Investigation of the Film Cooling Performance of Laminated SiCfSiC Composite Plates

Abstract

1. Introduction

2. The Thermal Conductivity of the SiCf/SiC

2.1. Material

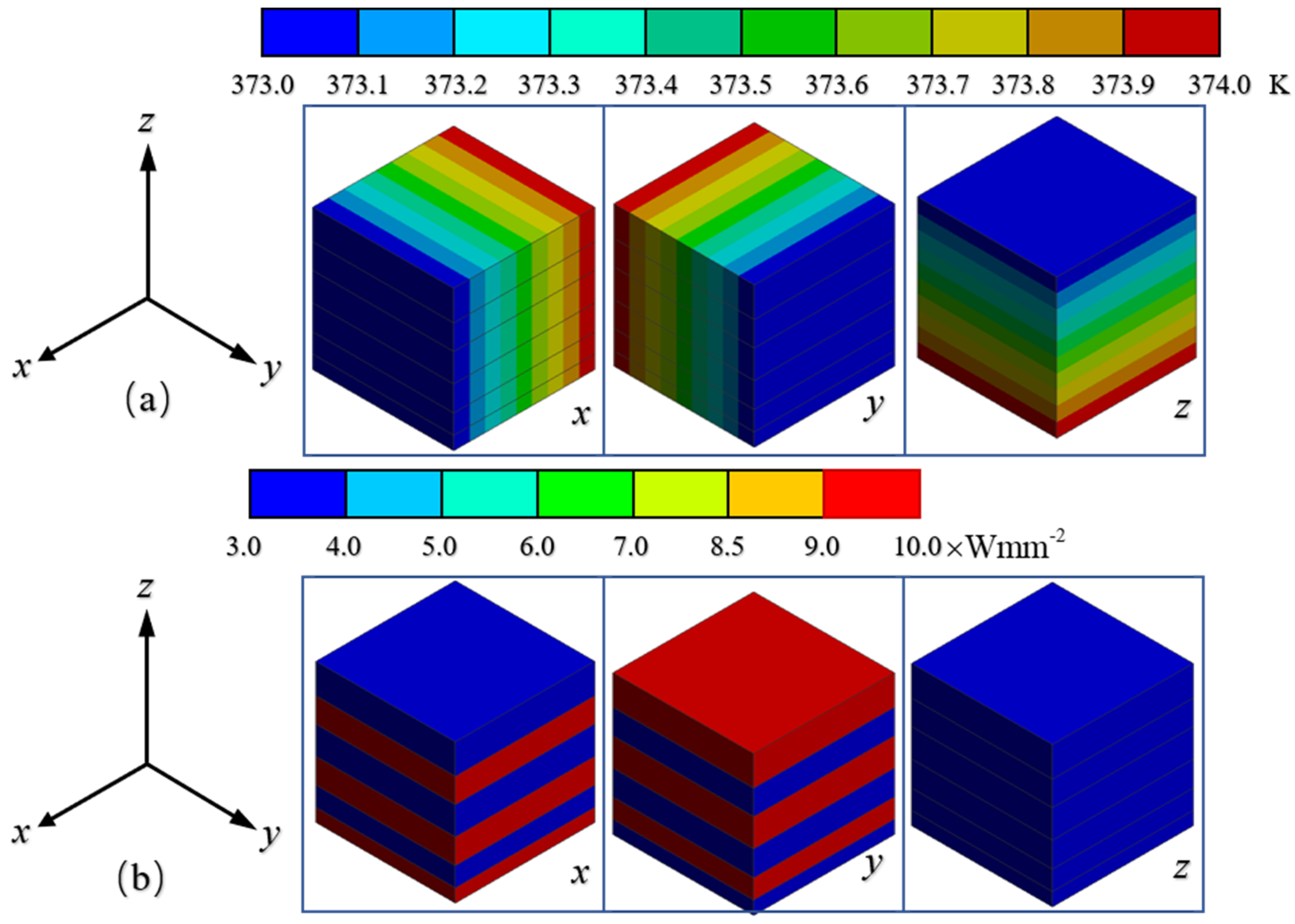

2.2. Anisotropic Thermal Conductivity

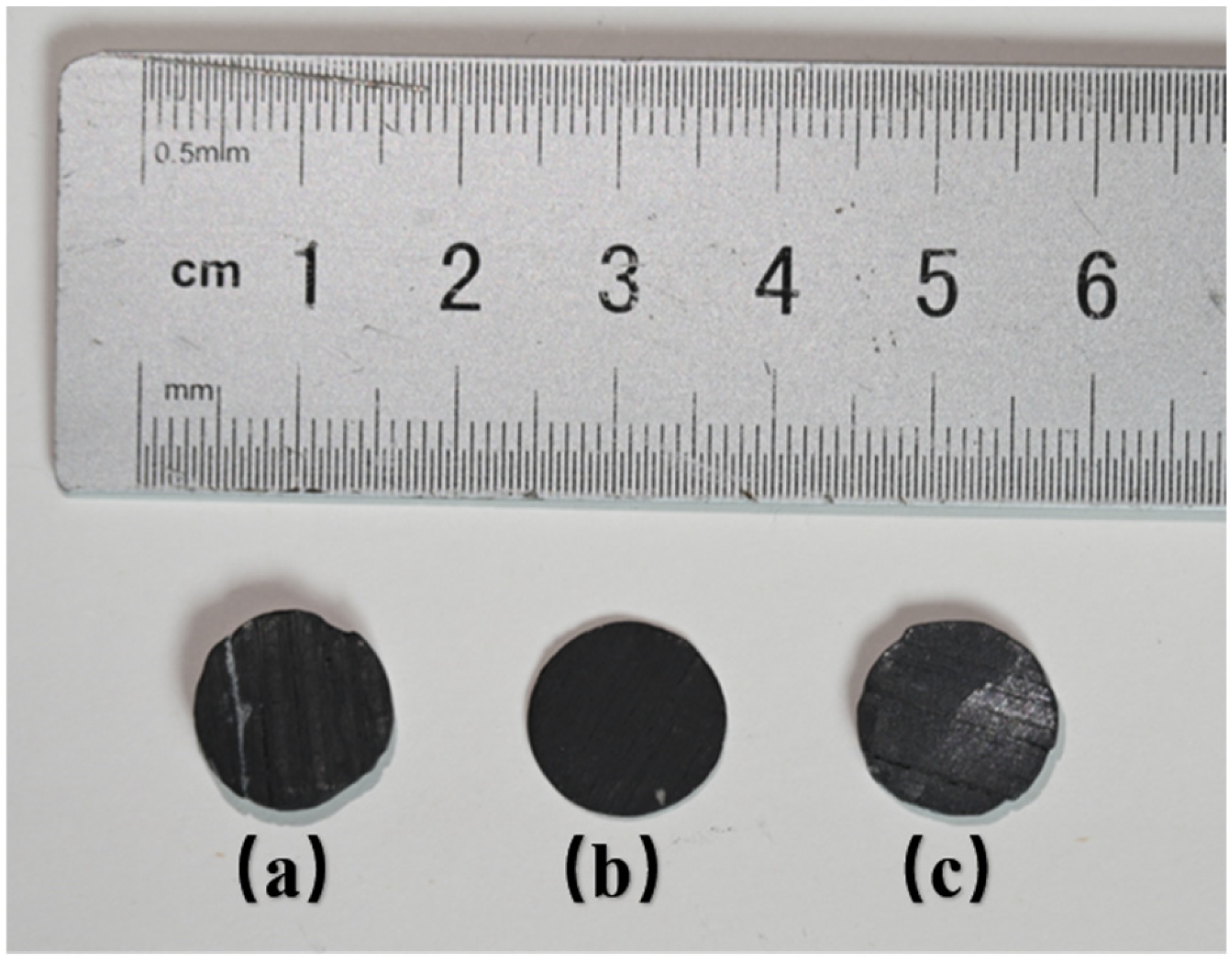

2.3. Measure

2.4. Analysis of Thermal Conductivity

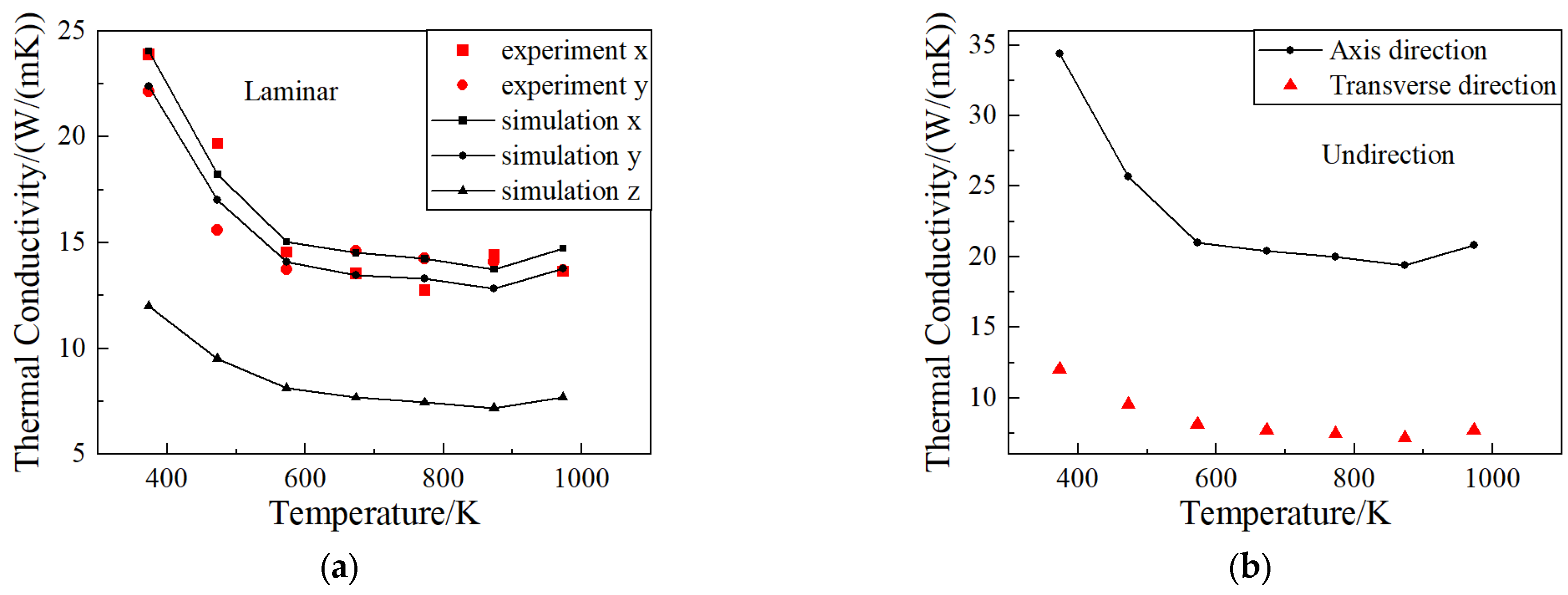

2.5. Result of Thermal Conductivity

3. Influence of Stacking Sequence and Layers on Film Cooling

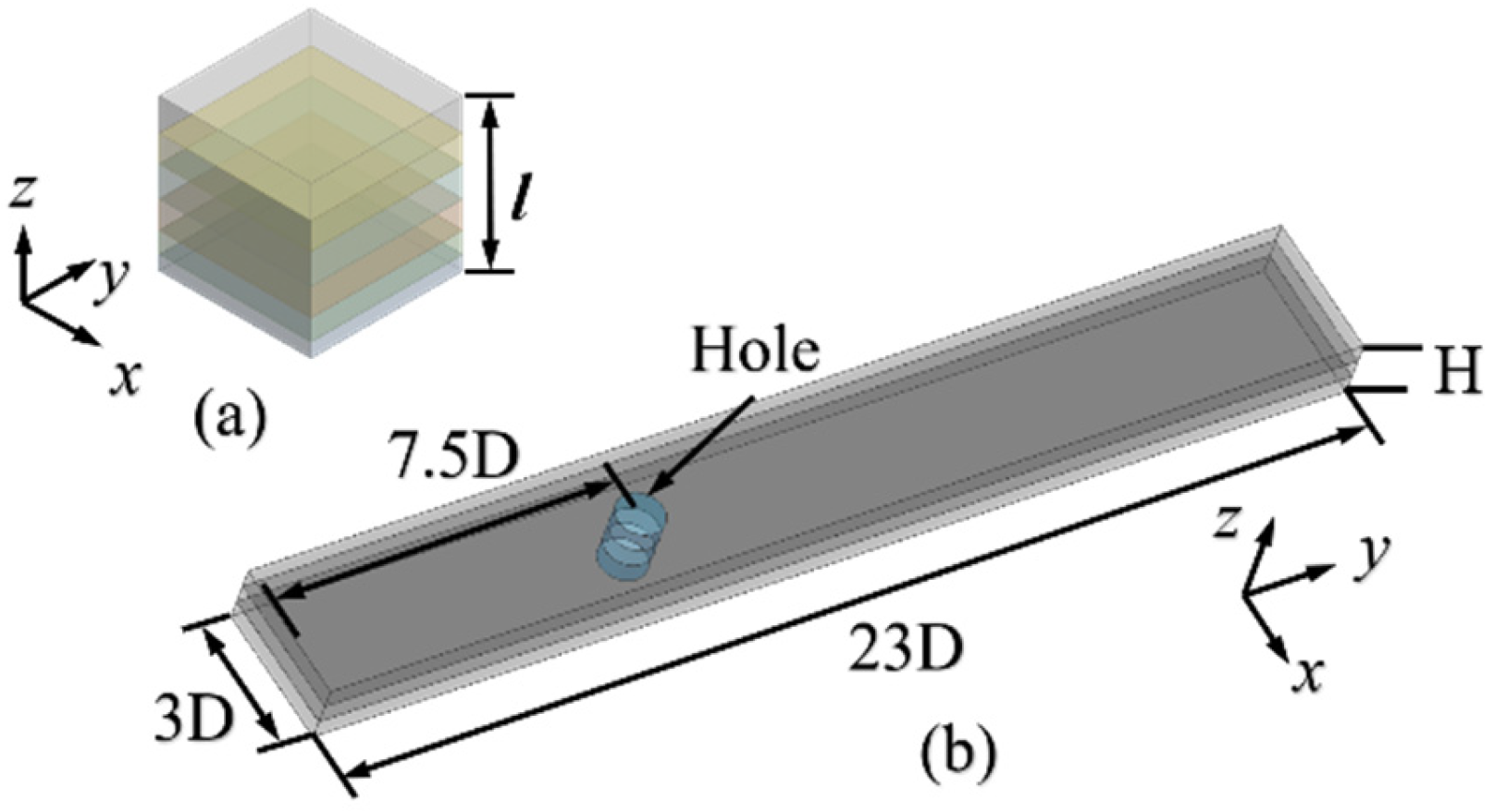

3.1. Simulation Model

3.2. Boundary Conditions and Parameter Definitions

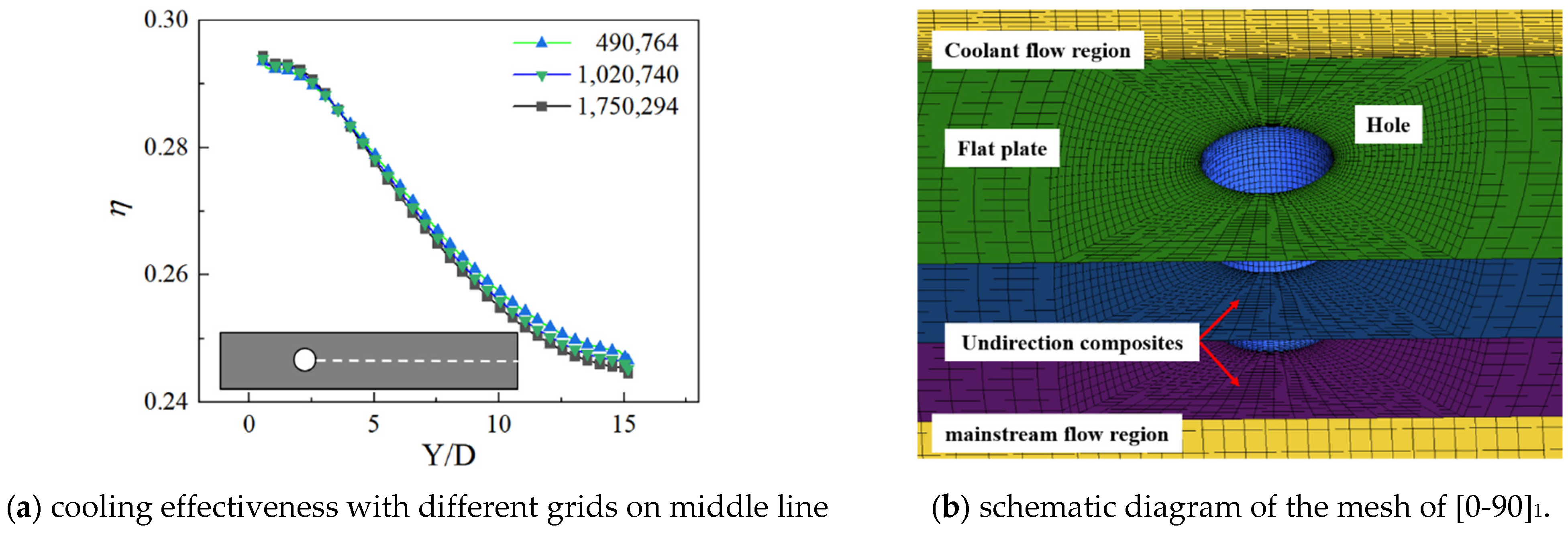

3.3. Mesh Independent

4. Result and Discussion

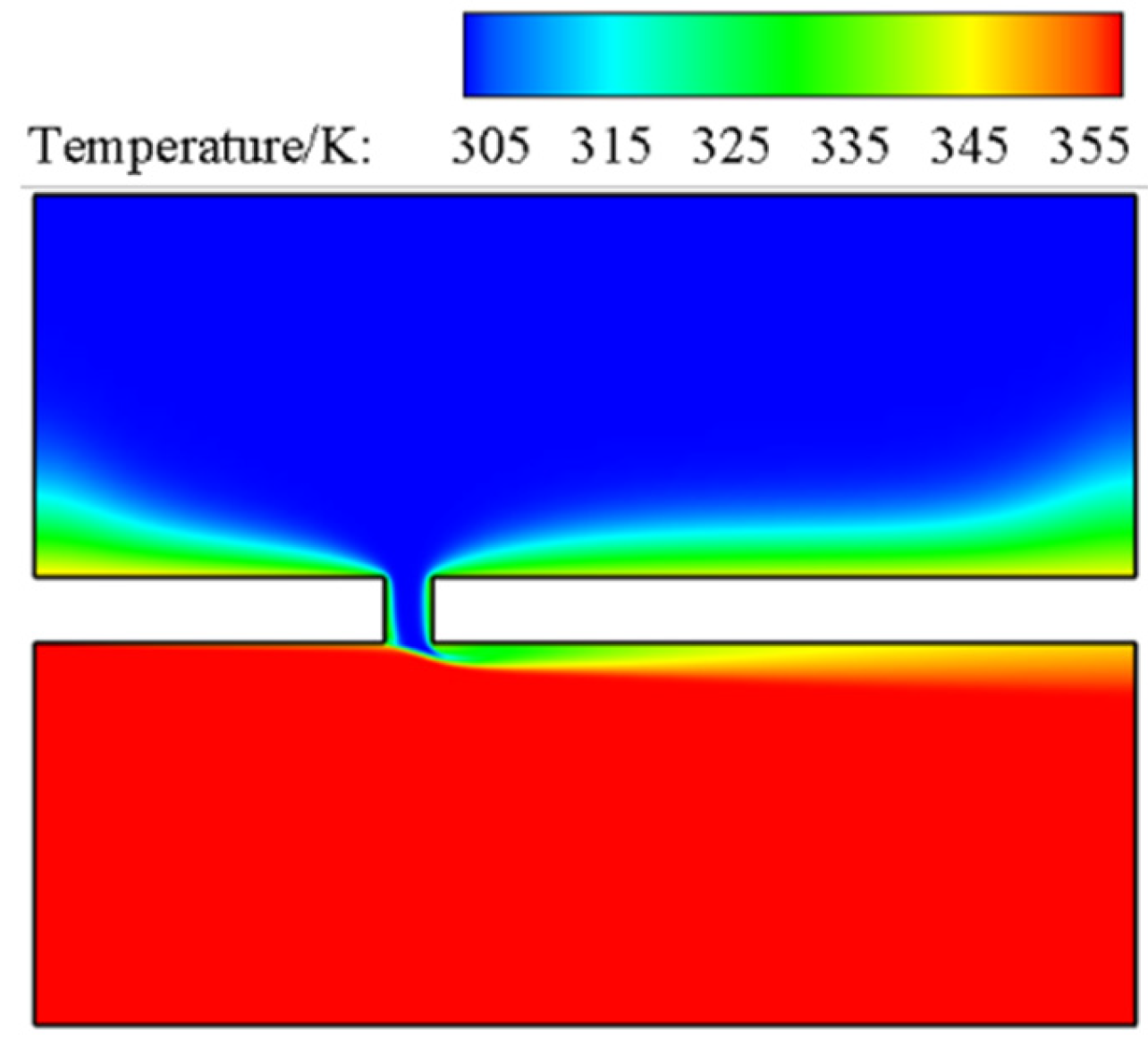

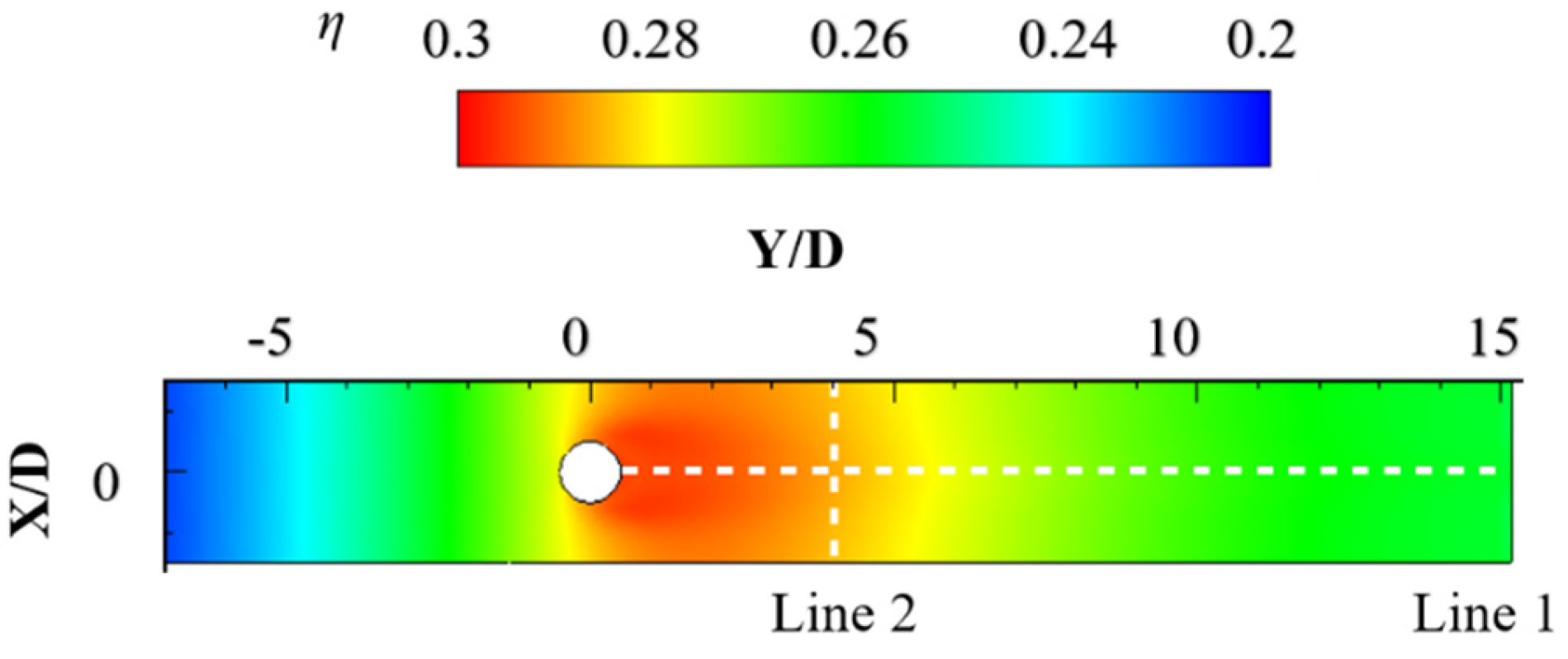

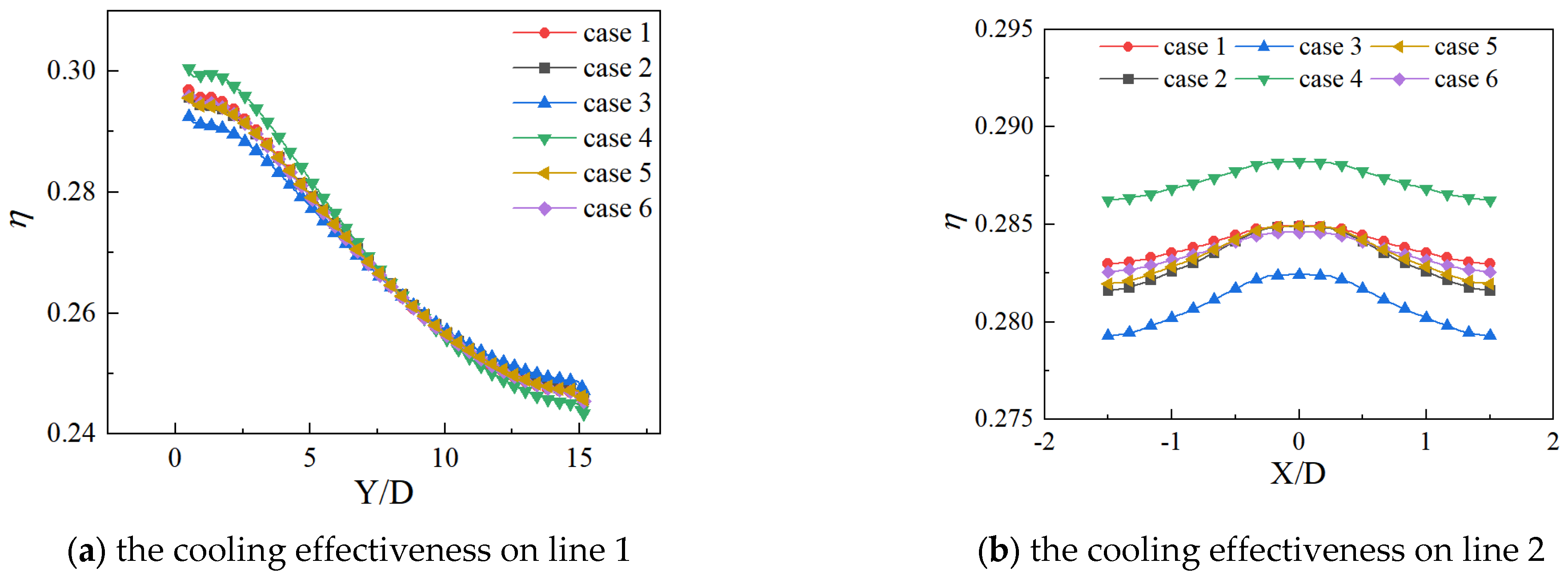

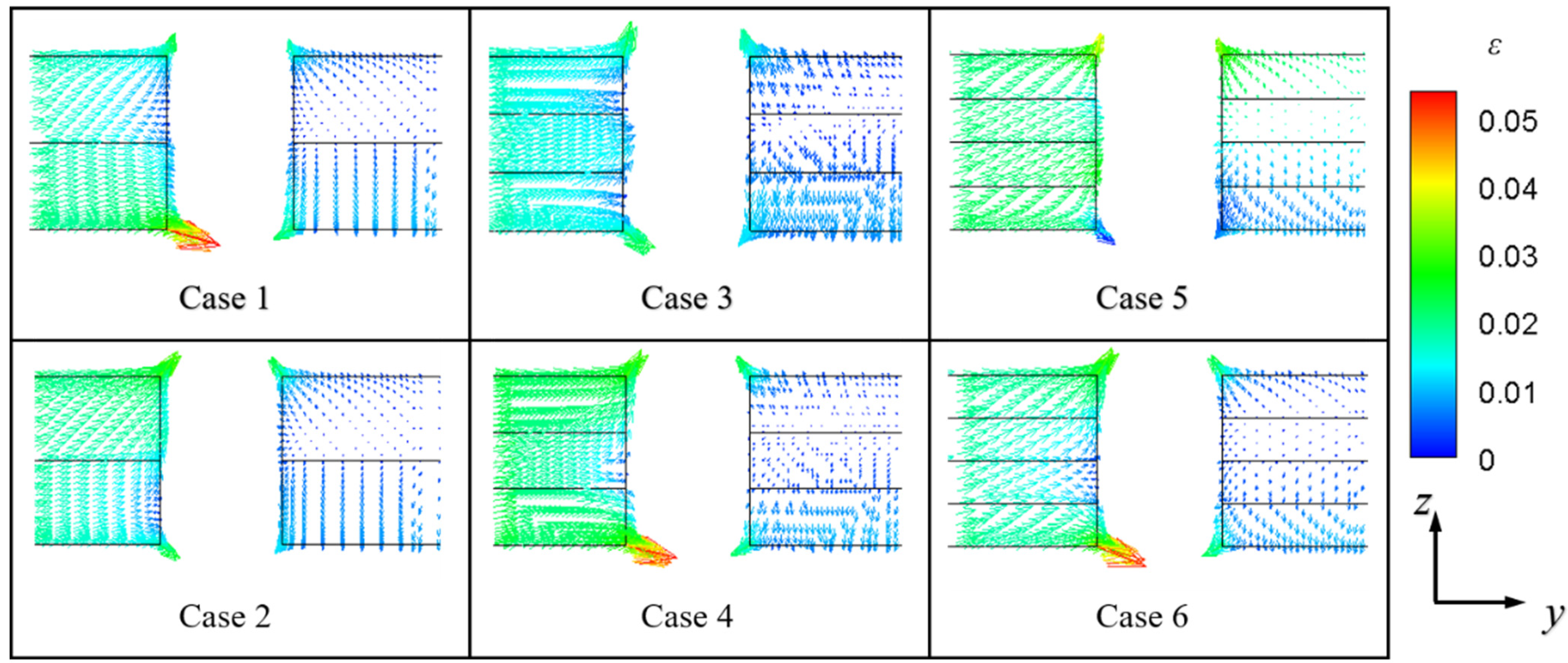

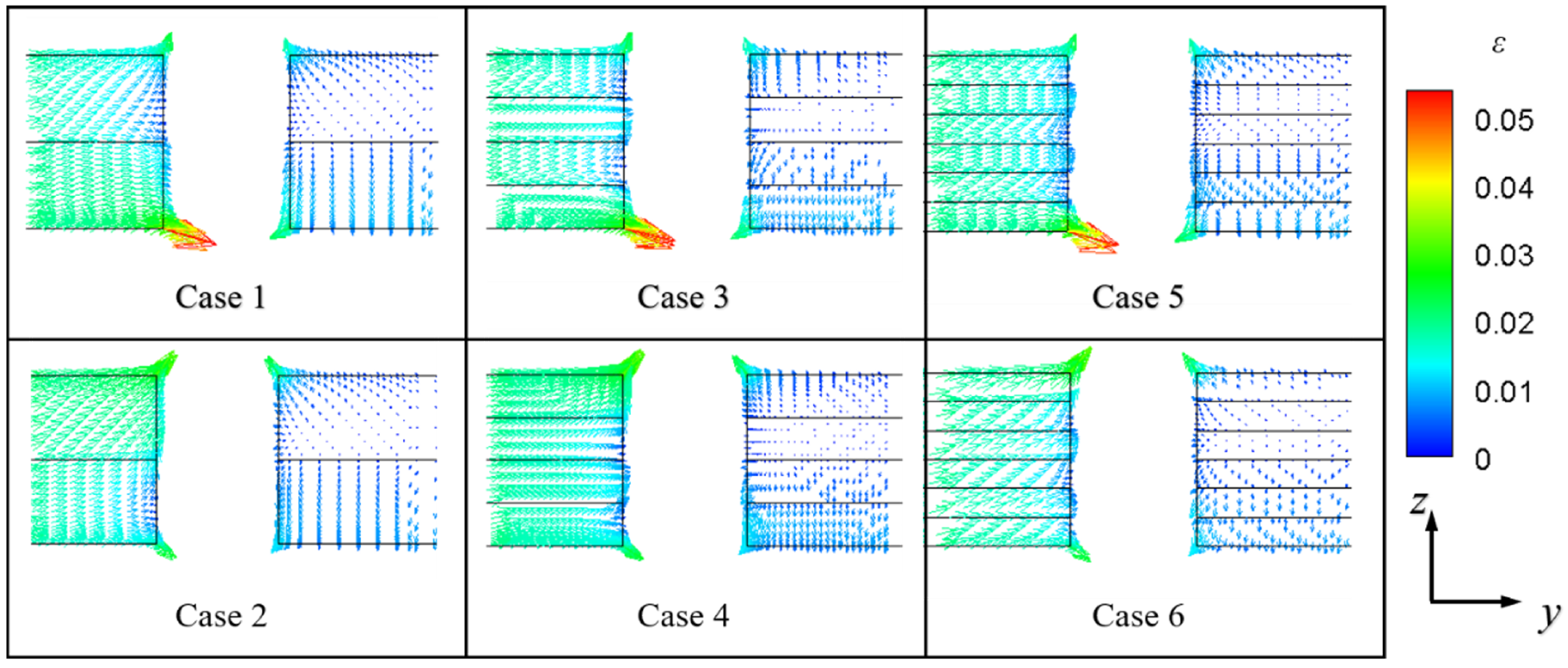

4.1. Influence of Stacking Sequence

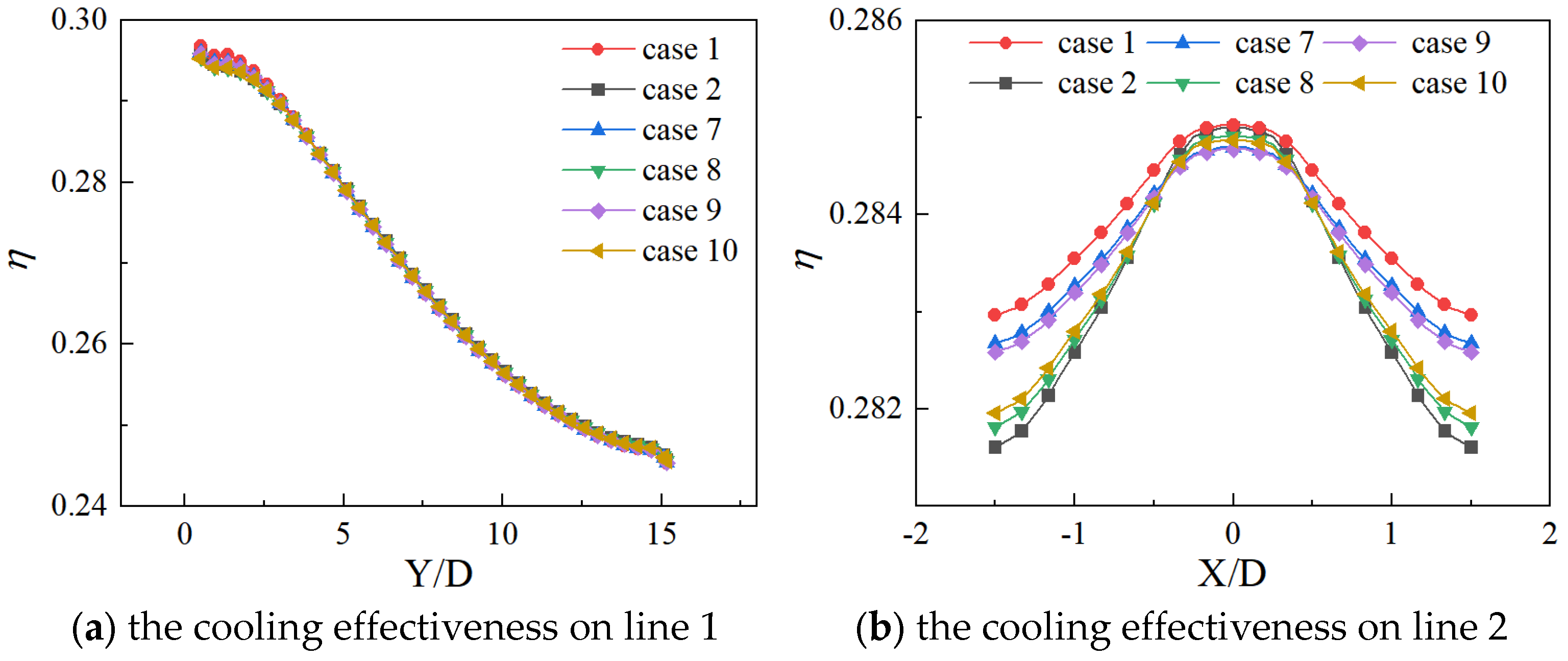

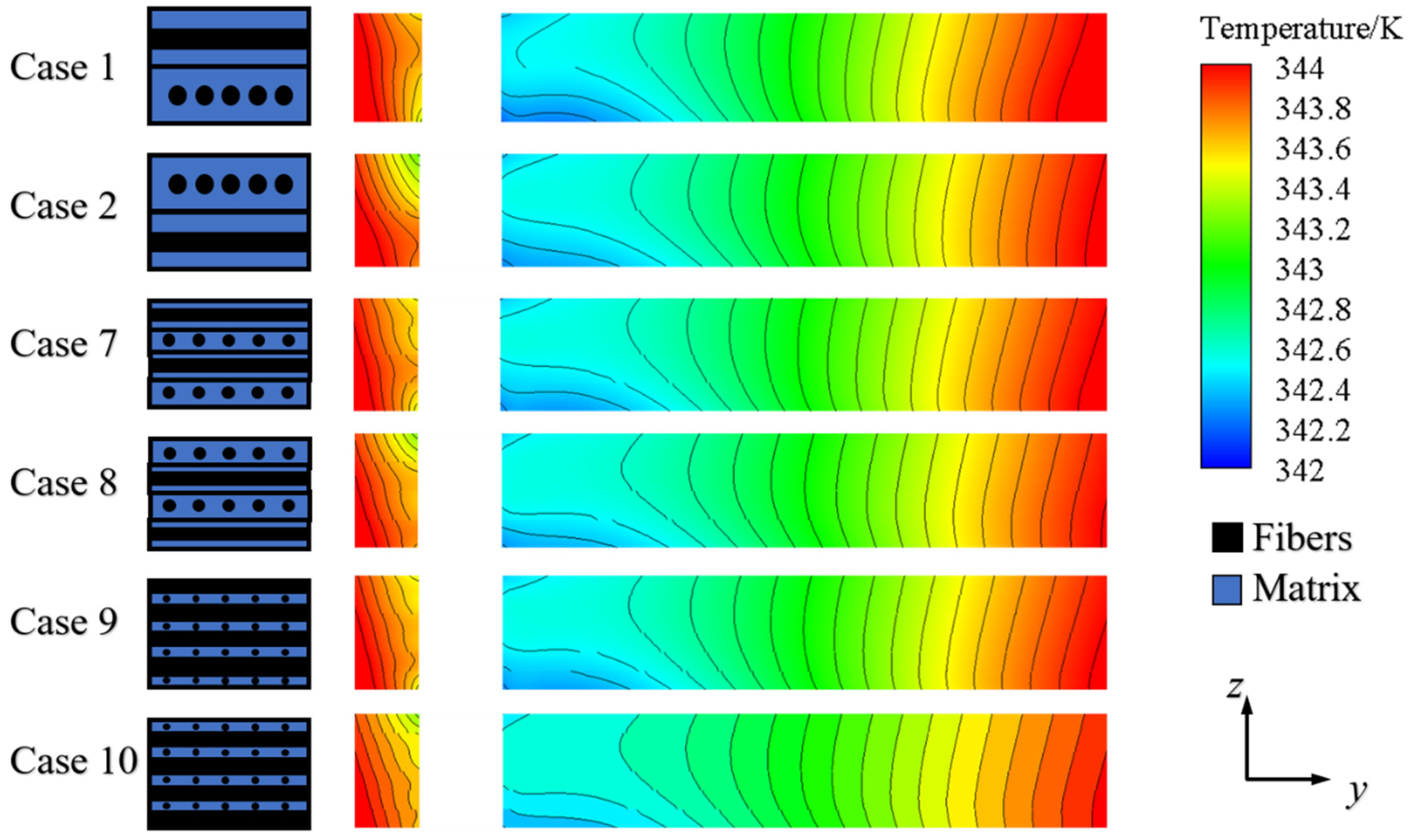

4.2. Influence of Stacking Layers

5. Conclusions

- The microscale RVE model predicted the thermal conductivity of SiCf/SiC composites well. In the range of 373 K to 973 K, the thermal conductivity of SiCf/SiC composites gradually decreased with increasing temperature, and the difference in out-of-plane thermal conductivity was slight. The in-plane thermal conductivity was about twice that in the thickness direction. The thermal conductivity in the fiber direction was about three times that in the transverse direction for the unidirectional SiCf/SiC composites. At 373 K, the in-plane thermal conductivities of the laminated SiCf/SiC composites were 22.4 W/(mK) and 24.0 W/(mK), and the out-of-plane thermal conductivity was 12.0 W/(mK). The thermal conductivities of the unidirectional SiCf/SiC composites were 12.0 W/(mK) and 34.4 W/(mK).

- The stacking sequence of the laminated SiCf/SiC composites had a certain impact on the performance of film cooling around the film hole. [0-90]1 and [0-90-90-0]1 showed similar distributions near the film hole. The maximum difference in overall cooling efficiency was 1.7% between [0-90-0]1 and [0-90]1 and [0-90-90-0]1. Additionally, the overall cooling efficiency of [0-90-0]1 was sensitive to the flow direction. The distribution of the temperature was different in different stacking sequences near the film-cooling hole.

- The stacking layers of the laminated SiCf/SiC composites were ignorable for the film cooling performance. The performance of the film cooling in the laminated SiCf/SiC composites was consistent across all stacking layers [0-90]1, [0-90]2, and [0-90]3. Additionally, the overall cooling efficiency was insensitive to the flow direction. The distribution of temperature was different in [0-90]1, [0-90]2, and [0-90]3 near the film-cooling hole.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jon, B.; Matt, P.; Ben, B.; Ji, Z.; Vinothini, V.; Rubio, D.V.; Andrea, D.A.; Prabhu, R.; Tailin, Z.; Murthy, T.S.R.C. Selection, processing, properties and applications of ultra-high temperature ceramic matrix composites, uhtcmcs—A review. Int. Mater. Rev. 2020, 65, 389–444. [Google Scholar]

- Chen, Q.; Li, S.; Zhu, L.A.; Bai, S.; Ye, Y. Research progress in high thermal conductivity of silicon carbide matrix composites reinforced with fibers. J. Mater. Eng. 2023, 51, 46–55. [Google Scholar]

- Wang, X.; Gao, X.; Zhang, Z.; Cheng, L.; Ma, H.; Yang, W. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: A focused review. J. Eur. Ceram. Soc. 2021, 41, 4671–4688. [Google Scholar] [CrossRef]

- Song, C.K.; Ye, F.; Cheng, L.F.; Liu, Y.S.; Zhang, Q. Long-term ceramic matrix composite for aeroengine. J. Adv. Ceram. 2022, 11, 1343–1374. [Google Scholar] [CrossRef]

- Zhu, D. Aerospace Ceramic Materials: Thermal, Environmental Barrier Coatings and Sic/Sic Ceramic Matrix Composites for Turbine Engine Applications; NASA: Washington, DC, USA, 2018. [Google Scholar]

- Verrilli, M.; Calomino, A.; Robinson, R.C.; Thomas, D.J. Ceramic matrix composite vane subelement testing in a gas turbine environment. In Proceedings of the ASME Turbo Expo 2004: Power for Land, Sea, and Air, Vienna, Austria, 14–17 June 2004. [Google Scholar]

- Zhong, F.; Brown, G.L. Experimental study of multi-hole cooling for integrally-woven, ceramic matrix composite walls for gas turbine applications. Int. J. Heat Mass Transf. 2009, 52, 971–985. [Google Scholar] [CrossRef]

- Bryant, C.E.; Rutledge, J.L. Conjugate heat transfer simulations to evaluate the effect of anisotropic thermal conductivity on overall cooling effectiveness. J. Therm. Sci. Eng. Appl. 2021, 13, 061013. [Google Scholar] [CrossRef]

- Bryant, C.E.; Rutledge, J.L. Influence of anisotropic thermal conductivity on overall cooling effectiveness on a film-cooled leading edge. J. Therm. Sci. Eng. Appl. 2022, 14, 041008. [Google Scholar] [CrossRef]

- Tu, Z.; Mao, J.; Han, X. Numerical study of film cooling over a flat plate with anisotropic thermal conductivity. Appl. Therm. Eng. 2017, 111, 968–980. [Google Scholar] [CrossRef]

- Yin, T.; Jiang, B.; Su, Z.; Huang, Q. The effects of anisotropic thermal conductivity on the leading edge thermal protection property. J. Eng. Thermophys. 2018, 39, 200–206. [Google Scholar]

- Zhang, D.; Hayhurst, D.R. Influence of applied in-plane strain on transverse thermal conductivity of 0°/90° and plain weave ceramic matrix composites. Int. J. Solids Struct. 2011, 48, 828–842. [Google Scholar] [CrossRef][Green Version]

- Zhao, X. Investigation on Film Cooling of Braided Composites Considering Film Hole and Braidedstructure Interference; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2018. [Google Scholar]

- Zhu, A.L.; Tu, Z.C.; Mao, J.K.; Zhao, C.W. Investigation of the film cooling performance of ceramic matrix composites plate with different braided structures. J. Phys. Conf. Ser. 2024, 2707, 012086. [Google Scholar] [CrossRef]

- Vitiello, D.; Nait-Ali, B.; Tessier-Doyen, N.; Tonnesen, T.; Laím, L.; Rebouillat, L.; Smith, D.S. Thermal conductivity of insulating refractory materials: Comparison of steady-state and transient measurement methods. Open Ceram. 2021, 6, 100118. [Google Scholar] [CrossRef]

- Thomas, M.; Boyard, N.; Jarny, Y.; Delaunay, D. Estimation of effective thermal conductivity tensor from composite microstructure images. J. Phys. Conf. Ser. 2008, 135, 012097. [Google Scholar] [CrossRef]

- Liu, Y.; Qu, Z.G.; Guo, J.; Zhao, X.M. Numerical study on effective thermal conductivities of plain woven c/sic composites with considering pores in interlaced woven yarns. Int. J. Heat Mass Transf. 2019, 140, 410–419. [Google Scholar] [CrossRef]

- Caccia, M.; Narciso, J. Key parameters in the manufacture of sic-based composite materials by reactive melt infiltration. Materials 2019, 12, 15. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Tu, Z.; Mao, J. Investigation of the film-cooling performance of 2.5d braided ceramic matrix composite plates with preformed hole. Aerospace 2021, 8, 116. [Google Scholar] [CrossRef]

- Sinha, A.K.; Bogard, D.G.; Crawford, M.E. Film-cooling effectiveness downstream of a single row of holes with variable density ratio. J. Turbomach. 1991, 113, 442–449. [Google Scholar] [CrossRef]

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | Case 7 | Case 8 | Case 9 | Case 10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Stacking structure | [0/90]1 | [90/0]1 | [0/90/0]1 | [90/0/90]1 | [0/90/90/0]1 | [90/0/0/90]1 | [0/90]2 | [90/0]2 | [0/90]3 | [90/0]3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mi, Z.; Chen, Z.; Jiang, K.; Yang, W. Investigation of the Film Cooling Performance of Laminated SiCfSiC Composite Plates. Aerospace 2024, 11, 642. https://doi.org/10.3390/aerospace11080642

Mi Z, Chen Z, Jiang K, Yang W. Investigation of the Film Cooling Performance of Laminated SiCfSiC Composite Plates. Aerospace. 2024; 11(8):642. https://doi.org/10.3390/aerospace11080642

Chicago/Turabian StyleMi, Zhaoguo, Zhenhua Chen, Kanghe Jiang, and Weihua Yang. 2024. "Investigation of the Film Cooling Performance of Laminated SiCfSiC Composite Plates" Aerospace 11, no. 8: 642. https://doi.org/10.3390/aerospace11080642

APA StyleMi, Z., Chen, Z., Jiang, K., & Yang, W. (2024). Investigation of the Film Cooling Performance of Laminated SiCfSiC Composite Plates. Aerospace, 11(8), 642. https://doi.org/10.3390/aerospace11080642