1. Introduction

As humanity sets its sights on venturing deeper into the cosmos, the Moon, our closest celestial neighbor, emerges as a pivotal stepping stone for ambitious long-term space exploration endeavors [

1]. However, establishing a sustainable human presence on the lunar surface presents formidable challenges due to its harsh and unforgiving environment [

1,

2]. The lunar environment, with extreme temperature swings, vacuum conditions, intense radiation, abrasive dust, and micrometeorite threats, starkly contrasts Earth’s conditions [

1,

3]. Addressing these challenges requires the development of habitats that can reliably protect human life and sensitive equipment [

2].

In recent years, the scientific community has increasingly focused on the lunar subsurface as a potential haven for long-term lunar bases [

4]. Of particular interest are lava tubes, ancient remnants of volcanic activity on the Moon. These natural cavities within the lunar crust offer a multitude of advantages for potential habitation [

4,

5]. Lava tubes provide a stable thermal environment, shielding inhabitants from harmful cosmic and solar radiation and offering protection against micrometeorite impacts [

4,

5,

6]. Moreover, they may harbor subsurface water ice and other valuable resources essential for sustaining a lunar colony [

7,

8,

9]. Advancements in remote sensing and data analysis have enabled the identification and characterization of numerous lunar lava tubes, offering valuable insights into their dimensions, morphology, and potential suitability for human habitation [

10,

11].

To harness the potential of these lava tubes and establish lunar subsurface habitats, efficient excavation methods are paramount. Traditional excavation techniques encounter significant hurdles due to the unique properties of lunar rocks, known for their high strength and abrasiveness [

12]. This study proposes a pioneering approach to lunar excavation by integrating Tunnel Boring Machine (TBM) technology with cutting-edge rock weakening techniques and precise strength estimation methods. TBMs have a proven track record in terrestrial tunneling projects, and their adaptability to the lunar environment holds immense promise for the efficient and safe excavation of lunar subsurface structures [

13,

14].

Microwave-assisted rock weakening presents a promising method for enhancing excavation efficiency. Terrestrial studies reveal that microwave irradiation induces thermal stresses and microfractures, significantly reducing rock strength [

15,

16,

17]. Terrestrial applications of microwave-assisted rock excavation have shown promising results, though adaptation to the lunar environment with its vacuum conditions, temperature extremes, and unique rock properties presents both opportunities and challenges requiring systematic investigation. Our research delves into the application of this technique to lunar rocks, considering the unique lunar environment and the potential advantages it offers for TBM operations on the Moon.

A critical factor in successful lunar excavation is the accurate estimation of rock strength. Given the limited availability of lunar rock samples for direct testing, we have developed an innovative approach to predict lunar rock strength using non-destructive measurements. Building upon the valuable data on density and P-wave velocity of lunar rock samples from the Apollo missions provided by Warren et al. [

18], we have integrated this information with an extensive dataset of terrestrial rocks to develop predictive models. Additionally, recent studies have explored the use of spectroscopic techniques to remotely estimate the mineralogy and physical properties of lunar rocks, further enriching the data available for strength prediction models [

19,

20].

Our study employs sophisticated machine learning techniques to establish correlations between rock physical properties and strength. The developed model, trained on a diverse dataset of terrestrial rocks, shows promising capabilities in estimating the strength of lunar rocks based on their physical properties. Machine learning algorithms, widely recognized for predicting geomechanical properties of rocks, offer substantial promise for optimizing lunar excavation by estimating rock strength with improved accuracy [

21,

22].

However, the unique nature of lunar rocks, forged under conditions vastly different from those on Earth, necessitates caution when applying these models. To address this limitation, we propose incorporating additional non-destructive testing methods, such as Leeb hardness measurements. The Leeb hardness test, known for its portability and rapid execution, could potentially capture unique aspects of lunar rock properties, thereby enhancing the accuracy of our strength predictions. Moreover, integrating data from multiple non-destructive testing methods can bolster the robustness and reliability of strength prediction models [

23,

24].

The integration of these innovative approaches—microwave-assisted rock weakening, machine learning-based strength prediction, and supplementary non-destructive testing—with TBM technology presents a comprehensive strategy for advancing lunar subsurface exploration and development. By tackling the challenges of lunar rock excavation from multiple angles, we aim to significantly enhance the feasibility of creating sustainable subsurface habitats on the Moon.

This research not only contributes to the expanding knowledge base on lunar geology and excavation techniques but also carries profound implications for future lunar missions. An improved understanding and prediction of lunar rock properties can inform the design of excavation equipment, support the meticulous planning of construction projects, and contribute to the development of in situ resource utilization strategies.

With NASA’s Artemis program and global collaborations heralding a new era of lunar exploration [

25], advancing subsurface excavation techniques has become a critical priority. Our work aspires to pave the way for the creation of safe, sustainable, and expandable lunar habitats, marking a pivotal step towards establishing a permanent human presence beyond the confines of Earth.

3. Review of Previous Lunar TBM Concepts

The concept of utilizing Tunnel Boring Machines (TBMs) for lunar subsurface development has captured the imagination of researchers and engineers for decades. As humanity sets its sights on establishing a permanent presence on the Moon, the need for safe, reliable, and efficient methods of creating underground habitats becomes increasingly apparent. The lunar environment presents unique challenges that make surface construction problematic, including extreme temperature fluctuations, radiation exposure, and the constant threat of micrometeorite impacts. Underground structures offer a promising solution to these challenges, providing natural shielding and a more stable environment for long-term habitation.

The idea of adapting terrestrial TBM technology for lunar applications is not new, but it has gained renewed interest in recent years as our understanding of the lunar environment has improved and space exploration technologies have advanced. This section examines two significant studies that explored the concept of lunar TBMs, highlighting the evolution of this technology and the challenges addressed over time. These studies, separated by three decades, demonstrate how approaches to lunar tunneling have evolved with our expanding knowledge of the Moon and advancements in engineering capabilities.

By reviewing these previous concepts, we can better understand the technical requirements, design considerations, and potential benefits of lunar TBMs. This understanding informs future research and development efforts, helping to pave the way for the realization of underground lunar habitats and the expansion of human presence beyond Earth.

3.1. Allen et al. (1988) [51] Lunar Tunneler Concept

In 1988, a team led by Christopher S. Allen at Texas A&M University proposed a groundbreaking concept for a Lunar Tunneler [

51]. This study, conducted in collaboration with NASA, was one of the first comprehensive attempts to design a TBM specifically for lunar applications. The team’s approach was ambitious and forward-thinking, addressing many of the unique challenges posed by the lunar environment.

The proposed Lunar Tunneler was envisioned as a fully automated machine capable of excavating lunar material while simultaneously creating a rigid, glass-like ceramic lining to support the tunnel walls. This dual-purpose functionality was a key innovation, addressing both the need for efficient excavation and the requirement for immediate tunnel support in the lunar environment.

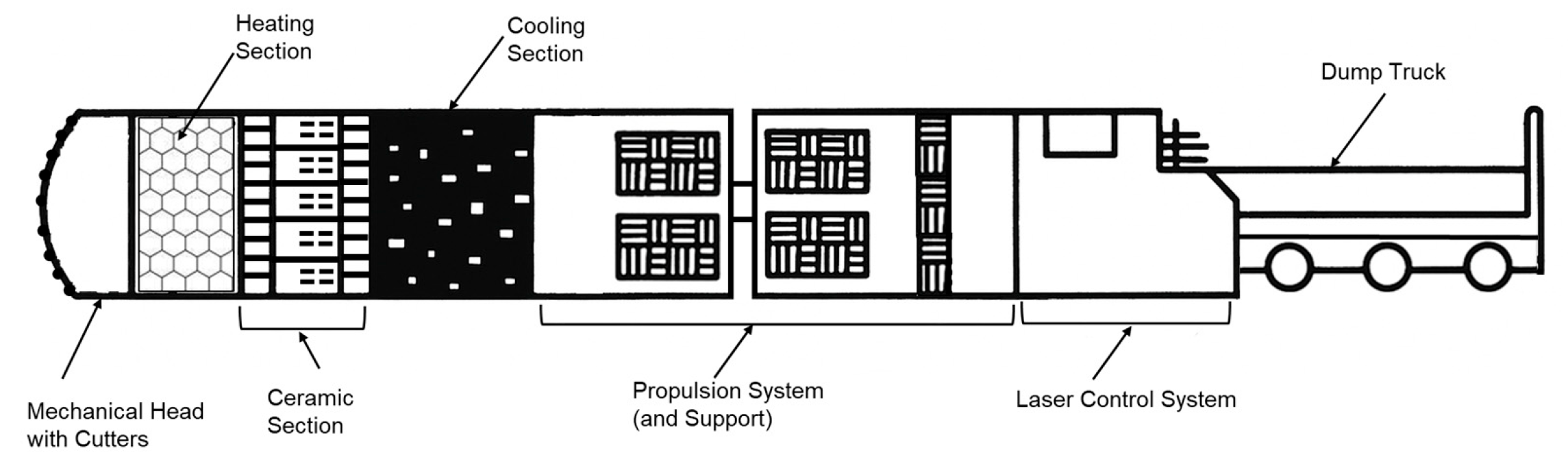

At the heart of the Lunar Tunneler design was a rotating mechanical head equipped with disc cutters, as illustrated in

Figure 2. The figure shows the key components of the integrated system: the mechanical cutting head at the front for excavation, followed by the nuclear reactor power unit and heat exchange systems for the glass-forming process. This cutting mechanism was adapted from terrestrial TBM technology but optimized for the expected properties of lunar regolith and bedrock. The team recognized that the abrasive nature of lunar soil would pose significant challenges to the longevity of the cutting tools, and they proposed using highly durable materials to mitigate this issue.

The propulsion system of the Lunar Tunneler was designed to overcome the challenges posed by the low lunar gravity. The team proposed a hydraulic gripper mechanism that would anchor the machine to the tunnel walls, providing the necessary reaction force for the cutting head to operate effectively. This system was crucial because the reduced gravity on the Moon would limit the machine’s ability to generate cutting forces through weight alone, as is common in terrestrial TBMs.

One of the most innovative aspects of the Allen et al. design was its approach to power generation and thermal management. The team proposed using a nuclear reactor as the primary power source, with an estimated output of several hundred kilowatts, recognizing the need for a reliable, long-term energy supply in the lunar environment. This reactor would not only provide power for the TBM’s operations but would also be integral to the tunnel lining process.

The heat generated by the nuclear reactor would be used in a novel heat exchange system. Operating at temperatures exceeding 1000 °C, this system would melt the excavated lunar material and form it into a glass-like ceramic lining along the tunnel walls. This approach served multiple purposes: it provided immediate structural support for the tunnel, created a barrier against the vacuum of space, and offered radiation shielding for future inhabitants.

Guidance and control of the Lunar Tunneler were to be managed by a sophisticated laser guidance and computer control system. This system would allow for precise navigation and real-time adjustments to the tunneling process, ensuring the creation of stable and accurately positioned underground structures.

While the Allen et al. study was limited by the technology and knowledge available in the late 1980s (particularly in areas like autonomous control and advanced materials), it laid important groundwork for future research in lunar tunneling. The team’s holistic approach to addressing excavation, habitat construction, and immediate tunnel support set a precedent for subsequent studies in this field.

3.2. Rostami, Dreyer, and Blair (2018) [13] Lunar TBM Concept

Three decades after Allen et al.’s pioneering work, Rostami, Dreyer, and Blair revisited the concept of lunar TBMs in their 2018 study [

13]. This more recent exploration of lunar tunneling technology benefited from significant advancements in our understanding of the Moon’s geology and environment, as well as progress in terrestrial TBM technology.

The authors of the 2018 study began by acknowledging the potential of underground spaces for future lunar bases, echoing the rationale of the earlier study. However, they also highlighted new opportunities that had been recognized in the intervening years, particularly the potential of lunar lava tubes as pre-existing underground structures that could be adapted for human use.

One of the key contributions of Rostami et al.’s study was its comprehensive analysis of the lunar environment and its implications for TBM design. The authors discussed the challenges posed by the Moon’s extreme temperature variations, noting that while these would be less pronounced underground, they would still significantly impact machine design and operation. They also addressed issues of operating in a vacuum environment, which would affect everything from material behavior to heat dissipation in a TBM system.

The study paid particular attention to the properties of lunar regolith and bedrock, emphasizing their highly abrasive nature. The authors noted that this abrasiveness would lead to accelerated wear on cutting tools and other machine components, necessitating the development of new, highly durable materials and innovative cutting technologies for a lunar TBM.

Rostami, Dreyer, and Blair also explored the potential for in situ resource utilization (ISRU) in lunar TBM operations. They suggested that lunar resources, such as the excavated basalt rock or regolith, could potentially be used in the construction and operation of the TBM itself (for example, as radiation shielding or processed into support structures), reducing the need to transport as much material from Earth. This approach aligns with broader efforts in the space exploration community to develop sustainable, self-sufficient lunar operations.

Several modifications to conventional TBM designs were proposed to address the unique challenges of the lunar environment. These included systems for maintaining internal air pressure within the TBM and tunnel (to protect equipment and possibly crews), innovative approaches to heat management given the absence of convective cooling, and adaptations to the propulsion and anchoring systems to account for the Moon’s reduced gravity.

One of the most significant aspects of the Rostami et al. concept was the use of TBMs to access and develop lunar lava tubes. The authors argued that TBMs could provide a safer and more controlled method of entering these large voids beneath the Moon’s surface compared to purely robotic or explosive methods of enlarging skylight entrances. By tunneling into the side of a lava tube, a TBM could create a graded entryway or connect multiple tubes, potentially opening up vast subsurface volumes for human use with minimal surface disturbance.

The study also addressed logistical challenges of deploying and operating a TBM on the Moon. The authors discussed the need for modular TBM designs that could be transported to the Moon in parts and assembled on-site. They emphasized the importance of high automation, given the limited real-time oversight possible from Earth and the desire to minimize astronaut labor in what would be a hazardous environment.

In conclusion, the Rostami, Dreyer, and Blair study represented a significant advancement in our understanding of the challenges and opportunities associated with lunar TBMs. By building on earlier work and incorporating new knowledge about the lunar environment and robotics, the authors provided a comprehensive roadmap for the development of this technology, paving the way for future research and development efforts in this exciting field.

4. Innovative Excavation Methods for Lunar TBM

Lunar excavation presents unique challenges that require novel approaches to TBM technology. In this section, we address these challenges by examining lunar rock properties and introducing new excavation techniques tailored for the Moon’s conditions. First, we assess lunar rock strength through modeling (using available Apollo sample data and terrestrial analogs) to understand the mechanical demands on a TBM. We then explore a promising excavation enhancement method, microwave-assisted rock weakening, which can significantly reduce the cutting effort and wear on TBM cutters. By combining accurate strength prediction with targeted rock weakening, we aim to lay the groundwork for the next generation of lunar TBMs capable of efficiently and reliably creating the subsurface infrastructure necessary for long-term lunar exploration and habitation.

4.1. Lunar Rock Strength Estimation

To date, there have been no direct measurements of lunar rock strength because the limited samples returned from Apollo missions were primarily used for scientific research, with minimal destructive testing conducted [

52]. However, we can estimate the strength of lunar rocks using data from Apollo mission samples and terrestrial analogs. According to Mizutani and Newbigging (1973) [

16], lunar basalt has a density of 2.56–3.18 g/cm

3 and a P-wave velocity of 3.02–5.60 km/s, while lunar anorthosite shows density values of 2.40–2.76 g/cm

3 and a P-wave velocity of 4.41–5.98 km/s (

Table 1).

Density and P-wave velocity are effective indicators of rock strength due to their relationship with porosity, mineral composition, and internal bonding. Denser rocks with higher P-wave velocities typically exhibit stronger interparticle cohesion, fewer microvoids, and greater elastic modulus, all of which contribute to higher UCS.

Using these physical property measurements, combined with terrestrial rock data and predictive modeling, we can develop estimates for lunar rock strength. We assembled a dataset of 195 terrestrial rock samples with known density, P-wave velocity, and uniaxial compressive strength (UCS) values. The dataset includes 70 igneous rocks, 82 sedimentary rocks, and 43 metamorphic rocks, providing a comprehensive representation of various rock types and their mechanical properties. We used this dataset to train and evaluate several machine learning models for UCS prediction. The dataset was split into training and test sets with a ratio of 8:2. In our analysis, we experimented with multiple algorithms, including Random Forest, K-Nearest Neighbors (KNN), Support Vector Machine (SVM), XGBoost, CatBoost, and LightGBM, using combinations of density and P-wave velocity as input features. The XGBoost model demonstrated robust performance with an average training R

2 of 0.839 and a testing R

2 of 0.680 when using density and P-wave velocity as predictors. Based on the P-wave velocity and density values from

Table 1, this initial model estimated UCS values on the order of 135–160 MPa for lunar basalts and 115–160 MPa for lunar anorthosites. These predicted strength ranges are quite high, comparable to very strong terrestrial rocks. We note that these predictions should be interpreted with caution, as the lunar samples’ properties may differ from our Earth-based training data, particularly due to the unique formation conditions and lack of weathering processes on the Moon. It is likely that the actual in situ strength of lunar rocks is even higher than our model predicts, given the Moon’s lack of weathering and the presence of shock effects from impacts. Thus, our initial estimates might be lower bounds on true lunar rock strength.

To enhance prediction accuracy and robustness, we incorporated additional non-destructive test data into the model, specifically Leeb hardness measurements. Leeb hardness is a portable hardness test known to correlate well with rock strength. Previous studies have shown strong correlations between Leeb hardness values and UCS for a variety of rocks [

23,

24,

48]. We expanded our terrestrial dataset to include Leeb hardness values for those samples (where available or from literature).

Using the augmented dataset with three inputs (density, P-wave velocity, and Leeb hardness), we retrained our models. Again, XGBoost performed best, improving to an average training R

2 of 0.884 and testing R

2 of 0.751 (with training and testing RMSE of ~17.1 MPa and 25.6 MPa, respectively). Other algorithms showed acceptable but lower performance (for example, Random Forest yielded a test R

2 = 0.74, and KNN showed signs of overfitting with a training R

2 = 0.999 but a test R

2 = 0.72).

Table 2 provides a comparison of the model performances.

The superior performance of the XGBoost model, particularly its higher test R2 value and lower test RMSE compared to others, suggests it is the most reliable choice for predicting lunar rock strength from our suite of inputs. Importantly, the XGBoost model’s balanced performance on training vs. testing indicates good generalization capability, which is crucial given the limited ability to validate predictions on actual lunar material.

Given the potential high strength of lunar rocks indicated by our models and geological reasoning, these non-destructive methods offer valuable tools for assessing lunar rock properties in situ. The ability to estimate rock strength using portable instruments like a Leeb hardness tester or seismic P-wave device could significantly enhance our capability to characterize the ground before or during TBM operations in a lunar mission.

We must note, however, that while our models show promising results for terrestrial rocks and lunar analog data, their application to real lunar rocks should be approached with caution. The Moon’s unique conditions, including the effects of long-term cosmic radiation exposure and lack of weathering, may result in rock properties that differ from Earth’s in ways not fully captured by our training data [

3,

31,

32]. Given the uncertainties in extrapolating terrestrial rock properties to lunar conditions, conservative design approaches with appropriate safety margins should be applied until in situ validation data becomes available. Thus, continued refinement of these models (potentially with data from future lunar sample returns or in situ tests) will be important.

4.2. Microwave-Assisted Rock Weakening

Microwave-assisted rock weakening represents an innovative approach to enhancing excavation efficiency for lunar exploration. This technique employs microwave energy to induce thermal stresses and microfractures in rocks. It is particularly effective with basalt, which serves as an analog for much of the lunar mare rock. The method’s effectiveness has been demonstrated through systematic laboratory studies showing significant reductions in rock strength and mechanical integrity after microwave treatment.

The mechanism operates through selective heating of different minerals within the rock matrix. When exposed to microwave radiation, the varying dielectric properties of minerals lead to differential heating, generating internal stresses due to uneven thermal expansion rates. These internal stresses result in the formation and propagation of microcracks, ultimately reducing the rock’s mechanical strength.

For this study, basalt samples from Cheorwon, South Korea, were selected due to their similarity to typical lunar basalts in composition and physical properties. Notably, Cheorwon basalt has been used in developing the Korean Lunar Simulant, KLS-1, underscoring its relevance as a lunar analog [

53]. A total of 40 cylindrical specimens were prepared according to NX core specifications (approximately 54 mm in diameter and 110 mm in length). Prior to testing, all specimens were dried in an oven at 105 °C for at least 24 h to eliminate moisture in order to better simulate the dry lunar conditions.

Microwave irradiation was performed using a 2.45 GHz microwave generator with an output power of approximately 2 kW. Each 3 min test consumed roughly 360 kJ of energy. After microwave exposure, all samples were allowed to cool to room temperature before uniaxial compressive strength (UCS) testing, ensuring consistency in mechanical evaluation. Out of the 40 basalt specimens, 30 were subjected to microwave exposure for varying durations (1 min, 3 min, and 5 min), with 10 samples allocated to each exposure time. The remaining 10 specimens were kept as a control group (no microwave treatment) to provide baseline strength values. The tests were conducted under ambient laboratory conditions (at standard atmospheric pressure and room temperature), since implementing a vacuum environment was beyond the scope of our experimental setup. However, by thoroughly drying the samples and insulating the test area, we mitigated moisture effects and convective cooling, partially mimicking the moisture-free and convectively limited environment of the Moon.

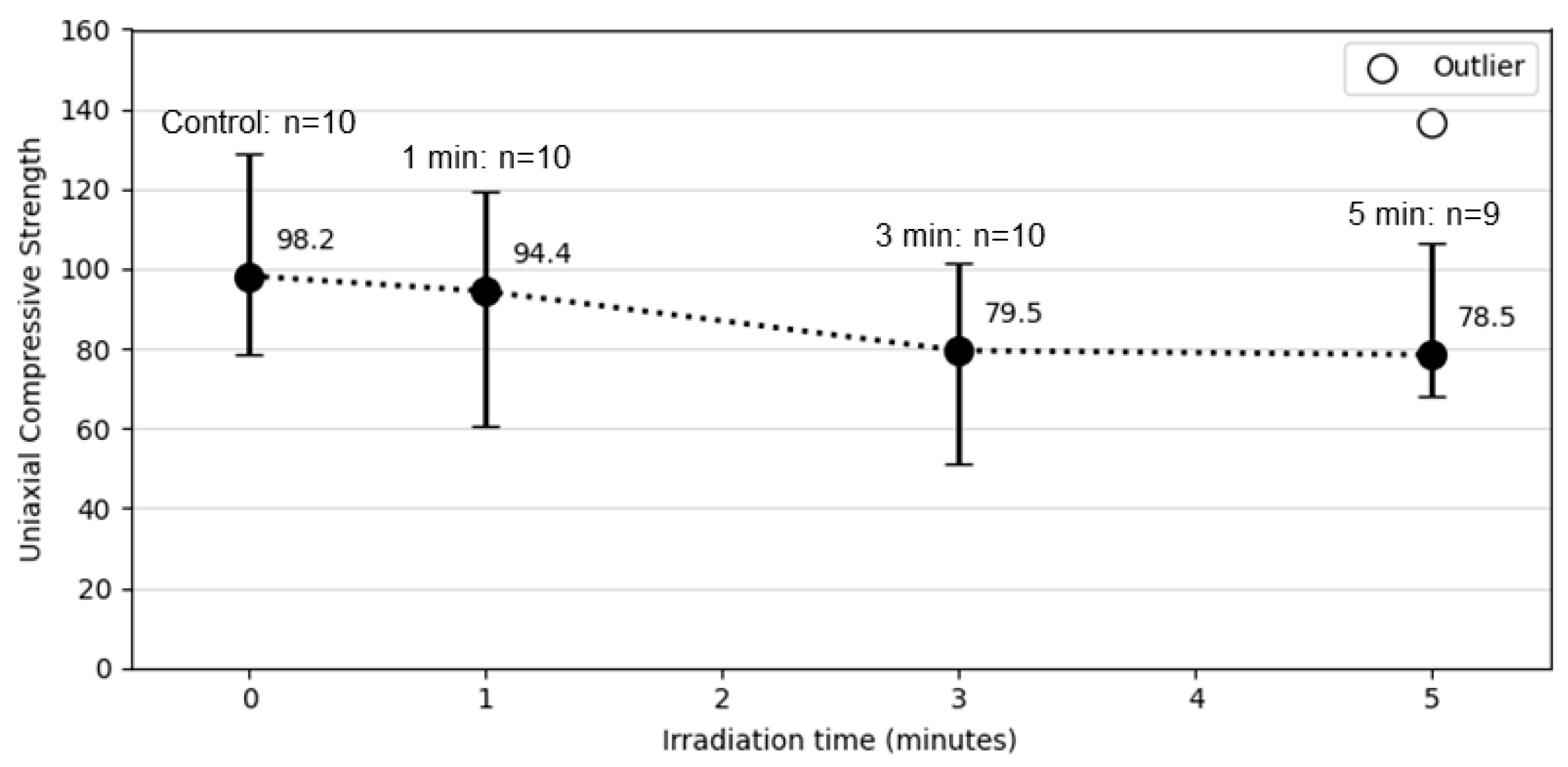

The results of our microwave weakening experiments are summarized in

Figure 3. The initial uniaxial compressive strength (UCS) of the control basalt samples (no microwave exposure) was measured at 98.2 MPa. After 1 min of microwave irradiation, the UCS of the treated samples dropped to 94.4 MPa, which represents roughly a 4% strength reduction. A much more pronounced weakening was observed at an exposure time of 3 min: the average UCS fell to 79.5 MPa, a substantial 19% reduction from the initial strength. Increasing the exposure to 5 min yielded a UCS of 78.5 MPa, only marginally lower than the 3 min result, suggesting that most of the weakening effect was achieved by about 3 min of irradiation.

These results indicate that roughly three minutes of microwave exposure is sufficient to achieve significant rock weakening effects in our basalt samples and that extending the exposure to five minutes produces minimal additional strength reduction. In practical terms, this suggests a point of diminishing returns around the 3 min mark for the power level used. The observed plateau in strength reduction between 3 and 5 min of microwave exposure can be attributed to the thermodynamic equilibrium reached in the rock’s microcrack network. During the initial 3 min, differential thermal expansion between minerals generates significant stress concentrations, initiating and propagating microcracks throughout the sample. This process is most active when thermal gradients are steepest. Beyond 3 min, the rate of new crack formation decreases as thermal gradients stabilize, existing cracks provide stress relief pathways, and the most susceptible mineral boundaries have already fractured. This self-limiting behavior is actually beneficial for operational efficiency, as it indicates that extended irradiation times yield diminishing returns.

We acknowledge that experiments conducted at ambient conditions may not fully represent lunar environment effects. The absence of convective cooling in a vacuum could alter heat transfer dynamics, while extreme temperature variations might enhance or modify thermal fracturing mechanisms. Validation in simulated lunar conditions is essential for refining operational parameters.

Although the experiments used core-sized samples (54 mm diameter × 110 mm length), we acknowledge that the weakening results may not scale linearly with larger rock volumes due to limited microwave penetration depth. Future studies should incorporate larger-scale samples and numerical modeling to simulate microwave energy distribution in full-scale excavation scenarios. Scaling from laboratory samples to full-scale tunneling presents important considerations. Microwave penetration depth in basalt would limit the thickness of the weakened zone regardless of tunnel diameter. Effective implementation would require strategic placement of multiple microwave sources and careful optimization of treatment patterns, which should be investigated through numerical modeling and scaled experiments.

It should also be noted that the tested basalt samples may contain microcracks resulting from core drilling and handling. In contrast, lunar rocks—especially those in undisturbed subsurface environments—might exhibit different microdefect patterns originating from long-term exposure to micrometeorite impacts or shock events. These differences in microcrack distributions can affect the microwave-induced fracture behavior. Further investigation using microscopy and acoustic emission analysis is recommended.

The application of microwave-assisted weakening shows particular promise for lunar operations due to the Moon’s environment. In a vacuum, the absence of convective heat loss means that a greater fraction of the microwave energy is used in heating the rock (rather than heating air), potentially improving the efficiency of the process. The reduced gravity on the Moon can aid in handling fragmented material, as broken rock and regolith weigh less and thus are easier to clear from the cutting face or tunnel area. The three-minute exposure time identified in our experiments provides a practical benchmark for developing operational protocols: for instance, a lunar TBM could be designed to irradiate the rock face for around 3 min ahead of mechanical cutting in each advance cycle.

Future research should focus on validating these findings under more representative lunar conditions. This includes conducting microwave experiments in vacuum chambers and at extremely low temperatures to simulate night-time or polar crater environments. Additionally, optimizing microwave power levels and exposure durations will be crucial for maximizing efficiency while managing energy consumption in an actual lunar mission scenario. For instance, higher-power microwaves could achieve the same weakening in shorter times but must be weighed against the available power supply and cooling constraints on a lunar TBM.

Comparison with alternative thermal rock weakening methods is also important for validating our approach. Laser-assisted rock weakening has been investigated for various materials, with studies showing that high-power laser systems can effectively weaken rocks through rapid surface heating [

54,

55]. Rossi et al. demonstrated that laser treatment can reduce rock strength through thermally assisted drilling, though this requires high heating rates and precise temperature control [

55]. However, laser systems typically require significantly higher instantaneous power densities and more complex optical delivery systems compared to microwave methods [

54].

Microwave heating provides volumetric heating with substantial penetration depths, creating more uniform temperature distribution throughout the treated volume, while laser heating primarily affects surface layers with limited penetration depth. For lunar applications, microwave systems offer several operational advantages, including simpler beam delivery through waveguides, reduced sensitivity to dust contamination of optical components, and potentially lighter equipment mass. The robust nature of microwave delivery systems, combined with their ability to treat larger rock volumes simultaneously, makes microwave treatment more suitable for integration with lunar TBM operations, where reliability and operational simplicity are critical factors.

5. Discussion

The concept of using Tunnel Boring Machines (TBMs) for lunar subsurface excavation evolved significantly over the years, driven by technological advancements and a deeper understanding of the lunar environment. Previous studies, such as those by Allen et al. (1988) [

51] and Rostami et al. (2018) [

13], laid the groundwork for lunar TBM design by addressing challenges like low gravity, abrasive regolith, and the need for autonomous, self-supporting operation. These pioneering concepts provide critical context for our development of a hybrid excavation system integrating microwave-assisted rock weakening.

Allen et al.’s Lunar Tunneler concept featured a nuclear-powered TBM with the ability to melt and vitrify tunnel walls for support [

51]. This early concept highlighted the importance of immediate tunnel stabilization in the lunar vacuum and proposed novel heat exchange systems for material processing. Three decades later, Rostami et al. expanded on these ideas, emphasizing adapting TBMs for lava tube exploration and incorporating in situ resource utilization (ISRU) to reduce Earth-supplied materials [

13]. Collectively, these studies highlight the critical role that TBMs could play in enabling sustainable and efficient lunar infrastructure.

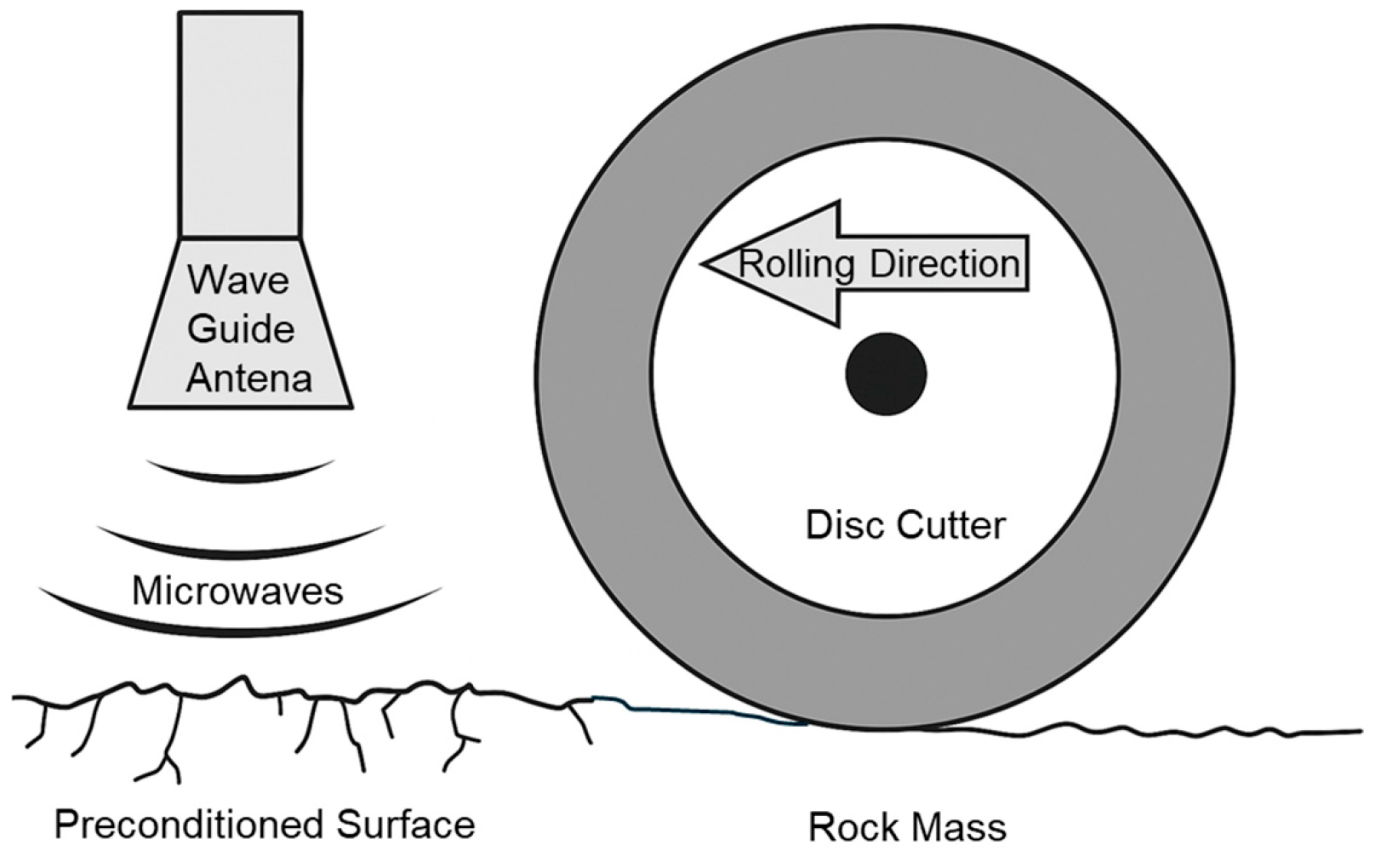

Building on this foundation, our work introduces microwave-assisted rock weakening as a transformative add-on to lunar TBM technology. As illustrated conceptually in

Figure 4, this hybrid approach combines in situ thermal pre-conditioning through microwaves with conventional mechanical excavation. A microwave integrated into the TBM directs energy into the rock face ahead of the mechanical cutterhead. Minerals in the rock absorb this energy and heat up, inducing thermal stresses and extensive microcracking in the rock. This pre-conditioning dramatically reduces the compressive strength of the rock (by roughly 15–20% in our tests), which in turn alleviates the mechanical load on the TBM’s cutters.

The lunar vacuum and low gravity conditions actually amplify the effectiveness of the microwave-assisted weakening. Without an atmosphere, there is no convective cooling, so microwave energy is used more efficiently. Reduced gravity helps in clearing chipped rock and dust, as debris is easier to move. These factors, combined with the unique thermal properties of lunar rocks, make microwave-assisted excavation particularly well suited for the Moon.

One of the critical advantages of this approach is its adaptability to the Moon’s diverse and harsh conditions. Lunar rocks are expected to have very high compressive strengths (our model estimates in the 100–200 MPa range). Such rock would normally slow down TBM progress, but pre-weakening the rock allows the TBM to maintain higher advance rates. The concept depicted in

Figure 4 shows how a microwave source could be incorporated into the cutting head assembly using a waveguide and horn antenna to focus microwaves onto the excavation face just prior to contact with the disc cutters. This integration is envisioned to be scalable and adjustable depending on the rock properties.

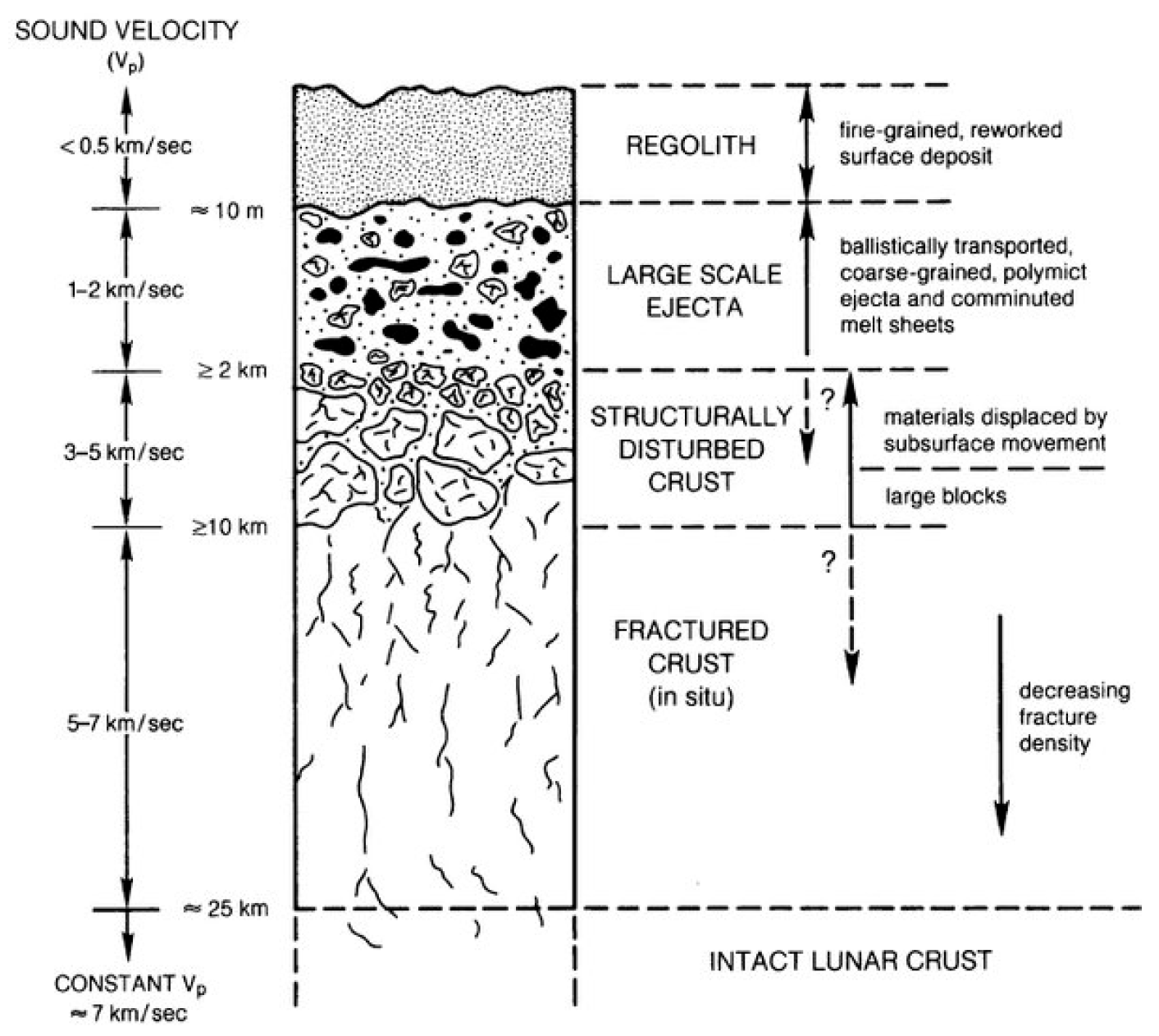

The stratification of the lunar subsurface into regolith, fractured crust, and intact bedrock has significant implications for TBM deployment. In the unconsolidated regolith layer, TBMs may advance easily but require frequent support installation to counteract collapse risks. In the fractured crust zone, the presence of discontinuities can complicate excavation, but it also presents an opportunity for microwave-assisted weakening to enhance rock breakage. In contrast, the intact lower crust—though mechanically strong—offers greater tunnel stability and thus benefits most from pre-conditioning treatments to improve TBM efficiency.

Microwave-assisted TBM excavation offers varying degrees of effectiveness depending on the geological environment on the Moon. In the loose regolith layer, the treatment is largely ineffective due to low cohesion and high thermal dissipation; however, it may still be useful for weakening embedded rocks. In the mega-regolith zone, which is composed of fractured and partially cemented rock, microwave weakening is expected to be effective by promoting additional fragmentation along existing cracks. In contrast, in coherent rock masses such as lava tube walls, the technique is most effective, where it can substantially reduce compressive strength in high-strength basalt or anorthosite through intense microcracking. This scenario enables significant reduction in TBM cutter loads and wear.

This differentiation informs the adaptive deployment of microwave systems during excavation in varying lunar geologies.

While this study focuses on feasibility demonstration, a detailed system-level engineering design of a microwave-integrated TBM—including waveguide placement and horn configuration—will be developed in future work.

Despite its potential, there are challenges that remain for implementing microwave-assisted TBM operations. The abrasive nature of lunar regolith and dust created during excavation necessitates extremely durable materials and effective dust mitigation strategies. The lunar dust is notoriously fine and clingy [

9], so sealing microwave components is crucial to prevent degradation or overheating.

Another important consideration is the variability of conditions across different lunar environments. Our discussion primarily focused on basaltic rocks akin to those in lunar mare regions, but in the highlands where anorthosite dominates, microwave response could differ. Even highland rocks contain minor minerals (like ilmenite or magnetite) that allow differential heating. The microwave technique can be tuned (e.g., higher power or longer exposure) to match the rock.

Likewise, operations in permanently shadowed polar craters will face extremely low temperatures (~40 K) and possibly volatile ices in the regolith. While cold could enhance thermal shock, water ice could absorb microwave energy or cause steam pressure issues. These factors will need to be tested.

We note that our approach is fundamentally flexible, as the system can adjust microwave parameters in real-time if the rock is not weakening as expected (e.g., based on feedback from cutter force sensors and rock strength predictions). We have updated the manuscript to emphasize that our integrated TBM would use the predicted rock strength (from

Section 4.1’s model) to decide how much microwave energy to apply. For instance, if exceptionally strong rock is predicted, the TBM could automatically increase power or irradiation time to maintain smooth tunneling.

To illustrate the operational concept of the integrated microwave-assisted TBM system,

Figure 5 presents a comprehensive flowchart showing the complete process from initial rock assessment through adaptive control. This systematic approach ensures optimal performance by continuously adjusting operational parameters based on real-time feedback. The flowchart demonstrates the adaptive nature of the system, where microwave treatment parameters are automatically adjusted based on predicted rock strength. This feedback mechanism ensures optimal energy utilization while maintaining excavation efficiency across varying geological conditions.

The selection of non-destructive parameters for our strength prediction model warrants further discussion. Density and P-wave velocity were chosen as primary predictors due to their fundamental relationship with rock microstructure and mineral bonding. Density reflects the packing efficiency and porosity of the rock matrix, while P-wave velocity indicates the elastic stiffness and continuity of the mineral framework. These parameters have been extensively validated in terrestrial rock mechanics studies and can be measured reliably in lunar conditions using portable instruments.

The addition of Leeb hardness as a third parameter significantly improved our model’s predictive capability. Leeb hardness testing offers particular advantages for lunar exploration due to its highly portable equipment. The entire Leeb hardness tester weighs less than 1 kg and operates on battery power, making it ideal for inclusion in lunar mission payloads where mass and volume constraints are critical. Unlike laboratory-based testing methods, Leeb hardness can be measured directly on exposed rock surfaces. This portability and ease of use make it an excellent complementary parameter to density and P-wave velocity measurements. Leeb hardness captures surface mechanical properties that complement the bulk properties measured by density and P-wave velocity.

However, we acknowledge limitations in applying these Earth-calibrated relationships to lunar rocks. The unique formation conditions on the Moon, including shock metamorphism from impacts and the absence of aqueous alteration, may create rock properties outside our training data range. Future missions should prioritize in situ validation of these non-destructive testing methods to refine our predictive models.

Future research should focus on fine-tuning the microwave parameters (power, frequency, and exposure duration) to maximize weakening efficiency while minimizing energy consumption. Simulated lunar environment tests (vacuum chambers, regolith, and low temp) are needed to validate that the microwave system performs as expected. Our results, obtained at Earth ambient conditions, are highly encouraging, but translating them to lunar conditions will be a key step.

While this study focuses on feasibility demonstration, a detailed system-level engineering design of a microwave-integrated TBM, including waveguide placement and horn configuration, will be developed in future work.

The practical implementation of microwave-assisted TBM technology on the Moon requires addressing several engineering challenges. The microwave system would need specialized waveguides with vacuum-compatible components and appropriate thermal insulation. While our laboratory experiments used 2 kW power levels, the actual power requirements for lunar operations would depend on tunnel diameter, rock properties, and operational constraints, requiring further optimization studies. Thermal management must rely on radiative cooling due to the absence of convection, while dust protection would require sealed systems and protective measures against abrasive lunar regolith. These engineering considerations highlight the technical challenges that must be systematically addressed through future research and development.

The microwave-assisted approach shows promise for improving TBM performance through reduced cutting forces and potentially faster advance rates. The magnitude of these improvements would depend on rock properties, operational parameters, and system design, warranting comprehensive comparative studies under simulated lunar conditions.

The limited availability of lunar rock samples and the inability to conduct experiments under true lunar conditions represent fundamental constraints in this research field. While our use of terrestrial basalt analogs and dried samples provides valuable insights, the unique formation history of lunar rocks, including shock metamorphism, solar wind implantation, and complete absence of aqueous alteration, creates uncertainties that cannot be fully resolved without in situ data. Future research should prioritize developing more sophisticated lunar simulants incorporating these unique characteristics and establishing testing facilities capable of simultaneously replicating vacuum, temperature extremes, and radiation exposure. International collaboration and data sharing will be essential to overcome these limitations and accelerate progress toward practical lunar excavation systems.

Overall, the integration of microwave-assisted rock weakening into a lunar TBM system represents a promising advancement toward efficient and sustainable subsurface development on the Moon. By addressing the mechanical and operational challenges posed by high-strength lunar rocks, this hybrid approach provides a feasible means to enhance excavation performance while reducing equipment wear. When coupled with robust rock strength prediction models, the system could intelligently adapt to varying geological conditions, improving both safety and operational efficiency. Continued refinement of this integrated technology guided by past TBM concepts and future lunar-focused experiments will be essential in supporting long-term human activity beneath the lunar surface.

6. Conclusions

This study explores innovative approaches to lunar subsurface excavation, focusing on integrating Tunnel Boring Machine (TBM) technology with advanced rock weakening and strength estimation techniques. The challenges posed by the Moon’s harsh environment, including high-strength rocks, abrasive regolith, and extreme conditions, necessitate the development of adaptable and efficient excavation strategies for long-term lunar exploration and habitation.

Lunar rocks present significant obstacles due to their high compressive strength and abrasive properties. Microwave-assisted weakening was shown to reduce strength by nearly 20% in basalt analogs, offering a pathway to reduce cutter wear and improve efficiency. Additionally, machine learning models using non-destructive parameters such as P-wave velocity and Leeb hardness enabled reliable prediction of rock strength, helping to guide operational strategies.

The vacuum and low gravity of the Moon further enhance the feasibility of these methods, allowing more efficient heat application and material handling. While the study highlights technical promise, additional research is required to validate results under simulated lunar conditions and develop fully integrated TBM systems for lunar missions.

The integration of real-time rock strength prediction with adaptive microwave weakening represents a significant advancement in lunar excavation technology. This feedback mechanism enables the TBM system to optimize energy consumption by adjusting microwave parameters based on predicted rock properties. For instance, when encountering high-strength basalts, the system could automatically increase microwave power or exposure time to maintain consistent excavation rates. Conversely, in weaker rock zones, the system could reduce or bypass microwave treatment entirely, conserving valuable power resources. This adaptive capability is particularly crucial for lunar operations, where energy efficiency directly impacts mission duration and success.

In summary, this work lays foundational knowledge for coupling microwave pre-treatment and predictive modeling in lunar excavation. These tools collectively offer a strategic path forward in achieving sustainable subsurface construction for future lunar habitation.