Flame Structure and Flame–Flow Interaction in a Centrally Staged Burner Featuring a Diffusion Pilot

Abstract

1. Introduction

2. Experimental Setup

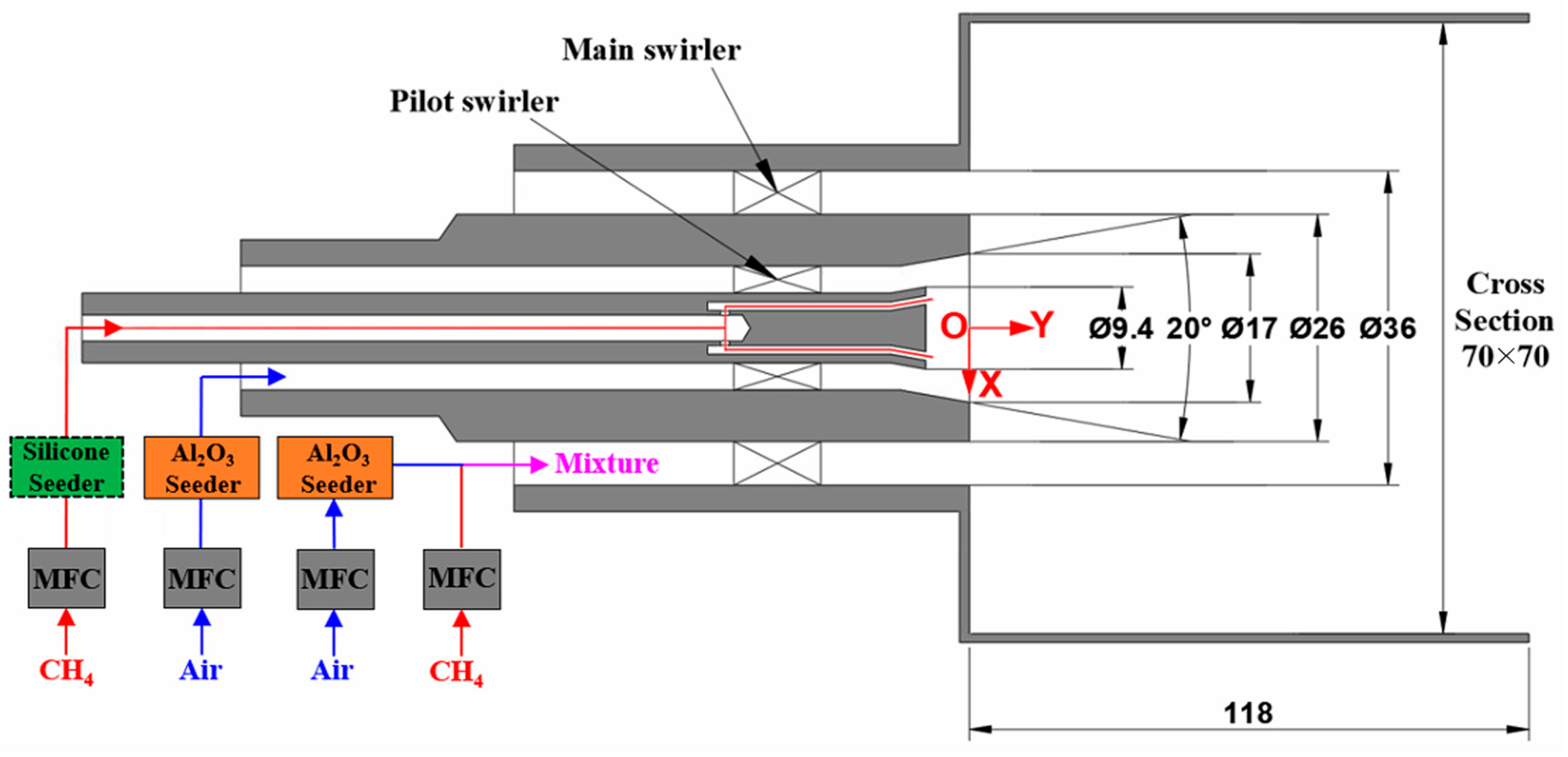

2.1. Burner and Operating Conditions

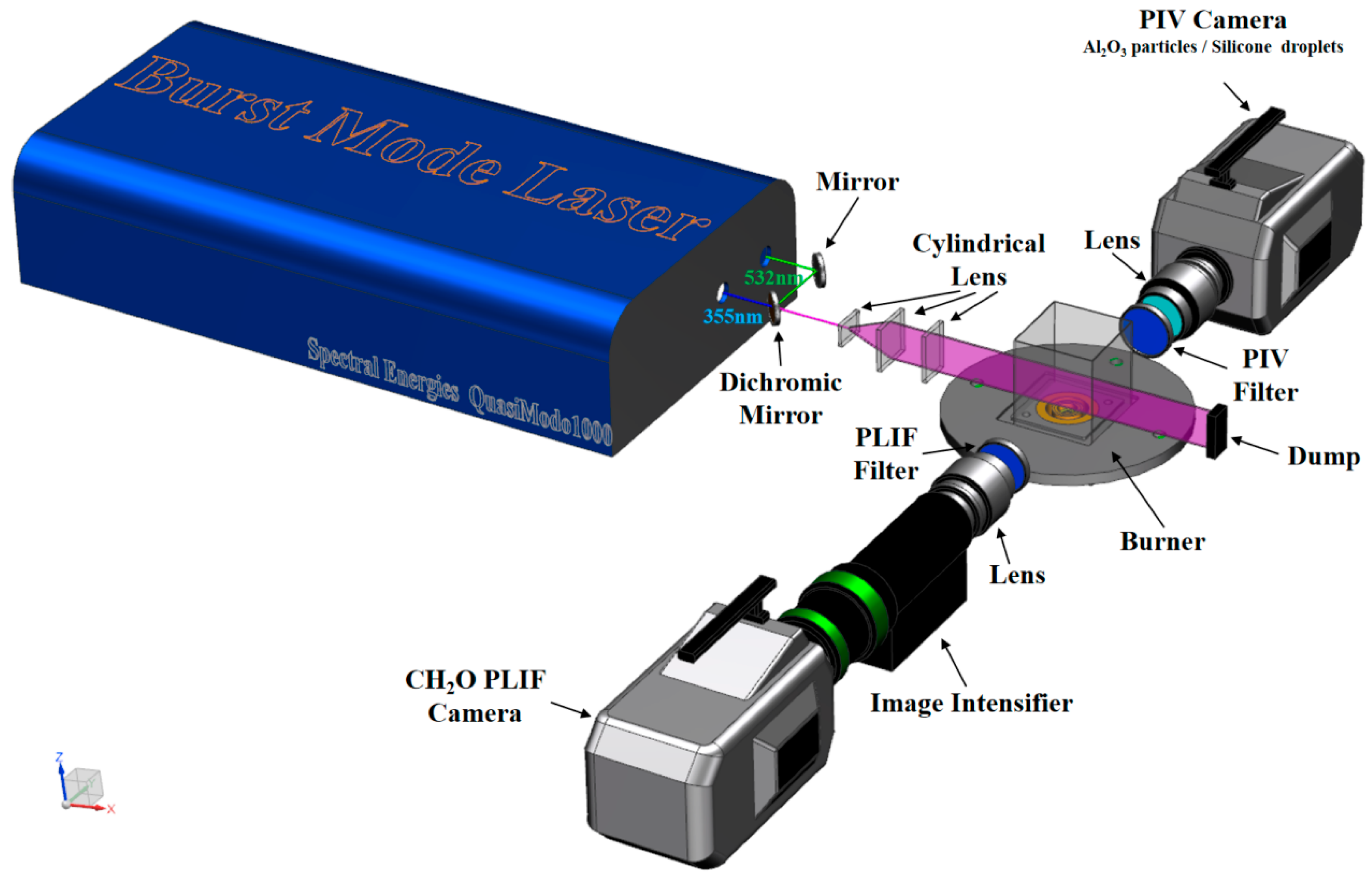

2.2. High-Frequency Optical Measurement

3. Result and Discussion

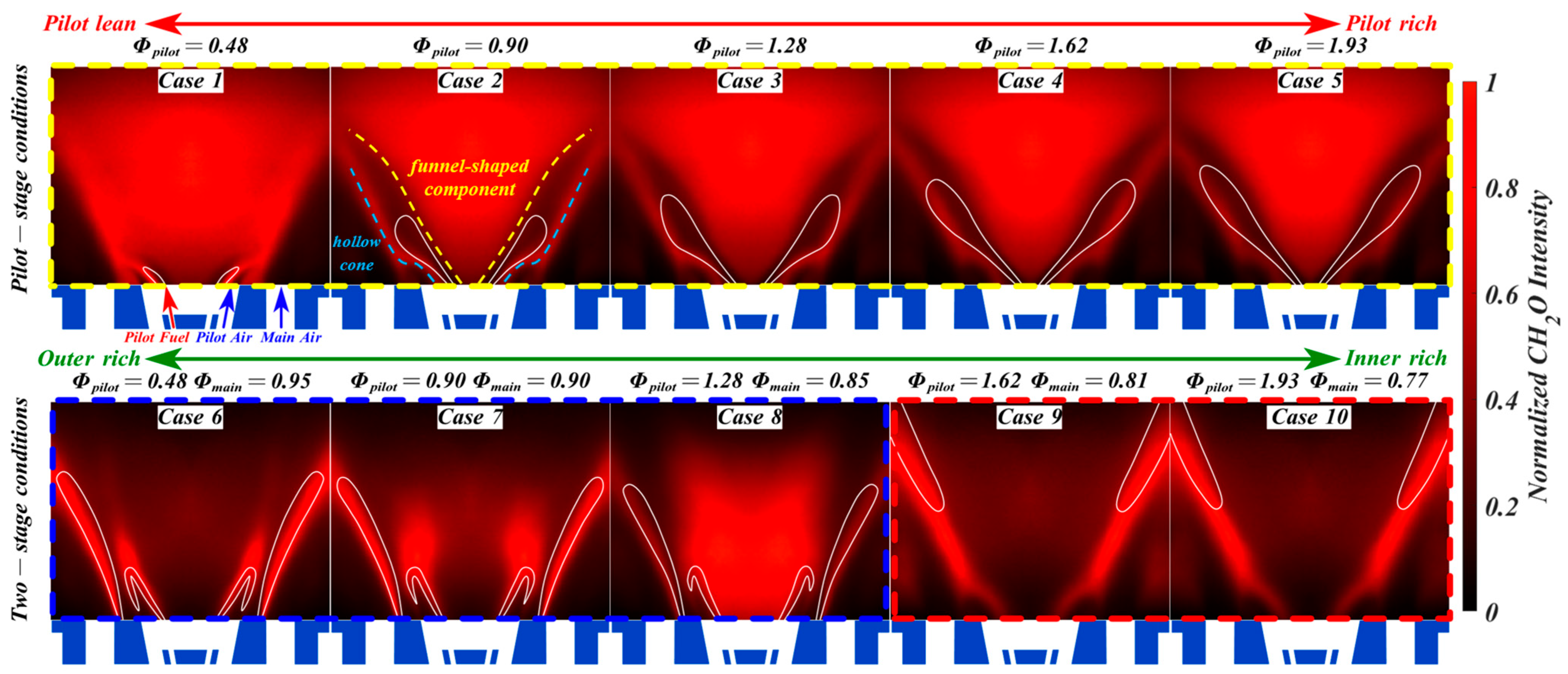

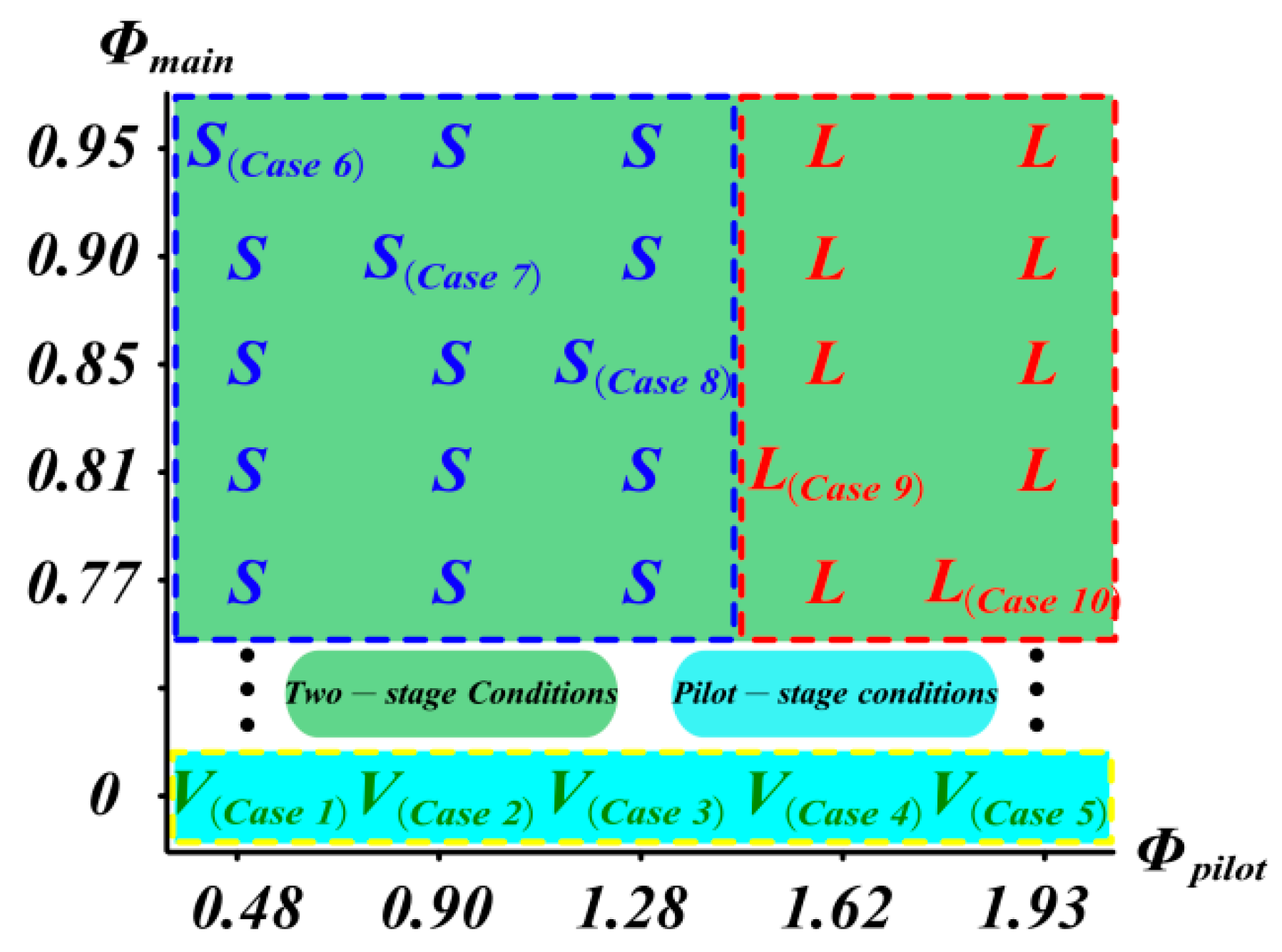

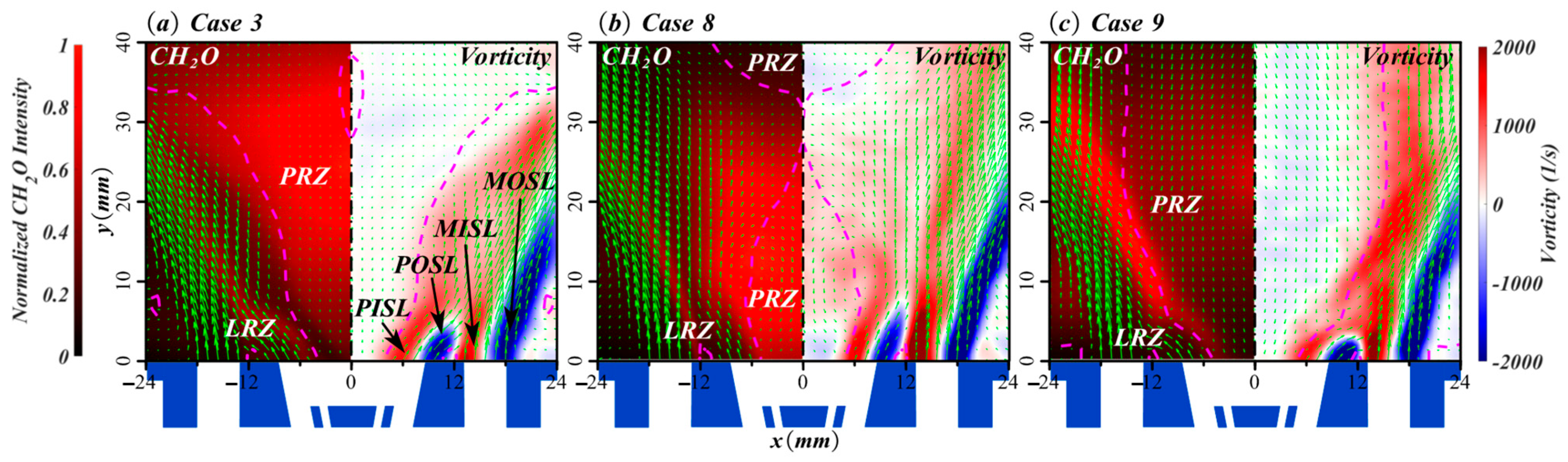

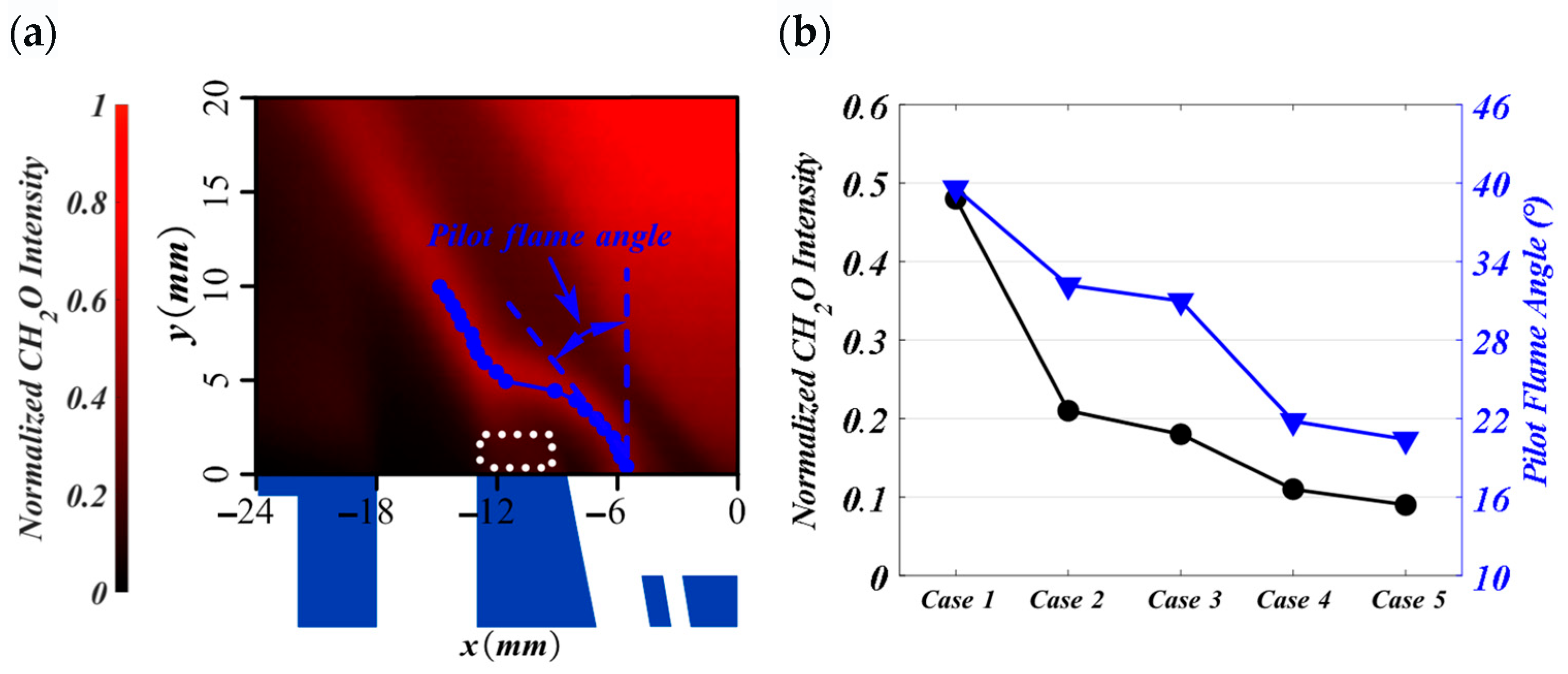

3.1. Average Flame Structures

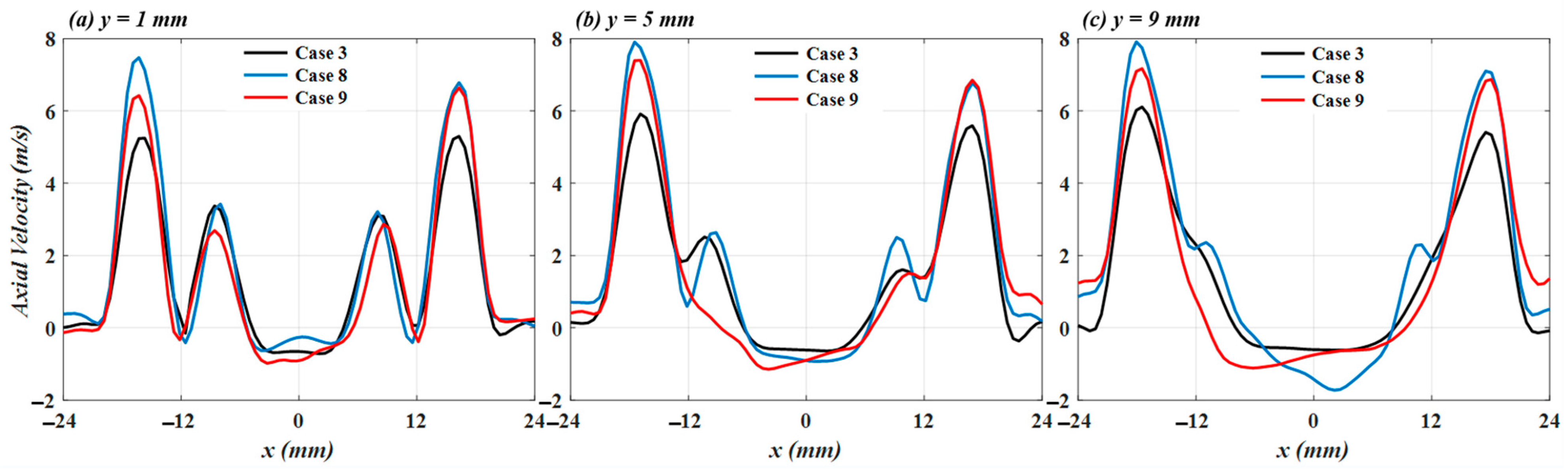

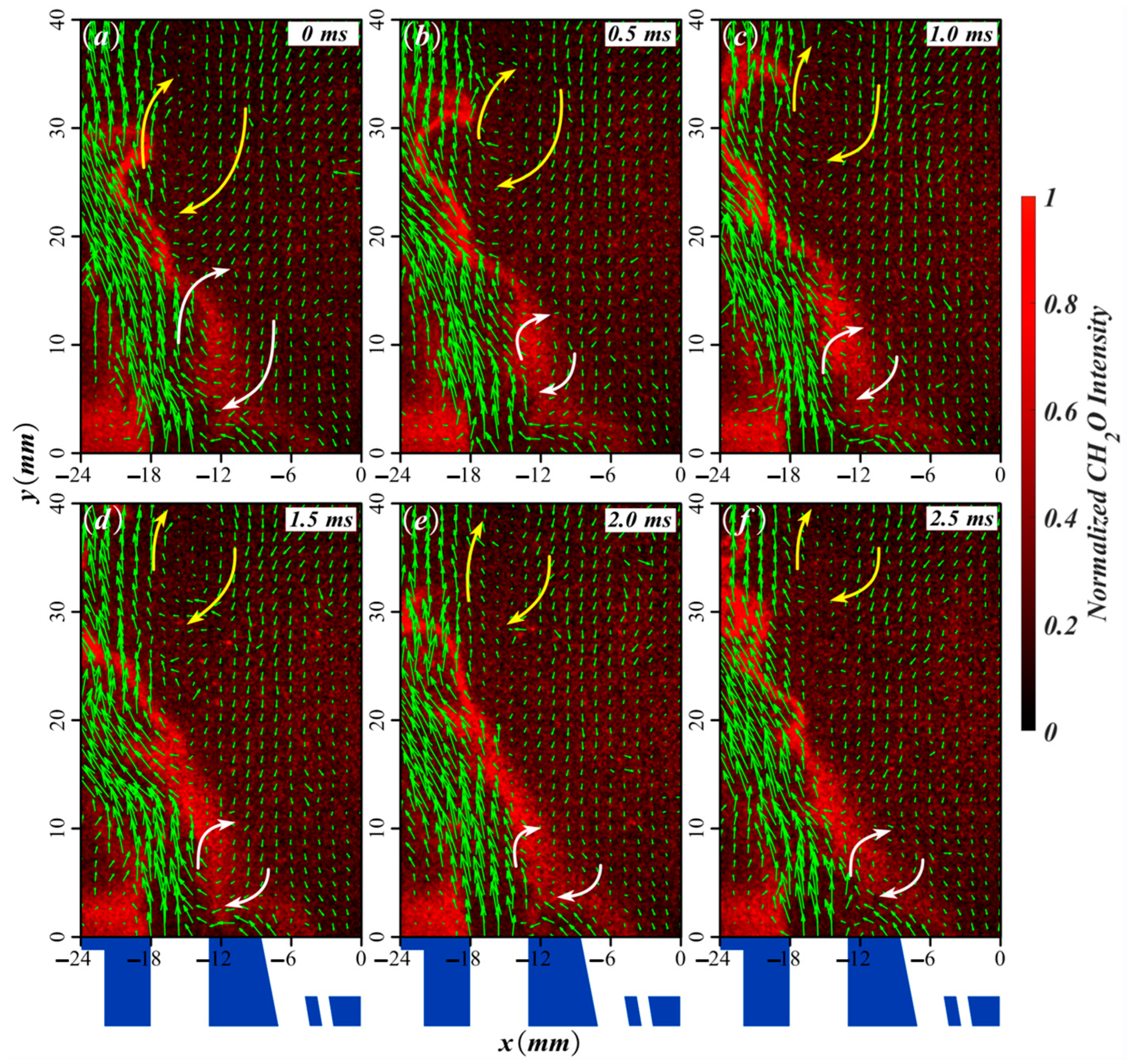

3.2. Flow Field Characteristics

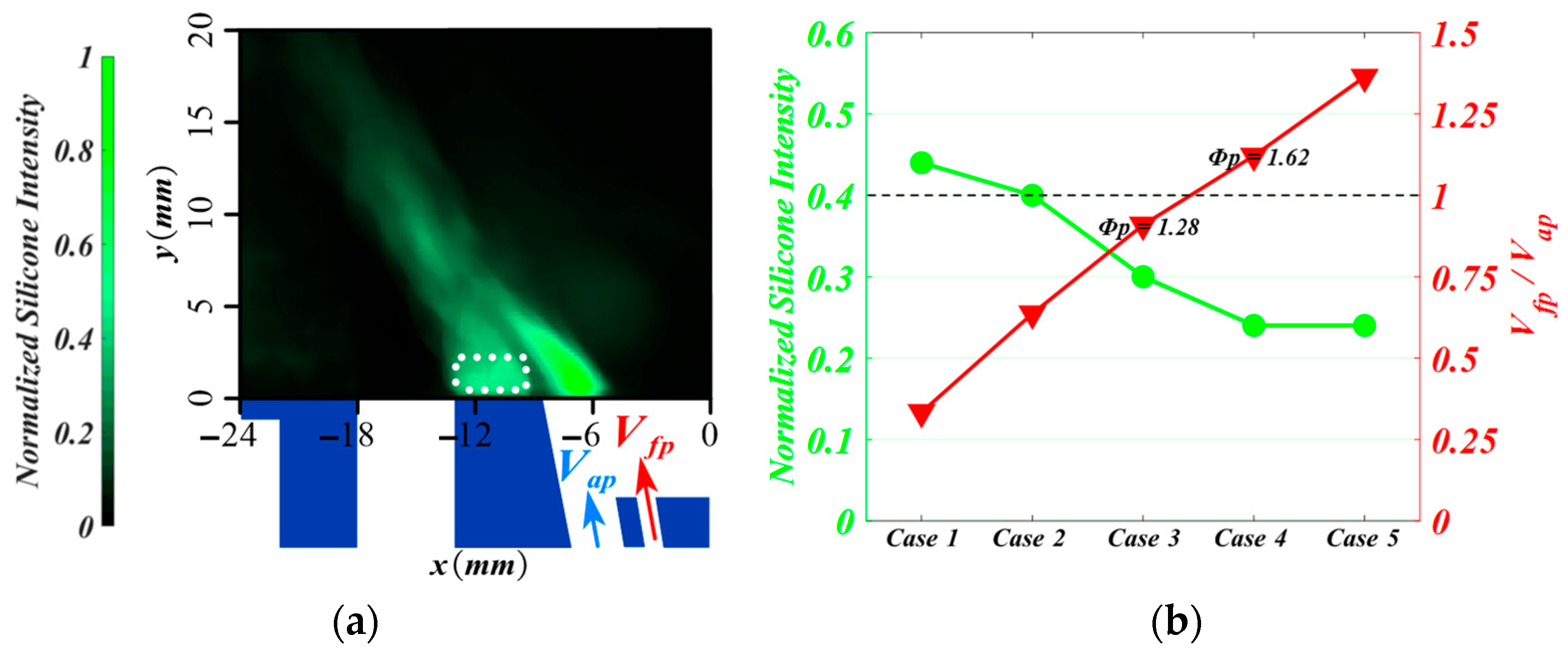

3.3. Pilot Fuel Transportation

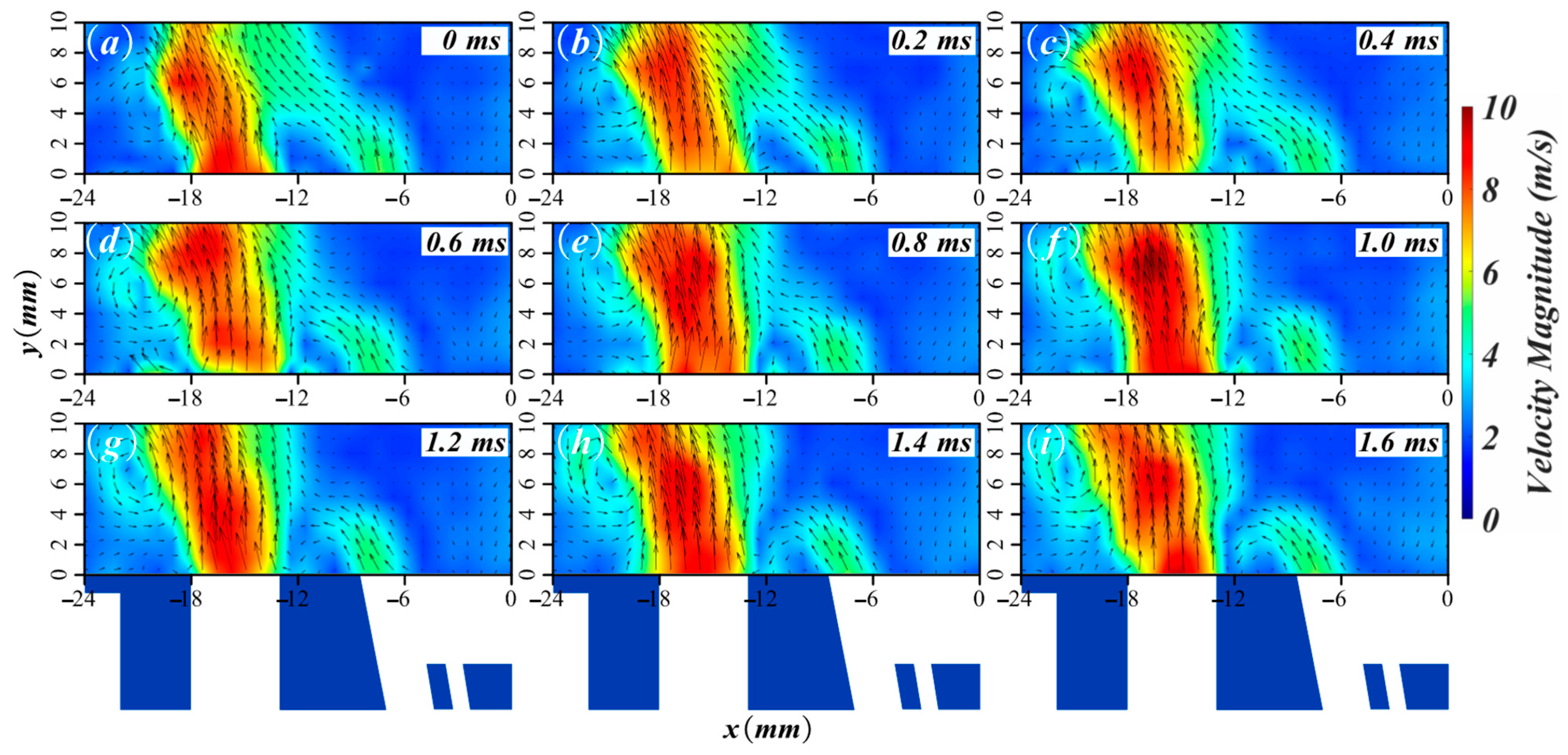

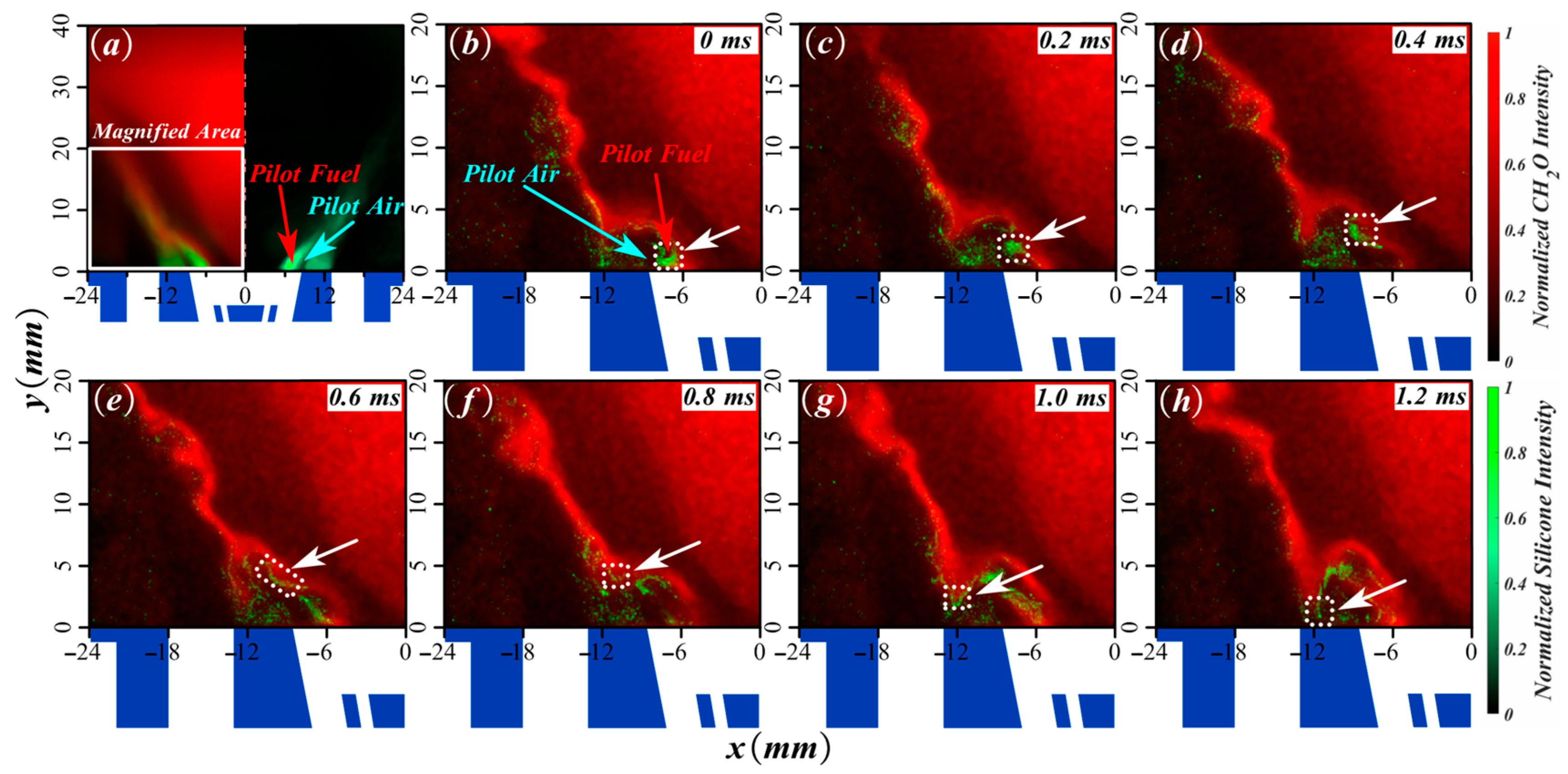

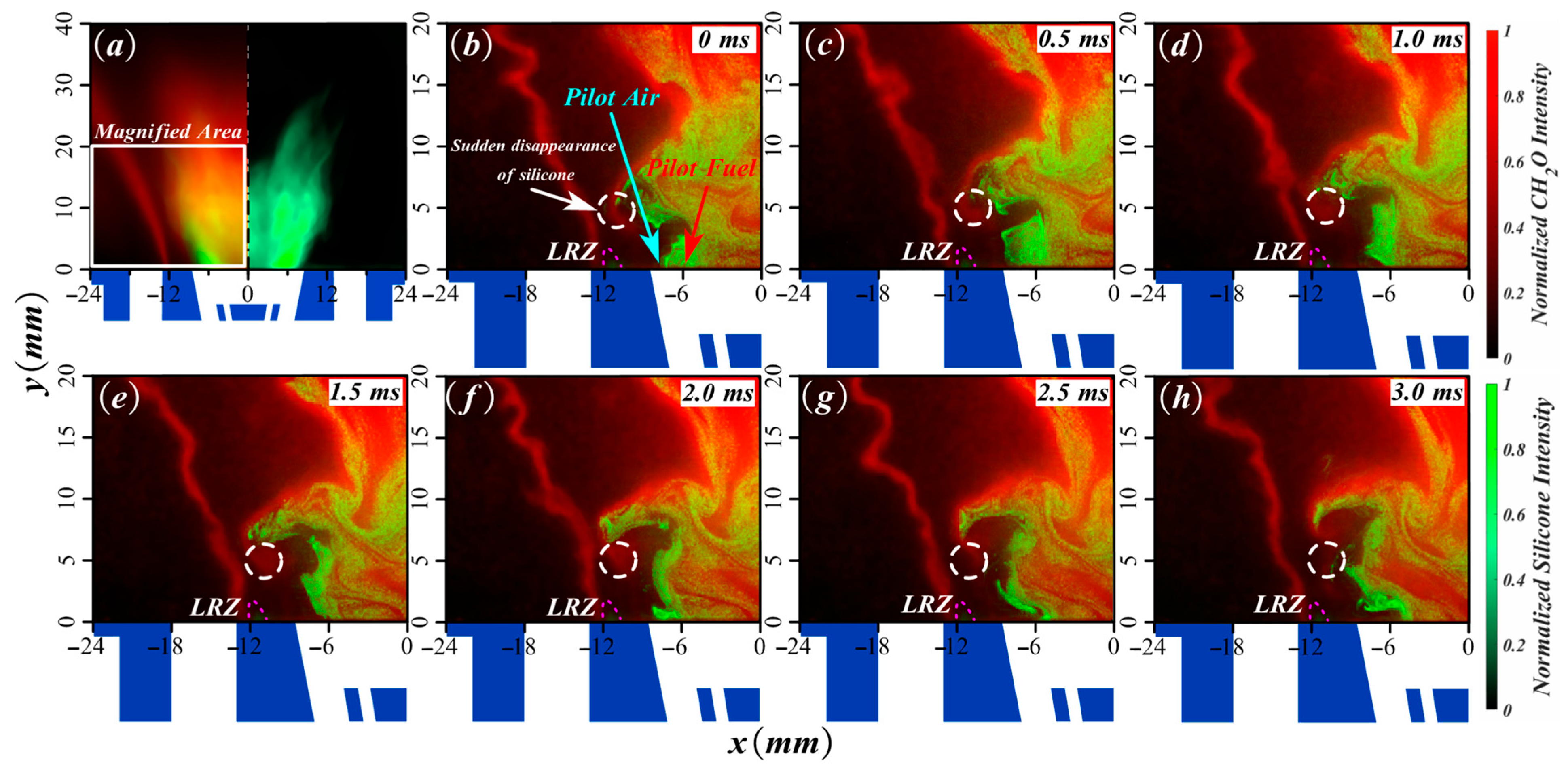

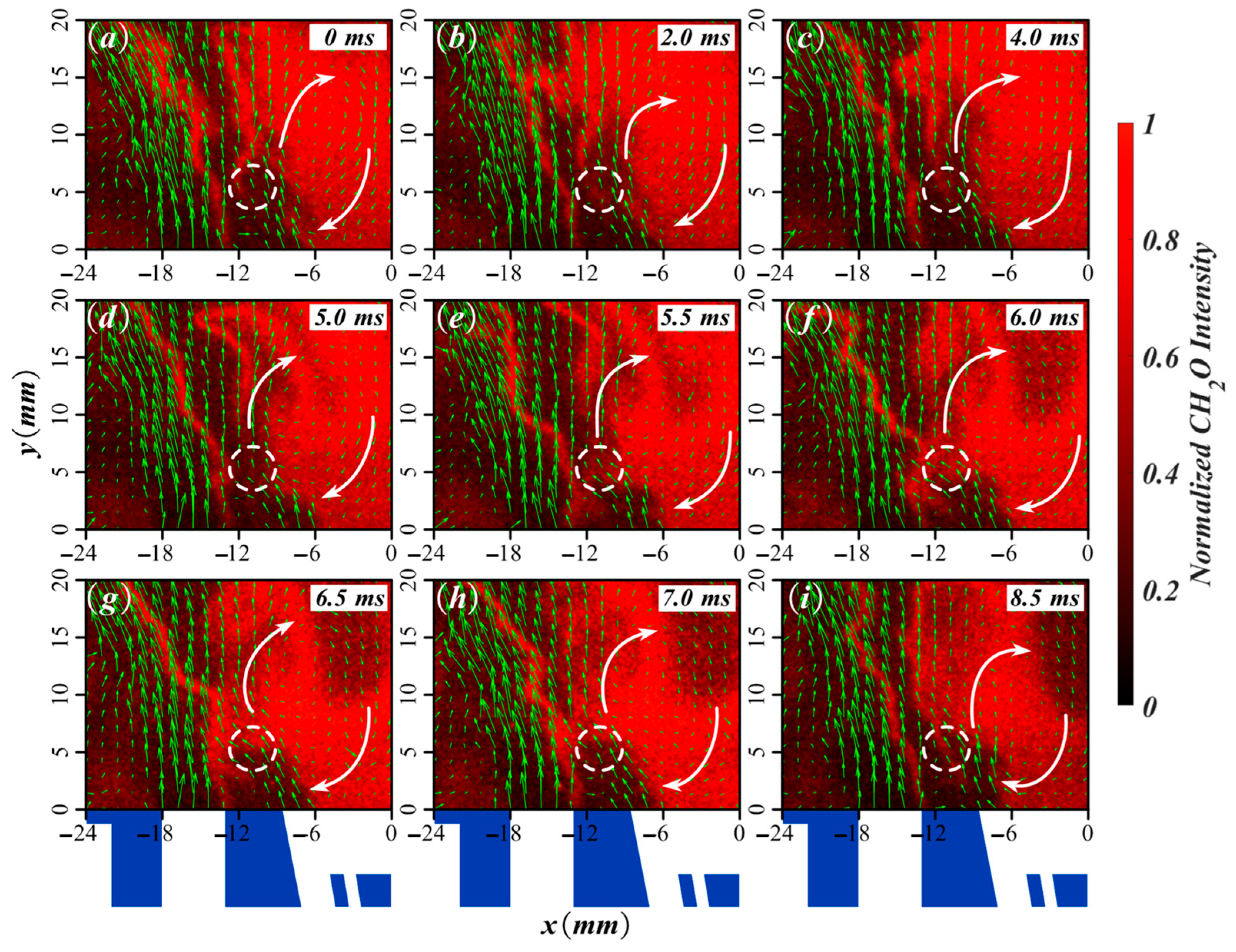

3.4. Flame–Flow Interaction

4. Conclusions

- (1)

- Under two-stage conditions, the flame structure is primarily governed by the pilot equivalence ratio, leading to the identification of two distinct modes: the stratified flame (S-flame) and the lifted flame (L-flame). This contrasts with premixed pilot systems and underscores the unique sensitivity of diffusion pilots to fuel–flow interactions.

- (2)

- The S-flame corresponds to the separated flow of the two stages, whereas the L-flame corresponds to the merged flow of the two stages. The pilot stage CH2O-PLIF mainly distributes in the PISL, and the main stage CH2O-PLIF mainly distributes in the MISL. The CH2O-PLIF of the two stages merges when the inner shear layers of the two stage air do, and it separates when the inner shear layers are separated. Significant radial oscillation of the pilot stage airflow is identified as a key dynamic feature.

- (3)

- The pilot fuel, despite being injected internally, is effectively transported to the outer side of the pilot air. With a low pilot fuel supply (Vfp/Vap < 1), flow oscillations entrain fuel and hot radicals towards the LRZ, accumulating them at the inner side of the main stage outlet. This accumulation provides a continuous ignition source, enabling the main premixed mixture to stabilize as a rooted S-flame.

- (4)

- At a higher pilot equivalence ratio (Vfp/Vap > 1), the reduced entrainment of pilot fuel and radicals prevents ignition at the main stage outlet. Consequently, the main stage mixture is ignited downstream upon intersecting with the pilot flame, forming an L-flame. Simultaneous measurements reveal that in this L-mode, hot products cannot recirculate to the pilot stage root, leading to its eventual extinction.

- (5)

- This study clarifies the governing role of the pilot equivalence ratio and the associated fuel–air velocity ratio in the transition between the S-flame and L-flame modes. For practical combustor design, this underscores the critical importance of precisely controlling the pilot fuel injection characteristics. Achieving the desired S-flame for stable operation requires careful management of the pilot fuel–air interaction to ensure adequate entrainment of fuel and radicals to the main stage outlet, avoiding unintended transitions to the L-flame mode with potential stability concerns.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Correa, S.M. Power generation and aero-propulsion gas turbines: From combustion science to combustion technology. In Symposium (International) on Combustion; Elsevier: Amsterdam, The Netherlands, 1998; Volume 27, pp. 1793–1807. [Google Scholar]

- Mongia, H.C. TAPS–A 4th generation propulsion combustor technology for low emissions. In Proceedings of the AIAA/ICAS International Air and Space Symposium and Exposition: The Next 100 Years, AIAA 2003–2657, Dayton, OH, USA, 14–17 July 2003. [Google Scholar]

- Lazlk, W.; Doerr, T.; Bake, S.V.; Vd Bank, R.; Rackwitz, L. Development of Lean-Burn low-NOx combustion technology at Rolls-Royce Deutschland. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; Amer Soc Mechanical Engineers: New York, NY, USA, 2008; Volume 3, pp. 797–807. [Google Scholar]

- Wang, B.; Zhang, C.; Lin, Y.Z.; Zhang, C.; Lin, Y.; Hui, X.; Li, J. Influence of the main swirler vane angle on the ignition performance of TELSESSI combustor. J. Eng. Gas Turbines Power 2017, 139, 011501. [Google Scholar] [CrossRef]

- Han, X.; Laera, D.; Morgans, A.S.; Lin, Y.; Sung, C.-J. The effect of stratification ratio on the macroscale structure of stratified swirling flames: Experimental and numerical study. J. Eng. Gas Turbines Power 2018, 140, 121004. [Google Scholar] [CrossRef]

- Guiberti, T.F.; Durox, D.; Zimmer, L.; Schuller, T. Analysis of topology transitions of swirl flames interacting with the combustor side wall. Combust. Flame 2015, 162, 4342–4357. [Google Scholar] [CrossRef]

- Carneiro Piton, L.; Senra Pessanha Rios Nobrega, G.; Figueira da Silva, L.F.; Scouflaire, P.; Darabiha, N. Experimental study of the influence of the swirl number on lean premixed combustion regimes. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 210. [Google Scholar] [CrossRef]

- Mercier, R.; Guiberti, T.; Chatelier, A.; Durox, D.; Gicquel, O.; Darabiha, N.; Schuller, T.; Fiorina, B. Experimental and numerical investigation of the influence of thermal boundary conditions on premixed swirling flame stabilization. Combust. Flame 2016, 171, 42–58. [Google Scholar] [CrossRef]

- Shanbhogue, S.J.; Sanusi, Y.; Taamallah, S.; Habib, M.; Mokheimer, E.; Ghoniem, A. Flame macrostructures, combustion instability and extinction strain scaling in swirl-stabilized premixed CH4/H2 combustion. Combust. Flame 2016, 163, 494–507. [Google Scholar] [CrossRef]

- Candel, S.; Durox, D.; Schuller, T.; Bourgouin, J.-F.; Moeck, J.P. Dynamics of swirling flames. Annu. Rev. Fluid Mech. 2014, 46, 147–173. [Google Scholar] [CrossRef]

- Han, X.; Laera, D.; Morgans, A.; Sung, C.; Hui, X.; Lin, Y. Flame macrostructures and thermoacoustic instabilities in stratified swirling flames. Proceedings of the ASME Turbo Expo 2012, Copenhagen, Denmark. 2012. Proc. Combust. Inst. 2019, 37, 5377–5384. [Google Scholar] [CrossRef]

- Song, H.; Lin, Y.; Han, X.; Yang, D.; Zhang, C.; Sung, C.-J. The thermoacoustic instability in a stratified swirl burner and its passive control by using a slope confinement. Energy 2020, 195, 116956. [Google Scholar] [CrossRef]

- Kim, K.T.; Hochgreb, S. The nonlinear heat release response of stratified lean-premixed flames to acoustic velocity oscillations. Combust. Flame 2011, 158, 2482–2499. [Google Scholar] [CrossRef]

- Wang, X.; Han, X.; Wang, J.; Du, J.; Sung, C.-J. Flame stabilization and thermoacoustic instability during operating condition modulations: Roles of pilot and main flames. Phys. Fluids 2022, 34, 125102. [Google Scholar] [CrossRef]

- Sweeney, M.S.; Hochgreb, S.; Dunn, M.J.; Barlow, R.S. The structure of turbulent stratified and premixed methane/air flames II: Swirling flows. Combust. Flame 2012, 159, 2912–2929. [Google Scholar] [CrossRef]

- Han, M.; Han, X.; Wang, J.; Zhang, C.; Tian, L. Effect of confinement size on flame macrostructures and thermoacoustic instability in a centrally-staged burner. Appl. Therm. Eng. 2025, 279, 127720. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, X.; Gong, Y.; Yang, Y.; Tang, Z.; Liu, G.; Deng, F.; Yang, J.; Zheng, H. Experimental study of stratified swirl flame dynamics in a model gas turbine combustor. Energy 2020, 211, 118699. [Google Scholar] [CrossRef]

- Han, X.; Yang, D.; Wang, J.; Zhang, C. The effect of inlet boundaries on combustion instability in a pressure-elevated combustor. Aerosp. Sci. Technol. 2021, 111, 106517. [Google Scholar] [CrossRef]

- Boxx, I.; Slabaugh, C.; Kutne, P.; Lucht, R.; Meier, W. 3 kHz PIV/OH-PLIF measurements in a gas turbine combustor at elevated pressure. Proc. Combust. Inst. 2015, 35, 3793–3802. [Google Scholar] [CrossRef]

- Li, L.; Lin, Y.; Fu, Z.; Zhang, C. Emission characteristics of a model combustor for aero gas turbine application. Exp. Therm. Fluid Sci. 2016, 72, 235–248. [Google Scholar] [CrossRef]

- Chong, C.T.; Lam, S.S.; Hochgreb, S. Effect of mixture flow stratification on premixed flame structure and emissions under counter-rotating swirl burner configuration. Appl. Therm. Eng. 2016, 105, 905–912. [Google Scholar] [CrossRef]

- Han, X.; Laera, D.; Yang, D.; Zhang, C.; Wang, J.; Hui, X.; Lin, Y.; Morgans, A.S.; Sung, C.-J. Flame interactions in a stratified swirl burner: Flame stabilization, combustion instabilities and beating oscillations. Combust. Flame 2020, 212, 500–509. [Google Scholar] [CrossRef]

- Wang, S.; Liu, X.; Li, L.; Han, X.; Zhang, C.; Qi, F. Effects of stratification ratio on flame stabilization and flow structure in stratified swirling flame. Acta Aerodyn. Sin. 2020, 38, 619–628. [Google Scholar]

- Xiang, J.; Li, J.; Mo, W.; Wang, B.; Yang, D.; Gan, X. The flame macrostructure and thermoacoustic instability in a centrally staged burner operating in different pilot stage equivalence ratios. Phys. Fluids 2024, 36, 075149. [Google Scholar] [CrossRef]

- Fu, P.; Li, S.; Hou, L.; Wen, Q.; Li, J.; Ma, H. Flame structure transition and instability excitation by pilot fuel in a centrally staged combustor. Phys. Fluids 2025, 37, 015138. [Google Scholar] [CrossRef]

- Fu, P.; Wen, Q.; Hou, L.; Li, J.; Ma, H. Interaction among flame structures and thermoacoustic instabilities in a centrally staged combustor. Appl. Therm. Eng. 2024, 254, 123862. [Google Scholar] [CrossRef]

- Law, C.K. Combustion Physics; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Cavaliere, D.E.; Kariuki, J.; Mastorakos, E. A Comparison of the Blow-Off Behaviour of Swirl-Stabilized Premixed, Non-Premixed and Spray Flames. Flow Turbul. Combust. 2013, 91, 347–372. [Google Scholar] [CrossRef]

- Dhanuka, S.K.; Temme, J.E.; Driscoll, J.F. Unsteady Aspects of Lean Premixed Prevaporized Gas Turbine Combustors: Flame-Flame Interactions. J. Propuls. Power 2011, 27, 631–641. [Google Scholar] [CrossRef]

- Dhanuka, S.K.; Temme, J.E.; Driscoll, J.F.; Mongia, H.C. Vortex-shedding and mixing layer effects on periodic flashback in a lean premixed prevaporized gas turbine combustor. Proc. Combust. Inst. 2009, 32, 2901–2908. [Google Scholar] [CrossRef]

- Temme, J.E.; Allison, P.M.; Driscoll, J.F. Combustion instability of a lean premixed prevaporized gas turbine combustor studied using phase-averaged PIV. Combust. Flame 2014, 161, 958–970. [Google Scholar] [CrossRef]

- Thielicke, W.; Sonntag, R. Particle image velocimetry for MATLAB: Accuracy and enhanced algorithms in PIVlab. J. Open Res. Softw. 2021, 9, 12. [Google Scholar] [CrossRef]

- Thielicke, W.; Stamhuis, E.J. PIVlab-Towards user-friendly, affordable and accurate digital particle image velocimetry in MATLAB. J. Open Res. Softw. 2014, 2, e30. [Google Scholar] [CrossRef]

- Wang, S.; Zheng, J.; Xu, L.; An, Q.; Han, X.; Zhang, C.; Li, L.; Xia, X.; Qi, F. Experimental investigation of the helical mode in a stratified swirling flame. Combust. Flame 2022, 244, 112268. [Google Scholar] [CrossRef]

| Case | Condition | Φtotal | Φp | Φm | SR |

|---|---|---|---|---|---|

| 1 | Pilot-stage conditions | 0.053 | 0.48 | 0 | - |

| 2 | 0.1 | 0.90 | |||

| 3 | 0.142 | 1.28 | |||

| 4 | 0.19 | 1.62 | |||

| 5 | 0.214 | 1.93 | |||

| 6 | Two-stage conditions | 0.9 | 0.48 | 0.95 | 0.5 |

| 7 | 0.90 | 0.90 | 1.0 | ||

| 8 | 1.28 | 0.85 | 1.5 | ||

| 9 | 1.62 | 0.81 | 2.0 | ||

| 10 | 1.93 | 0.77 | 2.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mo, W.; Liu, T.; Wang, B.; Ren, G.; Gan, X. Flame Structure and Flame–Flow Interaction in a Centrally Staged Burner Featuring a Diffusion Pilot. Aerospace 2025, 12, 1019. https://doi.org/10.3390/aerospace12111019

Mo W, Liu T, Wang B, Ren G, Gan X. Flame Structure and Flame–Flow Interaction in a Centrally Staged Burner Featuring a Diffusion Pilot. Aerospace. 2025; 12(11):1019. https://doi.org/10.3390/aerospace12111019

Chicago/Turabian StyleMo, Weishu, Te Liu, Bo Wang, Guangming Ren, and Xiaohua Gan. 2025. "Flame Structure and Flame–Flow Interaction in a Centrally Staged Burner Featuring a Diffusion Pilot" Aerospace 12, no. 11: 1019. https://doi.org/10.3390/aerospace12111019

APA StyleMo, W., Liu, T., Wang, B., Ren, G., & Gan, X. (2025). Flame Structure and Flame–Flow Interaction in a Centrally Staged Burner Featuring a Diffusion Pilot. Aerospace, 12(11), 1019. https://doi.org/10.3390/aerospace12111019