Static Aero-Propulsion Experiment of an Electric Ducted Fan

Abstract

1. Introduction

2. Experimental Method

2.1. Facility Description

2.1.1. Electric Ducted Propulsion Fan Model

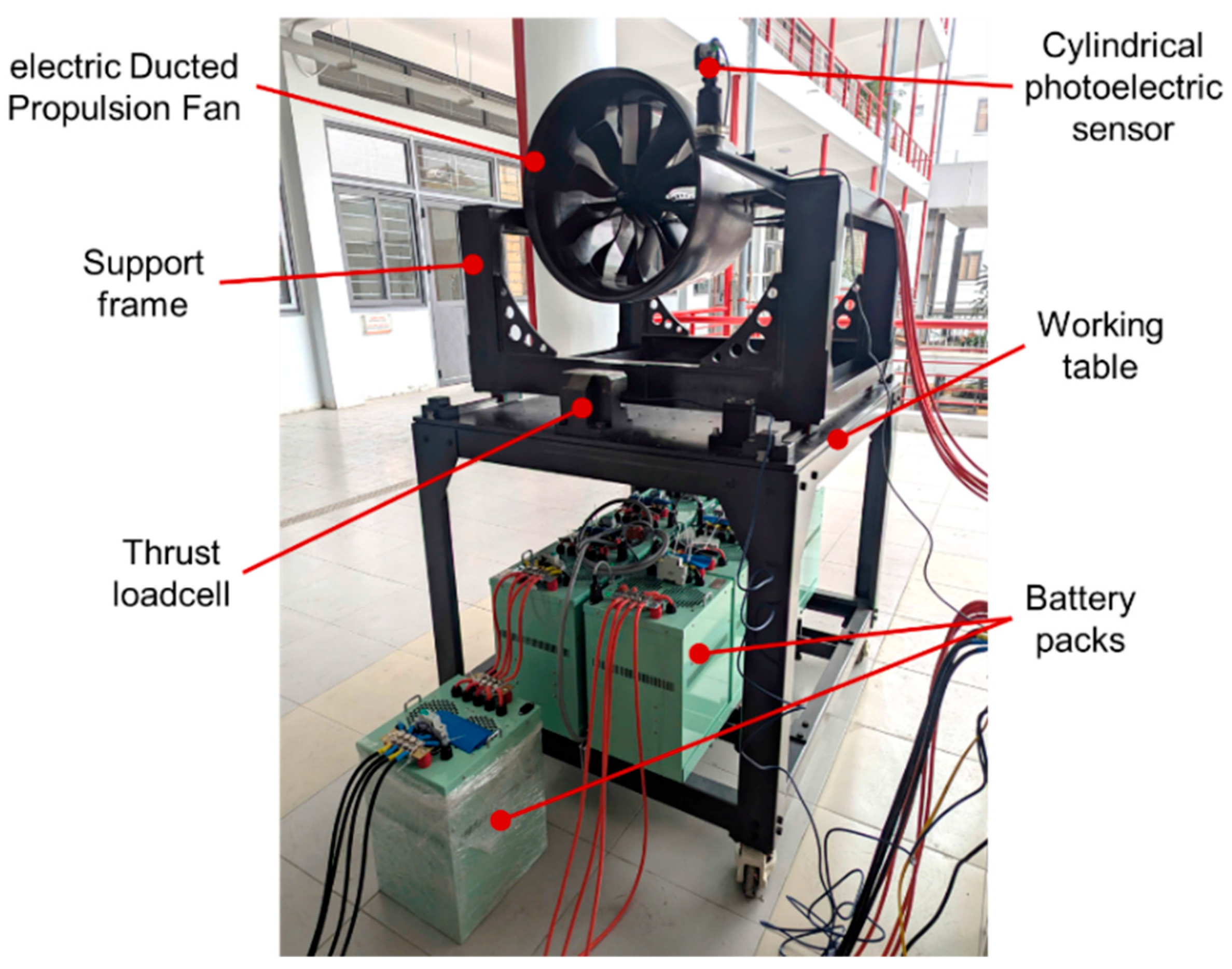

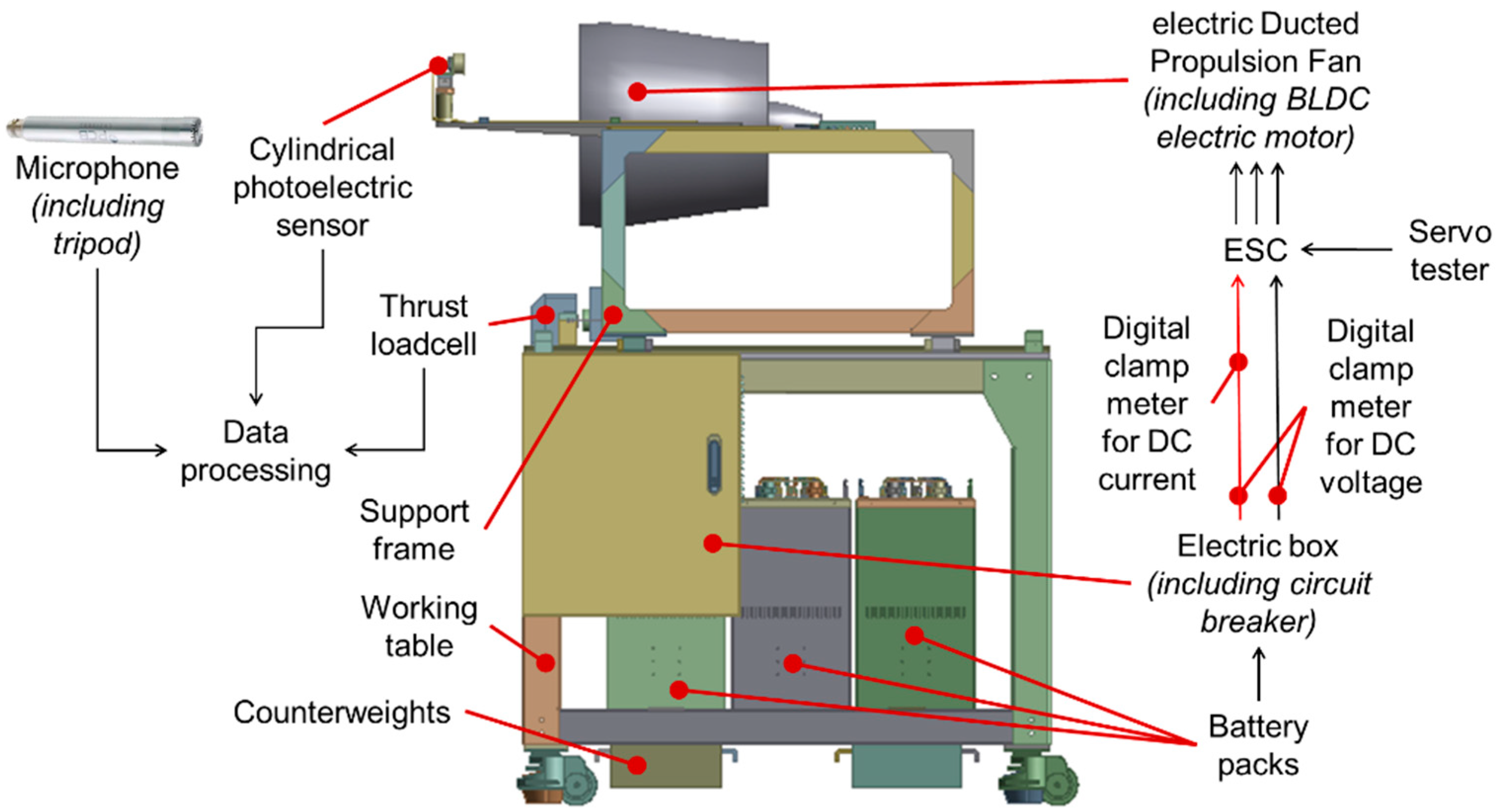

2.1.2. Thrust Testing Stand System

2.1.3. Measuring Equipment

2.1.4. Battery System

2.2. Experimental Setup

3. Data Processing

3.1. Testing Procedure

3.2. Sound Pressure Level

3.3. Background Noise

3.4. Uncertainty Analysis

4. Experimental Results and Discussion

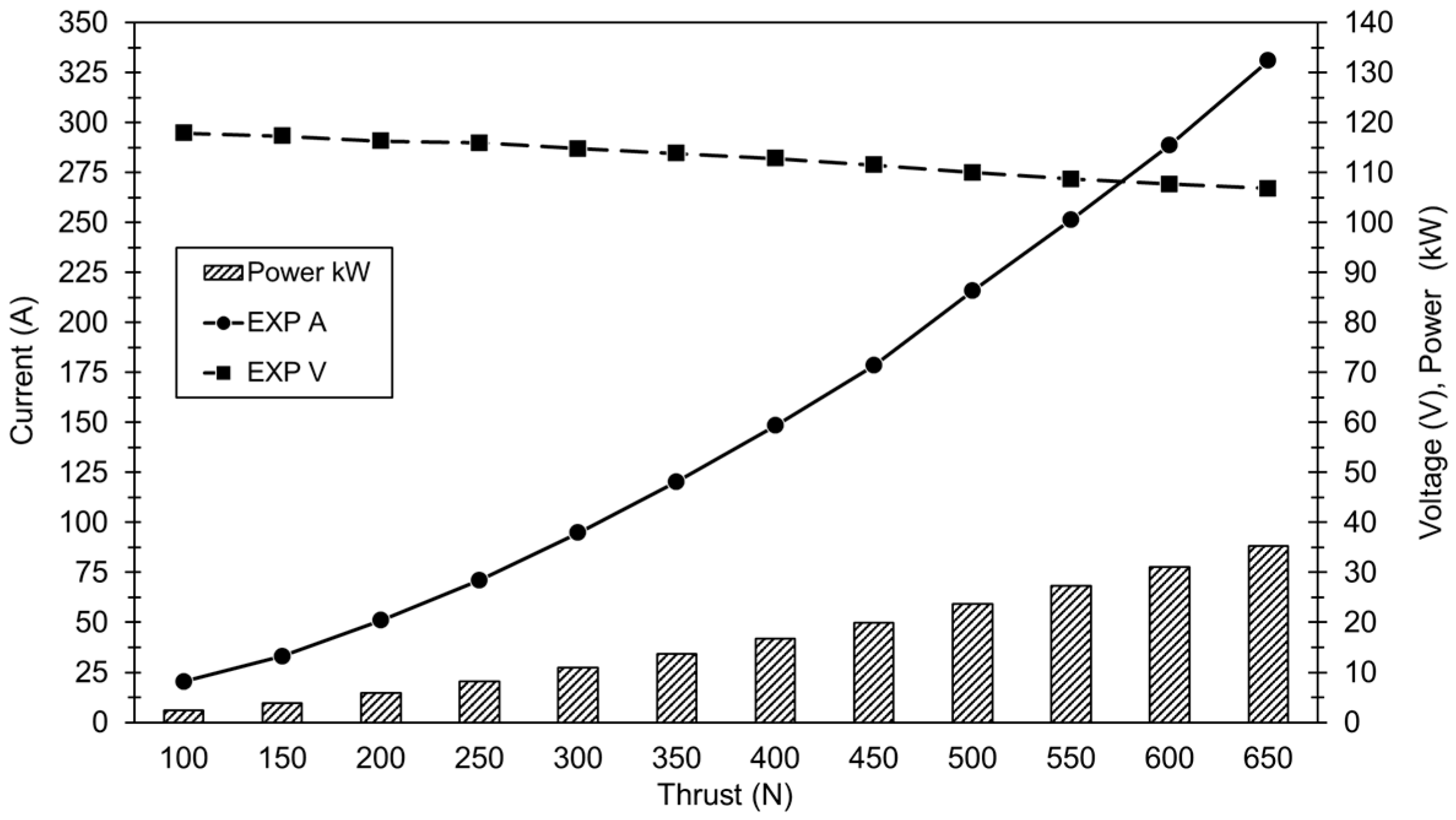

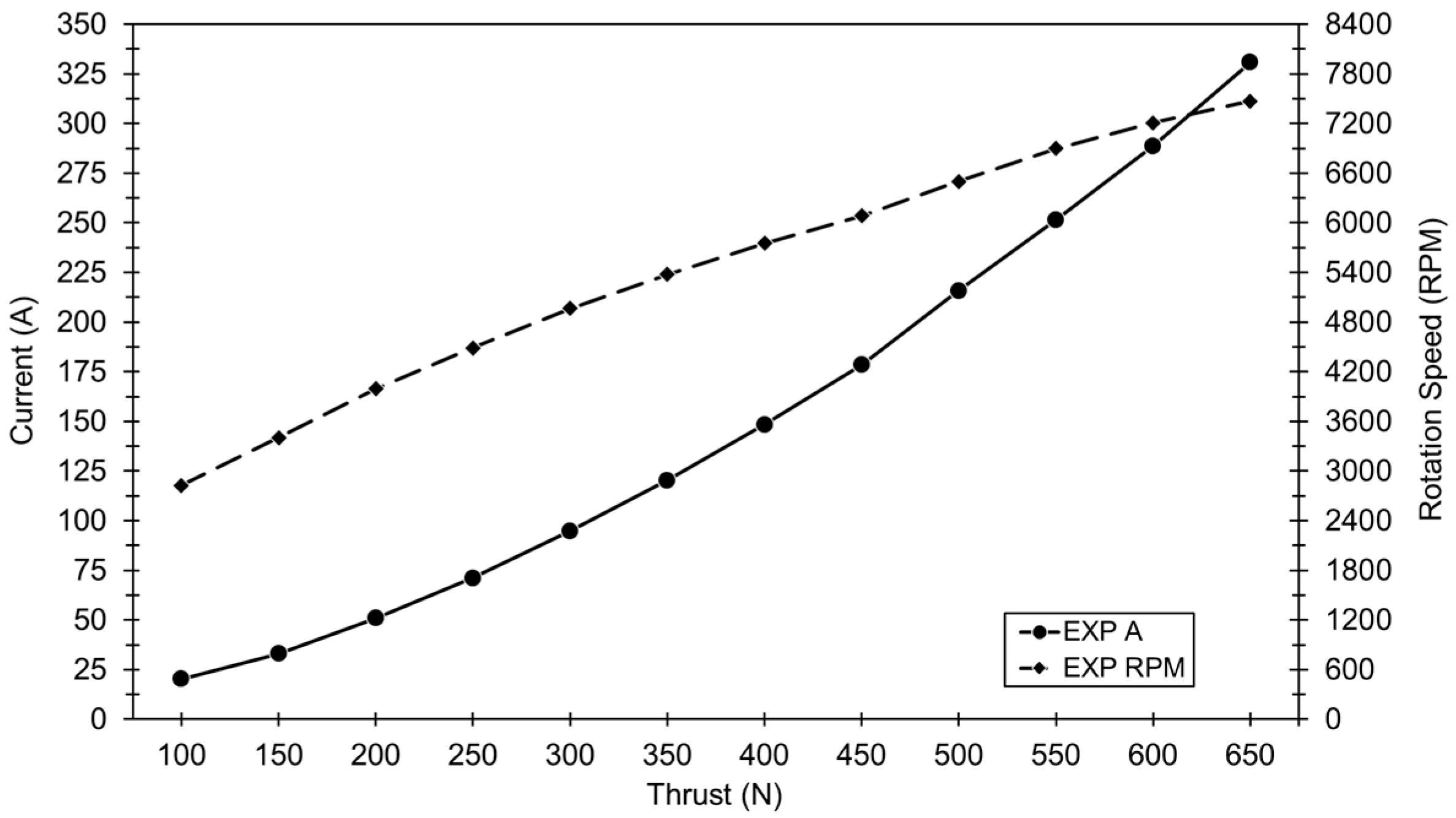

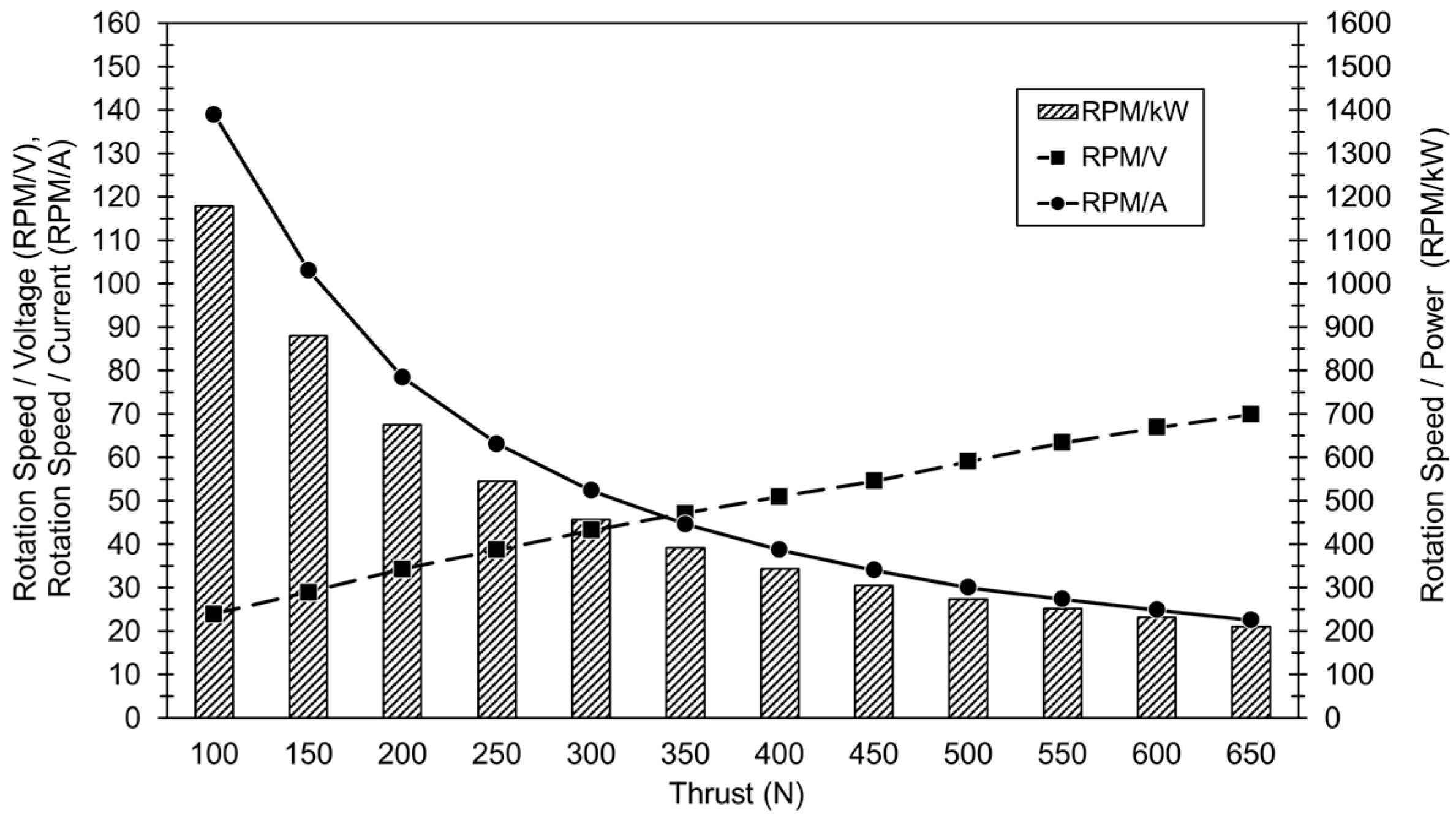

4.1. Experiment by Thrust Range

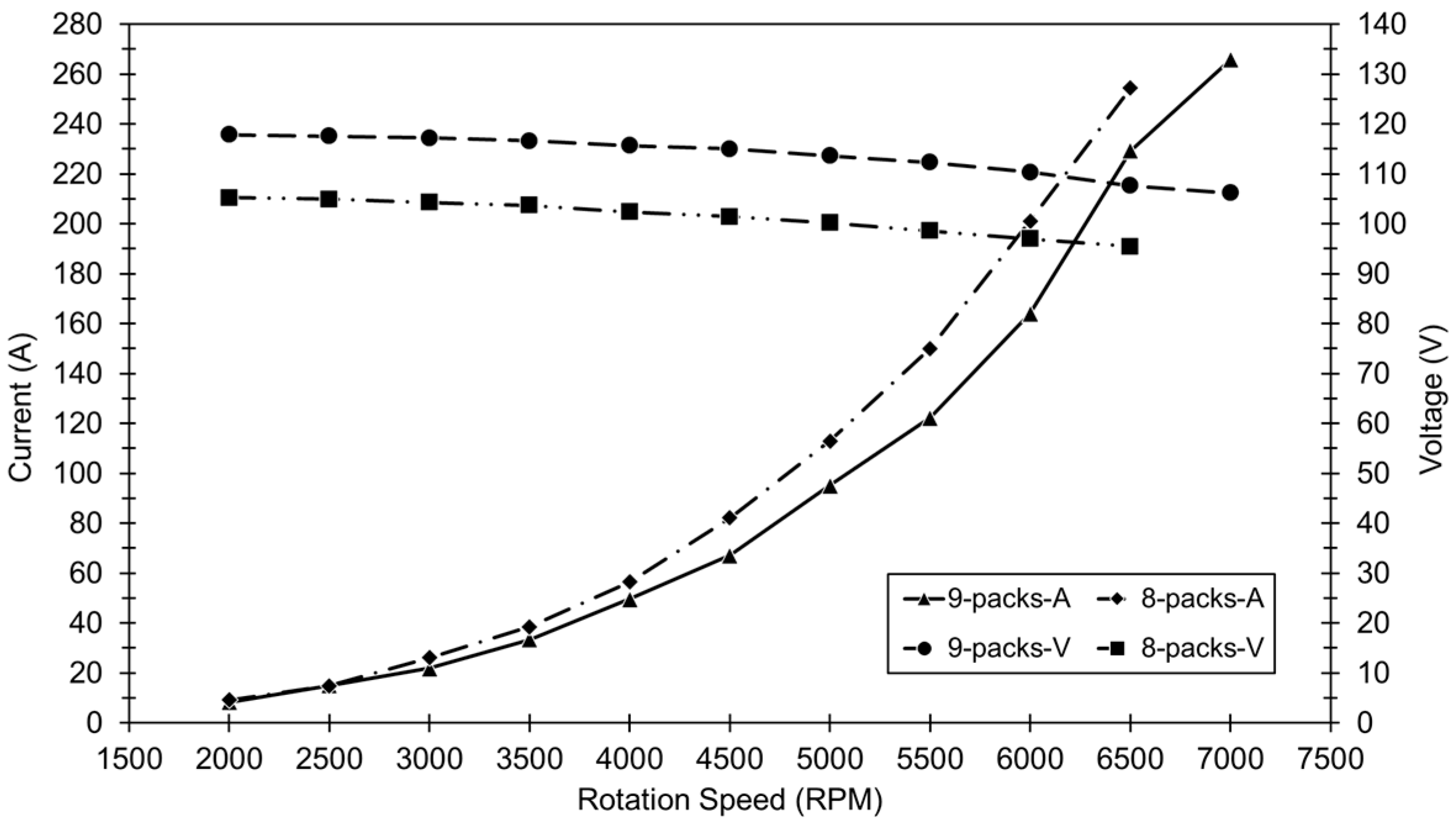

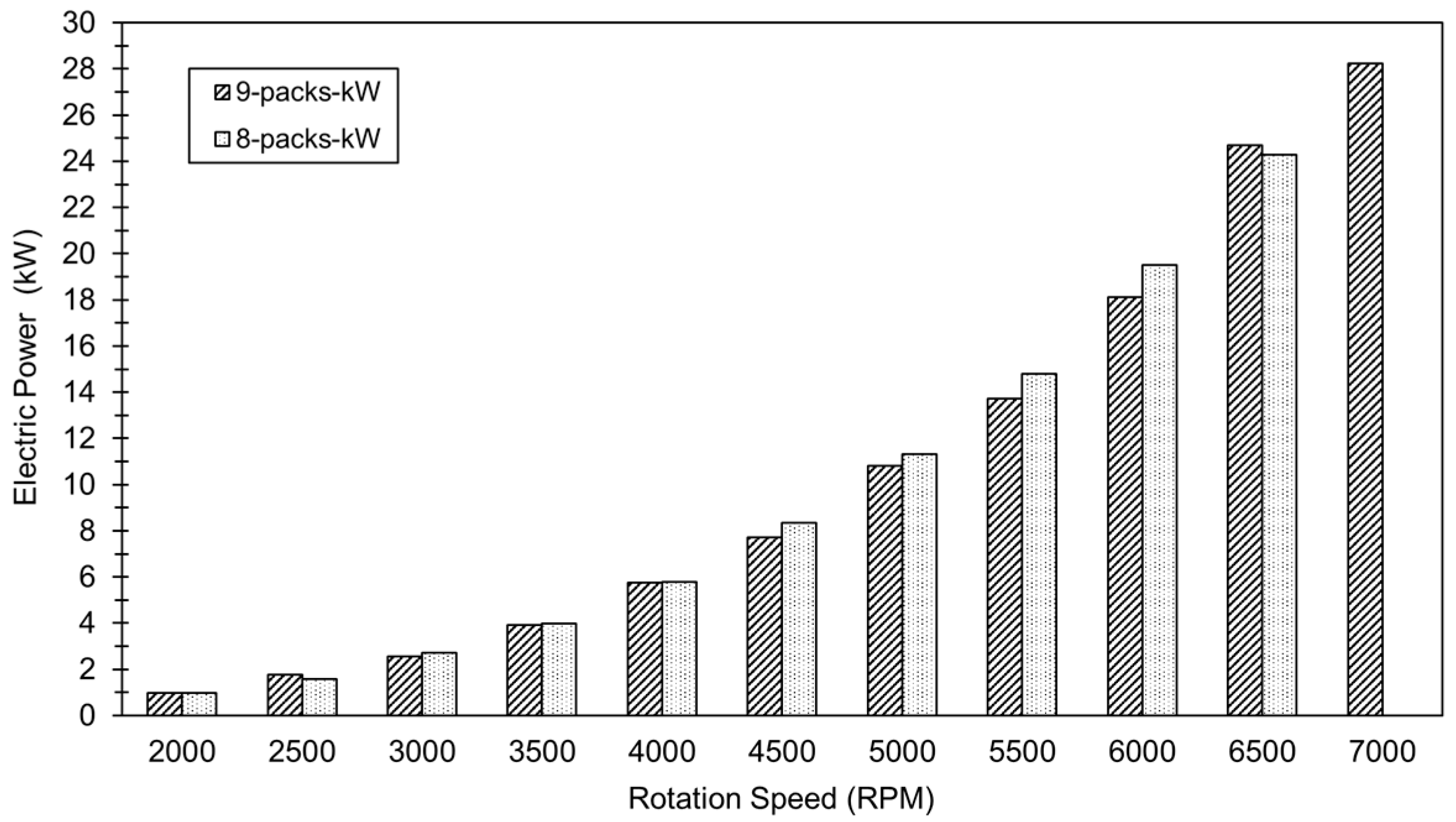

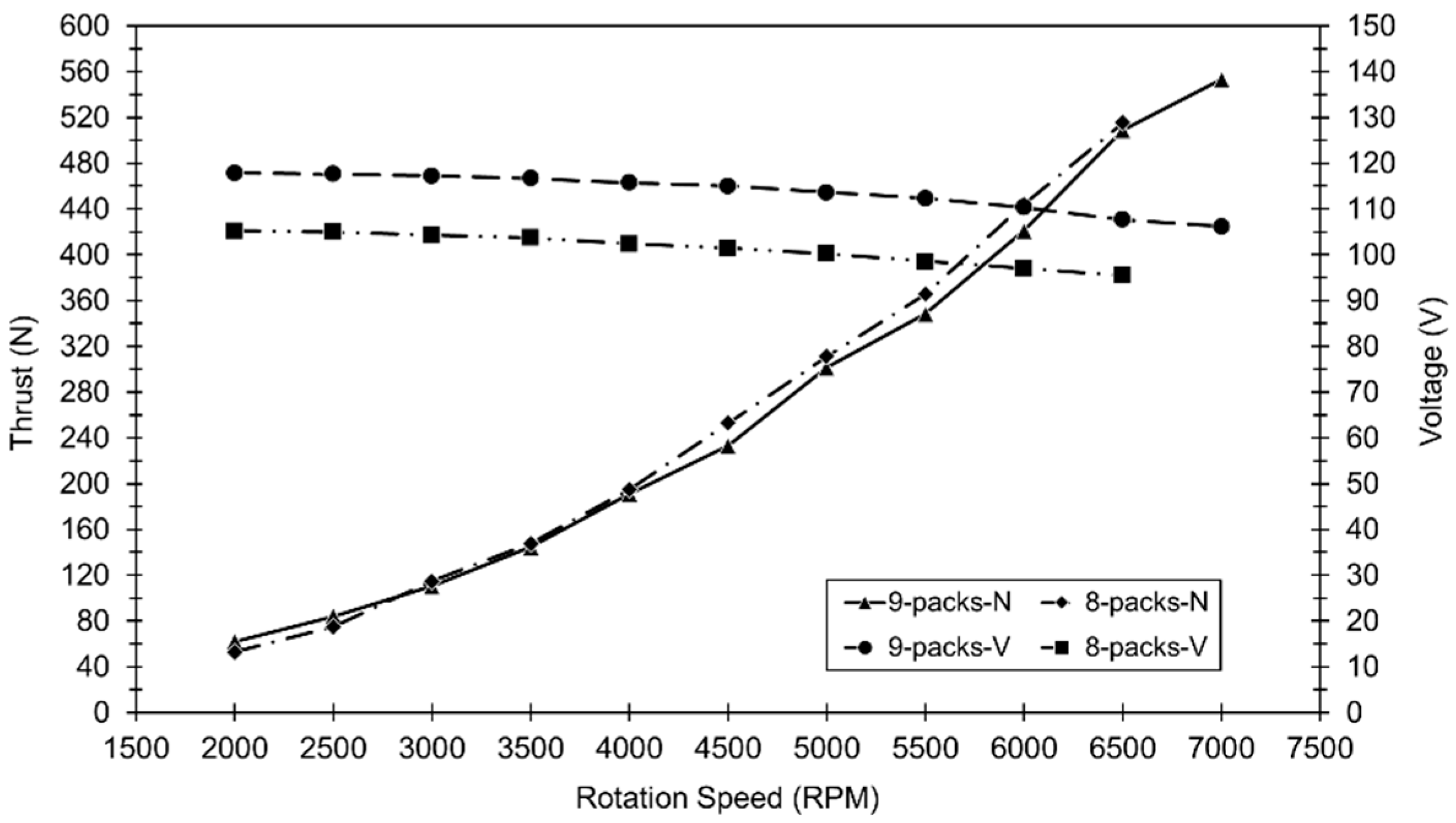

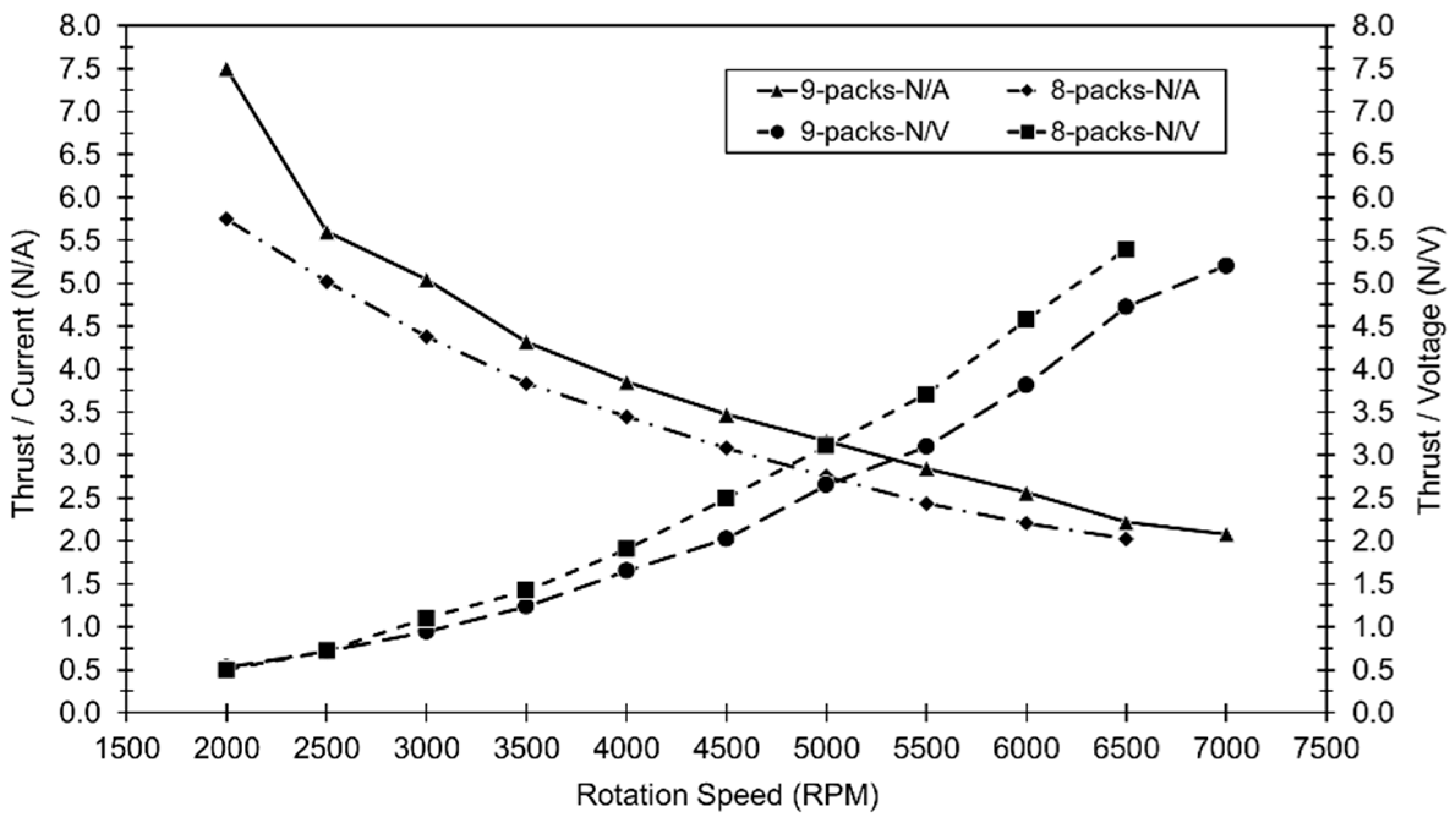

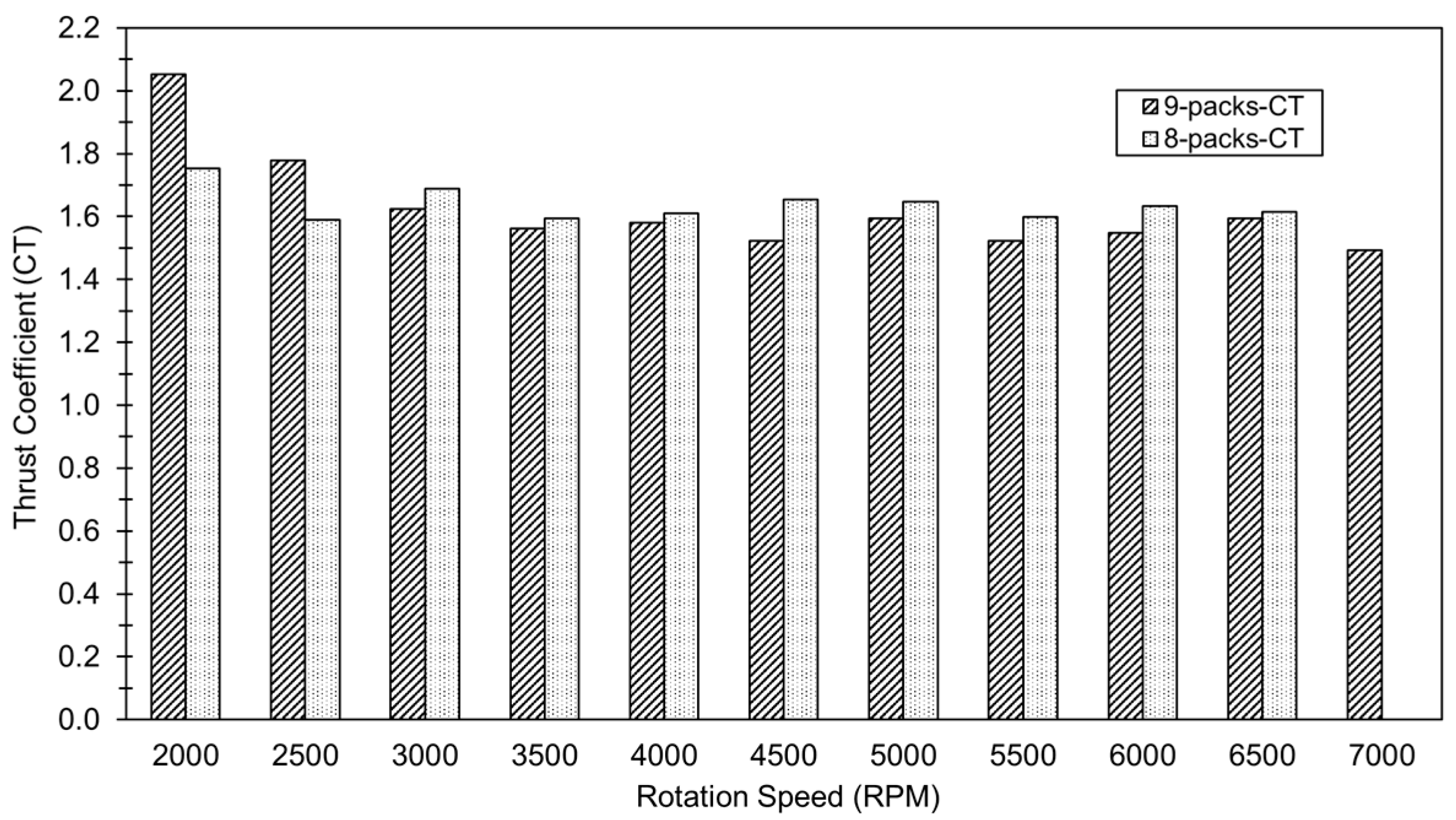

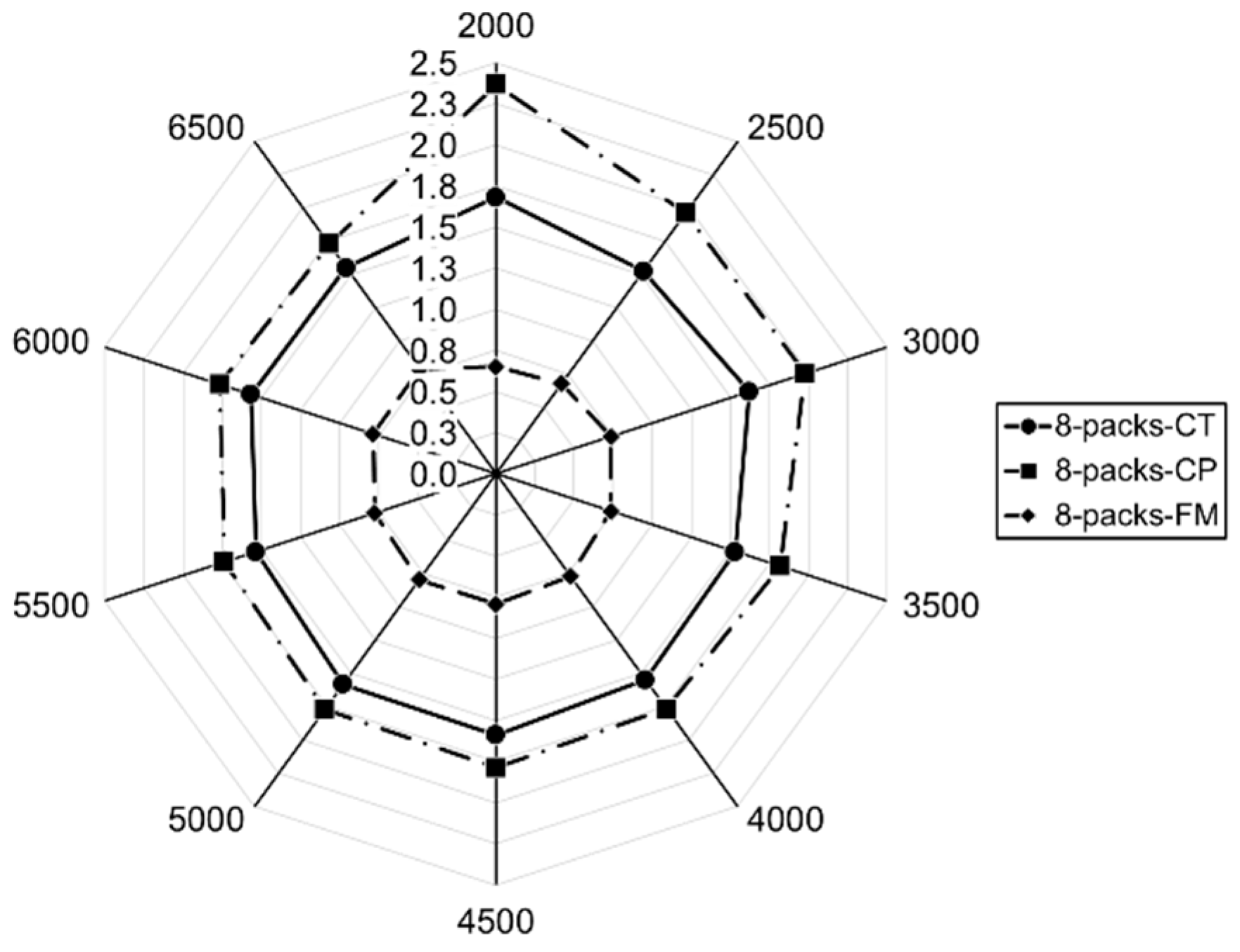

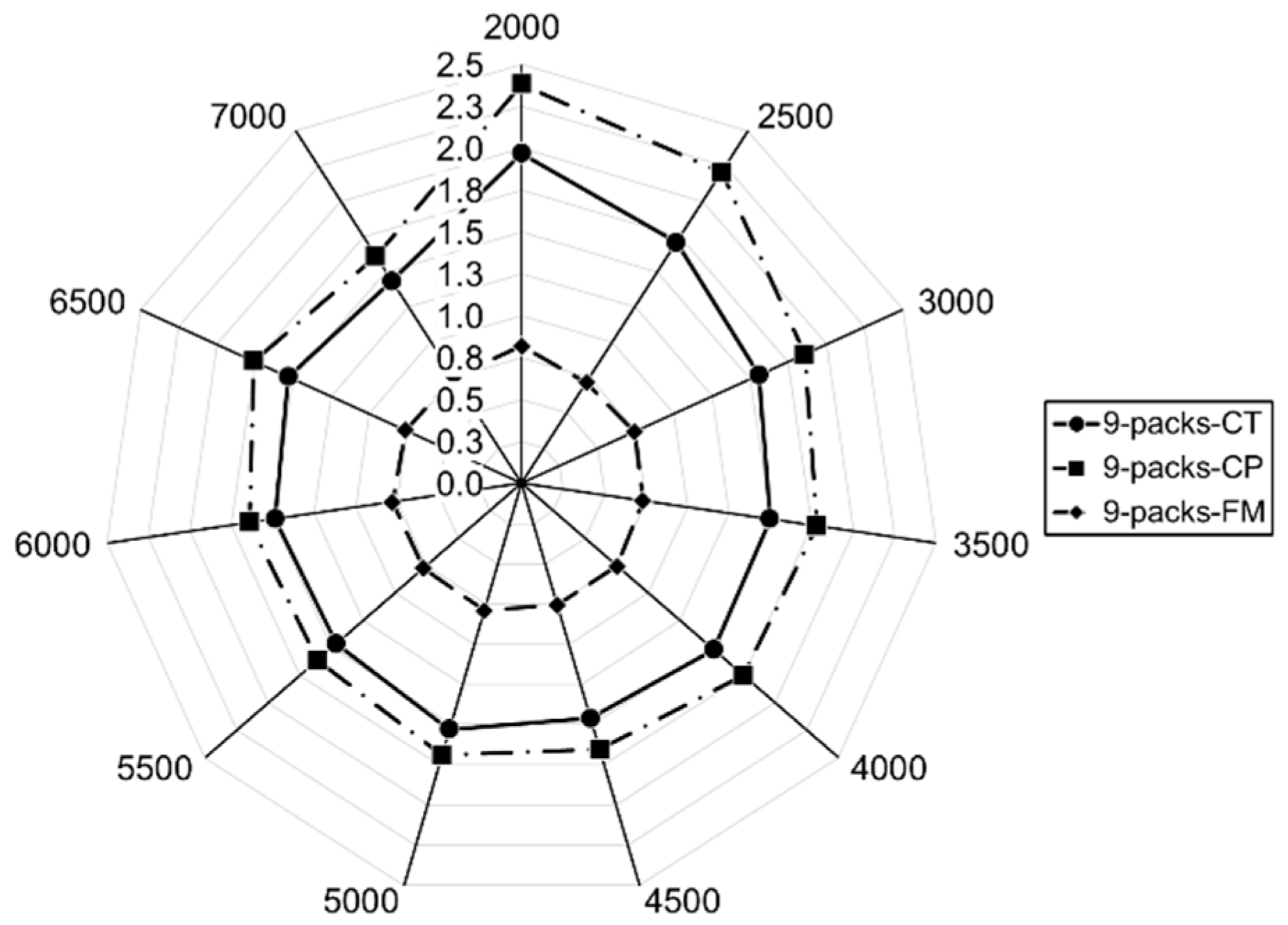

4.2. Experiment by Battery Pack Number

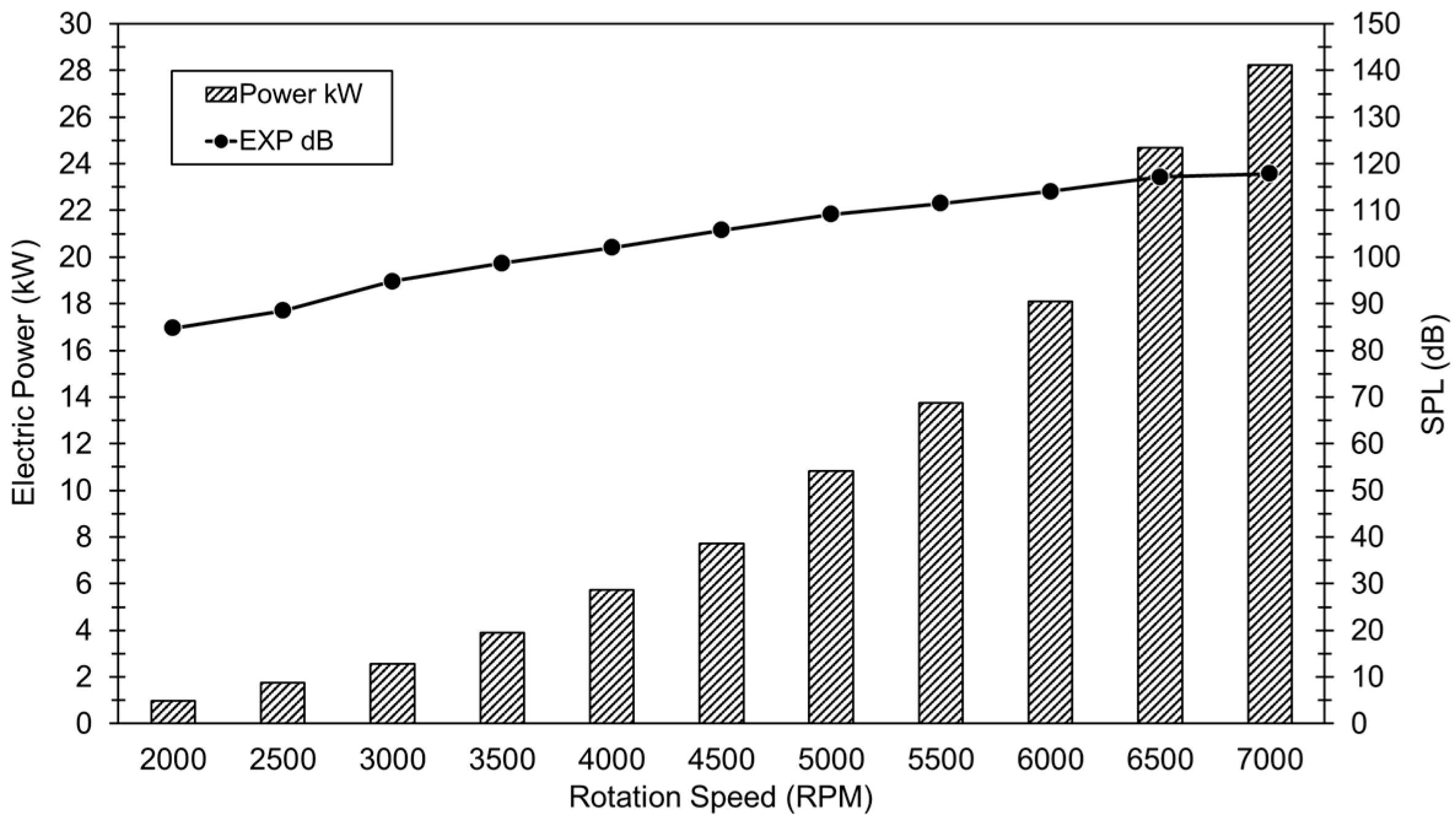

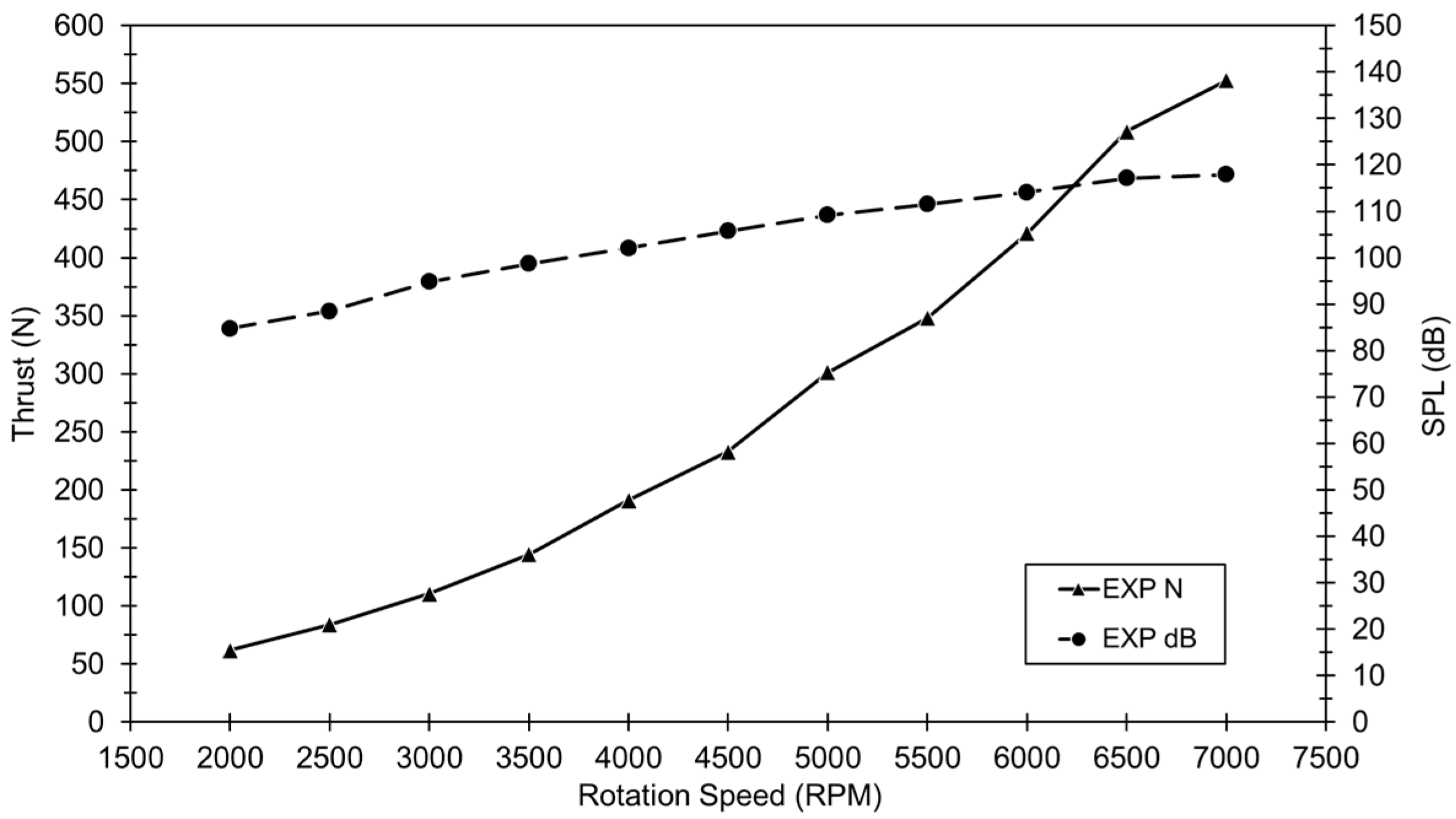

4.3. Aeroacoustic Testing

4.4. Relationship Between Electrical and Aero-Propulsion Characteristics

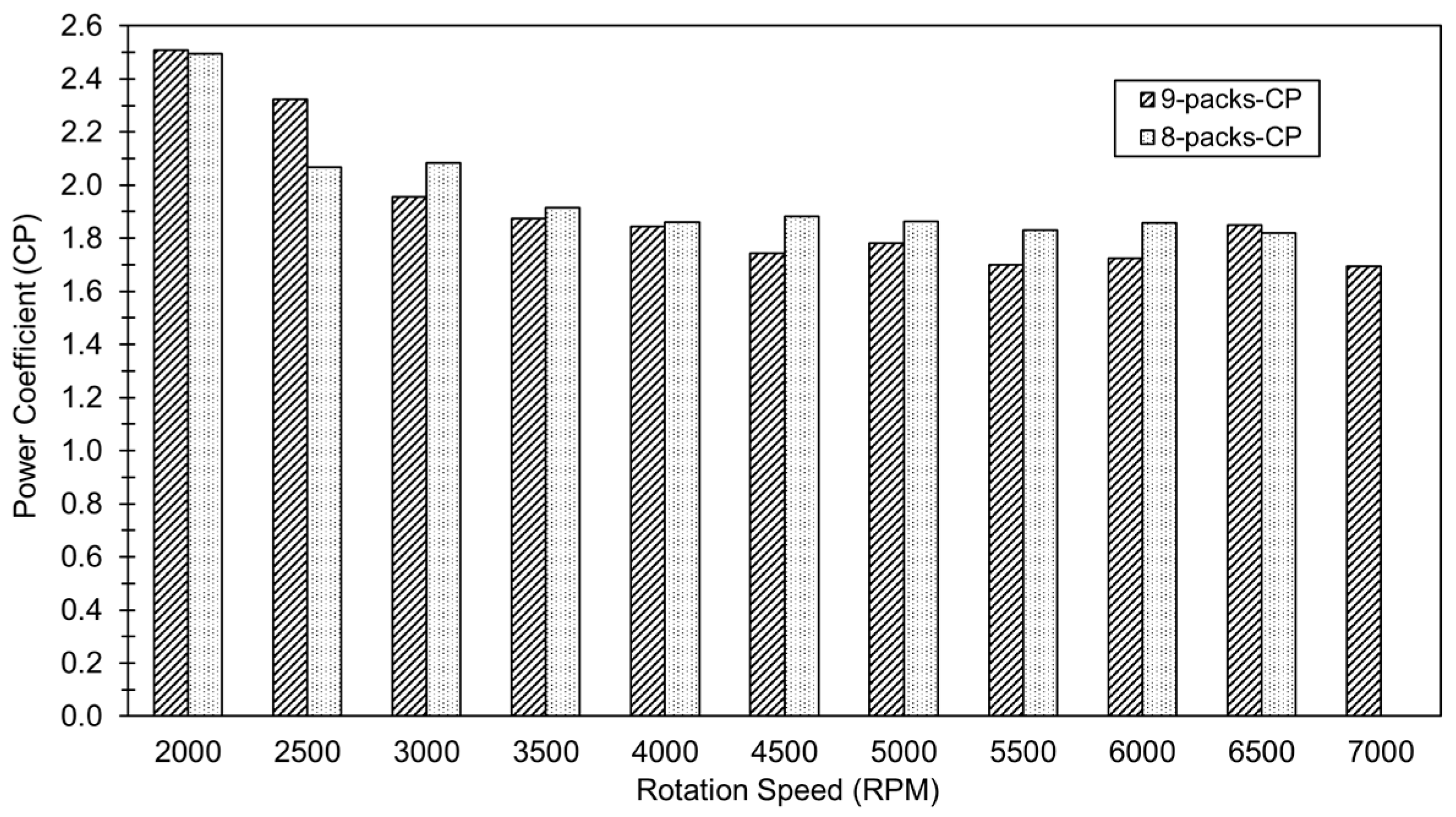

4.5. Non-Dimensional eDPF Data

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| D | fan blade diameter | (m) |

| N | number of samples | |

| p | pressure signal | (Pa) |

| S | microphone sensitivity | (V/Pa) |

| V | voltage signal | (V) |

| Greek | ||

| ρ | density of air | (kg/m3) |

| Ω | fan rotation speed | (rpm) |

| Subcripts | ||

| 0 | reference value | |

| P | Power | |

| T | Thrust | |

| Acronyms | ||

| APSs | Aerospace Propulsion Systems | |

| BLDC | Brushless Direct Current | |

| CP | Power Coefficient | |

| CT | Thrust Coefficient | |

| DAQ | Data Acquisition | |

| EDF | Electric Ducted Fan | |

| eDPF | electric Ducted Propulsion Fan | |

| ESC | Electronic Speed Controller | |

| EXP | Experimental | |

| FM | Figure of Merit | |

| PIV | Particle Image Velocimetry | |

| PWM | Pulse Width Modulation | |

| RMS | Root Mean Square | |

| rpm | Revolutions Per Minute | |

| S/VTOL | Short/Vertical Takeoff and Landing | |

| SPL | Sound Pressure Level | |

| UAV | Unmanned Aerial Vehicle | |

References

- Kondor, S.A.; Lee, W.; Englar, R.J.; Moore, M.D. Experimental investigation of circulation control on a shrouded fan. In Proceedings of the 21st AIAA Applied Aerodynamics Conference, Orlando, FL, USA, 23–26 June 2003. [Google Scholar] [CrossRef]

- Kondor, S.A.; Moore, M. Experimental investigation of a morphing nacelle ducted fan. In Proceedings of the NASA/ONR Circulation Control Workshop, Hampton, VA, USA, 16–17 March 2004; pp. 435–468. Available online: https://ntrs.nasa.gov/citations/20050192632 (accessed on 7 September 2013).

- Kondor, S.A. Further experimental investigation of circulation control morphing shrouded fan. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit—Meeting Papers, Reno, NV, USA, 10–13 January 2005; pp. 7765–7772. [Google Scholar] [CrossRef]

- Martin, P.; Tung, C. Performance and flow field measurements on a 10-inch ducted rotor VTOL UAV. In Proceedings of the 60th Annual Forum of the American Helicopter Society, Baltimore, MD, USA, 7–10 June 2004; Available online: https://ntrs.nasa.gov/citations/20050009943 (accessed on 7 September 2013).

- Martin, P.B.; Boxwell, D.A. Design, analysis, and experiments on a 10-inch ducted rotor VTOL UAV. In Proceedings of the AHS International Specialists’ Meeting—Unmanned Rotorcraft, Chandler, AZ, USA, 18–20 January 2005; pp. 399–420. Available online: https://www.researchgate.net/publication/259039691 (accessed on 1 January 2005).

- Graf, W.; Fleming, J.; Ng, W. Improving ducted fan UAV aerodynamics in forward flight. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 7–10 January 2008. [Google Scholar] [CrossRef]

- Ohanian, O.J.; Gelhausen, P.A.; Inman, D.J. A compact method for modeling the aerodynamics of ducted fan vehicles. In Proceedings of the 48th AIAA Aerospace Sciences Meeting, Orlando, FL, USA, 4–7 January 2010. [Google Scholar] [CrossRef]

- Akturk, A.; Shavalikul, A.; Camci, C. PIV measurements and computational study of a 5-inch ducted fan for V/STOL UAV applications. In Proceedings of the 47th AIAA Aerospace Sciences Meeting, Orlando, FL, USA, 5–8 January 2009. [Google Scholar] [CrossRef]

- Akturk, A.; Camci, C. Experimental and computational assessment of a ducted-fan rotor flow model. J. Aircr. 2012, 49, 885–897. [Google Scholar] [CrossRef]

- Akturk, A.; Camci, C. Tip clearance investigation of a ducted fan used in VTOL unmanned aerial vehicles—Part I: Baseline experiments and computational validation. J. Turbomach. 2013, 136, 021004. [Google Scholar] [CrossRef]

- Cho, B.L.; Lee, S.; Cho, J. Numerical and experimental analyses of the ducted fan for the small VTOL UAV propulsion. Trans. Jpn. Soc. Aeronaut. Space Sci. 2013, 56, 328–336. [Google Scholar] [CrossRef]

- Brezina, A.J.; Thomas, S.K. Measurement of static and dynamic performance characteristics of electric propulsion systems. In Proceedings of the 51st AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 7–10 January 2013. [Google Scholar] [CrossRef]

- Yilmaz, S.; Erdem, D.; Kavsaoglu, M.S. Performance of a ducted propeller designed for UAV applications at zero angle of attack flight: An experimental study. Aerosp. Sci. Technol. 2015, 45, 376–386. [Google Scholar] [CrossRef]

- McCrink, M.H.; Gregory, J.W. Blade element momentum modeling of low-Reynolds electric propulsion systems. J. Aircr. 2017, 54, 163–176. [Google Scholar] [CrossRef]

- Deng, Y. Experimental investigation on ground effect of ducted fan system for VTOL UAV. Lect. Notes Electr. Eng. 2019, 459, 1602–1609. [Google Scholar] [CrossRef]

- Ai, T.; Xu, B.; Xiang, C.; Fan, W.; Zhang, Y. Aerodynamic analysis and control for a novel coaxial ducted fan aerial robot in ground effect. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420953026. [Google Scholar] [CrossRef]

- Han, H.; Xiang, C.; Xu, B.; Yu, Y. Experimental and computational investigation on comparison of micro-scale open rotor and shrouded rotor hovering in ground effect. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2021, 235, 553–565. [Google Scholar] [CrossRef]

- Ebus, T.; Dietz, M.; Hupfer, A. Experimental and numerical studies on small contra-rotating electrical ducted fan engines. CEAS Aeronaut. J. 2021, 12, 559–571. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, Z. An efficient blade design method of a ducted fan coupled with the CFD modification. Aerospace 2022, 9, 241. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, Z. Multi-objective design of a distributed ducted fan system. Aerospace 2022, 9, 165. [Google Scholar] [CrossRef]

- Urban, D.; Kusmirek, S.; Socha, V.; Hanakova, L.; Hylmar, K.; Kraus, J. Effect of electric ducted fans structural arrangement on their performance characteristics. Appl. Sci. 2023, 13, 2787. [Google Scholar] [CrossRef]

- Luo, Y.; Ai, T.; He, Y.; Xu, B.; Qian, Y.; Zhang, Y. Numerical analysis of wind effects on aerodynamic characteristics of a ducted fan. Chin. J. Aeronaut. 2024, 37, 263–280. [Google Scholar] [CrossRef]

- Grava, A.; Jacopo, S.; Gaetano, I.; Luis, B.; Gioacchino, C. Experimental investigation of a small drone propeller aerodynamics in forward flight. J. Aircr. 2024, 63, 1855–1866. [Google Scholar] [CrossRef]

- Hirono, F.C.; Torija, A.J.; Grimshaw, S.D.; Cousins, D.; Farman, J.; Taylor, J.V. Aerodynamic and aeroacoustic design of electric ducted fans. Aerosp. Sci. Technol. 2024, 153, 109411. [Google Scholar] [CrossRef]

- Ahmed Snikdha, S.S.; Chen, S.-H. A Computational Investigation of the Hover Mechanism of an Innovated Disc-Shaped VTOL UAV. Drones 2023, 7, 105. [Google Scholar] [CrossRef]

- Lengyel-Kampmann, T.; Karboujian, J.; Charroin, G.; Winkelmann, P. Experimental Investigation of an Efficient and Lightweight Designed Counter- Rotating Shrouded Fan Stage. Int. J. Turbomach. Propuls. Power 2024, 9, 26. [Google Scholar] [CrossRef]

- ISO 3744:2010; Acoustics—Determination of Sound Power Levels and Sound Energy Levels of Noise Sources Using Sound Pressure—Engineering Methods for an Essentially Free Field over a Reflecting Plane. International Organization for Standardization: Geneva, Switzerland, 2010; Edition 3. Available online: https://www.iso.org/standard/52055.html (accessed on 1 October 2010).

| Fan Shroud Diameter | Fan Tip Clerance | Number of Fan Blades | Number of Strut Blades | eDPF Axial Length | eDPF Nacelle Diameter | Center Body Diameter |

|---|---|---|---|---|---|---|

| 390 mm | 2 mm | 10 | 6 | 554 mm | 498 mm | 110 mm |

| Measuring Equipment | Specification | Min | Max | Uncertainty | Unit |

|---|---|---|---|---|---|

| Thrust Load Cell (Compression type) | Thrust | 0 | 2700 | 0.88% | N |

| Cylindrical photoelectric sensor (Red LED light) | Angular velocity | 0 | 7200 | 0.1% | rpm |

| Microphone (PCB 377C01 + 426E01 + DAQ 20 kHz) | Sound Pressure | 0 | 200 | 0.25% | dB |

| Digital clamp meter (DC Voltage) | Voltage | 0 | 600 | 0.01% | V |

| Digital clamp meter (DC Current) | Current | 0 | 600 | 0.27% | A |

| Option (Serial Connection) | Max DC Voltage | Operating DC Voltage | Max DC Current | Operating DC Current | Efficiency |

|---|---|---|---|---|---|

| One battery pack | 14.4 V | 12.8 V | 400 A | 100 A | 98% |

| 8 battery packs | 115 ± 3 V | 105 ± 3 V | 400 ± 40 A | 100 ± 10 A | 98% |

| 9 battery packs | 130 ± 3 V | 115 ± 3 V | 400 ± 40 A | 100 ± 10 A | 98% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, H.-Q.; Dinh, Q.-N.; Vu, T.-S.; Pham, V.-Y.; Bui, V.-T.; Hoang, N.-M.; Nguyen, T.-K.; Nguyen, D.; Pham, G.-D.; Dinh, C.-T. Static Aero-Propulsion Experiment of an Electric Ducted Fan. Aerospace 2025, 12, 509. https://doi.org/10.3390/aerospace12060509

Chu H-Q, Dinh Q-N, Vu T-S, Pham V-Y, Bui V-T, Hoang N-M, Nguyen T-K, Nguyen D, Pham G-D, Dinh C-T. Static Aero-Propulsion Experiment of an Electric Ducted Fan. Aerospace. 2025; 12(6):509. https://doi.org/10.3390/aerospace12060509

Chicago/Turabian StyleChu, Hoang-Quan, Quang-Ngoc Dinh, Thai-Son Vu, Van-Yen Pham, Van-Trung Bui, Nhat-Minh Hoang, Trung-Kien Nguyen, Dong Nguyen, Gia-Diem Pham, and Cong-Truong Dinh. 2025. "Static Aero-Propulsion Experiment of an Electric Ducted Fan" Aerospace 12, no. 6: 509. https://doi.org/10.3390/aerospace12060509

APA StyleChu, H.-Q., Dinh, Q.-N., Vu, T.-S., Pham, V.-Y., Bui, V.-T., Hoang, N.-M., Nguyen, T.-K., Nguyen, D., Pham, G.-D., & Dinh, C.-T. (2025). Static Aero-Propulsion Experiment of an Electric Ducted Fan. Aerospace, 12(6), 509. https://doi.org/10.3390/aerospace12060509