1. Introduction

Aerodynamic shape design plays a critical role in the aerospace industry, with profound impacts on the performance, fuel efficiency, and environmental sustainability of aircraft. For example, lift augmentation and drag reduction not only directly affect energy consumption and operational costs but also influence system stability, speed, and safety. Therefore, optimizing aerodynamic shapes to improve engineering efficiency and reduce carbon emissions, while ensuring safety and reliability, has become a key area of research. Traditional aerodynamic shape optimization problems are associated with linear and nonlinear partial differential equation (PDE)-based behavior functions. Solving such problems requires repeated evaluations of objective functions and constraints, such as through the nested analysis and design (NAND) approach [

1,

2]. While Computational Fluid Dynamics (CFD) methods provide accurate aerodynamic performance predictions, their computational cost and time consumption are substantial, particularly in high-fidelity simulations and complex flow conditions, which limit the efficiency of optimization and the feasibility of practical applications.

In this context, reduced-order models (ROMs) have become an effective tool to address this issue. ROMs simplify complex high-dimensional problems by retaining the main physical features of the system while eliminating less important degrees of freedom, thereby significantly reducing computational complexity and cost. Many techniques have been proposed for model order reduction in high-dimensional models (HDMs), such as manifold learning, the Volterra series, proper orthogonal decomposition (POD), and dynamic mode decomposition (DMD) [

3,

4,

5,

6]. Additionally, within the broader context of intelligent fluids, a series of reduced-order models based on intelligent algorithms have emerged [

7,

8,

9,

10,

11]. It is important to note that different reduced-order models (ROMs) are suitable for different application scenarios. For rapid aerodynamic shape optimization design, ROMs must meet two key requirements. On one hand, the sampling space should be as small as possible to avoid excessive cost associated with constructing the sampling space (often obtained through full-order model (FOM) simulations or wind tunnel experiments). On the other hand, the model should provide high prediction accuracy. The LLE+COGA replaces traditional interpolation with a high-precision, low-dimensional prediction approach based on manifold learning geometric constraints combined with genetic algorithms (GAs). This method compensates for the inherent information loss in the dimensionality reduction process and effectively utilizes the geometric information of the high-dimensional space, requiring a smaller sampling space for the same prediction accuracy. Reference [

12] demonstrates, through examples of transonic strong nonlinear aerodynamic load prediction for both 2D airfoils and 3D wing–body configurations, that this reduced-order model achieves high prediction accuracy. Therefore, the LLE+COGA high-fidelity reduced-order model effectively meets the aforementioned requirements and can be used to accelerate aerodynamic shape optimization design.

Aerodynamic shape optimization design is a major application area of ROMs [

13,

14,

15,

16,

17,

18,

19,

20,

21]. The main challenge faced by aerodynamic shape optimization frameworks is the “curse of dimensionality” caused by an excessively large design space. Currently, two primary solutions are available: the adjoint method and design space dimensionality reduction. The adjoint method is widely used in aerodynamic shape optimization design. It calculates the sensitivity of design variables to the objective function (e.g., drag, lift) by solving the adjoint equations, thus enabling effective gradient-based optimization. While the adjoint method can handle high-dimensional design variable spaces, it requires solving the adjoint equations and calculating the gradients of the objective and constraints with respect to the design variables which can incur high computational costs. This is particularly challenging when dealing with nonlinearities, complex boundary conditions, or turbulence, as the solution of the adjoint equations becomes more difficult, potentially leading to model instability or poor convergence. Furthermore, the form of the adjoint equations and the solution method may vary under different optimization objectives and constraint conditions, adding to the complexity of implementation. Additionally, the method faces challenges in handling irregular, complex geometries, relies on high-quality meshes, and is sensitive to initial conditions. To avoid the computational resource consumption associated with gradient calculation, and to address issues such as gradient vanishing that can arise with certain reduced-order algorithms, design space dimensionality reduction has been widely researched. Boncoraglio and Farhat [

1] proposed the active manifold (AM) method, which assumes that the solution to the optimization problem depends on a low-dimensional nonlinear manifold. Their research found that AM outperforms active subspace (AS) techniques, such as the basic AS method [

22] and enhanced AS method [

23], in terms of performance. In addition, the acceleration of data transfer between geometric parameterization deformation and CFD mesh deformation is often overlooked. However, with the increasing complexity of geometric shapes and the widespread use of unstructured meshes, this issue has become more prominent. Taking the Radial Basis Function (RBF) dynamic mesh technique as an example, CFD meshes near the geometric surface often exhibit a large number of locally refined points. If all mesh points are selected, the resulting matrix computations incur substantial computational costs. Moreover, the excessive density of local data points may lead to numerical instability in the matrix operations, potentially resulting in errors. This work improves the efficiency of mesh deformation through the fast mesh deformation method based on a greedy algorithm.

This study aims to validate the feasibility of the high-fidelity nonlinear reduced-order model (LLE+COGA) in addressing aerodynamic optimization problems and to establish a novel rapid aerodynamic shape optimization framework. The proposed framework seeks to mitigate the excessive computational resource consumption associated with full-order optimization, thereby enhancing optimization efficiency. Furthermore, this research introduces a fast mesh deformation algorithm, which reduces the number of surface deformation control points to eliminate unnecessary computational resource expenditure. The remainder of this paper is organized as follows.

Section 2 formulates a general aerodynamic optimization design problem to ensure that this article is as self-contained as possible.

Section 3 describes the proposed optimization design framework.

Section 4 validates the proposed rapid aerodynamic optimization design framework by solving the transonic optimization problem of the undeflected Common Research Model (uCRM) three-dimensional wing (with a span-to-chord ratio of 9), which involves 241 design variables.

Section 5 provides a detailed analysis of the optimization results.

2. Problem Formulation

This study focuses on accelerating the aerodynamic shape optimization design problem, which includes both equality and inequality constraints. Such problems can be expressed in the following general form, as shown in Equation (

1):

where

represents a scalar objective function to minimize and

denotes a high-dimensional vector of

semidiscrete or discrete state variables involved in a high-dimensional, parametric, linear or nonlinear constraint.

denotes a vector of the dimensions

of design optimization parameters that typically represents displacement deformation in the context of aerodynamic shape optimization problems.

represents the high-dimensional design space, where it is assumed that

is relatively large (say,

) [

1].

represents a collection of both linear and nonlinear algebraic constraints.

is a parametric PDE in

q that is either semidiscretized or fully discretized in a high-dimensional space.

In practical problems, only the design variable

needs to be optimized. Therefore, in the nested analysis and design (NAND) approach, the state variable

q can be treated as an implicit function of

. By solving the PDE constraint

R, Equation (

1) can be rewritten as Equation (

2):

The design variable in the

i-th iteration is denoted as

, and

is obtained by solving

. This process can be written as Equation (

3).

It is important to note that as the dimension of the design space increases, the computational cost of evaluating the objective function and algebraic constraints increases rapidly. Therefore, the development of new, efficient optimization frameworks is of significant importance.

3. Innovative Optimization Framework

The fast aerodynamic shape optimization design framework based on ROMs is shown in

Figure 1. If a flow solver is used to compute the flow state variables and an adjoint solver is used to compute the gradients, this corresponds to the traditional adjoint-based optimization design framework, represented by the grey portion in the figure.

The solution of the flow control equations and the adjoint equations accounts for the majority of the computational cost in the traditional adjoint-based optimization framework. By replacing the FOMs with ROMs, not only can simulation time be significantly reduced, but solving the adjoint equations can also be avoided. It is worth noting that the computational cost associated with updating the CFD mesh due to geometric deformations is increasingly difficult to ignore. This is because complex geometric models often involve regions of local refinement near the surface, which leads to substantial matrix computation resource consumption for the mesh deformation algorithms. Furthermore, there is a risk that the dense distribution of mesh data points could cause numerical instability or even numerical errors, ultimately resulting in non-physical solutions in the optimization process. In addition, it is necessary to avoid the issue of the “curse of dimensionality” caused by excessively high dimensions in the design space.

3.1. Geometric Parameterization

The Free-Form Deformation (FFD) geometry parameterization method used in this study is a shape modeling technique employed in computer graphics and computer-aided design (CAD), widely applied for geometric deformation modeling [

24]. The FFD volume is used to parameterize changes in geometry rather than the geometry itself, leading to a more compact and efficient representation of design variables, which simplifies the manipulation of complex shapes. Any geometry can be embedded within the volume by applying a Newton search to map the parameter space to the physical space. Geometric modifications are applied to the outer boundary of the FFD volume, and any adjustments to this boundary indirectly affect the embedded geometries. A key assumption of the FFD method is that the geometry maintains constant topology throughout the optimization process, which is typically true in wing design. Additionally, because FFD volumes are based on trivariate B-splines, the derivatives of any point within the volume can be easily computed [

25,

26].

3.2. Reduced-Order Model: LLE+COGA

It is aspirational to construct a nonlinear reduced-order model (ROM) with the ability to predict Computational Fluid Dynamics (CFD) solutions accurately and efficiently. In our previous work, we proposed a novel, high-fidelity, nonlinear reduced-order model: the locally linear embedding plus constrained optimization genetic algorithm (LLE+COGA) [

12]. Our research found that one major challenge is that the nonlinearity cannot be adequately captured by interpolation algorithms in low-dimensional space. This implies that an ROM based on a dimensionality reduction algorithm combined with traditional interpolation methods requires a larger sampling space to achieve the same low-dimensional prediction accuracy as the COGA, without incorporating additional low-dimensional predictive information. This, in turn, leads to a higher computational resource consumption. To preserve the nonlinearity of CFD solutions for transonic flows, a new ROM is presented by integrating manifold learning (ML) into constrained optimization, whereby a neighborhood preserving mapping is constructed by a locally linear embedding (LLE) algorithm. Reconstruction errors are minimized by LLE by solving a least-square problem subject to weight constraints. The low-dimensional space obtained through LLE dimensionality reduction preserves the same geometric features as the high-dimensional space under the algorithm’s assumptions and can be expressed as Equation (

4):

where

represents the

i-th point in the high-dimensional space, and

denotes its corresponding point in the low-dimensional manifold space.

and

correspond to the neighboring points in the high-dimensional and low-dimensional spaces, respectively. The low-dimensional manifold preserves the same neighborhood relationships as the high-dimensional space, denoted as

. A loss function is proposed in the constrained optimization to preserve the geometric properties between high-dimensional space and low-dimensional manifolds, as shown in Equation (

5).

represents the Euclidean distance vector between the

i-th iteration’s low-dimensional predicted results and its neighboring points, while

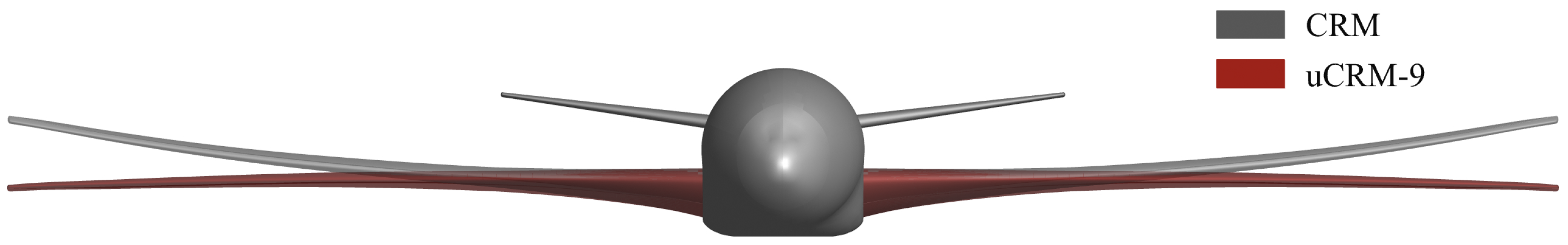

denotes the corresponding high-dimensional Euclidean distance vector under the same neighborhood relationship coefficient. In our previous research, the LLE+COGA was validated for predicting nonlinear transonic flows over the RAE 2822 airfoil and the undeflected NASA Common Research Model with an aspect ratio of 9 (uCRM-9), where nonlinearities were induced by shock waves. All results confirmed that the reduced-order model (ROM) accurately replicated CFD solutions at a fraction of the cost compared to CFD calculations or full-order modeling (FOM). For specific details, please refer to reference [

12].

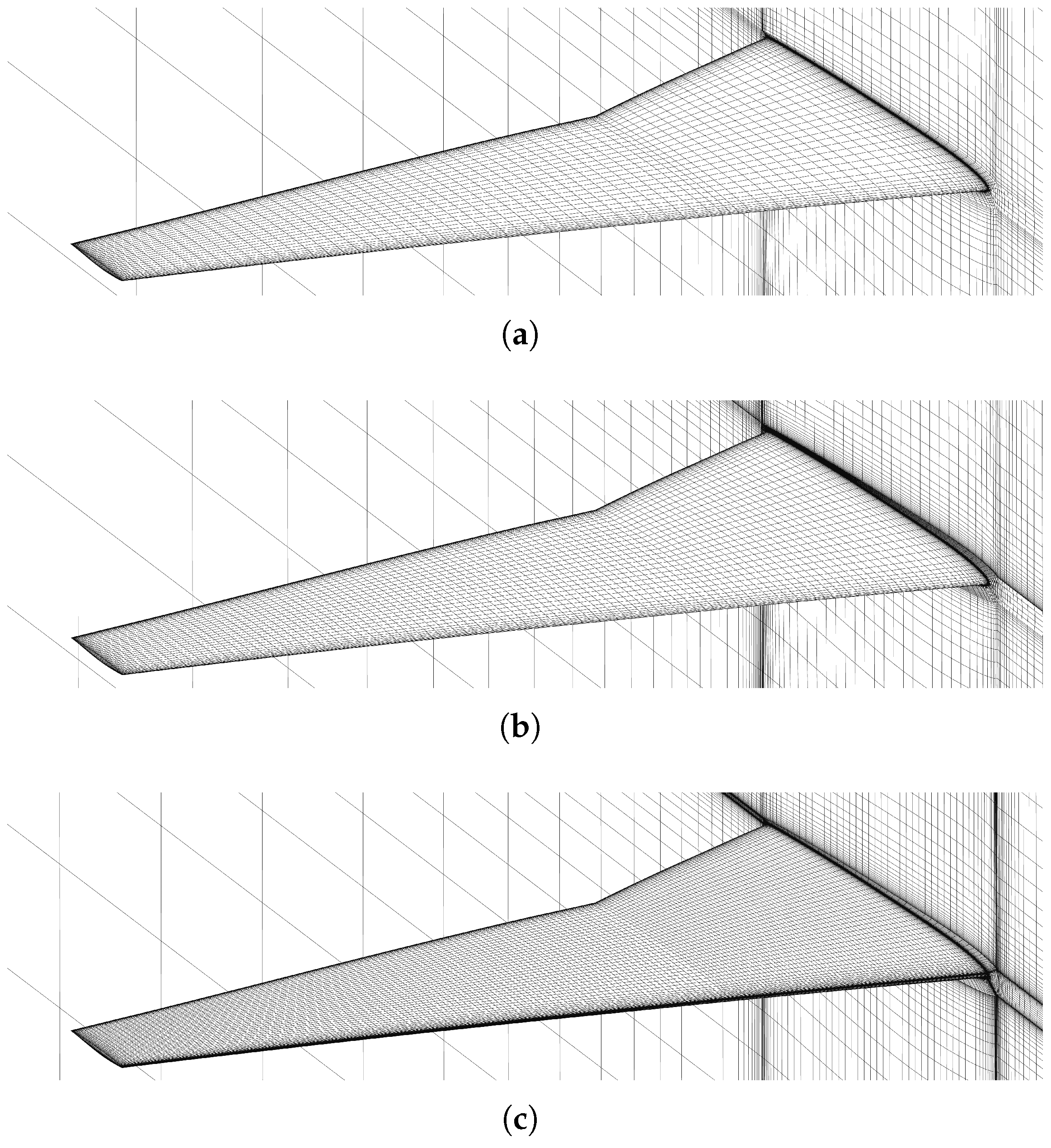

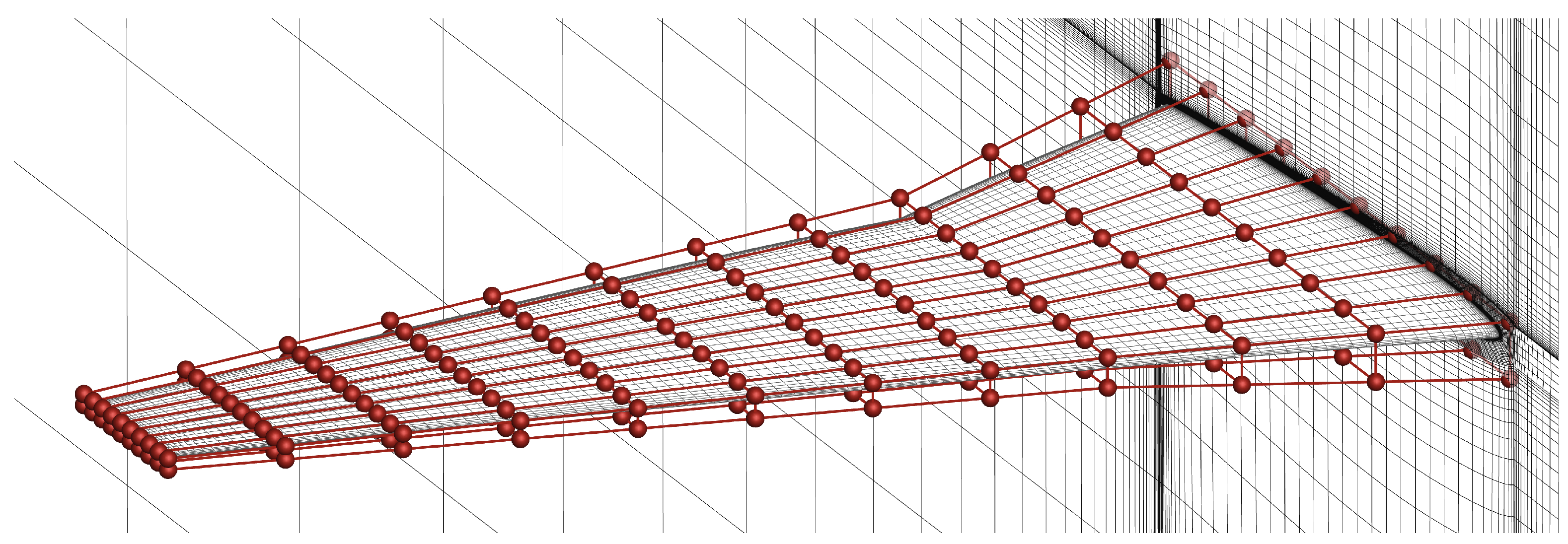

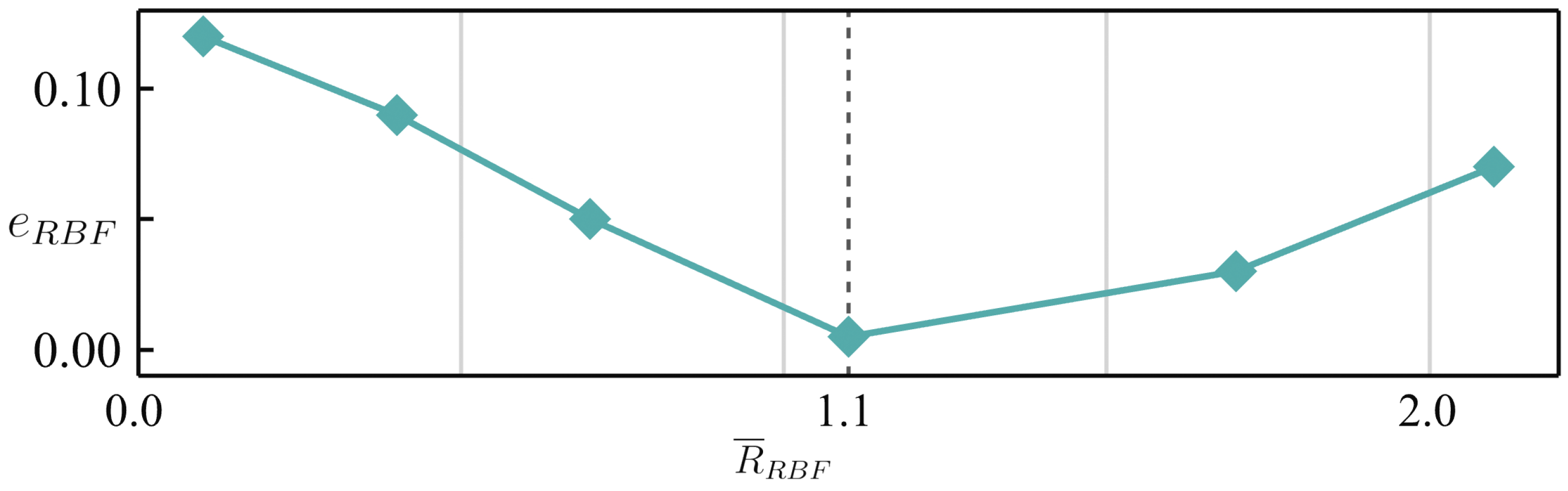

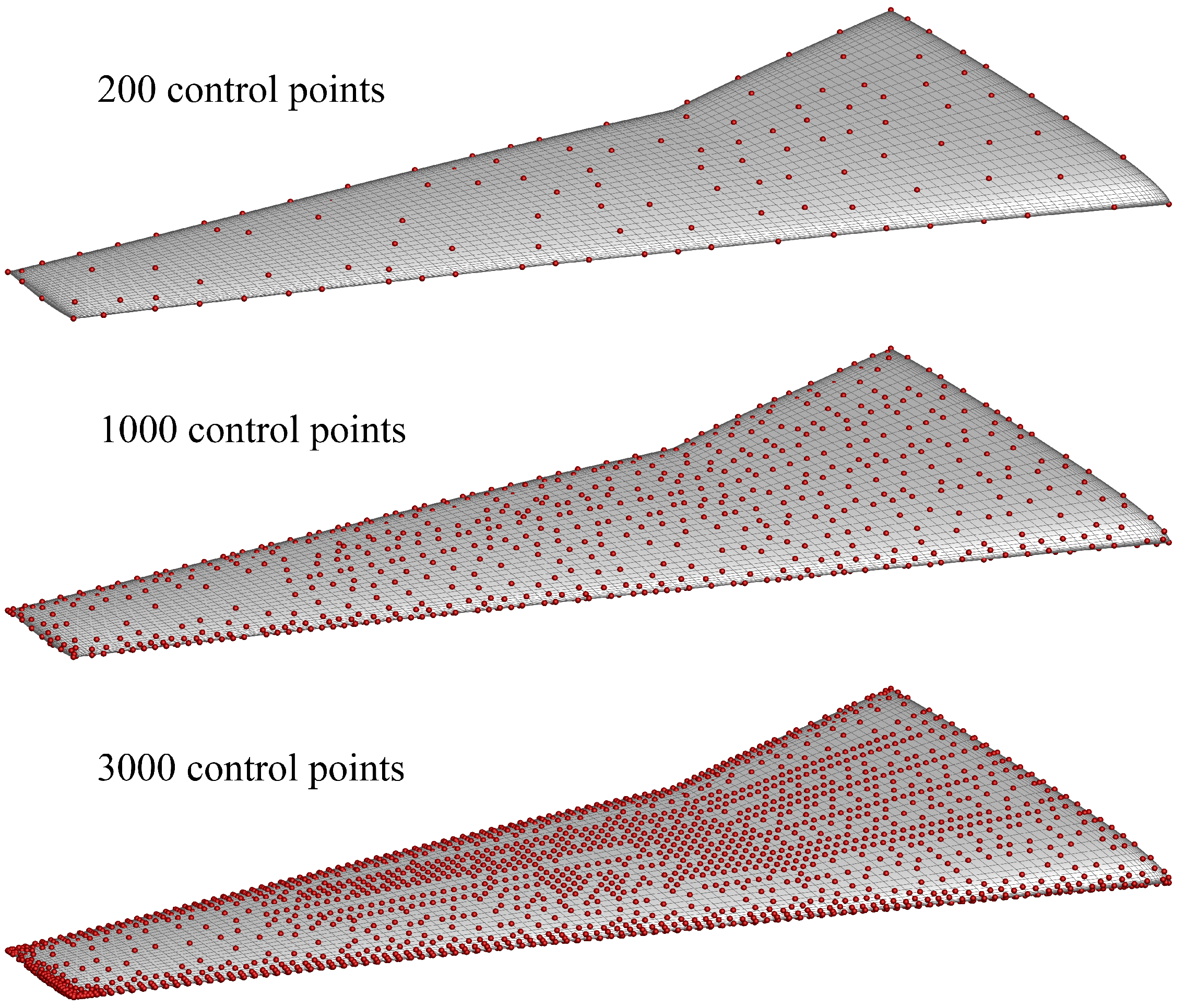

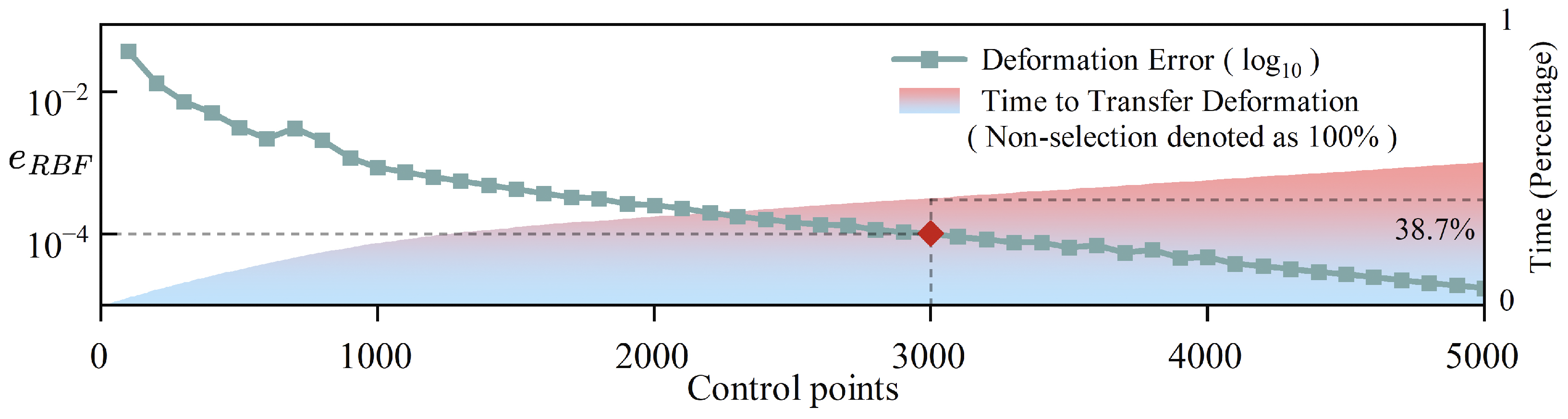

3.3. Fast Mesh Deformation

For CFD surface meshes with significant local refinement, it is necessary to quickly propagate the deformation to the CFD volume mesh in order to minimize computational costs. Taking the Radial Basis Function (RBF) mesh deformation algorithm as an example, it can be represented in the following form, as shown in Equation (

6):

Here,

represents the displacement, and

denotes the Radial Basis Function (RBF) interpolation coefficient. The subscripts

s and

v refer to the surface mesh quantities and volume mesh quantities, respectively. The matrix

is represented as Equation (

7), and

is similarly represented.

From Equation (

7), it can be observed that if there are too many surface points, the dimension of the matrix

M will increase, thereby raising the computational cost of solving the Radial Basis Function (RBF) deformation coefficients. Additionally, if there are too many points with very small Euclidean distances, it could lead to matrix singularity, causing numerical instability or even errors in the solution. Therefore, it is necessary to minimize the number of surface control points involved in the mesh deformation while ensuring the accuracy of the results. A greedy algorithm is employed here to select surface control points, as shown in Algorithm 1. The specific process is as follows:

Deform the geometry in the design variable space;

Select the two points that are the farthest apart in terms of Euclidean distance within the point set as the initial values for the iteration;

Use the selected points as surface control points, compute the RBF deformation results, and calculate the error between the deformed points and the original point set. Add the point with the largest error to the selected set, and repeat the process until the predefined acceptable error limit is reached.

In other words, under limited computational resources, by restricting the number of surface control points to the same amount, the fast mesh deformation method can minimize the error.

| Algorithm 1 Greedy selection of deformation points. |

Input: All Surface Mesh Points:

Output: Selected Points for Deformation: - 1:

▹ Manually deform mesh based on surface sensitivity - 2:

▹ A randomly selected point and the point farthest from it in Euclidean distance form the initial set - 3:

for to s do ▹ Start greedy point selection - 4:

▹ Reconstruct all points using - 5:

- 6:

▹ Add the point with the largest error to the selection set - 7:

if then - 8:

break ▹ Stop point selection when the error threshold is reached - 9:

end if - 10:

end for

|

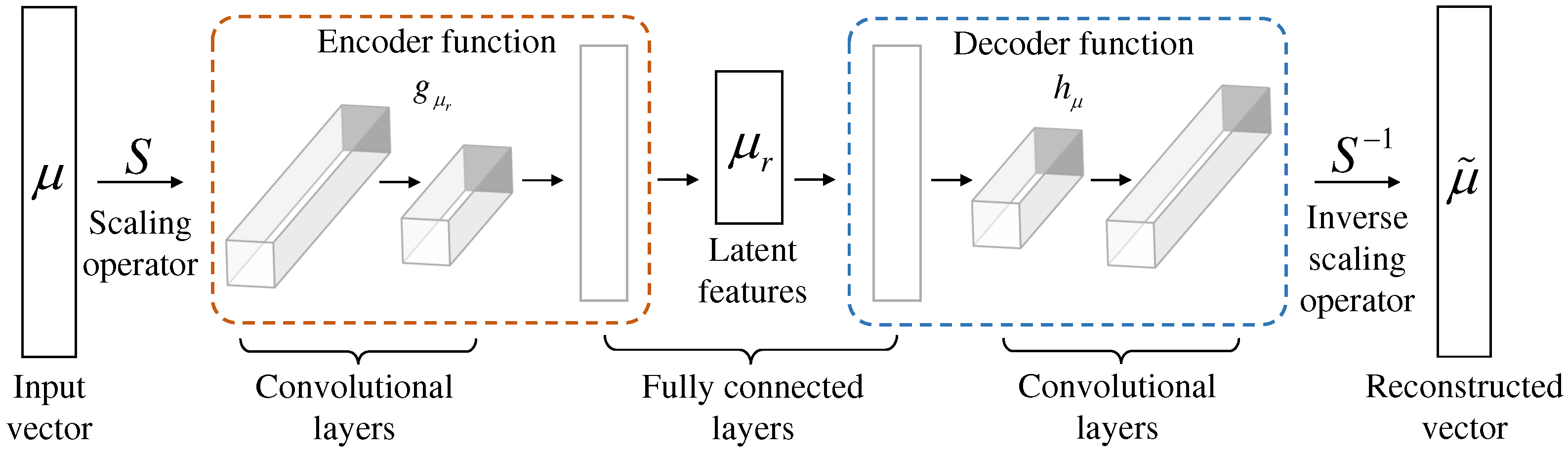

3.4. Active Manifold Auto-En/Decoder

For the fast aerodynamic shape optimization design framework based on a reduced-order model (ROM), the dimensionality of the design space becomes too high, leading to the curse of dimensionality. For instance, when constructing a sampling database in a moderately sized design variable space (

), if only two parameter points are sampled per dimension—this being the minimum required to construct an interpolation database—it would require as many as

sampling data points, which is computationally infeasible [

1]. Many studies have found that multilayer auto-encoders, due to the neural network’s (NN) exceptional ability to capture nonlinear features, often outperform other nonlinear dimensionality reduction methods in various cases [

27]. Researchers investigating the universal underlying NN structure for optimization problems with insensitive dependencies have found that, for PDE-based aerodynamic shape optimization problems, the most suitable auto-encoder should consist of two convolutional layers and one fully connected layer, as shown in

Figure 2.

Boncoraglio and Farhat [

1] proposed an efficient method for constructing the dataset, which involves quickly solving simplified models or simplified problems to record snapshots of the design space in the matrix

. Small perturbations are then added to each dimension, and the final constructed training set

is represented as Equation (

8):

Here,

denotes the perturbation matrix corresponding to the

k-th element in the snapshot matrix

, as expressed in Equation (

9).

is a vector with all elements equal to 1, and

is the identity matrix;

is a small constant, such as

.

The dataset is randomly split into a training set and a test set in an 8:2 ratio. The encoder network consists of two one-dimensional (1D) convolutional layers and one fully connected layer. The decoder has a structure that is symmetric to the encoder. More details of the auto-en/decoder can be found in reference [

1], and the neural network structure parameters used in this study are referenced from that work. The original problem, as expressed in Equation (

2), can be rewritten in the form of Equation (

10).

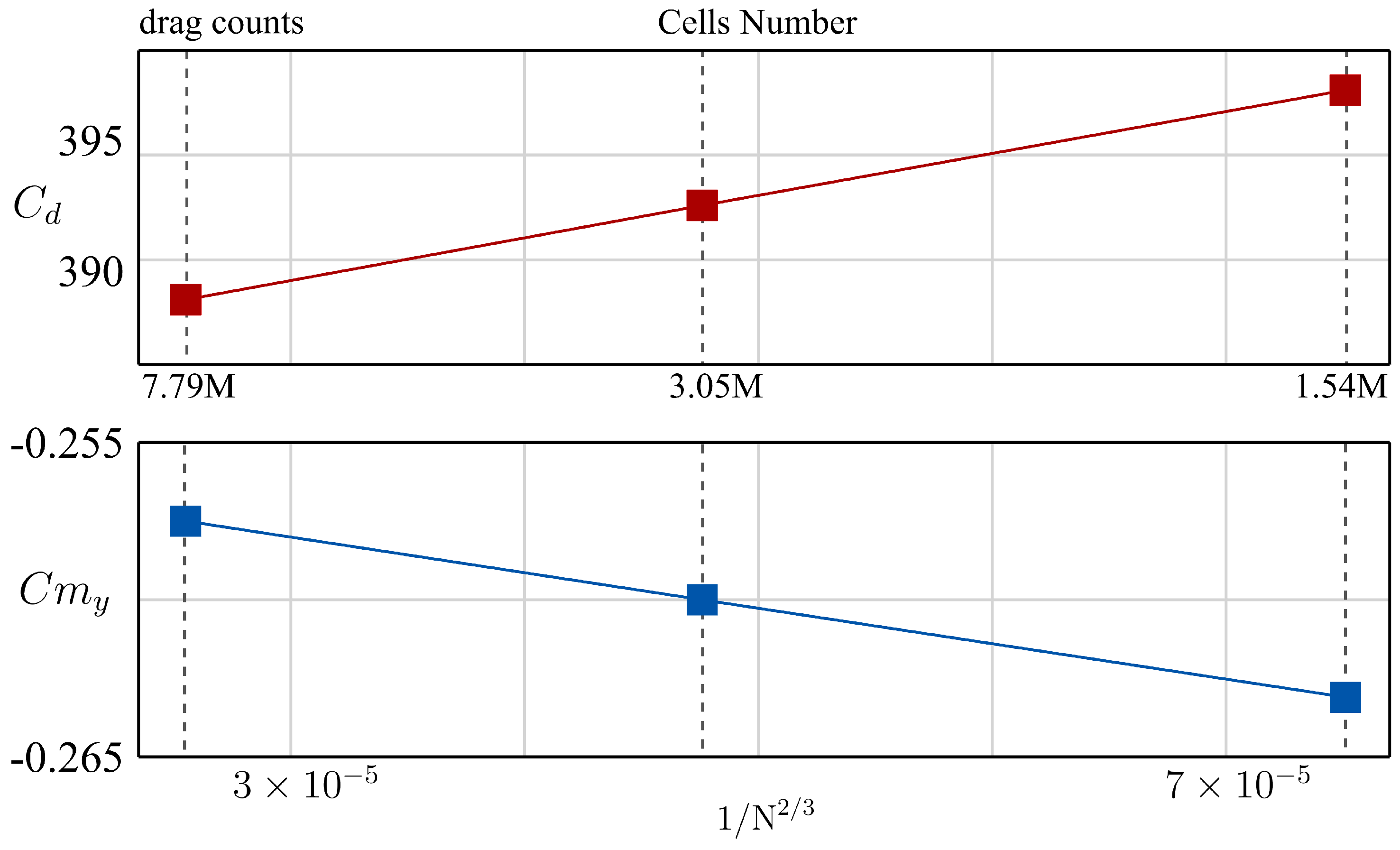

5. Results

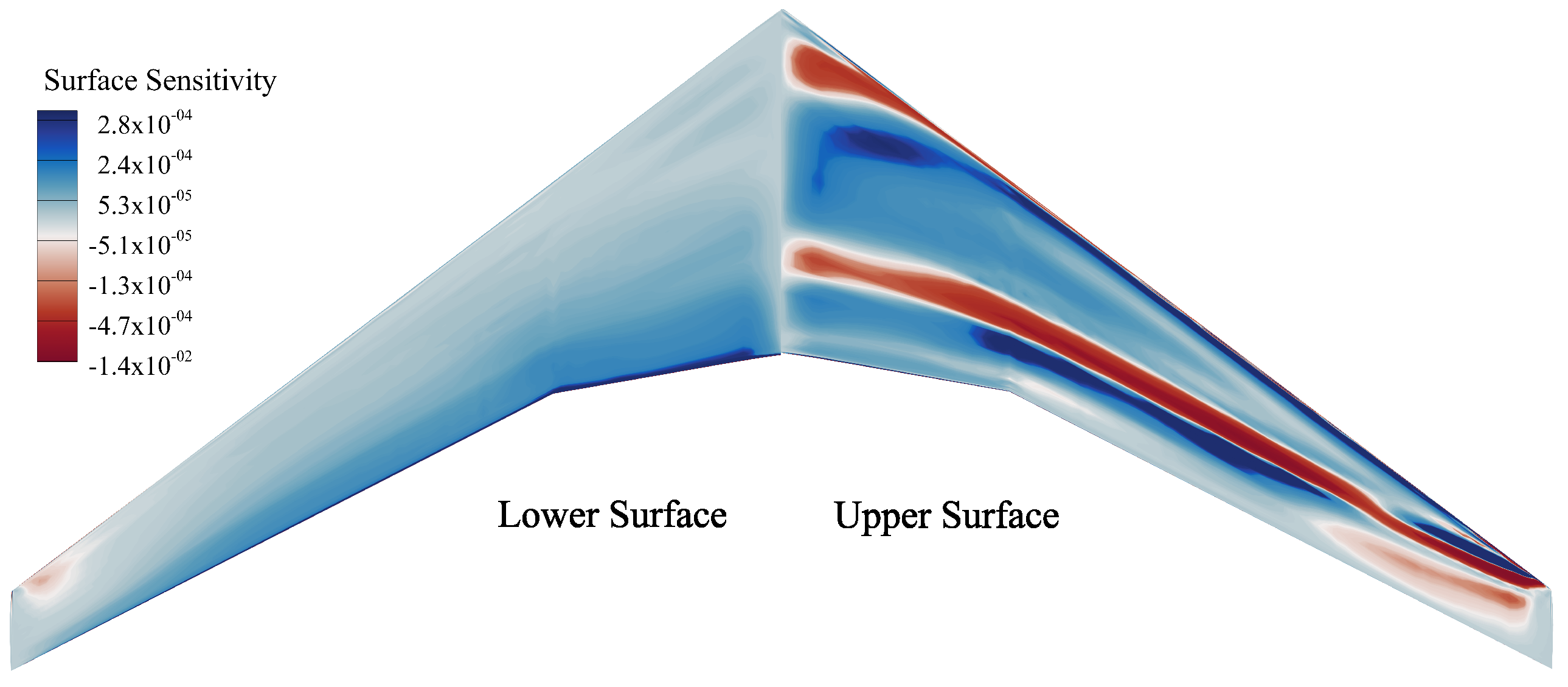

A priori sampling is a crucial element in the design of experiments (DoE), involving the systematic selection of samples from within the design space. This study employed a multi-round greedy Latin Hypercube Sampling (LHS) method to construct the sample space. In order to qualitatively assess, to some extent, the design variables that had a significant impact on the optimization objective function and constraints, surface sensitivity analysis was conducted first, as shown in

Figure 11. From the contour plot of the sensitivity of the objective function with respect to the displacement in the

z-direction, it can be observed that the design space regions with a significant impact on aerodynamic performance were concentrated near the shock wave occurrence location.

The sampling process was as follows:

The initial design space samples were generated using LHS based on surface sensitivity information.

The surface pressure coefficient was extracted from FOM simulations to construct the test dataset and the initial sample space.

The ROM was constructed using the sample space and was then employed to reconstruct the test dataset.

The design variables with larger errors were identified by comparing the discrepancies between the predicted reconstruction results and the FOM distribution.

Additional sampling points were introduced in the dimensions of design variables with larger errors. Each new sample was evaluated to ensure compliance with geometric constraints. If the constraints were satisfied and no negative volume errors were introduced in the mesh, the sample was added to the sample space; otherwise, it was discarded.

The above process was repeated for the next round of sampling.

The accuracy of ROMs typically increases with the expansion of the sample space, highlighting the iterative process of model improvement. A total of four rounds of DoE were conducted, with the test datasets existing independently. The arithmetic mean of the error between the predicted reconstruction results and the FOM distribution was defined as the iterative criterion. Starting from the initial samples, the DoE samples were gradually increased, and the error was reassessed in each iteration. This process was repeated until the error reached an acceptable threshold. Each round targeted 100 data points; points that did not satisfy the constraints or caused severe grid negative volume errors were discarded. A total of 331 data points were used to construct the database. It is noteworthy that the database could also be shared as an input for the active manifold network. The sampling process prioritized design variables based on their impact on aerodynamic performance by evaluating the ROM prediction errors. For aerodynamic optimization applications, it is particularly crucial to construct the test dataset based on surface sensitivity analysis. This ensures the accurate prediction of aerodynamic loads during the optimization process while avoiding unnecessary sampling costs.

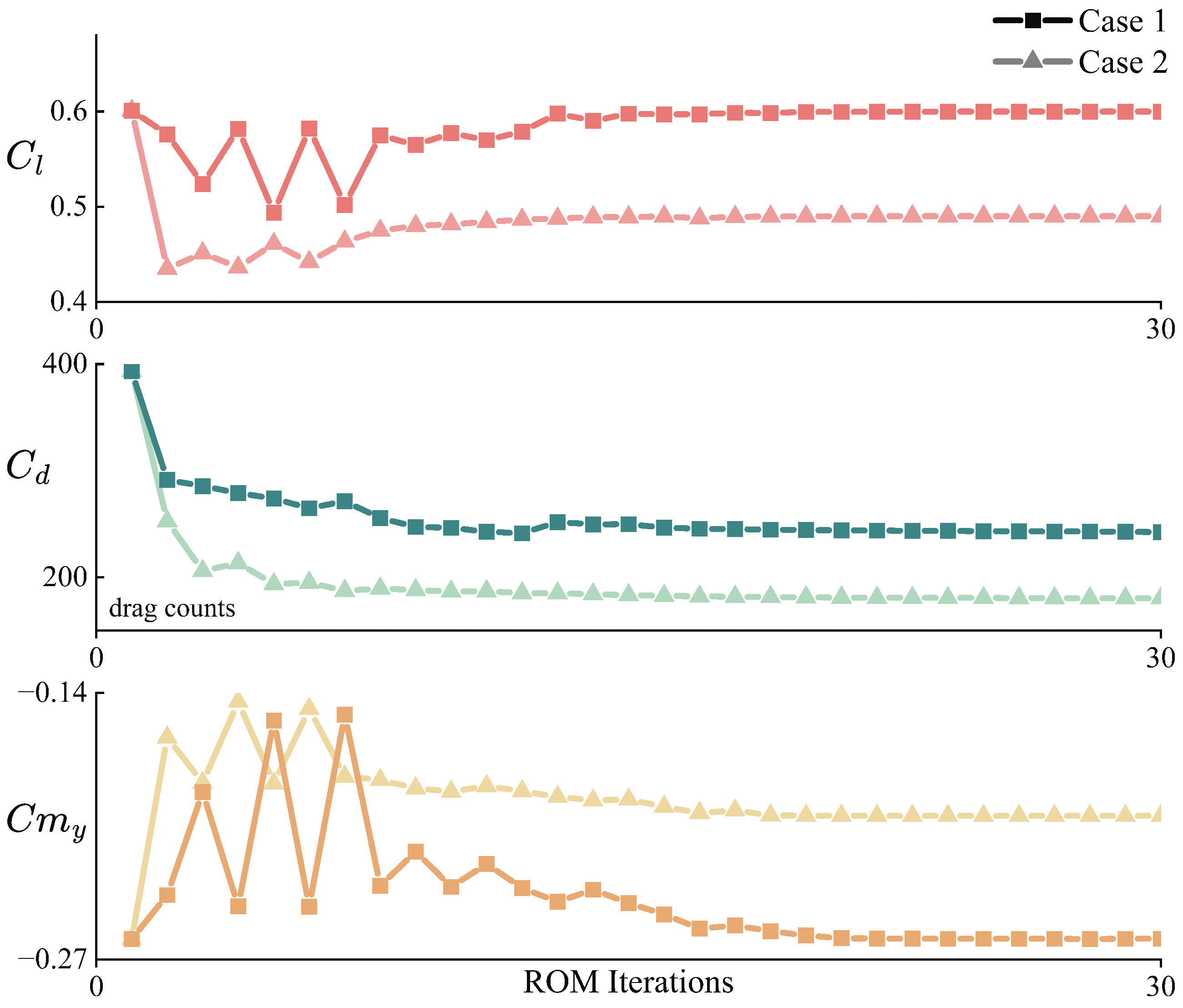

As shown in

Figure 12, after 20 iterations, the objective function essentially converged, and the constraints reached the preset values.

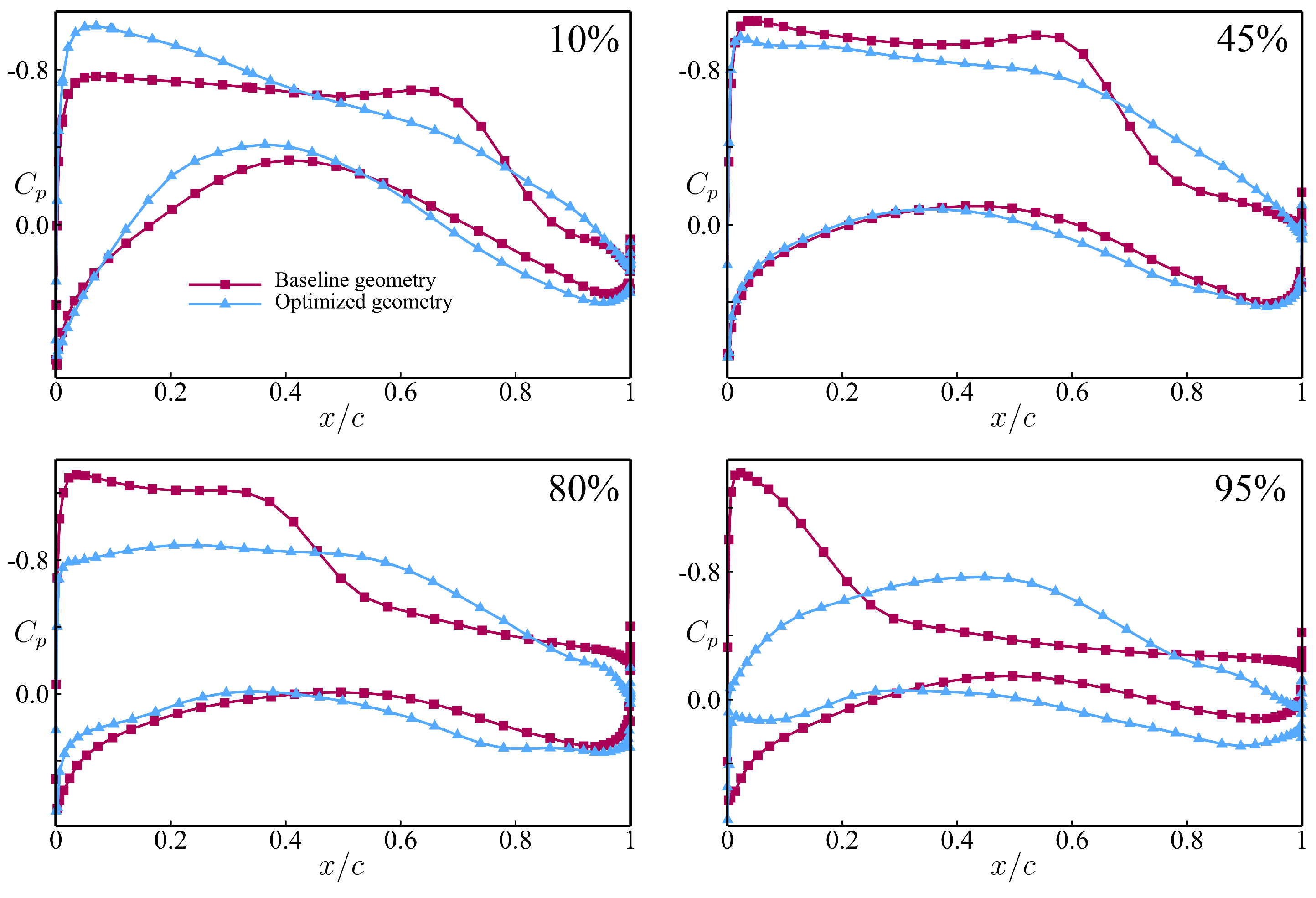

As shown in

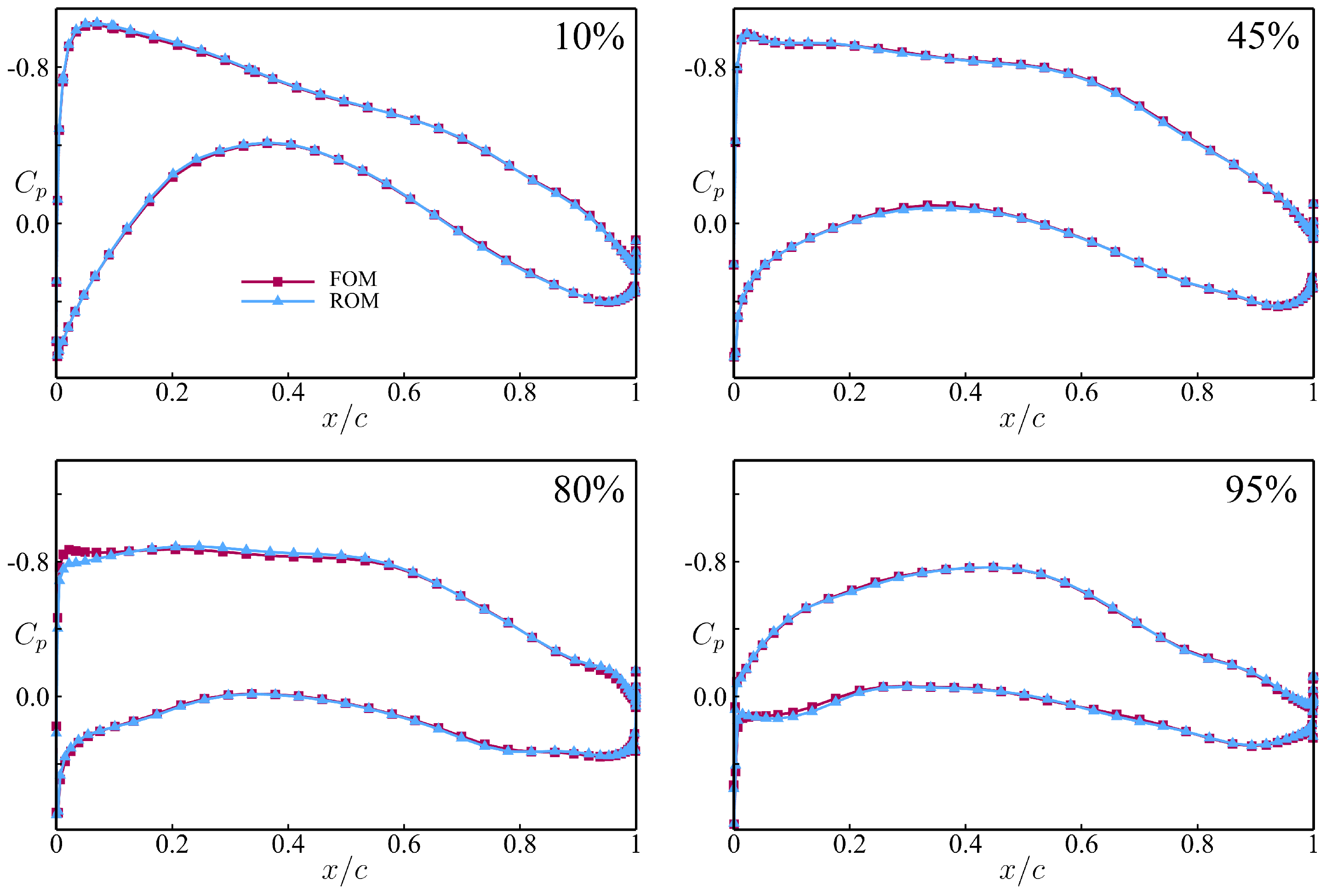

Figure 13, the change in wing thickness and the alteration in the twist angle led to a change in the local angle of attack, causing the shockwave position on the wing surface to shift. The shockwave on the upper surface moved towards the wing root. The local aerodynamic profile modification suppressed the shockwave diffusion, reducing the pressure drag. From the contour plots, it can be observed that the optimized wing exhibited a reduced shock wave region and decreased shock intensity. The optimized wing exhibited a delayed critical Mach number. In the mid-span section, the sectional load distribution indicated a reduction in shock intensity, with this trend becoming more pronounced toward the wingtip. The local aerodynamic load was more evenly distributed, and peak values were significantly reduced. Flow discontinuities disappeared, leading to an effective reduction in pressure drag. Ultimately, the drag coefficient decreased by 38.9%. Pressure coefficients were extracted at 10%, 45%, 80%, and 95% spanwise locations, as shown in

Figure 14. The optimized wing exhibited significant differences in pressure coefficients across the entire wing surface compared to the baseline geometry.

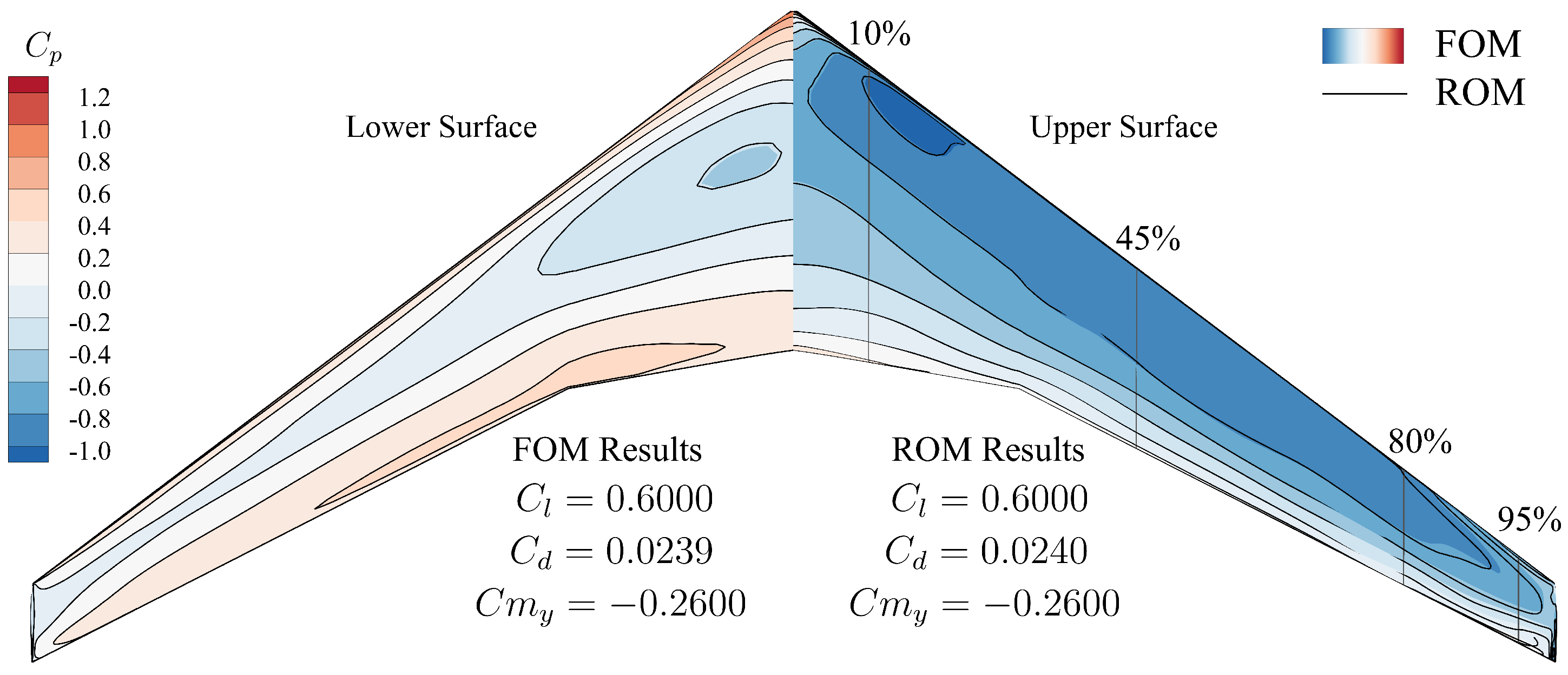

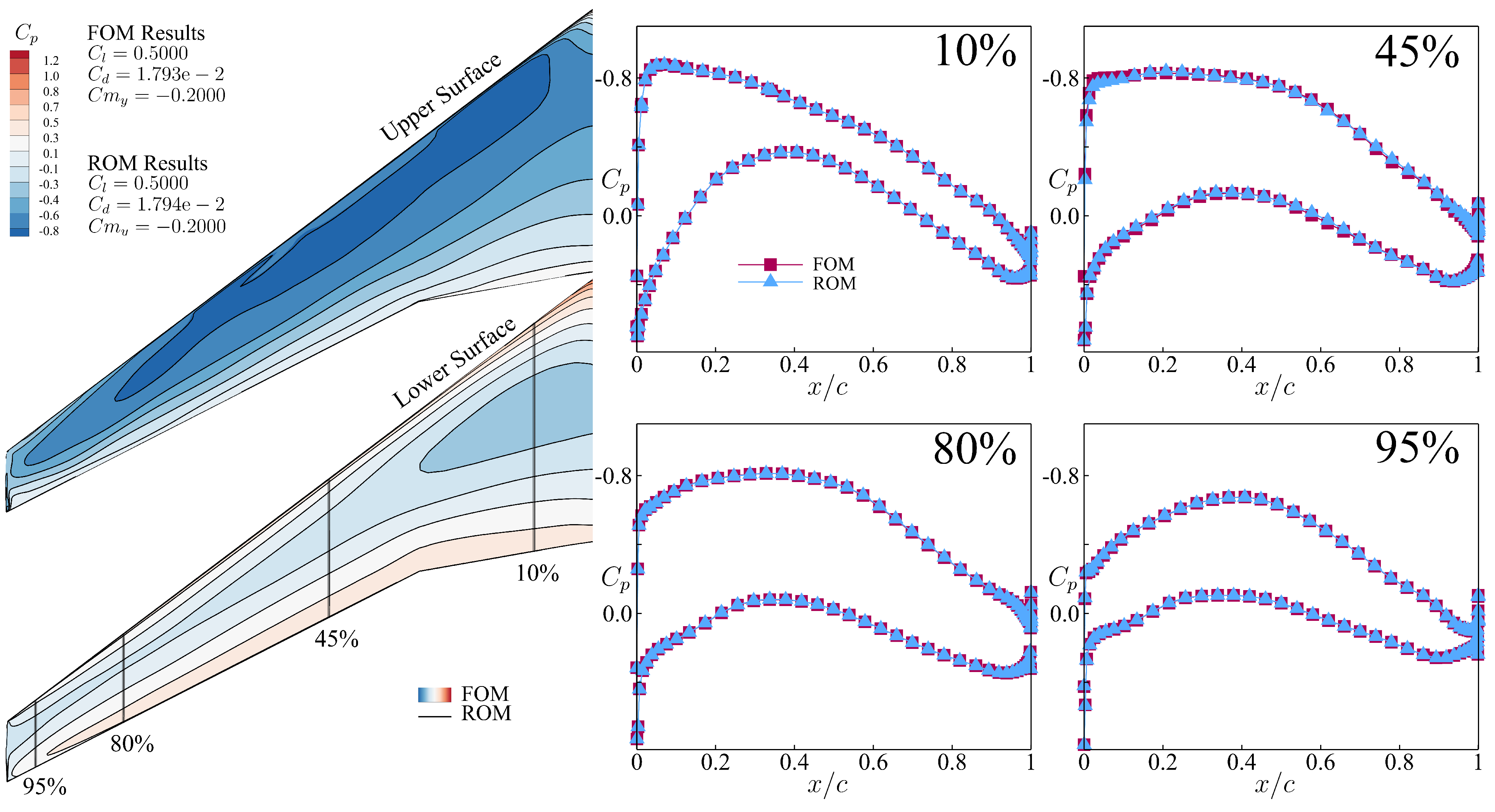

To further assess the accuracy of the ROM-based optimized design framework, the optimization results were compared with those obtained from the FOM-based optimization design framework. The concentrated aerodynamic loads are obtained by solving the RANS equations, while the design variable gradients were derived by solving the adjoint equations. As shown in

Figure 15, the optimization design framework based on ROM demonstrated high accuracy, with results that were nearly consistent with those from the FOM-based framework. By extracting sections in different spanwise locations, it could be observed that the local pressure coefficients aligned well, as shown in

Figure 16.

Table 5 compares the computational resource consumption between the ROM-based and FOM-based optimization frameworks. It can be observed that although the primary computational cost of the ROM-based optimization was concentrated in the building phase, the absence of the need to solve the computationally expensive adjoint equations led to a 62.6% reduction in the overall optimization time. This time was significantly lower than that of the FOM-based optimization framework, with the final optimization result exhibiting an error of 0.3%, demonstrating its high practical applicability.

Test Case 2 was employed to validate the generalization capability of the aerodynamic shape optimization framework proposed in this study for different problems. The details of the optimization setup are presented in

Table 4. The optimization objective was to minimize the drag coefficient

, while maintaining

and ensuring that

. The optimization process is illustrated in

Figure 12. As illustrated in

Figure 17, the newly developed rapid aerodynamic shape optimization framework based on the ROM demonstrated high accuracy. The drag coefficient was reduced by 54.5%, and the total computational resource consumption was decreased by 57.7%, as summarized in

Table 5.

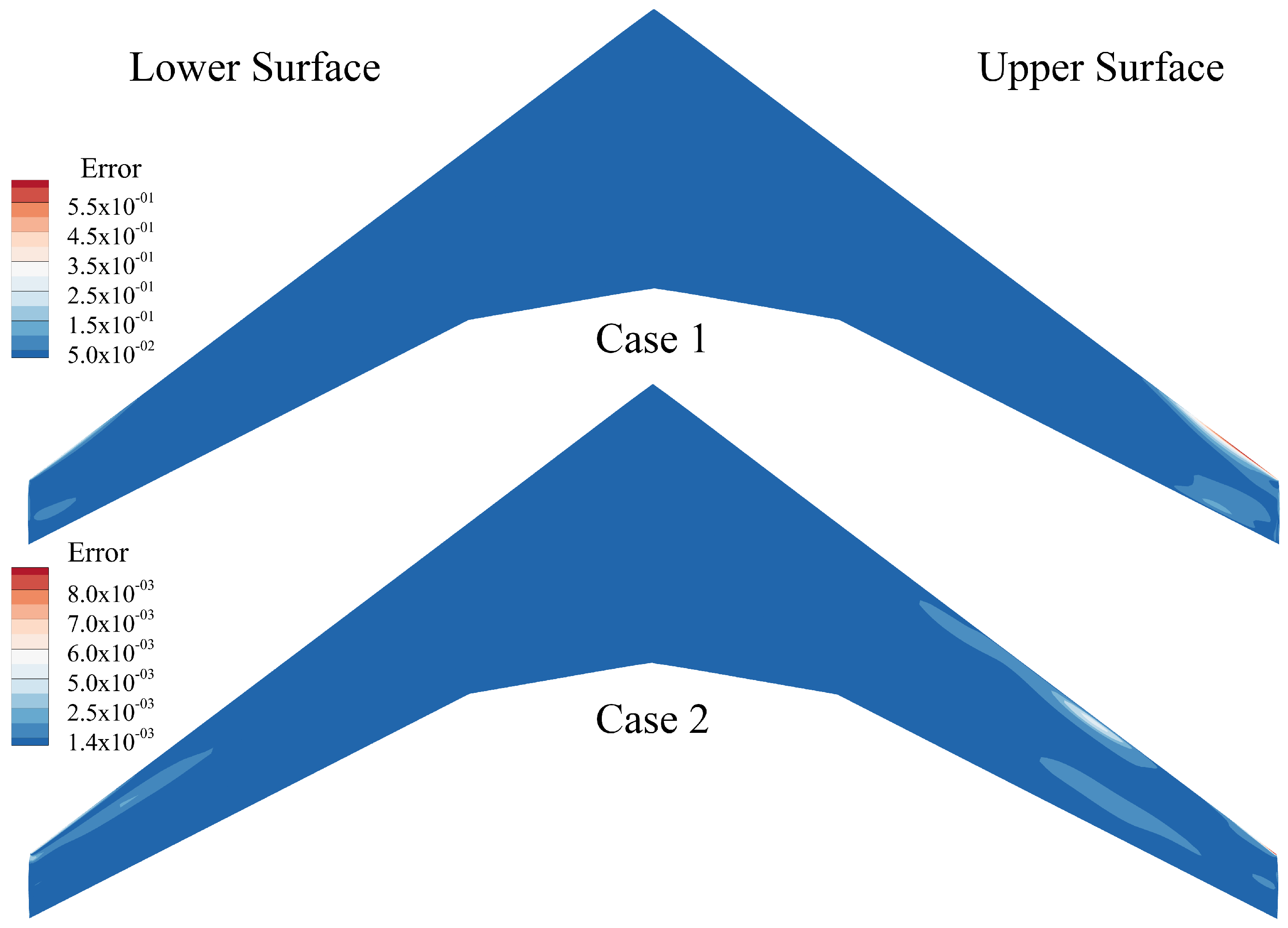

As shown in

Figure 18, the error was defined as the absolute difference in

between the ROM-based framework and the FOM-based framework optimization results. By comparing the contour plots, it can be observed that the errors in Case 1 and Case 2 were primarily concentrated near the wingtip. This was due to the increasing coupling effect between the twist angle and thickness design variables as the wingtip was approached. In contrast, near the wing root, the twist angle design variable had a relatively smaller impact, while the thickness design variable played a dominant role. As a result, most of the errors in the wing root and mid-span regions remained within a relatively small range.

6. Conclusions

This work presents a fast aerodynamic shape optimization design framework based on the LLE+COGA reduced-order model. By constructing an active manifold auto-en/ecoder neural network, the framework eliminates the unacceptable computational costs associated with high-dimensional design spaces. This study finds that for surface grids with a large number of locally refined regions, the computational expense of transferring geometric deformations from the surface grid to the volume grid via mesh deformation algorithms is substantial. To address this, a greedy point selection algorithm is proposed, which reduces the computation time by 71.3% while maintaining an error accuracy below 1 . The proposed ROM-based framework was validated through the drag reduction optimization of the UCRM9 wing, which involved 241 design variables and 777 constraints. Ultimately, under the given constraint conditions, the drag reduction achieved for Case 1 and Case 2 was 38.9% and 54.5%, respectively, which was consistent with the results obtained using the FOM-based optimization framework. The total optimization time for Case 1 and Case 2 was reduced by 62.6% and 57.7%, respectively, demonstrating the high practical value of the ROM-based optimization framework proposed in this study.