An Experimental Study on Pitot Probe Icing Protection with an Electro-Thermal/Superhydrophobic Hybrid Strategy

Abstract

1. Introduction

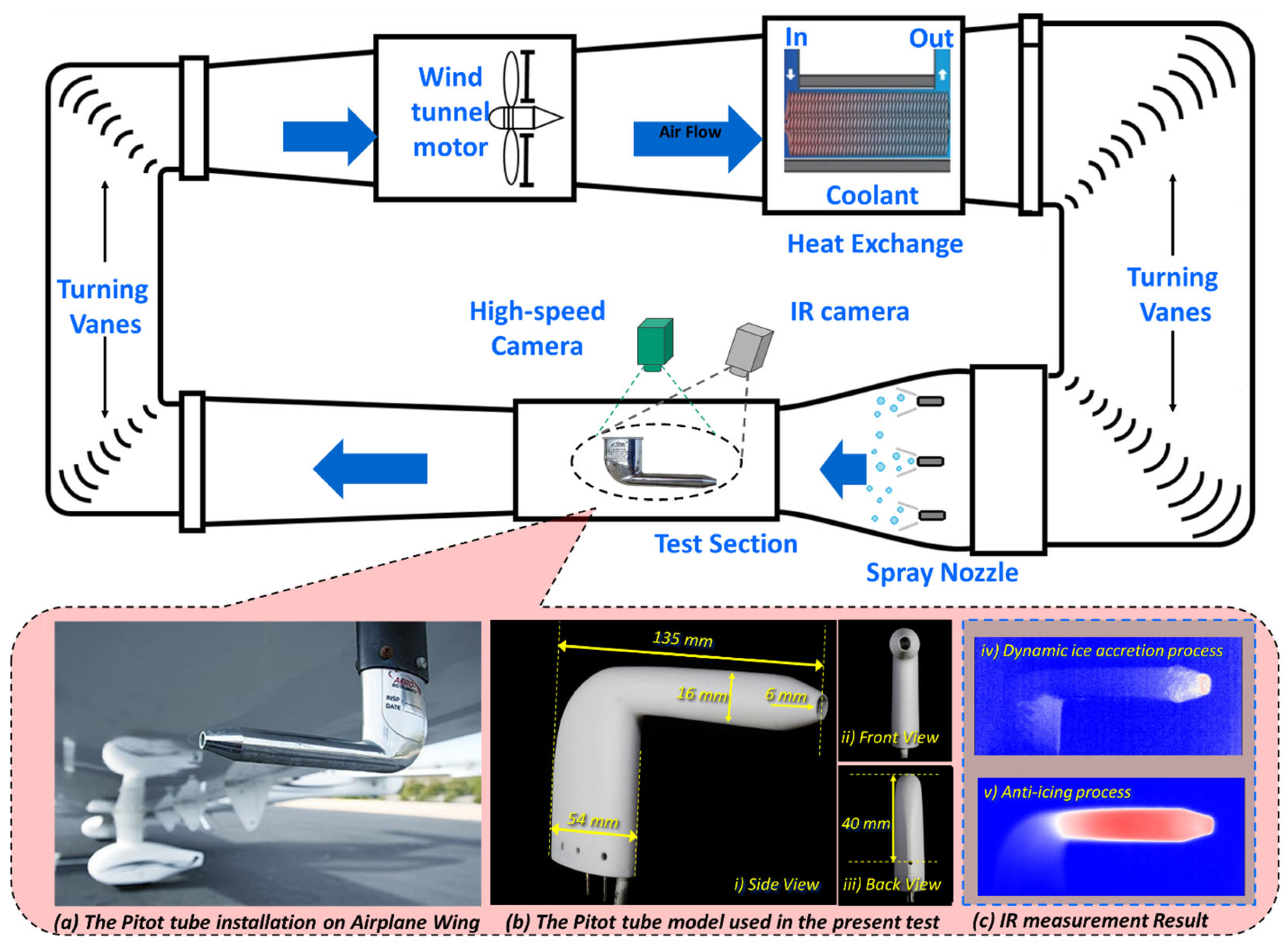

2. Experimental Setup and Test Model

2.1. ISU-IRT Used for the Present Study

2.2. The Pitot Probe Model Used for the Present Study

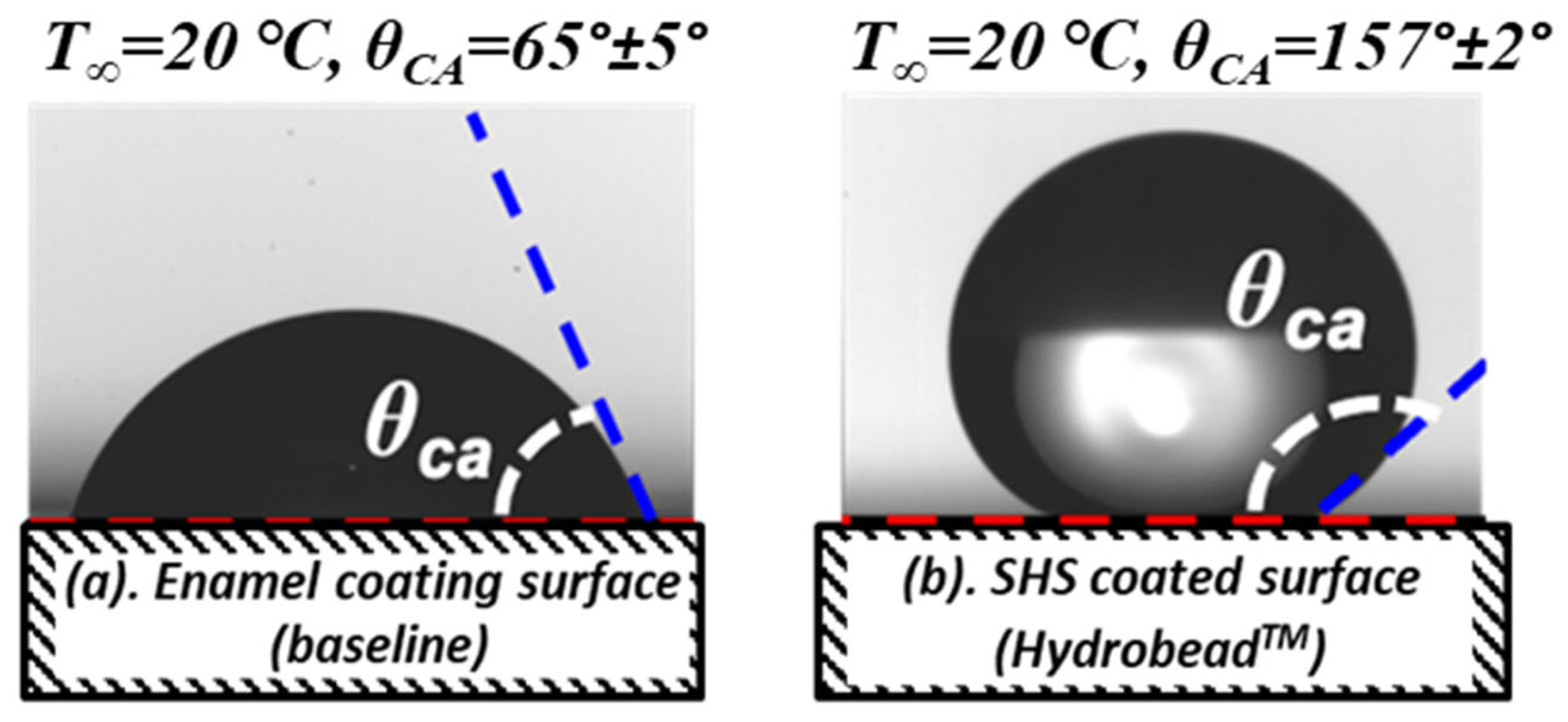

2.3. Surface Coatings Used in the Present Study

2.4. Icing Test Conditions and Measurement Systems

3. Measurement Results and Discussions

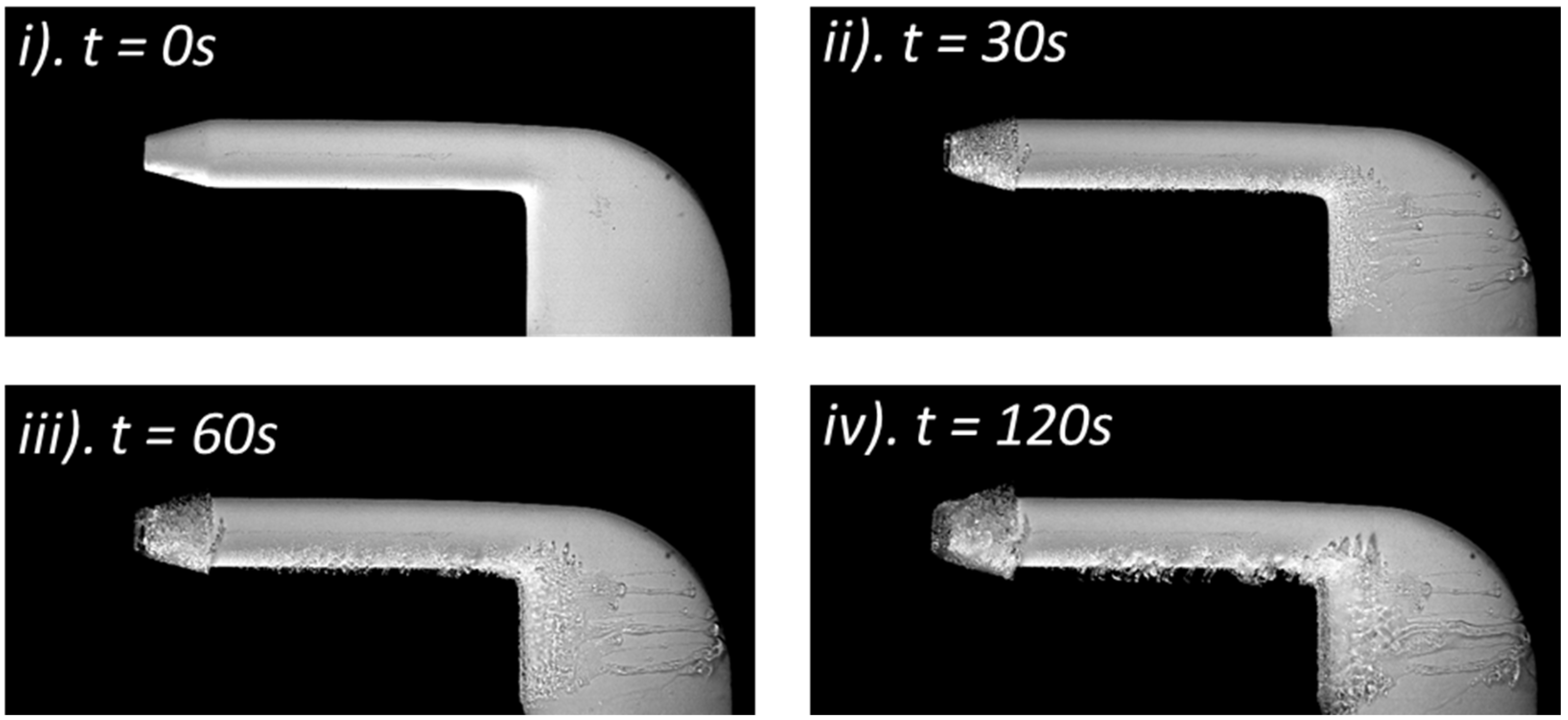

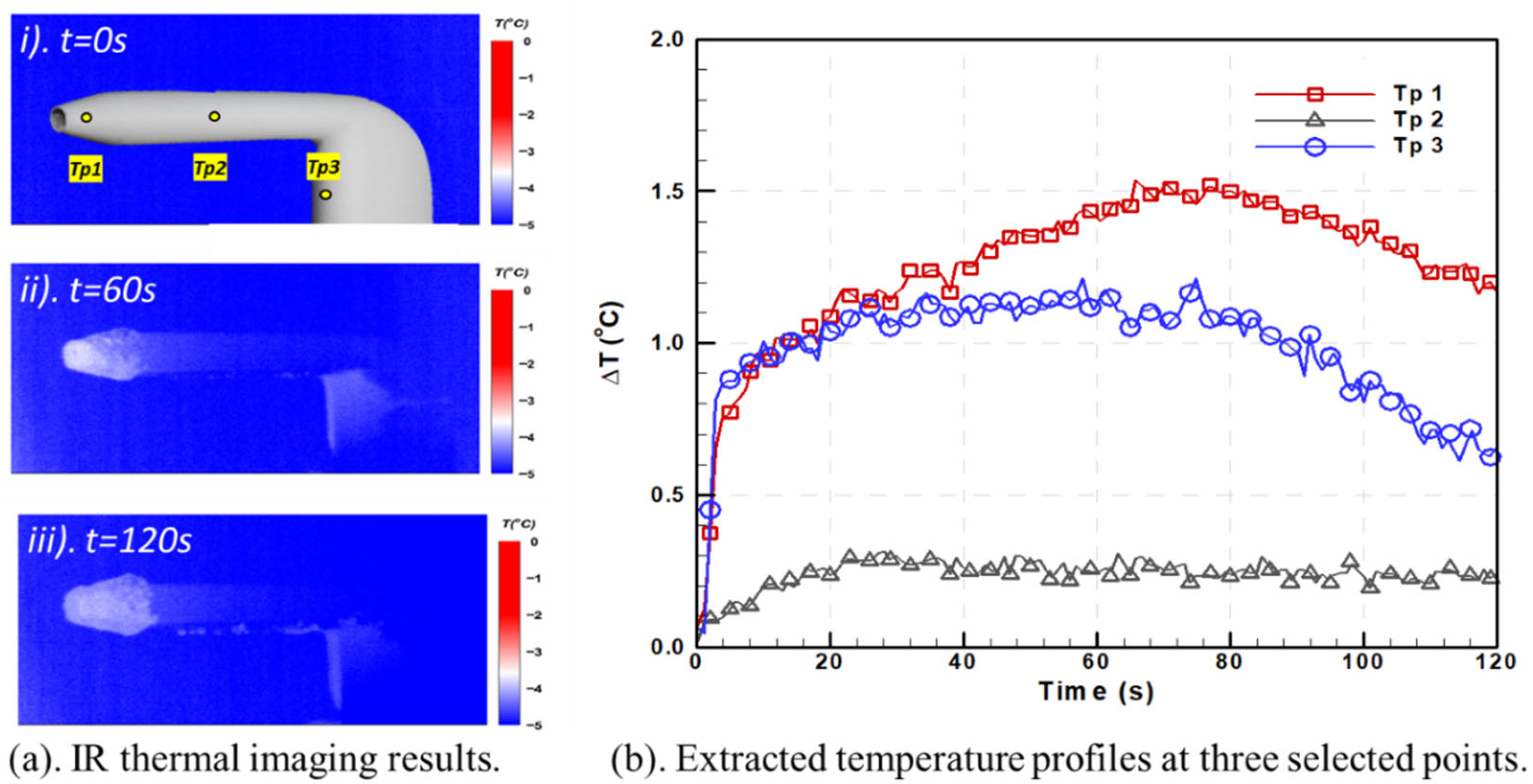

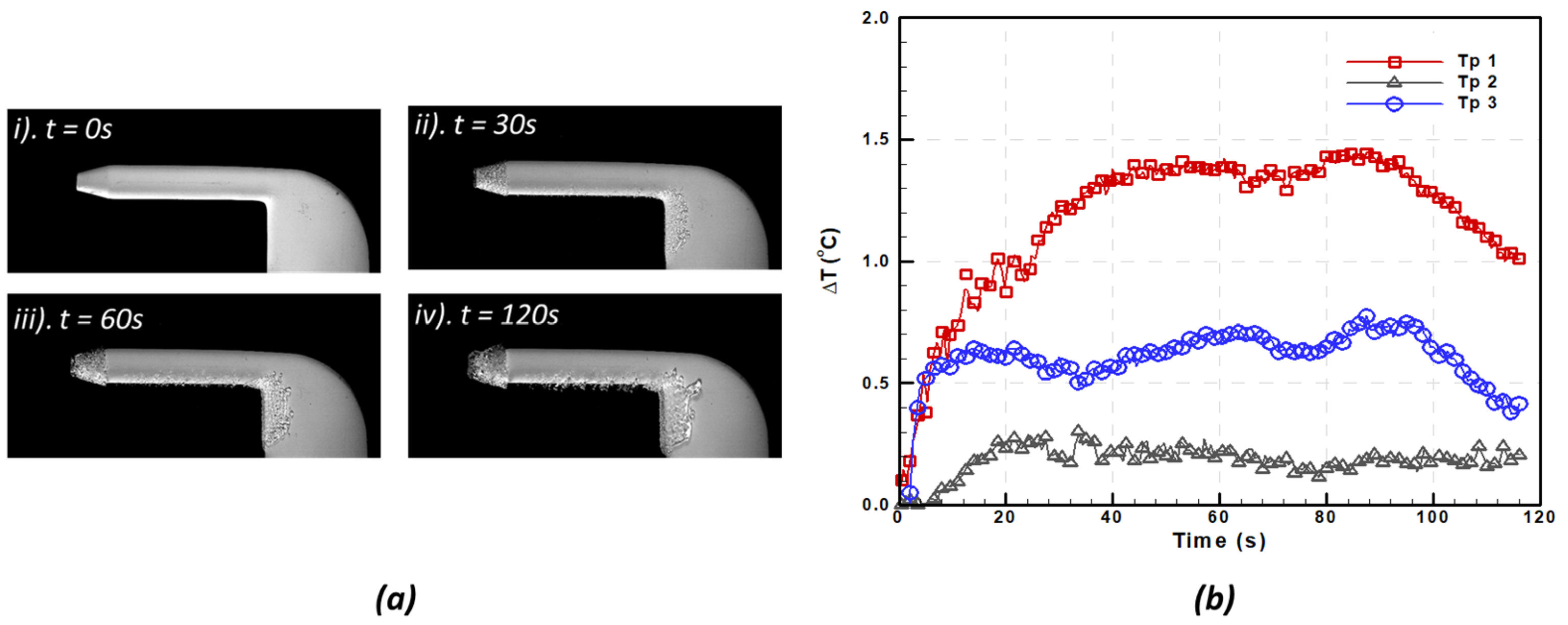

3.1. Ice Accretion Process on the Pitot Probe Without Turning on the Electrothermal Heater

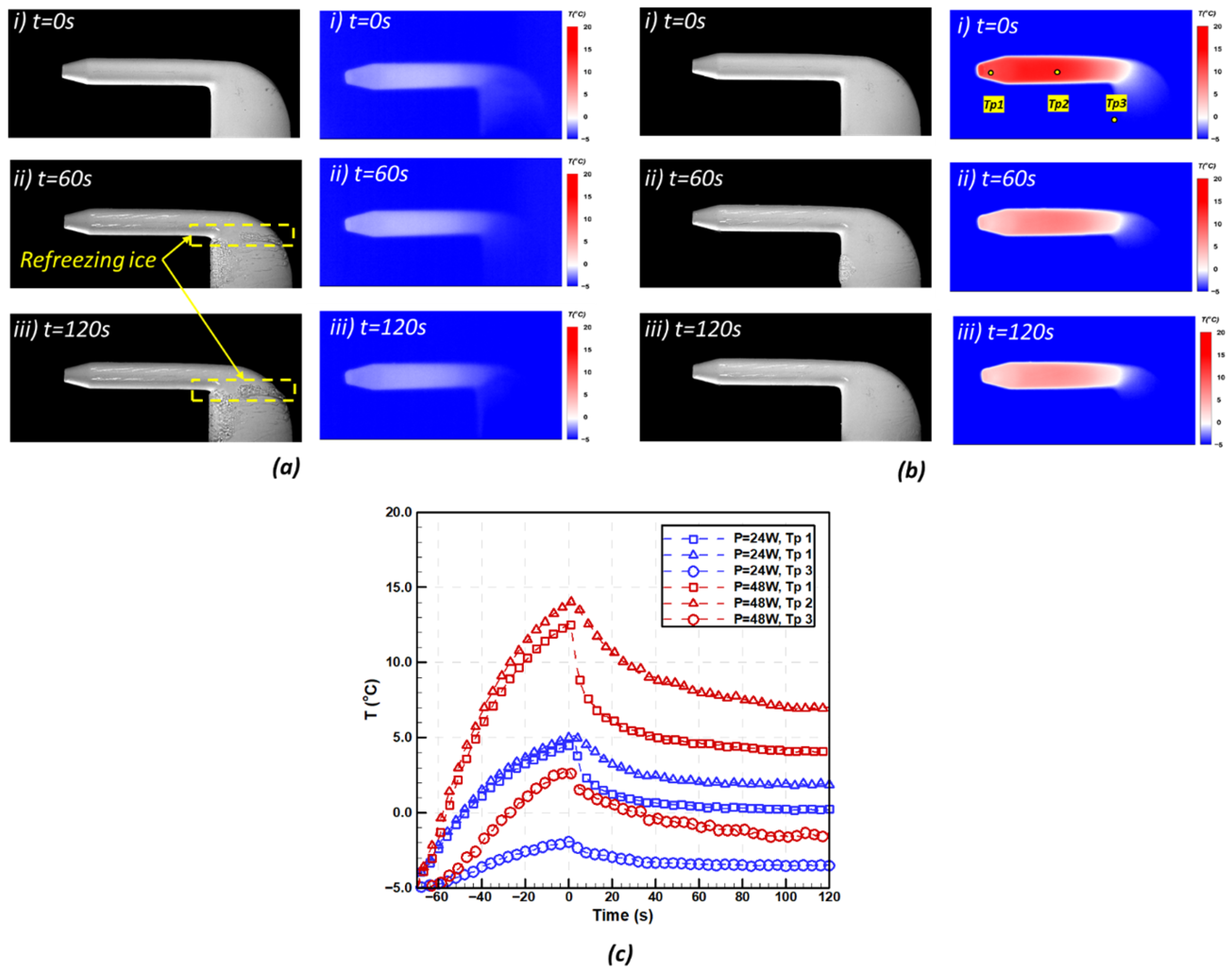

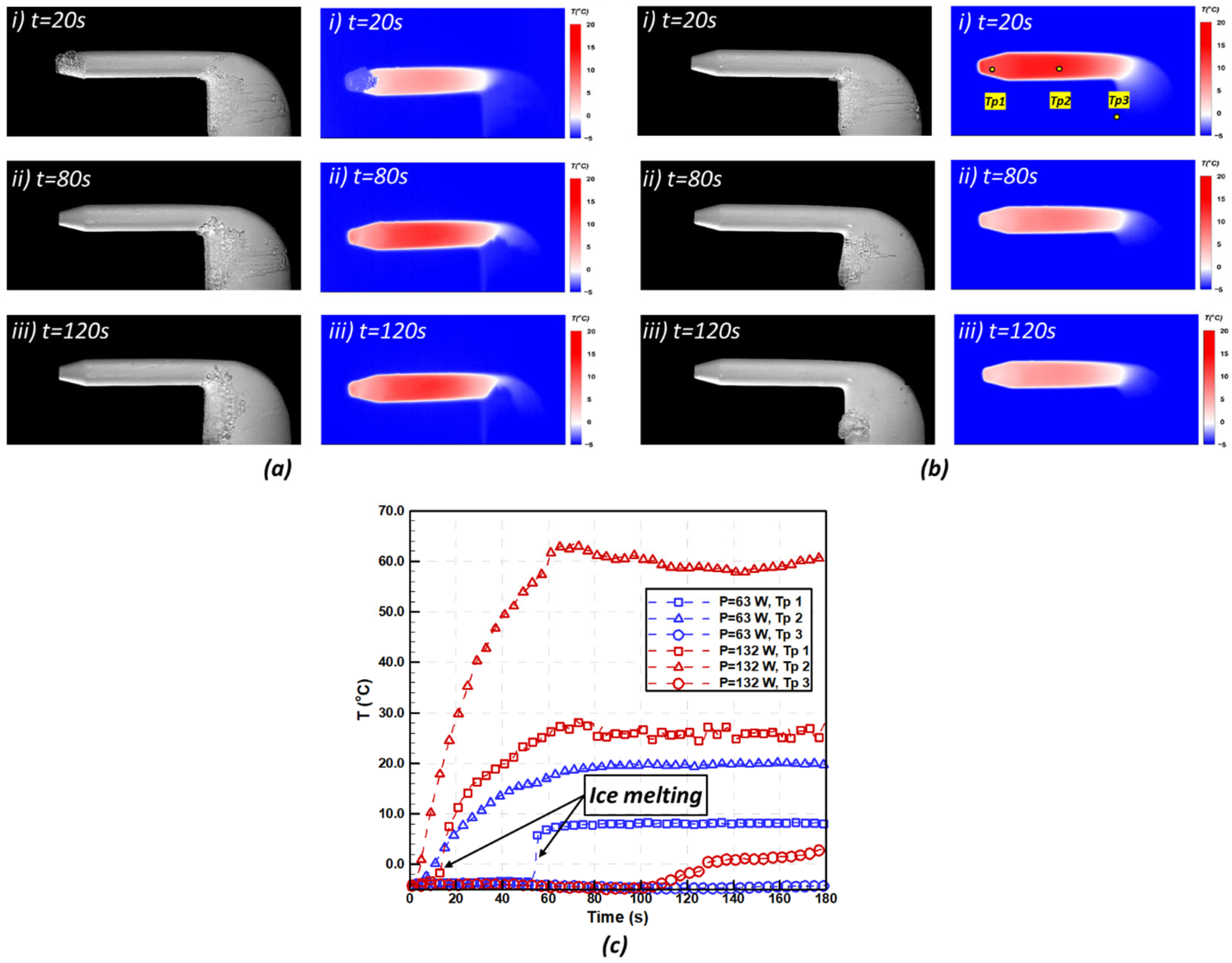

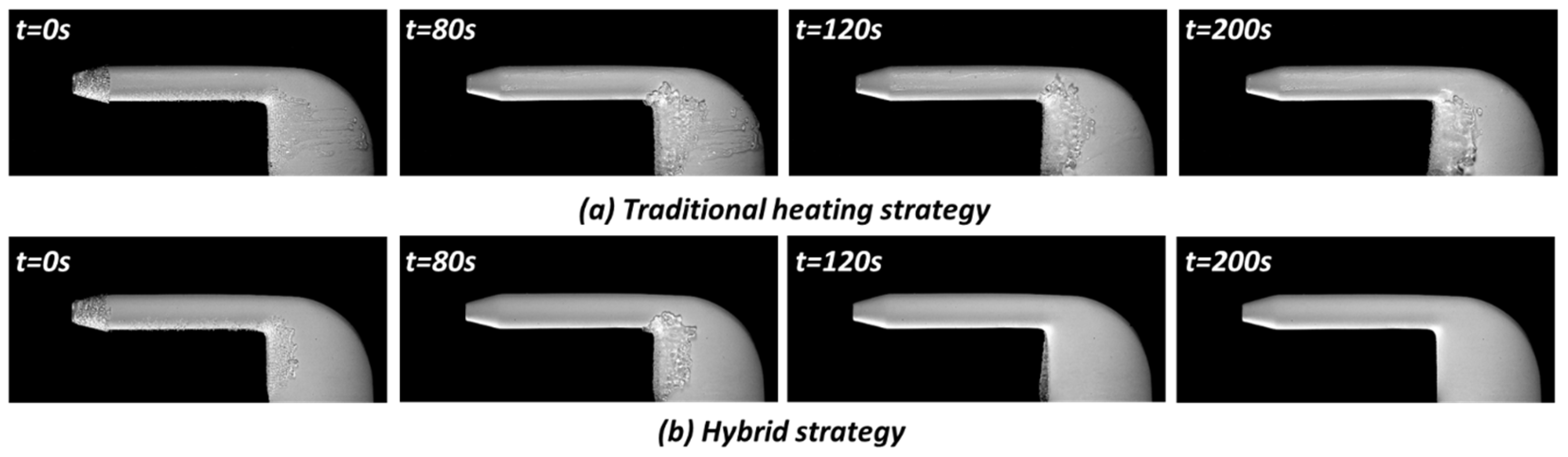

3.2. Anti-/De-Icing Operations of the Pitot Probe with the Electrothermal Heater Turned on

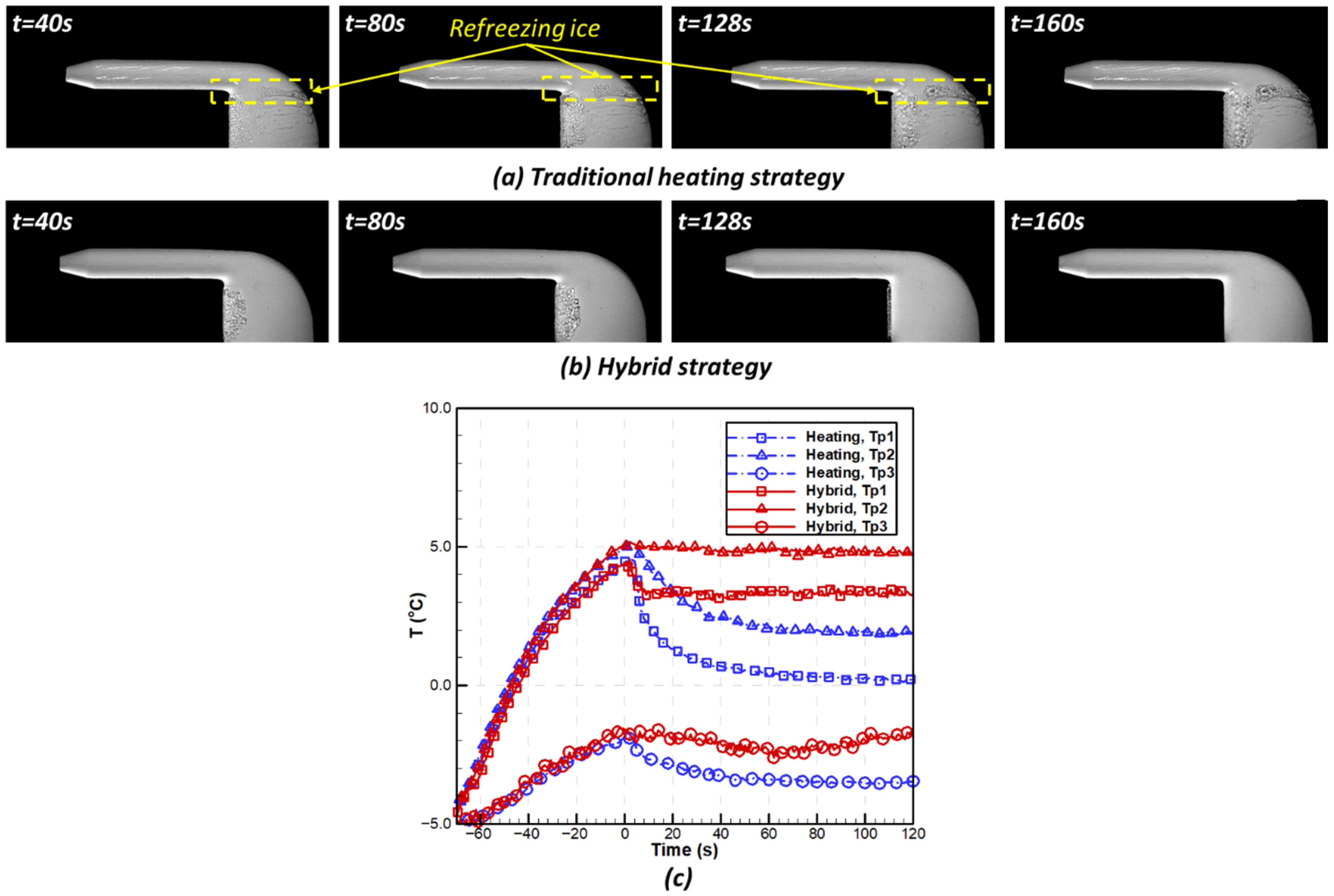

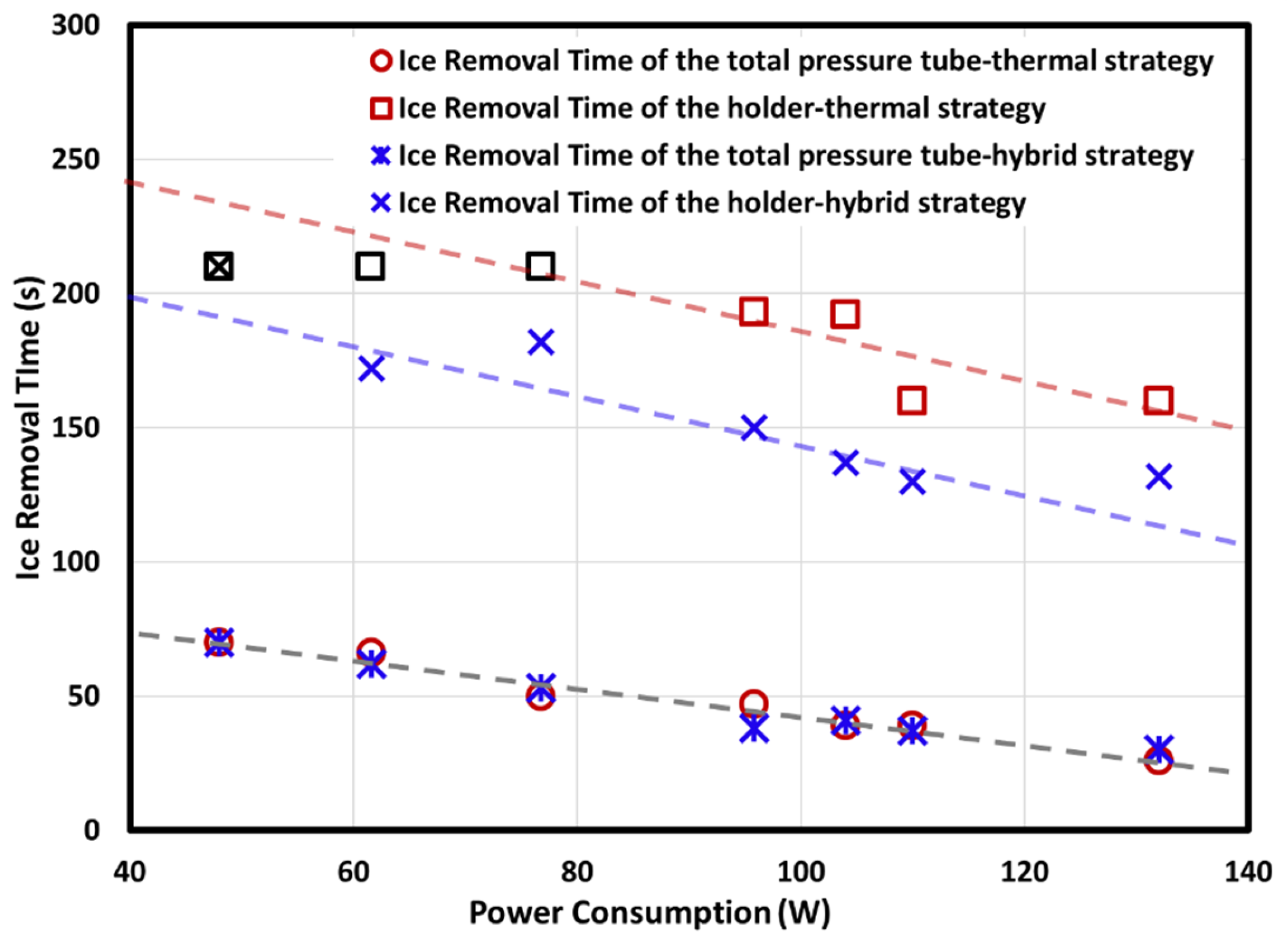

3.3. Comparison of the Anti-/De-Icing Performance Between Two Strategies

3.4. Benefits and Limitations of the Hybrid Anti-/De-Icing Methods

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bragg, M.B.; Gregorek, G.M.; Lee, J.D. Airfoil Aerodynamics in Icing Conditions. J. Aircr. 1986, 23, 76–81. [Google Scholar] [CrossRef]

- Campbell, S.E.; Broeren, A.P.; Bragg, M.B. Sensitivity of Aircraft Performance to Icing Parameter Variations. J. Aircr. 2007, 44, 1758–1760. [Google Scholar] [CrossRef]

- Cebeci, T.; Kafyeke, F. Aircraft icing. Annu. Rev. Fluid. Mech. 2003, 35, 11–21. [Google Scholar] [CrossRef]

- Ueno, K.; Farzaneh, M. Linear Stability Analysis of Ice Growth under Supercooled Water Film Driven by a Laminar Airflow. Phys. Fluids 2011, 23, 042103. [Google Scholar] [CrossRef]

- Fortin, G.; Laforte, J.L.; Ilinca, A. Heat and Mass Transfer during Ice Accretion on Aircraft Wings with an Improved Roughness Model. Int. J. Therm. Sci. 2006, 45, 595–606. [Google Scholar] [CrossRef]

- Waldman, R.M.; Hu, H. High-Speed Imaging to Quantify Transient Ice Accretion Process over an Airfoil. J. Aircr. 2016, 53, 369–377. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Chen, W.; Tian, W.; Hu, H. An Experimental Study on the Aerodynamic Performance Degradation of a UAS Propeller Model Induced by Ice Accretion Process. Exp. Therm. Fluid. Sci. 2019, 102, 101–112. [Google Scholar] [CrossRef]

- Li, L.; Liu, Y.; Tian, L.; Hu, H.; Hu, H.; Liu, X.; Hogate, I.; Kohli, A. An Experimental Study on a Hot-Air-Based Anti-/de-Icing System for Aero-Engine Inlet Guide Vanes. Appl. Therm. Eng. 2020, 167, 114778. [Google Scholar] [CrossRef]

- Liu, Y.; Kolbakir, C.; Hu, H.; Hu, H. A Comparison Study on the Thermal Effects in DBD Plasma Actuation and Electrical Heating for Aircraft Icing Mitigation. Int. J. Heat. Mass. Transf. 2018, 124, 319–330. [Google Scholar] [CrossRef]

- Tian, L.; Li, L.; Hu, H.; Hu, H. Experimental Study of Dynamic Ice Accretion Process over Rotating Aeroengine Fan Blades. J. Thermophys. Heat. Trans. 2023, 37, 353–364. [Google Scholar] [CrossRef]

- Tian, L.; Hu, H.; Veerakumar, R.; Hu, H. Ice Accretion Characteristics on Rotating Aeroengine Fan Blades. Exp. Therm. Fluid. Sci. 2024, 155, 111181. [Google Scholar] [CrossRef]

- Hu, H.; Al-Masri, F.; Tian, L.; Hu, H. Experimental Study of Dynamic Icing Process on a Pitot Probe Model. J. Thermophys. Heat. Trans. 2023, 37, 632–643. [Google Scholar] [CrossRef]

- Han, N.; Siddique, M.A.; Zhang, Z.; Tian, L.; Hu, H.; Hu, H. A Flight-Testing Campaign to Examine Inflight Icing Characteristics and Its Effects on the Flight Performance of an Unmanned-Aerial-Vehicle. Cold Reg. Sci. Technol. 2023, 207, 103775. [Google Scholar] [CrossRef]

- Jäckel, R.; Gutiérrez Urueta, G.L.; Tapia Rodríguez, F.; Monreal Jiménez, C. Numerical and Experimental Characterisation of an Aeronautic Pitot Probe. Aeronaut. J. 2019, 123, 890–911. [Google Scholar] [CrossRef]

- Ayra, E.S.; Sanz, Á.R.; Valdés, R.A.; Comendador, F.G.; Cano, J. Detection and Warning of Ice Crystals Clogging Pitot Probes from Total Air Temperature Anomalies. Aerosp. Sci. Technol. 2020, 102, 105874. [Google Scholar] [CrossRef]

- Carbonara, V.E.; Binnie, A.G. Icing of Pitot Static Tubes. 6th Annual Meeting of I. Ae. S. J. Aeronaut. Sci. 1938, 5, 400–403. [Google Scholar] [CrossRef]

- Bea. Interim Report on the Accident on 1st June 2009 to the Airbus A330-203 F-GZCP by Air France AF 447 Rio de Janeiro—Paris; Bea: Paris, France, 2009. [Google Scholar]

- Jäckel, R.; Gutiérrez-Urueta, G.; Tapia, F. A Review on Pitot probe Icing in Aeronautics: Research- Design and Characterization—Future Trends. Flow. Meas. Instrum. 2021, 81, 102033. [Google Scholar] [CrossRef]

- Ozcer, I.; Switchenko, D.; Baruzzi, G.S.; Chen, J. Multi-Shot Icing Simulations with Automatic Re-Meshing. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Zhang, H.; Zhao, R.; Wen, C.Y. Performance Deterioration of Pitot probes Caused by In-Flight Ice Accretion: A Numerical Investigation. Int. J. Aerosp. Eng. 2021, 2021, 5599116. [Google Scholar] [CrossRef]

- Hu, H.; Al-Masri, F.; Hu, H. An Experimental Study on Ice Accretion and Anti-/De-Icing of a Pitot probe. In AIAA Science and Technology Forum and Exposition, AIAA SciTech Forum 2022; American Institute of Aeronautics and Astronautics Inc.: San Diego, CA, USA, 2022. [Google Scholar]

- Liu, Y.; Ma, L.; Wang, W.; Kota, A.K.; Hu, H. An Experimental Study on Soft PDMS Materials for Aircraft Icing Mitigation. Appl. Surf. Sci. 2018, 447, 599–609. [Google Scholar] [CrossRef]

- Soltis, J.; Palacios, J.; Wolfe, D.; Eden, T. Evaluation of Ice Adhesion Strength on Erosion Resistant Materials. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; pp. 1–19. [Google Scholar] [CrossRef]

- Kent, R.A.; Andersen, D.; Caux, P.Y.; Teed, S. Canadian Water Quality Guidelines for Glycols—An Ecotoxicological Review of Glycols and Associated Aircraft Anti-Icing and Deicing Fluids. Environ. Toxicol. 1999, 14, 481–522. [Google Scholar] [CrossRef]

- Thomas, S.K.; Cassoni, R.P.; MacArthur, C.D. Aircraft Anti-Icing and de-Icing Techniques and Modeling. J. Aircr. 1996, 33, 841–854. [Google Scholar] [CrossRef]

- Overmeyer, A.; Palacios, J.; Smith, E. Ultrasonic De-Icing Bondline Design and Rotor Ice Testing. AIAA J. 2013, 51, 2965–2976. [Google Scholar] [CrossRef]

- Parent, O.; Ilinca, A. Anti-Icing and de-Icing Techniques for Wind Turbines: Critical Review. Cold Reg. Sci. Technol. 2011, 65, 88–96. [Google Scholar] [CrossRef]

- De Souza, J.R.B.; Lisboa, K.M.; Cerqueira, I.G.; Zotin, J.L.Z.; Naveira-Cotta, C.P.; Cotta, R.M. Conjugated Heat Transfer Analysis of Heated Aeronautical Pitot Probes With Flight Tests Experimental Validation. Heat Trans. Eng. 2014, 36, 991–1000. [Google Scholar] [CrossRef]

- Li, Q.; Yao, R.; Tan, V.B.C.; He, F.; Zhao, H.; Bai, T. A Review of Efficient Thermal Application for Ice Detection and Anti/de-Icing Technology. Appl. Therm. Eng. 2025, 263, 125366. [Google Scholar] [CrossRef]

- He, Z.; Xie, H.; Jamil, M.I.; Li, T.; Zhang, Q. Electro-/Photo-Thermal Promoted Anti-Icing Materials: A New Strategy Combined with Passive Anti-Icing and Active De-Icing. Adv. Mater. Interfaces 2022, 9, 2200275. [Google Scholar] [CrossRef]

- Arianpour, F.; Farzaneh, M.; Kulinich, S.A. Hydrophobic and Ice-Retarding Properties of Doped Silicone Rubber Coatings. Appl. Surf. Sci. 2013, 265, 546–552. [Google Scholar] [CrossRef]

- Wang, Z.-J.; Kwon, D.-J.; Lawrence DeVries, K.; Park, J.-M. Frost Formation and Anti-Icing Performance of a Hydrophobic Coating on Aluminum. Exp. Therm. Fluid. Sci. 2015, 60, 132–137. [Google Scholar] [CrossRef]

- Koch, K.; Bhushan, B.; Jung, Y.; Barthlott, W. Fabrication of Artificial Lotus Leaves and Significance of Hierarchical Structure for Superhydrophobicity and Low Adhesion. Soft Matter 2009, 5, 1386–1393. [Google Scholar] [CrossRef]

- Cheng, Y.; Rodak, D.; Wong, C.; Hayden, C. Effects of Micro-and Nano-Structures on the Self-Cleaning Behaviour of Lotus Leaves. Nanotechnology 2006, 17, 1359–1362. [Google Scholar] [CrossRef]

- Zhang, L.; Nie, Q.; Su, Y.; Xie, X.; Luo, W.; Jia, X.; Zhang, X. MicroRNA Profile Analysis on Duck Feather Follicle and Skin with High-Throughput Sequencing Technology. Gene 2013, 519, 77–81. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, X.; Xin, J. Hydrophobic Duck Feathers and Their Simulation on Textile Substrates for Water Repellent Treatment. Bioinspir. Biomim. 2008, 3, 046007. [Google Scholar] [CrossRef] [PubMed]

- Jones, C.; Mecham, D. The Dispersion of Keratins. II. Studies on the Dispersion of Keratins by Reduction in Neutral Solutions of Protein Denaturants. Arch. Biochem. 1943, 3, 193–202. [Google Scholar]

- Cao, L.; Jones, A.K.; Sikka, V.K.; Wu, J.; Gao, D. Anti-Icing Superhydrophobic Coatings. Langmuir 2009, 25, 12444–12448. [Google Scholar] [CrossRef] [PubMed]

- Mishchenko, L.; Hatton, B.; Bahadur, V. Design of Ice-Free Nanostructured Surfaces Based on Repulsion of Impacting Water Droplets. ACS Nano 2010, 4, 7699–7707. [Google Scholar] [CrossRef]

- Huang, W.; Huang, J.; Guo, Z.; Liu, W. Icephobic/Anti-Icing Properties of Superhydrophobic Surfaces. Adv. Colloid. Interface Sci. 2022, 304, 102658. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Z.; Gao, L.; Liu, Y.; Hu, H. Bio-Inspired Icephobic Coatings for Aircraft Icing Mitigation: A Critical Review. Rev. Adhes. Adhes. 2020, 8, 168–198. [Google Scholar] [CrossRef]

- Zhang, Z.; Lusi, A.; Hu, H.; Bai, X.; Hu, H. An Experimental Study on the Detrimental Effects of Deicing Fluids on the Performance of Icephobic Coatings for Aircraft Icing Mitigation. Aerosp. Sci. Technol. 2021, 119, 107090. [Google Scholar] [CrossRef]

- De Pauw, D.; Dolatabadi, A. Effect of Superhydrophobic Coating on the Anti-Icing and Deicing of an Airfoil. J. Aircr. 2017, 54, 490–499. [Google Scholar] [CrossRef]

- Coffman, H., Jr. Review of Helicopter Icing Protection Systems. In Proceedings of the Aircraft Design, Systems and Technology Meeting, Fort Worth, TX, USA, 17–19 October 1983. [Google Scholar] [CrossRef]

- Huang, X.; Tepylo, N.; Pommier-Budinger, V.; Budinger, M.; Bonaccurso, E.; Villedieu, P.; Bennani, L. A Survey of Icephobic Coatings and Their Potential Use in a Hybrid Coating/Active Ice Protection System for Aerospace Applications. Progress. Aerosp. Sci. 2019, 105, 74–97. [Google Scholar] [CrossRef]

- Waldman, R.M.; Li, H.; Hu, H. An Experimental Investigation on the Effects of Surface Wettability on Water Runback and Ice Accretion over an Airfoil Surface. In Proceedings of the 8th AIAA Atmospheric and Space Environments Conference, Washington, DC, USA, 13–17 June 2016; AIAA AVIATION Forum, American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2016. [Google Scholar]

- Gao, L.; Liu, Y.; Ma, L.; Hu, H. A Hybrid Strategy Combining Minimized Leading-Edge Electric-Heating and Superhydro-/Ice-Phobic Surface Coating for Wind Turbine Icing Mitigation. Renew. Energy 2019, 140, 943–956. [Google Scholar] [CrossRef]

- Hu, H.; Hu, H.; Liu, Y. An Explorative Study to Use Super-Hydrophilic/Super-Hydrophobic Hybrid Surfaces for Aircraft Icing Mitigation. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Kolbakir, C.; Hu, H.; Liu, Y.; Hu, H. A Hybrid Anti-/De-Icing Strategy by Combining NS-DBD Plasma Actuator and Superhydrophobic Coating for Aircraft Icing Mitigation. In Proceedings of the 019 AIAA Science and Technology Forum and Exposition (SciTech 2019), San Diego, CA, USA, 2019; p. AIAA-2019-0050., 7–11 January 2019. [Google Scholar]

- Hu, H.; Tian, L.; Eluchie, C.; Sista, H.; Hu, H. Comparative Study of Using Superhydrophobic and Icephobic Surface Coatings for Aircraft Icing Mitigation. AIAA J. 2024, 62, 1588–1600. [Google Scholar] [CrossRef]

- Tian, L.; Hu, H.; Hiller, J.; Han, N.; Hu, H. An Experimental Study on a Hybrid Anti-/De-Icing Strategy for Aero-Engine Inlet Guide Vane Icing Protection. In Proceedings of the AIAA AVIATION 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022; American Institute of Aeronautics and Astronautics Inc.: Reston, VA, USA, 2022. [Google Scholar]

- Veerakumar, R.; Gao, L.; Liu, Y.; Hu, H. Dynamic Ice Accretion Process and Its Effects on the Aerodynamic Drag Characteristics of a Power Transmission Cable Model. Cold Reg. Sci. Technol. 2020, 169, 102908. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, Y.; Hu, H.; Hu, H.; Meng, X. Utilization of Thermal Effect Induced by Plasma Generation for Aircraft Icing Mitigation. AIAA J. 2018, 56, 1097–1104. [Google Scholar] [CrossRef]

- Liu, Y.; Kolbakir, C.; Hu, H.; Meng, X.; Hu, H. An Experimental Study on the Thermal Effects of Duty-Cycled Plasma Actuation Pertinent to Aircraft Icing Mitigation. Int. J. Heat. Mass. Transf. 2019, 136, 864–876. [Google Scholar] [CrossRef]

- Li, L.; Liu, Y.; Hu, H. An Experimental Study on Dynamic Ice Accretion Process over the Surfaces of Rotating Aero-Engine Spinners. Exp. Therm. Fluid. Sci. 2019, 109, 109879. [Google Scholar] [CrossRef]

- Gao, L.; Hu, H. Wind Turbine Icing Characteristics and Icing-Induced Power Losses to Utility-Scale Wind Turbines. Proc. Natl. Acad. Sci. 2021, 118, 2111461118. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Z.; Gao, L.; Liu, Y.; Hu, H. An Exploratory Study on Using Slippery-Liquid-Infused-Porous-Surface (SLIPS) for Wind Turbine Icing Mitigation. Renew. Energy 2020, 162, 2344–2360. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Y.; Hu, H. An Experimental Investigation of Dynamic Ice Accretion Process on a Wind Turbine Airfoil Model Considering Various Icing Conditions. Int. J. Heat. Mass. Transf. 2019, 133, 930–939. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Peng, Y.; Hu, H. An Experimental Study on the Dynamic Ice Accretion Processes on Bridge Cables with Different Surface Modifications. J. Wind. Eng. Ind. Aerodyn. 2019, 190, 218–229. [Google Scholar] [CrossRef]

- Peng, Y.; Veerakumar, R.; Liu, Y.; He, X.; Hu, H. An Experimental Study on Dynamic Ice Accretion and Its Effects on the Aerodynamic Characteristics of Stay Cables with and without Helical Fillets. J. Wind. Eng. Ind. Aerodyn. 2020, 205, 104326. [Google Scholar] [CrossRef]

- Peng, Y.; Veerakumar, R.; Zhang, Z.; Hu, H.; Liu, Y.; He, X.; Hu, H. An Experimental Study on Mitigating Dynamic Ice Accretion Process on Bridge Cables with a Superhydrophobic Coating. Exp. Therm. Fluid. Sci. 2022, 132, 110573. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H. An Experimental Investigation on the Unsteady Heat Transfer Process over an Ice Accreting Airfoil Surface. Int. J. Heat. Mass. Transf. 2018, 122, 707–718. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Hu, H.; Hu, H.; Samanta, A.; Wang, Q.; Ding, H. An Experimental Study to Characterize a Surface Treated with a Novel Laser Surface Texturing Technique: Water Repellency and Reduced Ice Adhesion. Surf. Coat. Technol. 2019, 374, 634–644. [Google Scholar] [CrossRef]

- Hu, H.; Tian, L.; Hu, H. An Experimental Investigation on the Impinging Dynamics of Supercooled Large Droplets in Comparison to Water Droplets at Room Temperature. In AIAA AVIATION 2022 Forum; American Institute of Aeronautics and Astronautics: Chicago, IL, USA, 2022. [Google Scholar]

- Zhang, Z.; Ma, L.; Liu, Y.; Ren, J.; Hu, H. An Experimental Study of Rain Erosion Effects on a Hydro-/Ice-Phobic Coating Pertinent to Unmanned-Arial-System (UAS) Inflight Icing Mitigation. Cold Reg. Sci. Technol. 2021, 181, 103196. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhou, H.; Huang, J.; Guo, Z. Review on the Recent Development of Durable Superhydrophobic Materials for Practical Applications. Nanoscale 2021, 13, 11734–11764. [Google Scholar] [CrossRef]

- Zhang, Z.; Ge, B.; Men, X.; Li, Y. Mechanically Durable, Superhydrophobic Coatings Prepared by Dual-Layer Method for Anti-Corrosion and Self-Cleaning. Colloids Surf. A Physicochem. Eng. Asp. 2016, 490, 182–188. [Google Scholar] [CrossRef]

- Guo, X.-J.; Zhang, D.; Xue, C.-H.; Liu, B.-Y.; Huang, M.-C.; Wang, H.-D.; Wang, X.; Deng, F.-Q.; Pu, Y.-P.; An, Q.-F. Scalable and Mechanically Durable Superhydrophobic Coating of SiO2/Polydimethylsiloxane/Epoxy Nanocomposite. ACS Appl. Mater. Interfaces 2023, 15, 4612–4622. [Google Scholar] [CrossRef] [PubMed]

| Compared Surface | Static CA (°) | Advance CA(°) | Receding CA (°) | CA Hysteresis (°) | Ice Adhesion Strength at −10 °C (kPa) |

|---|---|---|---|---|---|

| Enamel Surface | 65 ± 5 | 85 ± 5 | 20 ± 5 | ~60 | 1400 ± 100 |

| SHS-coated surface | 157 ± 2 | 159 ± 2 | 154 ± 2 | ~5 | 110 ± 10 |

| Power Consumption (W) | Anti-Icing for the Total Pressure Tube (Within 200 s) | Anti-Icing for the Probe Holder (Within 200 s) | ||

|---|---|---|---|---|

| Heating Strategy | Hybrid Strategy | Heating Strategy | Hybrid Strategy | |

| 9 | Success | Success | Fail | Fail |

| 14 | Success | Success | Fail | Fail |

| 24 | Success | Success | Fail | Success |

| 35 | Success | Success | Fail | Success |

| 40 | Success | Success | Fail | Success |

| 48 | Success | Success | Success | Success |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Al-Masri, F.; Hu, H. An Experimental Study on Pitot Probe Icing Protection with an Electro-Thermal/Superhydrophobic Hybrid Strategy. Aerospace 2025, 12, 862. https://doi.org/10.3390/aerospace12100862

Hu H, Al-Masri F, Hu H. An Experimental Study on Pitot Probe Icing Protection with an Electro-Thermal/Superhydrophobic Hybrid Strategy. Aerospace. 2025; 12(10):862. https://doi.org/10.3390/aerospace12100862

Chicago/Turabian StyleHu, Haiyang, Faisal Al-Masri, and Hui Hu. 2025. "An Experimental Study on Pitot Probe Icing Protection with an Electro-Thermal/Superhydrophobic Hybrid Strategy" Aerospace 12, no. 10: 862. https://doi.org/10.3390/aerospace12100862

APA StyleHu, H., Al-Masri, F., & Hu, H. (2025). An Experimental Study on Pitot Probe Icing Protection with an Electro-Thermal/Superhydrophobic Hybrid Strategy. Aerospace, 12(10), 862. https://doi.org/10.3390/aerospace12100862