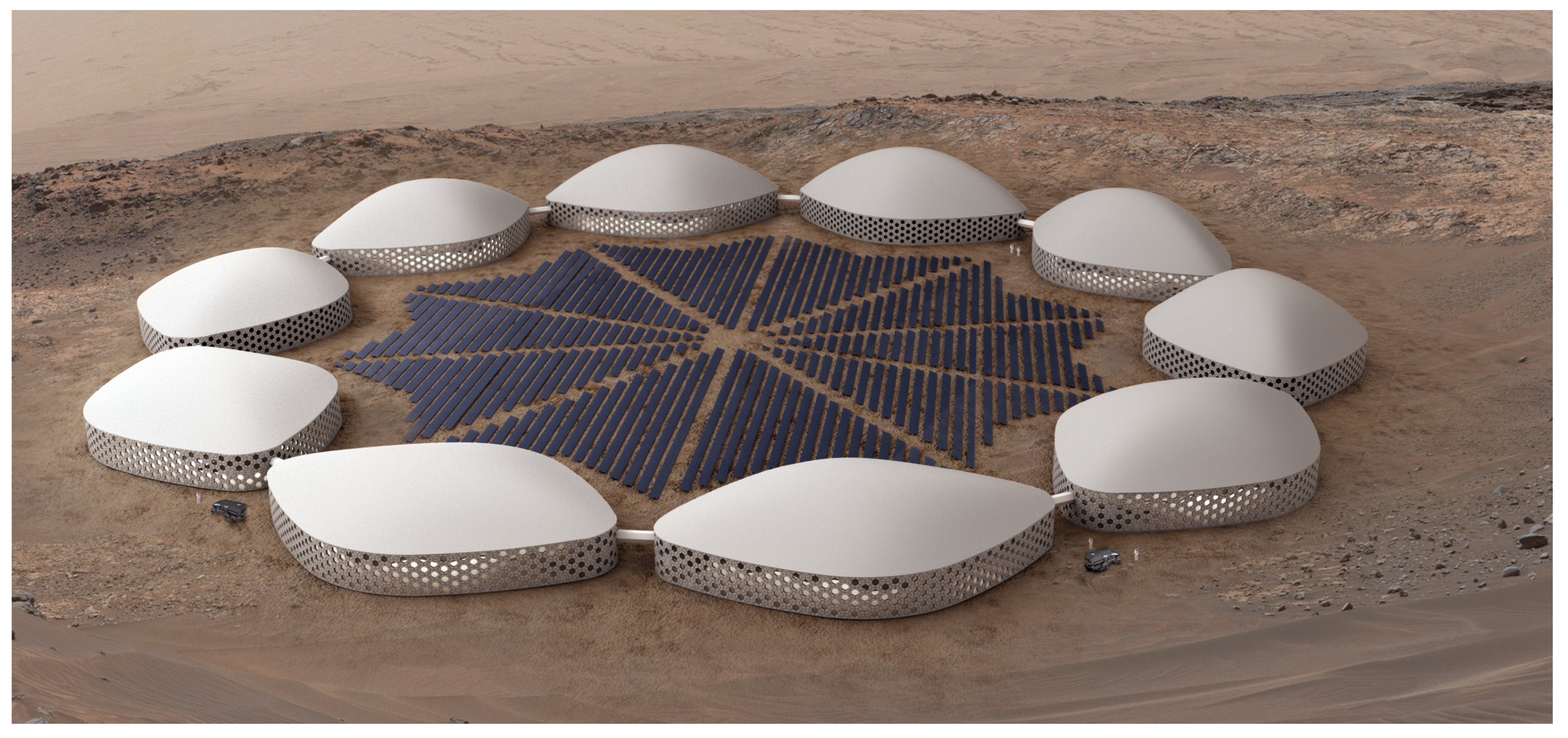

2. The Case—Martian Habitat Units (MHUs)

2.1. Mission Specifications

- ▪

- The mission is defined for the pre-terraforming era on Mars; however, the first generation of missions have already been performed.

- ▪

- The crew is composed of educated adults, spending years-long residence in the MHUs for the purpose of on-site expeditions of the planet.

- ▪

- There are flights available on and off Mars to Earth and the orbiting space stations.

- ▪

- The community is populated, and thereby designed for, up to 1000 crew members.

- ▪

- The research crew work full time on their tasks, and MHUs are responsive to the rest of their leisure time as well, since the duration of the mission dictates the presence of concepts such as lifestyle to a larger extent than what is currently available for the crew members of, for example, the ISS.

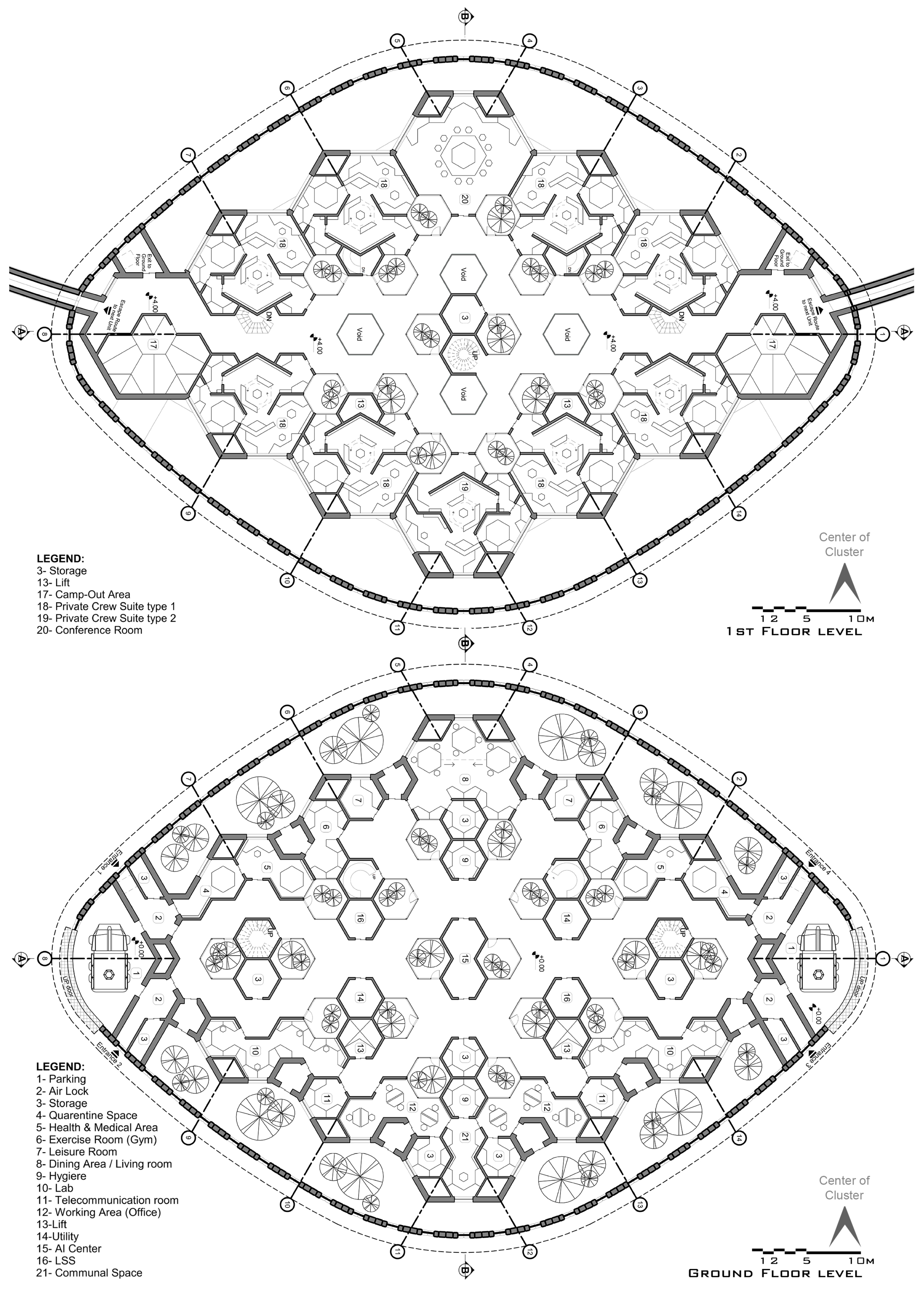

2.2. Operation and Geometry

2.3. Summary of Features

- ▪

- Mid-size population: Each MHU houses 9 crew members, which is large enough to have a variety of expertise for technical, medical, and mission-specific areas.

- ▪

- Mid-size community: Each cluster houses 90 crew members, for a more diverse local combination of tasks and societal duties.

- ▪

- ▪

- Multilayer fail-safe redundancies in passages, shelters, airlocks, equipment, LSS, gates, hatches, etc.

- ▪

- Multi-source power supply systems range from passive, semi-passive, to fully active fusion-based systems.

- ▪

- ▪

- Functional areas located at an inverse-proximity order to the entrance gates (with airlocks, quarantine, and medical units closest to the gates, whereas leisure and private segments are located further from it).

- ▪

- ADSM design provides flow control and streamlining to the exterior of MHUs, and maintains the minimum dust settlement in the central regions of the clusters, thereby minimizing maintenance and cleaning time and cost for PVs during the dust storm seasons.

- ▪

2.4. Environmental Conditions

2.4.1. Gravity

2.4.2. Atmosphere

2.4.3. Temperature

2.4.4. Radiation

2.4.5. Geology

3. Construction Specifications

3.1. Material

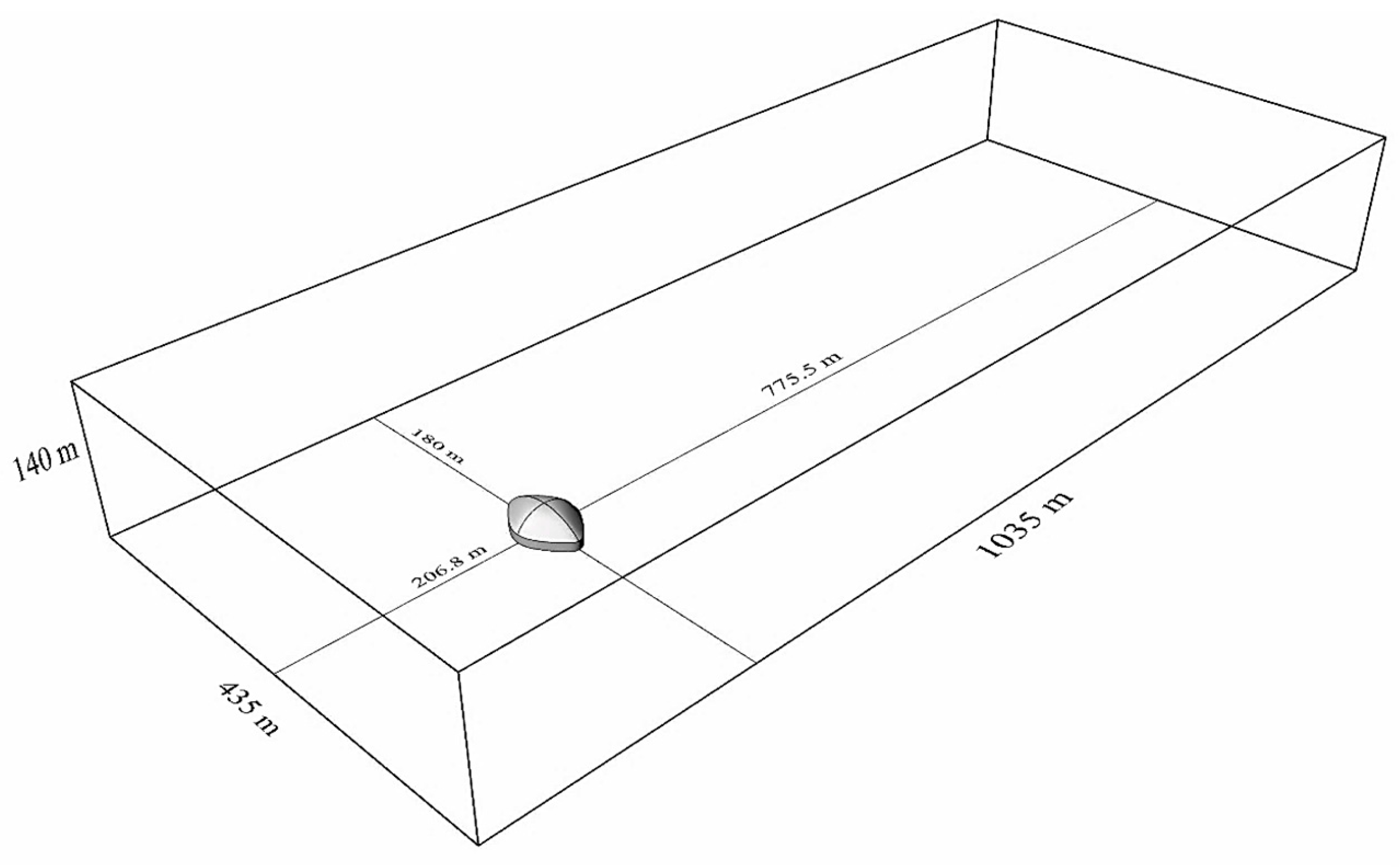

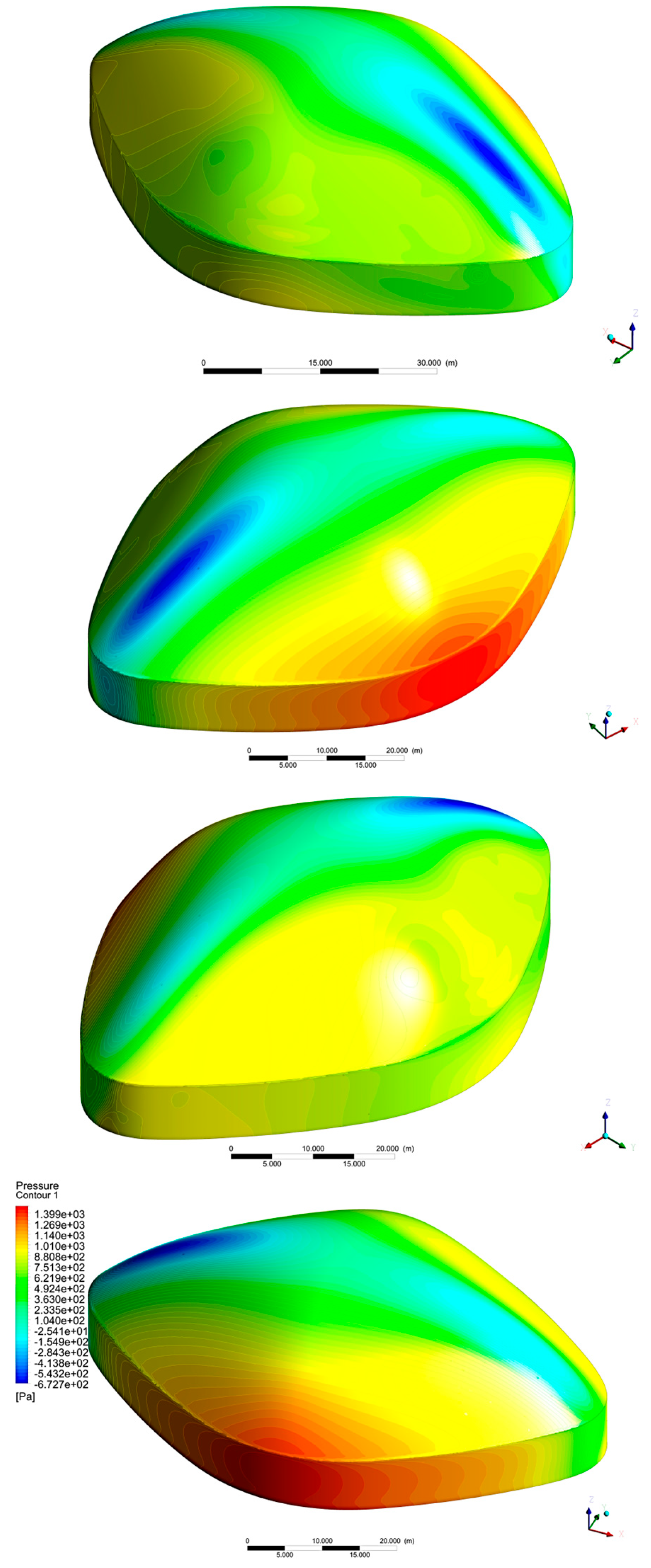

3.2. Wind Loads

3.2.1. Governing Equations

3.2.2. Domain, Grid, and Boundary Conditions

3.2.3. Intermediary Results—Flow Field

3.3. Seismic, Meteoroid, and Gravitational Impacts

3.4. Structural System

3.4.1. Typology

3.4.2. Structural Components

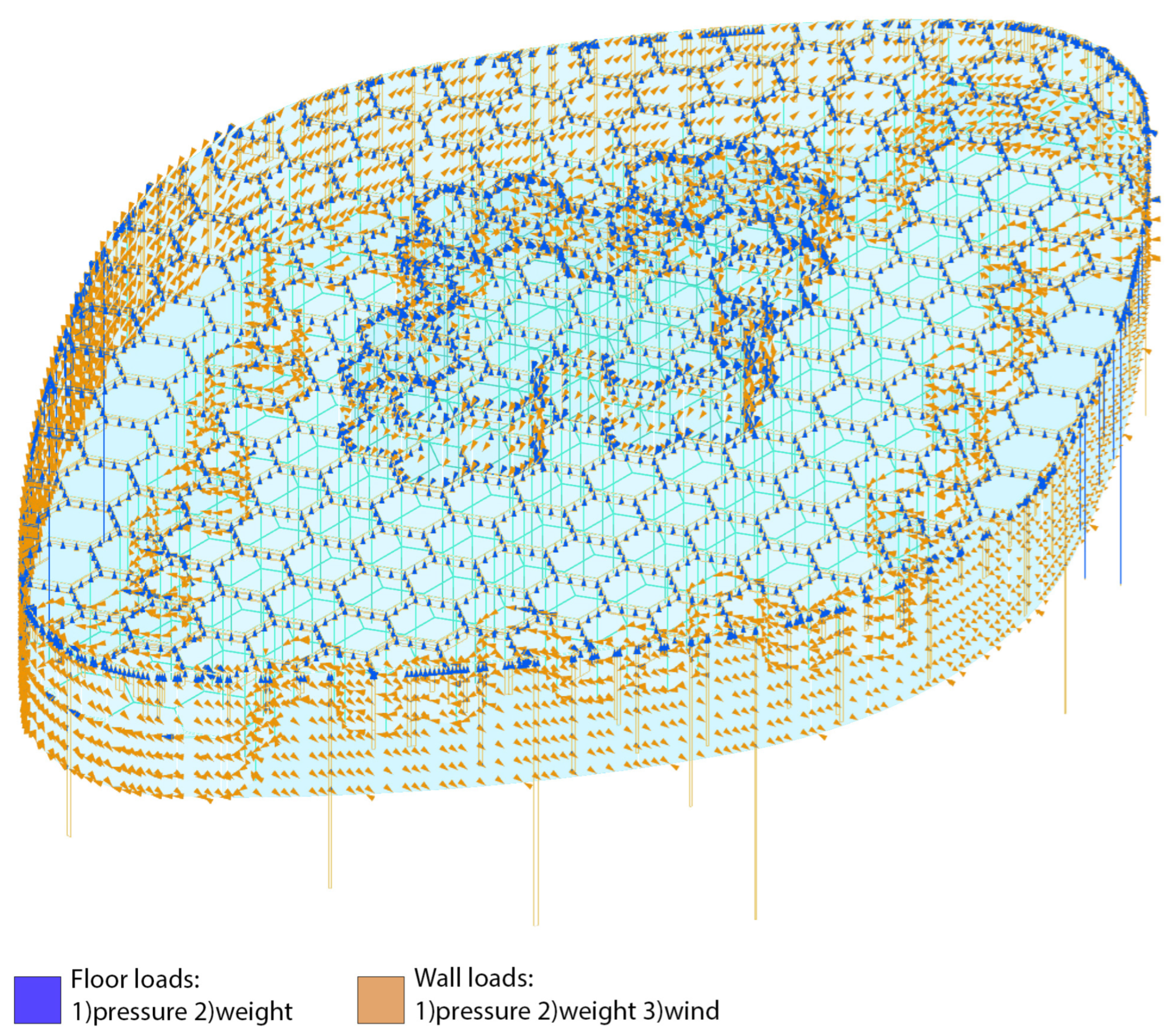

4. Structural Design

4.1. Building Model

4.2. Structural Model

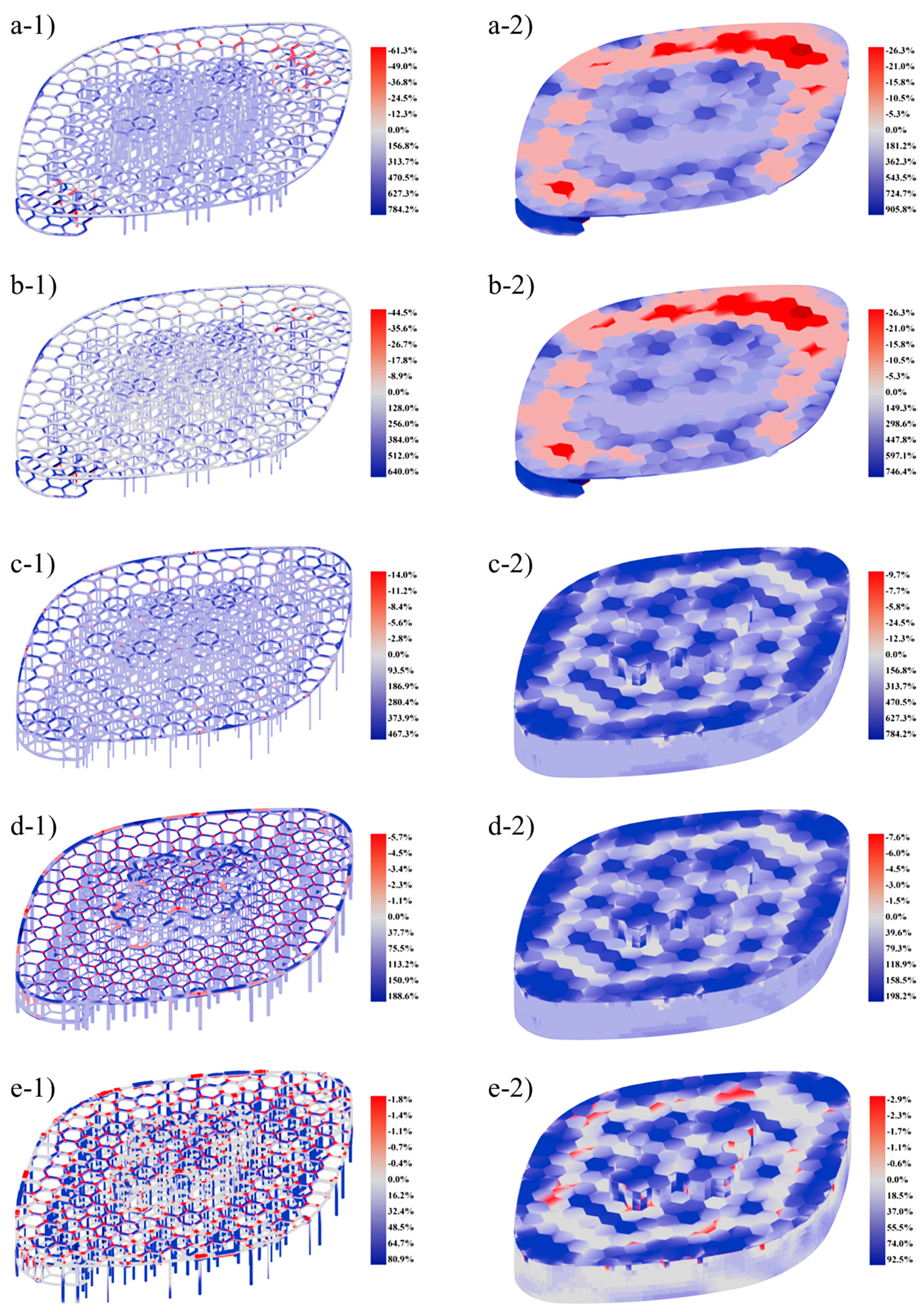

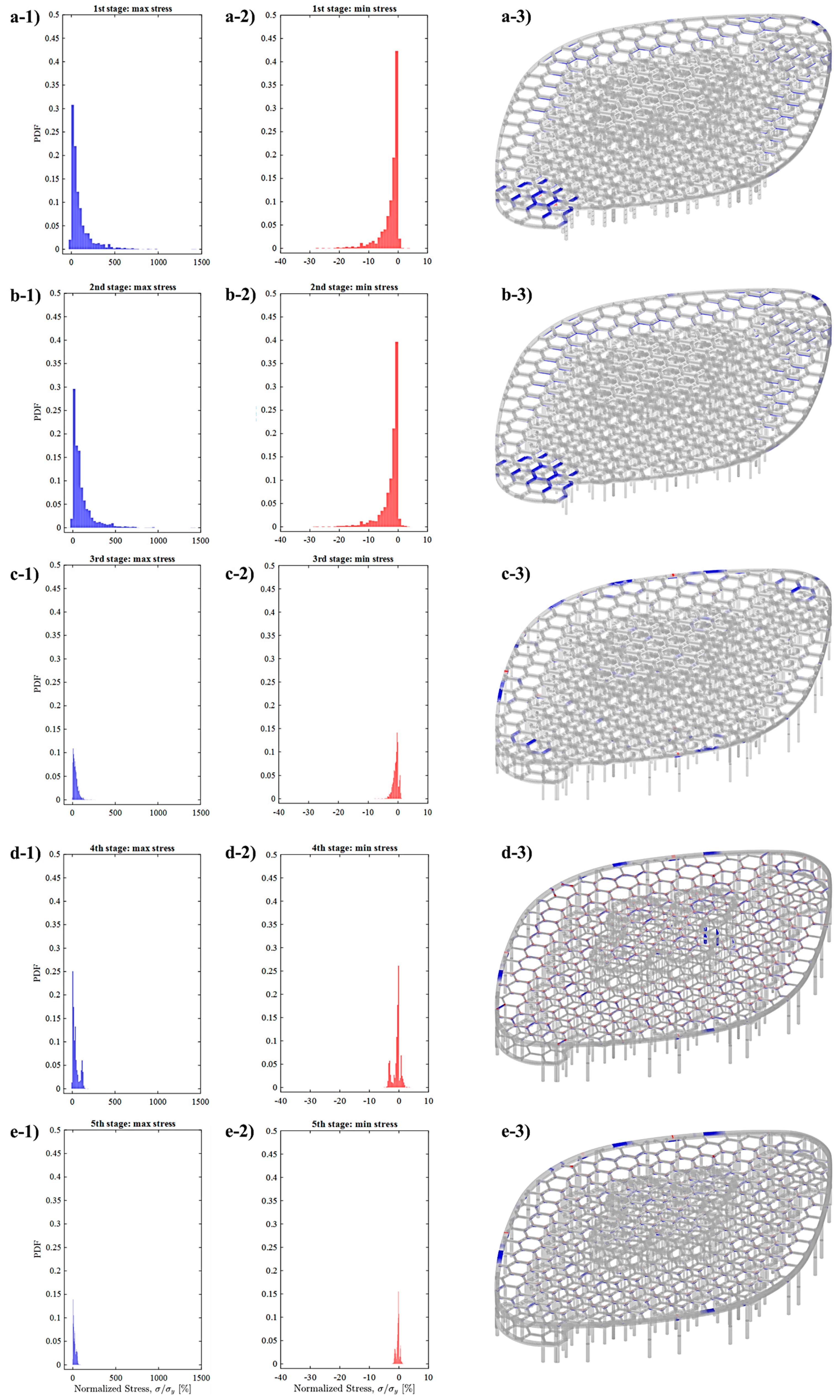

- ▪

- First analysis with custom setting;

- ▪

- Reshaping the cross-section of the axial component;

- ▪

- Adding structural role to exterior and garden space walls;

- ▪

- Dividing structural components based on their interaction with internal/external pressure;

- ▪

- Optimizing the range of cross-sections for structural components based on their utilization value (the ratio between von Mises stress and yield stress, which in the range above 100% shows structural instability).

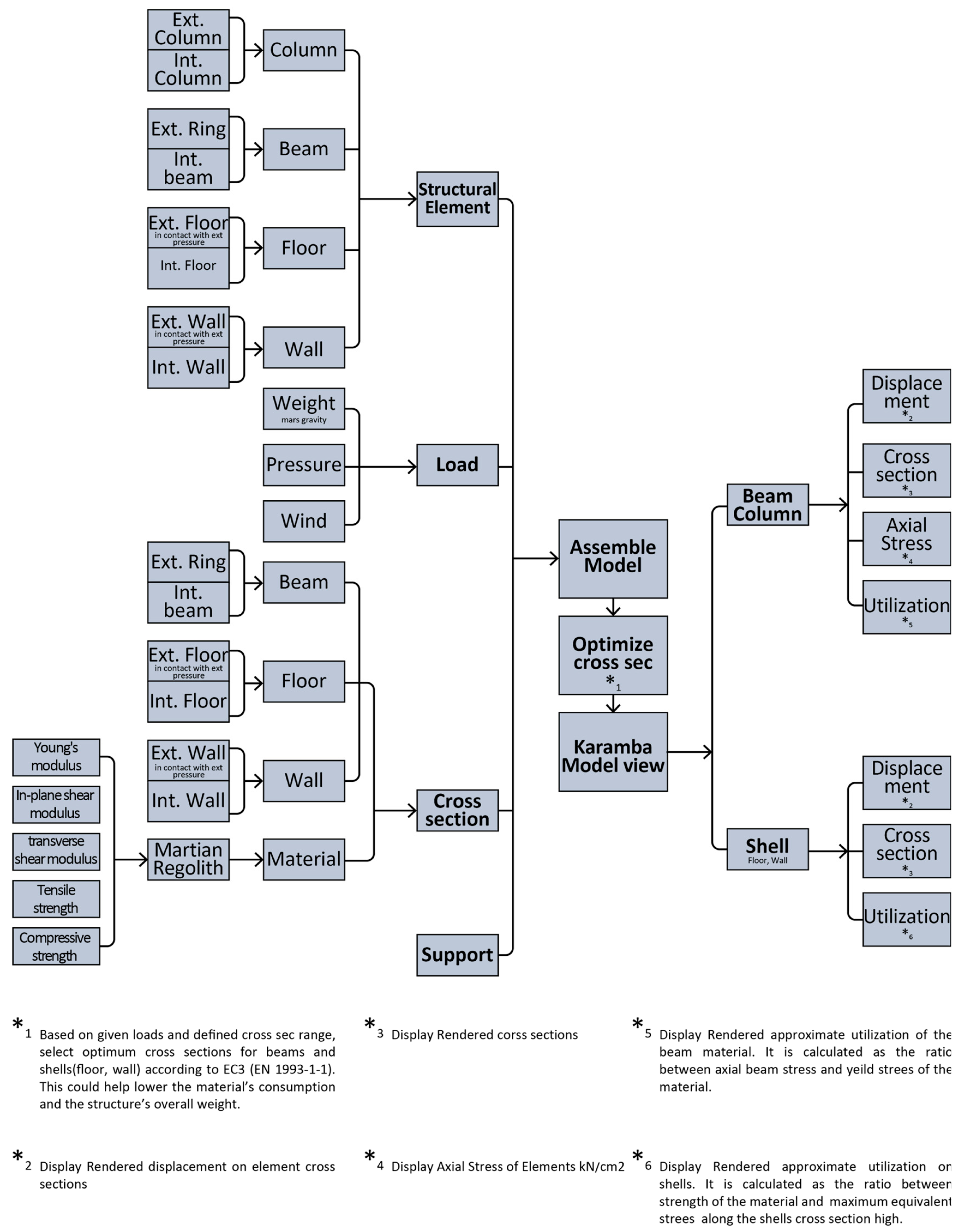

4.3. Simulation Specifications

- Inputs, which include creating the structural model, model discretization, defining material properties, loads, and boundary conditions;

- Optimizing the cross-sections;

- Analyses and results obtained from Karamba-3D.

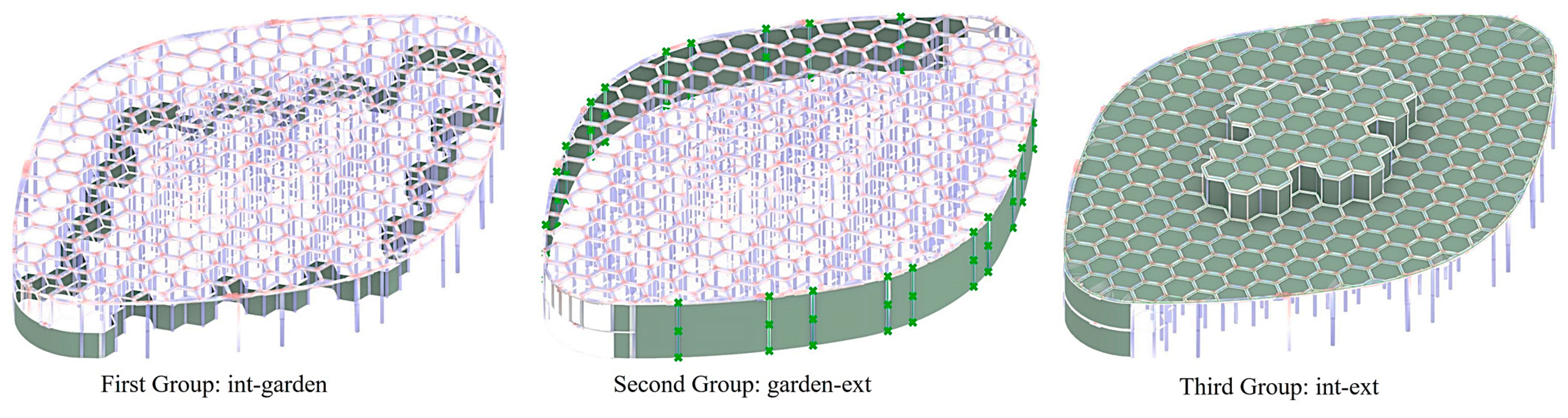

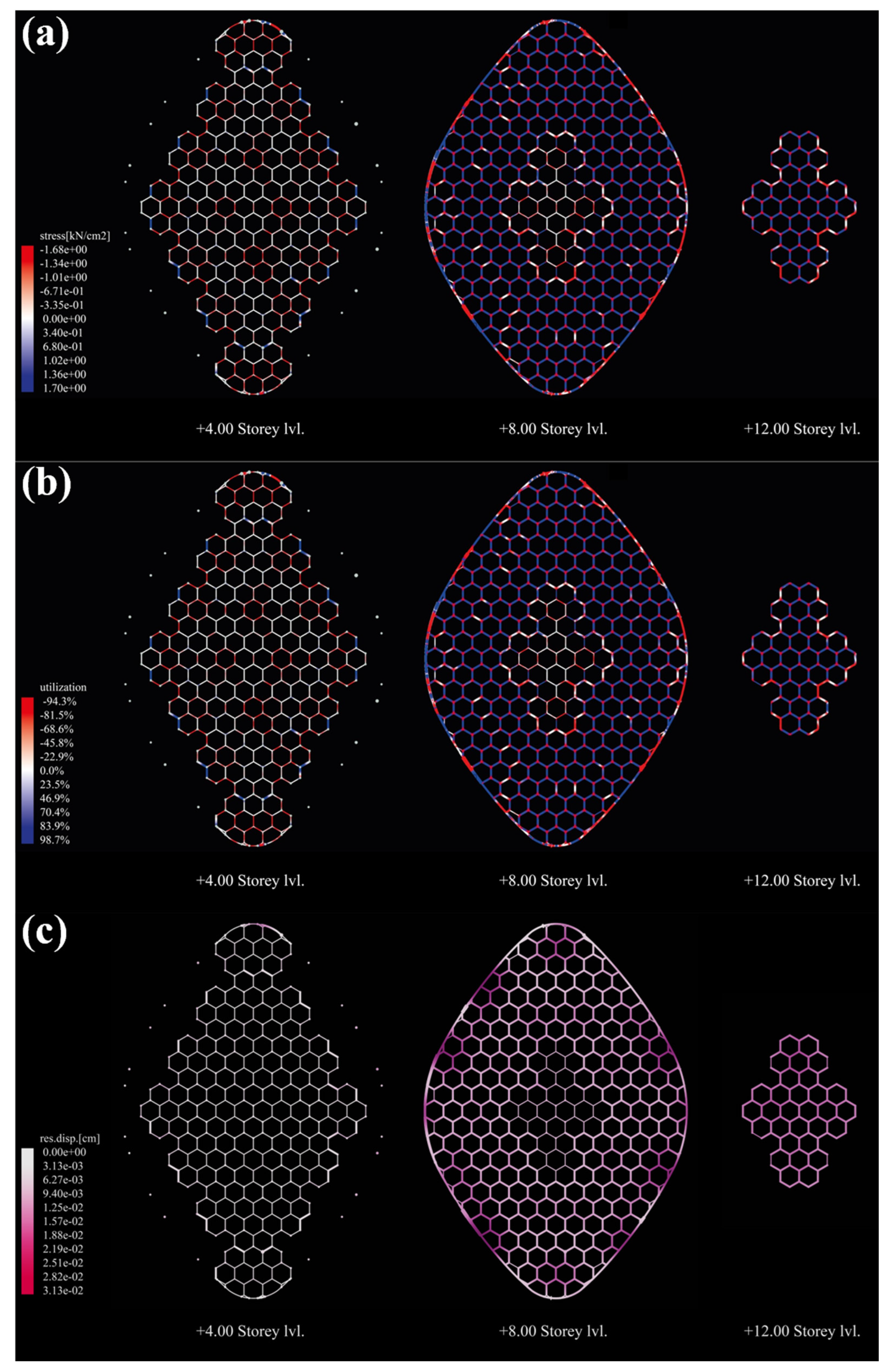

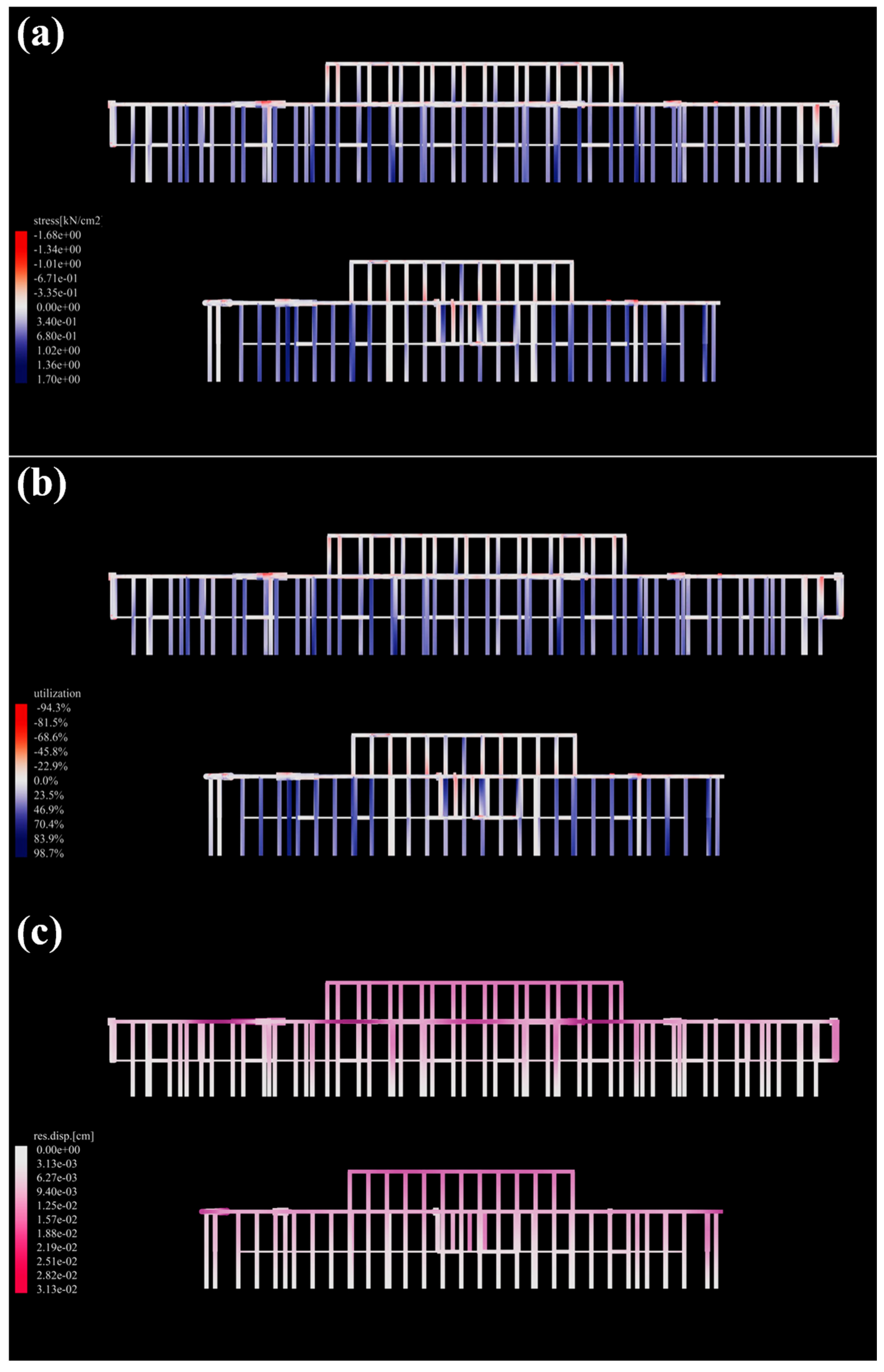

- First group: elements that are located between the interior spaces of the MHU and the garden areas;

- Second group: elements that are located between the garden area and exterior;

- Third group: elements that are located between the interior and the exterior area of the MHU.

| Walls and Roofs | Garden-Exterior | Garden-Interior | In/Exterior |

|---|---|---|---|

| P (%atm) | 74% | 25% | 99% |

| P (kN/m2) | 74.9805 | 25.33125 | 100.312 |

- Young’s modulus = 73,000 MPa

- Tensile strength = 14 MPa

- Compressive strength = 490 MPa

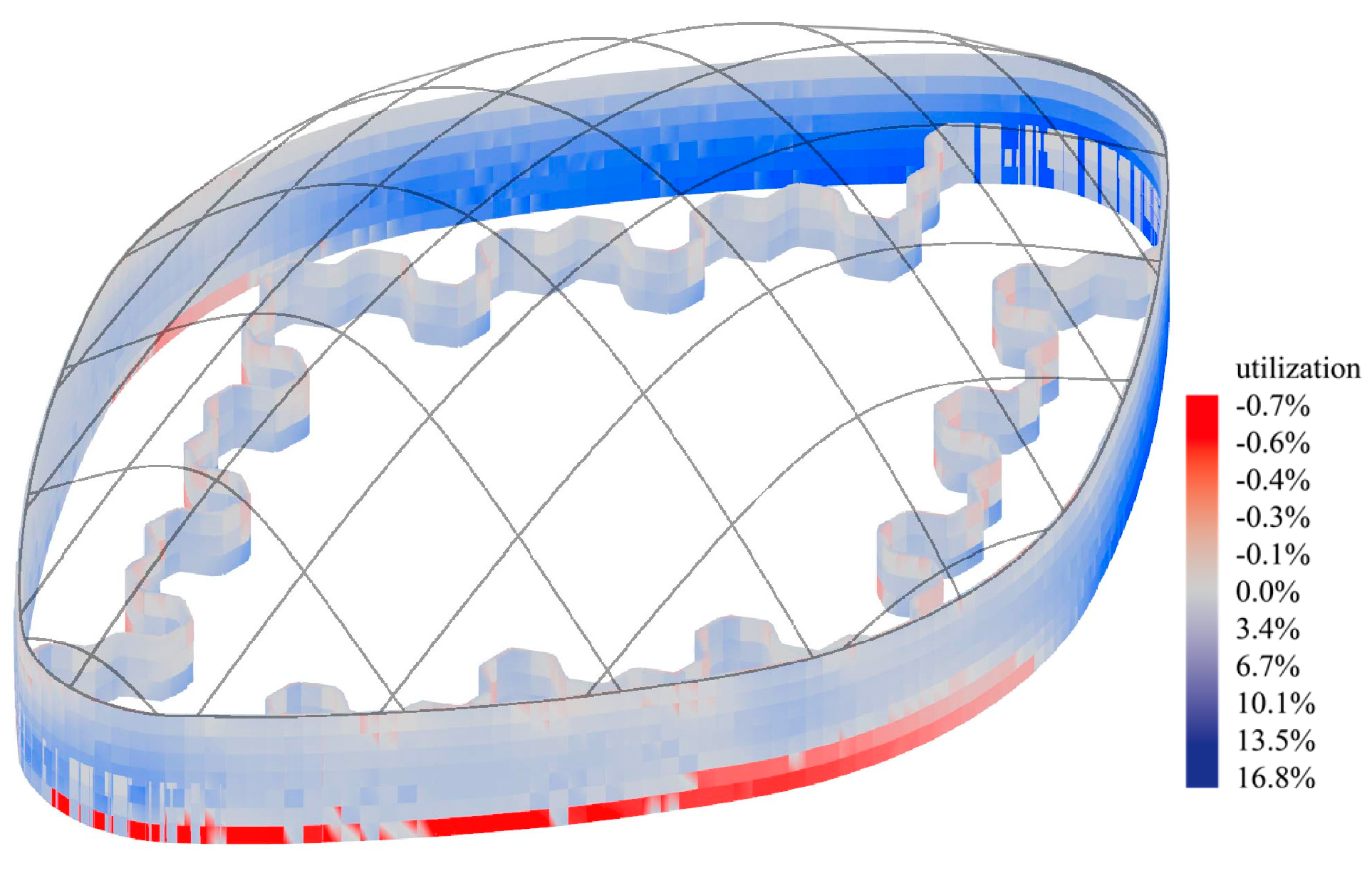

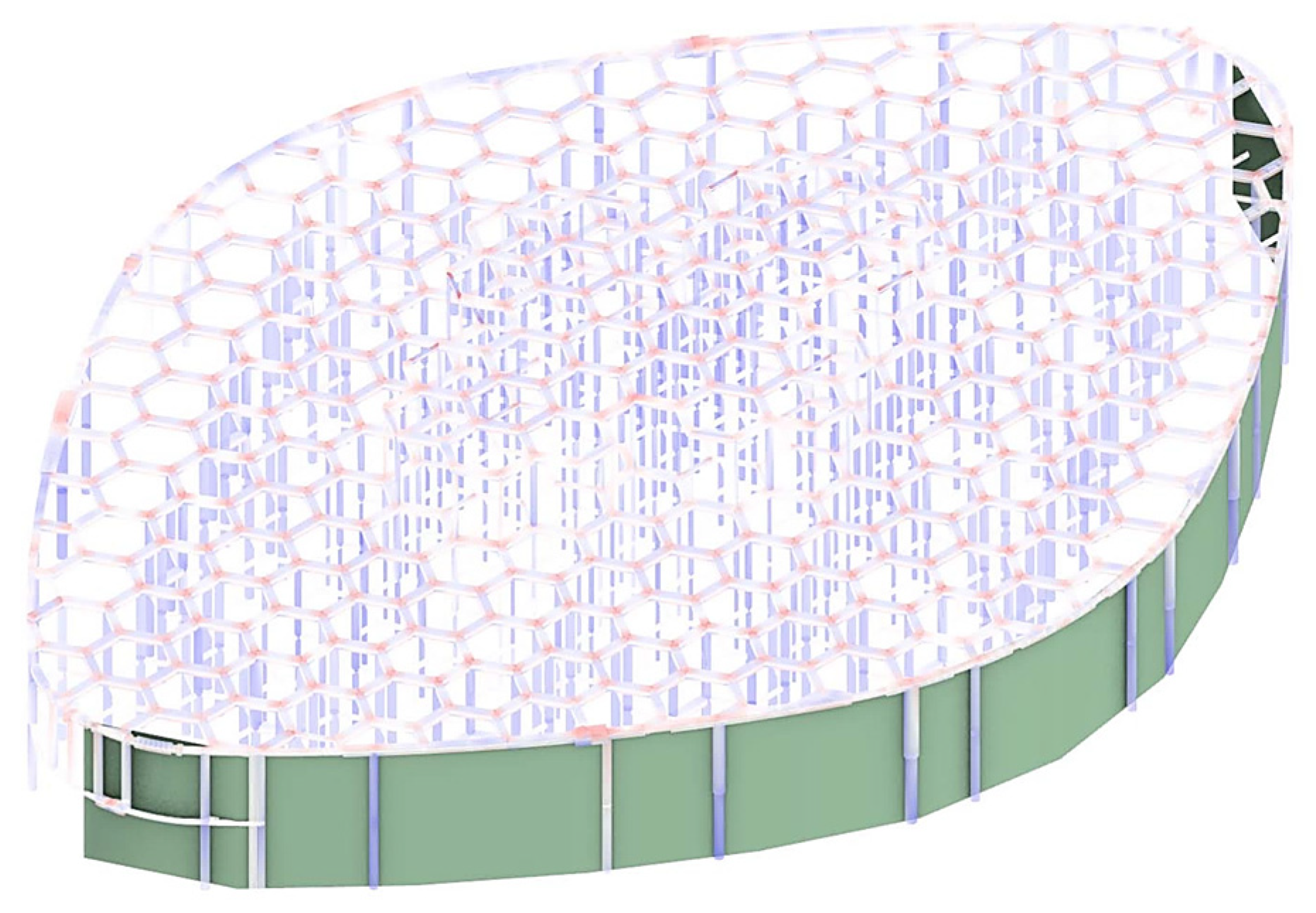

5. Results and Discussions

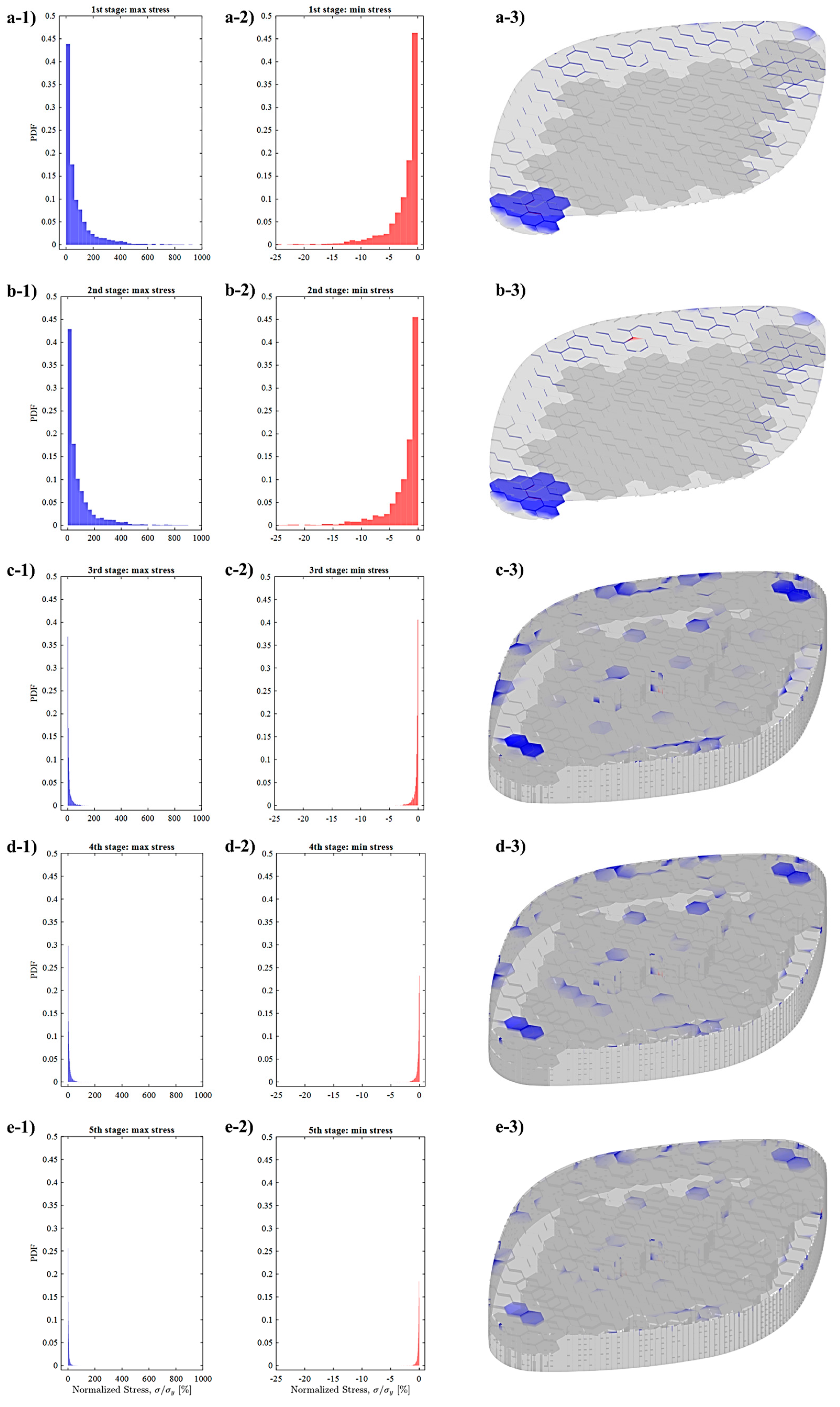

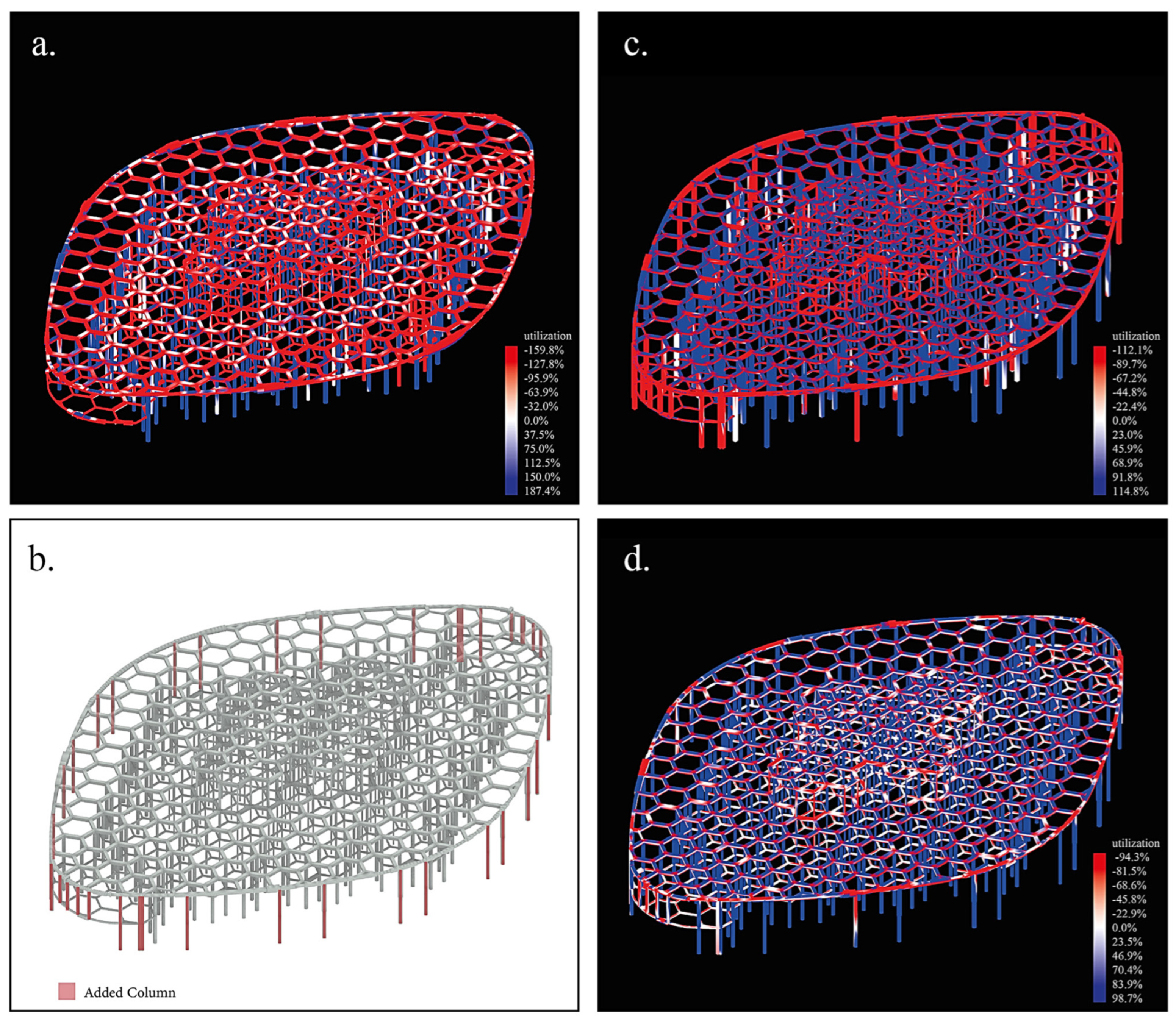

- ▪

- Categorization of the different structural elements based on their load-bearing conditions (the exerted pressures, among other parameters discussed in the previous sections);

- ▪

- Consideration of possible choices for the geometry of the members (i.e., cross-sectional types, etc.);

- ▪

- Sweeping a range of dimensions for the said geometries to obtain the optimal shape and sizes for the final chosen design);

- ▪

- Modification of the design by adding/subtracting members to fulfil the lacking capabilities of the design; the addition of a set of load-bearing exterior envelopes to maintain the structural integrity of the MHU in response to the previously mentioned pressurized-vessel layout.

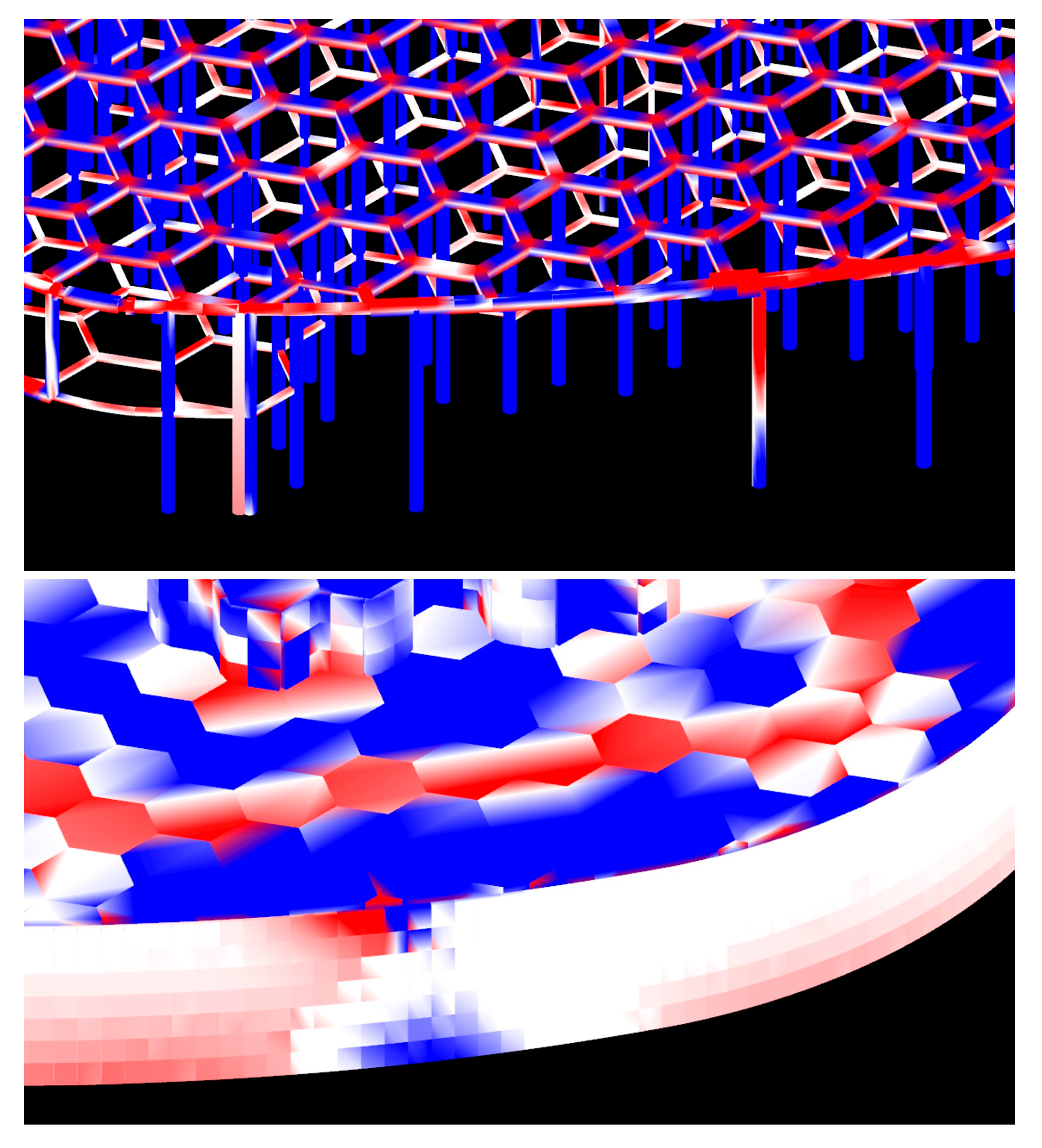

5.1. Structural Configuration

5.2. Structural and Architectural Collaboration

6. Conclusions

- Analyzing the loading using the custom setting;

- Reshaping the cross-section of the axial components;

- Adding structural role to exterior and garden exterior facades;

- Dividing structural components based on their interaction with internal/external pressure;

- Optimizing the range of cross-sections for structural components based on their utilization value.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Latin Letters | |

| A | Area |

| B | Strain-displacement |

| b | Width |

| Cw | Web height |

| D | Cross-diffusion term |

| E | Young’s modulus |

| f | Force |

| fy | Yield strength of the material |

| F | External body force |

| Fe | Element nodal forces |

| Fs | Effective tension/compression |

| Gω | Generation |

| G | Shear modulus |

| ge | Acceleration of gravity on Earth |

| gm | Acceleration of gravity on Mars |

| H | Energy |

| h | Cross-sectional height |

| I | Unit tensor |

| Iₓ | Moment of area in the x-axis |

| J | Mass flux |

| k | Thermal conductivity |

| K | Stiffness matrix |

| L | Distance (lateral restraints of beam)—buckling |

| Lₒ | Initial length (pre-load application) |

| M | Bending moment |

| Mcr | Elastic critical moment |

| N | Normal force |

| Ncr | Elastic critical force for flexural buckling |

| P | Static pressure |

| p | Gross bearing capacity |

| r | Cross-sectional radius |

| S | Source term |

| T | Temperature |

| U | Inlet wind velocity |

| u | Global displacement vector |

| U* | Friction velocity |

| υ | Velocity component |

| W | Moment of resistance |

| w | Density of the soil |

| Y | Turbulence dissipation |

| y | Furthest perpendicular distance to the neutral axis |

| z | Height |

| z0 | Aerodynamic roughness length |

| Greek Letters | |

| δ | Total displacement |

| ε | Basic strain |

| κ | von Karman coefficient |

| σ | Stress |

| v | Kinematic viscosity |

| Γ | Effective diffusivity |

| ρ | Density |

| τ | Shear stress |

| α | Buckling curve imperfection factor |

| χ | Reduction factor |

| χLT | Reduction factor for lateral-torsional buckling |

| Φ | Angle of response of the soil |

| ϕ | Over-strength factor |

| φ | Factor to determine the reduction factor χ |

| φLT | Factor to determine the reduction factor χLT |

| λ | Buckling load |

| λLT | beam slenderness (lateral torsional buckling) |

| γ | Taper ratio of the beam-end sections’ height |

| Abbreviations | |

| ADSM | Anti-dust-settlement membrane |

| AM | Additive manufacturing |

| AU | Astronomical unit |

| CC | Contour crafting |

| CFD | Computational fluid dynamics |

| CHTC | Convective heat transfer coefficient |

| FDM | Fused deposition modeling |

| FRP | Fiber-reinforced polymer |

| GCR | Galactic cosmic ray |

| HAWT | Horizontal axis wind turbine |

| ISRU | In situ resource utilization |

| ISS | International Space Station |

| MCD | Mars Climate Database |

| MHU | Martian Habitat Unit |

| MLI | Multilayer insulations |

| MRS | Martian regolith simulant |

| LSD | Layer-wise slurry deposition |

| LSS | Life Support System |

| RANS | Reynolds averaged Navier–Stokes |

| SLS | Selective laser sintering |

| SPE | Solar particle event |

| TSA | Temperature-swing absorption |

| Subscripts | |

| DoF | Degree of freedom |

| eff | Effective |

| m | Mass |

| SE | Super extremal |

| Specific dissipation rate | |

| y | Yielding |

Appendix A. Relevant Materials

| Material | Reference | Mineralogy, Physical and Chemical Properties | Mechanical Properties | Remarks | ||||

|---|---|---|---|---|---|---|---|---|

| Compressive Strength [MPa] | Tensile Strength [MPa] | Young’s Modulus [MPa] | Failure | Other | ||||

| JSC Mars-1A | Goulas et al. [91] (2017) | Volcanic ash, irregular morphology. For details, grain size, and chemical composition, see ref. | - | - | - | - | Melting point 1330 °C. 24.3% porosity |

|

| Jakus et al. [92] (2017) | Synthesized Martian regolith simulant inks (MRS). For details, morphology, and chemical composition, see ref. | - | - | 2–3 | 10–20% elastic strain, fracture at 50–175% strain at approx. 0.2–0.3 [MPa] tensile stress with strain rates 10−1–102 min−1 | 35.5 ± 4.7% porosity |

| |

| MMS-1 [75] | Fujikawa et al. [93] (2019) | Finely crushed or sorted granular basalt. For details, grain size, and chemical composition, see ref. | - | - | - | - | Internal friction angle 37.1°–46.0°. Cohesion 3.8 −15 kPa. Bulk density 1.2–1.5 g/cm3 |

|

| Peters et al. [73] (2008) | Mechanically crushed saddleback basalt. For details, grain size, minerology, and chemical composition, see ref. | (Whole rock, uniaxial) 89–144 | (Whole rock, Brazilian) 6.9–7.9 | 51,000–59,000 | - | (Rock, dust) angle of friction 30.0°–439.0°. Cohesion 0.38–1.96 kPa. Dry density 911–1384 kg/m3. (whole rock) Poisson’s ratio 0.24–0.29 |

| |

| MGS-1C | Karl et al. [94] (2020) | Clay modified version of MGS-1, produced by mixing 40 wt% smectite clay sodium montmorillonite | 30.8 ± 2.47 (LSD) | - | - | For 30 LSD samples with 16.89 ± 0.64% apparent porosity, the Weibull characteristic strength is 53.53 MPa | True density of 2.951 ± 0.011 g/cm3 |

|

| JEZ-1 | Yin et al. [71] (2021) | MGS-1 mineralogy, smectite clay, Mg-carbonate, and additional olivine. For details, grain size and chemical composition, see ref. | - | - | - | - | Peak and residual cohesion <4 kPa. Peak and critical internal friction angles of 40.6° and 39.7° |

|

| Processes Regolith | Naser [77] (2019) | Processed regolith into cast and sintered basalt | 162–490 (Cast) | 10 (Cast) 14 (Sintered) | 73,000 (Sintered) | - | (Cast) Density 2900–3000 kg/m3. Thermal coefficient of expansion 7.7–8.6 × 10−6 °C−1. Bending strength 40 MPa. Specific heat 500–800 J/kg K. Thermal conductivity 0.02–0.105 W/mK. |

|

| Concretes | Scott et al. [95] (2020) | Basaltic aggregates with magnesium silica binder. For details, see ref. | Up to 35 | - | - | - | - |

|

| Naser and Chehab [96] (2020) | Polyester concrete | 54 | 11.6 | 11,000 | - | Flexural strength 15.1 MPa |

| |

| Carbon fiber-reinforced polymer concrete | 30–69.2 | - | 11,500 | 0.1–0.2% strain | Flexural strength 42.6 MPa | |||

| Glass fiber-reinforced polymer concrete | 64.8 | - | 10,800 | 0–17% strain | Flexural strength 24–37.6 MPa | |||

| Epoxy concrete | 17–129 | 16.3 | 15,000 | 1–11% | Flexural strength 21.3 MPa | |||

| Meza et al. [22] (2016) | Cement-like aggregate mixture of basaltic regolith and a thermoplastic binding agent | 6.9 (lunar simulant, polyurethane binder) | 0.7 (lunar simulant, polyurethane binder) | - | - | - |

| |

| Wan et al. [54] (2016) | Martian regolith simulant JSC Mars-1A and sulfur mixture. For details (see ref.) | Up to 50 | (Brazilian/splitting) up to 3.9 ± 28% | 65,000 (LDPM) | - | Highest fracture energy 67 J/m2. Modulus of rupture (MOD) 7.24 MPa. |

| |

Appendix B. CFD Governing Equations

Appendix C. FEM Governing Equations

Appendix D. Construction Plan—Additive Manufacturing

References

- Amini, K.; Moradi, M.; Teymoori, P.E.B.; Vossoughi, B.; Janabadi, E.D.; Fayaz, R. Design of a set of habitat units and the corresponding surrounding cluster for long-term scientific missions in the pre-terraforming era on Mars. Icarus 2022, 385, 115119. [Google Scholar] [CrossRef]

- Prater, T.; Bean, Q.; Werkheiser, N.; Grguel, R.; Beshears, R.; Rolin, T.; Huff, T.; Ryan, R.; Ledbetter, F.; Ordonez, E. Analysis of specimens from phase I of the 3D printing in Zero G technology demonstration mission. Rapid Prototyp. J. 2017, 23, 1212–1225. [Google Scholar] [CrossRef]

- Werkheiser, M.J.; Dunn, J.; Snyder, M.P.; Edmunson, J.; Cooper, K.; Johnston, M.M. 3D Printing in Zero-G ISS Technology Demonstration. In Proceedings of the AIAA SPACE 2014 Conference and Exposition, San Diego, CA, USA, 4–7 August 2014; Volume 4470. [Google Scholar]

- Leach, N. 3D Printing in Space. Archit. Des. 2014, 84, 108–113. [Google Scholar] [CrossRef]

- Zabel, P.; Schubert, D.; Tajmar, M. Combination of Physico-Chemical Life Support Systems with Space Greenhouse Modules: A System Analysis. In Proceedings of the 43rd International Conference on Environmental Systems, Vail, CO, USA, 14–18 July 2013. [Google Scholar]

- Yan, Q.; Dong, H.; Su, J.; Han, J.; Song, B.; Wei, Q.; Shi, Y. A Review of 3D Printing Technology for Medical Applications. Engineering 2018, 4, 729–742. [Google Scholar] [CrossRef]

- Wong, J.Y.; Pfahnl, A.C. 3D Printing of Surgical Instruments for Long-Duration Space Missions. Aviat. Space Environ. Med. 2014, 85, 758–763. [Google Scholar] [CrossRef]

- Schuldt, S.J.; Jagoda, J.A.; Hoisington, A.J.; Delorit, J.D. A systematic review and analysis of the viability of 3D-printed construction in remote environments. Autom. Constr. 2021, 125, 103642. [Google Scholar] [CrossRef]

- Ceccanti, F.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. 3D Printing Technology for a Moon Outpost Exploiting Lunar Soil. In Proceedings of the 61st International Astronautical Congress, Prague, Czech Republic, 27 September–1 October 2010. [Google Scholar]

- Hirsch, M.; Straub, J. Development and design evolution of an in-space 3D printer. In AIAA SPACE and Astronautics Forum and Exposition; American Institute of Aeronautics and Astronautics Inc.: Reston, VA, USA, 2017. [Google Scholar]

- Patane, S.; Joyce, E.R.; Snyder, M.P.; Shestople, P. Archinaut: In-space manufacturing and assembly for next-generation space habitats. In AIAA SPACE and Astronautics Forum and Exposition; American Institute of Aeronautics and Astronautics Inc., AIAA: Reston, VA, USA, 2017. [Google Scholar]

- Howe, S.A.; Wilcox, B.H.; McQuin, C.; Townsend, J.; Rieber, R.R.; Barmatz, M.; Leichty, J. Faxing structures to the moon: Freeform Additive Construction System (FACS). In Proceedings of the AIAA SPACE 2013 Conference and Exposition, San Diego, CA, USA, 10–12 September 2013. [Google Scholar]

- Verseux, C.; Baqué, M.; Lehto, K.; de Vera, J.-P.P.; Rothschild, L.J.; Billi, D. Sustainable life support on Mars—The potential roles of cyanobacteria. Int. J. Astrobiol. 2015, 15, 65–92. [Google Scholar] [CrossRef]

- Meurisse, A.; Makaya, A.; Willsch, C.; Sperl, M. Solar 3D printing of lunar regolith. Acta Astronaut. 2018, 152, 800–810. [Google Scholar] [CrossRef]

- Duballet, R.; Baverel, O.; Dirrenberger, J. Space Truss Masonry Walls with Robotic Mortar Extrusion. Structures 2019, 18, 41–47. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Buswell, R.A.; De Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Bier, H.; Vermeer, E.; Hidding, A.; Jani, K. Design-to-robotic-production of underground habitats on Mars. arXiv 2021, arXiv:2105.02619. [Google Scholar]

- Li, H.; Meng, H.; Lan, M.; Zhou, J.; Xu, M.; Zhao, X.; Xiang, B. Development of a novel material and casting method for in situ construction on Mars. Powder Technol. 2021, 390, 219–229. [Google Scholar] [CrossRef]

- Yashar, M.; Ciardullo, C.; Morris, M.; Pailes-Friedman, R.; Moses, R.; Case, D. Mars X-House: Design Principles for an Autonomously 3D-Printed ISRU Surface Habitat. In Proceedings of the 49th International Conference on Environmental Systems, Boston, MA, USA, 7–11 July 2019. [Google Scholar]

- Gyollai, I.; Veres, M.; Földvári, M.; Nagy, S.; Horváth, A.; Kenesei, E.; Bérczi, S. Irradiation induced mineral changes of NWA10580 meteorite determined by infrared analysis. Astron. Astrophys. 2024, 683, A143. [Google Scholar] [CrossRef]

- Meza, L.; Singer, R.; Vazquez, N.; Keenan, R.; Burgoyne, H.; Hogstrom, K.; Tan, W.L. Concept for a fully in situ resource-derived habitat for Martian environment. In 15th Biennial ASCE Conference on Engineering, Science, Construction, and Operations in Challenging Environments; Malla, R.B., Agui, J.H., van Susante, P.J., Eds.; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2016; pp. 425–436. [Google Scholar]

- Mueller, R.P.; Prater, T.J.; Roman, M.; Edmunson, J.E.; Fiske, M.R.; Carrato, P. NASA centennial challenge: Three dimensional (3D) printed habitat. In Proceedings of the 70th International Astronautical Congress (IAC), International Astronautical Federation, IAF, Reston, VA, USA, 25 September 2017; pp. 12256–12265. [Google Scholar]

- Geneidy, O.; Ismaeel, W.S.; Abbas, A. A critical review for applying three-dimensional concrete wall printing technology in Egypt. Arch. Sci. Rev. 2019, 62, 438–452. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—Technical, economic, and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Kempton, K.; Ciardullo, C.; Rudakevych, O.; Thibeault, S.; Caswell, T.; Yashar, M.; Ngo, V.; Senter, I.; King, G.; Kang, J.; et al. Technical Risk Reduction for the Mars Ice Home Habitat Concept. In Proceedings of the 69th International Astronautical Congress (IAC), Bremen, Germany, 1–5 October 2018. [Google Scholar]

- Morris, M.; Ciardullo, C.; Lents, K.; Montes, J.; Rudakevych, O.; Sono, M.; Sono, Y.; Yashar, M. Mars Ice House: Using the physics of phase change in 3D printing a habitat with H2O. In Proceedings of the 46th International Conference on Environmental Systems, Vienna, Austria, 10–14 July 2016. [Google Scholar]

- Roman, M.; Yashar, M.; Fiske, M.; Nazarian, S.; Adams, A.; Boyd, P.; Bentley, M.; Ballard, J. 3D-printing lunar and martian habitats and the potential applications for additive construction. In Proceedings of the 2020 International Conference on Environmental Systems, Lisbon, Portugal, 31 July 2020. [Google Scholar]

- Ma, G.; Wang, L.; Ju, Y. State-of-the-art of 3D printing technology of cementitious material—An emerging technique for construction. Sci. China Technol. Sci. 2018, 61, 475–495. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Konstantatou, M.; Dall’Igna, M.; Wilkinson, S.; Gallou, I.; Piker, D. Learning lessons from Earth and Space towards Sustainable Multiplanetary Design. Spool 2021, 8. [Google Scholar]

- Amini, K.; Moradi, M.; Vossoughi, B.; Janabadi, E.D. Space-technological and architectural methodology and process towards design of long-term habitats for scientific human missions on mars. MethodsX 2023, 11, 102270. [Google Scholar] [CrossRef] [PubMed]

- Amini, K.; Janabadi, E.D.; Fayaz, R. Lighting and illumination investigation of long-term residence on Mars for the case of a set of designed Martian Habitat Units (MHUs). Acta Astronaut. 2022, 192, 210–232. [Google Scholar] [CrossRef]

- Stutte, G.W.; Yorio, N.; Edney, S.; Richards, J.; Hummerick, M.; Stasiak, M.; Dixon, M.; Wheeler, R. Effect of reduced atmospheric pressure on growth and quality of two lettuce cultivars. Life Sci. Space Res. 2022, 34, 37–44. [Google Scholar] [CrossRef] [PubMed]

- Ferl, R.J.; Paul, A.L.; Wheeler, R.M. Plant adaptation to low atmospheric pressures: Potential molecular insights. NASA Technical Reports Server (NTRS). Life Support Biosph. Sci. 2004, 8, 93–101. [Google Scholar]

- Chatzitheodoridis, E.; Clerc, P.; Kereszturi, A.; Mason, N.; Persson, E.; Possnig, C.; Poulet, L.; Puumala, M.; Sivula, O.; Brucato, J.R. Towards Permanent Settlements on Mars (from 1000 to 100,000 People). In Mars and the Earthlings: A Realistic View on Mars Exploration and Settlement; Verseux, C., Ed.; Space and Society; Springer: Cham, Switzerland, 2024; pp. 253–339. [Google Scholar]

- Amini, K.; Mehrjou, A.; Mani, M. Enhancing the resolution of the angular orientations of the flow controlling blades on a sustainable house by training an artificial neural network. Energy Effic. 2021, 14, 25. [Google Scholar] [CrossRef]

- Amini, K.; Rastegar, S.; Janabadi, E.D. Challenges in Illumination Analysis and Design for Martian Surface-Level Habitation. MethodsX 2024, 13, 102898. [Google Scholar] [CrossRef]

- Hirt, C.; Claessens, S.J.; Kuhn, M.; Featherstone, W.E. Kilometer-resolution gravity field of Mars: MGM2011. Planet. Space Sci. 2012, 67, 147–154. [Google Scholar] [CrossRef]

- Roman, M.C.; Kim, T.; Howard, D.; Sudnik, J.; Fiske, M.; Herblet, A.; Morris, H.; Cylar, R.; Brewer, D. Centennial Challenges Program Update: From Humanoids to 3D-Printing Houses on Mars, How the Public Can Advance Technologies for NASA and the Nation. In Space and Astronautics Forum (AIAA SPACE Forum); NASA Scientific and Technical Information (STI) Program Office: Baltimore, MD, USA, 2018. [Google Scholar]

- Prater, T.; Werkheiser, N.; Ledbetter, F.; Timucin, D.; Wheeler, K.; Snyder, M. 3D Printing in Zero G Technology Demonstration Mission: Complete experimental results and summary of related material modeling efforts. Int. J. Adv. Manuf. Technol. 2018, 101, 391–417. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C.J.A.M. Additive Manufacturing—A Review of 4D Printing and Future Applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Williams, D.R. Mars Fact Sheet; NASA: Washington, DC, USA, 2004. [Google Scholar]

- Kieffer, H.H.; Jakosky, B.M.; Snyder, C.W.; Matthews, M.S. Mars; Zurek, R.W., Ed.; Space Science Series; Arizona Press: Tucson, AZ, USA, 1992; p. 842, Chapter 26. [Google Scholar]

- Banfield, D.; Spiga, A.; Newman, C.; Forget, F.; Lemmon, M.; Lorenz, R.; Murdoch, N.; Viudez-Moreiras, D.; Pla-Garcia, J.; Garcia, R.F.; et al. The atmosphere of Mars as observed by InSight. Nat. Geosci. 2020, 13, 190–198. [Google Scholar] [CrossRef]

- White, R.D.; Neeson, I.; Schmid, E.S.; Merrison, J.; Iversen, J.J.; Banfield, D. Flow Testing of a Sonic Anemometer for the Martian Environment. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Montabone, L.; Lewis, S.R.; Read, P.L. Interannual variability of Martian dust storms in assimilation of several years of Mars global surveyor observations. Adv. Space Res. 2005, 36, 2146–2155. [Google Scholar] [CrossRef]

- Viúdez-Moreiras, D.; Newman, C.E.; Forget, F.; Lemmon, M.; Banfield, D.; Spiga, A.; Lepinette, A.; Rodriguez-Manfredi, J.A.; Gómez-Elvira, J.; Pla-García, J.; et al. Effects of a Large Dust Storm in the Near-Surface Atmosphere as Measured by InSight in Elysium Planitia, Mars. Comparison With Contemporaneous Measurements by Mars Science Laboratory. J. Geophys. Res. Planets 2020, 125, e2020JE006493. [Google Scholar]

- Aoki, S.; Vandaele, A.C.; Daerden, F.; Villanueva, G.L.; Liuzzi, G.; Thomas, I.R.; Erwin, J.T.; Trompet, L.; Robert, S.; Neary, L.; et al. Water Vapor Vertical Profiles on Mars in Dust Storms Observed by TGO/NOMAD. J. Geophys. Res. Planets 2019, 124, 3482–3497. [Google Scholar] [CrossRef]

- Andrew, T. State-of-the-Art Review on 3D Printing Technology Applications in Construction. Master’s Thesis, University of California, Irvine, CA, USA, 2019. [Google Scholar]

- Kawamoto, H. Improved Electrostatic Precipitator in Martian Environment. J. Aerosp. Eng. 2020, 33. [Google Scholar] [CrossRef]

- Liu, J.; Li, H.; Sun, L.; Guo, Z.; Harvey, J.; Tang, Q.; Lu, H.; Jia, M. In-situ Resources for Infrastructure Construction on Mars: A Review. Int. J. Transp. Sci. Technol. 2021, 11, 1–16. [Google Scholar] [CrossRef]

- Wan, L.; Wendner, R.; Cusatis, G. A novel material for in situ construction on Mars: Experiments and numerical simulations. Constr. Build. Mater. 2016, 120, 222–231. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Reches, Y. Concrete on Mars: Options, challenges, and solutions for binder-based construction on the Red Planet. Cem. Concr. Compos. 2019, 104, 103349. [Google Scholar] [CrossRef]

- Czupalla, M.; Aponte, V.; Chappell, S.; Klaus, D. Analysis of a Spacecraft Life Support Mission. Acta Astronaut. 2003, 55, 537–547. [Google Scholar] [CrossRef]

- Aureli, L.; Pacelli, C.; Cassaro, A.; Fujimori, A.; Moeller, R.; Onofri, S. Iron Ion Particle Radiation Resistance of Dried Colonies of Cryomyces antarcticus Embedded in Martian Regolith Analogues. Life 2020, 10, 306. [Google Scholar] [CrossRef]

- Yang, D.; Bayazitoglu, Y. Polymer Composites as Radiation Shield Against Galactic Cosmic Rays. J. Thermophys. Heat Transf. 2020, 34, 457–464. [Google Scholar] [CrossRef]

- Durante, M. Space radiation protection: Destination Mars. Life Sci. Space Res. 2014, 1, 2–9. [Google Scholar] [CrossRef]

- Belisheva, N.K.; Lammer, H.; Biernat, H.K.; Vashenuyk, E.V. The effect of cosmic rays on biological systems—An investigation during GLE events. Astrophys. Space Sci. Trans. 2012, 8, 7–17. [Google Scholar]

- Gouzman, I.; Grossman, E.; Verker, R.; Atar, N.; Bolker, A.; Eliaz, N. Advances in Polyimide-Based Materials for Space Applications. Adv. Mater. 2019, 31, 1807738. [Google Scholar] [CrossRef]

- Bibring, J.-P.; Langevin, Y.; Gendrin, A.; Gondet, B.; Poulet, F.; Berthé, M.; Soufflot, A.; Arvidson, R.; Mangold, N.; Mustard, J.; et al. Mars Surface Diversity as Revealed by the OMEGA/Mars Express Observations. Science 2005, 307, 1576–1581. [Google Scholar] [CrossRef] [PubMed]

- Murchie, S.; Arvidson, R.; Bedini, P.; Beisser, K.; Bibring, J.; Bishop, J.; Boldt, J.; Cavender, P.; Choo, T.; Clancy, R.T.; et al. Compact Reconnaissance Imaging Spectrometer for Mars (CRISM) on Mars Reconnaissance Orbiter (MRO). J. Geophys. Res. Planets 2007, 112, E05S03. [Google Scholar] [CrossRef]

- Zurek, R.W.; Smrekar, S.E. An overview of the Mars Reconnaissance Orbiter (MRO) science mission. J. Geophys. Res. 2007, 112, E05S01. [Google Scholar] [CrossRef]

- Ramsdale, J.D.; Balme, M.R.; Gallagher, C.; Conway, S.J.; Smith, I.; Hauber, E.; Orgel, C. Grid Mapping the Northern Plains of Mars: Geomorphological, Radar, and Water-Equivalent Hydrogen Results From Arcadia Planitia. J. Geophys. Res. Planets 2018, 124, 504–527. [Google Scholar] [CrossRef]

- Putzig, N.E.; Mellon, M.T. Apparent thermal inertia and the surface heterogeneity of Mars. Icarus 2007, 191, 68–94. [Google Scholar] [CrossRef]

- Viviano, C.E.; Seelos, F.P.; Murchie, S.L.; Kahn, E.G.; Seelos, K.D.; Taylor, H.W.; Taylor, K.; Ehlmann, B.L.; Wiseman, S.M.; Mustard, J.F.; et al. Revised CRISM spectral parameters and summary products based on the currently detected mineral diversity on Mars. J. Geophys. Res. Planets 2014, 119, 1403–1431. [Google Scholar] [CrossRef]

- Böse, M.; Stähler, S.C.; Deichmann, N.; Giardini, D.; Clinton, J.; Lognonné, P.; Ceylan, S.; van Driel, M.; Charalambous, C.; Dahmen, N.; et al. Magnitude Scales for Marsquakes Calibrated from InSight Data. Bull. Seism. Soc. Am. 2021, 111, 3003–3015. [Google Scholar] [CrossRef]

- Banerdt, W.B.; Smrekar, S.E.; Banfield, D.; Giardini, D.; Golombek, M.; Johnson, C.L.; Lognonné, P.; Spiga, A.; Spohn, T.; Perrin, C.; et al. Initial results from the InSight mission on Mars. Nat. Geosci. 2020, 13, 183–189. [Google Scholar] [CrossRef]

- Yin, K.; Liu, J.; Lin, J.; Vasilescu, A.-R.; Othmani, K.; Di Filippo, E. Interface Direct Shear Tests on JEZ-1 Mars Regolith Simulant. Appl. Sci. 2021, 11, 7052. [Google Scholar] [CrossRef]

- Allen, C.C.; Morris, R.V.; Jagr, K.M.; Golden, D.G.; Lindstrom, D.J.; Lindstrom, M.M.; Lockwood, J.P. Martian regolith simulant JSC Mars-1. Lunar Planet. Sci. 1998, 29, 1690. [Google Scholar]

- Peters, G.H.; Abbey, W.; Bearman, G.H.; Mungas, G.S.; Smith, J.A.; Anderson, R.C.; Douglas, S.; Beegle, L.W. Mojave Mars simulant—Characterization of a new geologic Mars analog. Icarus 2008, 197, 470–479. [Google Scholar] [CrossRef]

- Cannon, K.M.; Britt, D.T.; Smith, T.M.; Fritsche, R.F.; Batcheldor, D. Mars global simulant MGS-1: A Rocknest-based open standard for basaltic martian regolith simulants. Icarus 2019, 317, 470–478. [Google Scholar] [CrossRef]

- Clark, J.; Archer, P.; Gruener, J.; Ming, D.; Tu, V.; Niles, P.; Mertzman, S. JSC-Rocknest: A large-scale Mojave Mars Simulant (MMS) based soil simulant for in-situ resource utilization water-extraction studies. Icarus 2020, 351, 113936. [Google Scholar] [CrossRef]

- Gyollai, I.; Chatzitheodoridis, E.; Kereszturi, Á.; Szabó, M. Multiple generation magmatic and hydrothermal processes in a Martian subvolcanic environment based on the analysis of Yamato-000593 nakhlite meteorite. Meteorit. Planet. Sci. 2023, 58, 218–240. [Google Scholar] [CrossRef]

- Naser, M.Z. Extraterrestrial construction materials. Prog. Mater. Sci. 2019, 105, 100577. [Google Scholar] [CrossRef]

- Blocken, B.J.E. Computational Fluid Dynamics for urban physics: Importance, scales, possibilities, limitations and ten tips and tricks towards accurate and reliable simulations. Build. Environ. 2015, 91, 219–245. [Google Scholar] [CrossRef]

- Amini, K.; Mortazavi, S.M.; Elnaz, R.; Amir, F.N. Numerical Investigation on the Convection Heat Transfer and Drag Reduction by Utilizing a Novel Idea of Flow Controlling Blades Designed and Analyzed for a Smart Sustainable House. J. Energy Effic. 2019, 12, 757–776. [Google Scholar] [CrossRef]

- Franke, J.; Hellsten, A.; Schlünzen, H.; Carissimo, B. Best Practice Guideline for the CFD Simulation of Flows in the Urban Environment; COST Office Brussels: Bruxelles, Belgium, 2007. [Google Scholar]

- Tominaga, Y.; Mochida, A.; Yoshie, R.; Kataoka, H.; Nozu, T.; Yoshikawa, M.; Shirasawa, T. AIJ guidelines for practical applications of CFD to pedestrian wind environment around buildings. J. Wind Eng. Ind. Aerodyn. 2008, 96, 1749–1761. [Google Scholar] [CrossRef]

- Amini, K.; Mani, A. 2D-CFD Analyses of Flow Controlling Plates on Gable Roof Geometry Cross-Sections for Light Air to Strong Breeze Wind Speed Classifications—An Unsteady RANS Approach. Green Build. Constr. Econ. 2020, 1, 1–18. [Google Scholar] [CrossRef]

- Mars Climate Database (MCD-v5.3). Available online: http://www-mars.lmd.jussieu.fr/mcd_python/ (accessed on 1 January 2024).

- Mani, A.; Amini, K. 3D-CFD Study of Oblique Streamlining Membranes on the Roof-top of a Low-Rise Building, Targeting Pedestrian Comfort—A Case Study. J. Green Build. Constr. Econ. 2020, 1, 51–68. [Google Scholar] [CrossRef]

- Sun, W.; Tkalčić, H. Repetitive marsquakes in Martian upper mantle. Nat. Commun. 2022, 13, 1695. [Google Scholar] [CrossRef]

- EN1993-1-1; Eurocode 3: Design of Steel Structures-Part 1-1: General Rules for Buildings Authority: The European Union Per Regulation 305/2011, Directive 98/34/EC, Directive, 2.0.0.4./.1.8./.E.C. The European Union: Strasbourg, France, 2005. (In English)

- Jakobsson, N.A.; Bohman, S.A. Generative Design of Timber Structures According to Eurocode Development of a Parametric Model in Grasshopper. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2019. [Google Scholar]

- Van Vooren, T.G.J. Optimization of 3D Concrete Printed Arch Structures Creating a Parametric Model for Shape and Cross-Section Optimization of Arch Structures for Multiple Load Combinations Considering the Requirements of the 3D Concrete Printing Technique; Eindhoven University of Technology: Eindhoven, The Netherlands, 2018. [Google Scholar]

- Jaffe, L.D. Bearing strength of lunar soil. Earth Moon Planets 1971, 3, 337–345. [Google Scholar] [CrossRef]

- Kokelaar, B.P.; Bahia, R.S.; Joy, K.H.; Viroulet, S.; Gray, J.M.N.T. Granular avalanches on the Moon: Mass-wasting conditions, processes, and features. J. Geophys. Res. Planets 2017, 122, 1893–1925. [Google Scholar] [CrossRef]

- Goulas, A.; Binner, J.G.; Harris, R.A.; Friel, R.J. Assessing extraterrestrial regolith material simulants for in-situ resource utilisation based 3D printing. Appl. Mater. Today 2017, 6, 54–61. [Google Scholar] [CrossRef]

- Jakus, A.E.; Koube, K.D.; Geisendorfer, N.R.; Shah, R.N. Robust and Elastic Lunar and Martian Structures from 3D-Printed Regolith Inks. Sci. Rep. 2017, 7, 44931. [Google Scholar] [CrossRef]

- Fujikawa, T.; Newson, T.; Ahmed, A.; Safdar, M. Assessment of the geo-mechanical properties of Mojave Mars Simulant-1 (MMS-1) soil. In Proceedings of the XVI Pan-American Conference on Soil Mechanics and Geotechnical Engineering (XVI PCSMGE), Cancun, Mexico, 17–20 November 2019; pp. 268–277. [Google Scholar]

- Karl, D.; Duminy, T.; Lima, P.; Kamutzki, F.; Gili, A.; Zocca, A.; Günster, J.; Gurlo, A. Clay in situ resource utilization with Mars global simulant slurries for additive manufacturing and traditional shaping of unfired green bodies. Acta Astronaut. 2020, 174, 241–253. [Google Scholar] [CrossRef]

- Scott, A.N.; Oze, C.; Tang, Y.; O’Loughlin, A. Development of a Martian regolith simulant for in-situ resource utilization testing. Acta Astronaut. 2017, 131, 45–49. [Google Scholar] [CrossRef]

- Naser, M.Z.; Chehab, A.I. Polymers in space exploration and commercialization. Polym. Sci. Innov. Appl. 2020, 457–484. [Google Scholar]

- Wilcox, D. Turbulence Modeling for CFD; DCW Industries: La Canada, CA, USA, 2006. [Google Scholar]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Öchsner, A.; Merkel, M. One-Dimensional Finite Elements; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Yang, Z.; Wang, L.; Hu, Y. Displacement structures and fast inversion formulas for confluent polynomial Vandermonde-like matrices. J. Comput. Appl. Math. 2005, 180, 229–243. [Google Scholar] [CrossRef][Green Version]

- Khan, A.A.A.A. Shape Optimization of Compressed Members Under Buckling. Master’s Thesis, Politecnico Di Milano, Milan, Italy, 2021. [Google Scholar]

| Parameter | Specification |

|---|---|

| Surface layer thickness | 0.25 m |

| Total number of cells | 3,083,925 |

| Curvature normal angle | 18° |

| Min size | 3.08 × 10−3 m |

| Max size | 20 m |

| Boundary layer mesh | 5 leyers |

| Inflation growth rate | 2 |

| Element Type | Sub-Category | Cross-Sec | Height (cm) | Width (cm) |

|---|---|---|---|---|

| column | exterior | □ | 52.5 | 52.5 |

| interior | □ | 30 | 30 | |

| beam | exterior | □ | 60 | 60 |

| interior | □ | 30 | 30 | |

| floor | exterior | 50 | - | |

| interior | 30 | - | ||

| wall | exterior | 40 | - | |

| interior | 27.5 | - |

| Element Type | Sub-Category | Cross-Sec | Height (cm) | Width (cm) | Diameter (cm) |

|---|---|---|---|---|---|

| Column | exterior | ○ | - | - | 45–60 |

| interior | ○ | - | - | 20–40 | |

| Beam | exterior | □ | 40–80 | 40–80 | - |

| interior | □ | 20–40 | 20–40 | - | |

| Floor | exterior | 40–60 | - | - | |

| interior | 20–40 | - | - | ||

| Wall | exterior | 30–50 | - | - | |

| interior | 20–35 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janabadi, E.D.; Amini, K.; Rastegar, S. On the Structural Design and Additive Construction Process of Martian Habitat Units Using In-Situ Resources on Mars. Aerospace 2025, 12, 761. https://doi.org/10.3390/aerospace12090761

Janabadi ED, Amini K, Rastegar S. On the Structural Design and Additive Construction Process of Martian Habitat Units Using In-Situ Resources on Mars. Aerospace. 2025; 12(9):761. https://doi.org/10.3390/aerospace12090761

Chicago/Turabian StyleJanabadi, Ehsan Dehghani, Kasra Amini, and Sana Rastegar. 2025. "On the Structural Design and Additive Construction Process of Martian Habitat Units Using In-Situ Resources on Mars" Aerospace 12, no. 9: 761. https://doi.org/10.3390/aerospace12090761

APA StyleJanabadi, E. D., Amini, K., & Rastegar, S. (2025). On the Structural Design and Additive Construction Process of Martian Habitat Units Using In-Situ Resources on Mars. Aerospace, 12(9), 761. https://doi.org/10.3390/aerospace12090761