Design of the Aerial Deceleration Phase of an Aerostat Considering the Deployment Scale

Abstract

1. Introduction

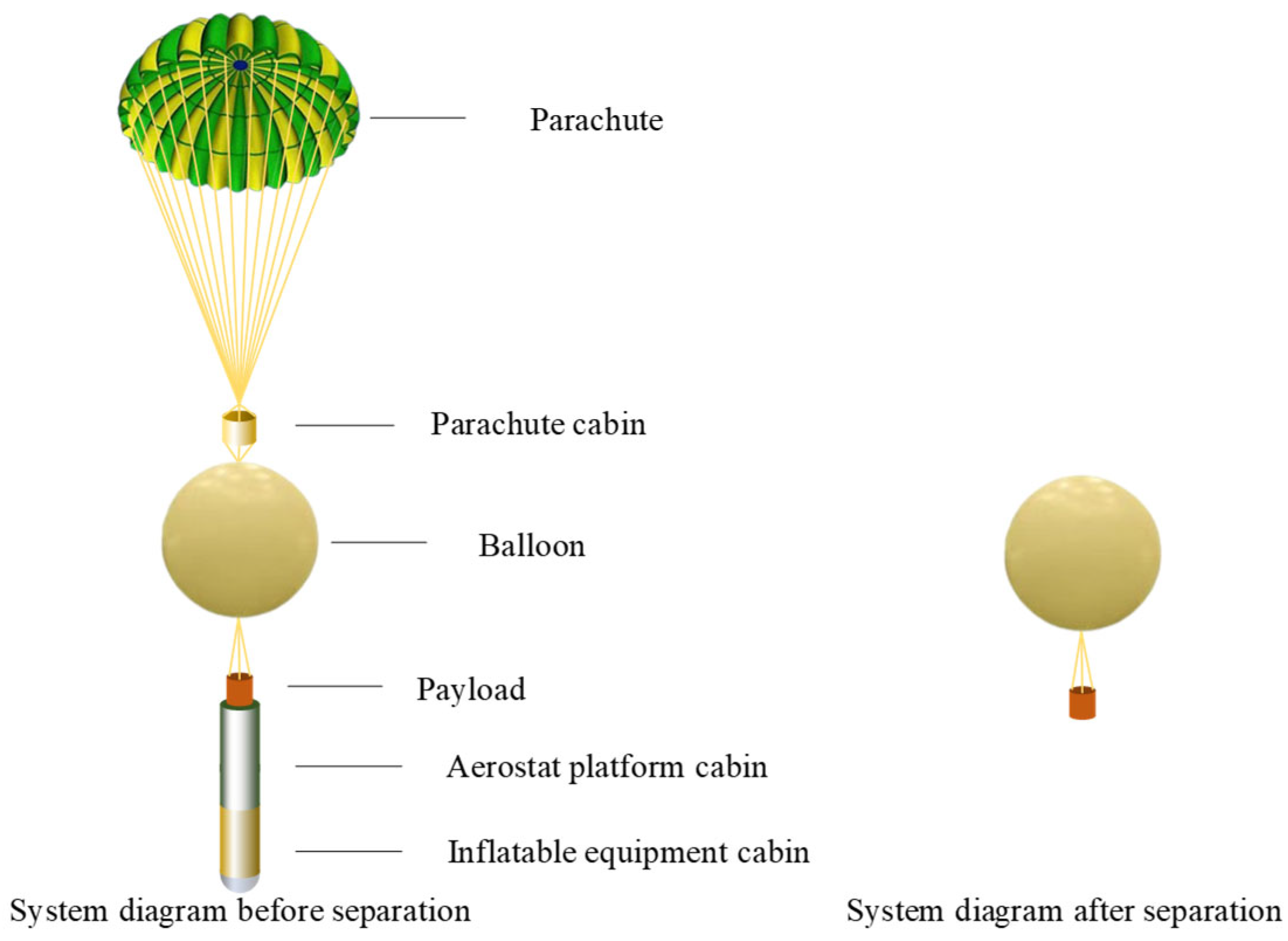

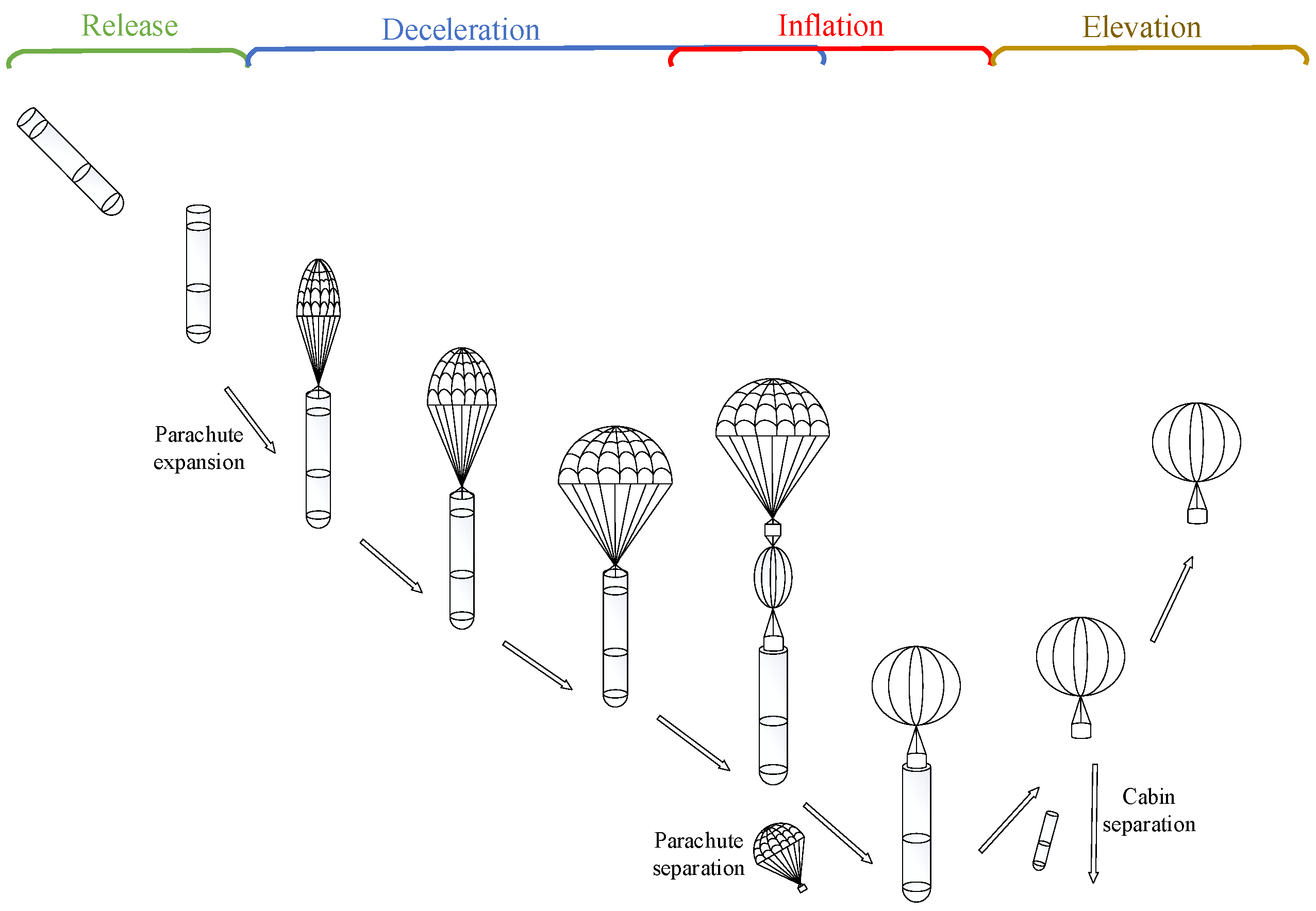

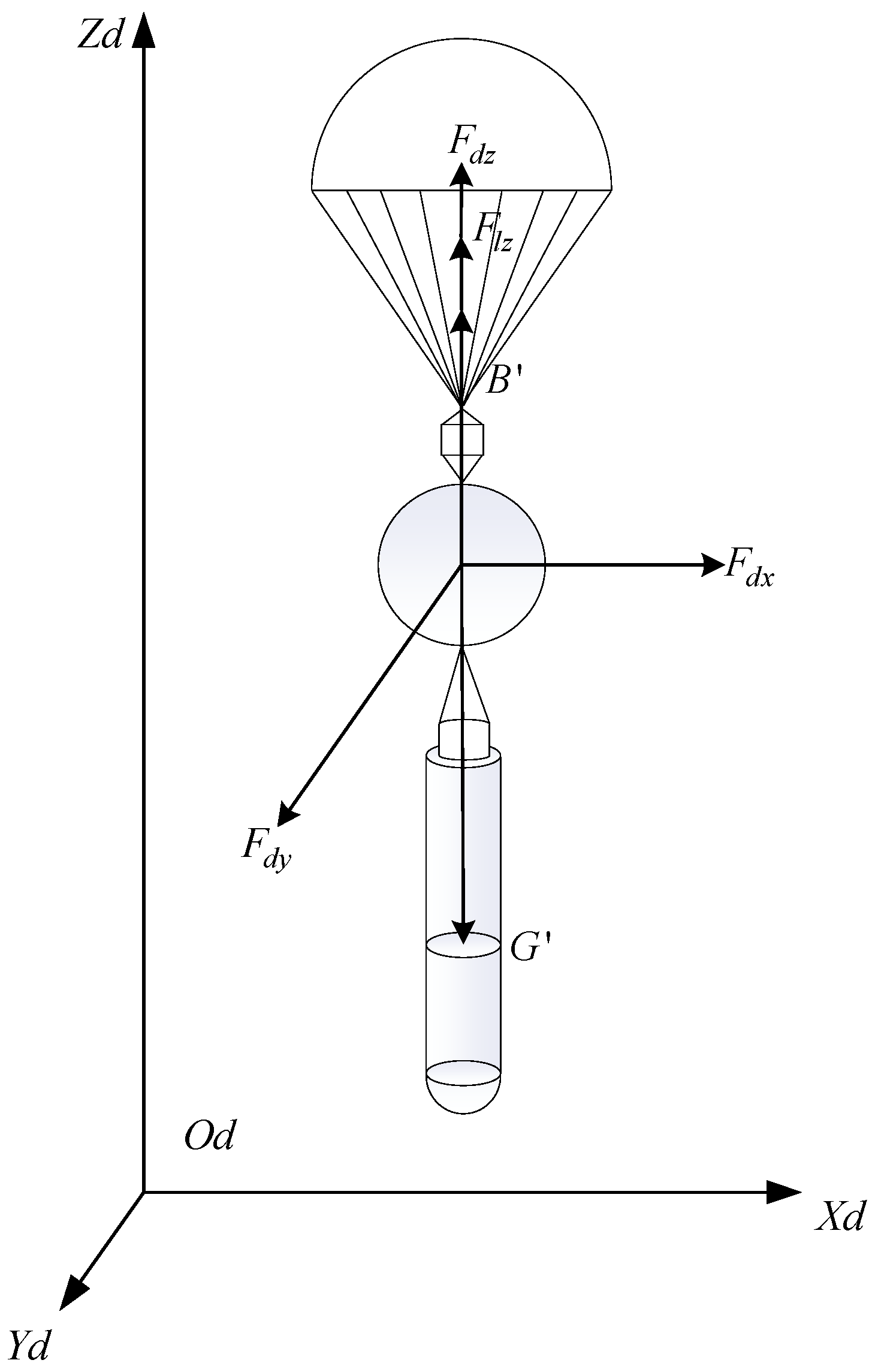

2. Modeling

- (1)

- The parachute and cabin are hinged together, with a constant distance between the centroid of the parachute and the hinge point.

- (2)

- The parachute, aerostat, and cabin are modeled as axisymmetric rigid bodies.

- (3)

- The pressure centers of the parachute, aerostat, and cabin coincide with their respective centroids.

- (4)

- The influence of the wake vortex effects of the cabin and balloon on the inflation process of the parachute is ignored.

- (5)

- The change in gravity due to the change in height is ignored; the gravity acceleration is assumed to be a constant of 9.8 m/s2.

- (6)

- The balloon hull is assumed to be spherical, and its projected area is time-dependent.

2.1. Atmospheric Model

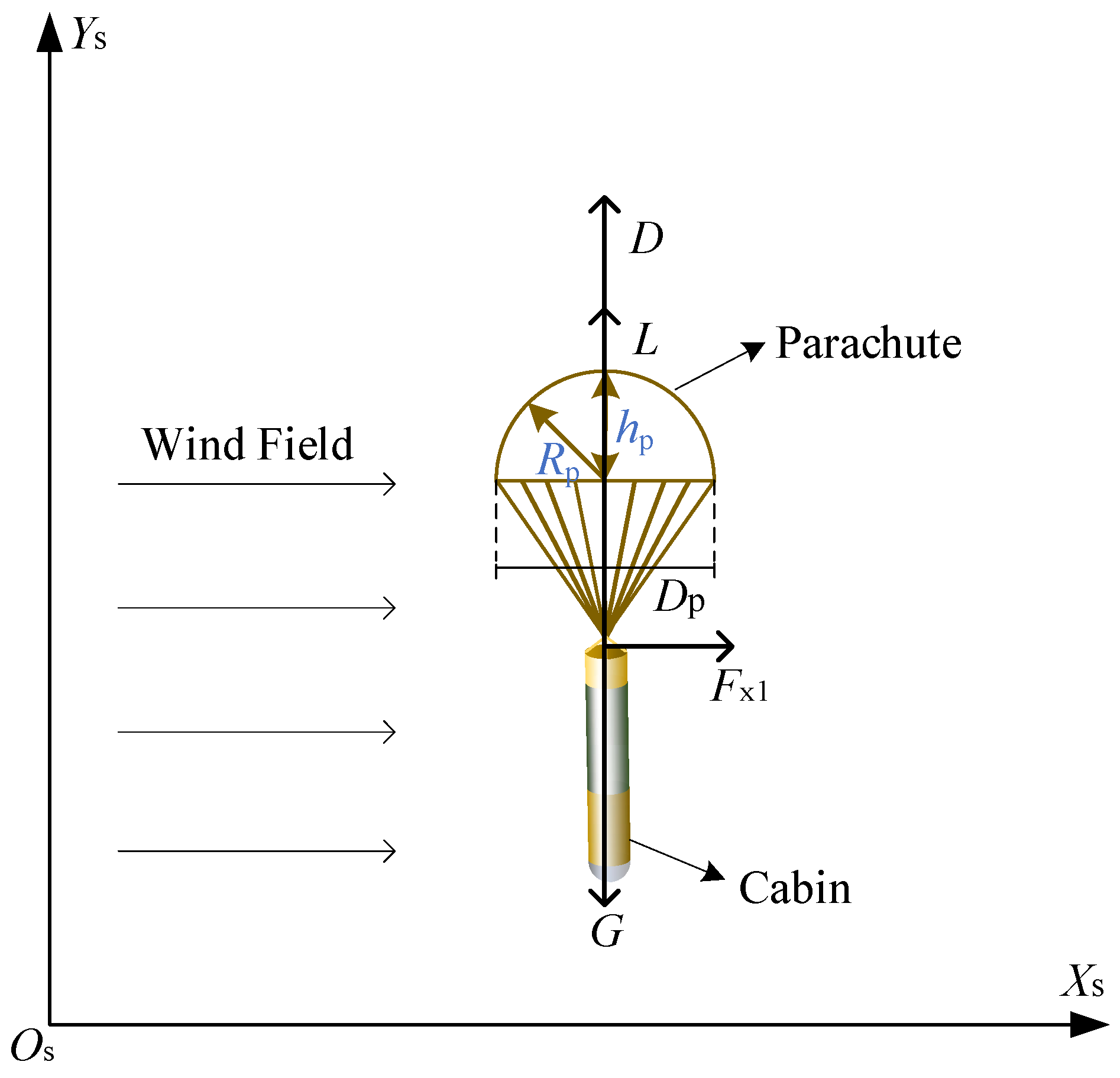

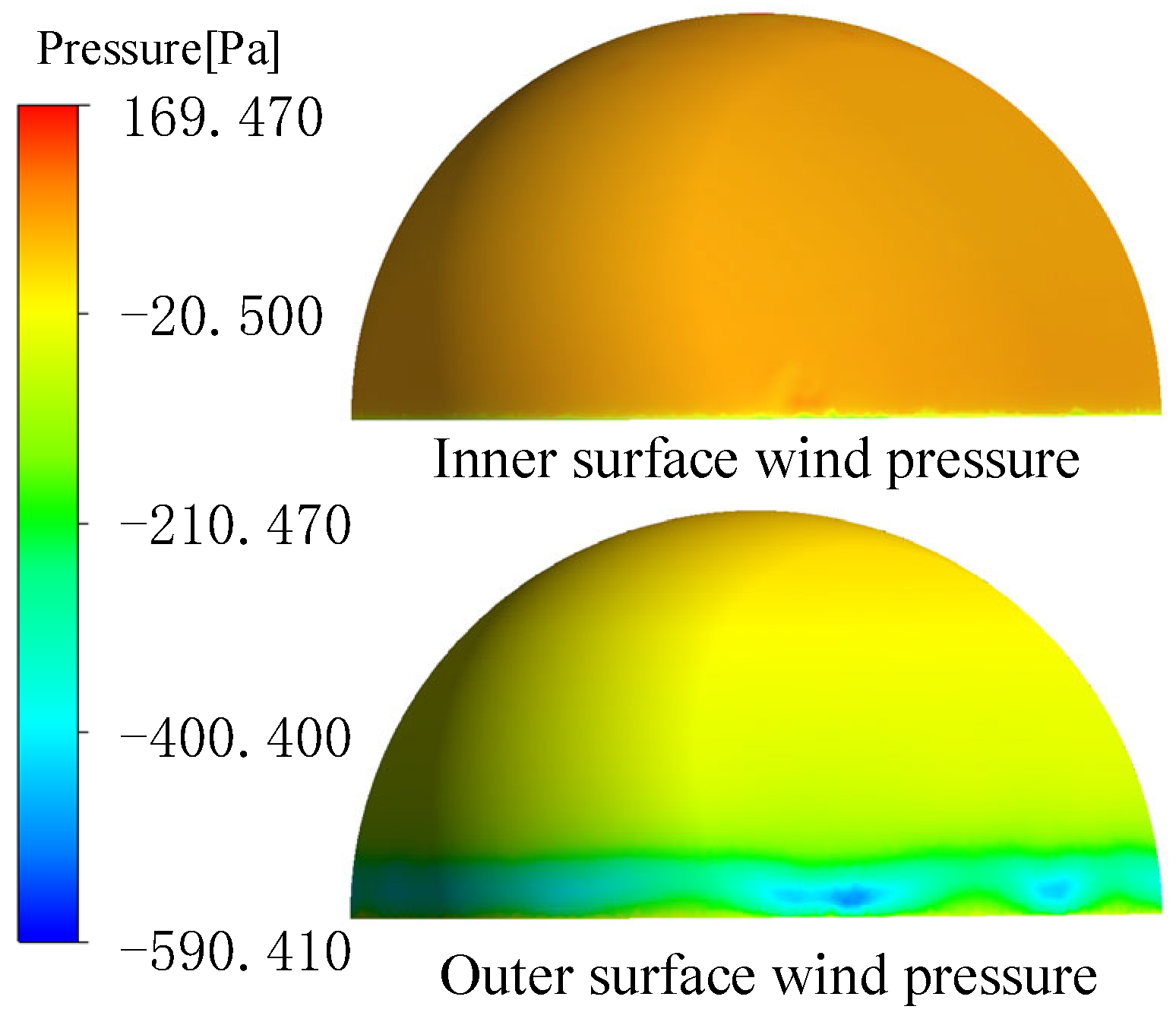

2.2. Dynamic Model of Parachute

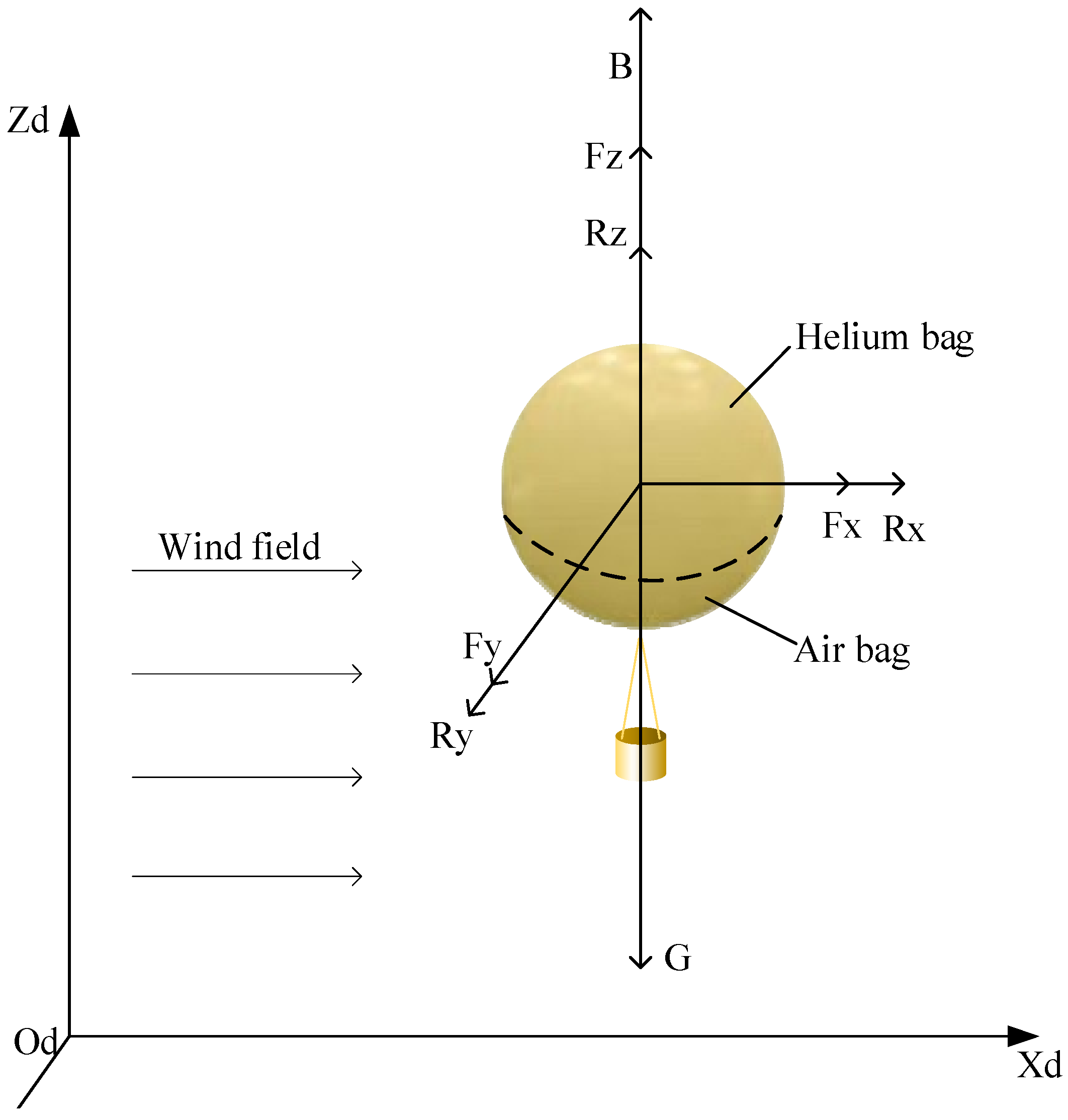

2.3. Model of the Aerostat

Dynamics Model of the Aerostat

2.4. Dynamics Model of the Deployment System

3. Results and Discussion

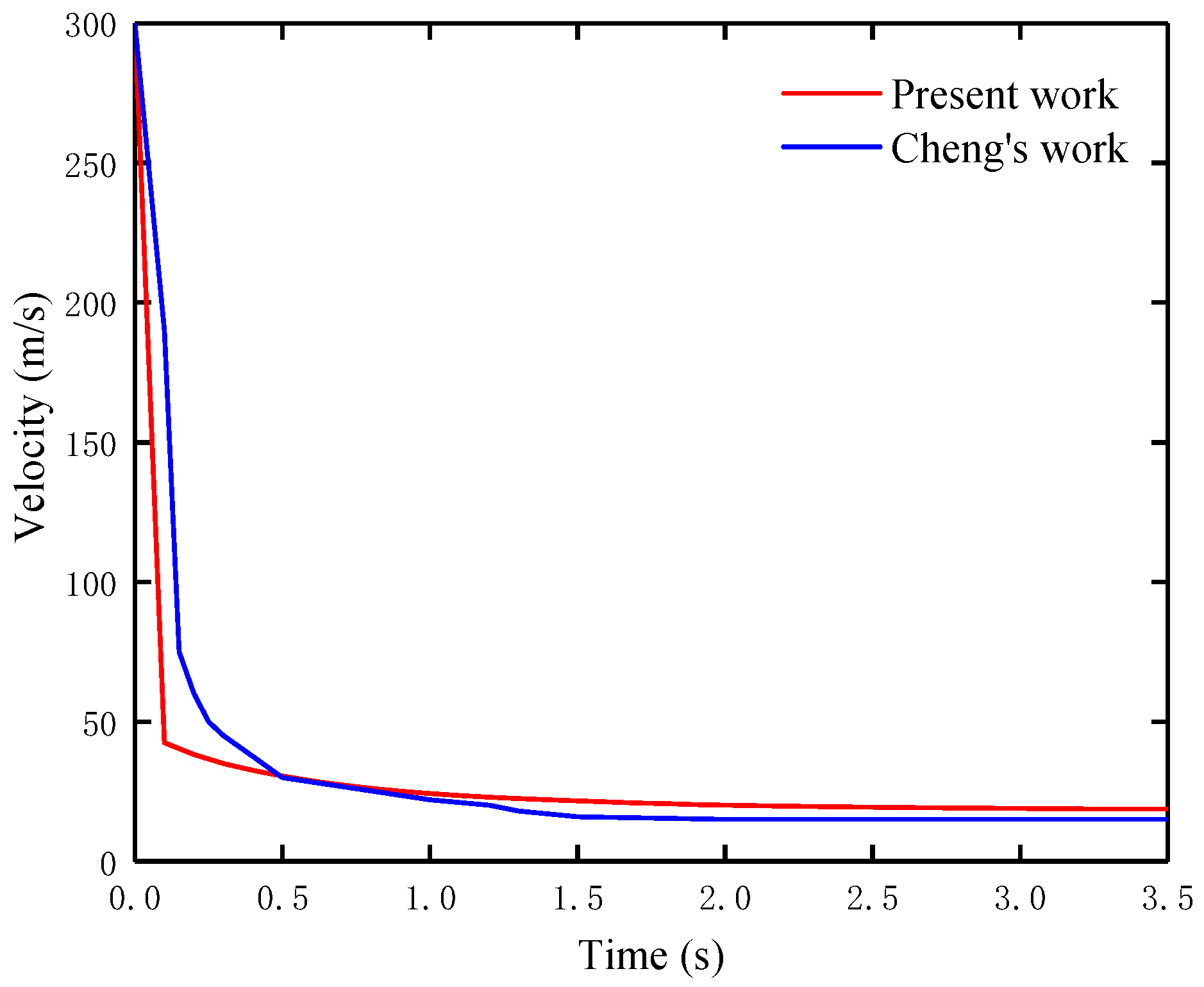

3.1. Model Verification

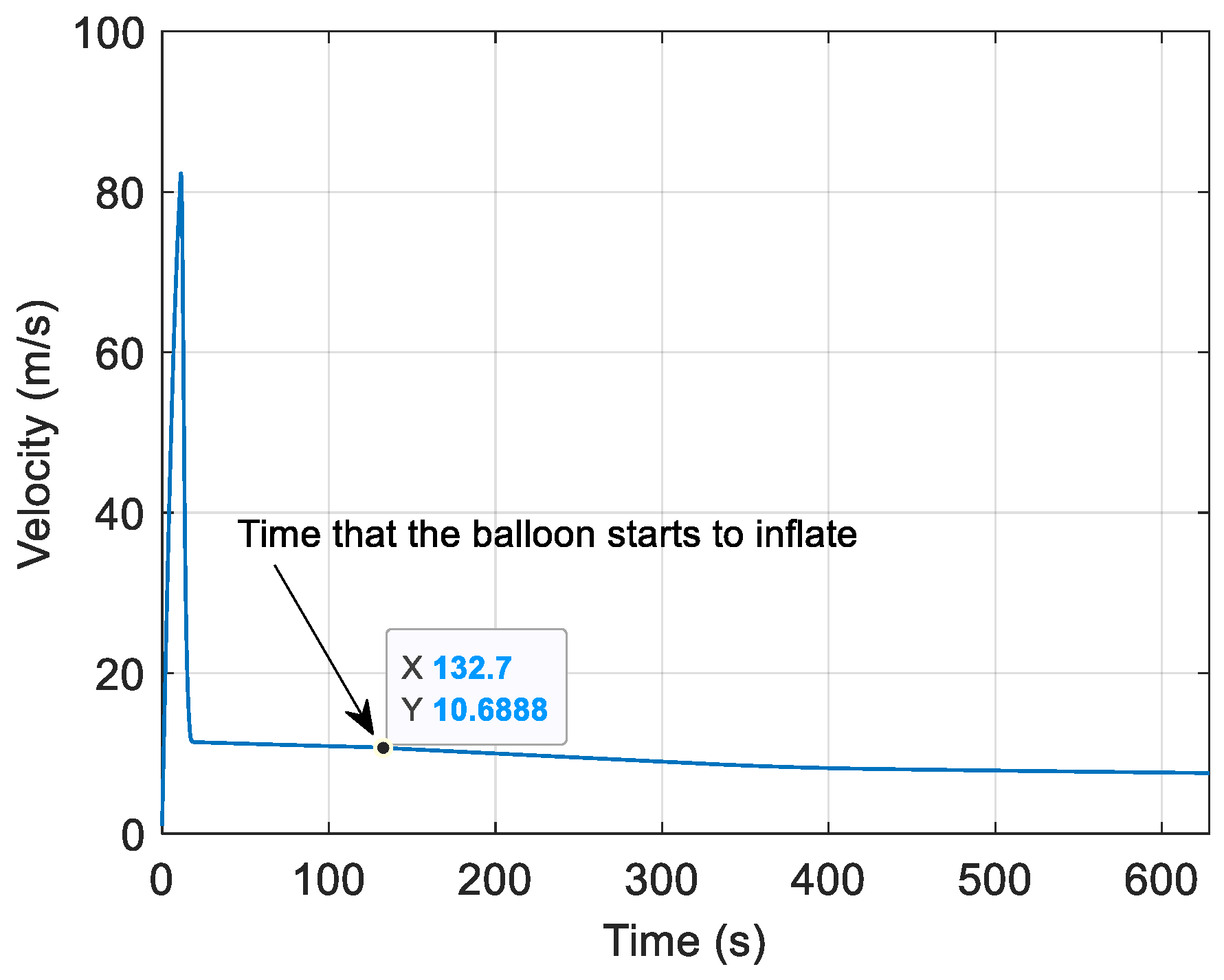

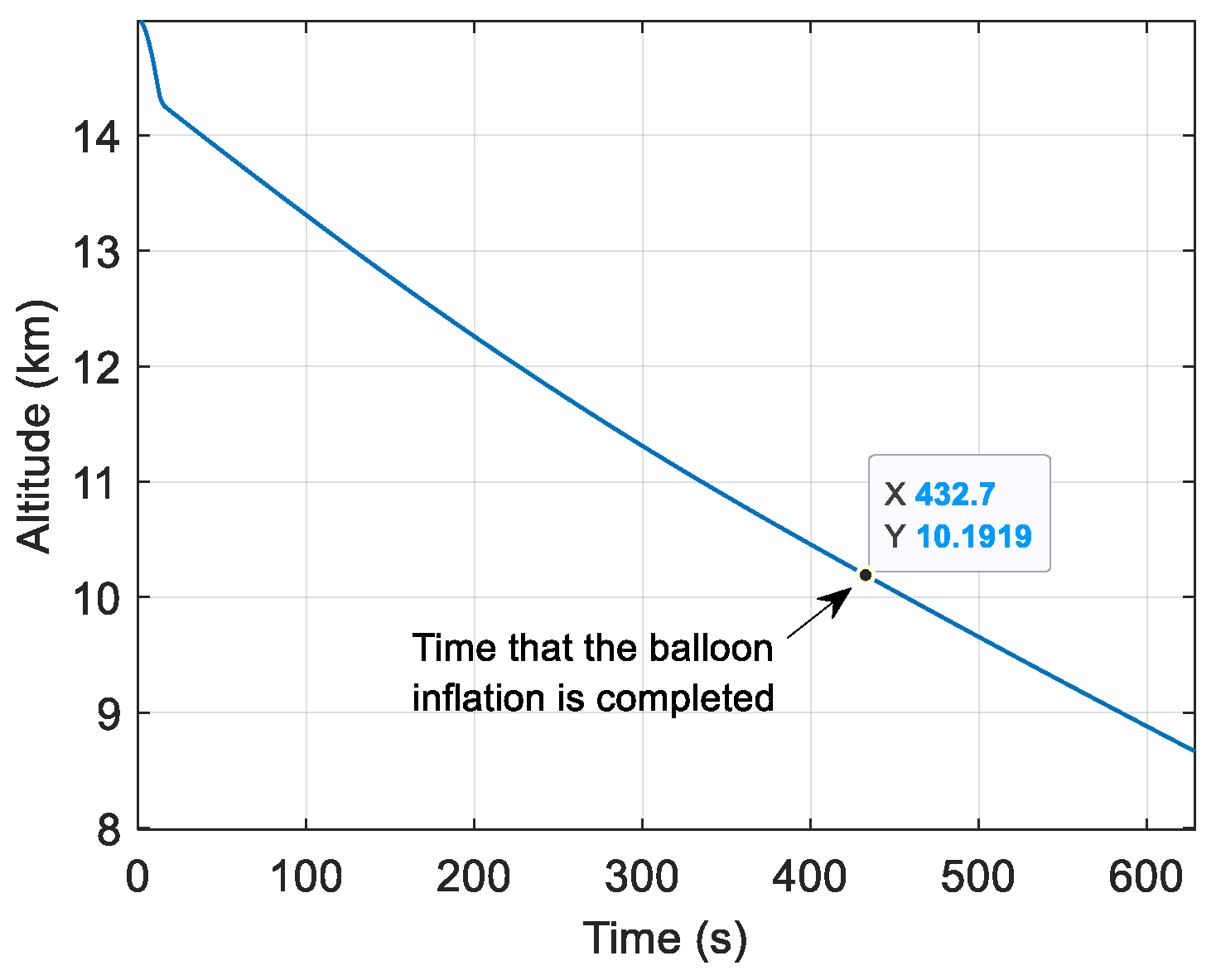

3.2. Simulation and Results

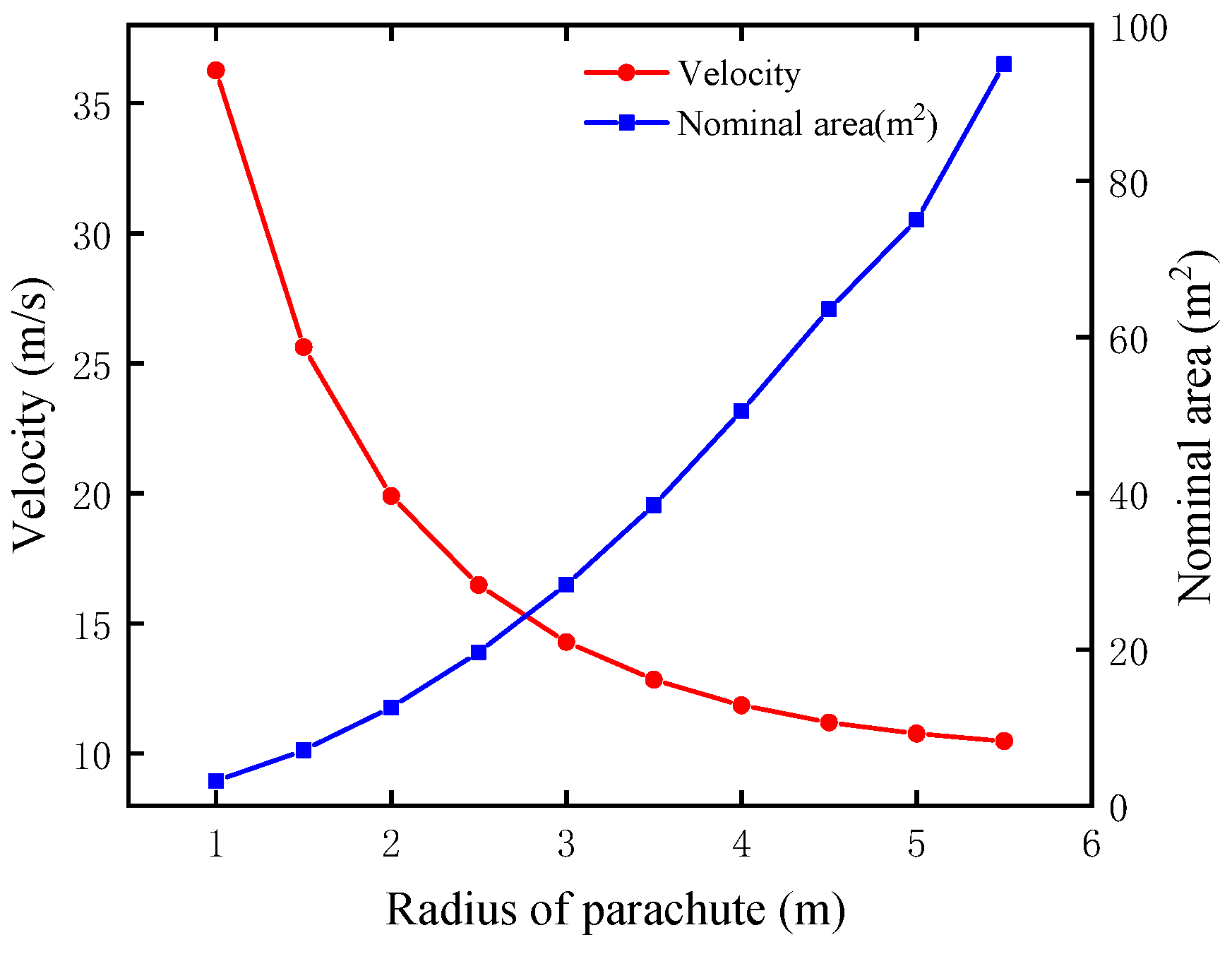

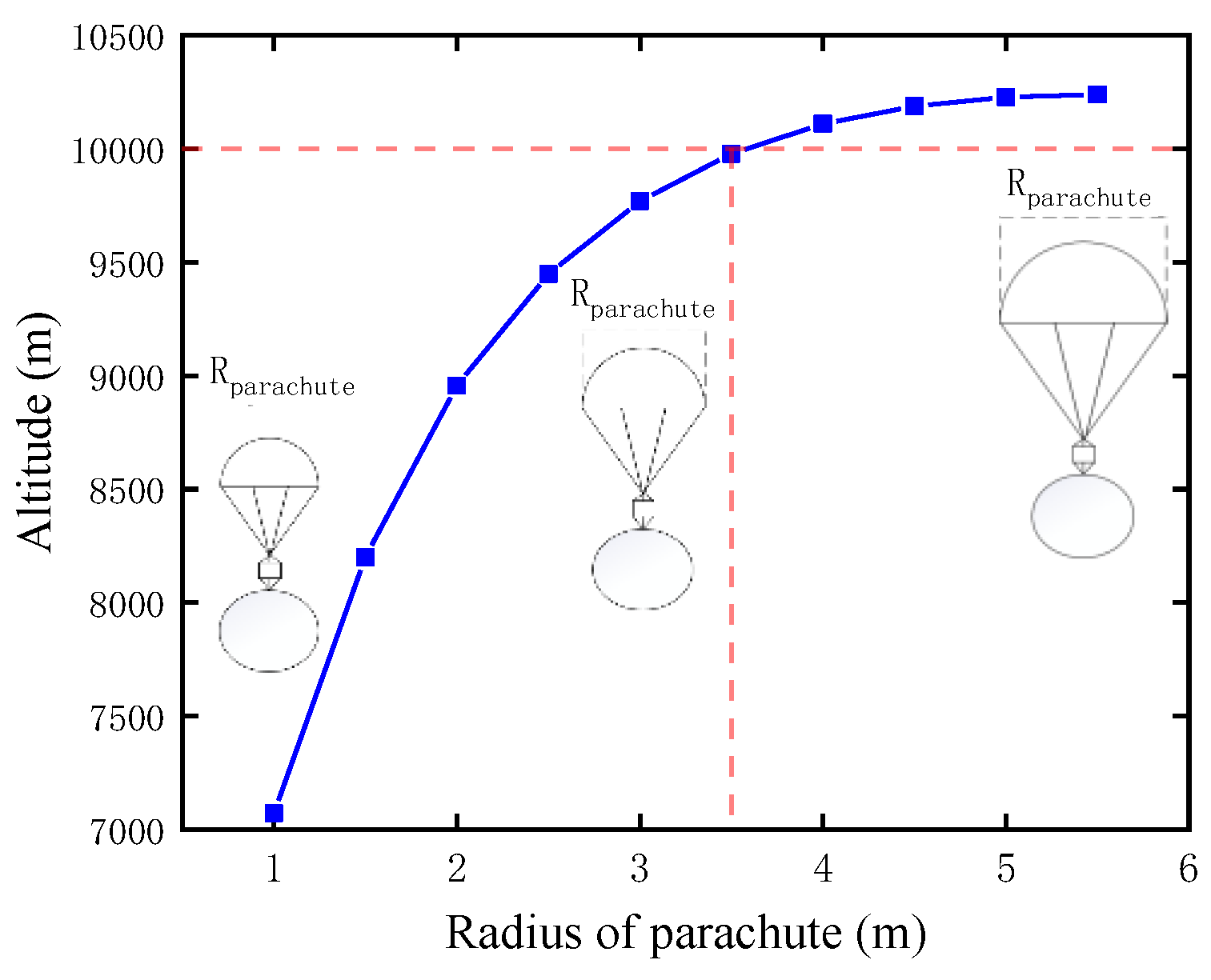

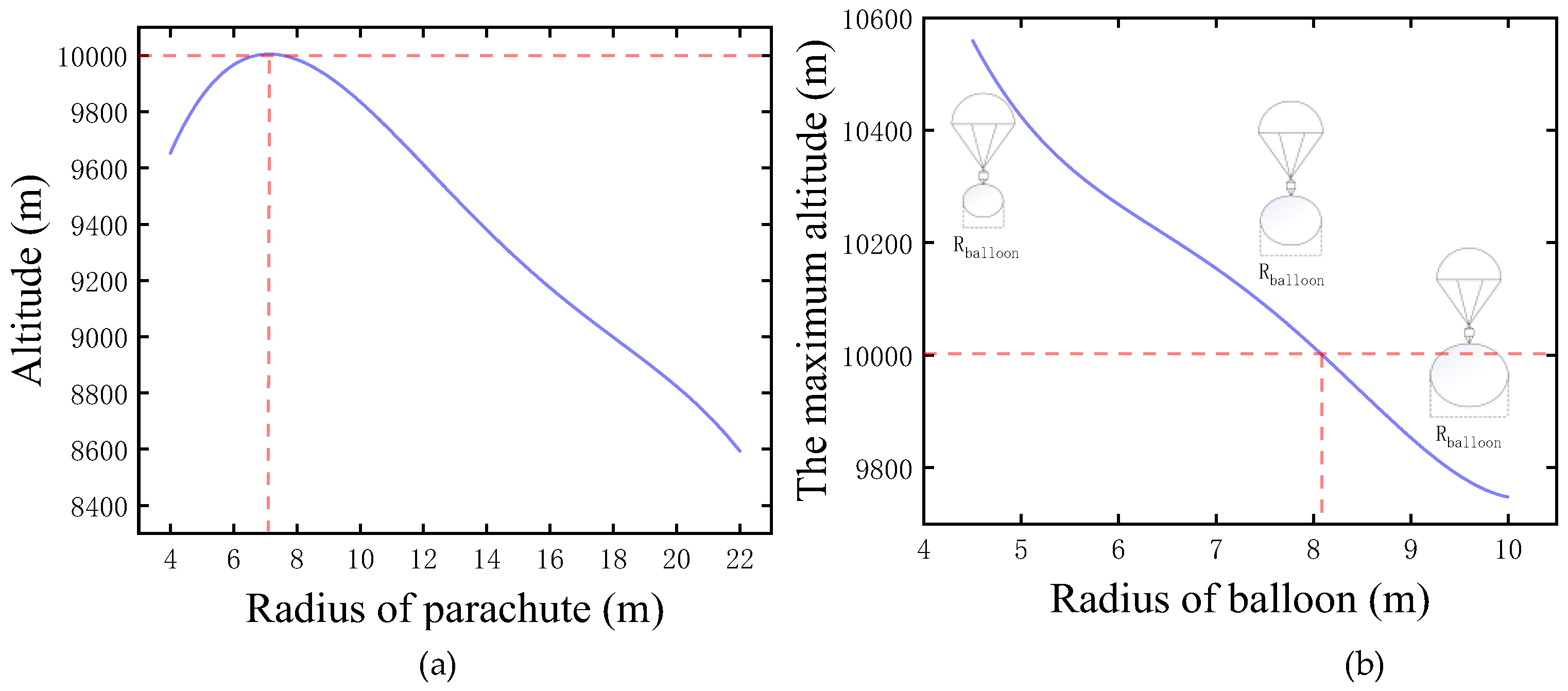

3.2.1. Analysis of the Nominal Radius of the Parachute

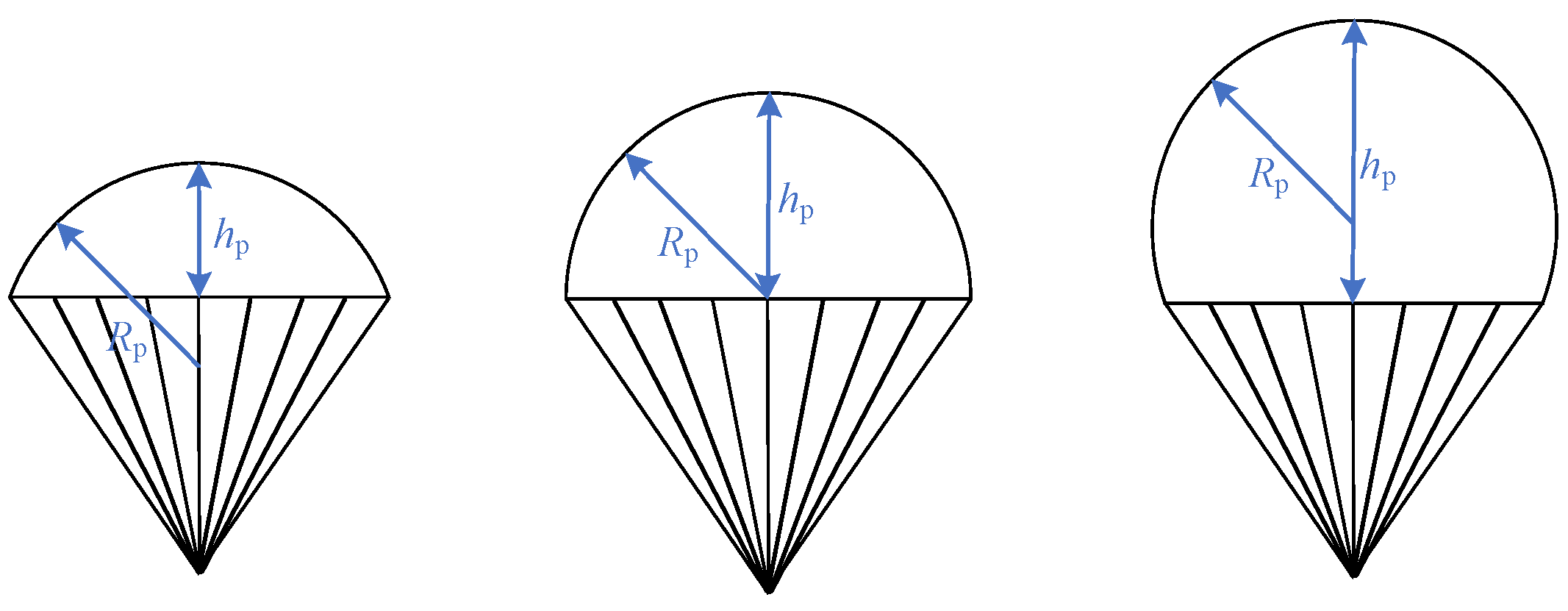

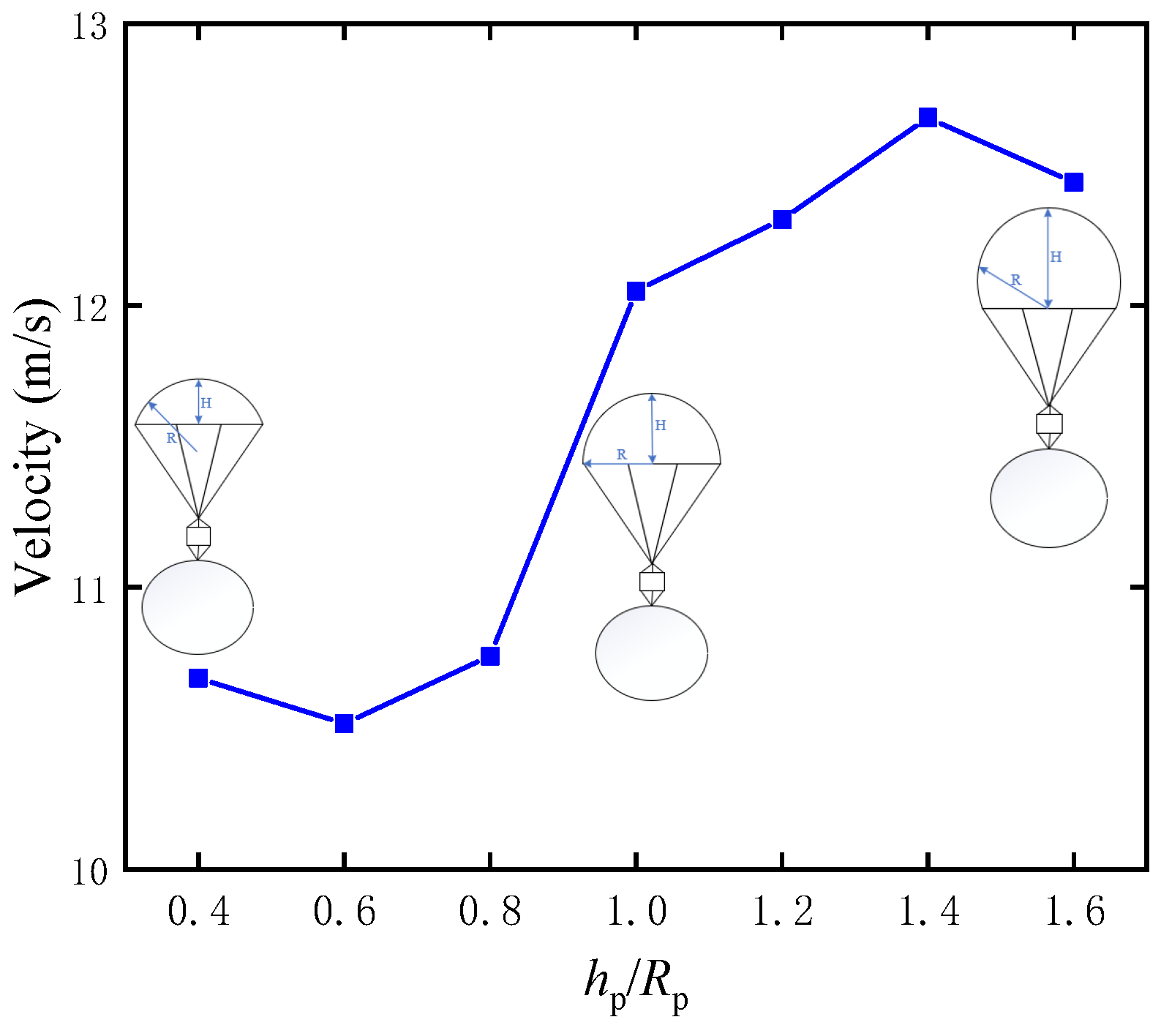

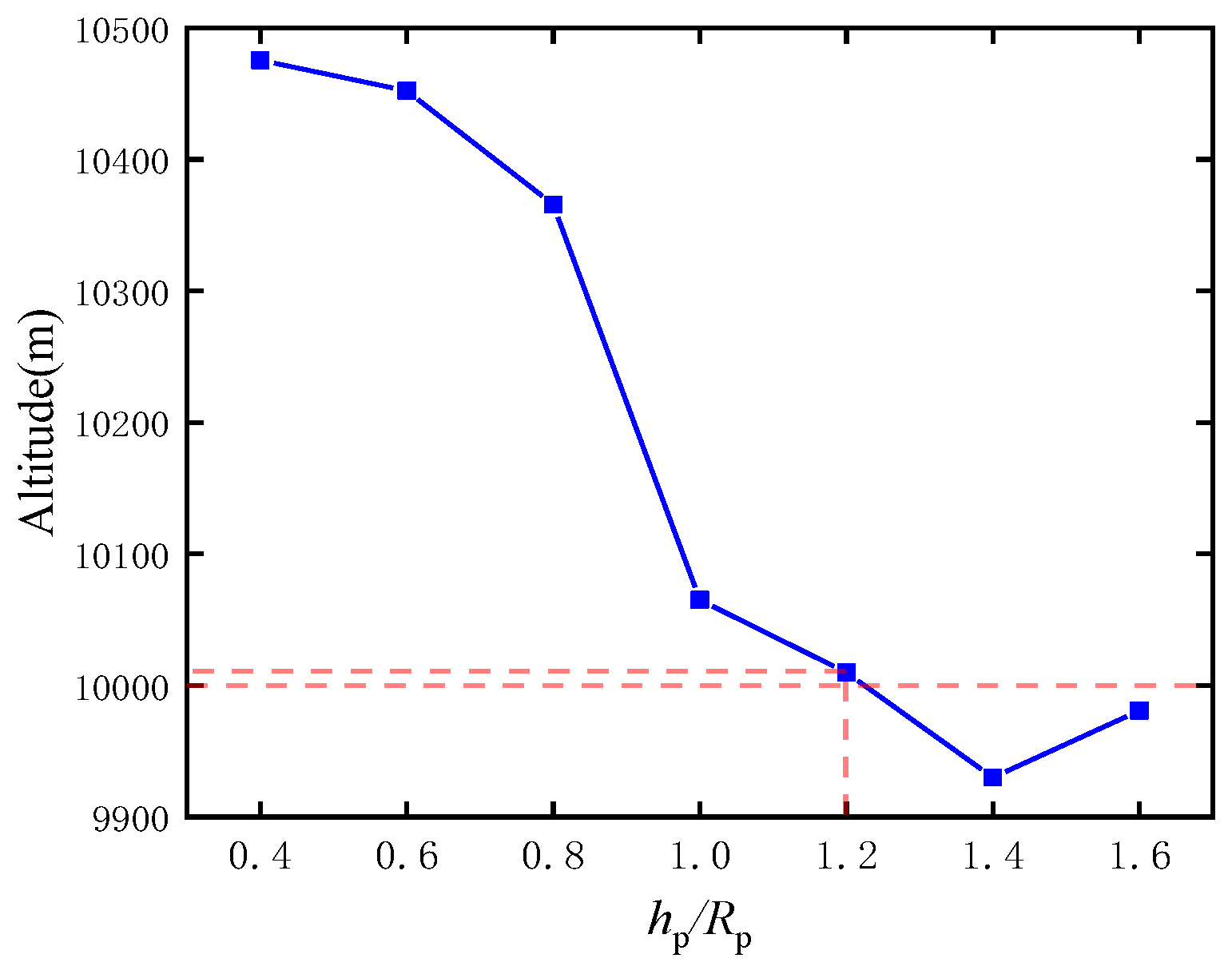

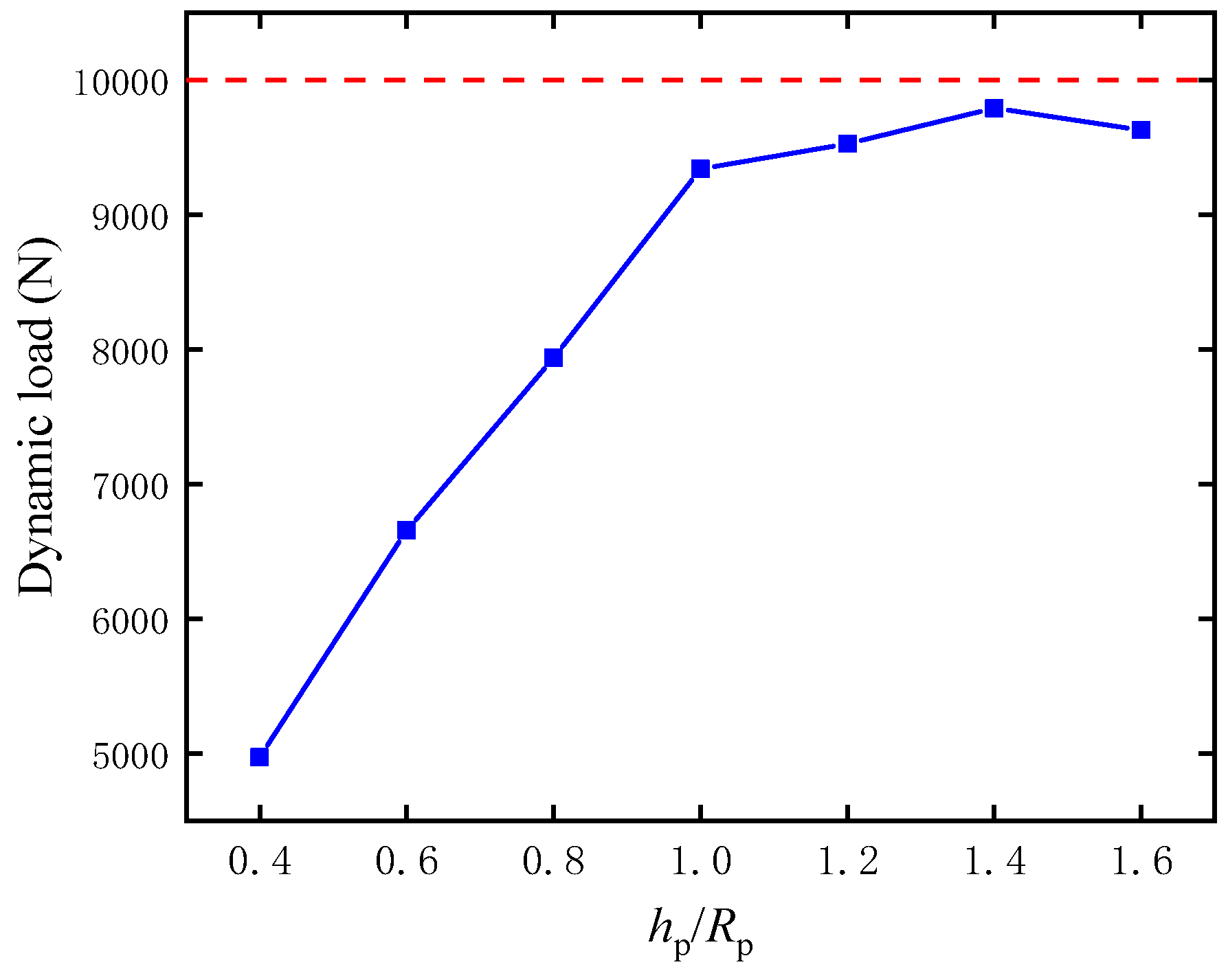

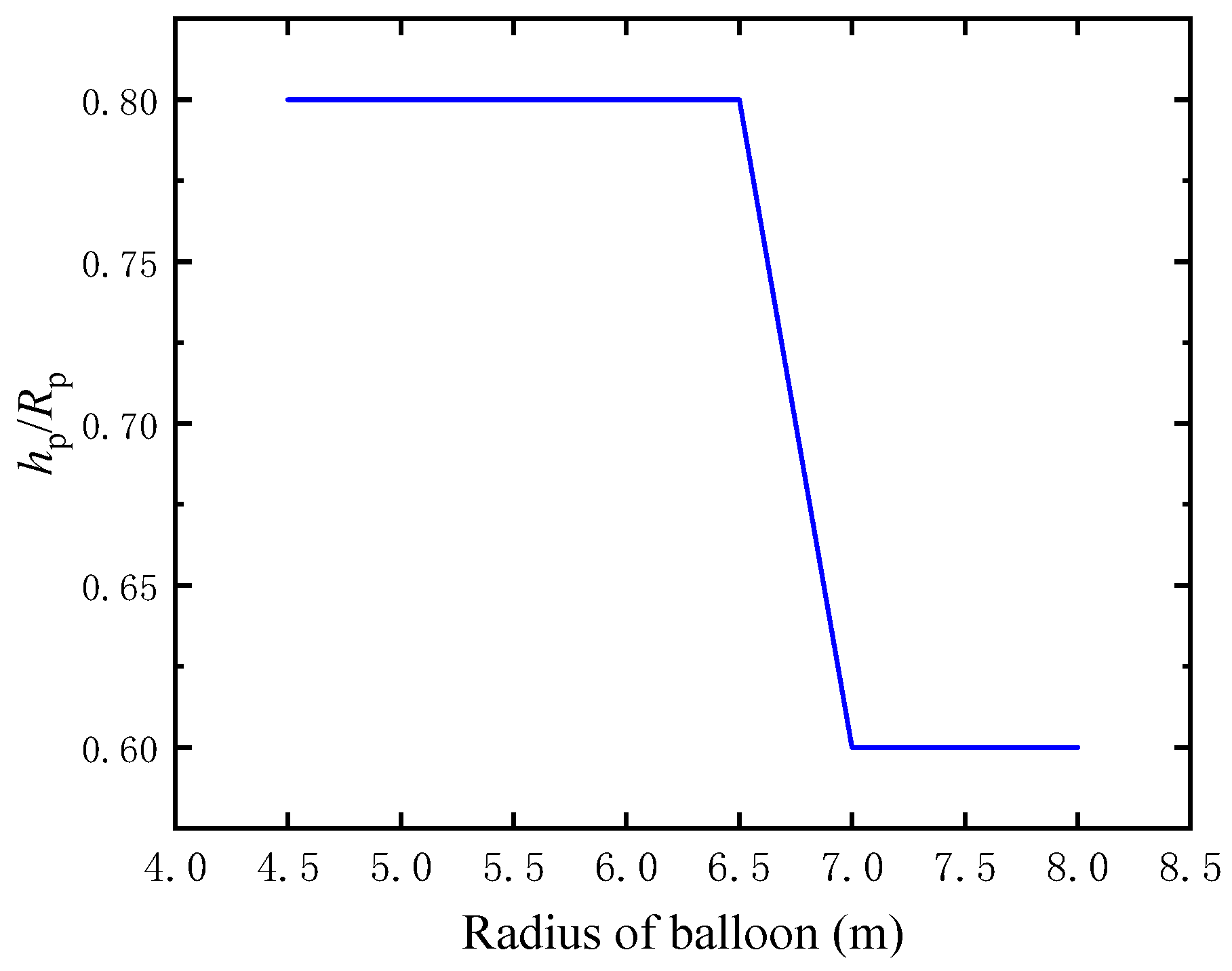

3.2.2. Analysis of the Rise–Radius Ratio of the Parachute

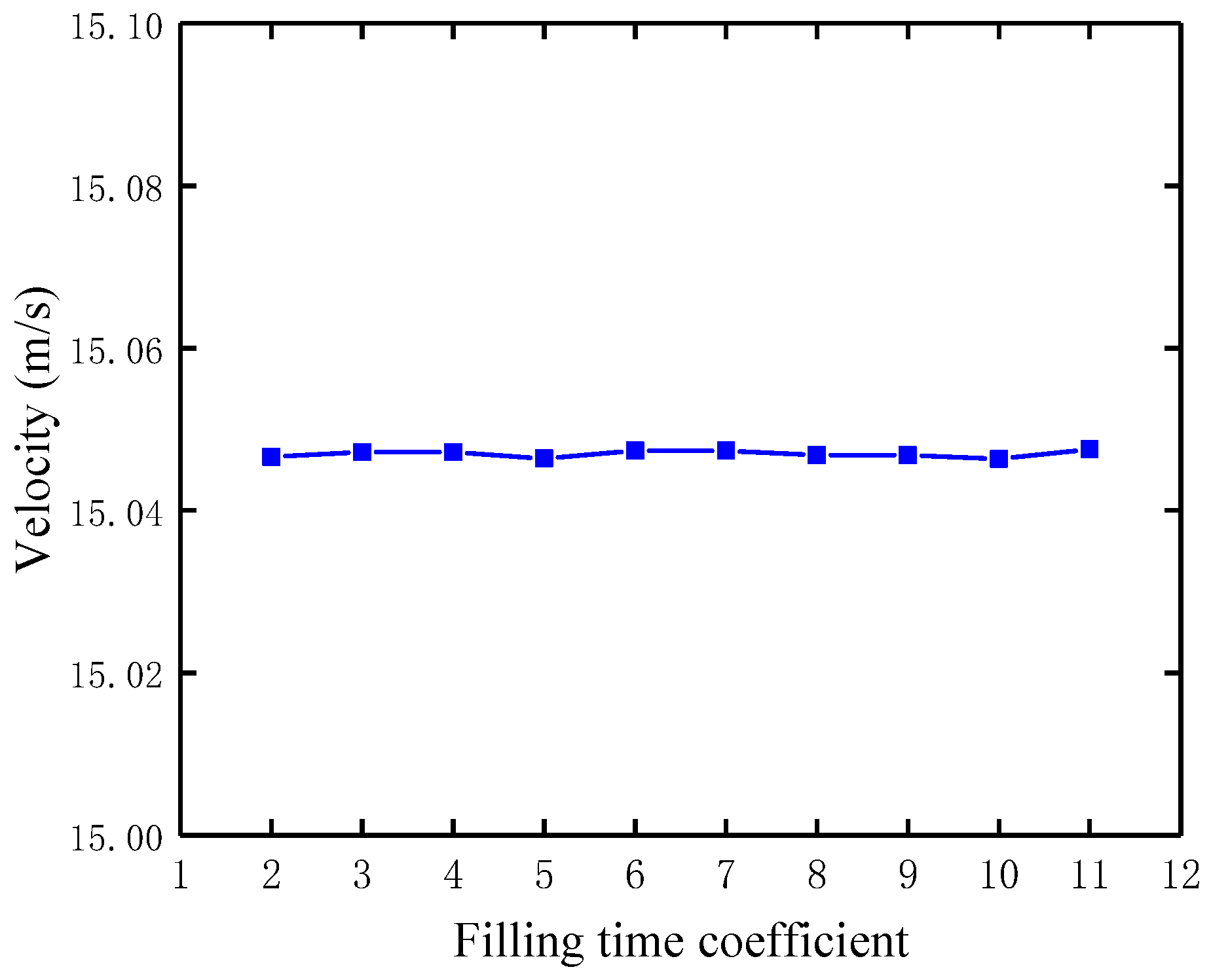

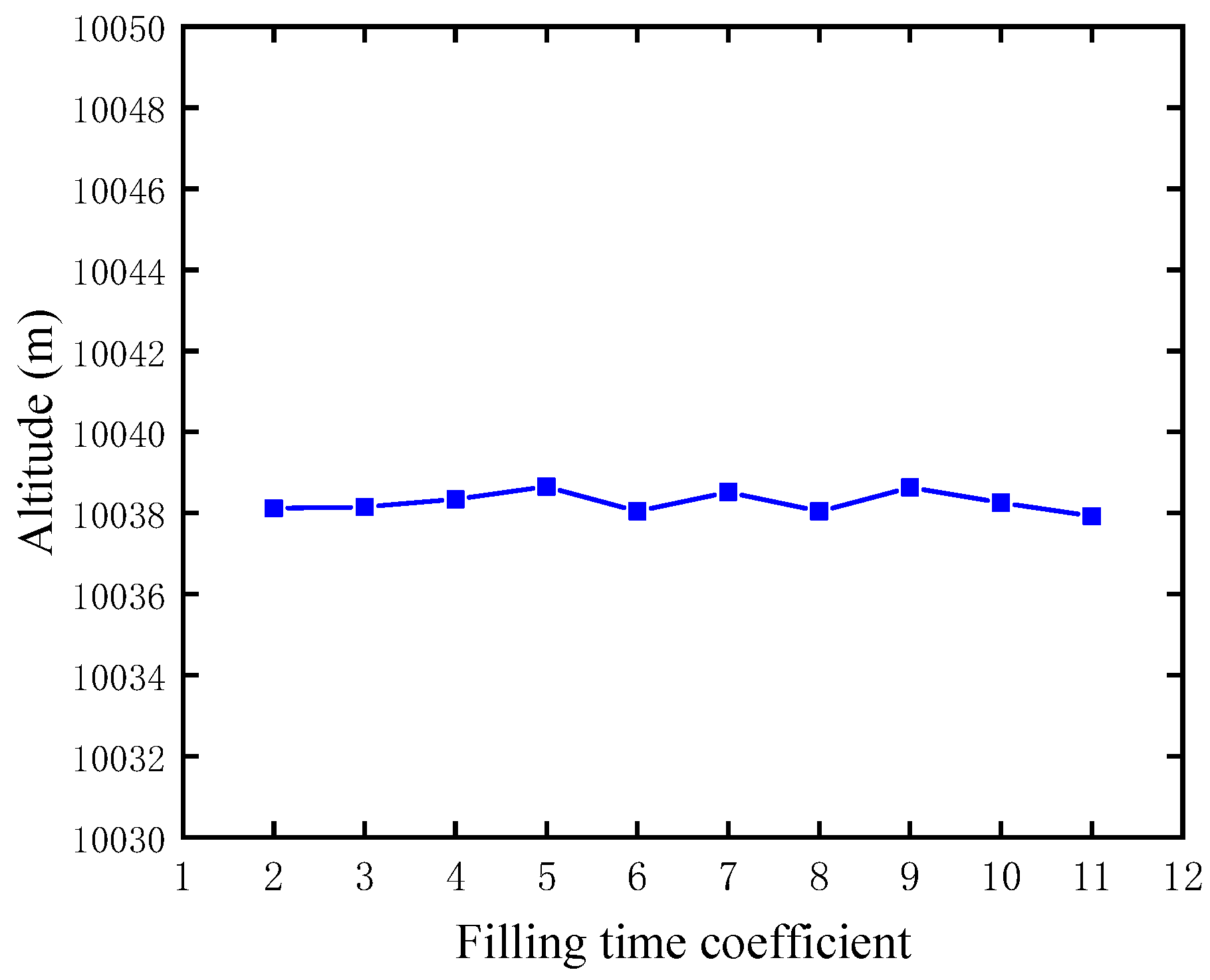

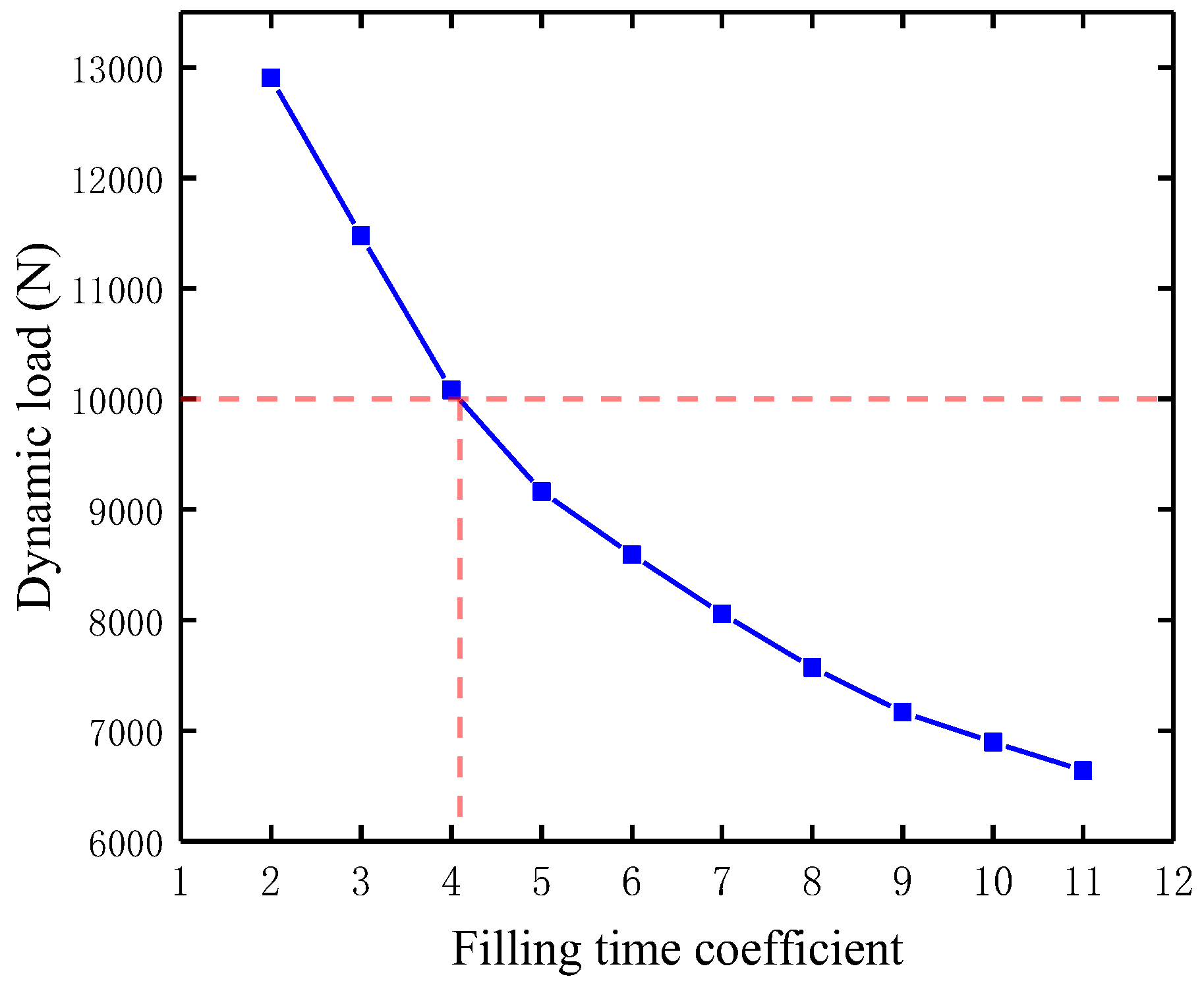

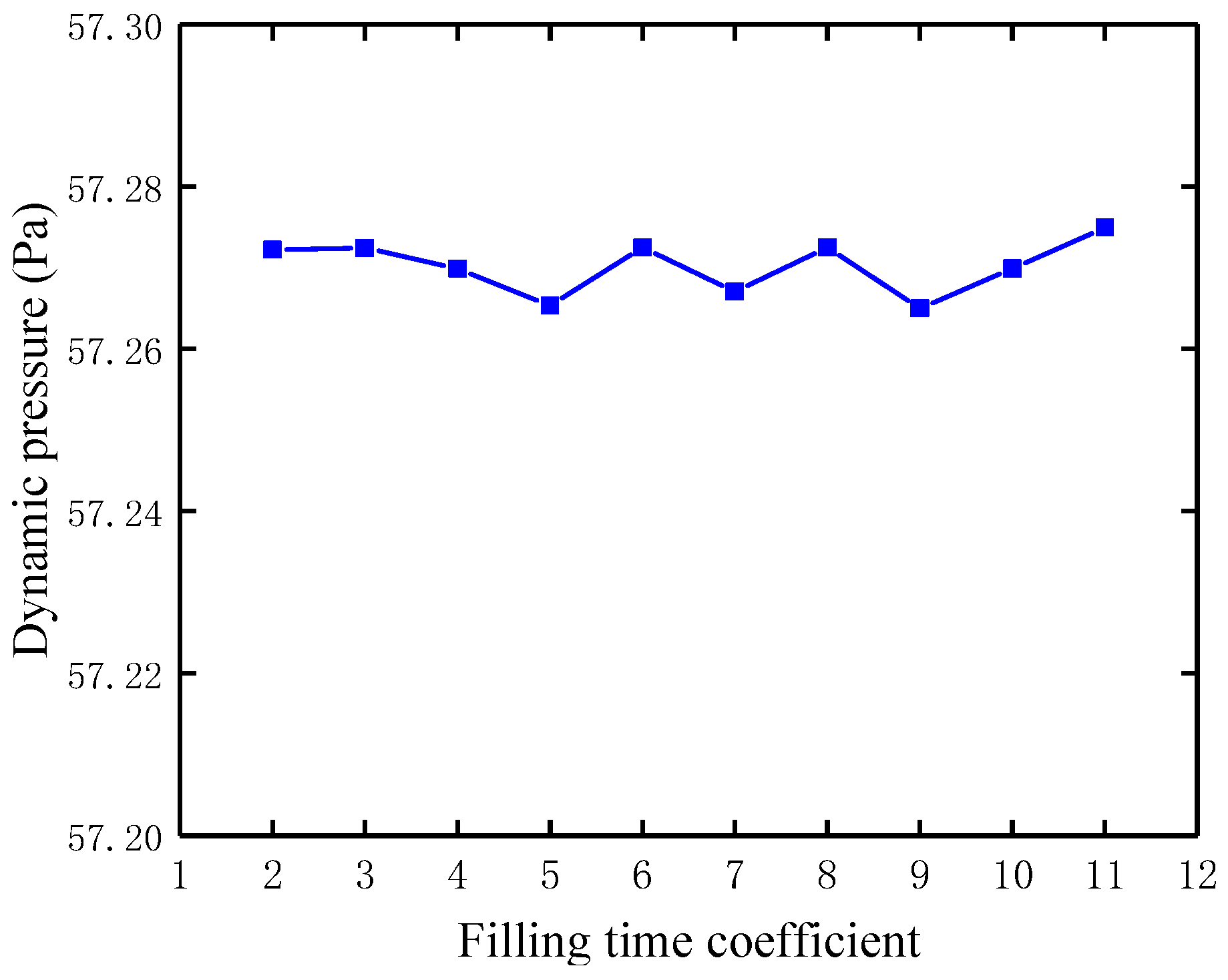

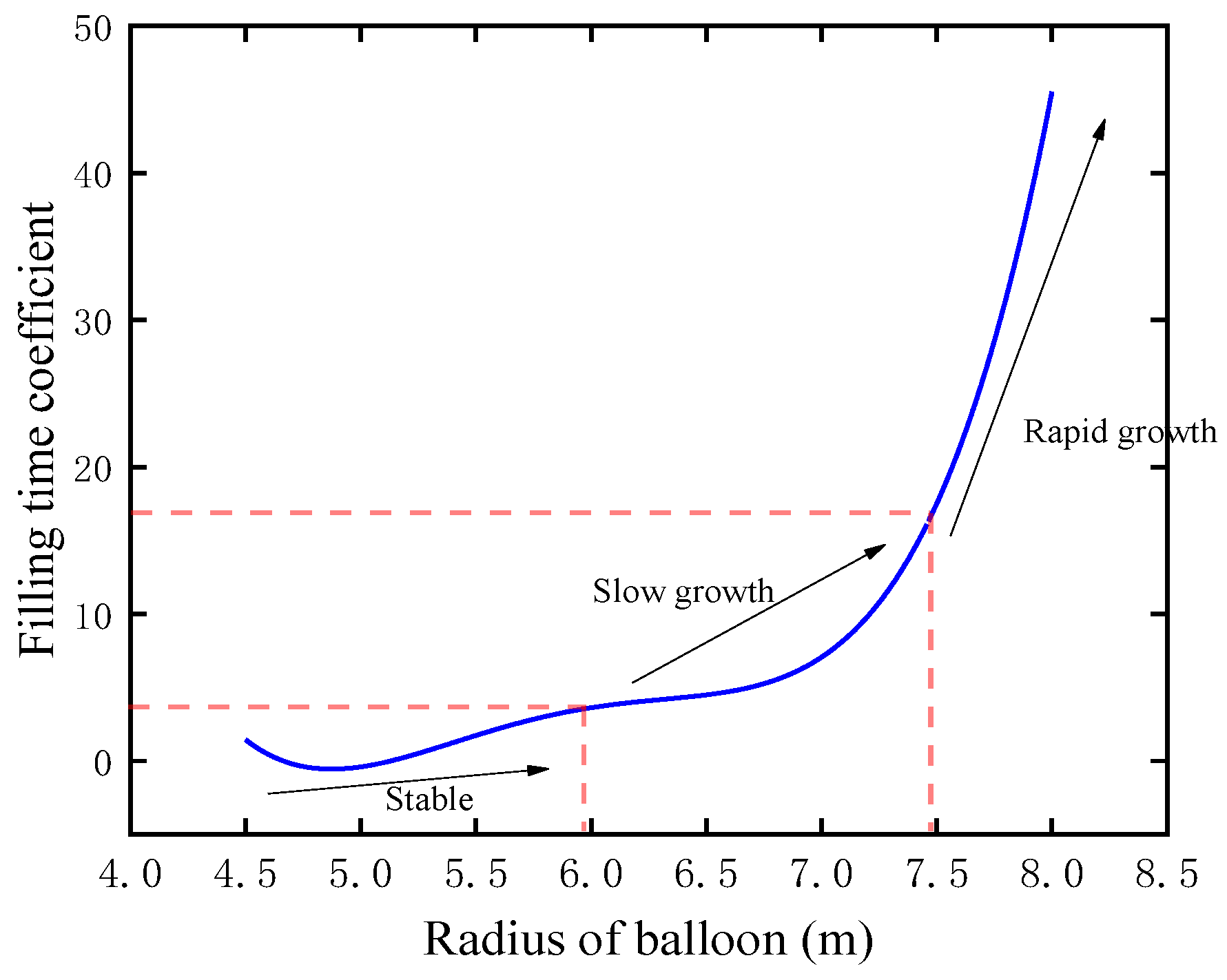

3.2.3. Analysis of the Filling-Time Coefficient of the Parachute

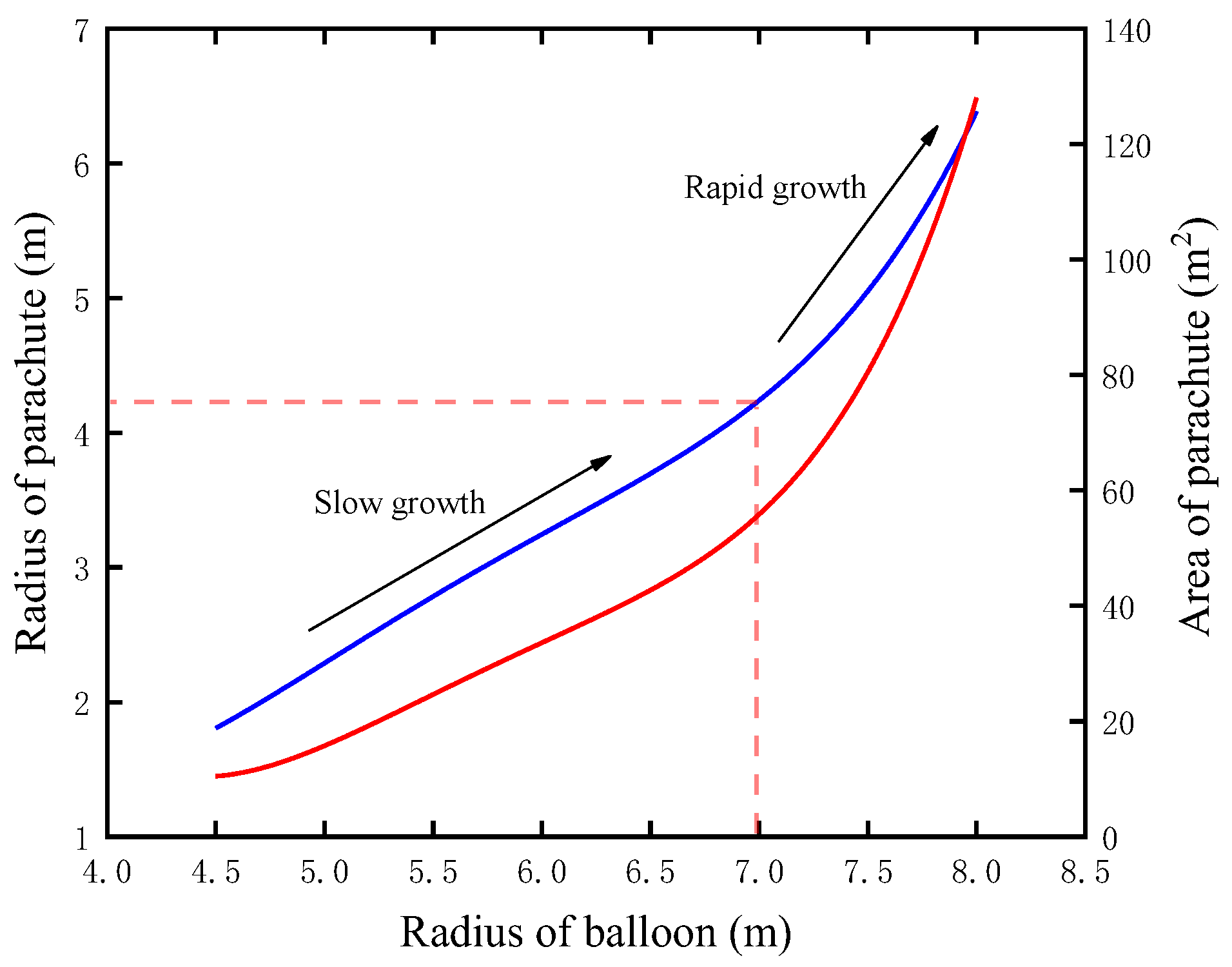

3.2.4. Design of the Parachute for Different Aerostats

4. Conclusions

- Increasing the radius enhances the deceleration effectiveness but raises the maximum dynamic loads and the cost of the parachute. When the nominal radius increases from 1 m to 5.5 m, the velocity when the balloon begins to inflate deceases from 36 m/s to about 10 m/s.

- The rise–radius ratio significantly affects the drag characteristic of the parachute, which means that it significantly affects the deceleration performance of the parachute. The drag characteristic reaches its maximum at about 86 m2 when hp/Rp is 0.8.

- The increase in the filling-time coefficient will lead to a significant reduction in the dynamic load of the parachute. The maximum dynamic load drops from approximately 12,800 N to 9000 N when the filling-time coefficient increases from 2 to 11.

- The system cannot be deployed above 10 km by changing the parachute radius when the balloon radius exceeds 8 m. A larger filling-time coefficient is required as the radius of balloon increases. A parachute with hp/Rp = 0.8 for the radius of a balloon below 6.5 m and an hp/Rp = 0.6 for the radius of a balloon over 6.5 m is recommended.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Ling, L.; Liao, J.; Chen, Z.; Luo, S. Effect of Lifting Gas Diffusion on the Station-Keeping Performance of a Near-Space Aerostat. Aerospace 2022, 9, 328. [Google Scholar] [CrossRef]

- Anoop, S.; Velamati, R.K.; Oruganti, V.R.M. Aerodynamic characteristics of an aerostat under unsteady wind gust conditions. Aerosp. Sci. Technol. 2021, 113, 106684. [Google Scholar] [CrossRef]

- Zuo, Z.; Song, J.; Zheng, Z.; Han, Q.-L. A survey on modelling, control and challenges of stratospheric airships. Control Eng. Pract. 2022, 119, 104979. [Google Scholar] [CrossRef]

- Riboldi, C.E.; Rolando, A. Thrust-based stabilization and guidance for airships without thrust-vectoring. Aerospace 2023, 10, 344. [Google Scholar] [CrossRef]

- Zhang, L.; Li, J.; Jiang, Y.; Du, H.; Zhu, W.; Lv, M. Stratospheric airship endurance strategy analysis based on energy optimization. Aerosp. Sci. Technol. 2020, 100, 105794. [Google Scholar] [CrossRef]

- Shan, C.; Sun, K.; Ji, X.; Cheng, D. A reconfiguration method for photovoltaic array of stratospheric airship based on multilevel optimization algorithm. Appl. Energy 2023, 352, 121881. [Google Scholar] [CrossRef]

- Jiang, Y.; Lv, M.; Chen, X.; Wu, Y. An optimization approach for improving the solar array output power of stratospheric aerostat. Aerosp. Sci. Technol. 2021, 118, 106916. [Google Scholar] [CrossRef]

- Jiang, Y.; Lv, M.; Sun, K. Effects of installation angle on the energy performance for photovoltaic cells during airship cruise flight. Energy 2022, 258, 124982. [Google Scholar] [CrossRef]

- Xie, M.; Long, Y.; Deng, X.; Yang, X. Station-keeping of Stratospheric Aerostat with Receding Horizon Tree Search Planning Method. J. Phys. Conf. Ser. 2022, 2410, 012008. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, M.; Chen, T.; Zheng, Z. Distributed event-triggered fixed-time formation and trajectory tracking control for multiple stratospheric airships. ISA Trans. 2022, 130, 63–78. [Google Scholar] [CrossRef]

- Yang, X.; Yang, X.; Deng, X. Horizontal trajectory control of stratospheric airships in wind field using Q-learning algorithm. Aerosp. Sci. Technol. 2020, 106, 106100. [Google Scholar] [CrossRef]

- Yuan, J.; Guo, X.; Zheng, Z.; Zhu, M.; Gou, H. Error-constrained fixed-time trajectory tracking control for a stratospheric airship with disturbances. Aerosp. Sci. Technol. 2021, 118, 107055. [Google Scholar] [CrossRef]

- Shi, Z.; Huo, W.; Zuo, Z. Motion-pressure coupled control and simulation of long-endurance capability for multicapsule stratospheric airships. Chin. J. Aeronaut. 2024, 37, 137–150. [Google Scholar] [CrossRef]

- Zhou, R.; Li, J.; Yang, Z.; Xu, Y.; Yu, Z.; Zhang, Y. Fractional-Order Sliding-Mode Fault-Tolerant Control of Unmanned Airship Against Actuator Faults. IFAC-PapersOnLine 2022, 55, 617–622. [Google Scholar] [CrossRef]

- Jiang, Y.; Lv, M.; Wang, C.; Meng, X.; Ouyang, S.; Wang, G. Layout optimization of stratospheric balloon solar array based on energy production. Energy 2021, 229, 120636. [Google Scholar] [CrossRef]

- Sun, P.; Long, F.; Cheng, H. Experimental and numerical study on rapid inflation process of air-launched balloon. Ind. Textila 2022, 73, 268–274. [Google Scholar] [CrossRef]

- Babu, K.K.; Pant, R.S. A review of Lighter-than-Air systems for exploring the atmosphere of Venus. Prog. Aerosp. Sci. 2020, 112, 100587. [Google Scholar] [CrossRef]

- Bai, Y.; Kang, R.; Gao, Y.; Fu, W. The design of aerostat platform system’s parameters which is launched form a ballistic missile. In Proceedings of the 2018 IEEE CSAA Guidance, Navigation and Control Conference (CGNCC), Xiamen, China, 10–12 August 2018. [Google Scholar]

- Gatto, V.L.; Izraelevitz, J.S.; Pauken, M.T.; Goel, A.; Lam, R.; Hall, J.L. Inflation sequence tradeoffs and laboratory demonstration of a prototype variable-altitude venus aerobot. Acta Astronaut. 2024, 214, 757–773. [Google Scholar] [CrossRef]

- El-Sadi, H.; Kruzyk, E.; Ashik, K.; Alcantara, C. Study the Effect of the Diameter of Annular Parachute on Drag Using CFD. Available online: https://avestia.com/MCM2023_Proceedings/files/paper/HTFF/HTFF_148.pdf (accessed on 3 July 2024).

- Tripathy, S. Aerodynamics of Parachutes of Different Configurations and Sizes. 2023. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4499469 (accessed on 9 November 2024).

- Cheng, H.; Ouyang, Y.; Zhang, Y.; Pan, J. Research on the influence of length-width ratio on cruciform parachute airdropping performance. J. Ind. Text. 2022, 51 (Suppl. 5), 7694S–7713S. [Google Scholar] [CrossRef]

- López, D.; Domínguez, D.; Delgado, A.; García-Gutiérrez, A.; Gonzalo, J. Experimental Calculation of Added Masses for the Accurate Construction of Airship Flight Models. Aerospace 2024, 11, 872. [Google Scholar] [CrossRef]

- Pepermans, L.; Britting, T.; Jodehl, J.; Menting, E.; Sujahudeen, M. Architectures for parachute testing. J. Space Saf. Eng. 2023, 10, 35–44. [Google Scholar] [CrossRef]

- Hou, X.-Y.; Hu, J.; Yu, Y. Numerical study on ring slot parachute finite mass inflation process and wake recontact phenomenon. Aerosp. Sci. Technol. 2022, 128, 107763. [Google Scholar] [CrossRef]

- Nie, S.; Yu, L.; Sun, Z.; Wu, Z. Analytical model for the air permeability of parachute fabric and structure parameters sensitivity analysis. J. Text. Inst. 2022, 113, 761–768. [Google Scholar] [CrossRef]

- Cao, Y.; Wei, N. Flight trajectory simulation and aerodynamic parameter identification of large-scale parachute. Int. J. Aerosp. Eng. 2020, 2020, 5603169. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Yu, L.; Masarati, P.; Qiu, B.W. New general correlations for opening shock factor of ram-air parachute airdrop system. Aerosp. Sci. Technol. 2022, 129, 107844. [Google Scholar] [CrossRef]

- An, W.; Lin, T.; Wang, S. Optimal structural design for a certain near-space composite propeller of airship using adaptive region division blending model. Chin. J. Aeronaut. 2023, 37, 301–316. [Google Scholar] [CrossRef]

- Sun, L.; Sun, K.; Guo, X.; Yuan, J.; Zhu, M. Prescribed-time error-constrained moving path following control for a stratospheric airship with disturbances. Acta Astronaut. 2023, 212, 307–315. [Google Scholar] [CrossRef]

- Zhu, Q.; Tang, X.; Tong, M. Study on unsaturated shapes of helium ballonet of rigid airship during ascent process. Aerosp. Sci. Technol. 2021, 118, 107001. [Google Scholar] [CrossRef]

- Manikandan, M.; Pant, R.S. Research and advancements in hybrid airships—A review. Prog. Aerosp. Sci. 2021, 127, 100741. [Google Scholar]

- Wachlin, J.; Ward, M.; Pacheco, J.; Costello, M. Design and testing of an ultra-low-power persistent parachute use logger. Aerosp. Sci. Technol. 2023, 132, 108017. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, W.; Hou, Z. Improved thermal and vertical trajectory model for performance prediction of stratospheric balloons. J. Aerosp. Eng. 2015, 28, 04014075. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Atmospheric model | GB1920-80 | Skin thermal emissivity | 0.78 |

| Wind field location | A central region in China | Parachute shape | Annular parachute |

| Deployment method | Air-based or missile-based | Surface density of parachute, g/m2 | 75 |

| Velocity of system delivery, m/s | 0 | Velocity of parachute opening m/s | 80 |

| Release altitude, km | 15 | Percentage of the critical dynamic load | 40% |

| Time of balloon inflation, s | 300 | Maximum dynamic load, N | 10,000 |

| Skin thickness, mm | 0.7 | Inflation gas | Helium |

| Skin areal density, g/m2 | 50 | Types of gas cylinders | Composite high-pressure gas cylinder |

| Balloon skin density, kg/m3 | 2190 | Gas cylinder pressure, Mpa | 70 |

| Balloon skin specific heat capacity, J/(kg·K) | 1470 | Inflation pressure, Mpa | 2 |

| Balloon skin thermal conductivity, W/(m·K) | 0.29 | Compressor inlet and outlet flow rate, L/s | 150 |

| Skin thermal absorptivity | 0.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, J.; Mai, Y.; Li, J.; Jiang, Y.; Wang, S.; Zhang, K. Design of the Aerial Deceleration Phase of an Aerostat Considering the Deployment Scale. Aerospace 2025, 12, 481. https://doi.org/10.3390/aerospace12060481

Liao J, Mai Y, Li J, Jiang Y, Wang S, Zhang K. Design of the Aerial Deceleration Phase of an Aerostat Considering the Deployment Scale. Aerospace. 2025; 12(6):481. https://doi.org/10.3390/aerospace12060481

Chicago/Turabian StyleLiao, Jun, Yu Mai, Jun Li, Yi Jiang, Siyuan Wang, and Kai Zhang. 2025. "Design of the Aerial Deceleration Phase of an Aerostat Considering the Deployment Scale" Aerospace 12, no. 6: 481. https://doi.org/10.3390/aerospace12060481

APA StyleLiao, J., Mai, Y., Li, J., Jiang, Y., Wang, S., & Zhang, K. (2025). Design of the Aerial Deceleration Phase of an Aerostat Considering the Deployment Scale. Aerospace, 12(6), 481. https://doi.org/10.3390/aerospace12060481