Main Structure of the Survey Camera for CSST: A Paradigm for Structural Design of Large-Scale Complex Space Optical Instruments

Abstract

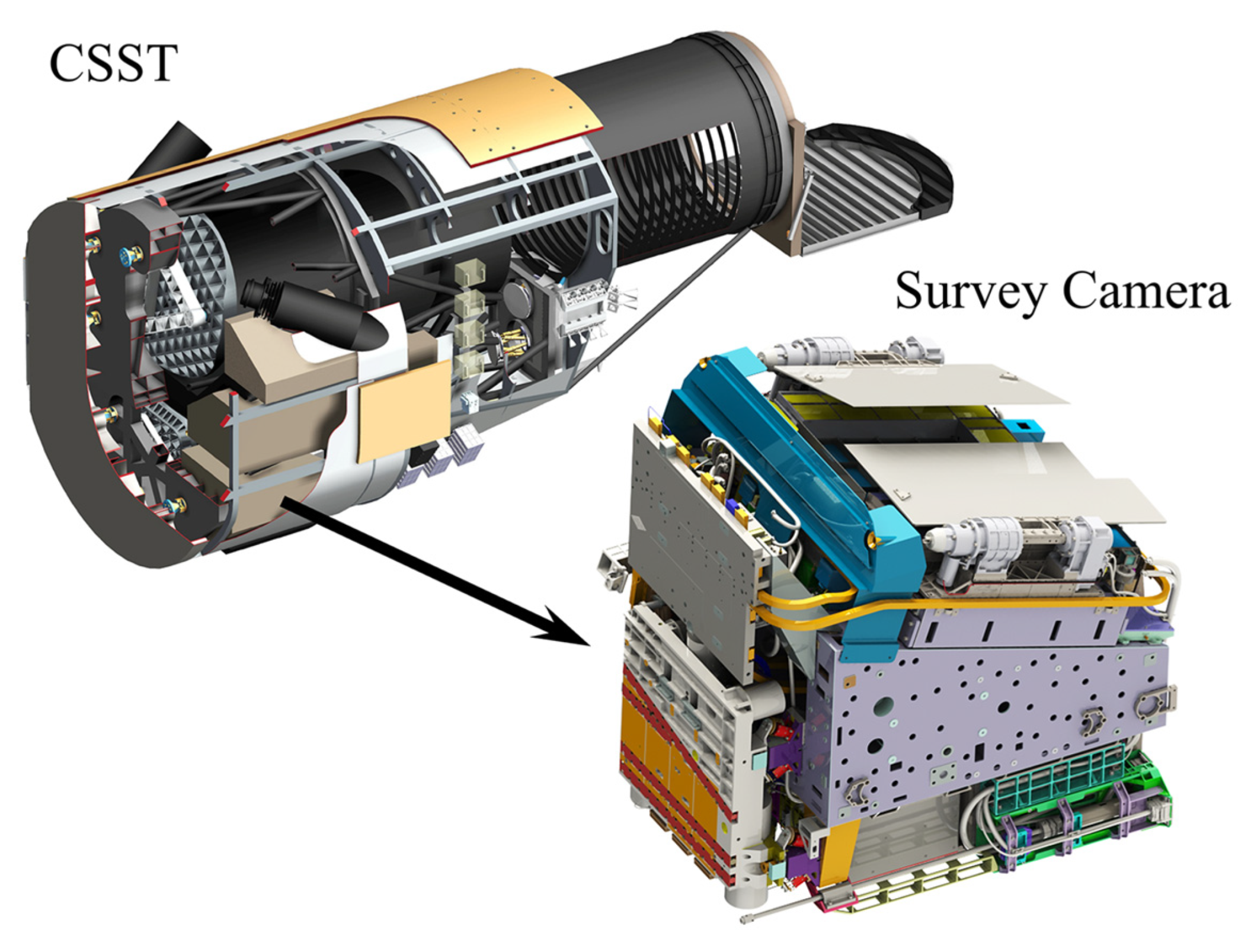

1. Introduction

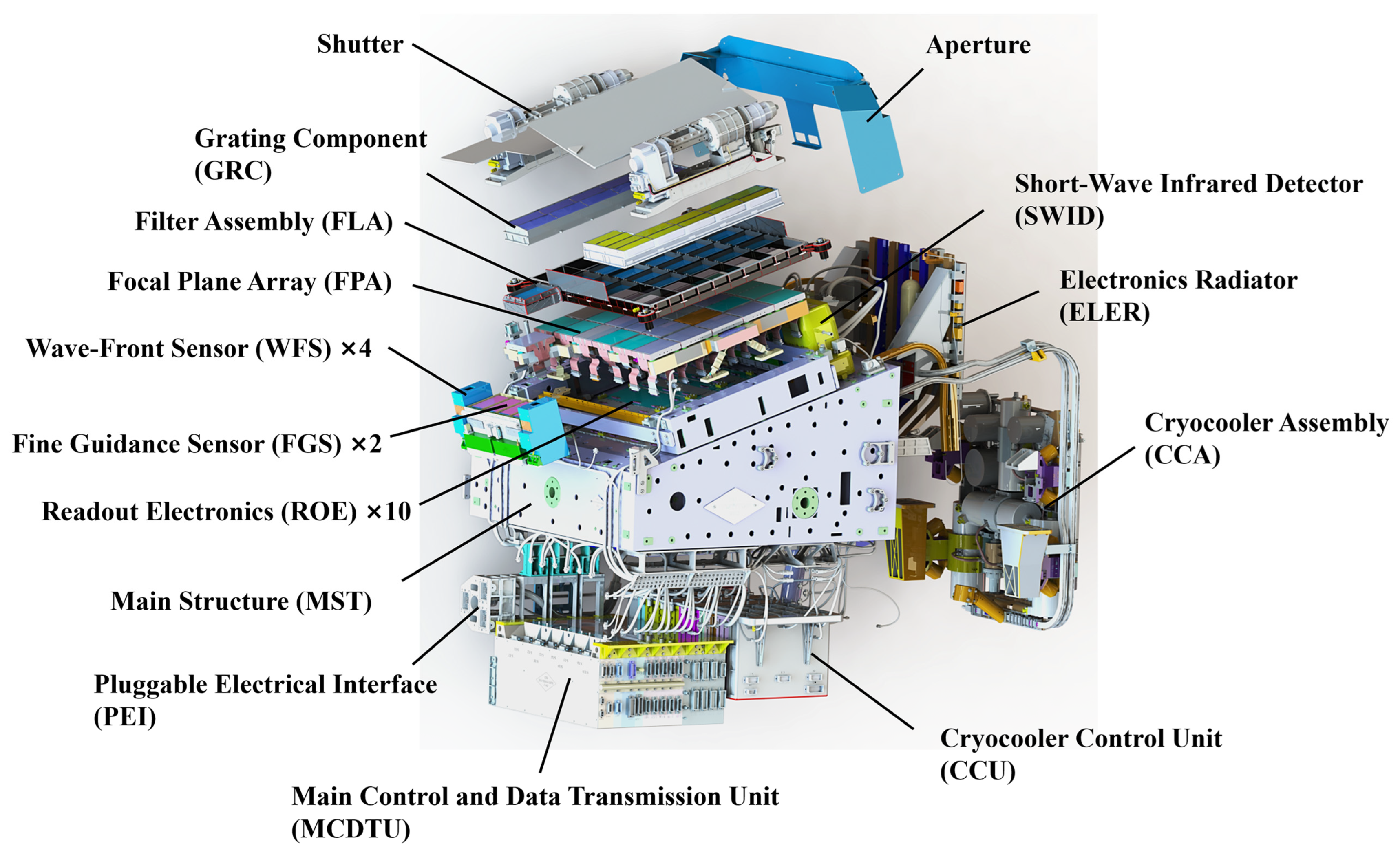

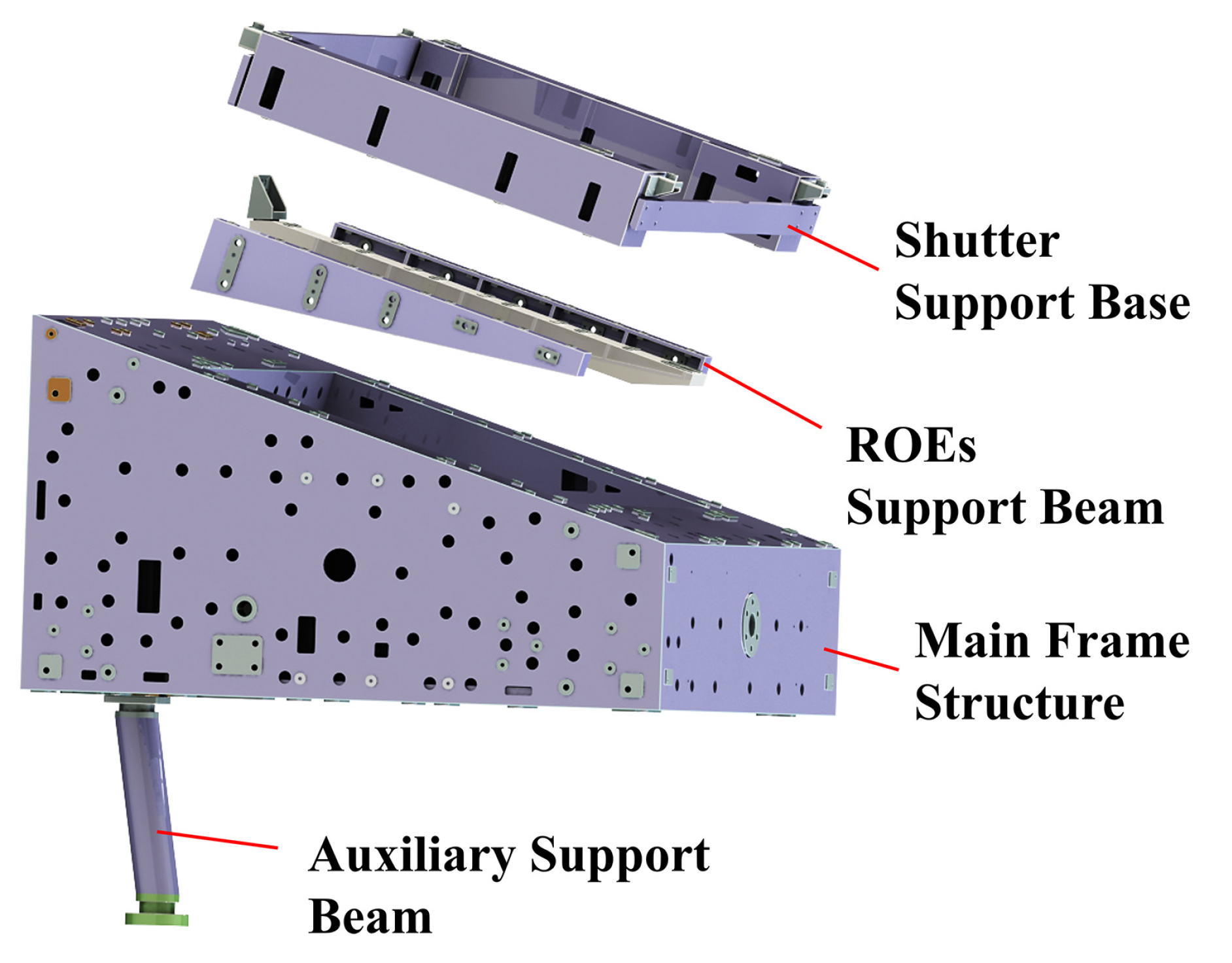

2. Composition of the SC and Requirements for the MST

3. MST Design and Optimization

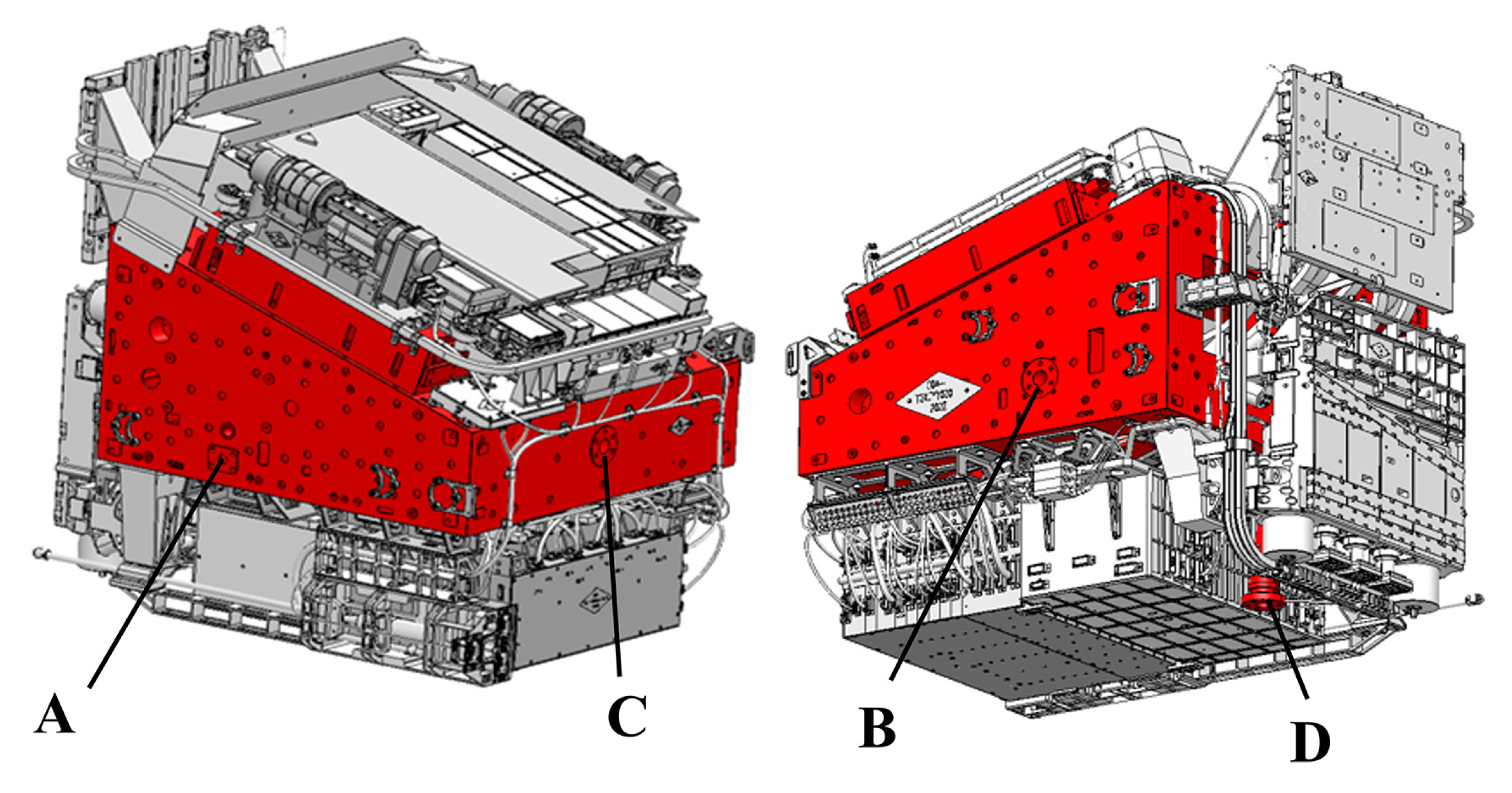

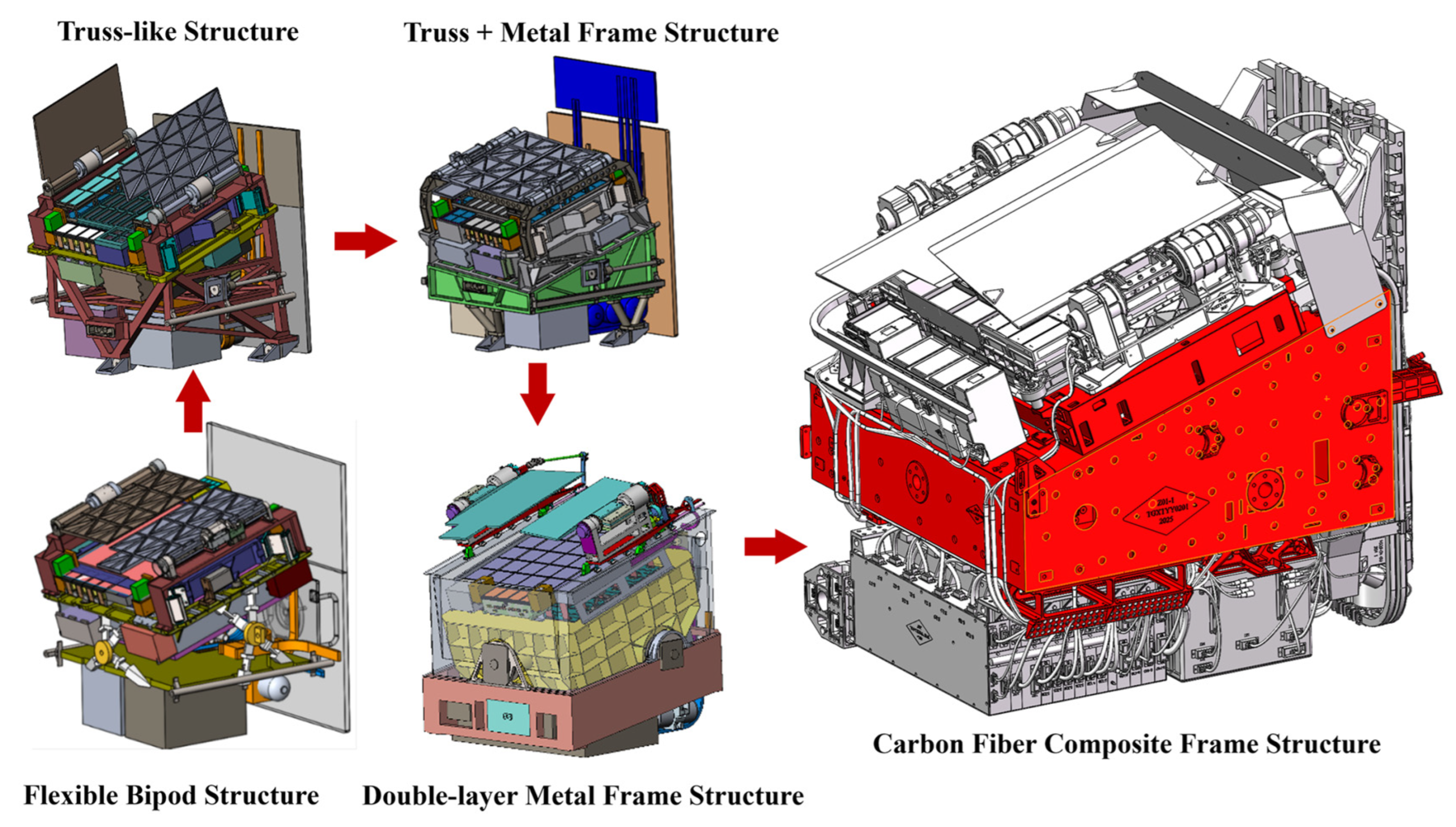

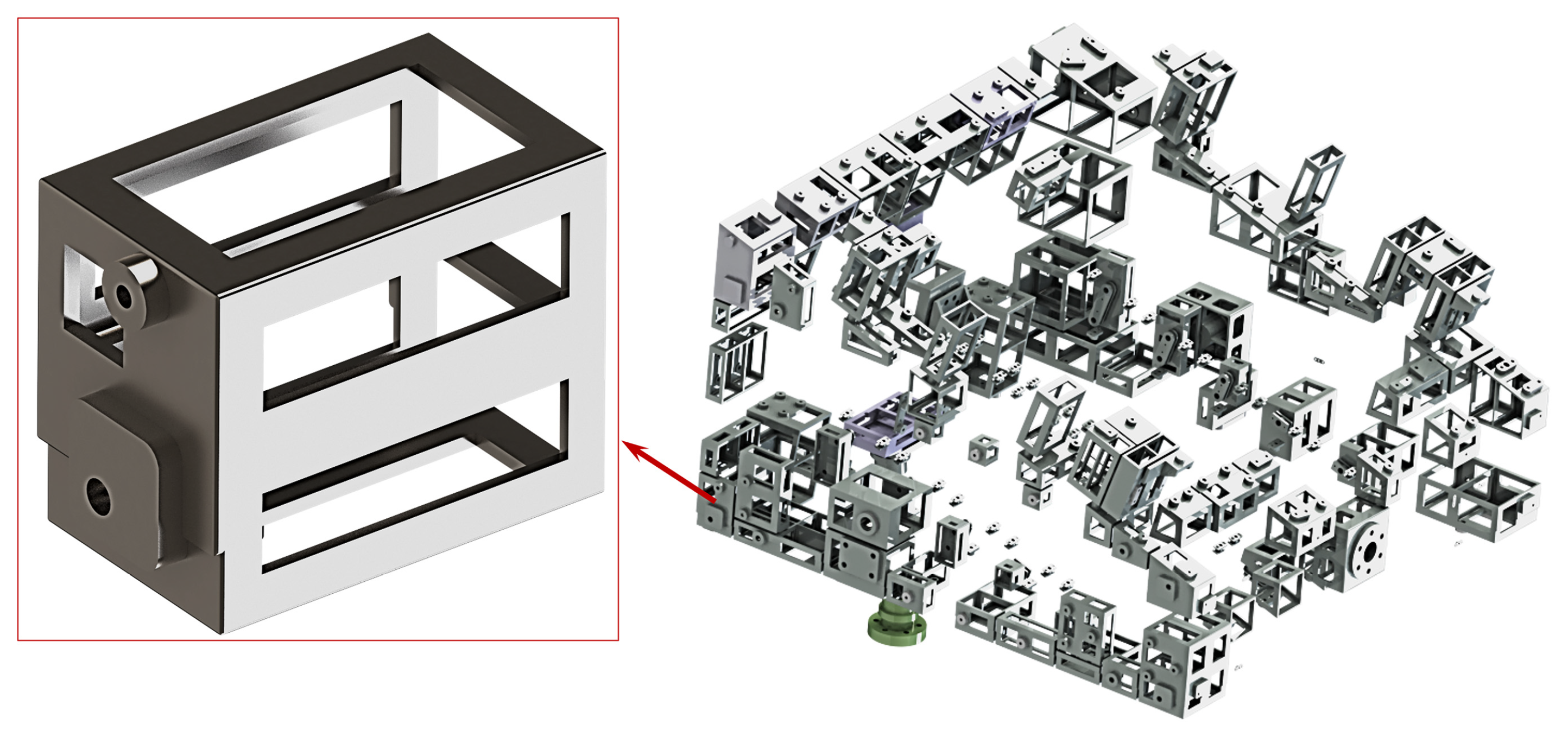

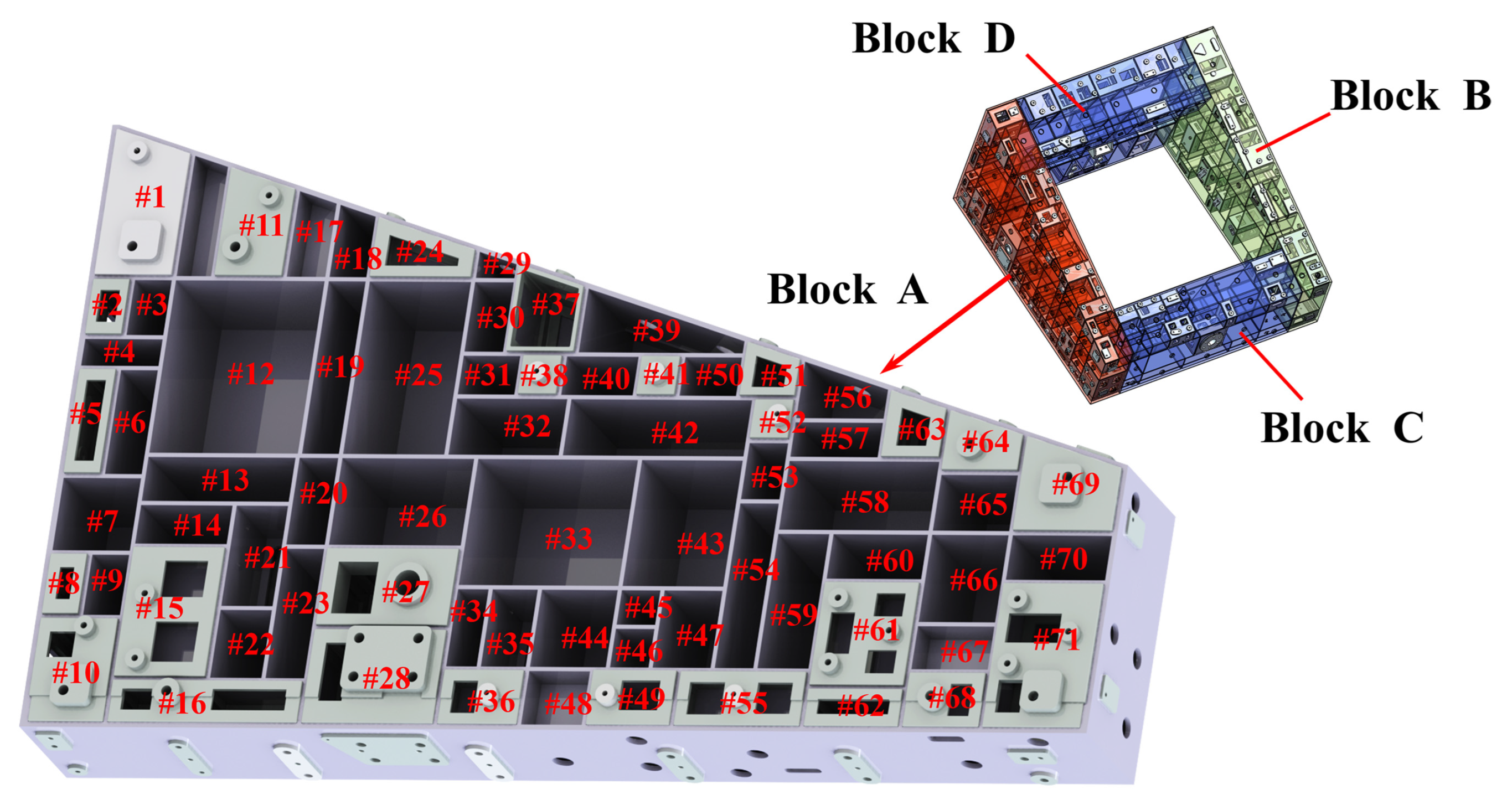

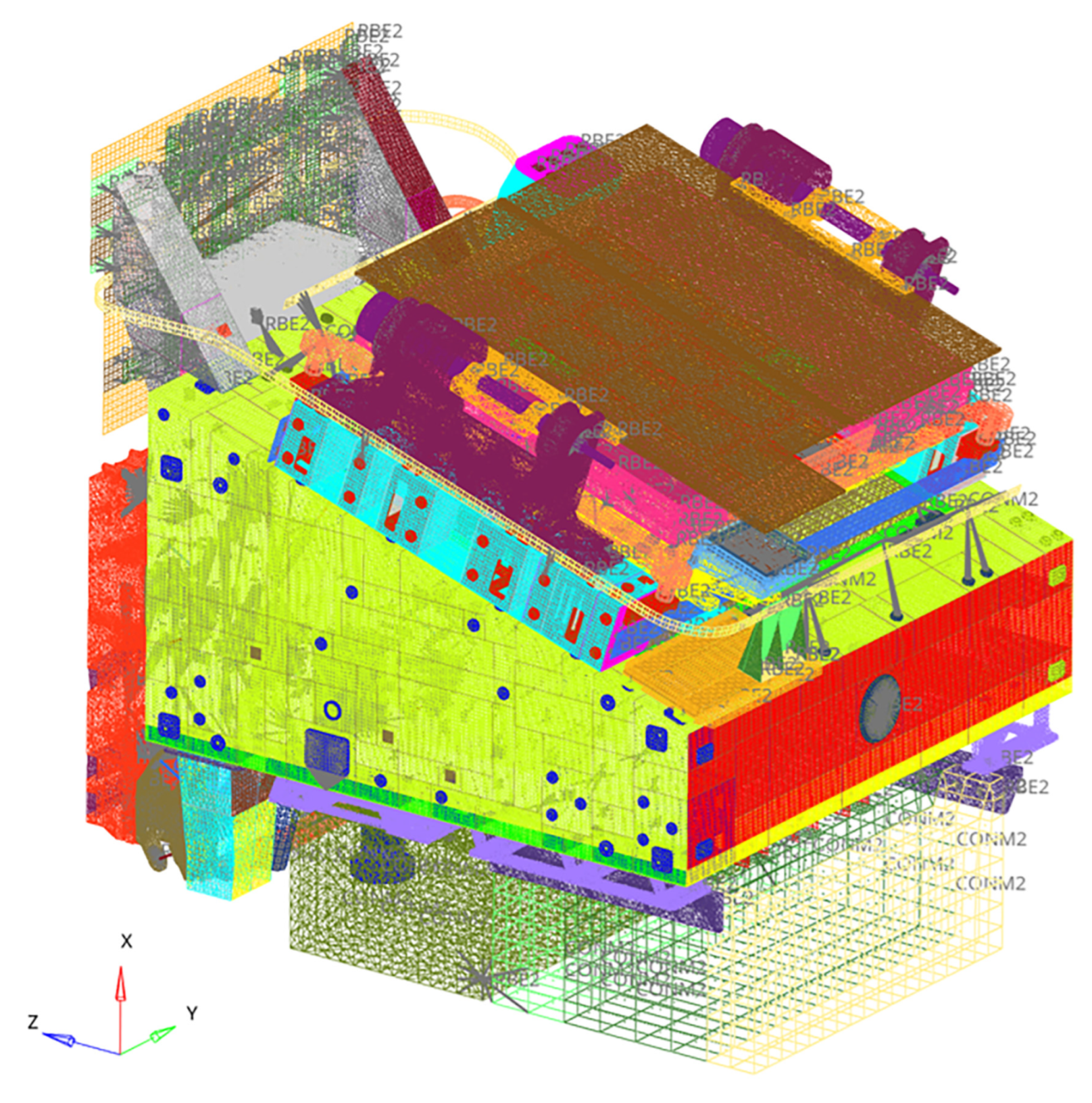

3.1. Configuration and Composition

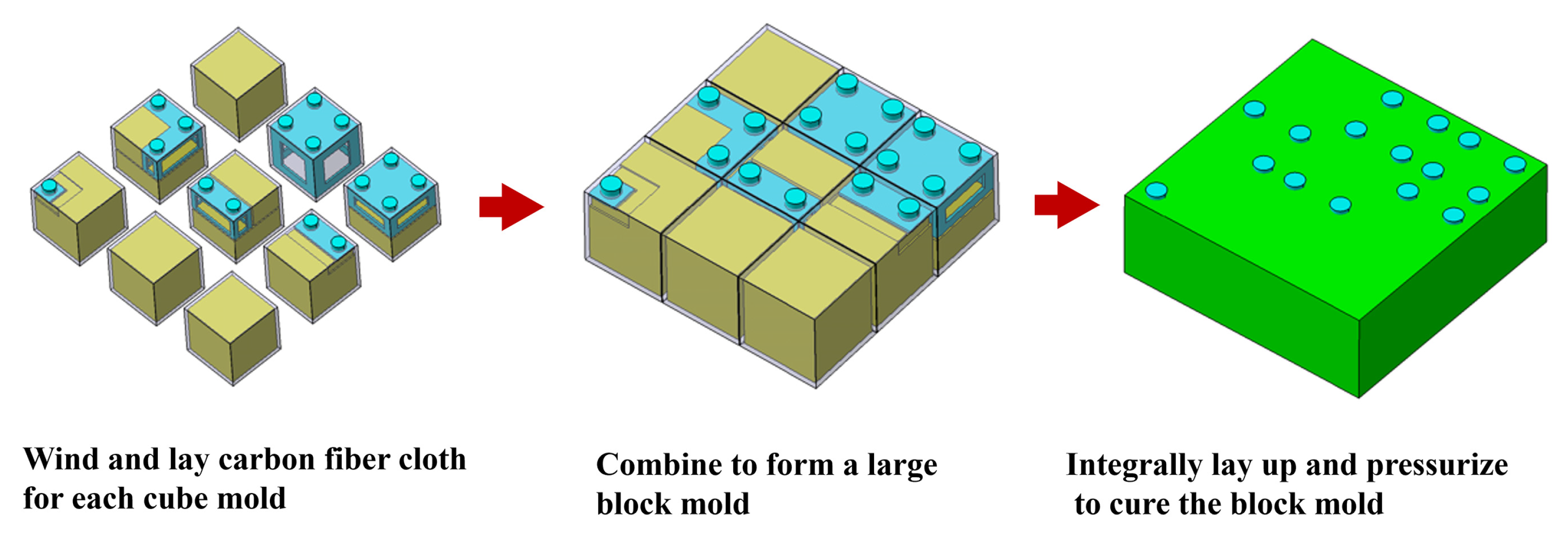

3.2. Carbon Fiber Layup Process and Material Selection

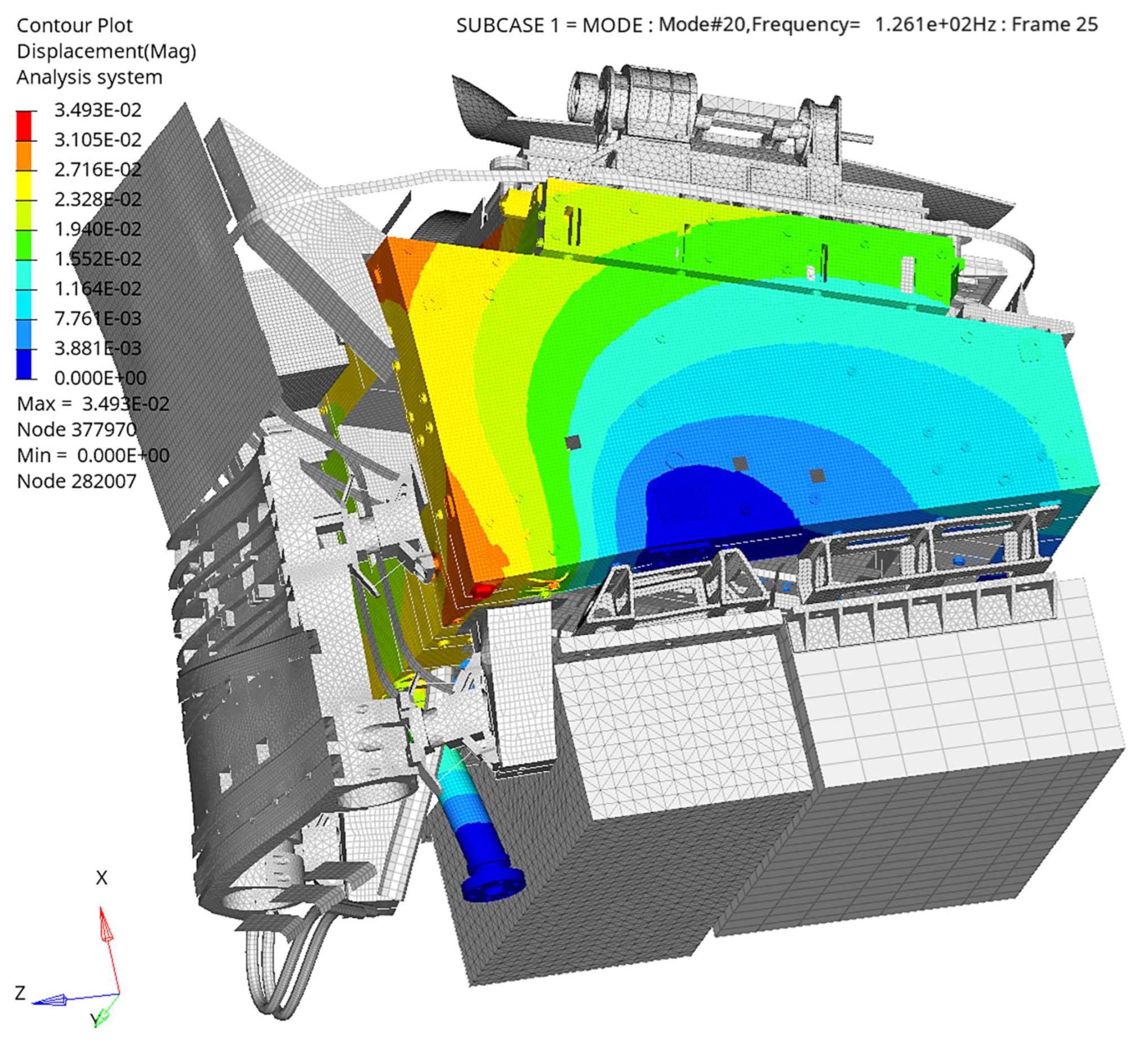

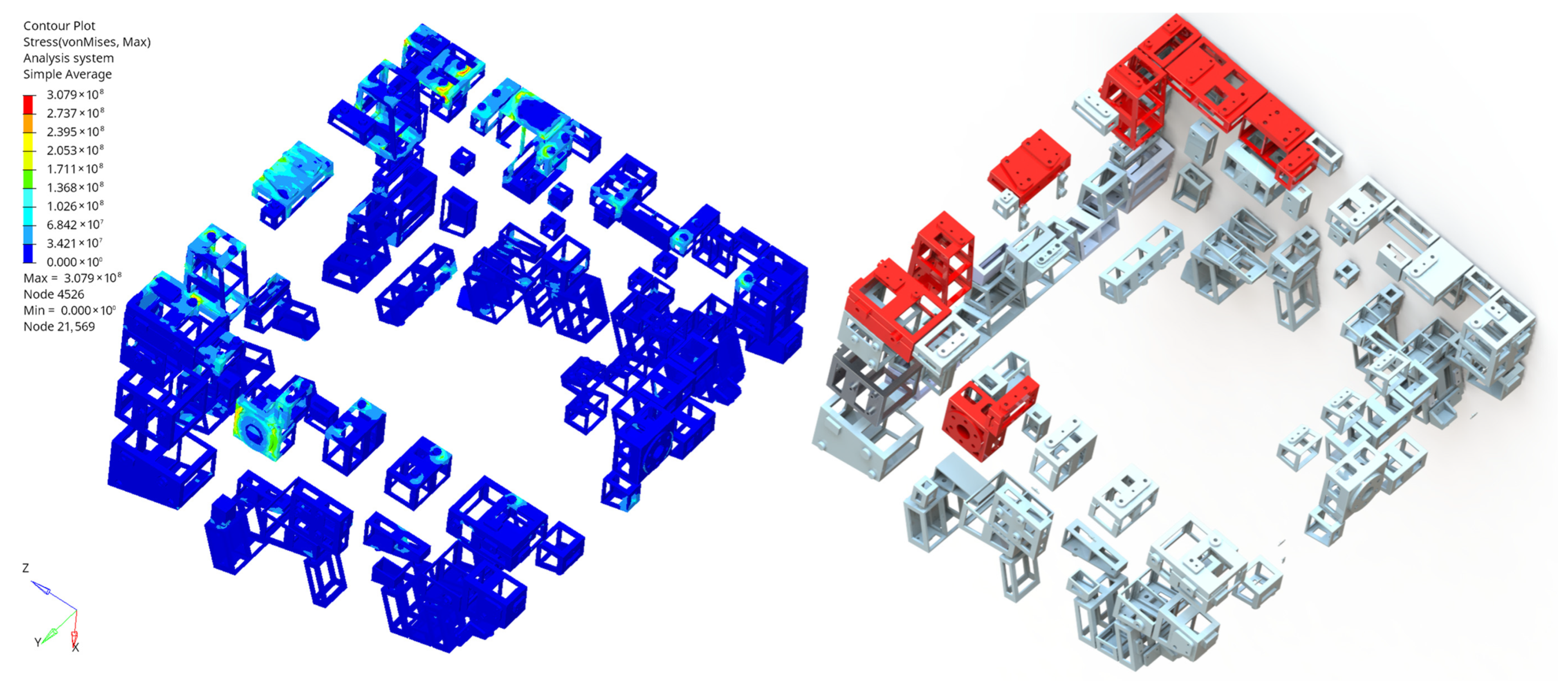

3.3. Optimal Design and Performance Analysis

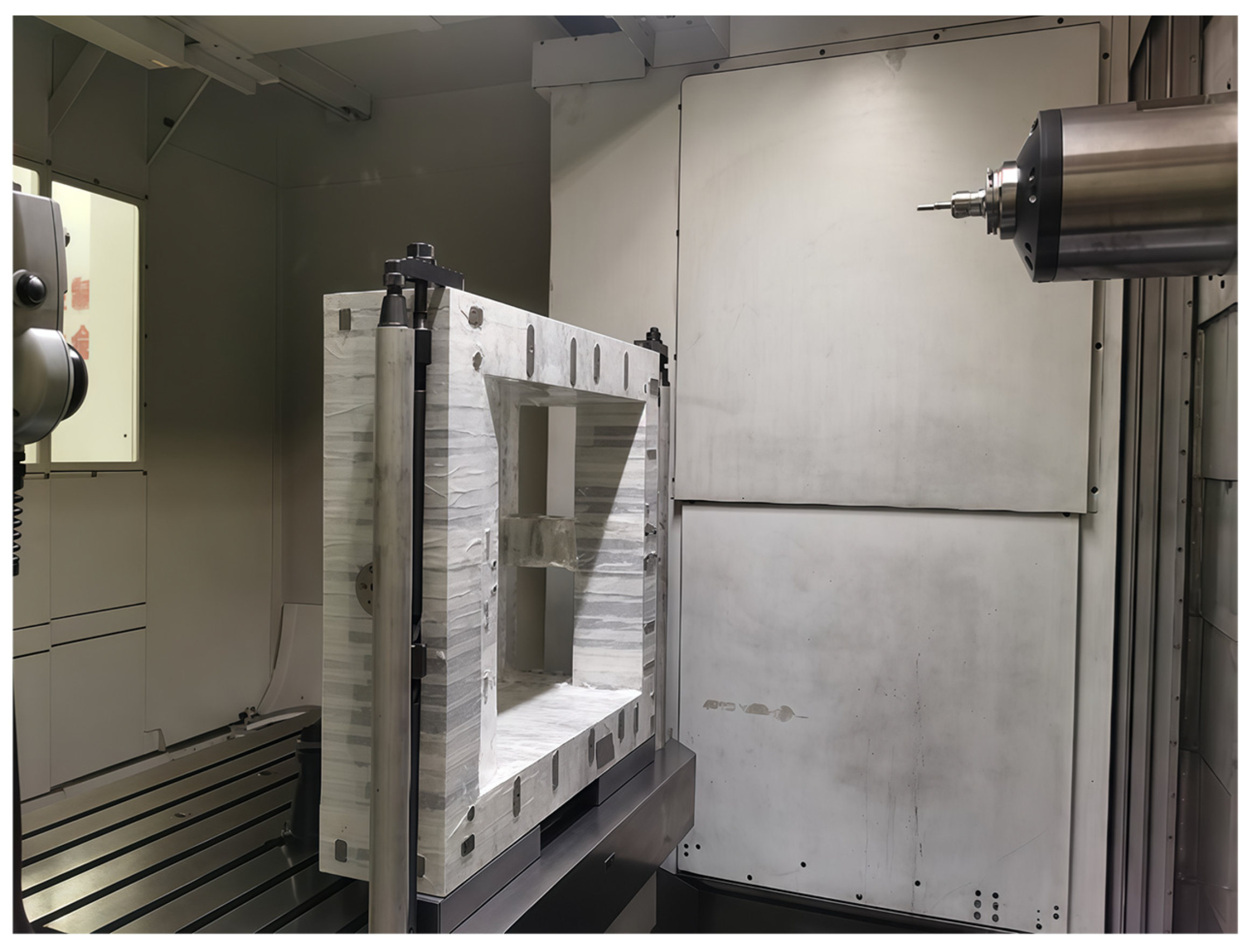

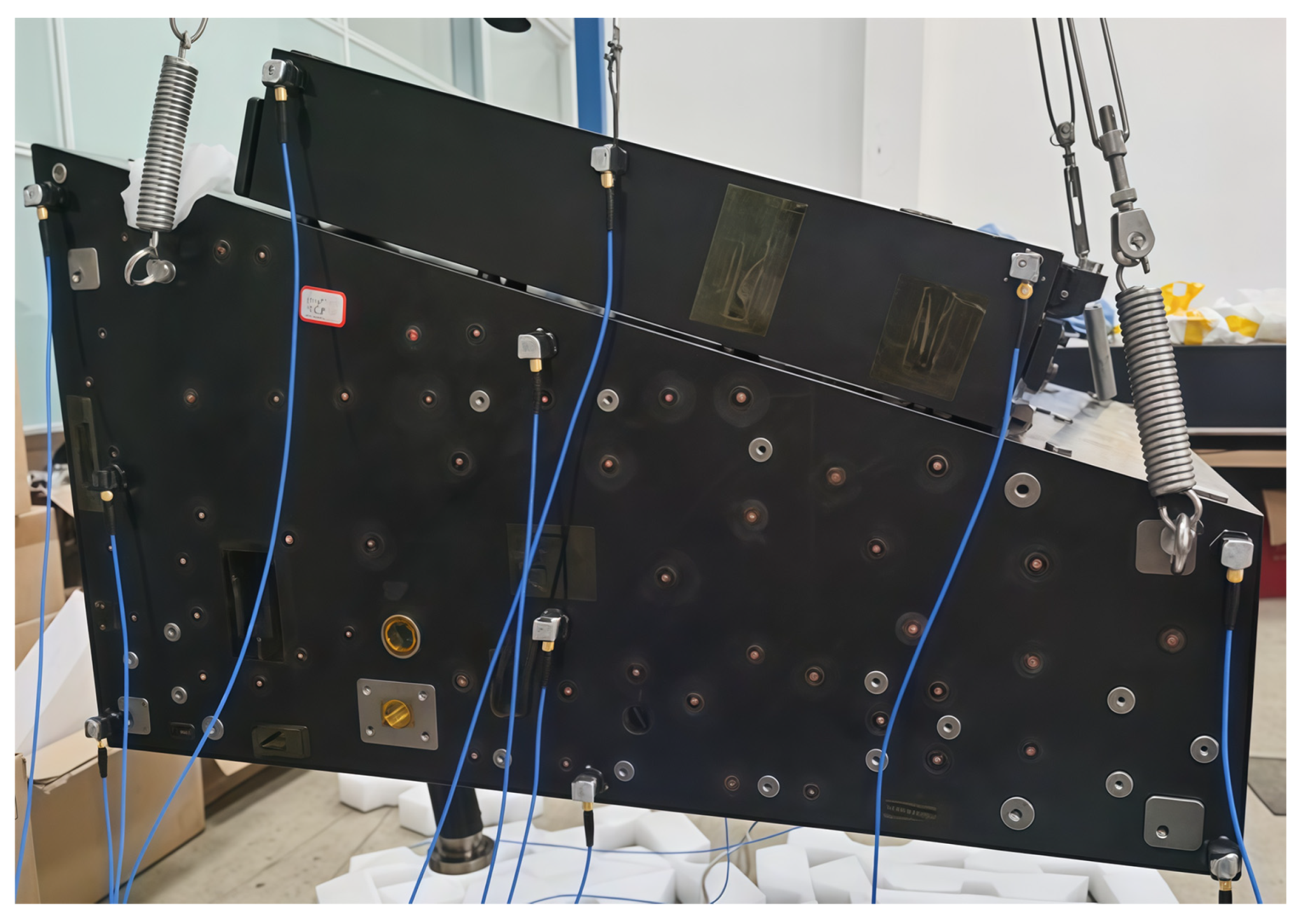

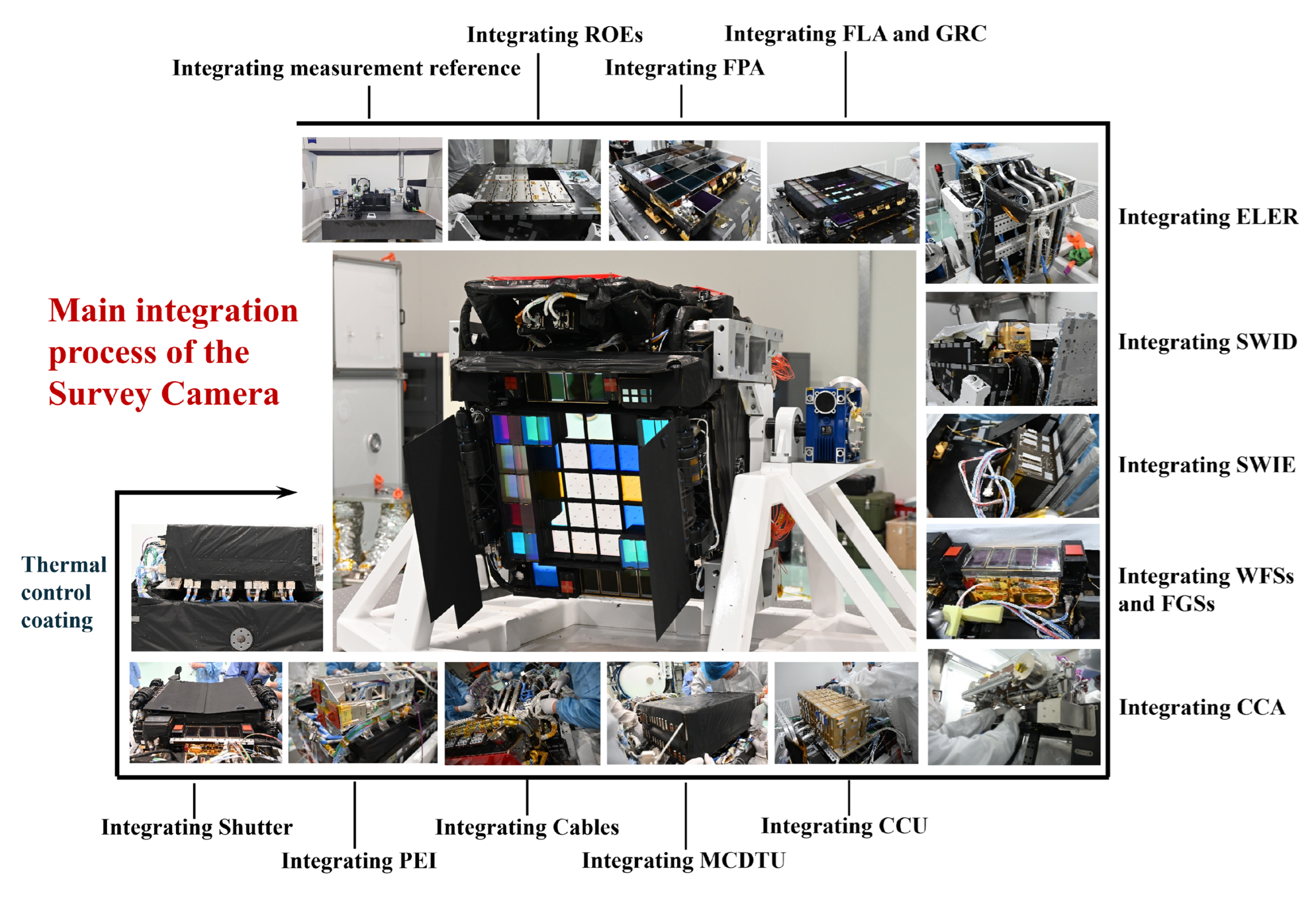

4. Manufacturing and Testing of the MST

4.1. Manufacturing and Machining

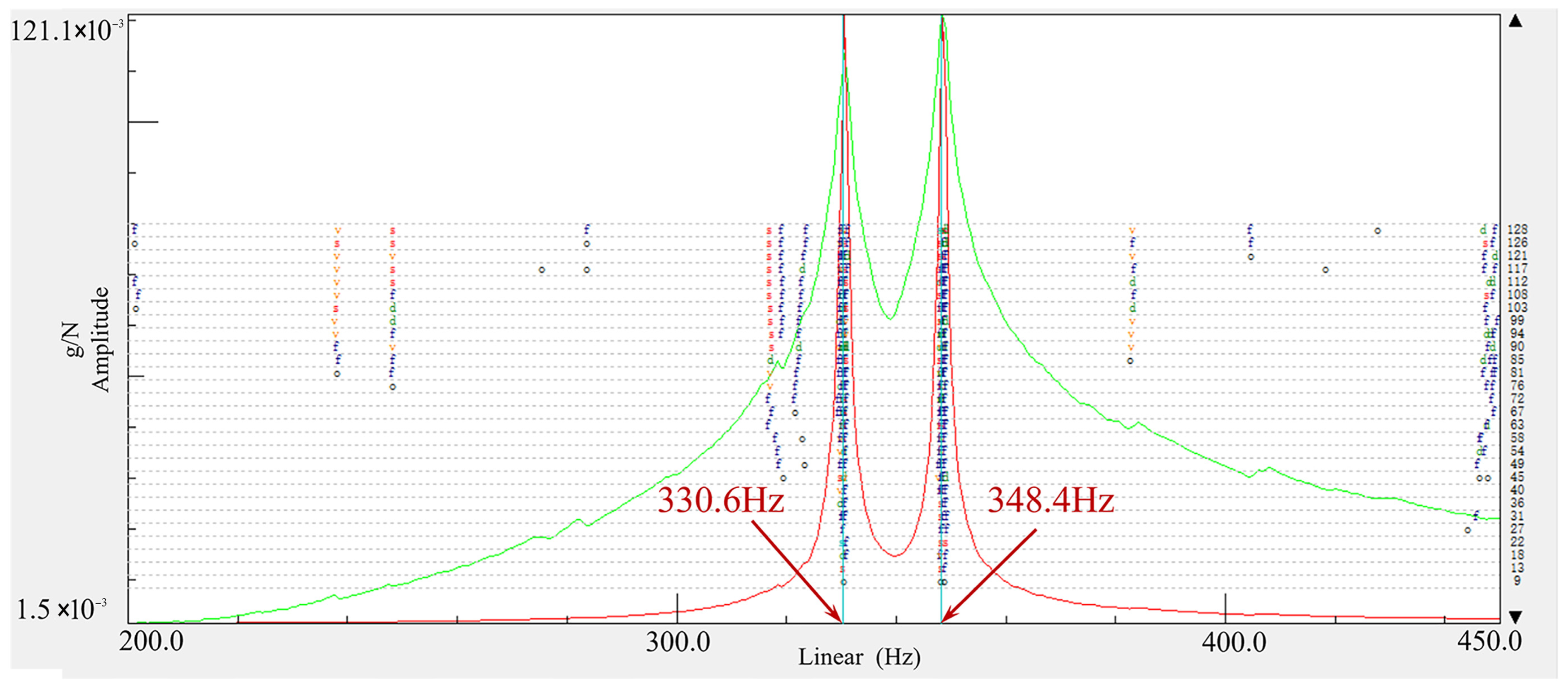

4.2. Free Modal Testing

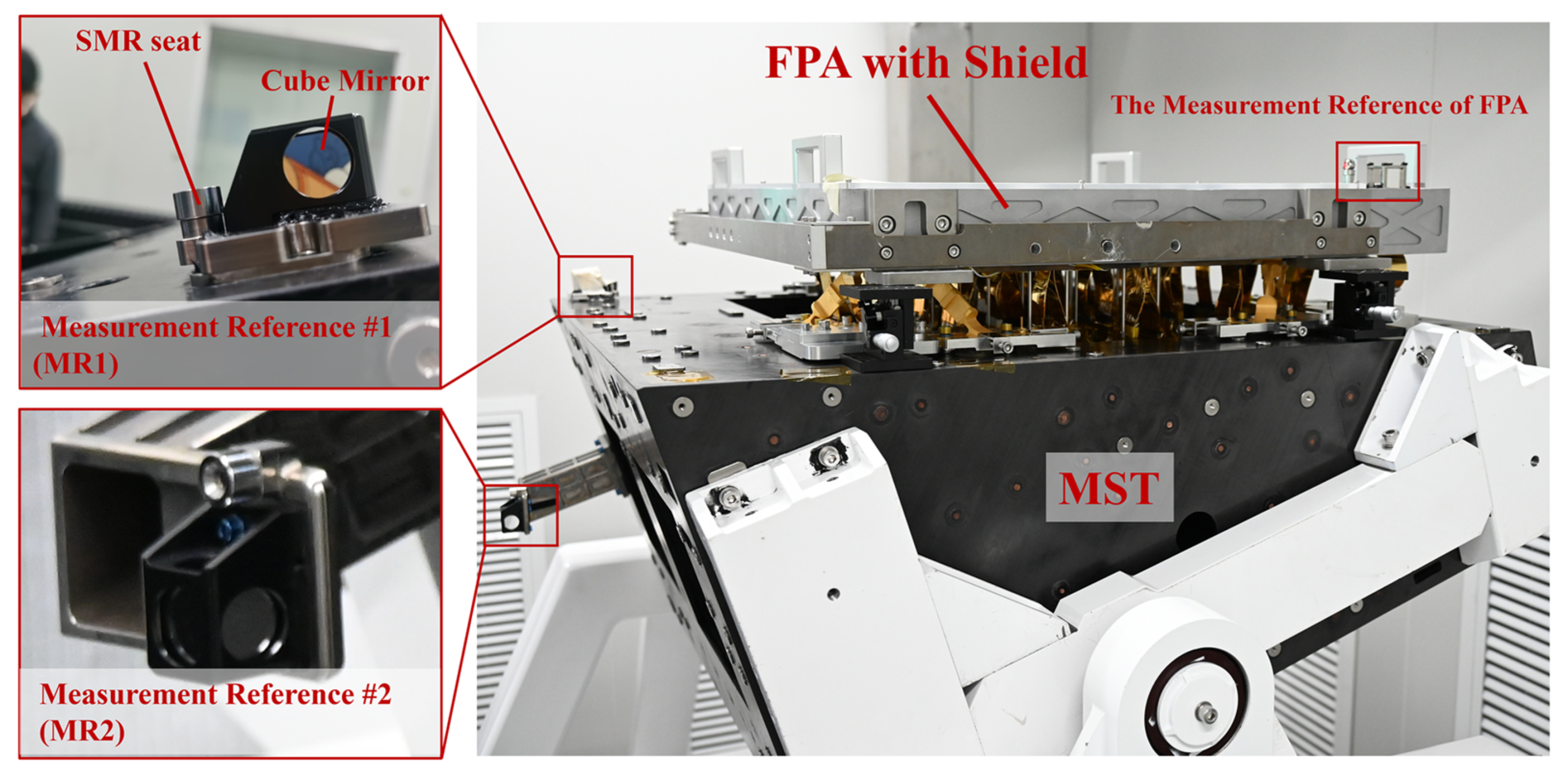

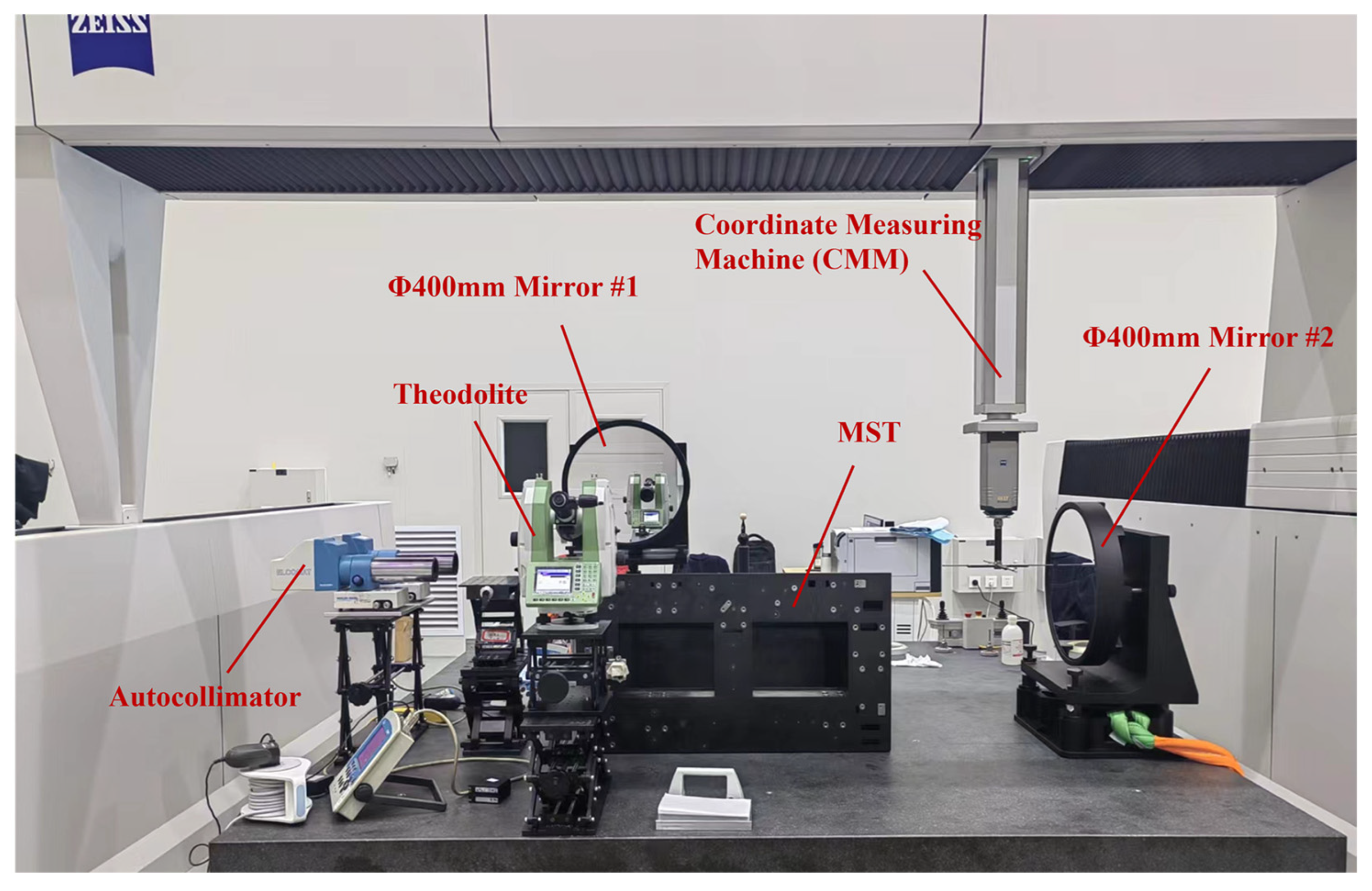

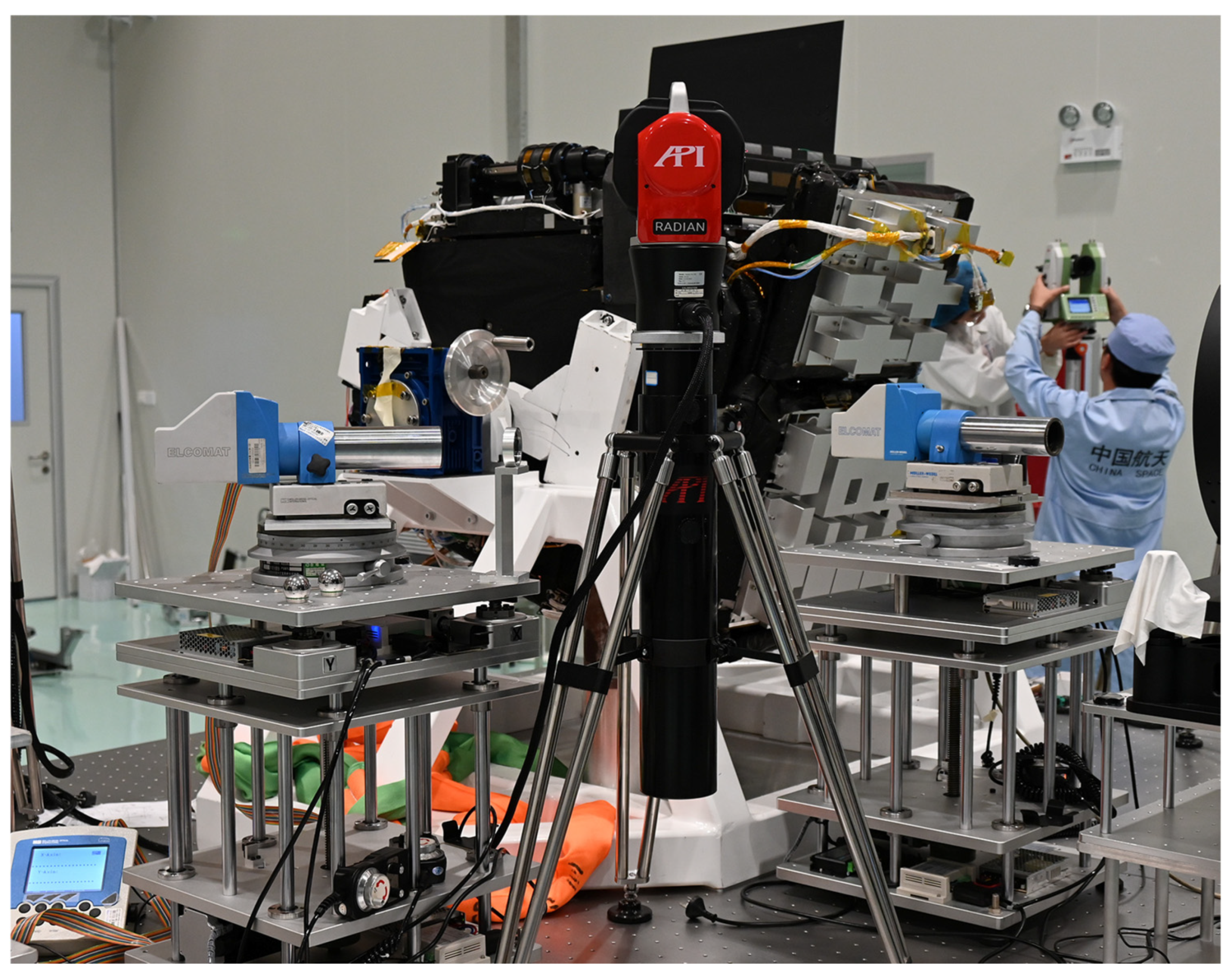

4.3. Integration and Calibration of the MRs

4.4. Vibration Test

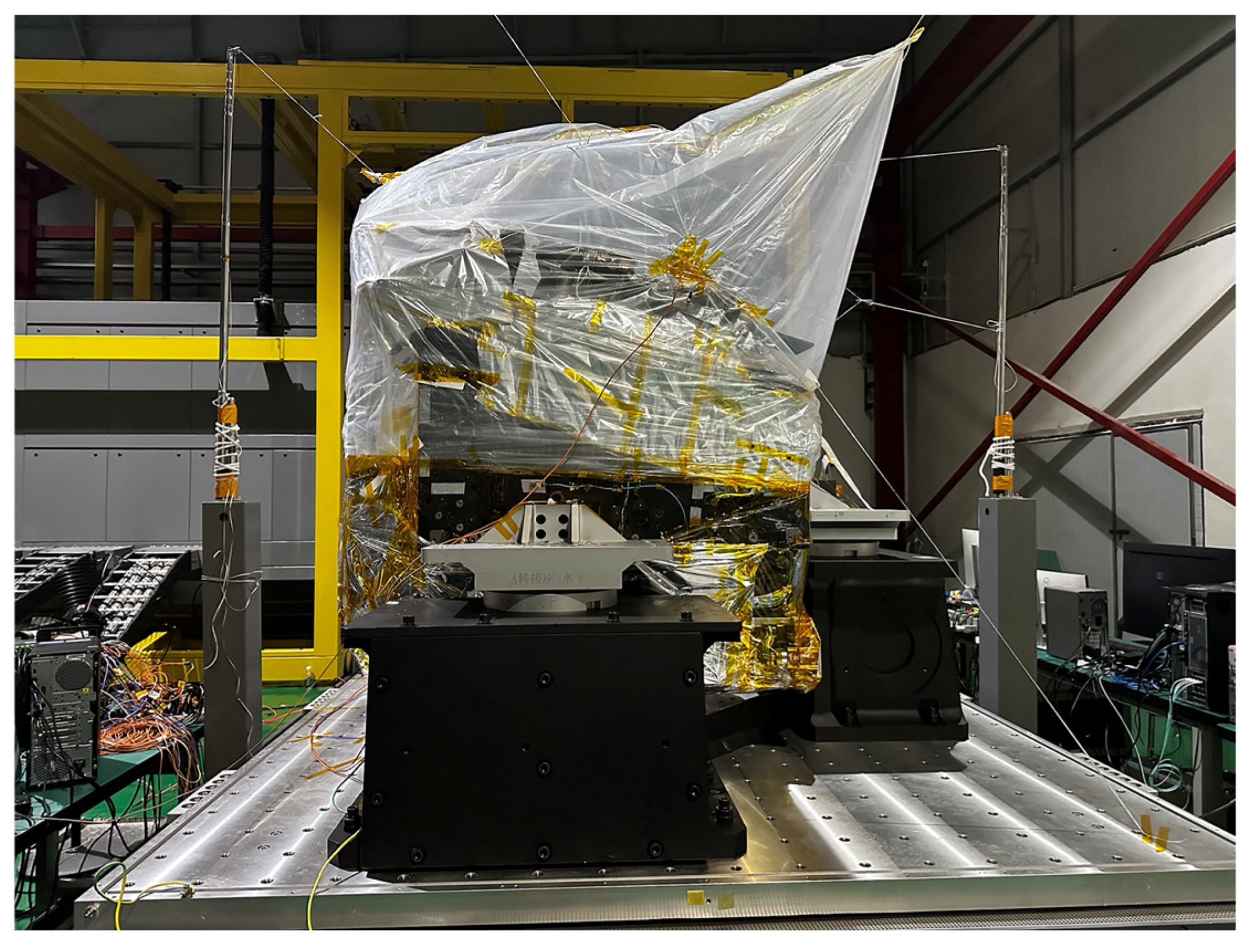

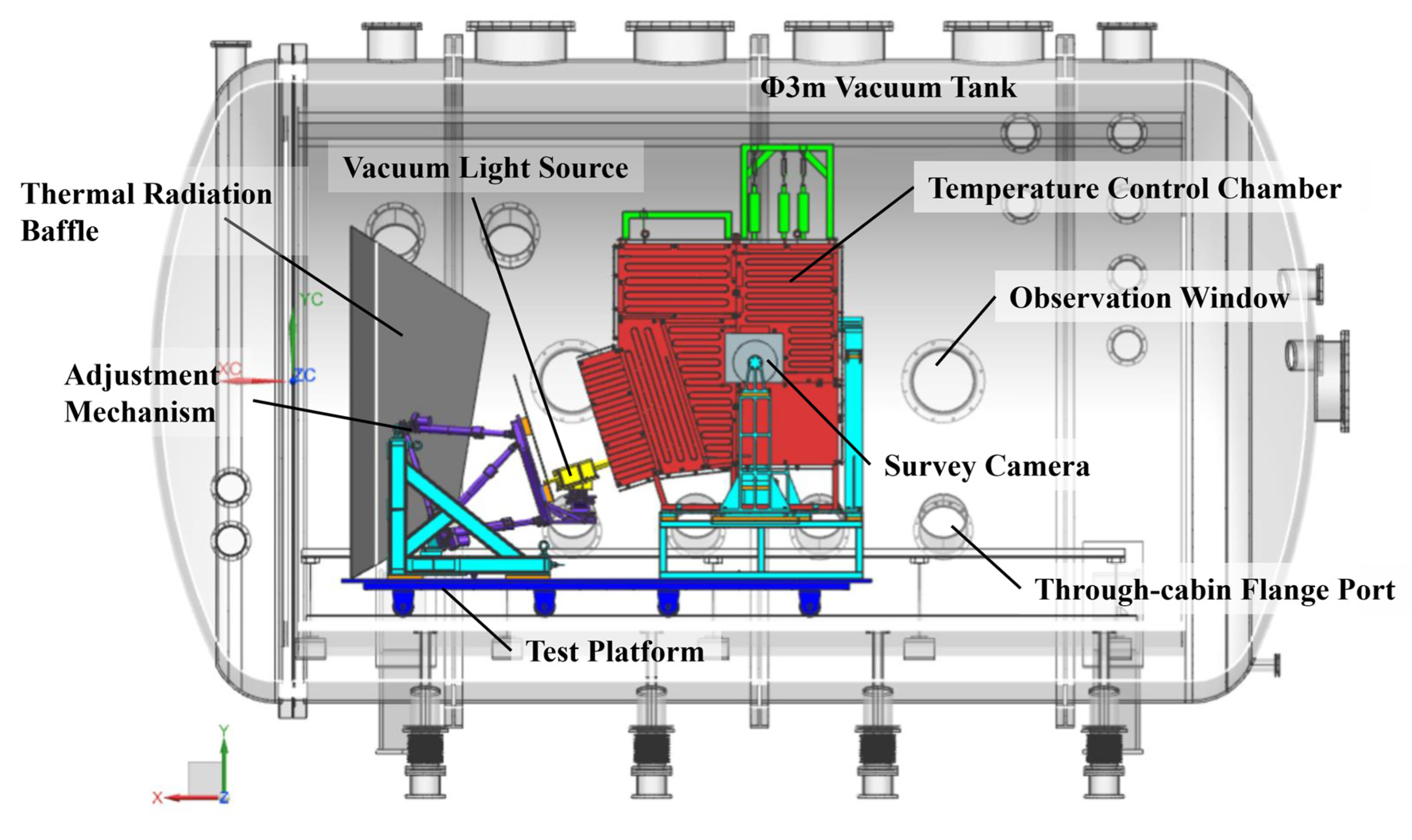

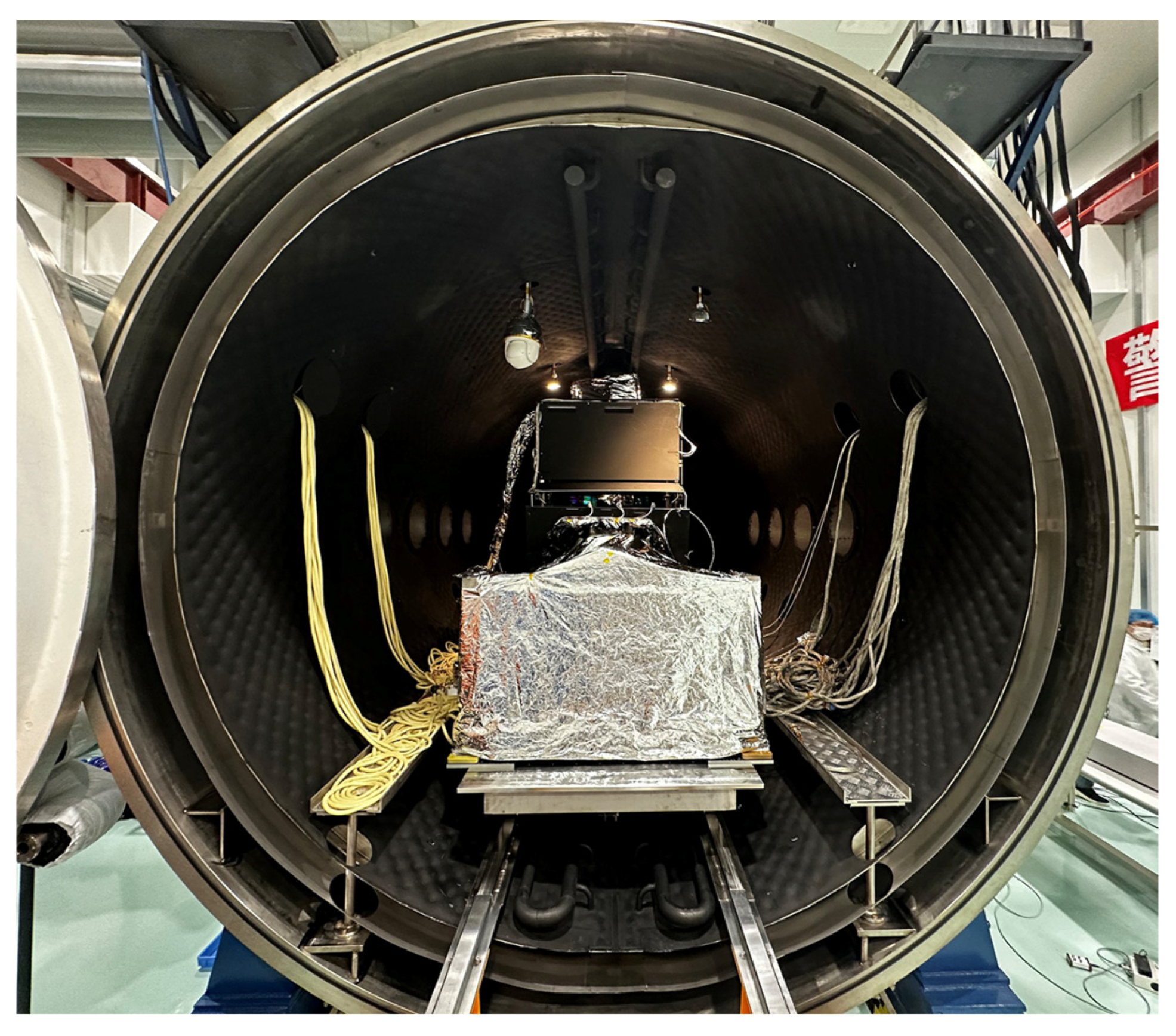

5. Testing and Experimentation of the SC

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Edeson, R.; Aglietti, G.S.; Tatnall, A.R.L. Conventional Stable Structures for Space Optics: The State of the Art. Acta Astronaut. 2010, 66, 13–32. [Google Scholar] [CrossRef]

- Liu, X.; Gu, K.; Li, M.; Cheng, Z. Optimization Design of Large-Aperture Primary Mirror for a Space Remote Camera. Sensors 2023, 23, 5441. [Google Scholar] [CrossRef]

- Peng, J.; Liu, S.; Wang, D.; Xu, A.; Huang, X.; Ma, T.; Wang, J.; Li, H. Design and Optimization of Thin-Walled Main Support Structure for Space Camera Based on Additive Manufacturing. Micromachines 2024, 15, 211. [Google Scholar] [CrossRef]

- Men, S.; Shen, J.; Shi, Y.; Liang, Z.; Li, Z. Optimization Design and Analysis for Support Structure of Space Camera. In Proceedings of the International Conference on Precision Instruments and Optical Engineering (PIOE 2023), Shanghai, China, 25–27 August 2023; Tao, W., Pan, H., Yao, B., Eds.; SPIE: Ile-de-France, France; p. 48. [Google Scholar]

- Kang, S.-Y.; Jo, M.-S.; Choi, J.-Y.; Yang, S.S. Cost Effectiveness of Reusable Launch Vehicles Depending on the Payload Capacity. Aerospace 2025, 12, 364. [Google Scholar] [CrossRef]

- Sairajan, K.K.; Aglietti, G.S.; Mani, K.M. A Review of Multifunctional Structure Technology for Aerospace Applications. Acta Astronaut. 2016, 120, 30–42. [Google Scholar] [CrossRef]

- Wei, L.; Zhang, L.; Gong, X.; Ma, D. Design and Optimization for Main Support Structure of a Large-Area off-Axis Three-Mirror Space Camera. Appl. Opt. 2017, 56, 1094. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Z. A Review of Lightweight Design for Space Mirror Core Structure: Tradition and Future. Machines 2022, 10, 1066. [Google Scholar] [CrossRef]

- Djojodihardjo, H. Structural Integrity of Spacecraft Structures Subject to Motion, Thermo-Structural Dynamics and Environmental Effects—An Overview. Acta Astronaut. 2024, 222, 219–243. [Google Scholar] [CrossRef]

- Chen, S.; Duan, S.; Zhang, B.; Xiao, J.; Zhang, L.; Zhong, X.; Luo, Z. A Novel Variable-Stiffness Structure for Microvibration Suppression of High-Resolution Optical Microsatellites. Acta Astronaut. 2024, 218, 137–146. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, B.; Zhang, X.; Wei, L.; Zhang, L.; Song, C.; Yin, L. Optimal Design of Integrated Main Supporting Structure with Ultra-Light Weight and High Stability for Space Camera. J. Vibroengineering 2021, 23, 1694–1706. [Google Scholar] [CrossRef]

- Kimble, R.A.; MacKenty, J.W.; O’Connell, R.W. Status and Performance of HST Wide Field Camera 3, Mather, J.C., Ed.; 2004; 266.

- Borders, T.M.; Baggett, S.; Bushouse, H.; Gilliland, R.; Kalirai, J.; Petro, L.; Kozhurina-Platais, V.; MacKenty, J.; Noeske, K.; Rajan, A. WFC3 UVIS Detector: On-Orbit Performance. In Proceedings of the American Astronomical Society Meeting Abstracts# 217, Seattle, WA, USA, 9–13 January 2011; Volume 217, pp. 237–254. [Google Scholar]

- Holz, J.M.; Kunt, C.; Lashley, C.; McGuffey, D.B. Development of a Lightweight Near-Zero CTE Optical Bench for the Wide-Field Camera 3 Instrument, Blades, J.C., Siegmund, O.H.W., Eds.; 2003; 435.

- Jahnke, K.; Gillard, W.; Schirmer, M.; Ealet, A.; Maciaszek, T.; Prieto, E.; Barbier, R.; Bonoli, C.; Corcione, L.; Dusini, S.; et al. Euclid. Astron Astrophys. 2025, 697, A3. [Google Scholar] [CrossRef]

- Morgante, G.; Maciaszek, T.; Martin, L.; Riva, M.; Bortoletto, F.; Prieto, E.; Bonoli, C.; Corcione, L.; De Caprio, V.; Grupp, F. Euclid NISP Thermal Control Design. In Proceedings of the Space Telescopes and Instrumentation 2012: Optical, Infrared, and Millimeter Wave, Amsterdam, The Netherlands, 1–6 July 2012; SPIE: Ile-de-France, France, 2012; Volume 8442, pp. 1122–1133. [Google Scholar]

- Bagnasco, G.; Kolm, M.; Ferruit, P.; Honnen, K.; Koehler, J.; Lemke, R.; Maschmann, M.; Melf, M.; Noyer, G.; Rumler, P.; et al. Overview of the Near-Infrared Spectrograph (NIRSpec) Instrument on-Board the James Webb Space Telescope (JWST); Heaney, J.B., Burriesci, L.G., Eds.; SPIE: Ile-de-France, France, 2007; p. 66920M. [Google Scholar]

- Tan, S.; Yao, Q.; Li, J.; Shi, S.-C. Modified Genetic Algorithm for China Space Station Telescope High-Sensitivity Terahertz Detection Module Observation Schedule. J. Astron. Telesc. Instrum. Syst. 2024, 10, 037002. [Google Scholar] [CrossRef]

- Gu, Y. The China Space Station: A New Opportunity for Space Science. Natl. Sci. Rev. 2022, 9, nwab219. [Google Scholar] [CrossRef]

- Zhan, H. The Wide-Field Multiband Imaging and Slitless Spectroscopy Survey to Be Carried out by the Survey Space Telescope of China Manned Space Program. Chin. Sci. Bull. (Chin. Version) 2021, 66, 1290–1298. [Google Scholar] [CrossRef]

- Cao, Y.; Gong, Y.; Liu, D.; Cooray, A.; Feng, C.; Chen, X. Anisotropies of Cosmic Optical and Near-IR Background from the China Space Station Telescope (CSST). Mon. Not. R. Astron. Soc. 2022, 511, 1830–1840. [Google Scholar] [CrossRef]

- Li, C.; Zheng, Z.; Li, X.; Pang, X.; Tang, B.; Milone, A.P.; Wang, Y.; Wang, H.; Jiang, D. Searching for Multiple Populations in Star Clusters Using the China Space Station Telescope. Res. Astron. Astrophys. 2022, 22, 095004. [Google Scholar] [CrossRef]

- De Bruijne, J.; Kohley, R.; Prusti, T. Gaia: 1000 Million Stars with 100 CCD Detectors. In Proceedings of the Space Telescopes and Instrumentation 2010: Optical, Infrared, and Millimeter Wave, San Diego, CA, USA, 27 June–2 July 2010; SPIE: Ile-de-France, France, 2010; Volume 7731, pp. 395–409. [Google Scholar]

- Ren, J.; Kong, N.; Zhuang, Y.; Zhang, J.; Ma, S.; Wang, B.; Liu, W. A Review on the Interfaces of Orbital Replacement Unit: Great Efforts for Modular Spacecraft. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2021, 235, 1941–1967. [Google Scholar] [CrossRef]

- Chen, P.C.; Bowers, C.W.; Content, D.A.; Marzouk, J.; Romeo, R.C. Advances in Very Lightweight Composite Mirror Technology. Opt. Eng. 2000, 39, 2320–2329. [Google Scholar] [CrossRef]

- Frame, B.J. Characterization and Process Development of Cyanate Ester Resin Composites; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 1999.

- Rao, G.R.; Srikanth, I.; Reddy, K.L. Mechanical, Thermal and Ablative Behavior of Organo Nanoclay Added Carbon Fiber/Cyanate Ester Resin Composites and Effect of Heat Flux on Its Ablative Performance. Polym. Polym. Compos. 2021, 29, S250–S261. [Google Scholar] [CrossRef]

- Zheng, X.; Fei, J.; Gu, Y.; Li, M.; Huang, J. Constructing Interfacial Path for Enhancing Mechanical and Thermal Performances of Carbon Fiber/Cyanate Ester Resin Composite. Colloids Surf. A Physicochem. Eng. Asp. 2021, 617, 126311. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Wang, J.; Han, E.; Tian, G.; Wu, D. Dielectric and Mechanical Properties of Polyimide Fiber Reinforced Cyanate Ester Resin Composites with Varying Resin Contents. J. Polym. Res. 2020, 27, 160. [Google Scholar] [CrossRef]

- Ren, P.; Liang, G.; Zhang, Z. Epoxy-modified Cyanate Ester Resin and Its High-modulus Carbon-fiber Composites. Polym. Compos. 2006, 27, 402–409. [Google Scholar] [CrossRef]

- Chung, K.; Seferis, J.C. Evaluation of Thermal Degradation on Carbon Fiber/Cyanate Ester Composites. Polym. Degrad. Stab. 2001, 71, 425–434. [Google Scholar] [CrossRef]

- Ahrari, A.; Atai, A.A. Fully Stressed Design Evolution Strategy for Shape and Size Optimization of Truss Structures. Comput. Struct. 2013, 123, 58–67. [Google Scholar] [CrossRef]

- Peeters, B.; Van der Auweraer, H.; Guillaume, P.; Leuridan, J. The PolyMAX Frequency-domain Method: A New Standard for Modal Parameter Estimation? Shock Vib. 2004, 11, 395–409. [Google Scholar] [CrossRef]

- Bonnefoi, A.; Bon, W.; Niclas, M.; Solheim, B.G.B.; Torvanger, O.; Schistad, R.; Foulon, B.; Garcia, J.; Vives, S. Focal Plane Mechanical Design of the NISP/Euclid Instrument. In Proceedings of the Space Telescopes and Instrumentation 2016: Optical, Infrared, and Millimeter Wave, Edinburgh, UK, 26 June–1 July 2016; SPIE: Ile-de-France, France, 2016; Volume 9904, pp. 939–948. [Google Scholar]

- Hadjimichael, T.; Ohl, R.G.; Berrier, J.; Gum, J.; Hayden, J.; Khreishi, M.; McLean, K.; Redman, K.; Sullivan, J.; Wenzel, G. Metrology for Trending Alignment of the James Webb Space Telescope before and after Ambient Environmental Testing. In Proceedings of the Optical System Alignment, Tolerancing, and Verification XI, San Diego, CA, USA, 6–7 August 2017; SPIE: Ile-de-France, France, 2017; Volume 10377, pp. 121–134. [Google Scholar]

| Project Category | Value |

|---|---|

| Total Mass Loss (TML) | 0.114% |

| Condensable Volatile Content (CVC) | 0.009% |

| Water Vapor Regain (WVR) | 0.099% |

| Area | Thickness of Plies | |

|---|---|---|

| Block A | Cube Mold | 1.6~3.2 mm |

| Outer Skin | 4.0 mm | |

| Block B | Cube Mold | 1.6~3.2 mm |

| Outer Skin | 4.0 mm | |

| Block C | Cube Mold | 1.6~3.2 mm |

| Outer Skin | 4.0 mm | |

| Block D | Cube Mold | 1.6~3.2 mm |

| Outer Skin | 4.0 mm | |

| Shutter Support Base | Cube Mold | 1.6~3.2 mm |

| Outer Skin | 3.2 mm | |

| ROEs Support Beam | Cube Mold | 3.2~4.0 mm |

| Outer Skin | 5.6 mm | |

| Auxiliary Support Beam | 5.6 mm | |

| Analysis Category | Analysis Item | Value (MPa) | Allowable Value (MPa) | Safety Margin |

|---|---|---|---|---|

| Sine Vibration | Maximum longitudinal stress of carbon fiber layers | 132.3 | 500 | 1.80 |

| Maximum transverse stress of carbon fiber layers | 2.4 | 20 | 5.17 | |

| Maximum shear stress of carbon fiber layers | 2.4 | 50 | 14.43 | |

| Maximum von Mises stress of titanium alloy inserts | 220.1 | 800 | 1.69 | |

| Random Vibration | Maximum longitudinal stress of carbon fiber layers | 140.5 | 500 | 1.64 |

| Maximum transverse stress of carbon fiber layers | 2.8 | 20 | 4.29 | |

| Maximum shear stress of carbon fiber layers | 2.4 | 50 | 5.17 | |

| Maximum von Mises stress of titanium alloy inserts | 265.3 | 800 | 1.23 |

| Modal Order | Measured (Hz) | Simulated (Hz) | Deviation | Mode Shape |

|---|---|---|---|---|

| 1st | 330.6 | 354.5 | 7.2% | 1st Torsional |

| 2nd | 348.4 | 369.5 | 6.1% | 2nd Torsional |

| 3rd | 507.5 | 547.2 | 7.8% | 1st Radial |

| 4th | 661.0 | 624.1 | −5.6% | 2nd Radial |

| 5th | 702.8 | 675.9 | −3.8% | Bending |

| Sine Vibration-X | |||||

|---|---|---|---|---|---|

| Frequency Range (Hz) | 5~10 | 10~14 | 14~30 | 30~45 | 45~100 |

| Amplitude | 7.45 mm | 3.0 g | 4.5 g | 6.0 g | 4.0 g |

| Sweep Rate | 2 oct/min | ||||

| Sine Vibration-Y, Z | |||||

| Frequency Range (Hz) | 5~10 | 10~14 | 14~60 | 60~100 | |

| Amplitude | 9.93 mm | 4.0 g | 6.0 g | 4.0 g | |

| Sweep Rate | 2 oct/min | ||||

| Random Vibration-X, Y, Z | |||||

| Frequency Range (Hz) | 20~100 | 100~600 | 600~2000 | ||

| Power Spectral Density (PSD) | 3 dB/oct | 0.02 g2/Hz | −9 dB/oct | ||

| Root Mean Square (RMS) | 4.02 g | ||||

| Test Duration per Direction | 3 min | ||||

| Items | Direction | Before Vibration Test | After Vibration Test | Difference |

|---|---|---|---|---|

| Angles of FPA-MR Relative to MST-MR | X | 1.3674° | 1.3681° | 2.5″ |

| Y | 340.4″ | 345.8″ | 5.4″ | |

| Z | −20.5″ | −25.7″ | −5.2″ | |

| Positions of FPA-MR Relative to MST-MR | X | 393.500 mm | 393.521 mm | 21 μm |

| Y | 564.548 mm | −564.552 mm | −4 μm | |

| Z | −816.868 mm | −816.846 mm | 22 μm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, R.; Zhang, A.; Li, Z.; Liu, E.; Wang, L.; Le, S.; Zhang, Y.; Zhang, H.; Wang, H.; Guan, S.; et al. Main Structure of the Survey Camera for CSST: A Paradigm for Structural Design of Large-Scale Complex Space Optical Instruments. Aerospace 2025, 12, 1036. https://doi.org/10.3390/aerospace12121036

Jiang R, Zhang A, Li Z, Liu E, Wang L, Le S, Zhang Y, Zhang H, Wang H, Guan S, et al. Main Structure of the Survey Camera for CSST: A Paradigm for Structural Design of Large-Scale Complex Space Optical Instruments. Aerospace. 2025; 12(12):1036. https://doi.org/10.3390/aerospace12121036

Chicago/Turabian StyleJiang, Renkui, Ang Zhang, Zhaoyang Li, Enhai Liu, Libin Wang, Sixian Le, Yongchao Zhang, Haini Zhang, Hongyu Wang, Shaohua Guan, and et al. 2025. "Main Structure of the Survey Camera for CSST: A Paradigm for Structural Design of Large-Scale Complex Space Optical Instruments" Aerospace 12, no. 12: 1036. https://doi.org/10.3390/aerospace12121036

APA StyleJiang, R., Zhang, A., Li, Z., Liu, E., Wang, L., Le, S., Zhang, Y., Zhang, H., Wang, H., Guan, S., Luo, Q., Mao, Y., Xu, W., Chen, P., Su, H., Zhang, Y., Du, J., Shao, J., Huang, M., & Liang, W. (2025). Main Structure of the Survey Camera for CSST: A Paradigm for Structural Design of Large-Scale Complex Space Optical Instruments. Aerospace, 12(12), 1036. https://doi.org/10.3390/aerospace12121036