1. Introduction

Carrier-based aircraft rely on arresting hooks to achieve rapid deceleration by engaging the arresting cable during landing. During the arrested landing process, the hook head endures repeated high-rate impact loadings, which impose stringent durability requirements on its high-strength steel structure. When the strain rate induced by impact becomes sufficiently high to significantly affect the material’s fatigue performance, the phenomenon is commonly referred to as impact fatigue. Because the steels used in naval arresting systems are highly strain-rate sensitive, their fatigue degradation behavior cannot be accurately captured using conventional quasi-static fatigue analysis. Therefore, a systematic investigation into the dynamic response and fatigue behavior of arresting hooks under repeated impact loading is essential for ensuring the safety and reliability of carrier-based aircraft operations.

Recent years have witnessed considerable progress in the study of arresting hook dynamics and fatigue mechanisms. Peng and Xie [

1] experimentally investigated the bounce dynamics of a carrier-based aircraft arresting hook during deck impact, establishing a collision–rebound test platform to characterize transient contact behavior. Shao et al. [

2] developed a full-scale rigid–flexible coupling dynamic model for the aircraft arresting process, effectively capturing the hook–cable engagement and deceleration response. Complementarily, Li et al. [

3] proposed a parameter inversion method to model the transient dynamics of arresting hooks and cables, bridging the gap between experimental observations and numerical predictions. From the fatigue-resistance perspective, Rankin et al. [

4] studied the effect of laser peening on the fatigue life of an arrestment hook shank, reporting a more than threefold improvement in fatigue performance. Similarly, the ASTM investigation [

5] on the F/A-18E/F hook point shank demonstrated that fatigue cracks initiated at the root fillet region after approximately 1361 arrested landings, revealing the critical failure mode of high-strength steel hooks. Additionally, Chen et al. [

6] optimized a carrier-based UAV drawbar through strain fatigue analysis, providing a methodological reference for the fatigue-oriented parameter optimization of carrier-borne components. Although these studies have significantly advanced the understanding of arresting hook mechanics, most have focused either on single-impact dynamics or static fatigue enhancement, while systematic research integrating cyclic high-strain-rate impacts with virtual fatigue modeling remains limited.

For the high-strength steels used in arresting hooks, a large body of literature has explored their dynamic constitutive and deformation behaviors under high-strain-rate and temperature conditions. Kuang et al. [

7] optimized the Johnson–Cook constitutive model for HRB400 steel under multi-condition high strain rate and high temperature validation, improving model accuracy for impact scenarios. Dekhtyar et al. [

8] analyzed deformation and strain hardening mechanisms of titanium alloys and metal–matrix composites under both quasi-static and dynamic compression, providing key insights into high-rate plasticity. Zhang et al. [

9] reported the superior dynamic mechanical properties of high-nitrogen austenitic stainless steel, highlighting its exceptional strain-rate strengthening effect. Wang et al. [

10] investigated the dynamic mechanical response of laser-directed energy deposited AerMet100 ultra-high-strength steel, identifying its strain-rate-dependent fracture behavior and deformation mechanisms. Song et al. [

11] examined the coupling effects of temperature and strain rate on a refractory high-entropy alloy, revealing a strong thermomechanical interaction on deformation resistance. At the microstructural and atomistic level, Reis et al. [

12] demonstrated via molecular dynamics that Fe and Co additions markedly influence the high-strain-rate mechanical behavior of NiTi shape-memory alloys. Kim et al. [

13] simulated the fracture behavior of AH36 shipbuilding steel under drop-test conditions using the GISSMO damage model, validating its predictive accuracy for ductile fracture. Furthermore, Duntu and Boakye-Yiadom [

14] investigated adiabatic shear band formation in tempered AISI 4340 steel under high-strain-rate and elevated-temperature impacts, confirming the role of thermal softening in shear localization. These studies together enrich the understanding of rate-dependent plasticity, thermal coupling, and microstructural evolution of metallic materials, laying a theoretical foundation for modeling arresting hook steels under cyclic high-strain-rate conditions.

In addition, numerous investigations have addressed the dynamic strength and fatigue degradation of high-strength steels commonly used in aerospace and naval applications. Bouce et al. [

15] examined dynamic plastic deformation in high-strength steels under tension, identifying strong strain-rate sensitivity. Gilat and Goldberg [

16] characterized compressive responses at 10–200 s

−1 strain rates using split Hopkinson pressure bar tests. Xu and Zhang [

17] analyzed dynamic fracture toughness using finite element simulations, while Yu et al. [

18] proposed a fatigue life prediction model for aircraft steel components under impact conditions based on linear damage accumulation theory. However, most of these studies were limited to uniaxial loading or low-velocity impacts and did not replicate the cyclic high-strain-rate environment typical of carrier-based aircraft landings.

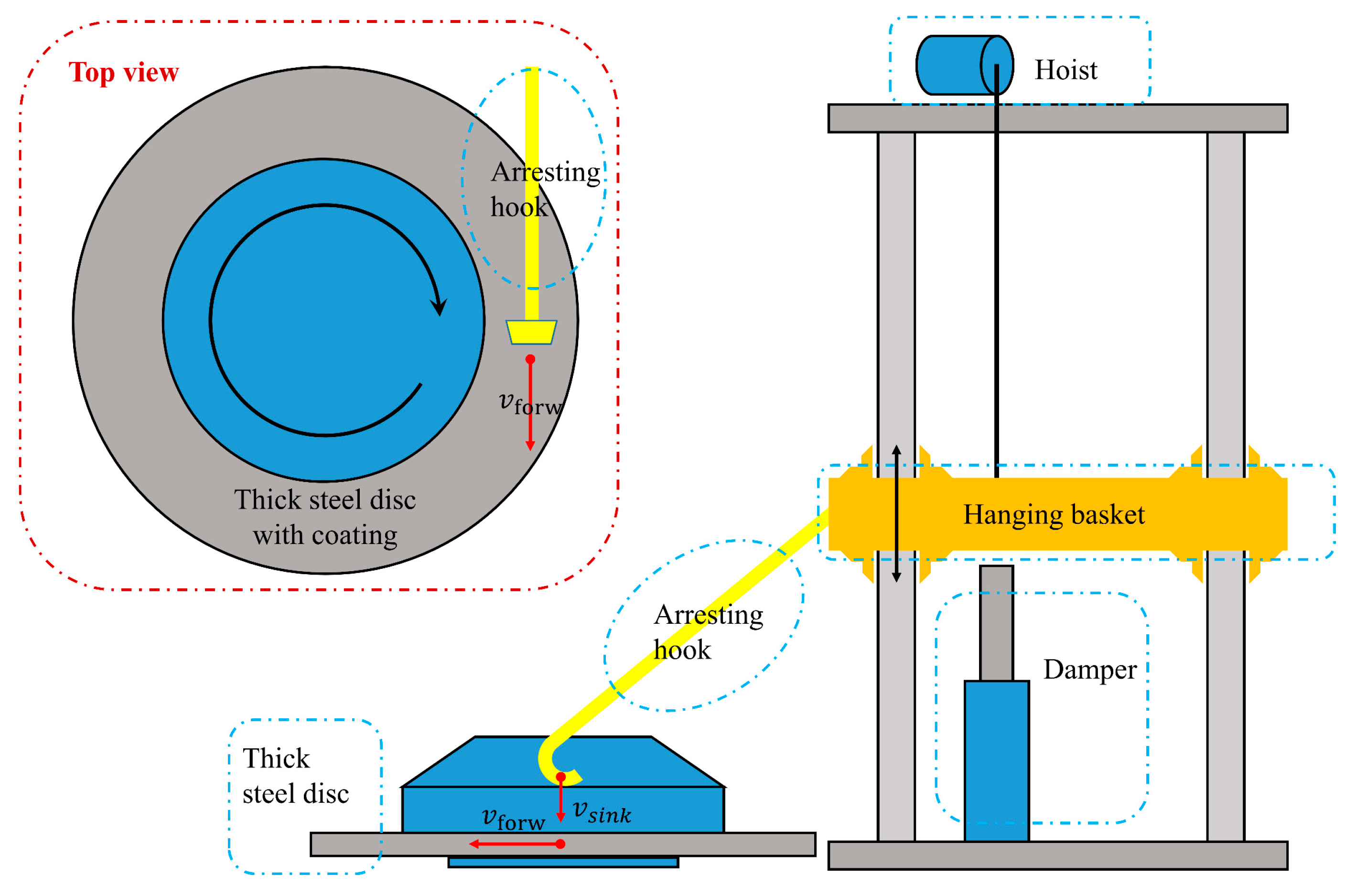

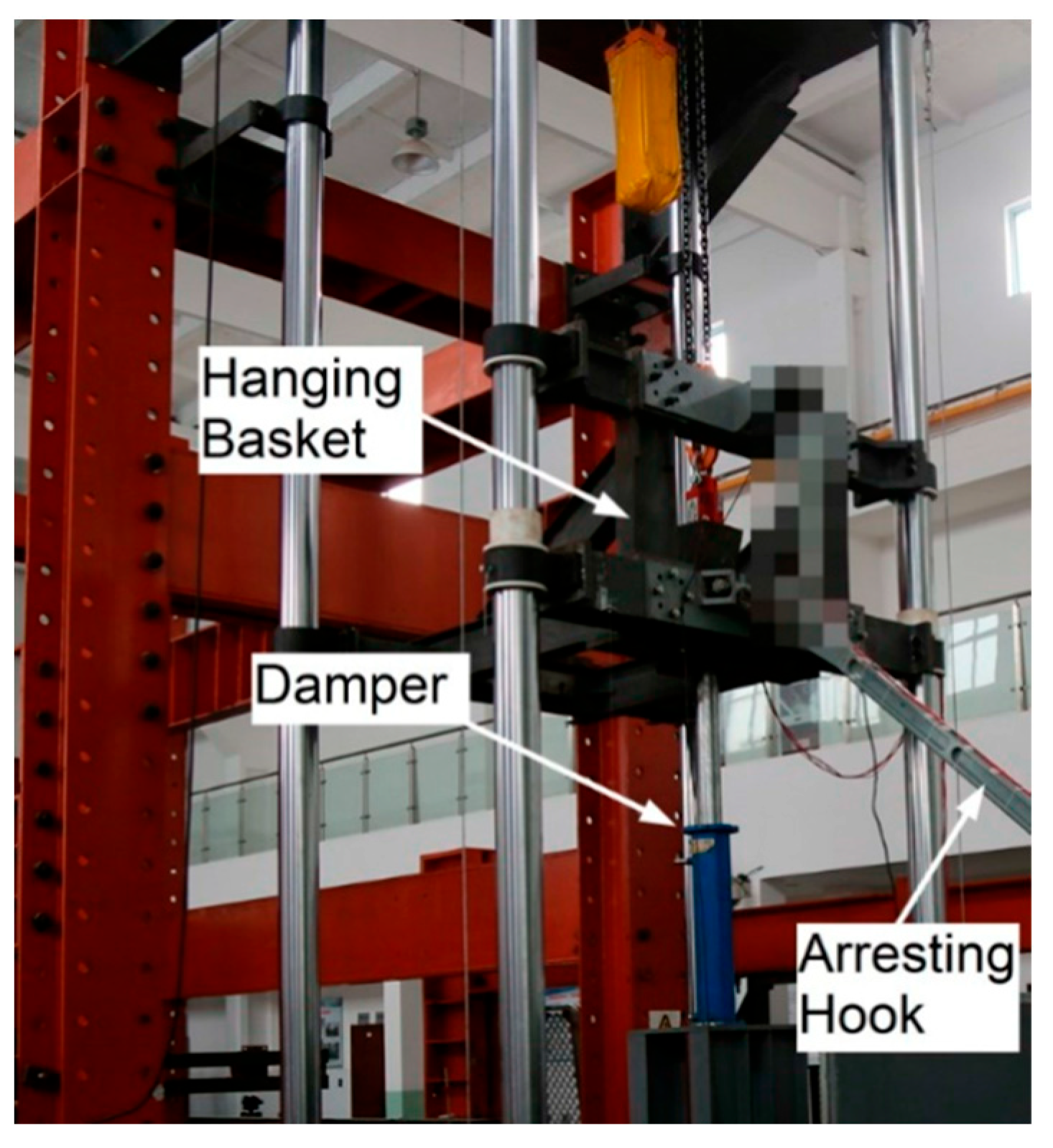

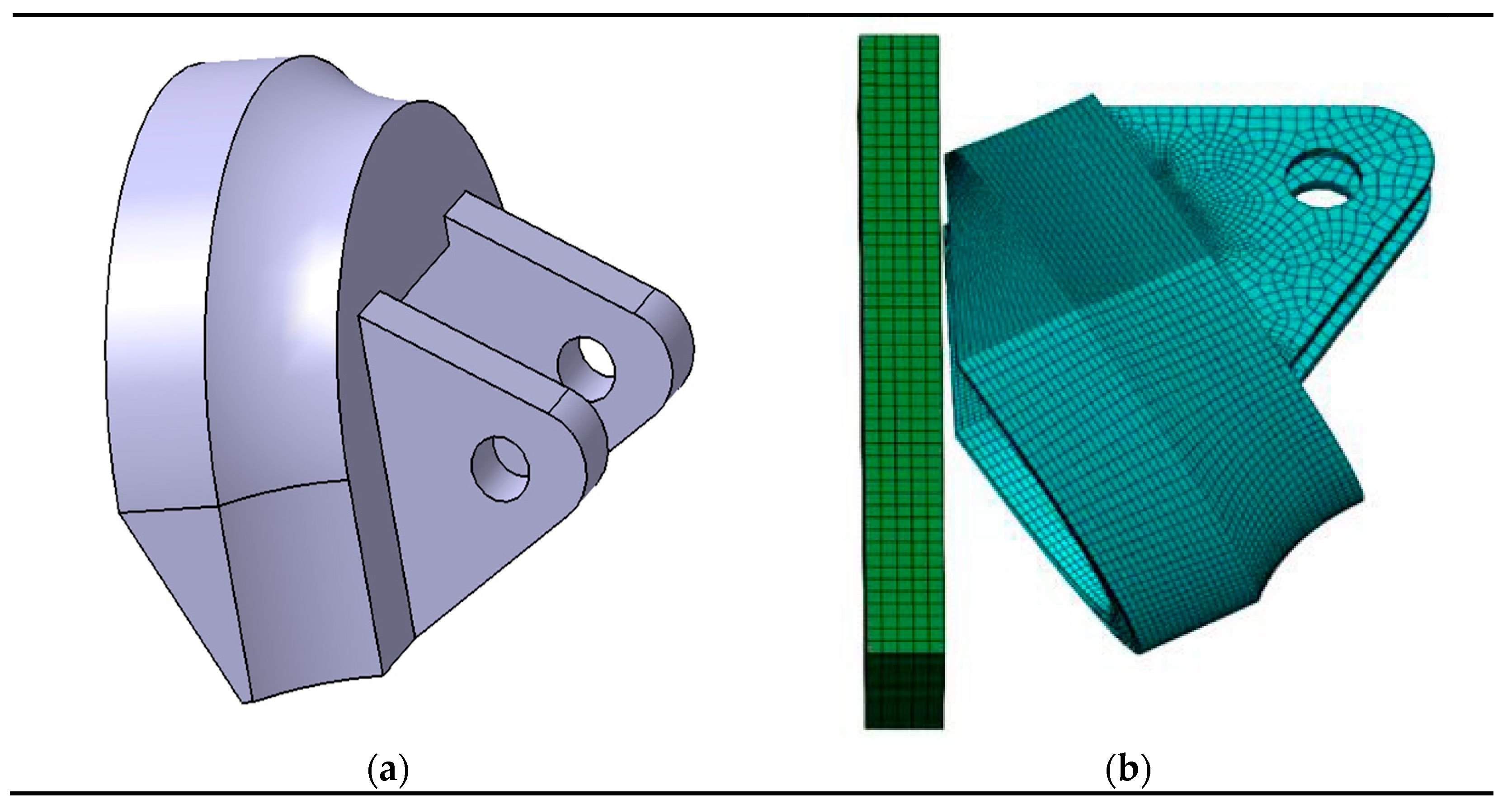

To overcome the aforementioned limitations and achieve a quantitative understanding of impact-induced fatigue in carrier-based arresting hooks, this study establishes a comprehensive experimental–numerical framework integrating collision–rebound testing, finite element impact simulation, and fatigue damage modeling. First, repeated impact experiments were conducted on a custom-built collision–rebound platform to characterize the transient strain evolution and cyclic plasticity behavior in critical regions of the hook head. Subsequently, a validated finite element (FE) dynamic impact model was developed using the experimentally derived boundary conditions, incorporating the VDISP subroutine to reproduce cyclic impact loading sequences with high numerical stability. Finally, based on the simulated strain histories, a continuum damage mechanics (CDM)-based fatigue life prediction model for 30CrMnSiNi2A high-strength steel was formulated and calibrated, enabling virtual fatigue assessment under arbitrary deck impact conditions. The proposed framework not only bridges the gap between experimental observation and numerical prediction but also provides a generalized methodology for evaluating rate-dependent fatigue degradation in high-strength steel components of carrier-based aircraft.

3. Results and Analysis

3.1. Comparison Between Simulation and Experiment

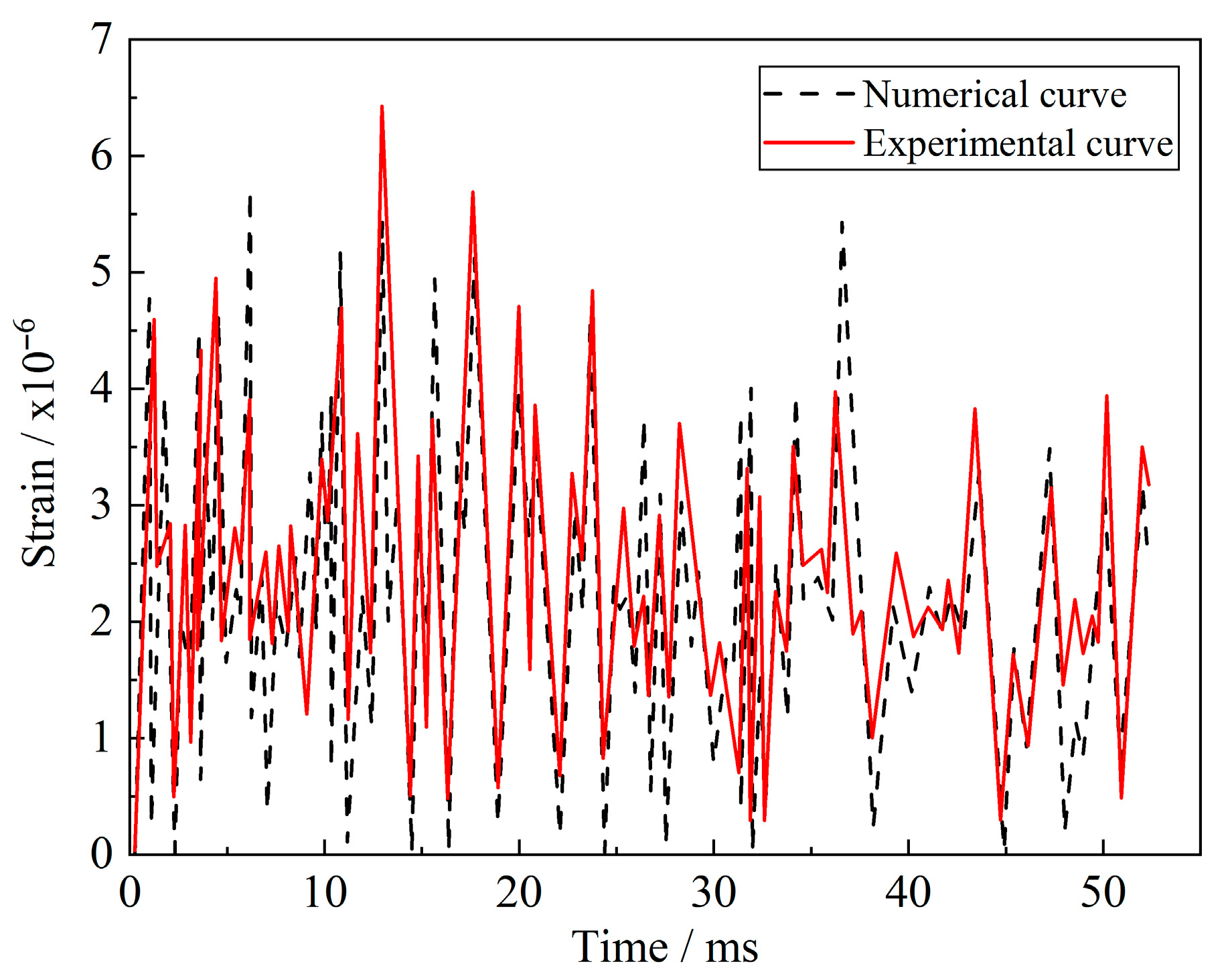

Due to experimental constraints and the limitations of strain-gauge placement, strain data could only be obtained from the lug-side region of the hook head (

Figure 4a), and the corresponding simulation data were extracted from the same area.

Figure 5 compares the simulated and experimental impact forces of the hook head under a single impact, while

Figure 6 presents the strain responses of typical regions under three repeated impacts.

The results demonstrate close agreement between the experimental and numerical data. The experimentally measured peak impact force was 39.3 kN, while the simulated value was 41.9 kN, yielding a relative error of 6.6%. The amplitude and waveform of the simulated strain histories are consistent with the experimental observations, confirming that the finite-element (FE) model can accurately reproduce the transient contact and deformation process of the hook–deck system.

The slightly higher simulated values are attributed to the idealized frictionless boundary and the neglect of microscale surface roughness, which tend to increase model stiffness. Nevertheless, the consistency in response trends verifies the reliability of the FE model for further dynamic and fatigue simulations.

3.2. Dynamic Response of the Hook Head Impact Zone

After validation, the dynamic response of the hook head during repeated impacts was analyzed in detail.

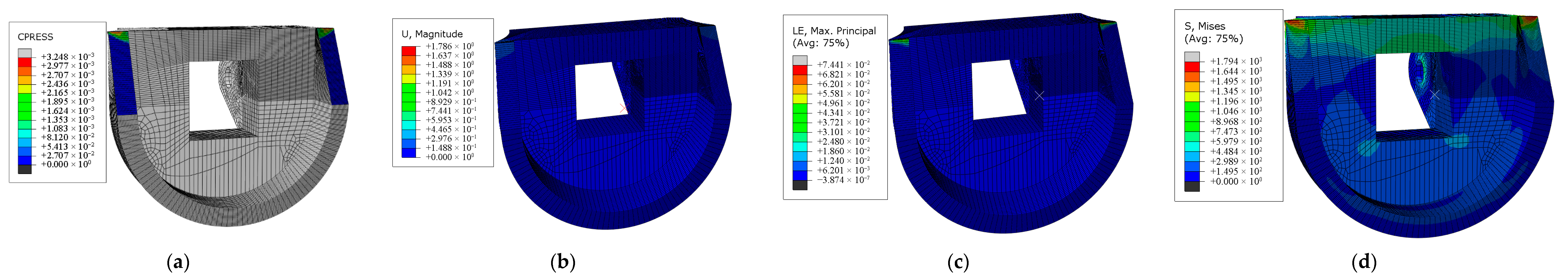

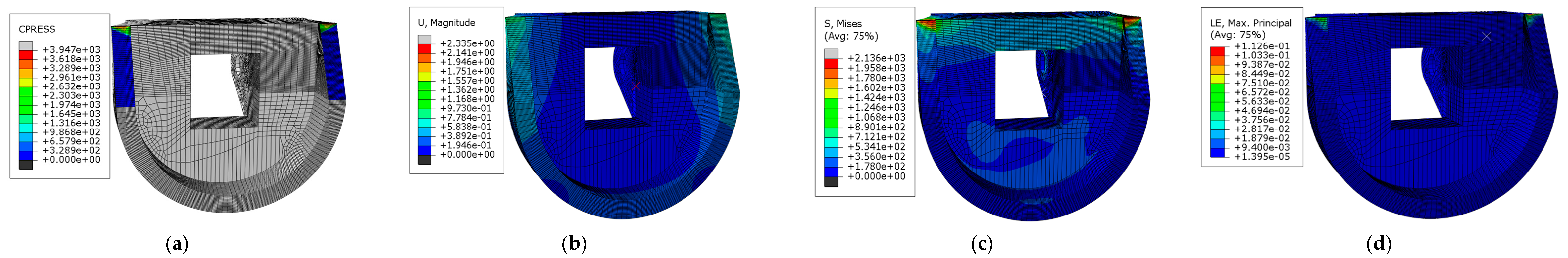

Figure 7 shows the contour distributions of maximum contact force, displacement, stress, and strain at a representative sink speed of 3.6 m/s. All responses exhibit strong localization in the hook–deck contact region, corresponding to the zone most prone to damage during service.

The maximum stress in this region (≈1794 MPa) exceeds the yield strength of 30CrMnSiNi2A steel, resulting in local plastic deformation and strain accumulation. With successive impacts, both the peak stress and the plastic strain slightly decrease, indicating the onset of material hardening and a reduction in incremental plastic energy dissipation.

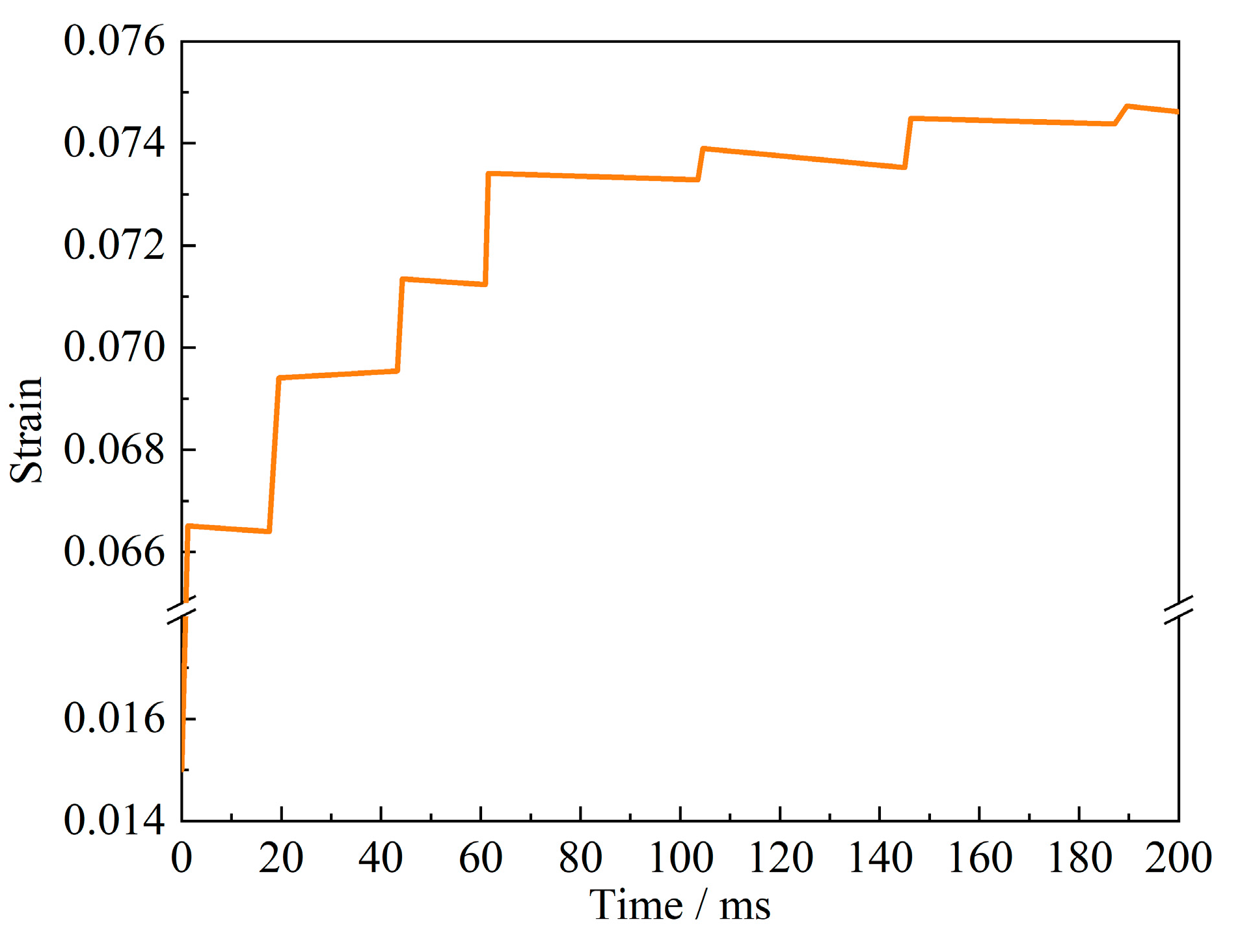

Figure 8 depicts the strain–time history of the critical element in the contact zone. A clear ratcheting effect of plastic strain is observed: the strain increases rapidly during the first several impacts and gradually stabilizes after about ten cycles. This evolution reflects the progressive increase in dislocation resistance and the transition from initial plastic accommodation to stable cyclic plasticity.

Quantitative results are summarized in

Table 3. The first impact produced a plastic-strain increment of 0.0669, which decreased to approximately 0.0002 after ten impacts, confirming that plastic energy dissipation becomes less significant with repeated loading. This phenomenon is typical for high-strength steels subjected to transient impact loads.

3.3. Effect of Sink Speed on Dynamic Response

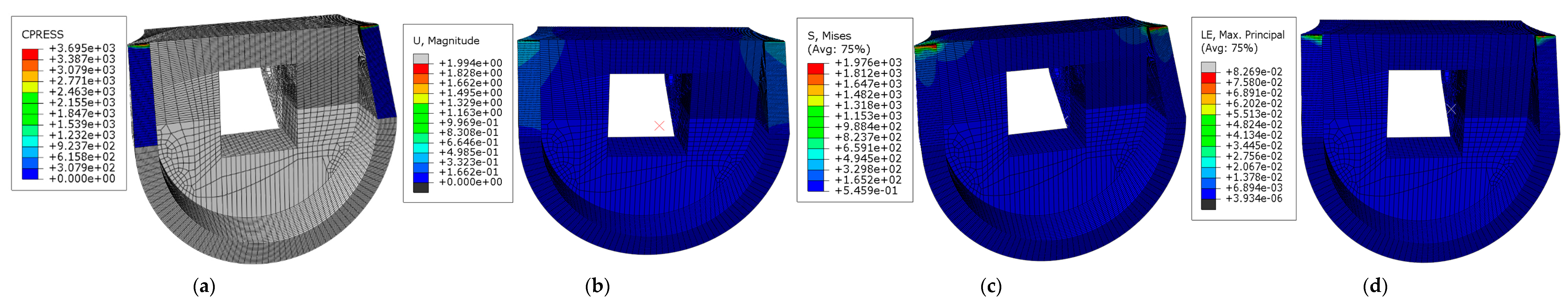

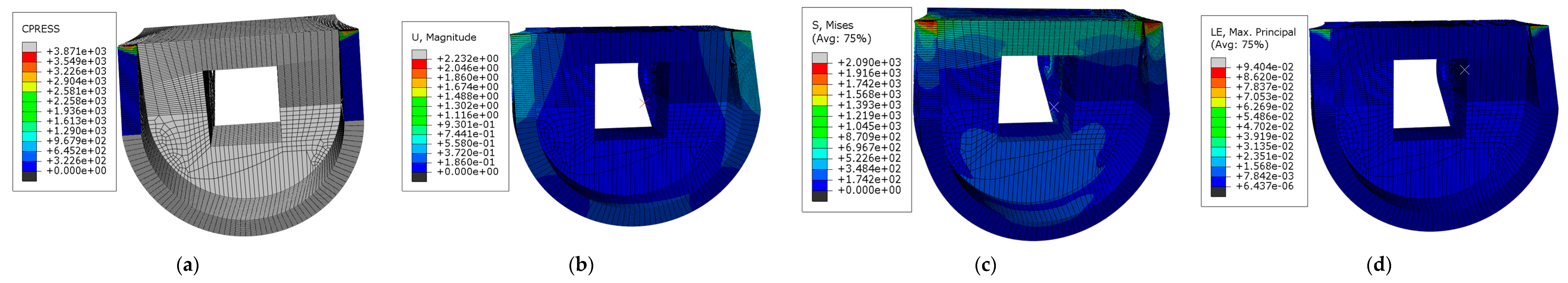

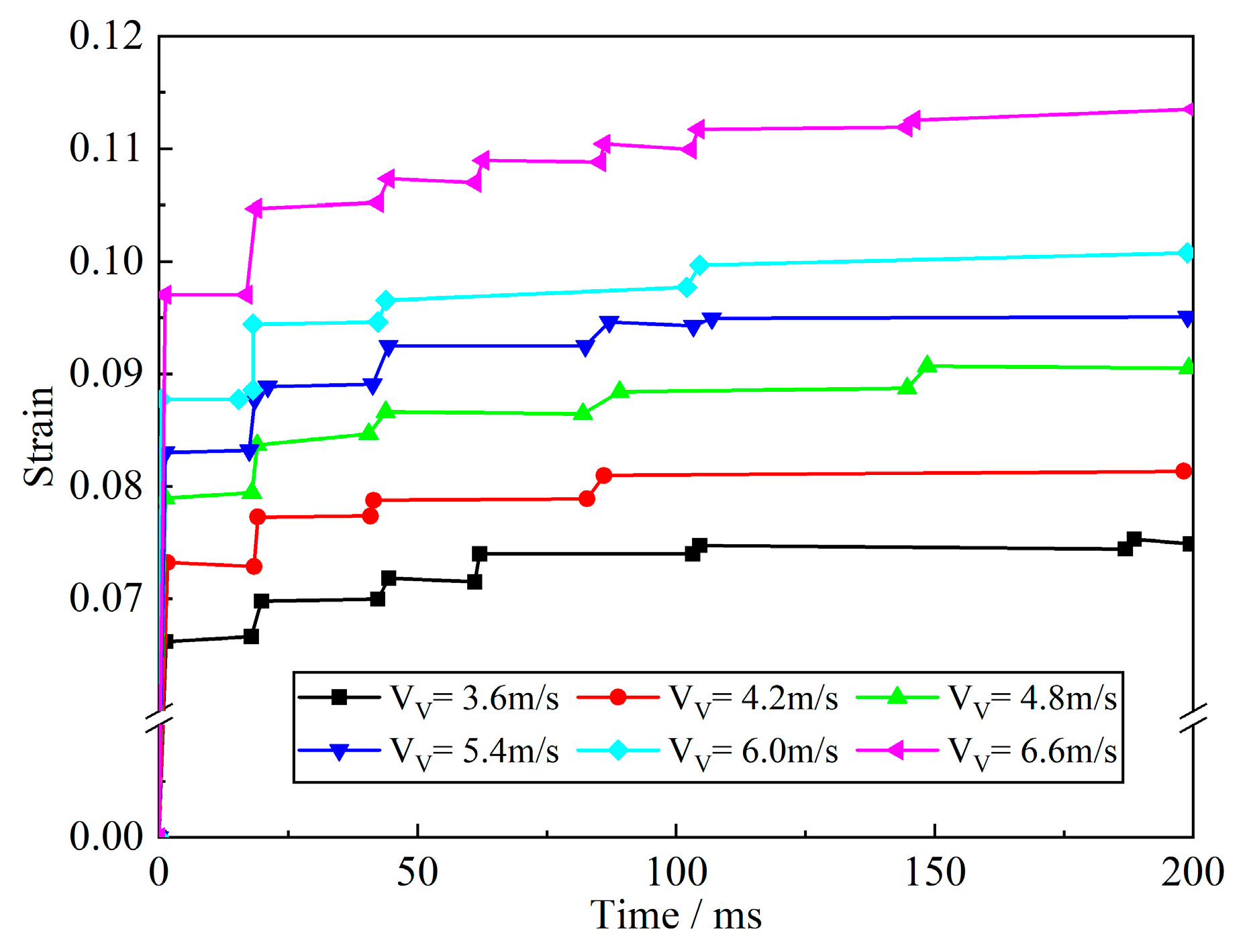

To investigate the influence of landing severity, six sink-speed conditions (3.6, 4.2, 4.8, 5.4, 6.0, and 6.6 m/s) were simulated using the validated FE model.

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13 display the distributions of maximum contact force, displacement, stress, and strain for each case, while

Figure 14 presents the corresponding strain–time histories of the critical regions.

As the sink speed increases, both contact force and stress–strain amplitudes rise markedly. The growth of plastic strain, however, is nonlinear and exhibits an increasingly pronounced ratcheting behavior. For sink speeds ≤ 4.2 m/s, plastic strain stabilizes after about five cycles; for ≥6.0 m/s, accumulation persists beyond ten cycles. The cumulative plastic strain and its incremental evolution are listed in

Table 3, showing that higher sink speeds lead to larger residual strain and faster accumulation rates.

The cumulative plastic strain and its incremental evolution are listed in

Table 3, showing that higher sink speeds lead to larger residual strain and faster accumulation rates. These results confirm that sink speed is the dominant factor controlling impact-induced fatigue damage. Consequently, maintaining a lower vertical descent velocity during carrier landings can effectively mitigate local plastic deformation and extend the service life of the arresting hook.

3.4. Discussion

The above experimental and numerical analyses reveal the mechanisms governing the deformation and fatigue evolution of the arresting hook under repeated impacts. The good agreement between experimental and simulated impact forces verifies that the Johnson–Cook constitutive model accurately captures the strain-rate-dependent behavior of 30CrMnSiNi2A steel. The slightly higher peaks in the simulation stem mainly from idealized boundary assumptions and material homogeneity. In real deck conditions, friction and the anti-slip coating introduce additional damping, slightly lowering the measured impact forces.

The strain–time histories demonstrate that cyclic impacts induce a non-uniform ratcheting process: early cycles dominate plastic energy dissipation, followed by gradual stabilization as the microstructure hardens. This behavior corresponds to the low-cycle fatigue characteristics commonly observed in high-strength steels under dynamic loading. The decreasing incremental strain per impact indicates that the system eventually reaches a quasi-stable cyclic state, transitioning from rapid damage accumulation to steady plastic response.

As sink speed increases, the accelerated accumulation of plastic strain leads to a shorter number of cycles to failure. The dependence of cumulative strain on sink speed provides a quantitative link between impact severity and fatigue degradation rate. These findings serve as the experimental and numerical foundation for the virtual fatigue testing framework introduced in

Section 2.2.2 and the fatigue life prediction model developed in

Section 4.

Overall, the combined experimental–numerical results confirm that the fatigue behavior of the arresting hook is governed primarily by the evolution of local plastic strain in the hook–deck interface. Accurate modeling of this region is thus essential for reliable fatigue-life prediction and for guiding structural optimization in carrier-based arresting systems.

4. Virtual Fatigue Testing and Fatigue Life Prediction Model

4.1. Virtual Fatigue Simulation Results

Based on the validated finite-element model and the VDISP subroutine framework described in

Section 2.2.2, a series of virtual impact fatigue simulations was performed under different sink speeds ranging from 3.6 to 6.6 m/s. Each simulation reproduced the cyclic contact–rebound process of the hook head impacting the deck surface. The number of cycles was automatically controlled through the displacement–time function defined in the VDISP subroutine, which enabled continuous impact–separation–recontact cycles until local failure occurred.

Plastic strain accumulation and equivalent stress evolution were monitored at the critical elements near the lug region, where experimental strain gauges had been placed. As shown in

Figure 15, the cumulative plastic strain increased progressively with each impact. The slope of the strain accumulation curve decreased after approximately ten cycles, indicating strain stabilization and the transition from rapid damage accumulation to a steady-state phase.

At higher sink speeds, the plastic strain accumulation rate was significantly accelerated, and local yielding propagated toward the fillet region. Once the equivalent plastic strain reached the critical threshold

, local failure was considered to occur. The number of impacts required to reach this limit defined the impact fatigue life

. To summarize, the fatigue life under six sink speeds was determined through virtual fatigue testing, as listed in

Table 4.

4.2. Development of the Fatigue Life Prediction Model

Building upon the virtual fatigue dataset in

Table 4, the fatigue life prediction model was developed using the framework of Continuum Damage Mechanics (CDM). The fatigue life prediction model was developed within the framework of Continuum Damage Mechanics (CDM), which quantifies material degradation in terms of a scalar damage variable

(ranging from 0 for an undamaged state to 1 for complete failure). Under cyclic plastic loading, damage evolution can be expressed as

where

—scalar damage variable ();

—damage coefficient reflecting material sensitivity to plastic strain;

—plastic strain increment per cycle;

—cyclic hardening exponent;

—damage saturation parameter describing the rate at which damage slows down as approaches 1.

Integrating Equation (4) with the initial condition

at

gives

Which yields the analytical expression for the number of cycles to failure

:

Here,

represents the critical damage at macroscopic failure, generally assumed to be 1. Substituting

simplifies the equation to

Equation (7) reveals a power-law relationship between the fatigue life and the plastic strain amplitude. By taking logarithms, this relationship can be linearized for regression analysis:

This framework establishes a clear physical relationship between fatigue life and cyclic plastic strain amplitude.

4.3. Model Calibration and Validation

Nonlinear least-squares regression was used to identify the parameters , , , and , corresponding, respectively, to the material’s damage coefficient, cyclic hardening exponent, saturation parameter, and fatigue resistance constant.

By logarithmic linearization of Equation (8), a direct regression between

and

was obtained, yielding the best-fit relationship:

The coefficient of determination

indicates excellent agreement between simulation and prediction. The fitted curve and simulation data are illustrated in

Figure 16, where the solid curve represents the fitted model and the data points correspond to the virtual simulation results.

The fitted parameters and regression quality are summarized in

Table 5. The obtained values of

,

and

are consistent with the strain rate sensitivity and hardening characteristics of 30CrMnSiNi

2A steel discussed in

Section 3.4, confirming the physical consistency of the model.

The fatigue life and damage accumulation predicted under different impact severities are shown in

Figure 17. With increasing sink speed, the plastic strain amplitude and damage rate both increase, leading to shorter fatigue lives. The damage evolution curve clearly demonstrates the transition from rapid ratcheting to a stable cyclic response, validating the physical reliability of the model. For quantitative verification,

Table 6 compares the fatigue lives obtained from simulation, model prediction, and experimental references. The deviations are within 5%, confirming that the CDM model provides accurate life predictions for 30CrMnSiNi

2A steel under cyclic impact conditions.

Overall, the maximum deviation between simulated, predicted, and measured data remains below 5%, demonstrating that the developed fatigue model can reliably capture both the trend and magnitude of life degradation under impact cyclic loading.

4.4. Discussion and Engineering Implications

The CDM-based fatigue life model effectively captures the progressive damage evolution of 30CrMnSiNi

2A steel under cyclic impact loading. The calibrated parameters (

) show strong physical consistency with the material’s strain hardening and saturation behavior. As shown in

Table 6, the deviation among simulated, predicted, and experimental fatigue lives remains below 5%, confirming the reliability of the model across varying impact severities.

The model successfully describes the transition from rapid ratcheting to stabilized cyclic plasticity. At low sink speeds, uniform plastic deformation dominates; at higher velocities, strain localization accelerates damage accumulation and initiates early failure near the lug fillet. This behavior aligns with the stress–strain evolution presented in

Figure 5 and

Figure 6 and the damage-rate trends in

Figure 17.

From an engineering perspective, the proposed model provides an efficient tool for estimating the service life of arresting hooks without repetitive testing. It enables rapid evaluation under different sink speeds or impact energies and supports optimization of material selection and geometric parameters. The same framework can be extended to other high-strength alloys in carrier recovery systems, offering a unified approach for fatigue life management under cyclic impact conditions.