Optimization of Fused Deposition Modeling Parameters for Mechanical Properties of Polylactic Acid Parts Based on Kriging and Cuckoo Search

Abstract

1. Introduction

2. Problem Formulation

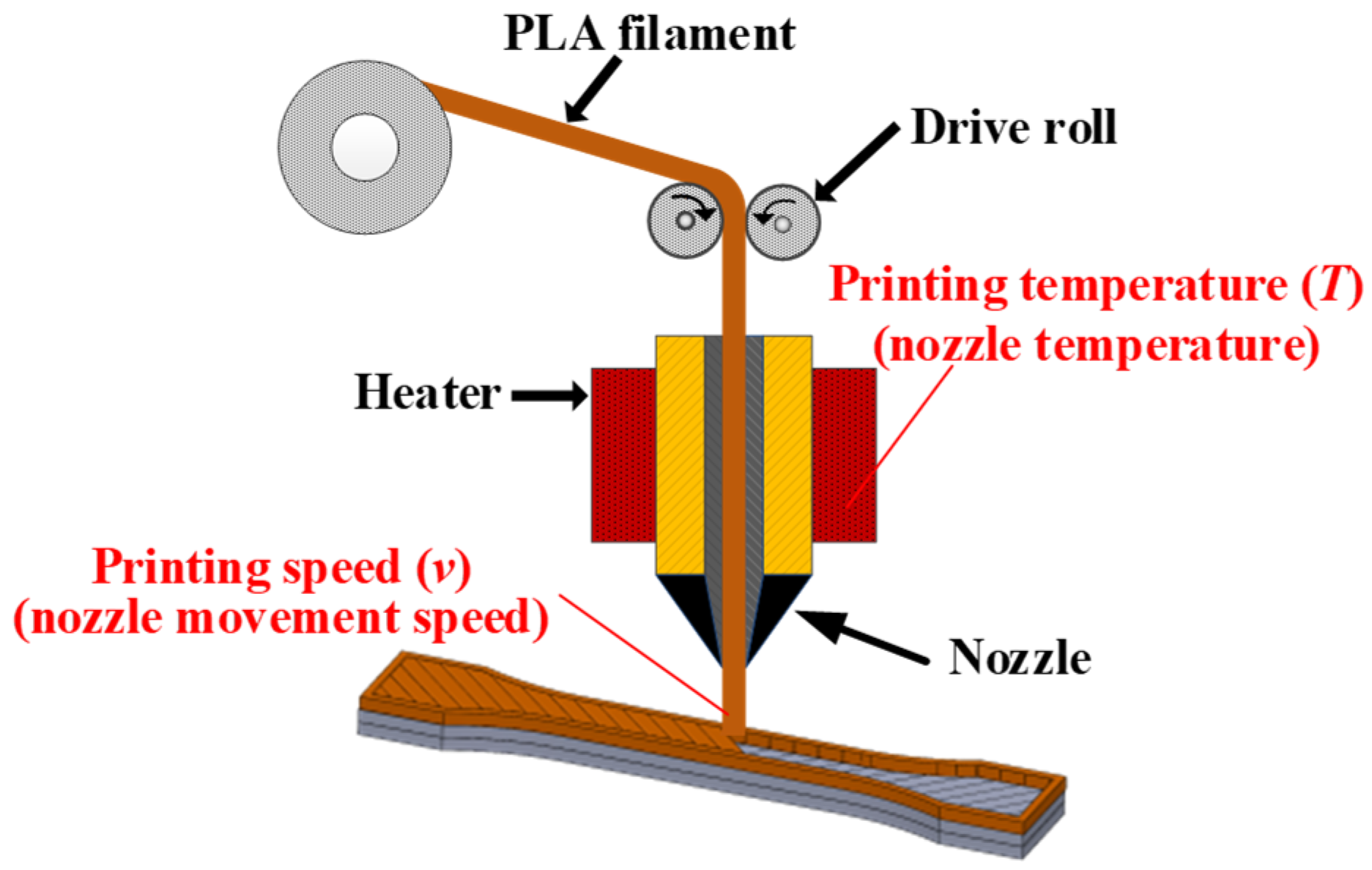

2.1. FDM Principle and Process Parameters

2.2. Optimization Model

3. Kriging and CS

3.1. Kriging

3.2. CS

- (1)

- Local random walks can be written as

- (2)

- Global random walk flight using levy:

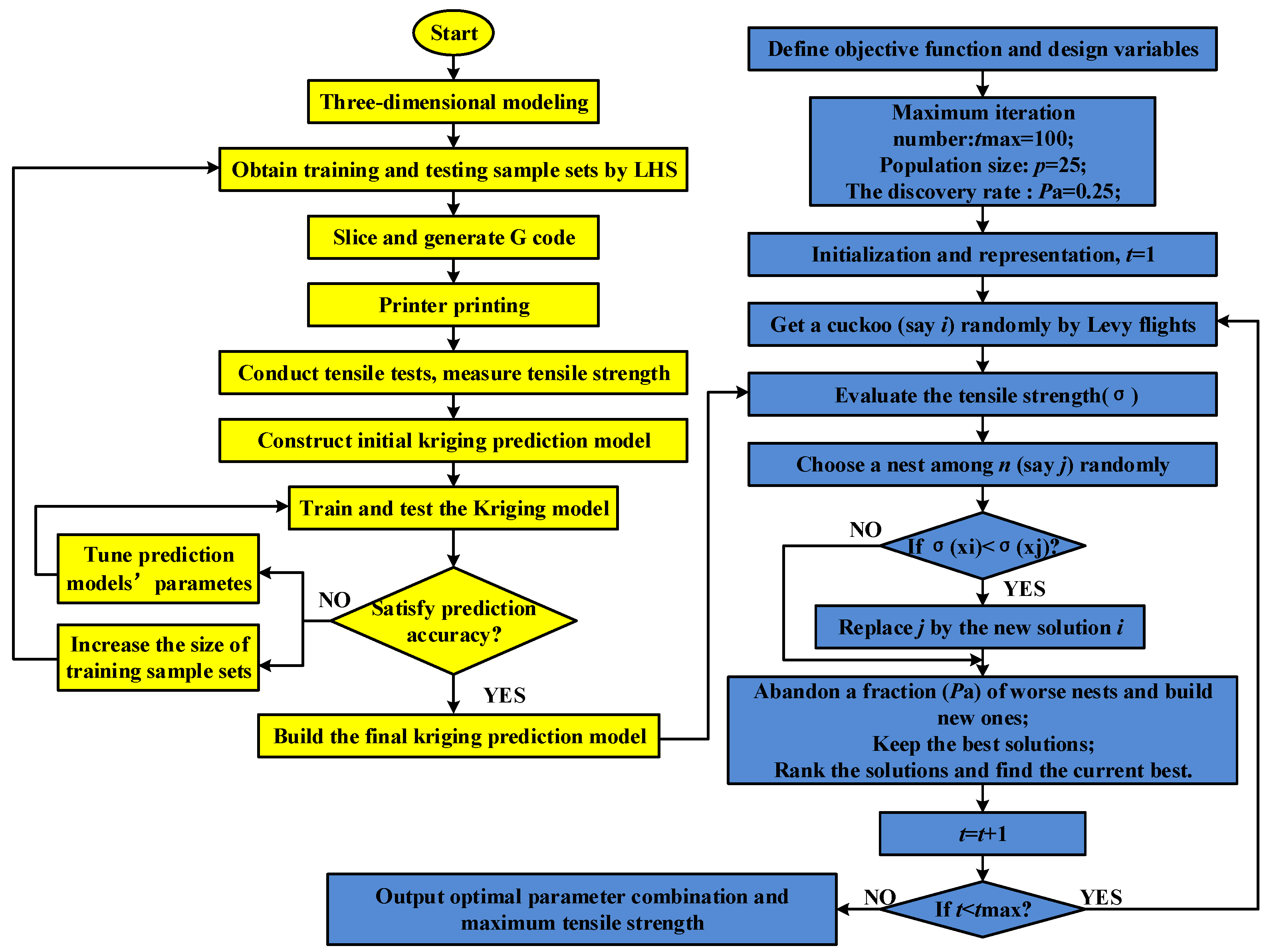

4. Proposed Method

5. Case Study

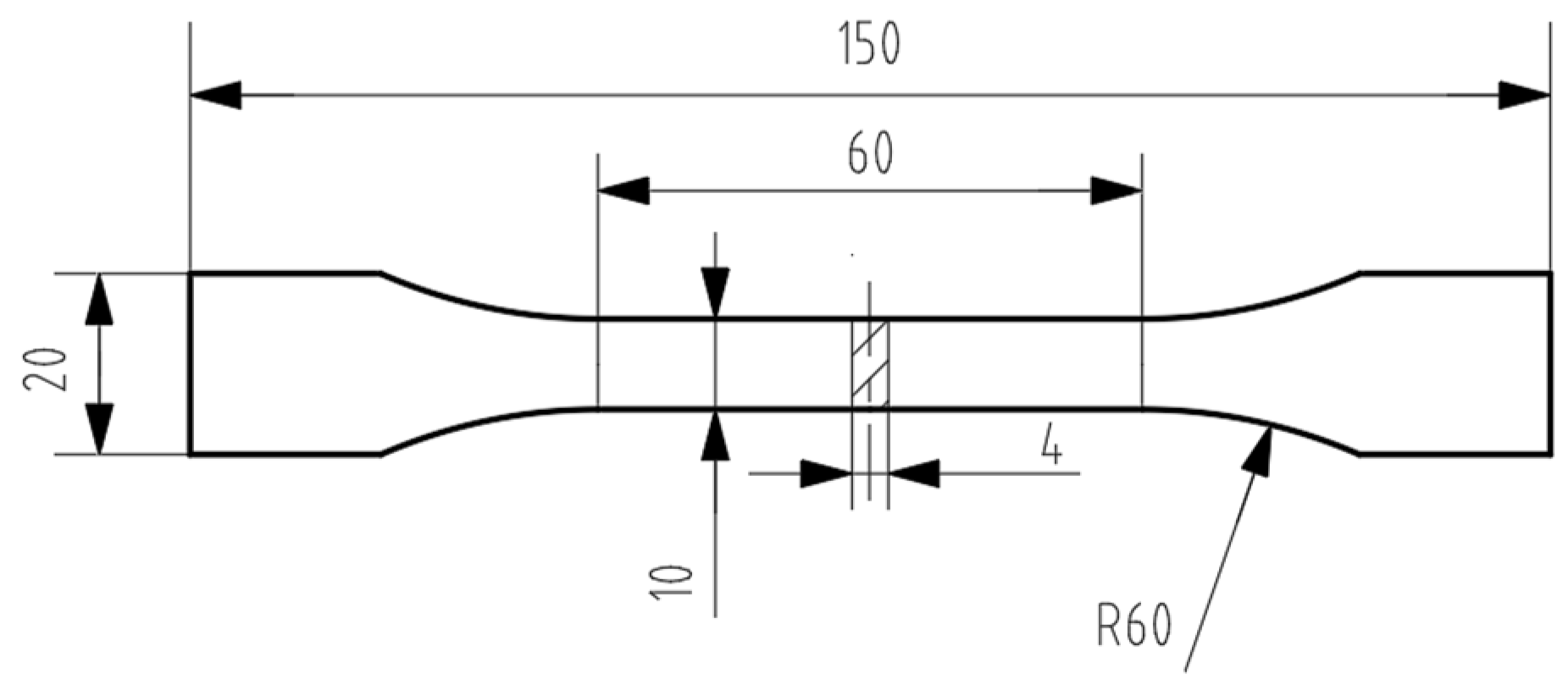

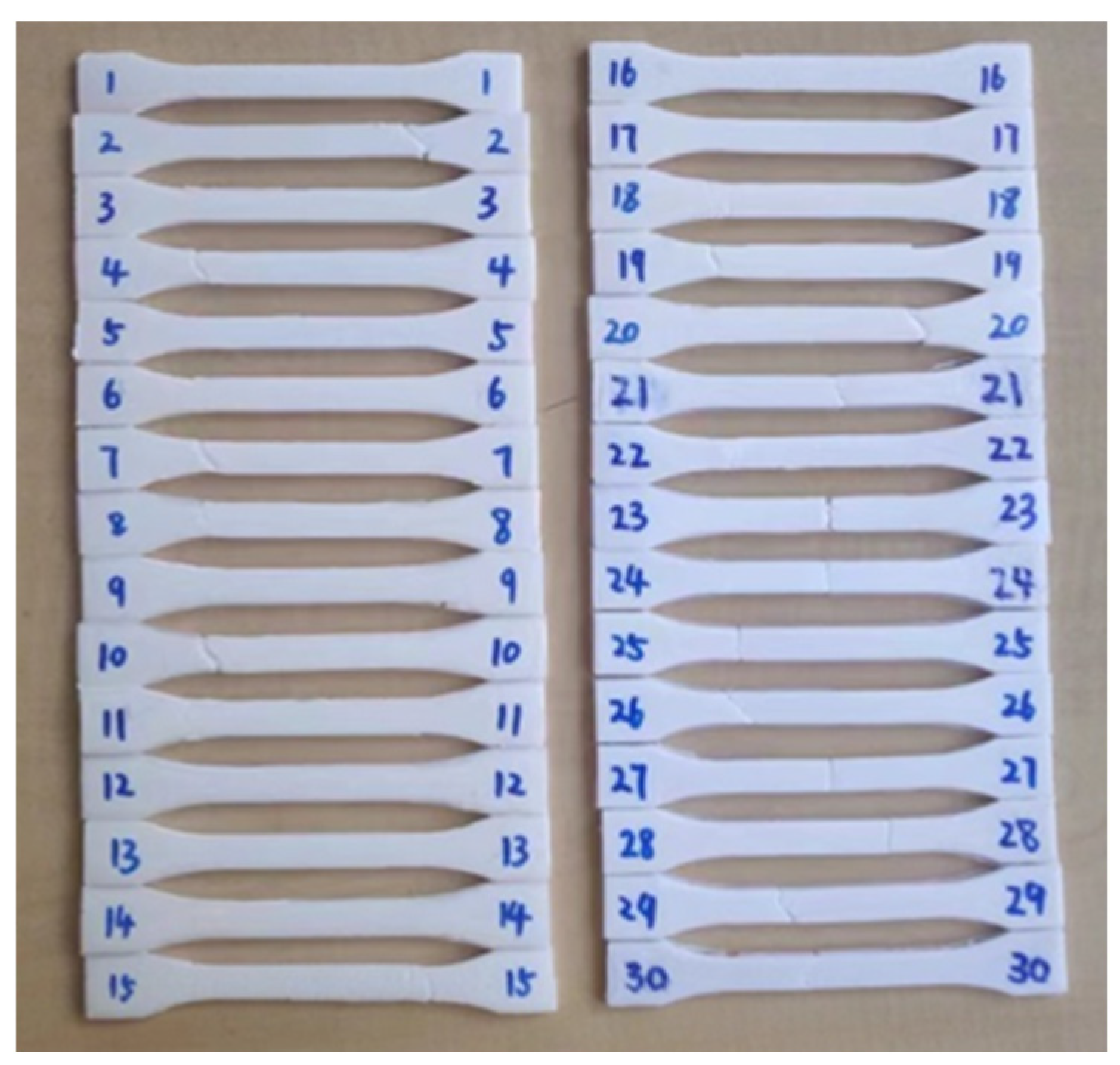

5.1. Experimental Process

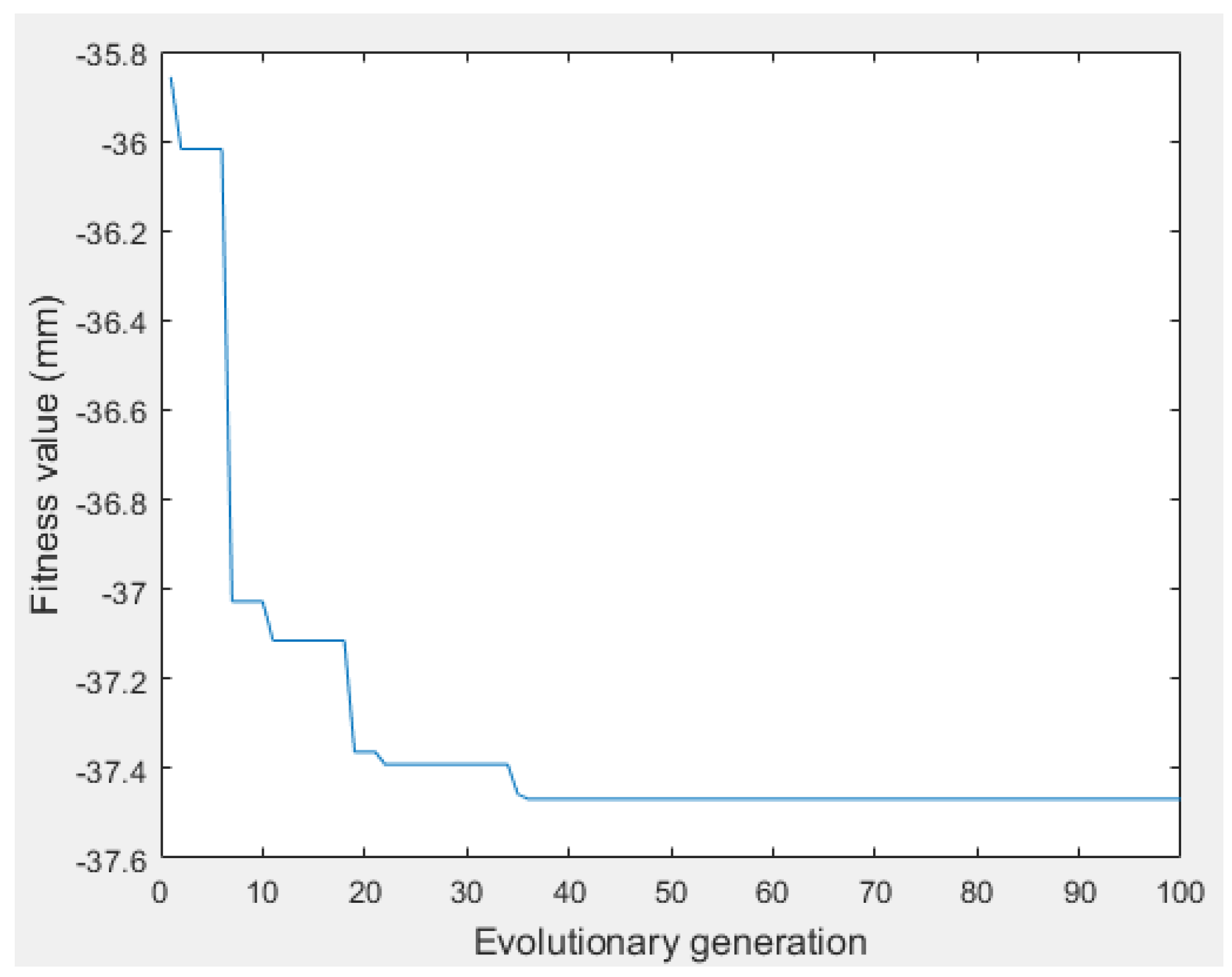

5.2. Result Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| No. | X | σ(X) (MPa) | |

|---|---|---|---|

| v (mm/s) | T (°C) | ||

| 1 | 34 | 196 | 31.97 |

| 2 | 54 | 223 | 31.83 |

| 3 | 48 | 205 | 33.79 |

| 4 | 40 | 211 | 34.91 |

| 5 | 56 | 199 | 34.55 |

| 6 | 28 | 216 | 34.25 |

| 7 | 52 | 204 | 35.29 |

| 8 | 49 | 218 | 34.88 |

| 9 | 35 | 220 | 34.43 |

| 10 | 42 | 222 | 35.76 |

| 11 | 25 | 209 | 34.68 |

| 12 | 22 | 194 | 34.22 |

| 13 | 40 | 200 | 34.82 |

| 14 | 53 | 226 | 34.62 |

| 15 | 60 | 195 | 32.15 |

| 16 | 28 | 225 | 37.22 |

| 17 | 44 | 213 | 33.95 |

| 18 | 37 | 228 | 34.65 |

| 19 | 21 | 191 | 34.18 |

| 20 | 32 | 208 | 34.39 |

| 21 | 35 | 219 | 33.58 |

| 22 | 30 | 207 | 33.56 |

| 23 | 44 | 228 | 35.77 |

| 24 | 55 | 197 | 30.71 |

| 25 | 25 | 225 | 36.55 |

| 26 | 39 | 192 | 31.69 |

| 27 | 47 | 211 | 35.63 |

| 28 | 49 | 202 | 33.8 |

| 29 | 58 | 216 | 32.44 |

| 30 | 23 | 205 | 29.97 |

| No. | X | σ(X) (MPa) | |

|---|---|---|---|

| v (mm/s) | T (°C) | ||

| 1 | 27 | 215 | 33.79 |

| 2 | 31 | 206 | 32.39 |

| 3 | 38 | 193 | 32.75 |

| 4 | 51 | 227 | 34.76 |

| 5 | 57 | 198 | 32.97 |

| 6 | 29 | 224 | 35.58 |

| 7 | 36 | 217 | 33.82 |

| 8 | 45 | 214 | 33.58 |

| 9 | 52 | 203 | 34.88 |

| 10 | 58 | 201 | 34.12 |

References

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3-D printing: Creating a map of additive manufacturing products and services. Addit. Manuf. 2014, 1–4, 64–76. [Google Scholar] [CrossRef]

- Mengesha Medibew, T. A Comprehensive Review on the Optimization of the Fused Deposition Modeling Process Parameter for Better Tensile Strength of PLA-Printed Parts. Adv. Mater. Sci. Eng. 2022, 2022, 5490831. [Google Scholar] [CrossRef]

- Dey, A.; Yodo, N. A Systematic Survey of FDM Process Parameter Optimization and Their Influence on Part Characteristics. J. Manuf. Mater. Process. 2019, 3, 64. [Google Scholar] [CrossRef]

- Rodríguez-Reyna, S.L.; Mata, C.; Díaz-Aguilera, J.H.; Acevedo-Parra, H.R.; Tapia, F. Mechanical properties optimization for PLA, ABS and Nylon + CF manufactured by 3D FDM printing. Mater. Today Commun. 2022, 33, 104774. [Google Scholar] [CrossRef]

- Cheng, H.; Tang, M.; Zhang, J.; Wang, H.; Zhou, J.; Wang, Q.; Qian, Z. Effects of rCF attributes and FDM-3D printing parameters on the mechanical properties of rCFRP. Compos. Part B Eng. 2024, 270, 111122. [Google Scholar] [CrossRef]

- Portoacă, A.I.; Ripeanu, R.G.; Diniță, A.; Tănase, M. Optimization of 3D Printing Parameters for Enhanced Surface Quality and Wear Resistance. Polymers 2023, 15, 3419. [Google Scholar] [CrossRef]

- Pereira, R.J.R.; de Almeida, F.A.; Gomes, G.F. A multiobjective optimization parameters applied to additive manufacturing: DOE-based approach to 3D printing. Structures 2023, 55, 1710–1731. [Google Scholar] [CrossRef]

- Alzyod, H.; Borbas, L.; Ficzere, P. Rapid prediction and optimization of the impact of printing parameters on the residual stress of FDM-ABS parts using L27 orthogonal array design and FEA. Mater. Today Proc. 2023, 93, 583–588. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Y.; Deng, Z.; Zhang, S.; Cai, J. Effects of fused deposition modeling process parameters on tensile, dynamic mechanical properties of 3D printed polylactic acid materials. Polym. Test. 2020, 86, 106483. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Sadeghian, H.; Ayatollahi, M.R.; Reinicke, T. Optimization of fracture toughness in 3D-printed parts: Experiments and numerical simulations. Compos. Struct. 2024, 329, 117766. [Google Scholar] [CrossRef]

- Algarni, M. Tensile strength and strain behavior study and modeling of PLA printed parts with optimized AM parameters. Procedia Struct. Integr. 2023, 51, 185–191. [Google Scholar] [CrossRef]

- Huang, B.; Meng, S.; He, H.; Jia, Y.; Xu, Y.; Huang, H. Study of processing parameters in fused deposition modeling based on mechanical properties of acrylonitrile-butadiene-styrene filament. Polym. Eng. Sci. 2019, 59, 120–128. [Google Scholar] [CrossRef]

- Mani, M.; Karthikeyan, A.G.; Kalaiselvan, K.; Muthusamy, P.; Muruganandhan, P. Optimization of FDM 3-D printer process parameters for surface roughness and mechanical properties using PLA material. Mater. Today Proc. 2022, 66, 1926–1931. [Google Scholar] [CrossRef]

- Sahoo, S.; Sutar, H.; Senapati, P.; Mohanto, B.S.; Dhal, P.R.; Baral, S.K. Experimental investigation and optimization of the FDM process using PLA. Mater. Today Proc. 2023, 74, 843–847. [Google Scholar] [CrossRef]

- Kafshgar, A.R.; Rostami, S.; Aliha, M.R.M.; Berto, F. Optimization of Properties for 3D Printed PLA Material Using Taguchi, ANOVA and Multi-Objective Methodologies. Procedia Struct. Integr. 2021, 34, 71–77. [Google Scholar] [CrossRef]

- Long, Y.; Zhang, Z.; Yan, C.; Huang, Z.; Fu, K.; Li, Y. Multi-objective optimization for improving printing efficiency and mechanical properties of 3D-printed continuous plant fibre composites. Compos. Commun. 2022, 35, 101283. [Google Scholar] [CrossRef]

- Fountas, N.A.; Papantoniou, I.; Kechagias, J.D.; Manolakos, D.E.; Vaxevanidis, N.M. Modeling and optimization of flexural properties of FDM-processed PET-G specimens using RSM and GWO algorithm. Eng. Fail. Anal. 2022, 138, 106340. [Google Scholar] [CrossRef]

- Patil, P.; Singh, D.; Raykar, S.J.; Bhamu, J. Multi-objective optimization of process parameters of Fused Deposition Modeling (FDM) for printing Polylactic Acid (PLA) polymer components. Mater. Today Proc. 2021, 45, 4880–4885. [Google Scholar] [CrossRef]

- Dusanapudi, S.; Krupakaran, R.L.; Srinivas, A.; Nikhil, K.S.; Vamshi, T. Optimization and experimental analysis of mechanical properties and porosity on FDM based 3D printed ABS sample. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Singh, J.; Goyal, K.K.; Kumar, R.; Gupta, V. Development of artificial intelligence-based neural network prediction model for responses of additive manufactured polylactic acid parts. Polym. Compos. 2022, 43, 5623–5639. [Google Scholar] [CrossRef]

- Poonia, V.; Kumar, R.; Kulshrestha, R.; Sangwan, K.S. Optimization of Specific Energy, Scrap, and Surface Roughness in 3D Printing Using Integrated ANN-GA Approach. Procedia CIRP 2023, 116, 324–329. [Google Scholar] [CrossRef]

- Yang, B.; Wang, Z.; Yang, Y.; Kang, Y.; Li, X. Optimum fixture locating layout for sheet metal part by integrating kriging with cuckoo search algorithm. Int. J. Adv. Manuf. Technol. 2017, 91, 327–340. [Google Scholar] [CrossRef]

- Yang, B.; Wang, Z.; Yang, Y.; Kang, Y.; Li, C. Optimization of fixture locating layout for sheet metal part by cuckoo search algorithm combined with finite element analysis. Adv. Mech. Eng. 2017, 9, 168781401770483. [Google Scholar] [CrossRef]

- Yang, Y.; Dai, X.; Yang, B.; Zou, P.; Gao, F.; Duan, J.; Wang, C. Optimization of polylactic acid 3D printing parameters based on support vector regression and cuckoo search. Polym. Eng. Sci. 2023, 63, 3243–3253. [Google Scholar] [CrossRef]

- Nielsen, H.B.; Lophaven, S.N.; Sondergaard, J. DACE, a MATLAB Kriging Toolbox. Informatics and Mathematical Modelling; Technical University of Denmark, DTU: Lyngby, Denmark, 2002. [Google Scholar]

- Yang, X.S.; Deb, S. Engineering optimisation by cuckoo search. Int. J. Math. Model. Numer. Optim. 2010, 1, 330–343. [Google Scholar] [CrossRef]

- McKay, M.D.; Beckman, R.J.; Conover, W.J. A compari son of three methods for selecting values of input vari ables in the analysis of output from a computer code. Technometrics 2000, 42, 55–61. [Google Scholar] [CrossRef]

- ISO 527-1-2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

| FDM Parameters | Values | |

|---|---|---|

| PLA parameters | Filament diameter (mm) | 1.75 |

| Density (kg/m3) | 1250 | |

| FDM process parameters | Nozzle diameter (mm) | 0.4 |

| Filling rate (%) | 100 | |

| Layer thickness (mm) | 0.2 | |

| Raster angle (°) | [45, 135] | |

| Substrate temperature (°C) | 30 |

| Optimal Parameters | Maximum σ by CS | The Corresponding σ by Experiment | Relative Error |

|---|---|---|---|

| (31 mm/s, 225 °C) | 37.47 MPa | 38.27 MPa | 2.09% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Wang, Y.; Xue, B.; Wang, C.; Yang, B. Optimization of Fused Deposition Modeling Parameters for Mechanical Properties of Polylactic Acid Parts Based on Kriging and Cuckoo Search. Aerospace 2025, 12, 38. https://doi.org/10.3390/aerospace12010038

Yang Y, Wang Y, Xue B, Wang C, Yang B. Optimization of Fused Deposition Modeling Parameters for Mechanical Properties of Polylactic Acid Parts Based on Kriging and Cuckoo Search. Aerospace. 2025; 12(1):38. https://doi.org/10.3390/aerospace12010038

Chicago/Turabian StyleYang, Yuan, Yiyang Wang, Bowen Xue, Changxu Wang, and Bo Yang. 2025. "Optimization of Fused Deposition Modeling Parameters for Mechanical Properties of Polylactic Acid Parts Based on Kriging and Cuckoo Search" Aerospace 12, no. 1: 38. https://doi.org/10.3390/aerospace12010038

APA StyleYang, Y., Wang, Y., Xue, B., Wang, C., & Yang, B. (2025). Optimization of Fused Deposition Modeling Parameters for Mechanical Properties of Polylactic Acid Parts Based on Kriging and Cuckoo Search. Aerospace, 12(1), 38. https://doi.org/10.3390/aerospace12010038