1. Introduction

In China, most communities are independent and enclosed areas. The roads within the community are narrow, making it difficult for trucks to pass. In addition, trucks in central urban districts face strict speed limits, which further diminishes their operational efficiency. Therefore, the current logistics delivery model is that each community has its own dedicated station, where customers pick up their packages. Actually, this is not a door-to-door service. Drone delivery is a new method for achieving door-to-door service. The integration of long-distance truck transportation and short-distance drone delivery for door-to-door service in Chinese communities presents a joint scheduling problem. In this setup, the truck serves as a mobile platform for drone takeoff and landing. At each waypoint, which represents the center of gravity of the mission set, the truck can either move or wait. The center of gravity is defined as the geometric center of the customer cluster, calculated using the mean latitude and longitude of the customers. This problem involves numerous decision variables, including the truck’s route, stopping points, schedule, drone allocation, drone routes (which may differ in start and end locations), and drone scheduling. As a result, constructing and solving an overall optimization model becomes highly complex. To address this integrated challenge, three key aspects must be determined: the drone task set, the truck route, and the cooperative execution between drones and the truck. The process begins with identifying the drone task set and their execution times. Next, the truck’s route is determined. Based on the known execution and endurance times of each drone, the model allocates drones and calculates their travel times to each truck waypoint after completing tasks. This enables the system to decide whether the truck should proceed to the next station or remain at its current position. The primary objective is to minimize the total delivery time as much as possible.

Due to the fact that establishing a collaborative relationship (joint scheduling) between drones and trucks is the main optimization problem, this paper proposes a solution process pattern that divides the problem into three stages. Joint scheduling is the primary scheduling that determines the main part of optimization (the third stage). The division of distribution areas based on drone loading capacity and the planning of drone and truck routes are secondary parts of optimization (first and second stages). This article will achieve a more efficient collaborative relationship with drones by deciding whether to move or wait for trucks. This will help improve the optimization performance of the model and greatly reduce complexity. This solving method, although unable to obtain an optimized solution, can obtain quasi optimal or near optimal solutions. Because in the first stage, the division of drone delivery areas based on the number of communities, geographical location, and drone loading capacity ensures macro level optimization, in the second stage, truck and drone path planning is used to achieve micro level path optimization, and in the third stage, the adjustment of truck movement further enhances the optimization degree. In summary, it can be applied to solve practical problems in the joint transportation or distribution of trucks and drones, and has certain application value.

In the early stages of UAV involvement in logistics and distribution, UAVs are primarily viewed as auxiliary tools. For example, Murray and Chu examined the use of a single-flight UAV to assist truck delivery based on the Traveling Salesman Problem (TSP) [

1]. Ferrández et al. compared the improvements in delivery time and energy consumption between collaborative and independent modes of operation for trucks and UAVs [

2]. Contrary to static parking node assumptions, Marinelli et al. proposed a MILP model for dynamic drone dispatch/recovery during truck movement (not limited to fixed nodes), laying the foundation for on-the-fly coordination [

3].

With the foundational model for solving the UAV-truck collaborative delivery problem established, researchers have refined scenario settings and optimized solution algorithms. Bouman et al. introduced an exact solution method for the UAV-truck traveling salesman problem (TSP-D) using dynamic programming [

4]. Agatz et al. further improved Bouman’s work by developing heuristic algorithms based on local search and dynamic programming for fast path prioritization and cluster secondary [

5]. Boysen et al. refined scenarios by considering the number of UAVs per truck and whether UAV takeoff and landing points are identical [

6]. Ha et al. proposed a greedy randomized adaptive search procedure that delivered higher solution quality than Murray’s improved 2015 algorithm with local search [

7]. Keeney and R. L. divided the problem into three subproblems and proposed a corresponding three-stage model [

8]. Yurek and Ozmutlu developed an iterative, decom-position-based algorithm that assigns UAV delivery points using pre-established truck routes as the baseline [

9].

As research progressed, scholars addressed the UAV-truck collaborative delivery problem based on the Vehicle Routing Problem (VRP) and began improving the efficiency of solving large-scale problems. Wang and Sheu solved the problem by incorporating constraints on UAV endurance and takeoff/landing points into the traditional VRP modeling approach [

10]. To tackle the challenge of convergence to optimal solutions in large-scale problems, Sacramento et al. proposed an adaptive large neighborhood search metaheuristic algorithm [

11]. Schermer et al. developed a VRP-D (Vehicle Routing Problem with Drones) model by introducing the Drone Assignment and Scheduling Problem (DASP) scheduling model [

12]. Additionally, Schermer et al. proposed a heuristic algorithm based on variable neighborhood search and tabu search to enhance the efficiency of solving large-scale VRP-D problems [

13].

Starting in 2020, drones increasingly became the primary agents for delivery tasks, with multi-drone delivery and single-flight visits to multiple demand points becoming key topics. Murray and Raj expanded their 2015 Flying Sidekick TSP model by increasing the number of drones collaborating with a single truck, introducing the m-FSTSP (Multiple Flying Sidekicks TSP) model [

14]. Moshref-Javadi et al. proposed a model based on the Traveling Repairman Problem (TRP), allowing trucks to deploy multiple drones for delivery operations [

15]. Liu et al. developed a model where drones are the main delivery agents, capable of serving multiple customer points per trip without requiring vehicles to wait at fixed points [

16]. Vu et al. examined logistics problems where drones can be launched from warehouses or trucks and proposed a metaheuristic algorithm to enhance the solving speed for large-scale problems [

17]. Masmoudi et al. improved the existing VRP-D model to allow drones to deliver multiple packages per trip and proposed an adaptive multi-start simulated annealing metaheuristic algorithm for solving it [

18]. Zeng et al. studied the route coordination problem where drones visit multiple designated locations and periodically meet trucks for battery replacement, establishing the Nested-VRP model and solving it with a neighborhood heuristic algorithm [

19]. Freitas et al. proposed an improved mixed-integer programming (MIP) formulation for solving Murray’s FSTSP model, achieving improved results in over 80% of cases [

20]. Rave et al. developed a tactical planning model that combines truck-only, drone-only, and truck-drone collaborative delivery methods based on delivery demand distribution [

21]. Ndiaye et al. proposed a variable neighborhood search metaheuristic algorithm for the FSTSP model, accelerating the solving speed for medium to large-scale problems [

22].

For UAV-truck coordinated delivery, solution approaches can be categorized into direct optimization and dividing the problem into several subproblems for solving. The direct optimization approach typically employs a Mixed-Integer Linear Programming (MILP) model, solved via exact solvers or heuristic algorithms. This approach, rooted in TSP/VRP frameworks, faces challenges in solving efficiency as node/arc numbers increase, due to exponential growth in network complexity. In contrast, decomposition-based methods split the problem into truck routing and drone routing subproblems, linked by a scheduling model. These methods often assume static truck positions or use heuristic algorithms for scheduling, leading to suboptimal solutions and limited practical applicability. The joint scheduling model proposed herein is a MILP framework solved exactly by Gurobi, addressing the limitations of both approaches. Unlike decomposition methods, it optimizes truck-drone coordination dynamically. The three-stage solution method presented in this paper leverages the computational speed advantages of decomposition-based approaches when dealing with large-scale demand distributions, while also incorporating the benefits of integrated optimization methods for constructing and optimizing the collaborative relationship between UAVs and trucks. This method can be regarded as a balanced solution that optimizes both solution speed and the effective coordination of UAV-truck collaboration.

In summary, the community logistics solution proposed in this paper aims to minimize total delivery time, taking into account drone endurance and payload limitations, and is based on the community-distributed nature of urban logistics demand. The following assumptions are made in solving the problem:

Trucks do not retrace their routes.

Drones only deliver packages at customer nodes and do not pick up items.

Trucks serve as the sole platform for cargo storage and drone launch and recovery.

Delivery point locations and weights are known in advance, with no new delivery demands arising during the process.

Both drone flight speed and truck travel speed are constant.

The community airspace is fully open to drones without restrictions, allowing safe direct flights to demand points.

The paper is organized as follows:

Section 2 covers model development, with

Section 2.1 focusing on the generation of drone mission sets and release point locations,

Section 2.2 on the truck and drone route planning and

Section 2.3 on the establishment of the drone-truck collaborative model.

Section 3 presents experiments and discussions, while

Section 4 provides the conclusion.

2. Mathematical Programming Formulation

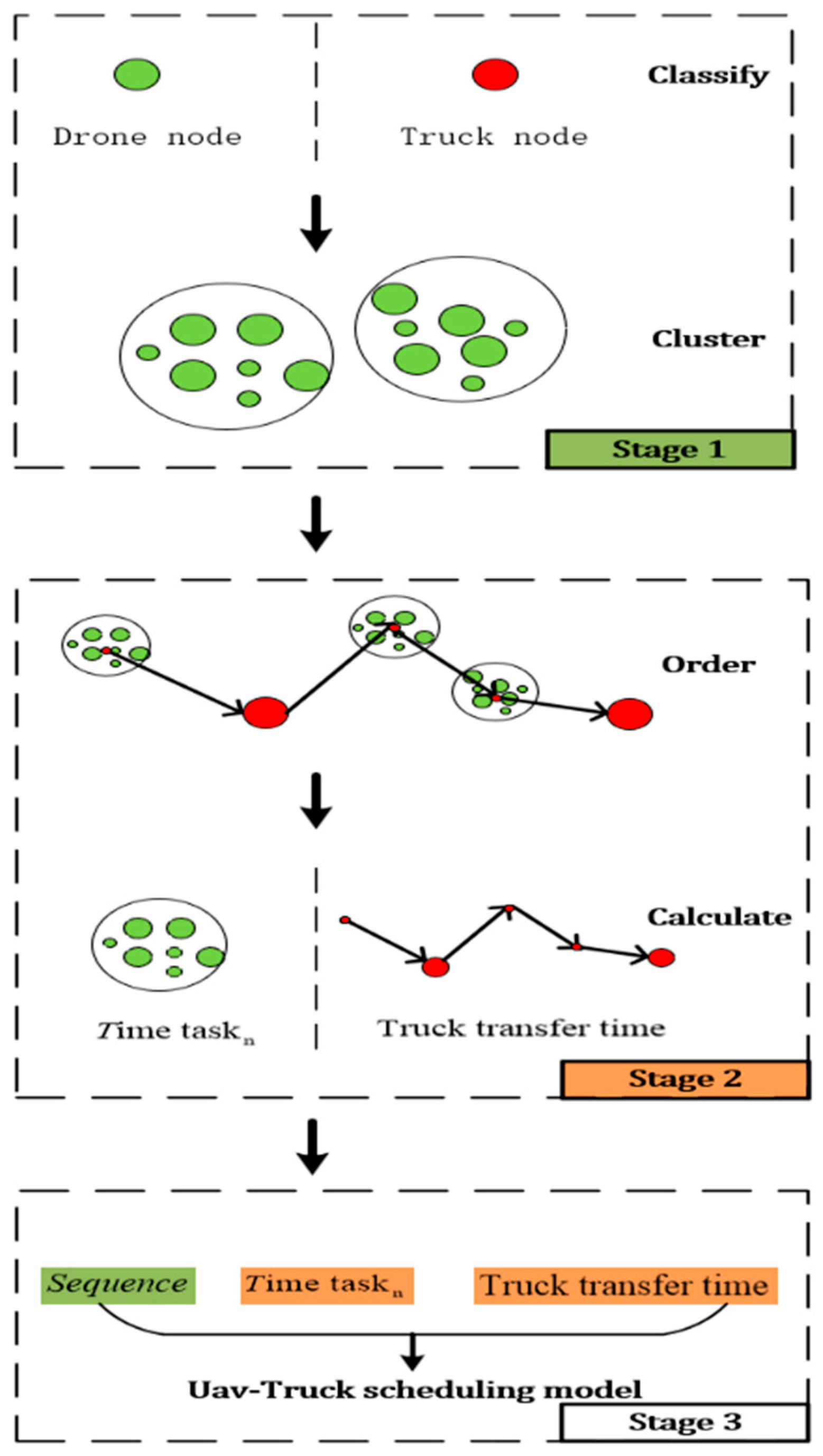

To address the terminal logistics distribution problem, this paper presents a three-stage solution scheme for UAV-truck collaborative delivery, integrating weight-based categorization, geographic clustering, and joint scheduling. The workflow is as follows:

Stage 1: Categorize items into truck-deliverable (over payload limit) and drone-deliverable (within payload limit) based on weight.

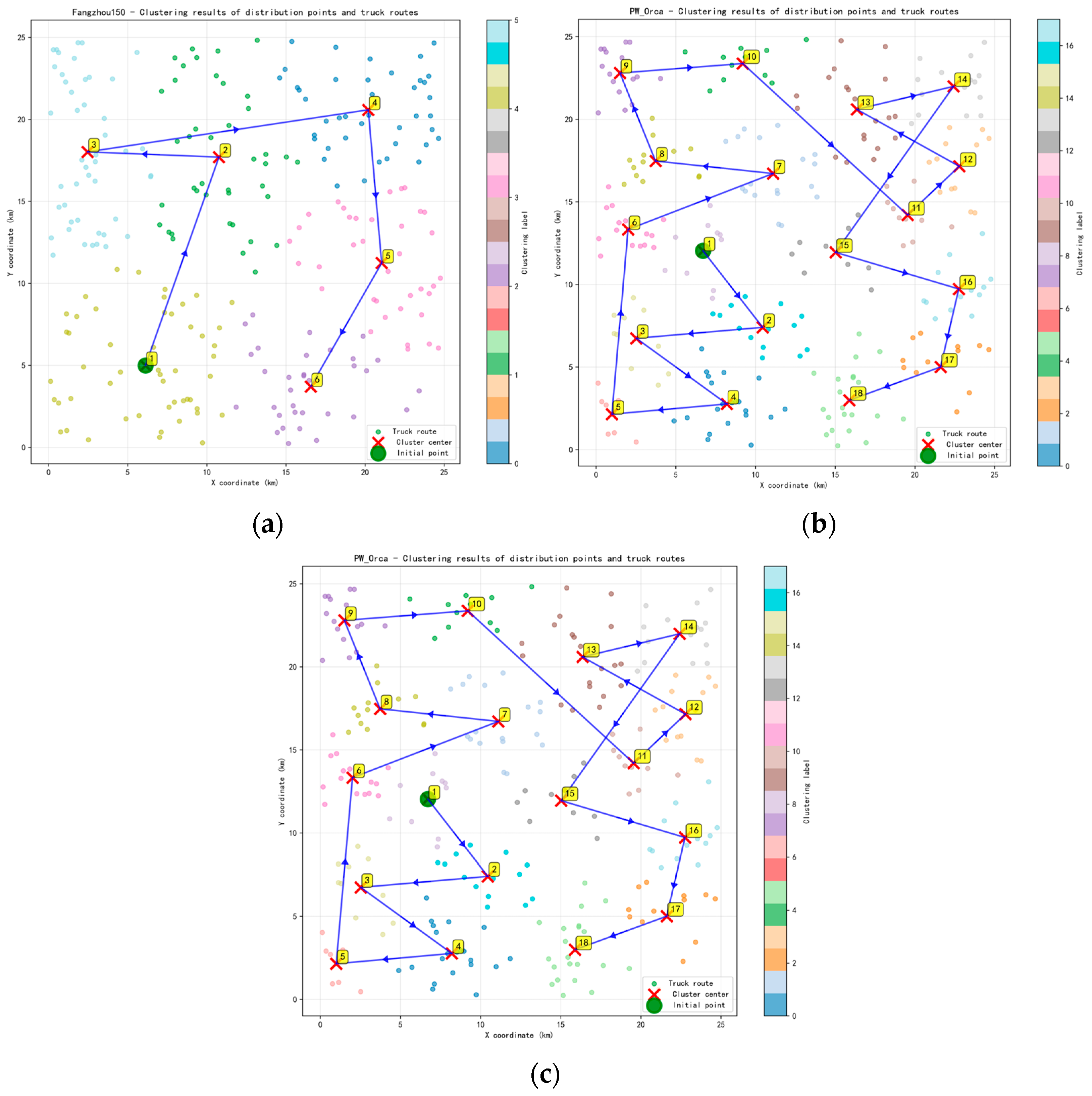

Stage 2: Cluster drone-deliverable demand points using K-means, with cluster centroids as truck release nodes, and determine truck routing via GIS-based sequencing.

Stage 3: Optimize UAV-truck coordination through a Mixed-Integer Linear Programming (MILP) model, scheduling drone missions and truck movements to minimize total delivery time. The collaborative logic across stages is visualized in

Figure 1, highlighting how task duration (Stage 1–2 outputs) and operational sequences drive joint scheduling decisions (Stage 3).

The chapter details:

Section 2.1: Task Set Generation: Clustering methodology for demand points;

Section 2.2: Task Execution Sequencing: Truck routing and drone path planning;

Section 2.3 (core work): Joint Scheduling Model: MILP formulation for dynamic coordination.

2.1. Generation of UAV Mission Sets and Release Point Locations

The operational limitations of UAVs are primarily constrained by their industrial load capacity and the range of their power supply. Additionally, the number of demand points that can be serviced by a single UAV release is also limited. In this paper, UAVs are firstly classified into multiple UAV delivery mission sets based on their delivery capacity limitations and the geographic distribution characteristics of the demand points. The generation of UAV mission sets is a process that can be outlined as follows: initial classification is conducted, followed by the implementation of clustering.

Initially, demand points are categorized based on the delivery weight and the drone payload limit . Points exceeding the payload limit are designated as truck delivery points , while those within the limit are classified as drone delivery points .

Subsequently, the K-means algorithm is employed to group demand points into multiple drone delivery mission sets, with cluster centroids serving as drone release points. As a matter of intuitive experience, it can be roughly assumed that the weights of the individual tasks to be delivered close to maximum drone capacity

, and the initial number of clusters (mission sets) is approximated by using the upper bound of quotient of the total demanded weight (

) divided by the UAV’s industry load limit

rounded upwards, as in (1). Given that delivery points are distributed across gated communities, the final number of clusters

must satisfy

, where

is the total number of communities, ensuring each community

is assigned at least one cluster point (As in (2) and (3)).

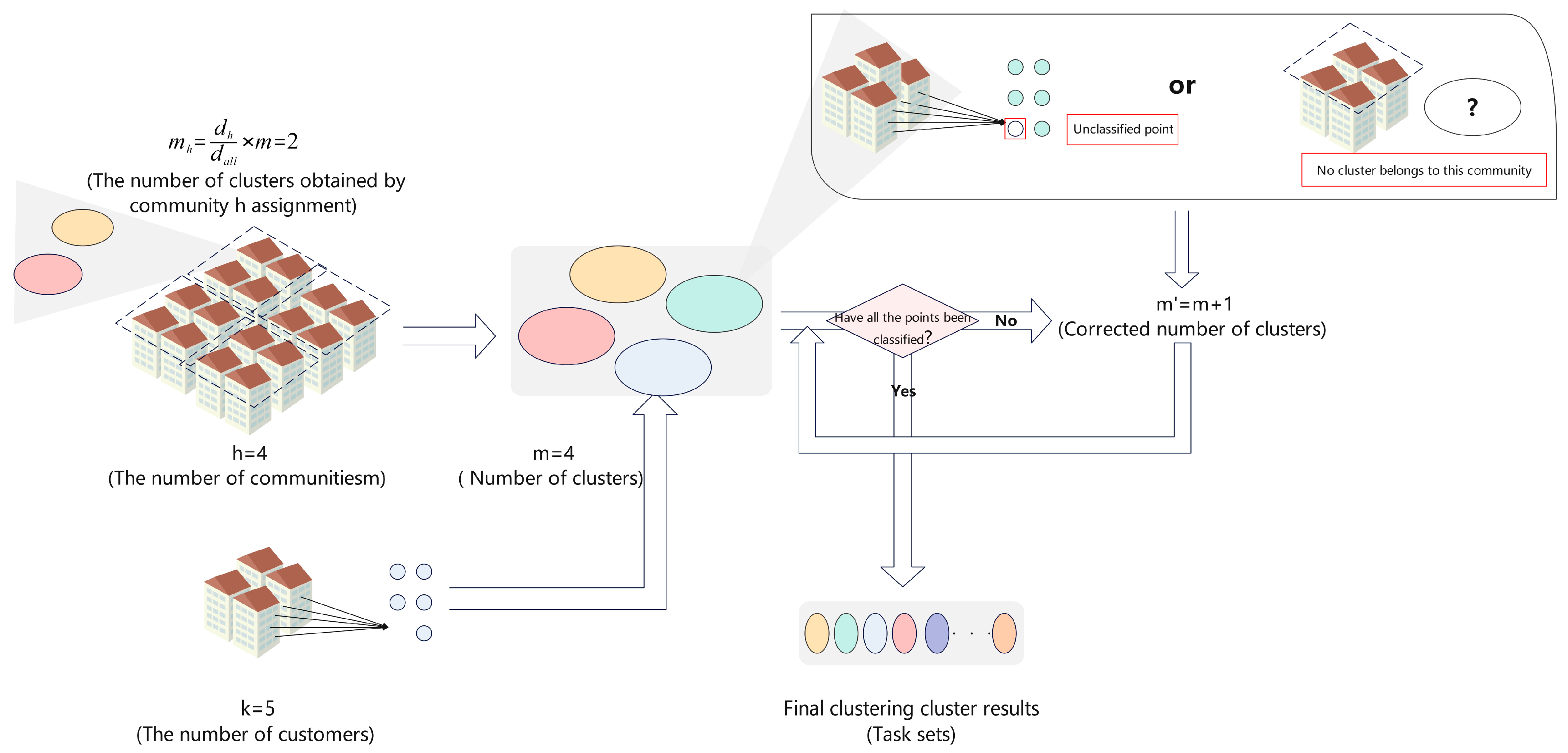

The value of

is the initial number of clusters derived under the assumption of equal delivery weight at each customer node. However, in reality, weights vary across points and are distributed across gated communities. When grouping points into

clusters, some points may remain non-clustered due to overweight items, exceeding flight range, or belonging to separate communities. To address this, we introduce an iterative clustering mechanism: Perform initial clustering based on pre-solved parameters. If non-clustered points exist, increment the cluster count by 1. Repeat clustering until all points are assigned, ensuring the final cluster count

satisfies Equation (3) (

, where

is the number of communities). The diagram in

Figure 2 illustrates the clustering concept mentioned above.

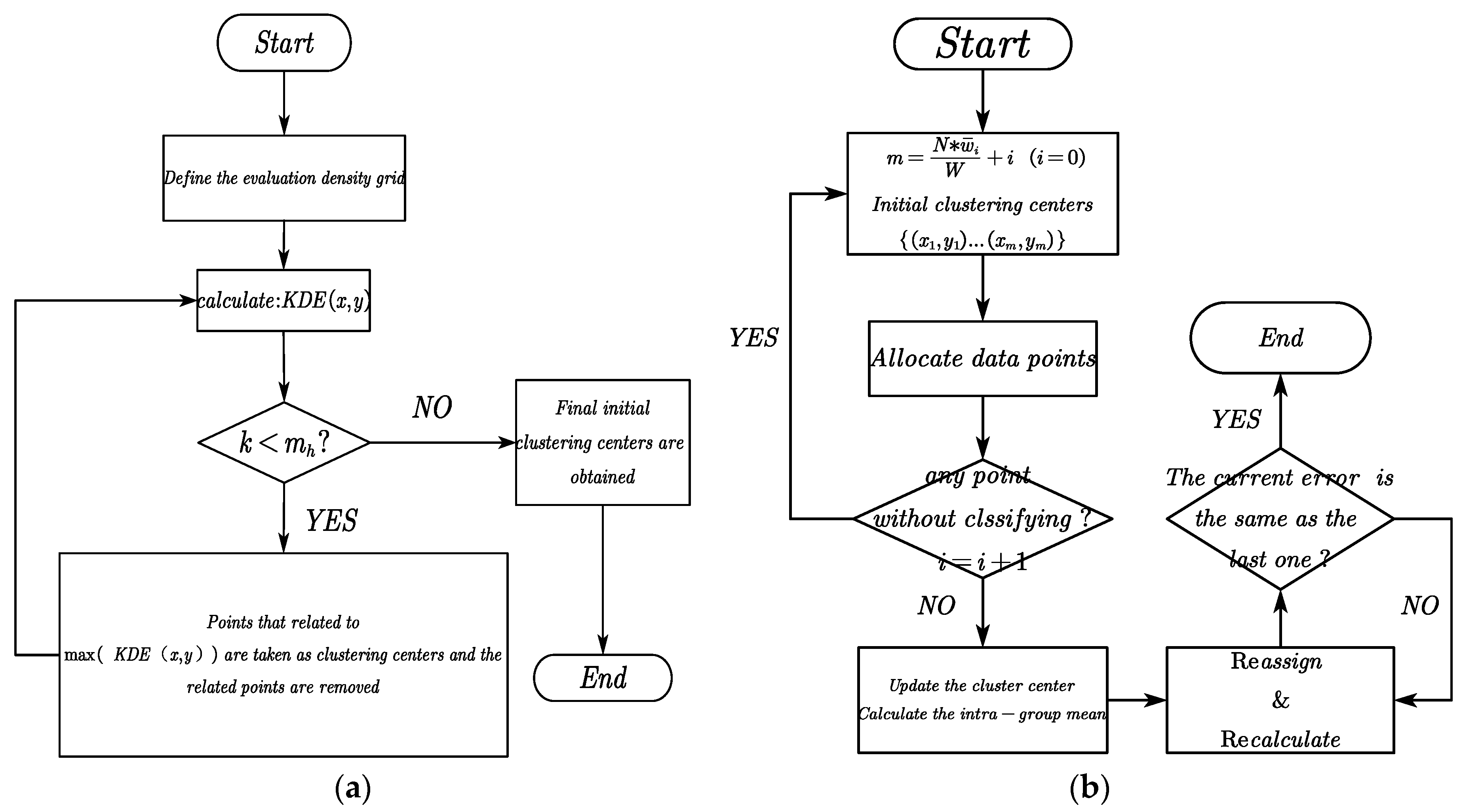

When initializing cluster centers, the number of clusters is first allocated based on the proportion of delivery points within a community relative to the total number of points . To effectively reduce the sensitivity of clustering results to the choice of initial centers, the method of initializing K-means cluster centers using the maximum density approach based on Kernel Density Estimation (KDE) is employed. KDE is a parameter-insensitive density estimation method that is used to estimate the density of a distribution of customer points. The clustering algorithm prioritizes points with the highest KDE values (x, y) as cluster centers, selecting nodes surrounded by the densest point distributions. After the initialization of the number of clusters, the K-means algorithm is used for demand clustering.

The initialization workflow is illustrated in

Figure 3a, while the full K-means process is shown in

Figure 3b.

Let

represent the x-coordinate and

represent the y-coordinate of the task set

, which contains

demand points (distribution points). The drone release point for task set

is defined as the “center of gravity”, calculated by Equation (4).

2.2. Path Planning for Truck Paths and Drone Paths

In this subsection, the UAV-truck delivery problem is divided into two interdependent subproblems: truck routing on ground networks and drone mission scheduling in airspace. To resolve these subproblems and their interconnections, we develop two models:

PART 1: A geographic routing model leveraging GIS APIs to compute truck travel times between pre-scheduled nodes.

PART 2: A shortest-path model using the Floyd-Warshall algorithm to optimize drone flight paths within mission sets.

These models provide foundational data (truck arrival times, drone mission durations) for the joint scheduling model in

Section 2.3.

2.2.1. Calculation of Truck Node Passing Time

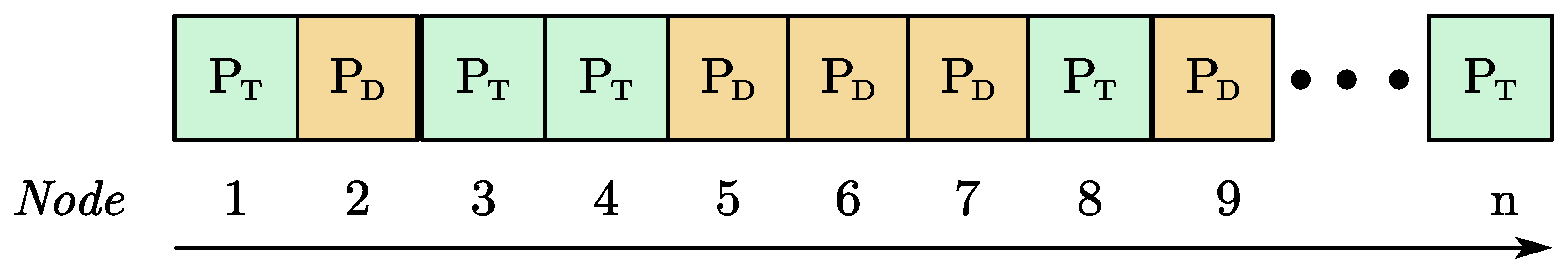

In this study, it is assumed that the trucks will pass through each point in a sequential manner in order to be allocated. In both academia and industry, ground path planning for trucks is a well-studied problem with established solutions. Here, truck travel times between nodes are derived using a two-step approach: Pre-sort nodes geographically (north-to-south, west-to-east ordering); Invoke a GIS mapping API (Google Maps Platform) to retrieve real-world road travel times for the pre-sorted sequence. The details are shown as follows:

Step 1:

denotes points where trucks stop to release drones, while

indicates points requiring truck deliveries. Since the main objective of this paper is to propose a joint scheduling model, we simplify the process in this section. Specifically, given the block-by-block nature of urban delivery, the two types of points are arranged sequentially from north to south and west to east. In this context, “Node” refers to the points that the truck sequentially passes through after the planning phase, while

and

represent the delivery attributes associated with these points. The northwesternmost point is designated as waypoint 1, forming a sequence of nodes for truck visitation, as shown in

Figure 4.

Step 2: Invoke the route planning interface provided by the navigation map API, restricting the vehicle type to small and medium-sized trucks, to export the travel time between each truck point. Truck delivery time is cumulative to the time taken by the truck to leave point and travel to the next node.

Through the data processing in this subsection, the truck-related decision variables in the joint model are replaced by their arrival times at waypoints, specifically the variable

defined in

Section 2.3.

2.2.2. Solving for Drone Mission Time

The problem of solving the drone path is a classic shortest path problem in graph theory. In this paper, the problem is formulated as a graph network model. The model employs

, 0–1 decision variable, where 1 indicates traversal of arc

and 0 indicates no traversal.

represents the Euclidean distance between points

and

.

denotes the set of all points in the nth set, and

represents the set of all arcs in the nth set.

In Equation (5), and denote the source node and destination node, respectively. In the context of our research problem, the truck’s path is pre-determined and fixed. As a result, the order in which the UAV services customer nodes between two consecutive truck nodes is also pre-determined, based on the spatial proximity to the truck’s movement direction. The problem we are solving for the UAV on each segment of the path is a shortest path problem through a fixed sequence of nodes. Under this problem definition, the optimal UAV path is simply the sequence of shortest paths between each pair of adjacent nodes. The Floyd algorithm is used to calculate the shortest path distances between all pairs of nodes in the graph.

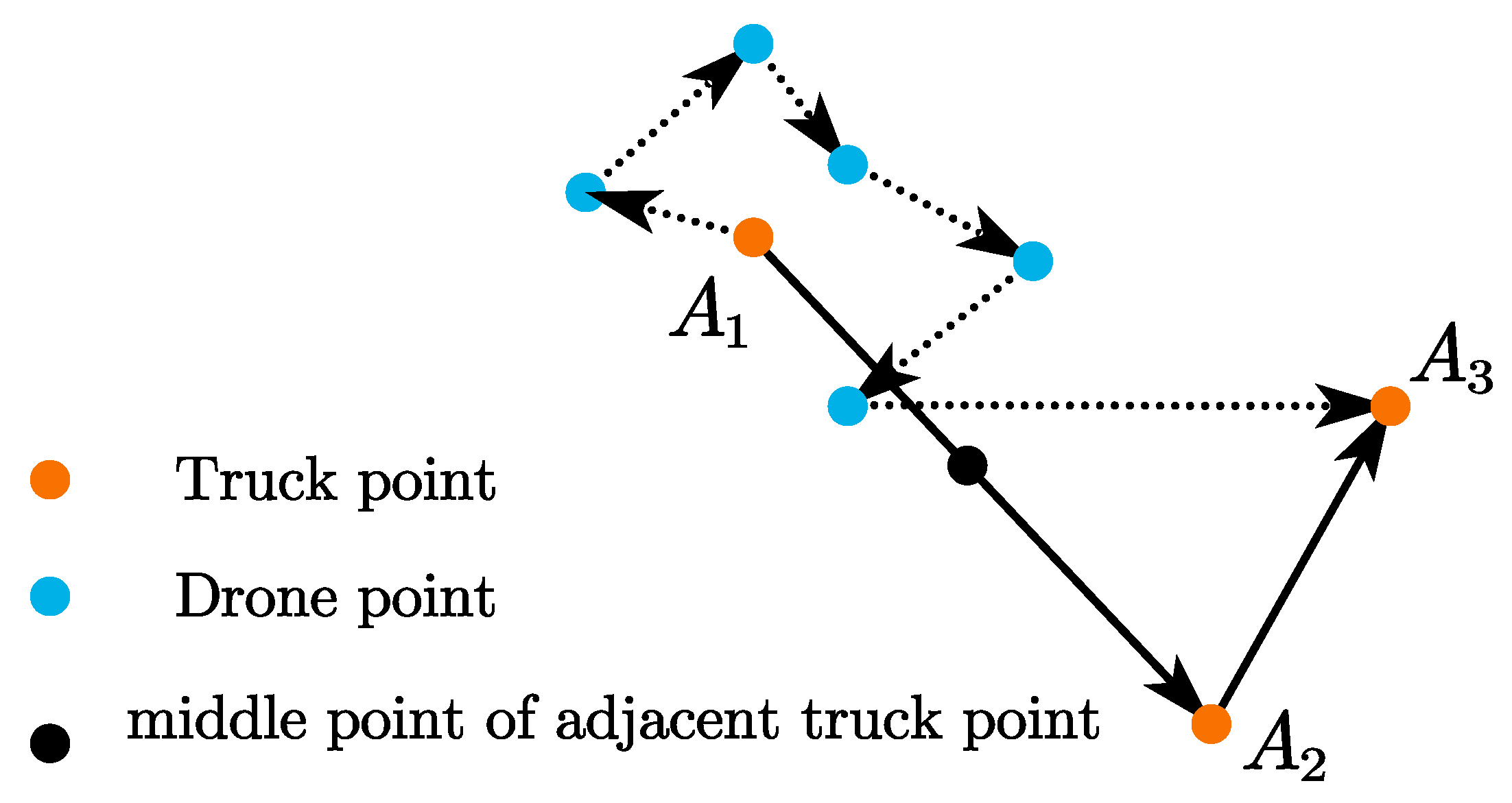

As shown in

Figure 5, orange nodes represent truck routes, blue nodes denote drone flight paths, and black nodes signify midpoints. The dashed line represents the UAV’s flight path, while the solid line represents the truck’s route. Notably, the flight time from the last demand node to midpoint

is omitted from the total mission time to focus on operational efficiency.

After computing the shortest total flight distance

for task set

, the horizontal flight time is derived as

, where

is the drone’s constant flight speed. This time excludes vertical operations (takeoff, landing and delivery). To account for these, an average time

(per node) is introduced.

is a tunable parameter representing the total ground operation time, ensuring that the model considers the duration required to implement the planned interactions between the UAV and the truck. The adjusted duration is calculated as

, where

is the number of nodes in the task set. Thus, the total task duration

for task set

is composed of two parts: the horizontal flight duration and the adjusted duration, as shown in Equation (6).

2.2.3. Solving the Projected Recovery Nodes for Drones

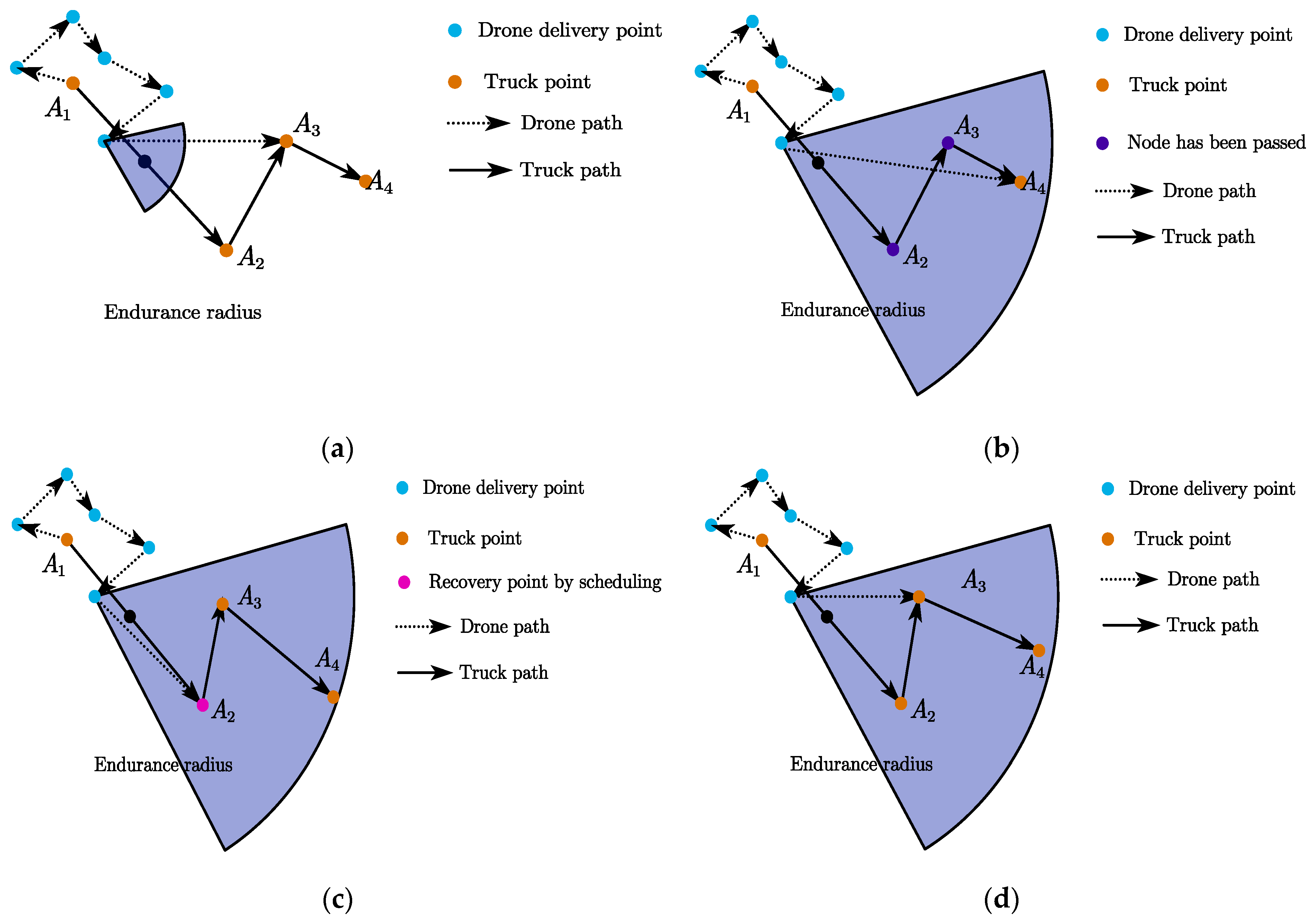

Upon task completion, drone recovery nodes are classified into two categories: the current release node or subsequent truck nodes. Given the model’s assumptions (no truck route reversal and no access to departed nodes), four recovery scenarios arise:

(a) No Subsequent Nodes Available

If no subsequent truck nodes lie within the drone’s remaining flight range, the drone recovers at the current release node.

Figure 6b–d assume the drone detects subsequent nodes within its range.

(b) Truck Departed from Nearest Node

If the truck has left the nearest node by the drone’s task completion time, the drone must select an alternative recovery node where the truck is present or enroute. As shown in

Figure 6b, after task completion, the truck has departed nodes

and

, leaving only

within range, so the drone flies to

.

(c) Scheduled Recovery Node Override

When subsequent nodes exist but scheduling dictates a specific recovery point, the drone prioritizes the assigned node over the nearest option. In

Figure 6c, despite

being closer, the drone is directed to recover at

for operational coherence.

(d) Autonomous Recovery Selection

In the absence of scheduled points, the drone autonomously chooses the nearest accessible node or a subsequent node that avoids truck waiting. As illustrated in

Figure 6d, if

is nearest or

requires truck waiting, the drone selects

to minimize delays.

Based on the four potential operational scenarios outlined above, it is clear that, regardless of the type of node where the UAV performs recovery, coordination with the truck is essential. Since the sequence of node visits is predetermined and remains unchanged when new nodes are introduced, the essence of truck-UAV coordination lies in optimizing the truck’s waiting strategy and operational scheduling. This involves determining when and where to deploy and recover the UAV. To address this dynamic UAV-truck collaboration problem, a unified MILP model is proposed in

Section 2.3. The MILP model introduced in this paper does not rely on specific scenario rules. Instead, it makes comprehensive decisions by simultaneously considering the truck’s route schedule, the UAV’s flight endurance, and the objective of minimizing total task time. This ensures a globally optimal solution, rather than a short-sighted, rule-based choice.

2.3. Drone-Truck Collaboration Model

The model proposed in this section treats the pre-determined truck traversal sequence as a series of task operations, enabling the joint scheduling of UAVs and trucks. This UAV-truck joint scheduling problem involves numerous parameters and variables, which can result in dimensionality and complexity issues that hinder model development and solution.

The key challenge in joint scheduling lies in coupling the UAV and truck in both time and space. To address this, key UAV parameters, such as flight capability, are converted into time metrics, facilitating system-level optimization. From a practical perspective, particularly in low-altitude logistics systems, time is often the primary optimization objective due to several driving factors. First, from an operational eco-nomic standpoint, the UAV’s limited endurance makes transport time a critical determinant of energy consumption and operational costs. Therefore, the most time-efficient path is inherently the most energy-efficient. Second, in terms of service quality, timely deliveries are a core indicator of service reliability, especially in time-sensitive scenarios like urgent deliveries or emergency logistics. This is particularly true for high-priority goods such as fresh produce or medical supplies. Furthermore, the low-altitude environment itself underscores the importance of time optimization. UAVs leverage their speed advantage by avoiding ground congestion, while the complex low-altitude airspace and safety regulations require careful path planning that minimizes uncertainty during flight. This ensures optimal system throughput and response time. Thus, prioritizing time optimization is crucial for enhancing the efficiency, reliability, and economic viability of low-altitude logistics systems.

In light of these considerations, this study establishes a scheduling model with time as the unified dimension for all parameters and decision variables. The objective is to minimize the total execution time of all tasks, which not only aligns with the goal of improving logistics efficiency but also serves as a critical lever for enhancing the economic, reliability, and overall effectiveness of low-altitude logistics systems.

2.3.1. Definitions and Model Descriptions

| Sets: |

| : | Set of nodes to be visited by trucks (mission sets). |

| : | Set of time cost for trucks to pass between points. |

| : | Set of time cost for drones to pass between points. |

| : | Set of number of drones required for set . |

| : | The execution time of the task set |

| Initial endurance power value of the drone. |

| : | the set of drones |

| Variable: |

| : | Whether drone performs task , 1 if yes, 0 otherwise. |

| : | Truck arrival time at node . |

| : | When task was actually executed. |

| : | Whether drone is released before node , yes is 1, otherwise 0. |

| : | Corrected power of drone at node . |

| : | The earliest available time for drone to reach node . |

| : | Whether UAV i’s current charge can perform task and fly to point to be recovered, yes is 1, otherwise 0. |

| : | Whether drone i’s current power level is sufficient to perform the whole task , yes is 1, otherwise 0. |

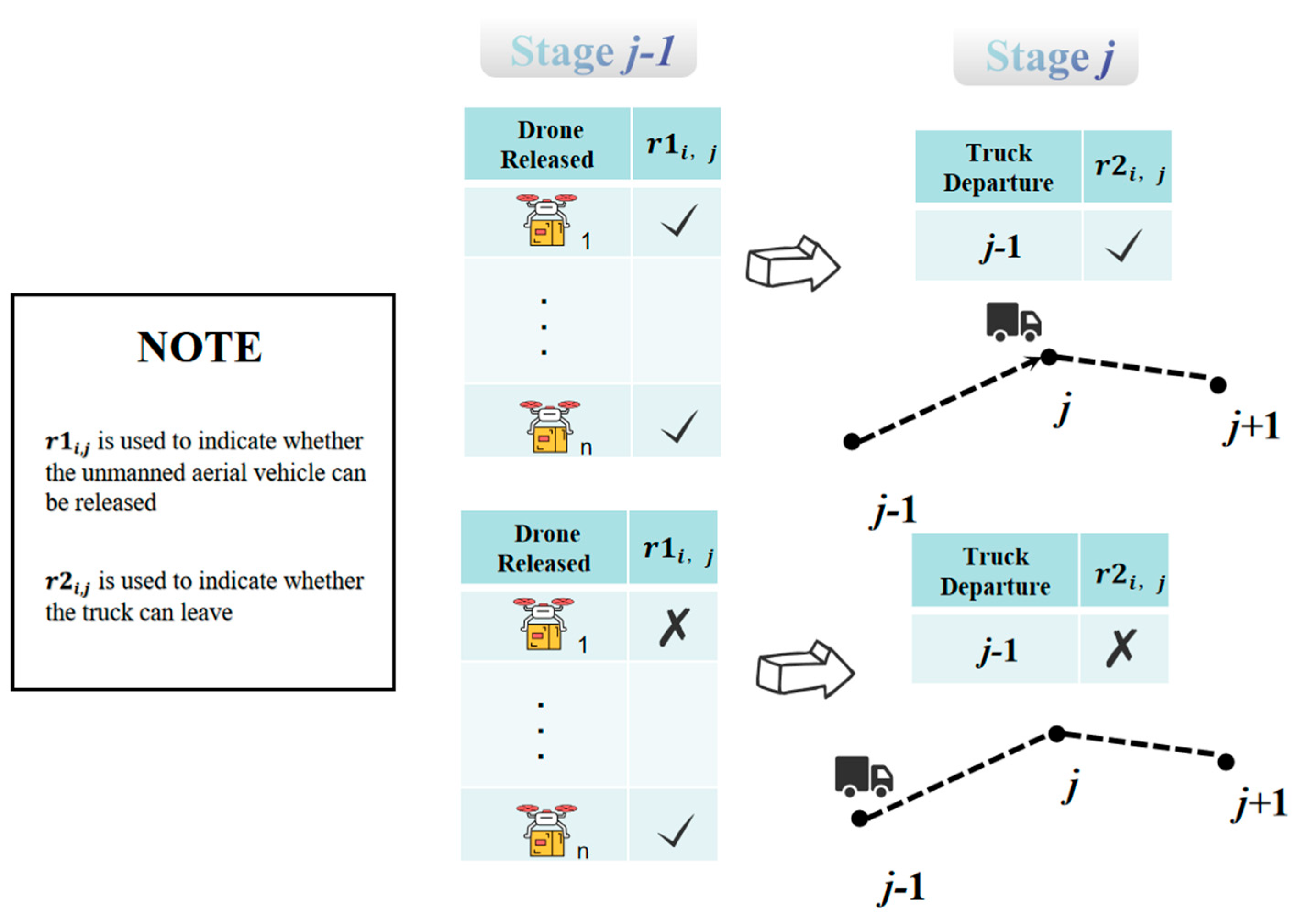

Based on the definitions of

and

in the model, the scheduling logic of the model is now explained with reference to stage

and in conjunction with

Figure 7. As depicted in the figure, the position of the truck at stage

is determined by whether all the released drones can fly to the next node

after completing their tasks. If all the released drones are able to proceed to node

, the truck is allowed to depart from node

and move to node

. Otherwise, the truck must stay at node

to wait for the return of the drones.

2.3.2. Model

|

| s.t | | | (7) |

| | | | (8) |

| | | | (9) |

| | | | (10) |

| | | | (11) |

| | | | (12) |

| | | | (13) |

| | | | (14) |

| | | | (15) |

| | | | (16) |

| | | | (17) |

| | | | (18) |

| | | | (19) |

| | | | (20) |

| | | | (21) |

| | | | (22) |

| | | | (23) |

| | | | (24) |

| | | | (25) |

| | | | (26) |

| | | | (27) |

| | | | (28) |

| | | | (29) |

| | | | (30) |

| | | | (31) |

| | | | (32) |

| | | | (33) |

| | | | (34) |

| | | | (35) |

| | | | (36) |

The model comprises a total of 33 constraints, explained as follows. Equations (7) and (8) differentiate between truck and drone delivery points. For truck delivery points, the value of is set to 0, while for drone delivery points, the necessary number of drones must be released to meet demand. Equations (9) and (10) impose constraints on the earliest service time for each drone at a node. If the drone is detached from the truck platform upon arrival, its earliest available time is calculated based on its task execution status. If it remains on the truck, the time aligns with the truck’s arrival at the node. The earliest execution time for subsequent tasks is constrained by Equations (11) and (12) to accommodate both truck and drone conditions. Equations (13) and (15) constrain the truck’s arrival time at nodes. Ideally, the truck can leave immediately after releasing the drone, as per Equation (13). However, if the drone’s battery only suffices for the current node’s task, the truck must wait to recover the drone, as per Equation (14). Equation (15) enforces that if drone is assigned to node , the truck must remain at node until the drone arrives, ensuring synchronization between truck movements and drone operations. Equations (16)–(19) correct for drone battery usage. During the truck-bound phase before release, the drone’s battery does not deplete. Thus, the first release node must be identified to adjust the battery level by adding back the amount deducted for the in-transit period. Equations (20)–(23) assess whether a drone can continue to the next adjacent node after completing a task at node . If not, the current node task can be executed, but the truck must wait for recovery (as per Equation (14)). For drone , task execution start time is constrained by both the drone’s earliest arrival and the truck’s earliest arrival, addressed by Equations (20) and (21) from the drone’s perspective and Equations (22) and (23) from the truck’s perspective. Equations (24)–(27) evaluate whether a drone can execute only the current node’s task. If not, Equation (28) ensures that the task is not assigned to drone . Equations (29) and (30) provide logical coordination constraints: Equation (28) sets the arrival time at subsequent nodes to infinity for low-battery drones, while Equation (30) ensures that each drone’s subsequent node visit time is not earlier than the preceding node. Equations (31)–(34) assign initial values to model variables. Equations (35) and (36) define variable constraint types: are binary decision variables, while are continuous variables. The value of big M should be a sufficiently large constant, typically set as multiples of large values such as 100 or 1000.

4. Conclusions

This paper addresses the drone-truck collaborative scheduling problem in community-based demand scenarios. Existing methodologies predominantly build on two classic optimization frameworks: the Vehicle Routing Problem with Drones (VRPD) and Traveling Salesman Problem (TSP), often transformed into VRP with Drone Delivery (VRPDD) or multi-Drone TSP (TSP-mD) models that enforce constraints via graph-theoretic edge/node traversal rules. However, these approaches suffer from combinatorial explosion in complex networks and scalability limitations for large-scale problems. Since the VRPD problem was initially considered a special case of vehicle scheduling, this paper focuses on scheduling optimization to solve the truck–drone collaborative delivery problem. A three-stage optimization model for community terminal logistics is proposed, featuring adaptability to both dense urban and sparse suburban operation point distributions. Comparative experiments validate the model’s feasibility, demonstrating superior solution quality over heuristic baselines and highlighting its practical utility in multi-agent scheduling contexts.

Notably, the current model incorporates several simplifying assumptions to maintain focus on the core scheduling mechanism, including predetermined truck routes without backtracking, simplified platform service times and capacity, constant speed and deterministic operating conditions. These choices, while enabling a tractable and insightful analysis of cooperative logistics, highlight specific limitations in real-world applicability, such as the exclusion of route reversals and concurrent operational constraints.

Meanwhile, although this research establishes a robust scheduling framework, real-world community logistics entail granular constraints such as zone-specific delivery agreements and drone airspace authorization protocols. Future work will focus on integrating these operational nuances into an enhanced model and optimizing solution efficiency for large-scale implementations. In addition, we plan to extend the current deterministic framework to handle stochastic elements commonly encountered in dynamic environments, as illustrated in

Figure 11. Potential extensions will address:

Demand uncertainty: via robust optimization or scenario-based approaches;

Weather impacts: using chance constraints or real-time weather API integration;

Drone battery uncertainty: through stochastic battery consumption models;

Travel time variability: by incorporating buffer times or contingency strategies;

Actual deployment differences: by establishing a more refined service time model and deck capacity constraints.