A Novel Shape Memory Alloy Actuated Bearing Active Preload System (SMA-BAPS) for Space Spindles

Abstract

1. Introduction

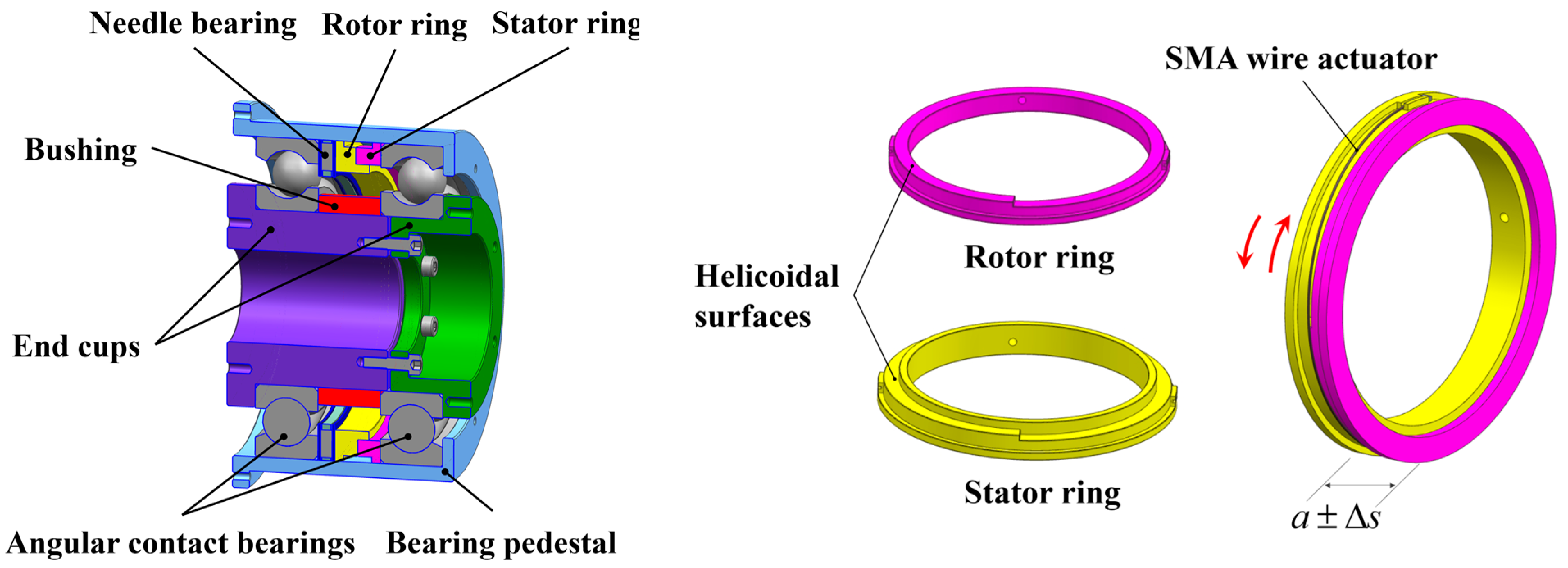

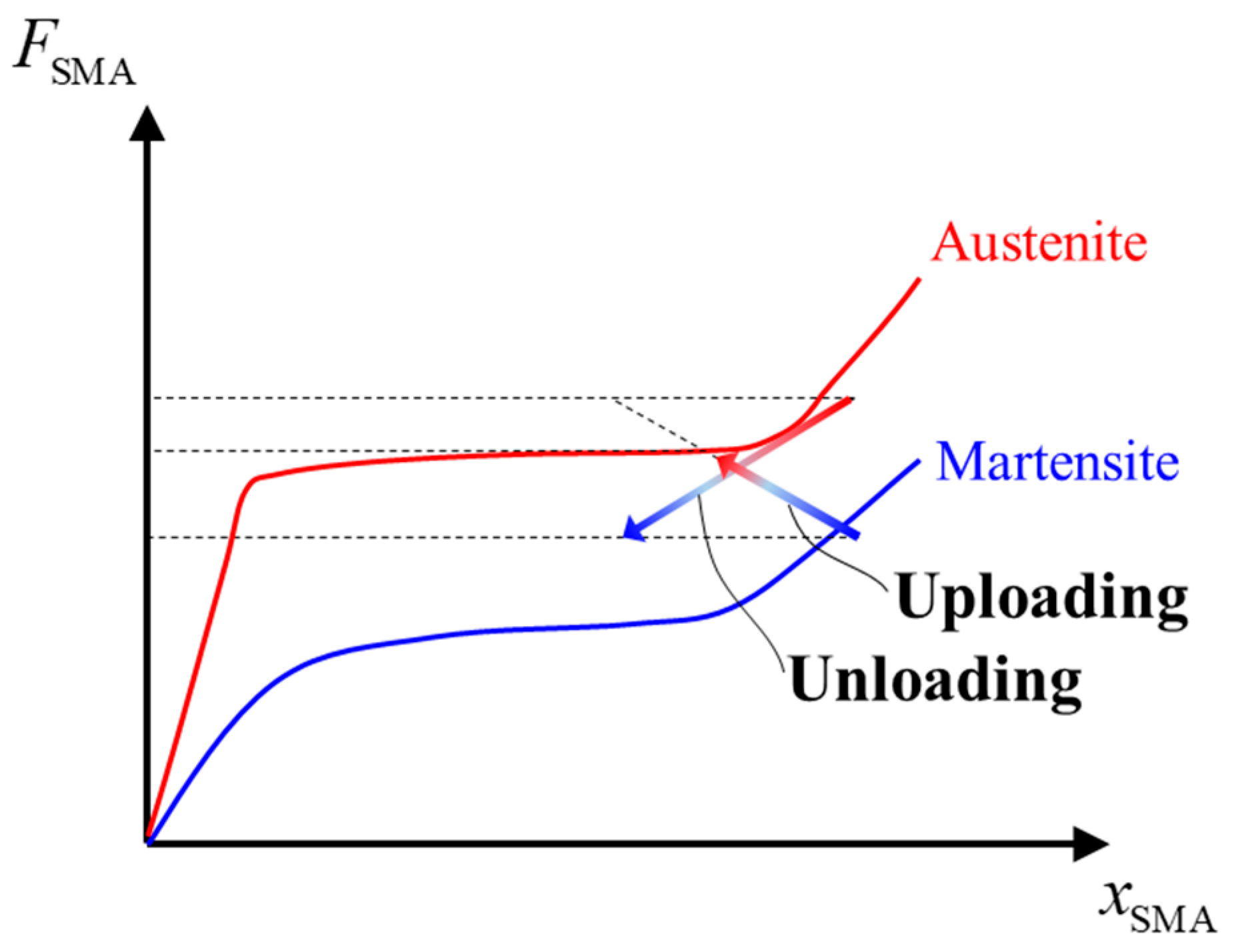

2. Concept Configuration and Operation Principle

3. Design of SMA-BAPS

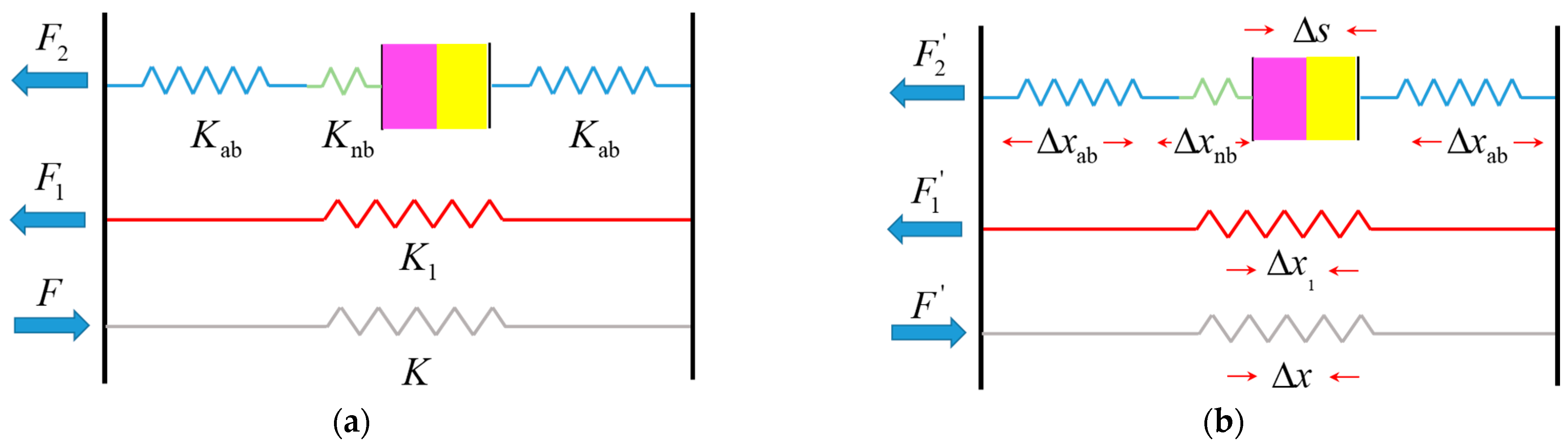

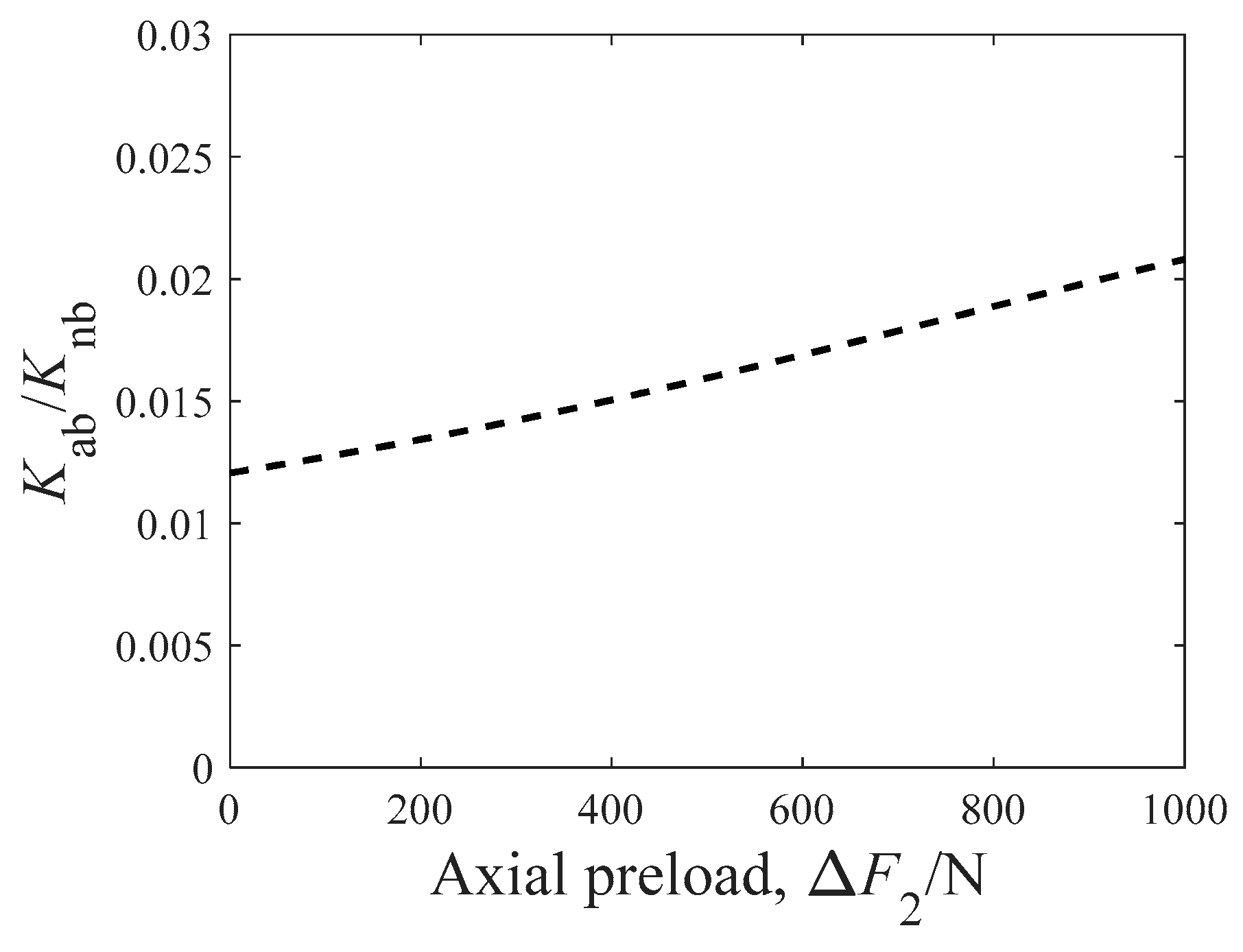

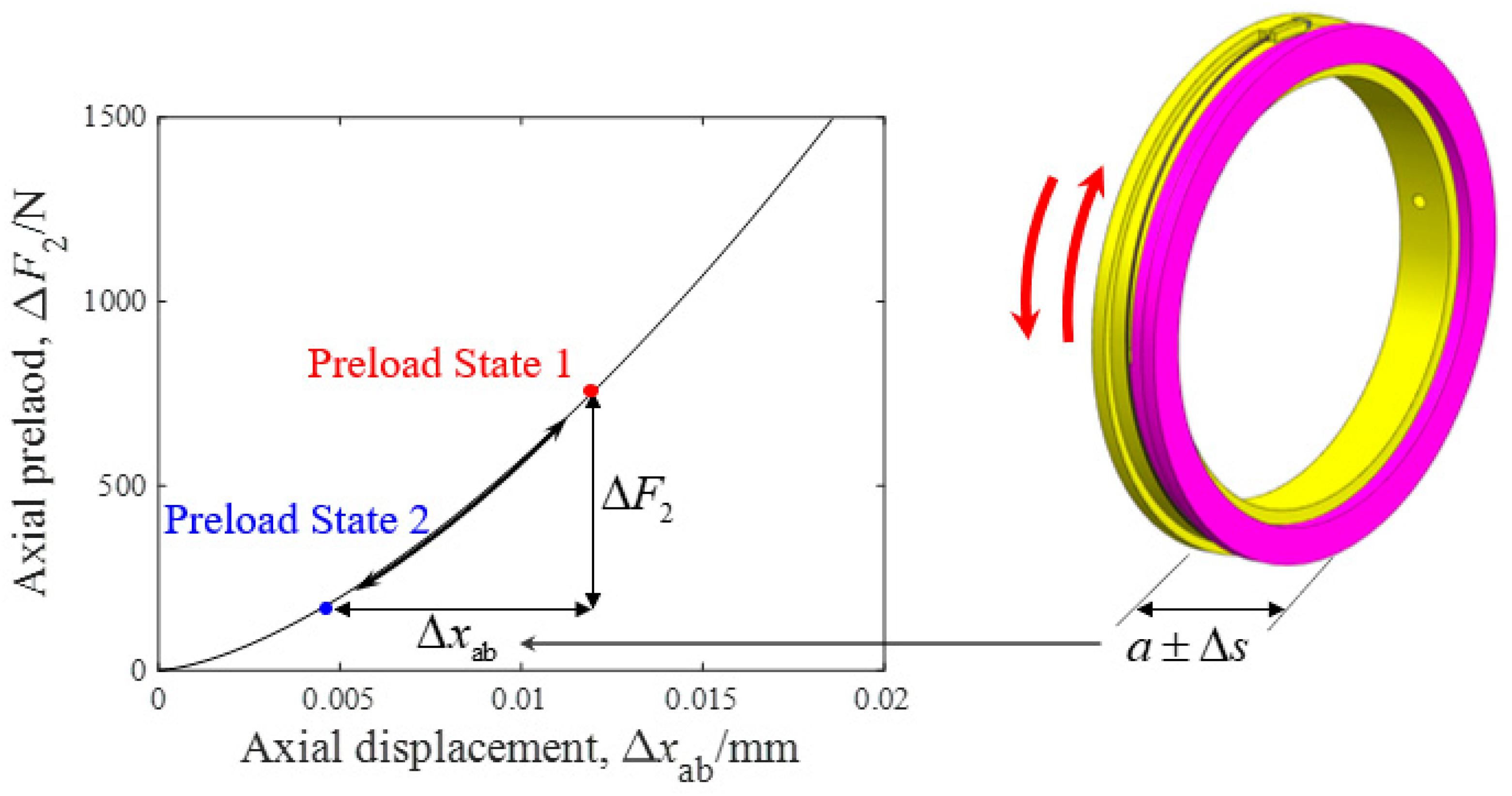

3.1. Preload Adjustment Analysis

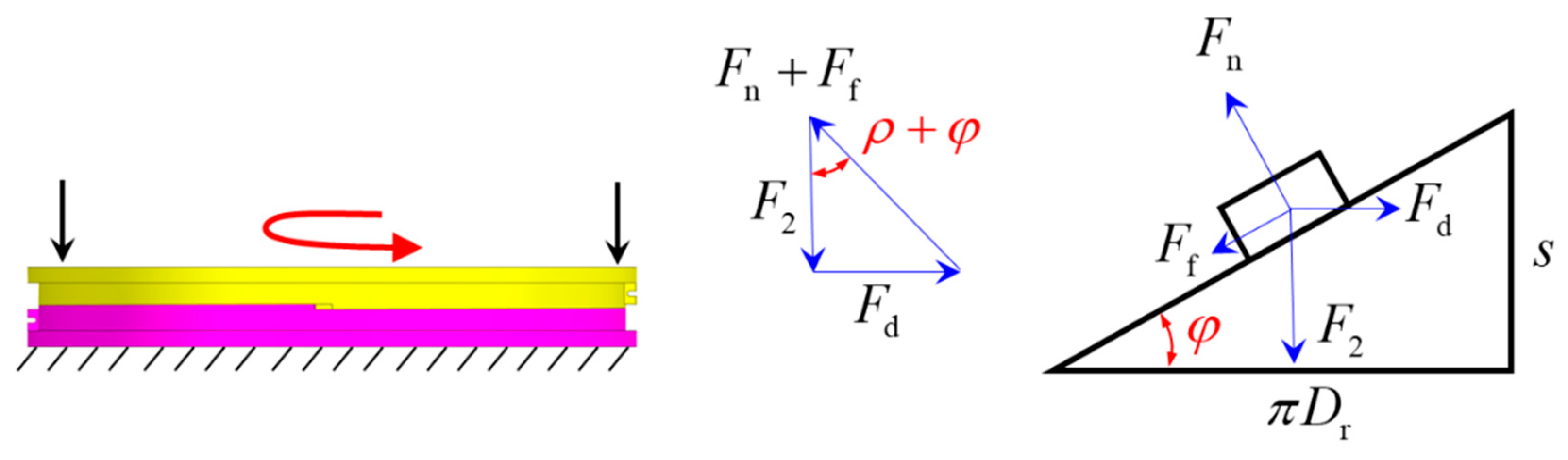

3.2. Design of Screw Pair

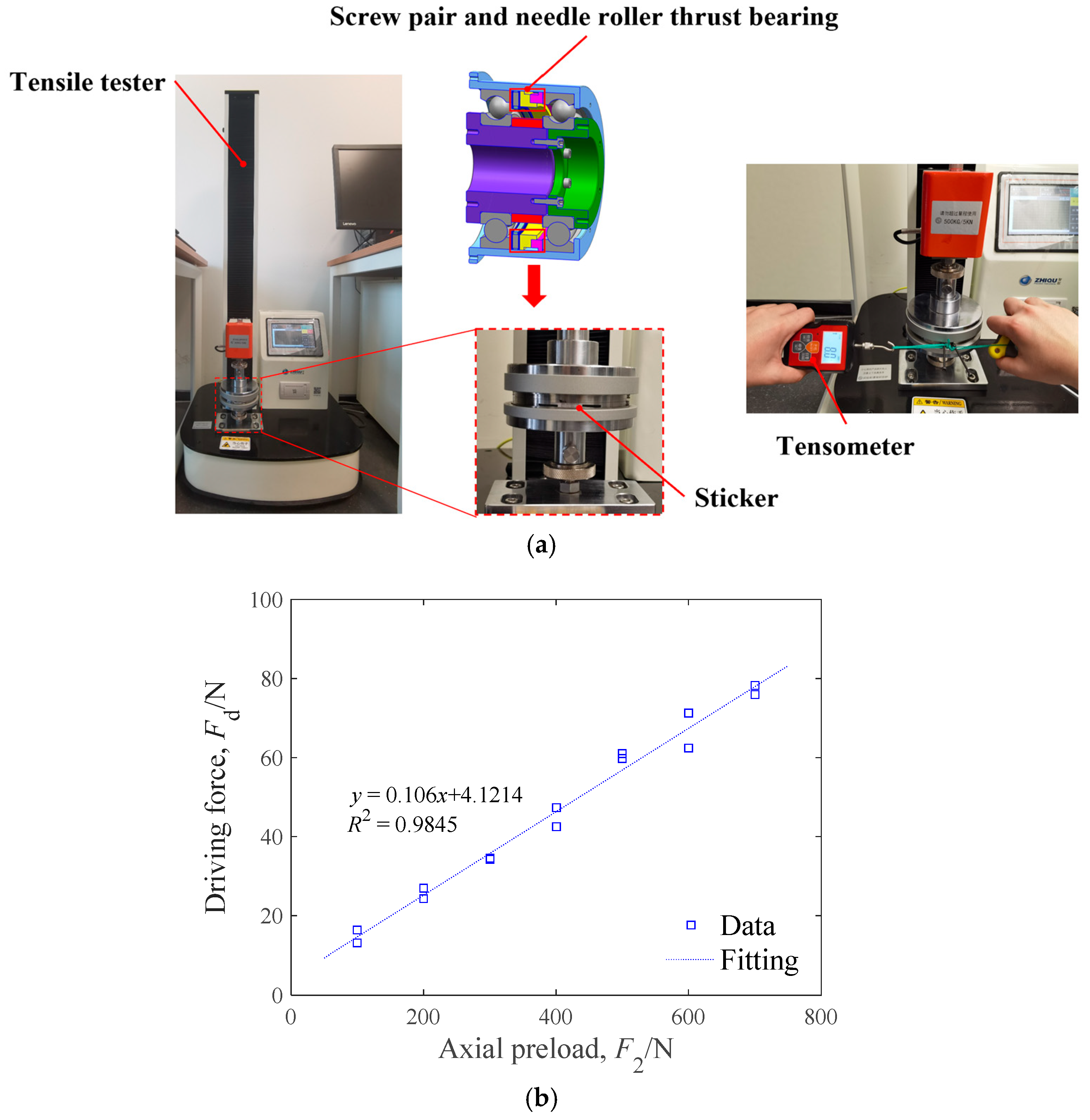

3.3. Design of SMA Actuator

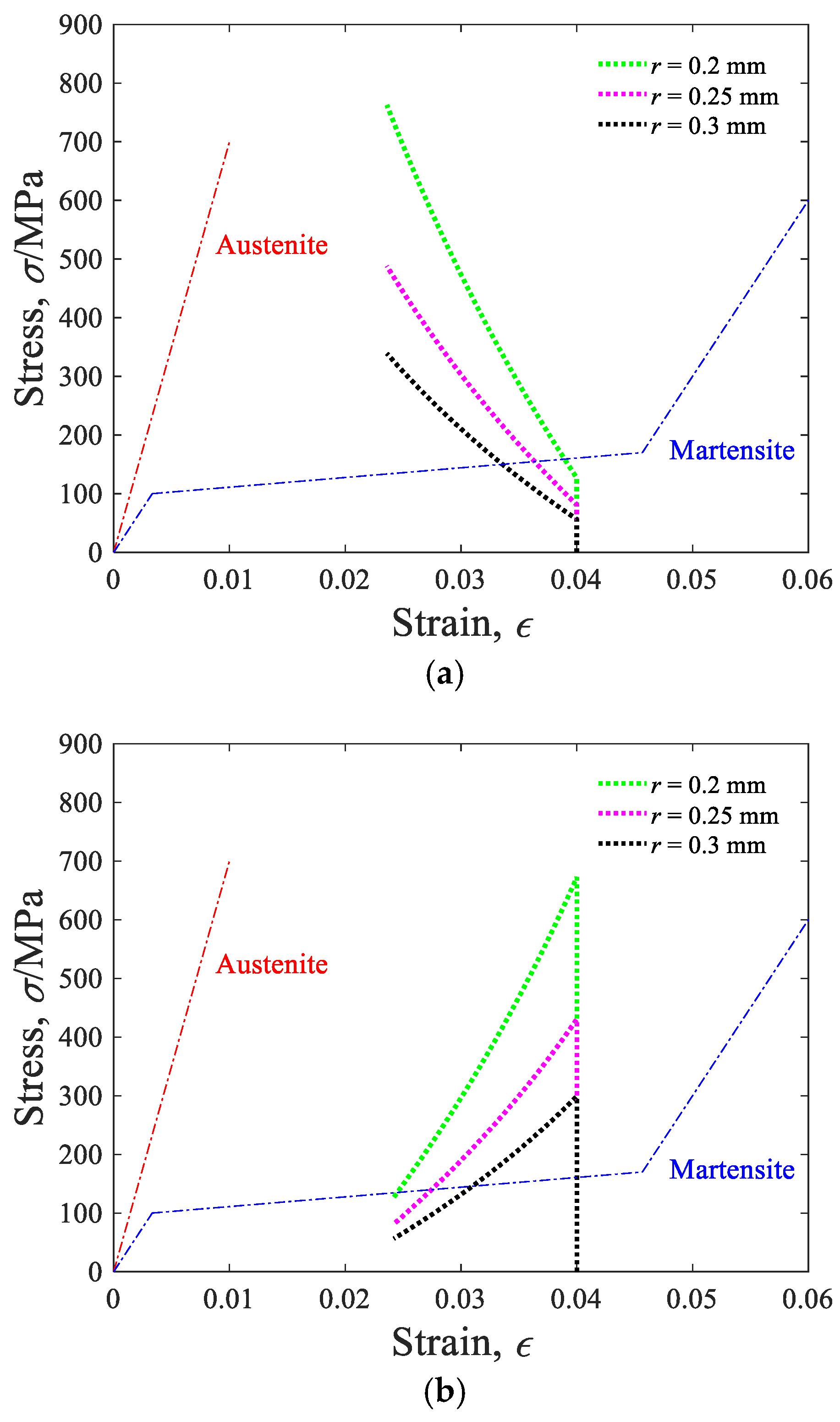

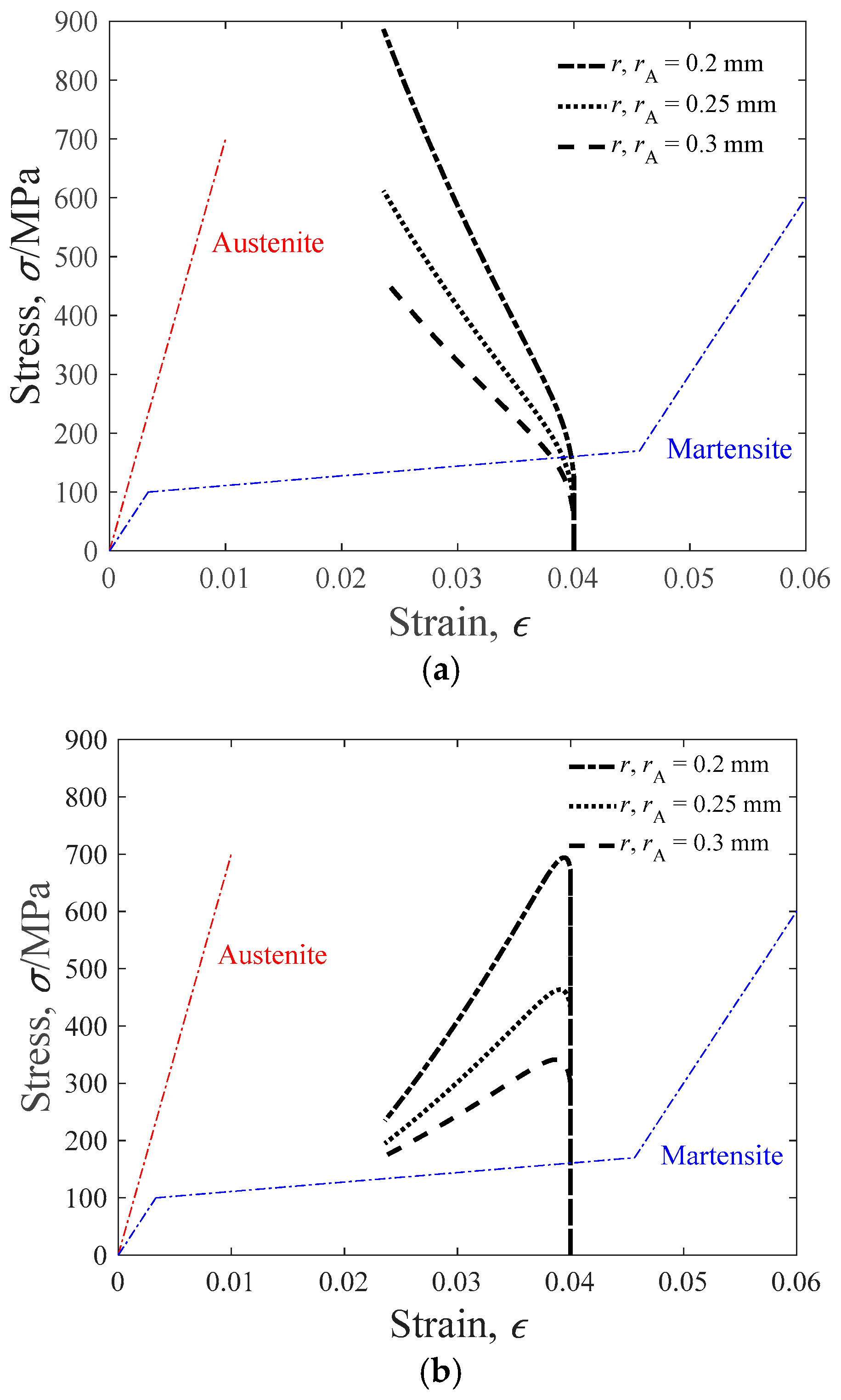

3.3.1. Determination of SMA Radius and Length

3.3.2. Electrical Parameter Design

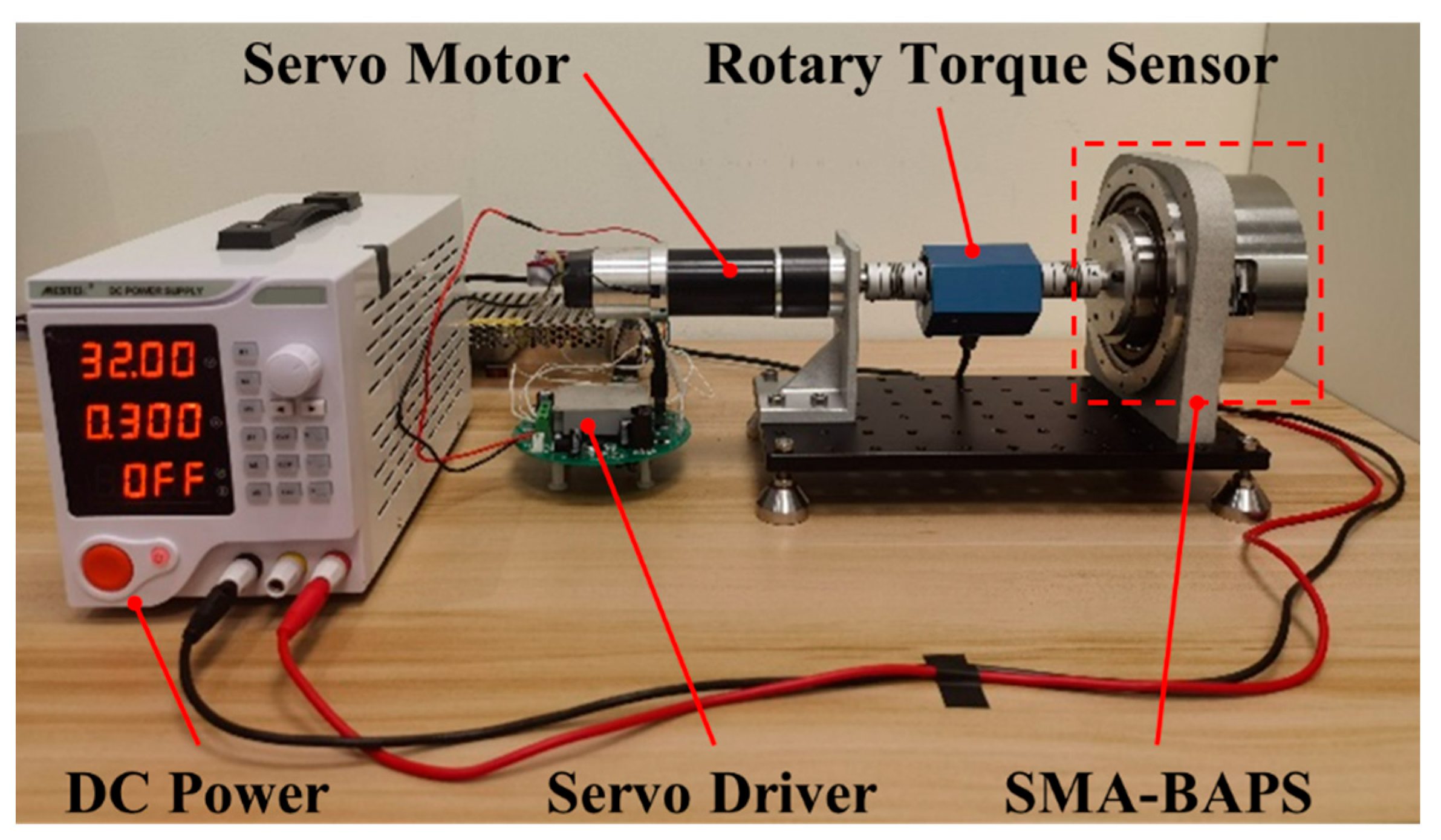

4. Prototype Tests

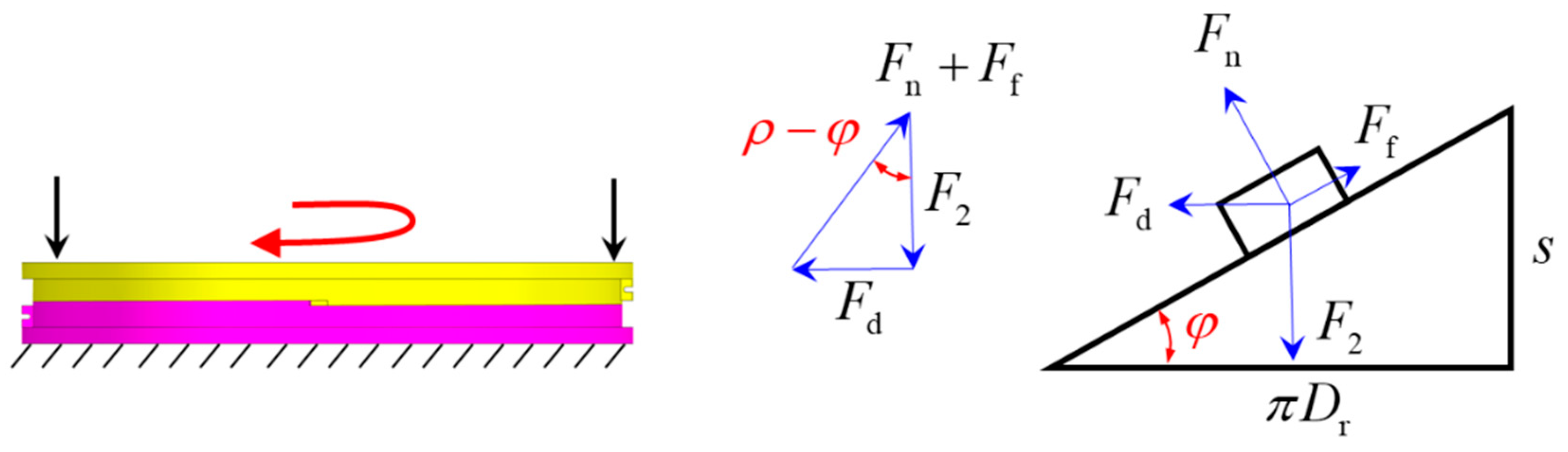

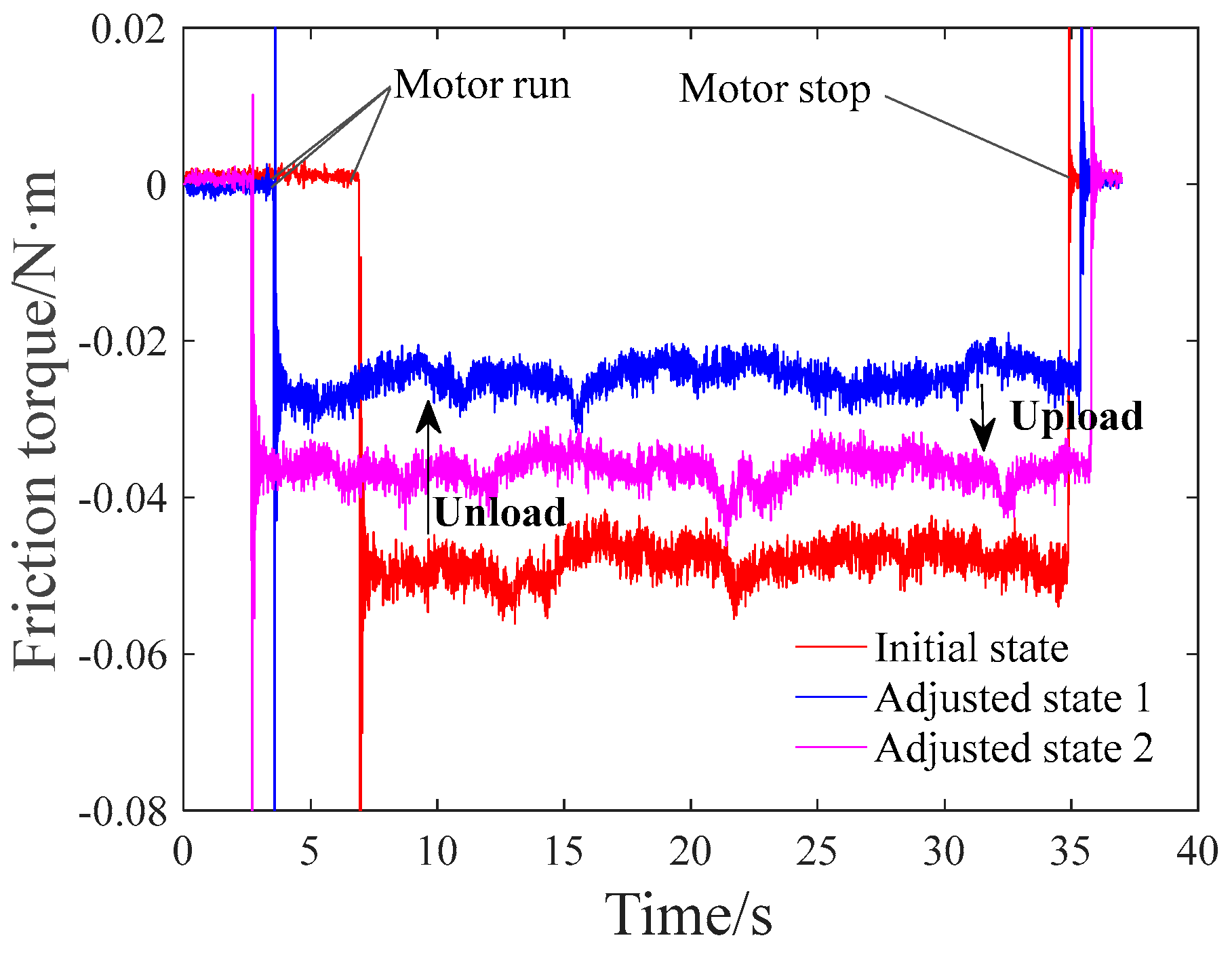

4.1. Resistive Torque Test

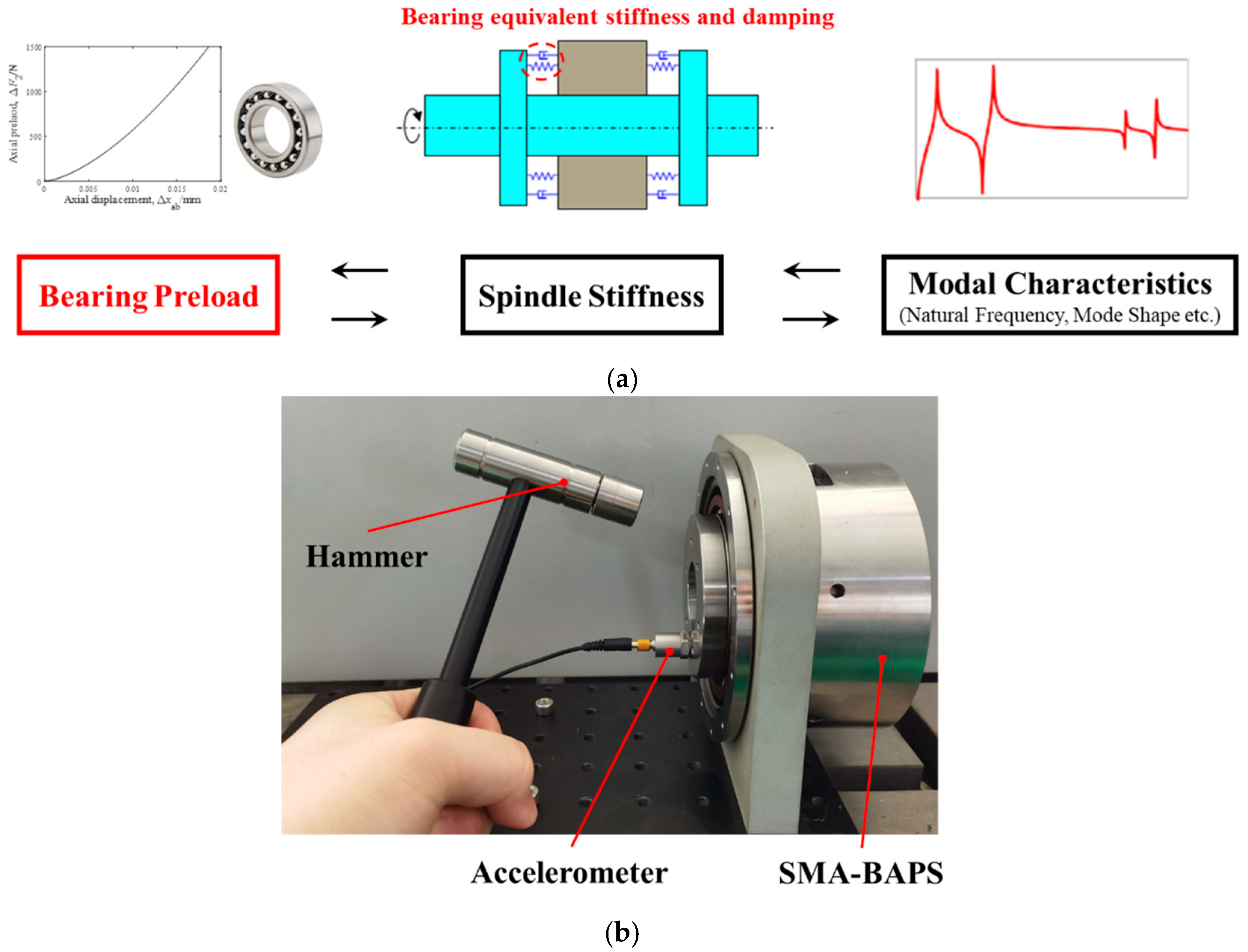

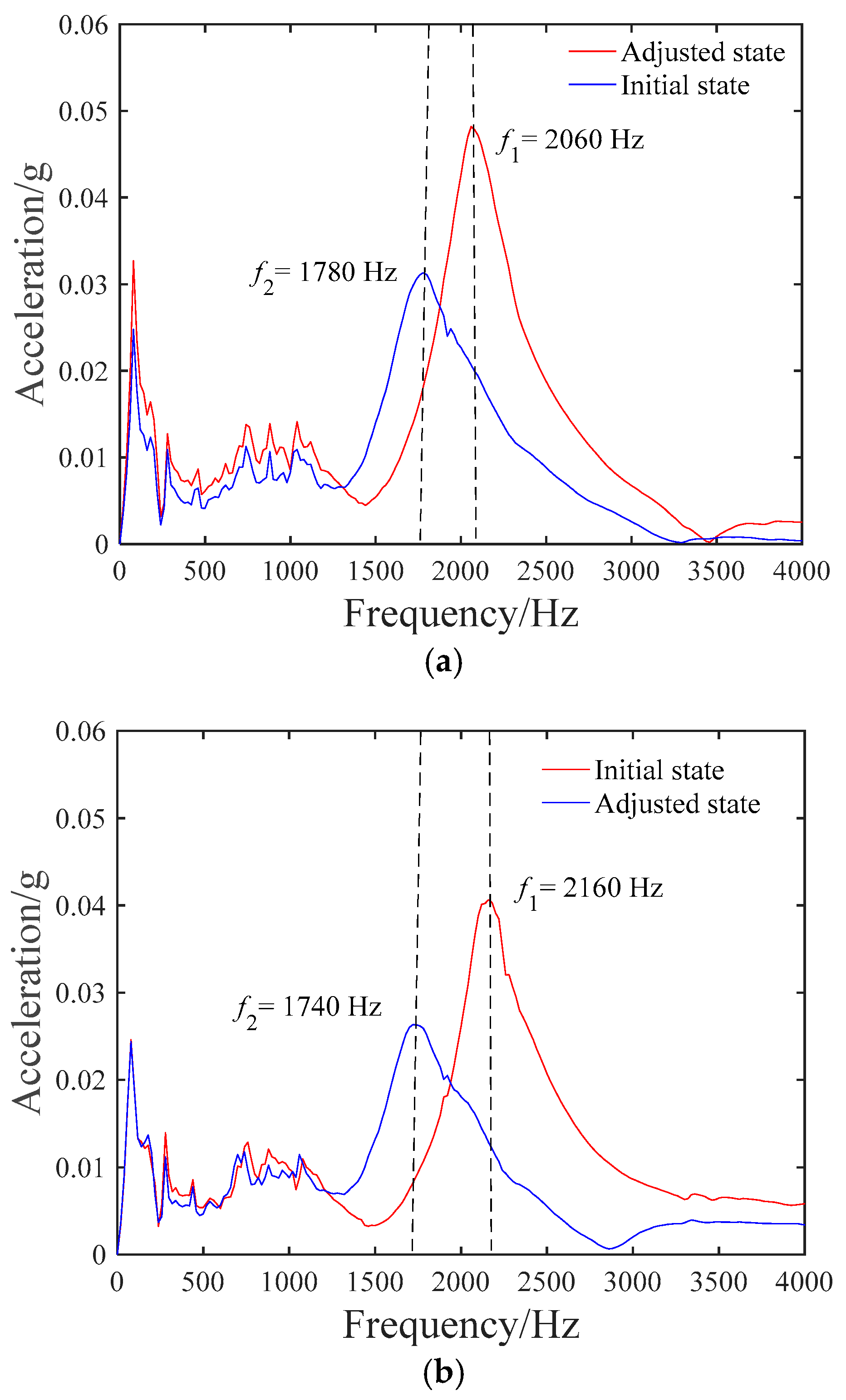

4.2. Modal Impact Test

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Harris, T.A.; Kotzalas, M.N. Advanced Concepts of Bearing Technology: Rolling Bearing Analysis, 5th ed.; Taylor & Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- Roberts, E.W. Space Tribology Handbook, 4th ed.; ESR Technology: Warrington, UK, 2007. [Google Scholar]

- Hwang, Y.-K.; Lee, C.-M. A review on the preload technology of the rolling bearing for the spindle of machine tools. Int. J. Precis. Eng. Manuf. 2010, 11, 491–498. [Google Scholar] [CrossRef]

- Lee, C.; Woo, W.; Kim, D. The latest preload technology of machine tool spindles: A review. Int. J. Precis. Eng. Manuf. 2017, 18, 1669–1679. [Google Scholar] [CrossRef]

- Li, T.; Kolar, P.; Li, X.; Wu, J. Research development of preload technology on angular contact ball bearing of high speed spindle: A review. Int. J. Precis. Eng. Manuf. 2020, 21, 1163–1185. [Google Scholar] [CrossRef]

- Lewis, S.D.; Humphries, M.E. An introduction to bearing active preload systems—Technology and performance benefits. In Proceedings of the 11th European Space Mechanisms and Tribology Symposium, Lucerne, Switzerland, 21–23 September 2005. [Google Scholar]

- Jiang, S.; Mao, H. Investigation of variable optimum preload for a machine tool spindle. Int. J. Mach. Tools Manuf. 2010, 50, 19–28. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Hong, J.; Wang, S.; Li, B.; Sun, Y.; Zheng, S. Rotation Accuracy Analysis of Spindle Under Variable Preload. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Volume 4A: Dynamics, Vibration, and Control, Tampa, FL, USA, 3–9 November 2017. [Google Scholar]

- Zverv, I.; Pyoun, Y.; Lee, K.; Kim, J.; Jo, I.; Combs, A. An elastic deformation model of high speed spindles built into ball bearings. J. Mater. Process. Technol. 2005, 170, 570–578. [Google Scholar] [CrossRef]

- Hwang, Y.; Lee, C. Development of a newly structured variable preload control device for a spindle rolling bearing by using an electromagnet. Int. J. Mach. Tools Manuf. 2010, 50, 253–259. [Google Scholar] [CrossRef]

- Hwang, Y.; Park, I.; Paik, K.; Lee, C. Development of a variable preload spindle by using an electromagnetic actuator. Int. J. Precis. Eng. Manuf. 2014, 15, 201–207. [Google Scholar] [CrossRef]

- Tsutsui, S.; Aoyama, T.; Inasaki, I. Development of a spindle system with an adjustable preload mechanism using a piezoelectric actuator. JSME Int. J. 1988, 31, 593–597. [Google Scholar] [CrossRef]

- Chen, J.; Chen, K. Bearing load analysis and control of a motorized high speed spindle. Int. J. Mach. Tools Manuf. 2005, 45, 1487–1493. [Google Scholar] [CrossRef]

- Hu, G.; Zhang, D.; Gao, W.; Chen, Y.; Liu, T.; Tian, Y. Study on variable pressure/position preload spindle-bearing system by using piezoelectric actuators under close-loop control. Int. J. Mach. Tools Manuf. 2018, 125, 68–88. [Google Scholar] [CrossRef]

- Hwang, Y.; Lee, C. Development of automatic variable preload device for spindle bearing by using centrifugal force. Int. J. Mach. Tools Manuf. 2009, 49, 781–787. [Google Scholar] [CrossRef]

- Razban, M.; Movahhedy, M.R. A speed-dependent variable preload system for high speed spindles. Precis. Eng. 2015, 40, 182–188. [Google Scholar] [CrossRef]

- Lewis, S.D.; Humphries, M.E. Development, pre-qualification and application of an active bearing preload system. In Proceedings of the 38th Aerospace Mechanisms Symposium, Williamsburg, VA, USA, 17–19 May 2006. [Google Scholar]

- Lewis, S.D.; Munro, G.; Humphries, M.E.; Székely, G. Development of an adjustable bearing preload enabled-optical terminal. In Proceedings of the 13th European Space Mechanisms and Tribology Symposium, Vienna, Austria, 23–25 September 2009. [Google Scholar]

- Florian, S.; Yann, M.; Thomas, A.; Jean-Bernard, M. Discharge component for pair of bearings using shape memory actuators. In Proceedings of the 18th European Space Mechanisms and Tribology Symposium, Munich, Germany, 18–20 September 2019. [Google Scholar]

- Thomas, A.; Yann, M.; Florian, S. Unloading mechanism using shape memory alloy actuators for ball bearings—Space qualification tests sequence. In Proceedings of the 2019 PEGASUS Student Conference, Glasgow, UK, 10–12 April 2019. [Google Scholar]

- Videira, E.; Lebreton, C.; Lewis, S.D.; Gaillard, L. Design, assembly and preloading of ball bearings for space applications—Lessons learned and guidelines for future success. In Proceedings of the 15th European Space Mechanisms and Tribology Symposium, Noordwijk, The Netherlands, 25–27 September 2013. [Google Scholar]

- El-Latlf, A.K.A.; Ziada, H.H. Stiffness of bolted joints. J. Eng. Appl. Sci. 1981, 1, 17–27. [Google Scholar]

- Wileman, J.; Choudhury, M.; Green, I. Computation of member stiffness in bolted connections. Trans. ASME 1991, 113, 432–437. [Google Scholar] [CrossRef]

- Zhang, D.; Gao, S.; Xu, X. A new computational method for threaded connection stiffness. Adv. Mech. Eng. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- Meier, H.; Oelschlaeger, L. Numerical thermomechanical modelling of shape memory alloy wires. Mater. Sci. Eng. A 2004, 378, 484–489. [Google Scholar] [CrossRef]

- Jani, J.M.; Huang, S.; Leary, M.; Subic, A. Numerical modeling of shape memory alloy linear actuator. Comput. Mech. 2015, 56, 443–461. [Google Scholar] [CrossRef]

- Gunduz, A.; Dreyer, J.T.; Singh, R. Effects of preloads on vibration transmission through double row angular contact ball bearings. In Proceedings of the ASME 2011 International Design Engineering Technical Conferences & Computers and Information in Engineering Conference, Washington, DC, USA, 28–31 August 2011. [Google Scholar]

- Gunduz, A.; Dreyer, J.T.; Singh, R. Effect of bearing preloads on the modal characteristics of a shaft-bearing assembly: Experiments on double row angular contact ball bearings. Mech. Syst. Signal Process. 2012, 31, 176–195. [Google Scholar] [CrossRef]

| d1 (mm) | D1 (mm) | α0 (°) | fi | fo | Dw1 (mm) | Z1 |

|---|---|---|---|---|---|---|

| Inner diameter | Outer diameter | Initial contact angle | Inner groove curvature | Outer groove curvature | Diameter of ball | Number of balls |

| 60 | 110 | 25 | 0.525 | 0.535 | 14.28 | 15 |

| d2 (mm) | D2 (mm) | l (mm) | Dw2 (mm) | Z2 |

|---|---|---|---|---|

| Inner diameter | Outer diameter | Length of the contact line | Diameter of needle | Number of needles |

| 85 | 110 | 9.2 | 4 | 46 |

| Parameters | Values |

|---|---|

| s (mm) | 3 |

| μ | 0.15 |

| Dr (mm) | 106 |

| EM (GPa) | 30 |

| EA (GPa) | 70 |

| εL | 0.04 |

| σs (MPa) | 100 |

| σf (MPa) | 170 |

| Parameters | Values |

|---|---|

| R (Ω) | 0.6 |

| cp1 (J·(kg °C)−1) | 836.8 |

| cp2 (J·(kg °C)−1) | 1030 |

| m1 (kg) | 1.6 × 10−4 |

| m2 (kg) | 7.4 × 10−5 |

| Tmax (°C) | 140 |

| T0 (°C) | 25 |

| λ (J·kg−1) | 24,184 |

| h (J·(m2·°C·s)−1) | 39.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Jiang, J.; Zhang, Q.; Zhou, Y.; Zhang, X.; Sun, R. A Novel Shape Memory Alloy Actuated Bearing Active Preload System (SMA-BAPS) for Space Spindles. Aerospace 2025, 12, 637. https://doi.org/10.3390/aerospace12070637

Zhang Y, Jiang J, Zhang Q, Zhou Y, Zhang X, Sun R. A Novel Shape Memory Alloy Actuated Bearing Active Preload System (SMA-BAPS) for Space Spindles. Aerospace. 2025; 12(7):637. https://doi.org/10.3390/aerospace12070637

Chicago/Turabian StyleZhang, Yuhang, Jun Jiang, Qiang Zhang, Yuanzi Zhou, Xiaoyong Zhang, and Ruijie Sun. 2025. "A Novel Shape Memory Alloy Actuated Bearing Active Preload System (SMA-BAPS) for Space Spindles" Aerospace 12, no. 7: 637. https://doi.org/10.3390/aerospace12070637

APA StyleZhang, Y., Jiang, J., Zhang, Q., Zhou, Y., Zhang, X., & Sun, R. (2025). A Novel Shape Memory Alloy Actuated Bearing Active Preload System (SMA-BAPS) for Space Spindles. Aerospace, 12(7), 637. https://doi.org/10.3390/aerospace12070637