High-Temperature DIC Deformation Measurement under High-Intensity Blackbody Radiation

Abstract

1. Introduction

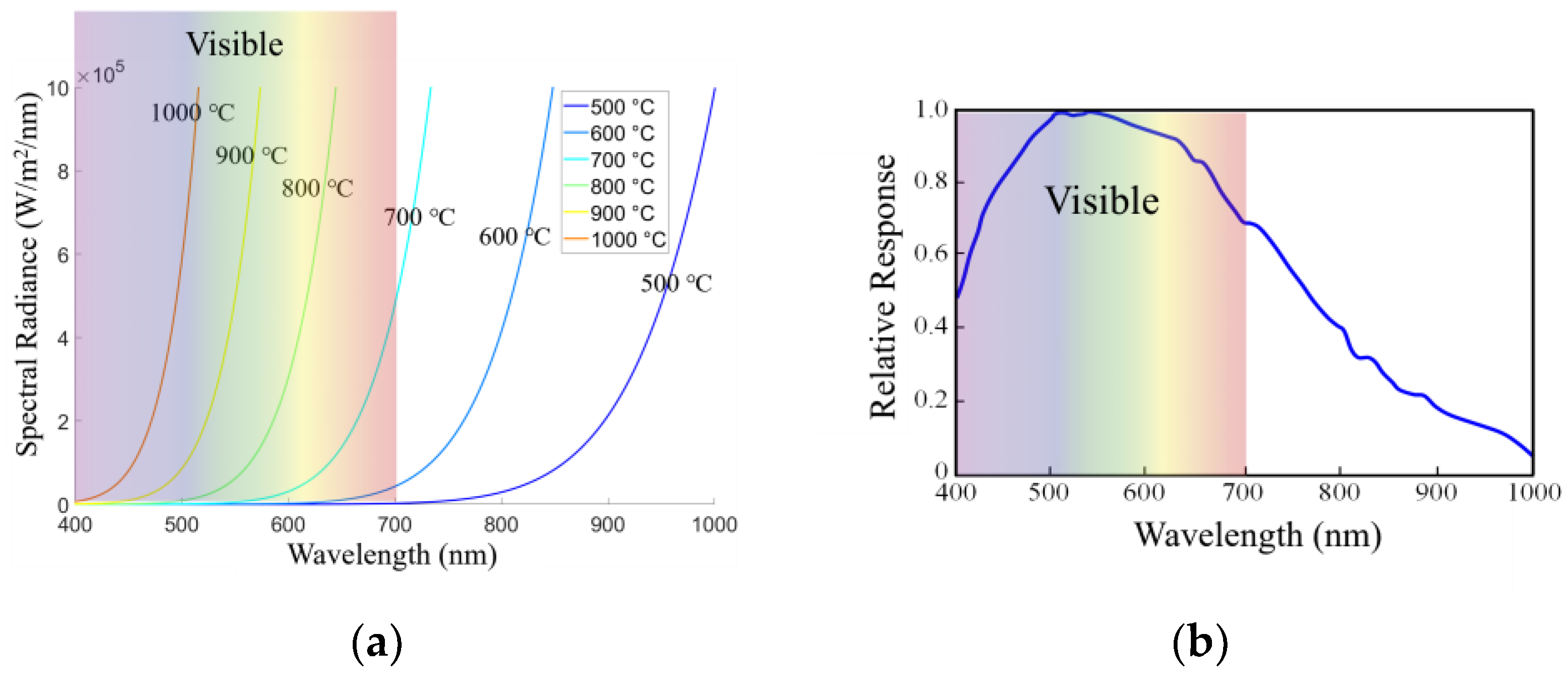

2. Theory

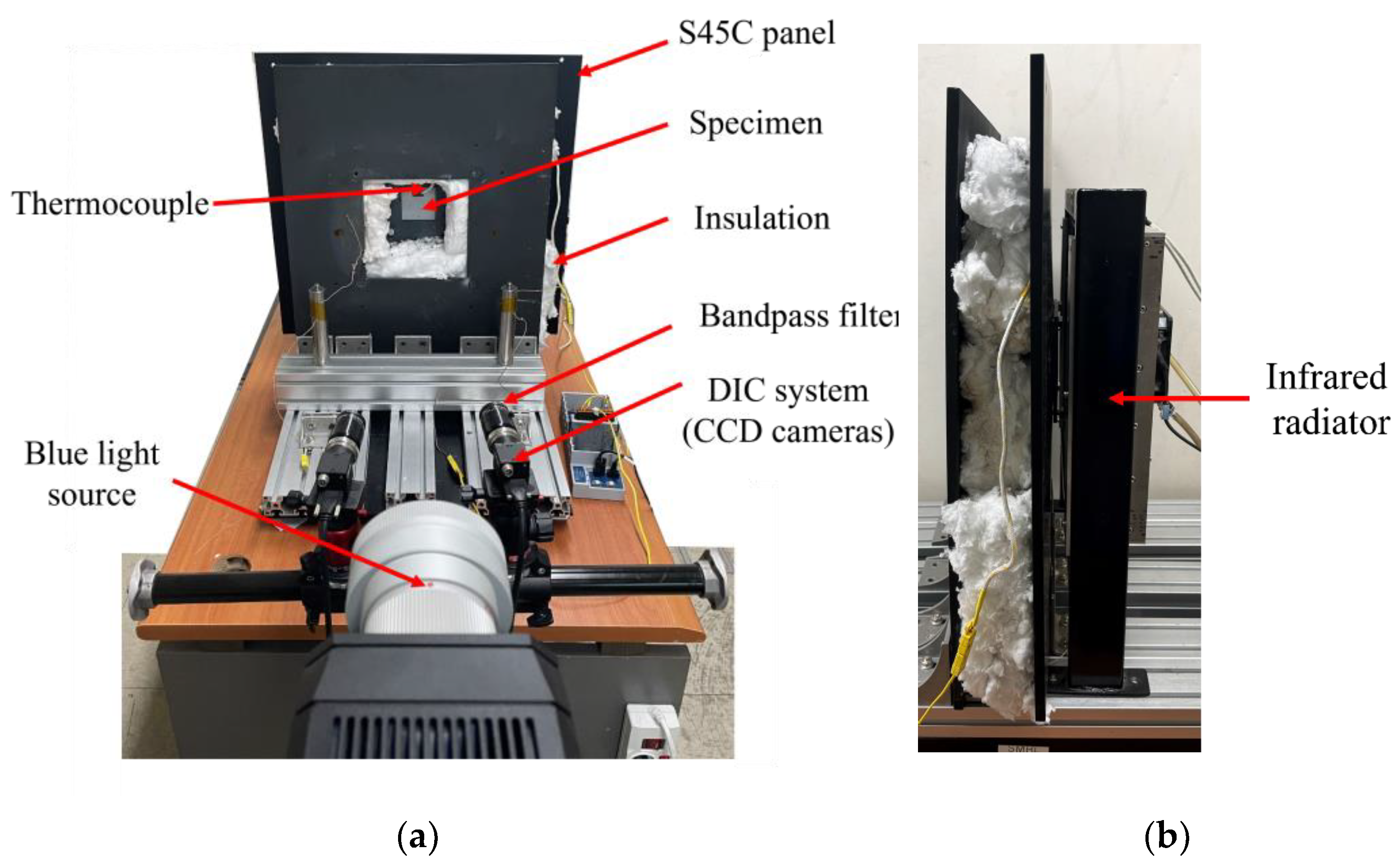

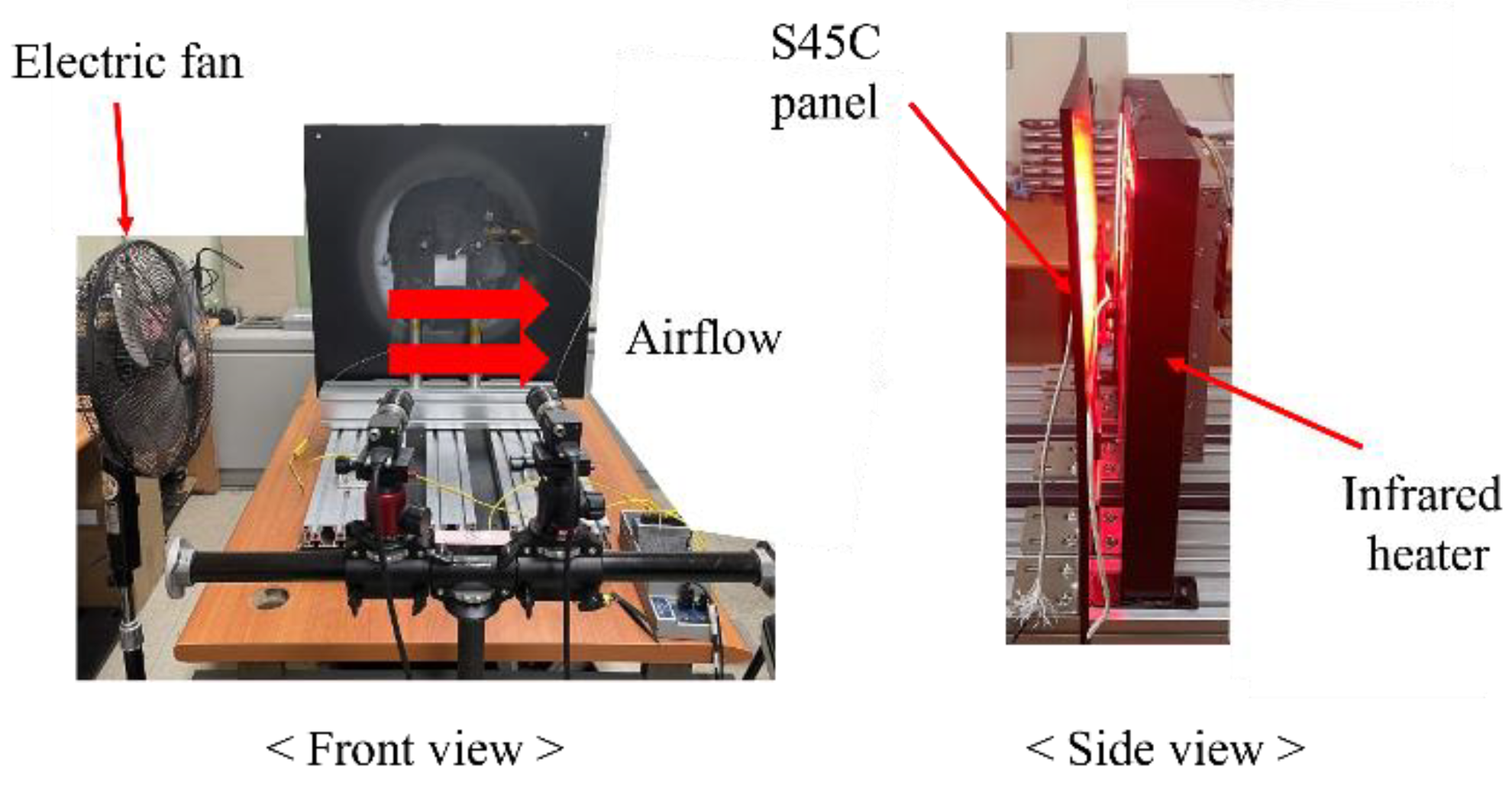

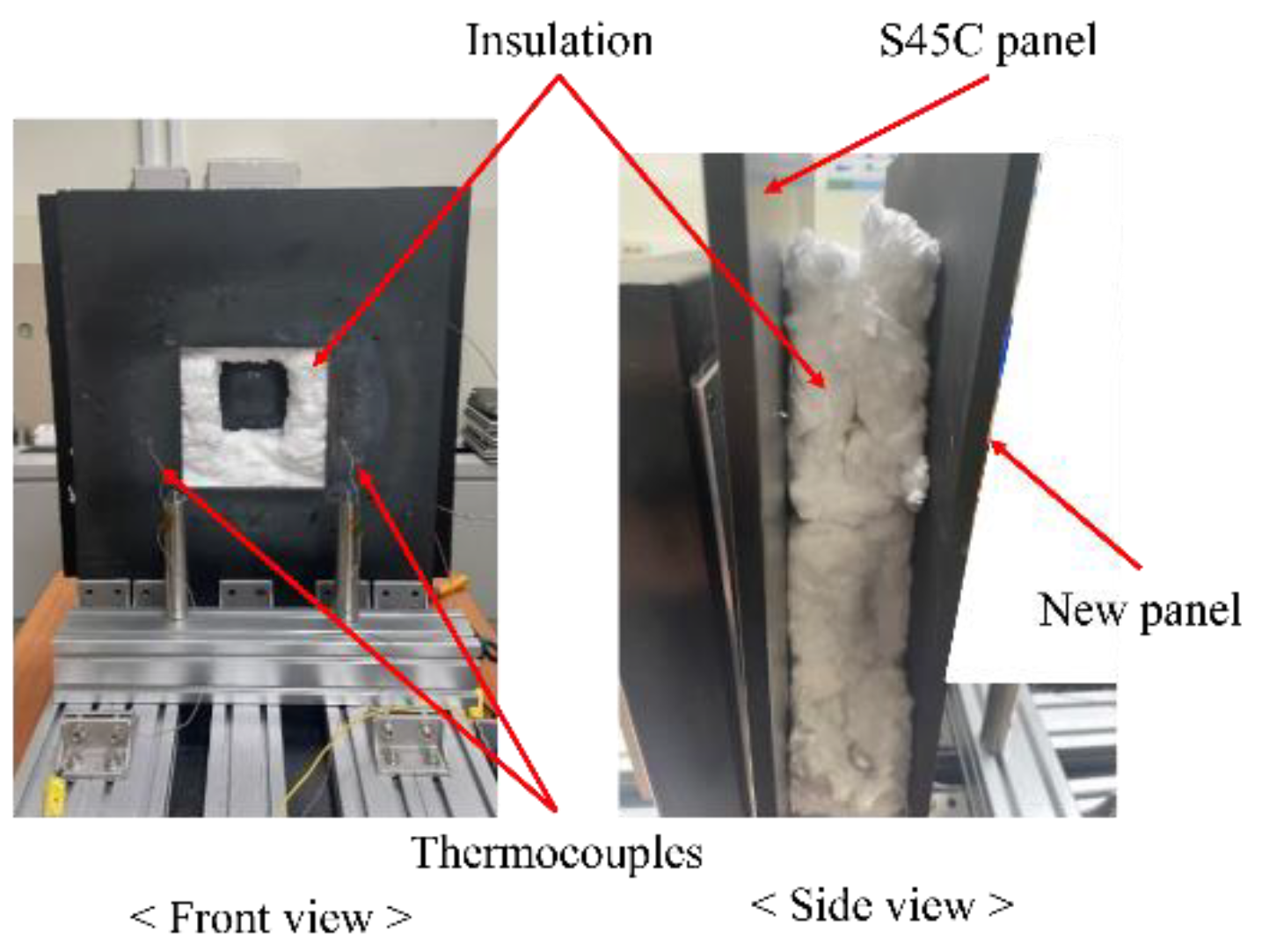

3. Experimental Setup

4. Results and Discussion

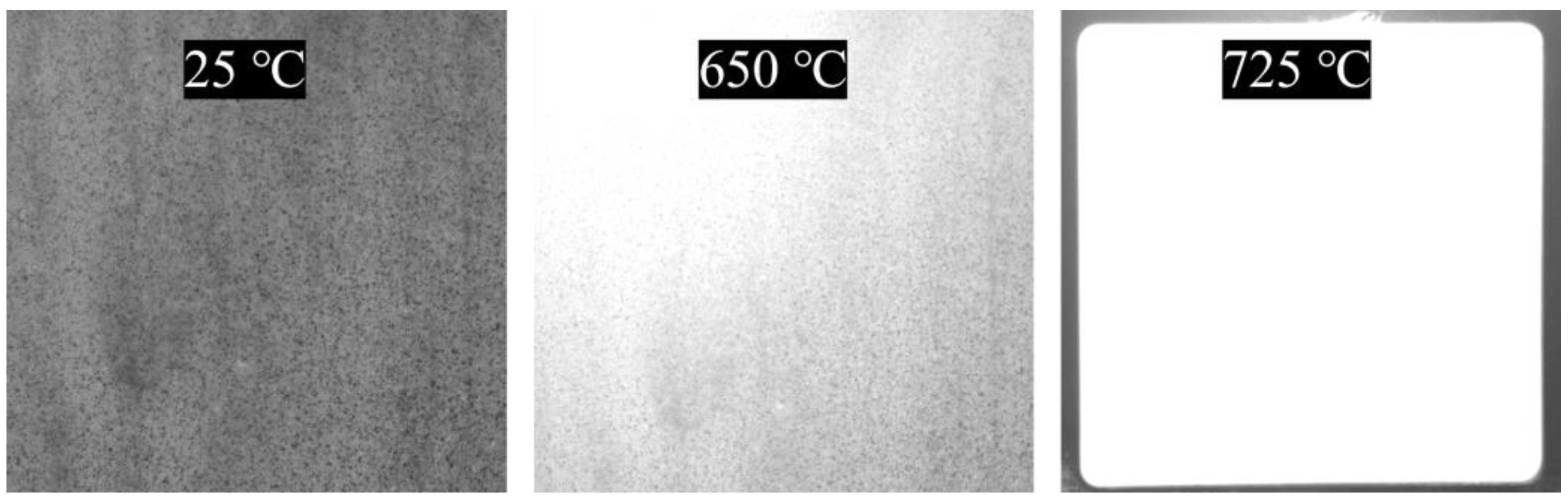

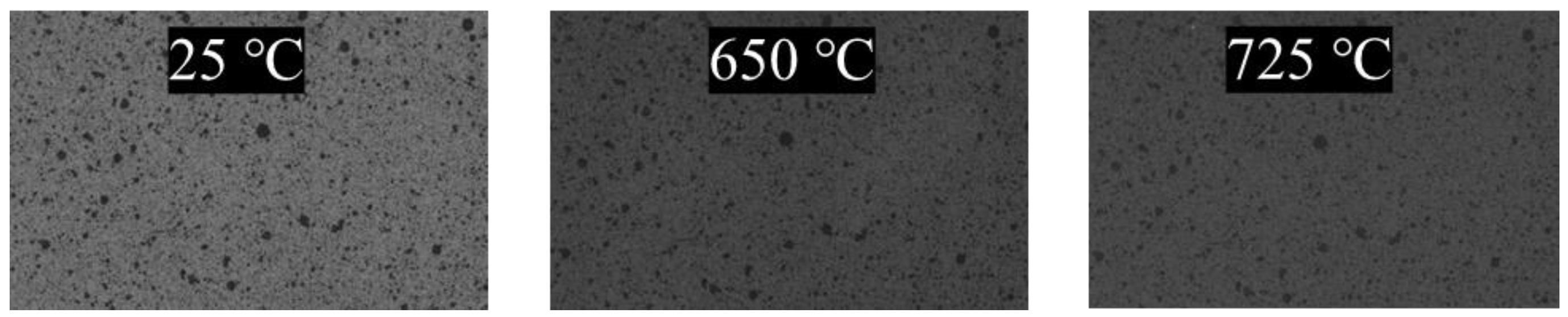

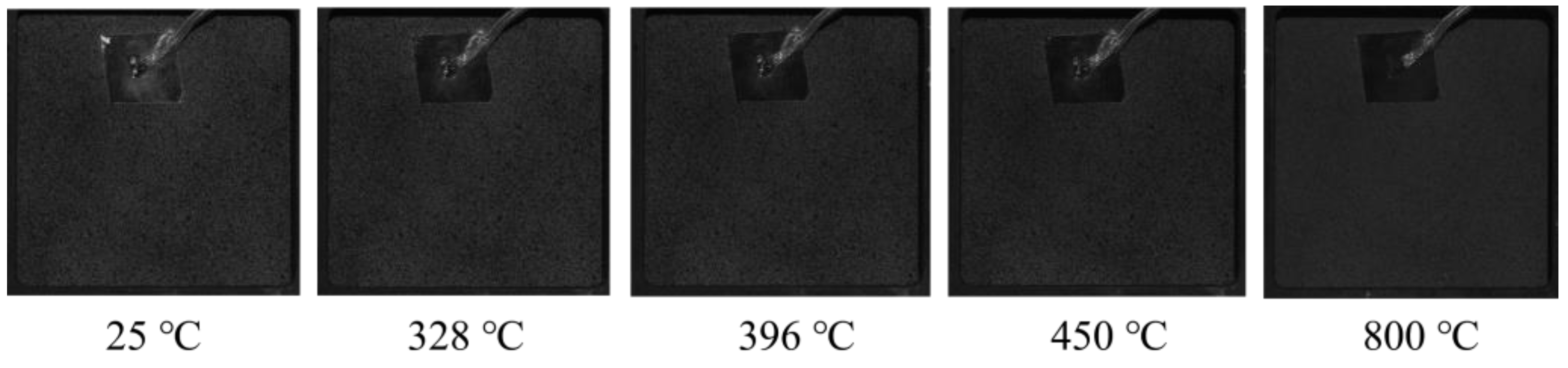

4.1. Image Saturation Phenomenon

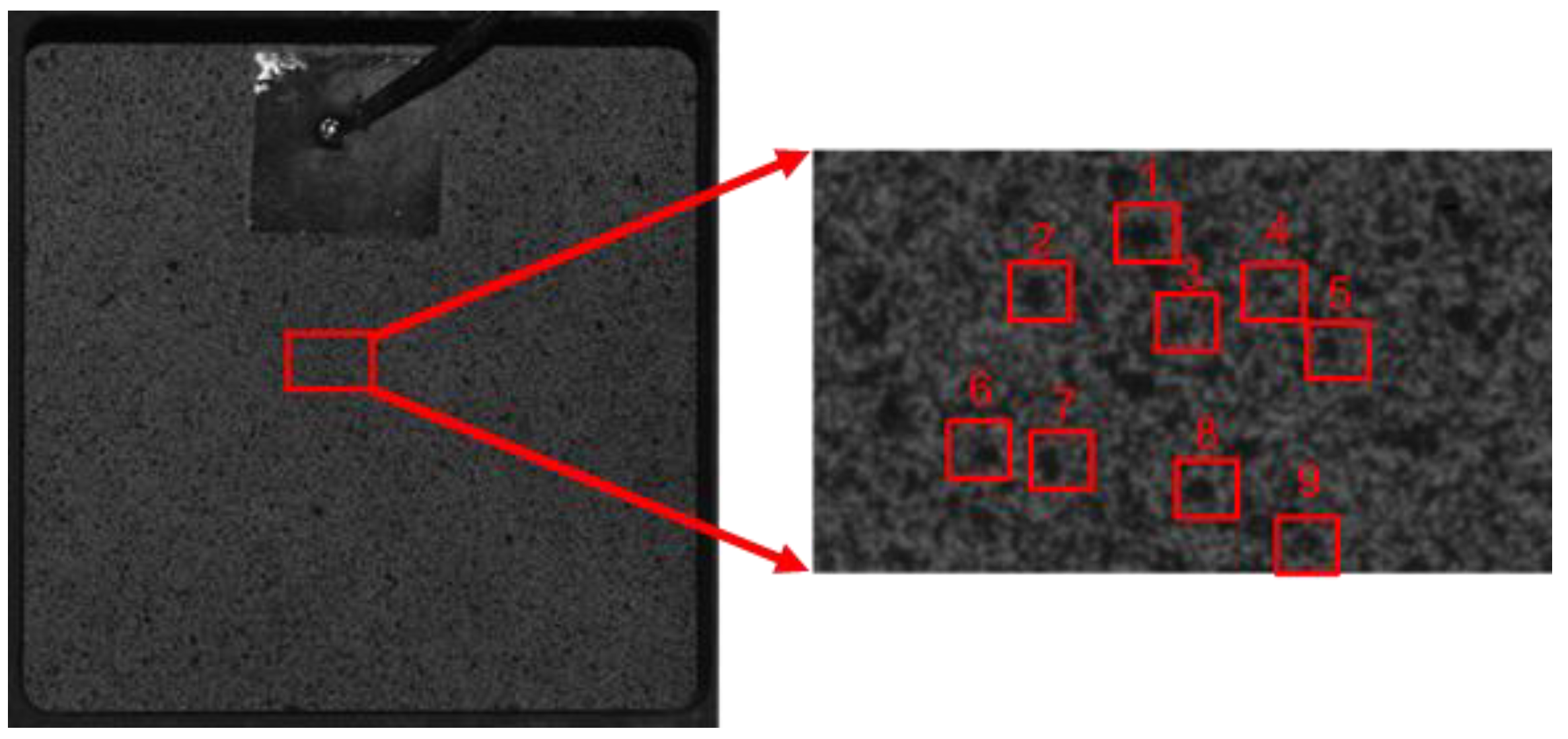

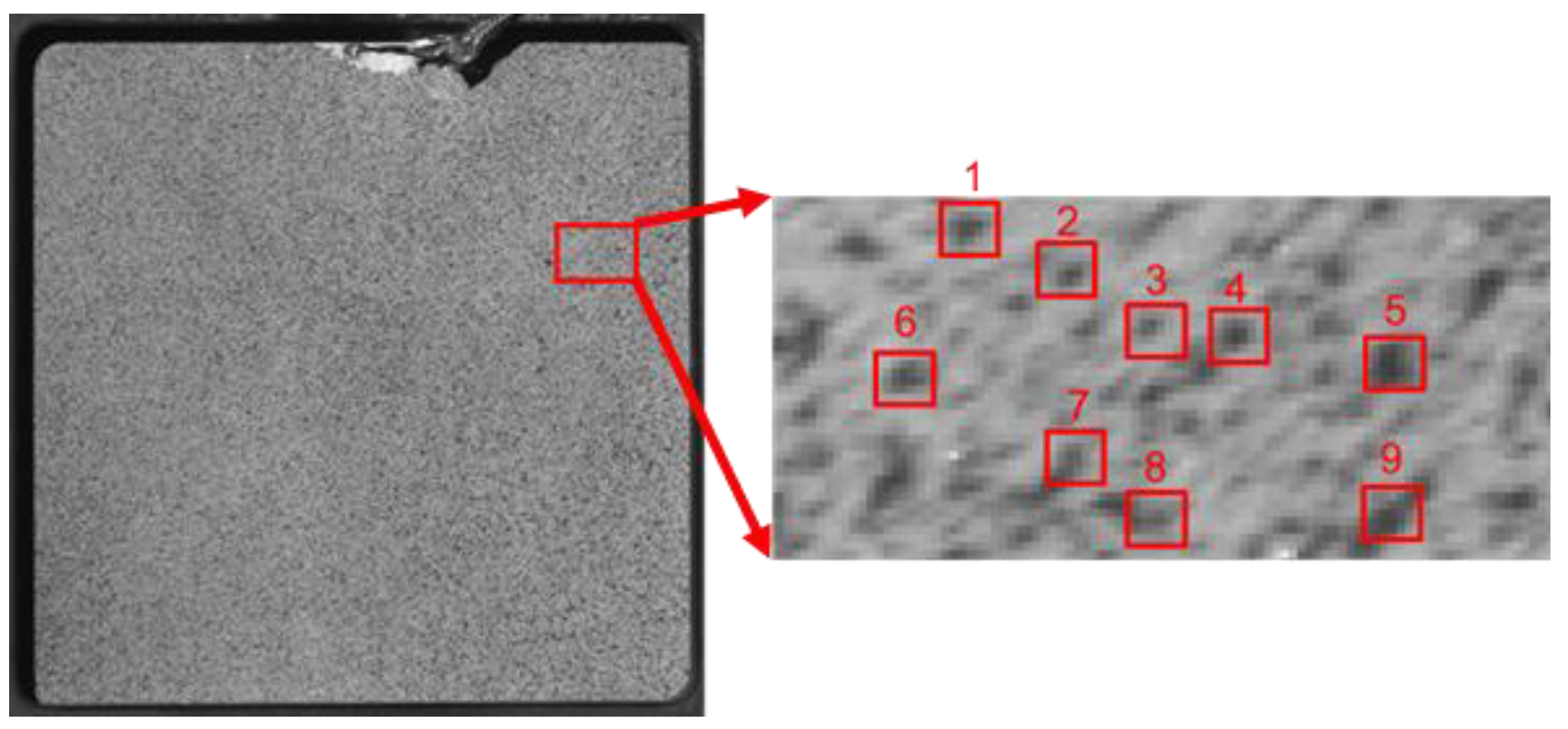

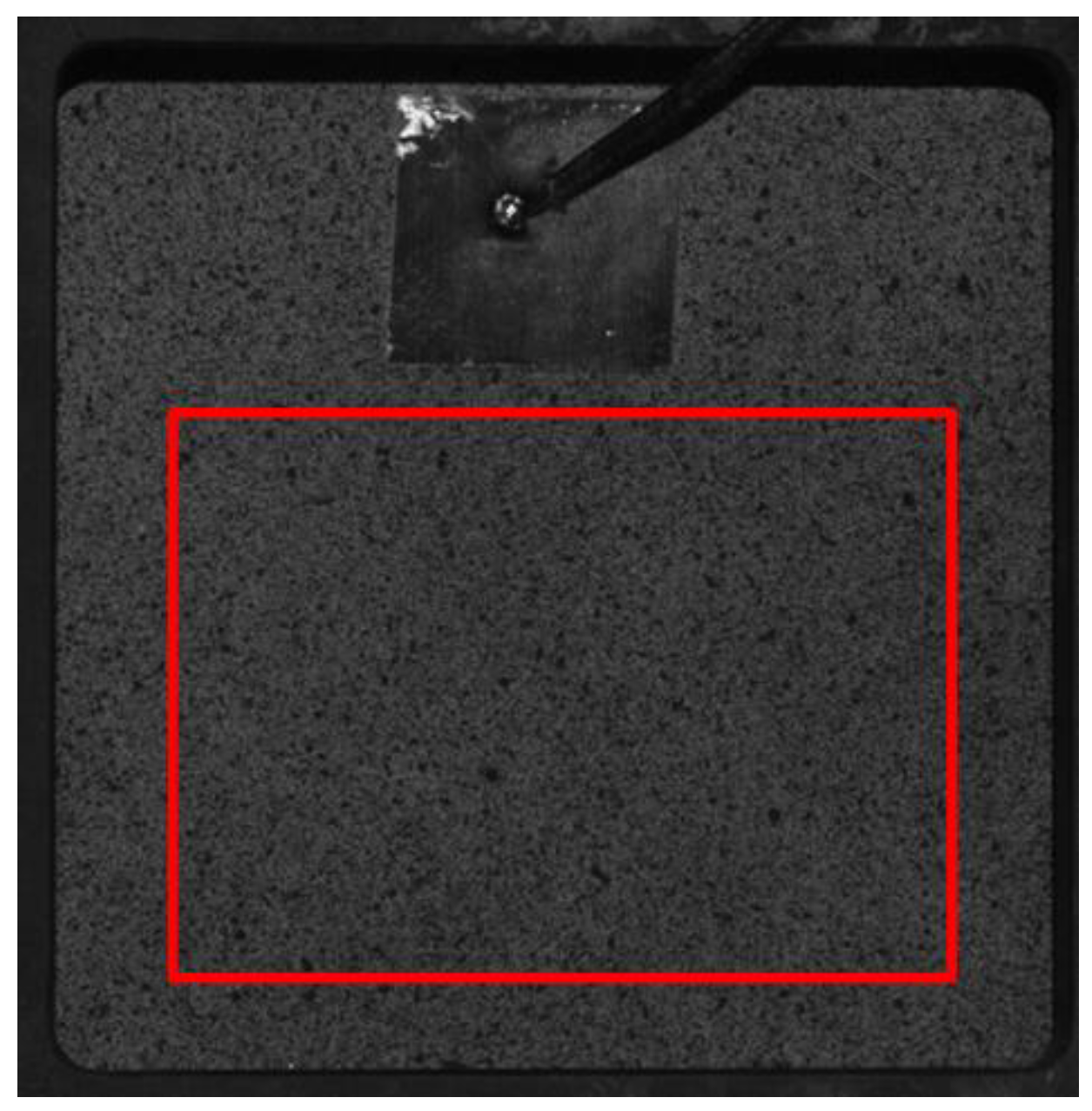

4.2. Proper Speckle Pattern Fabrication

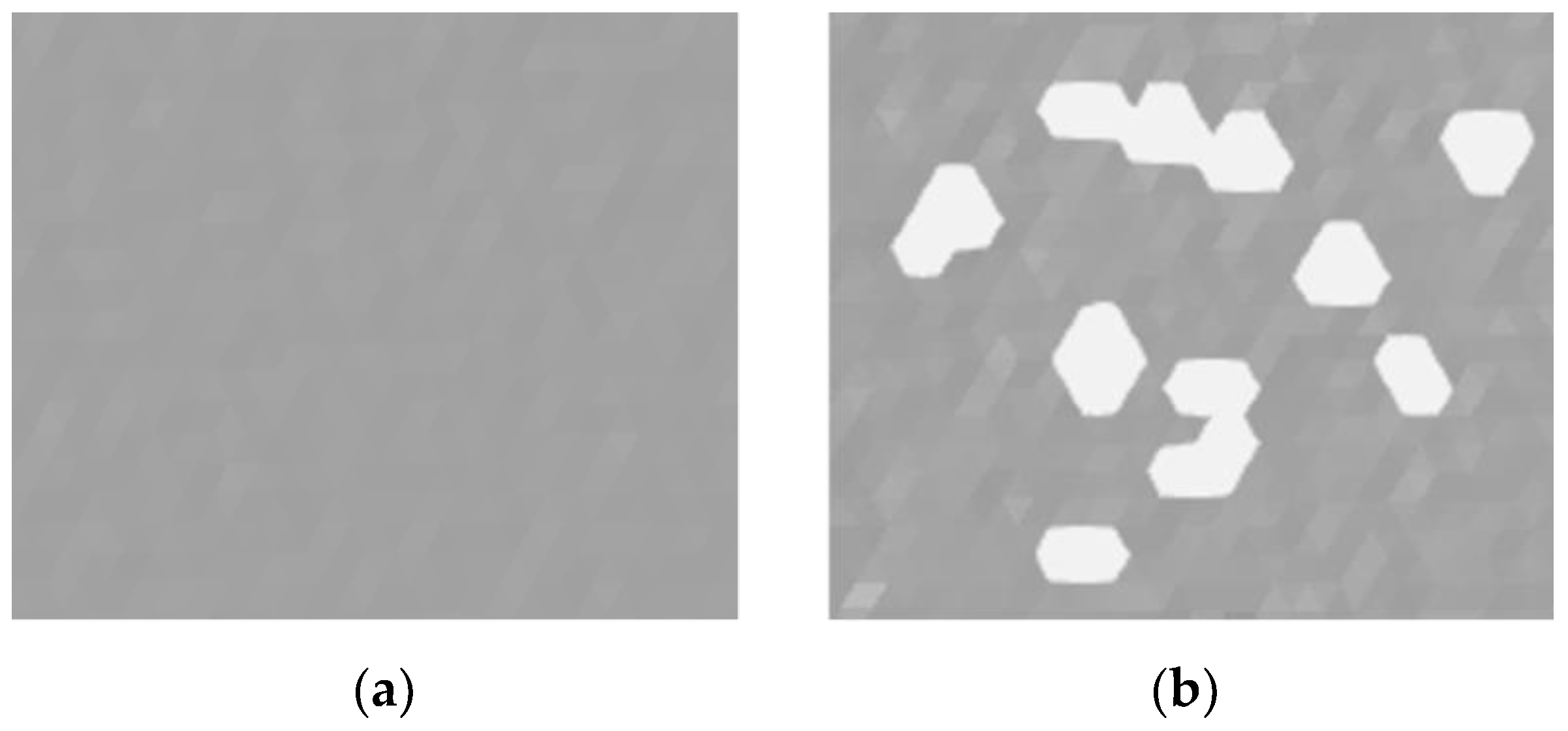

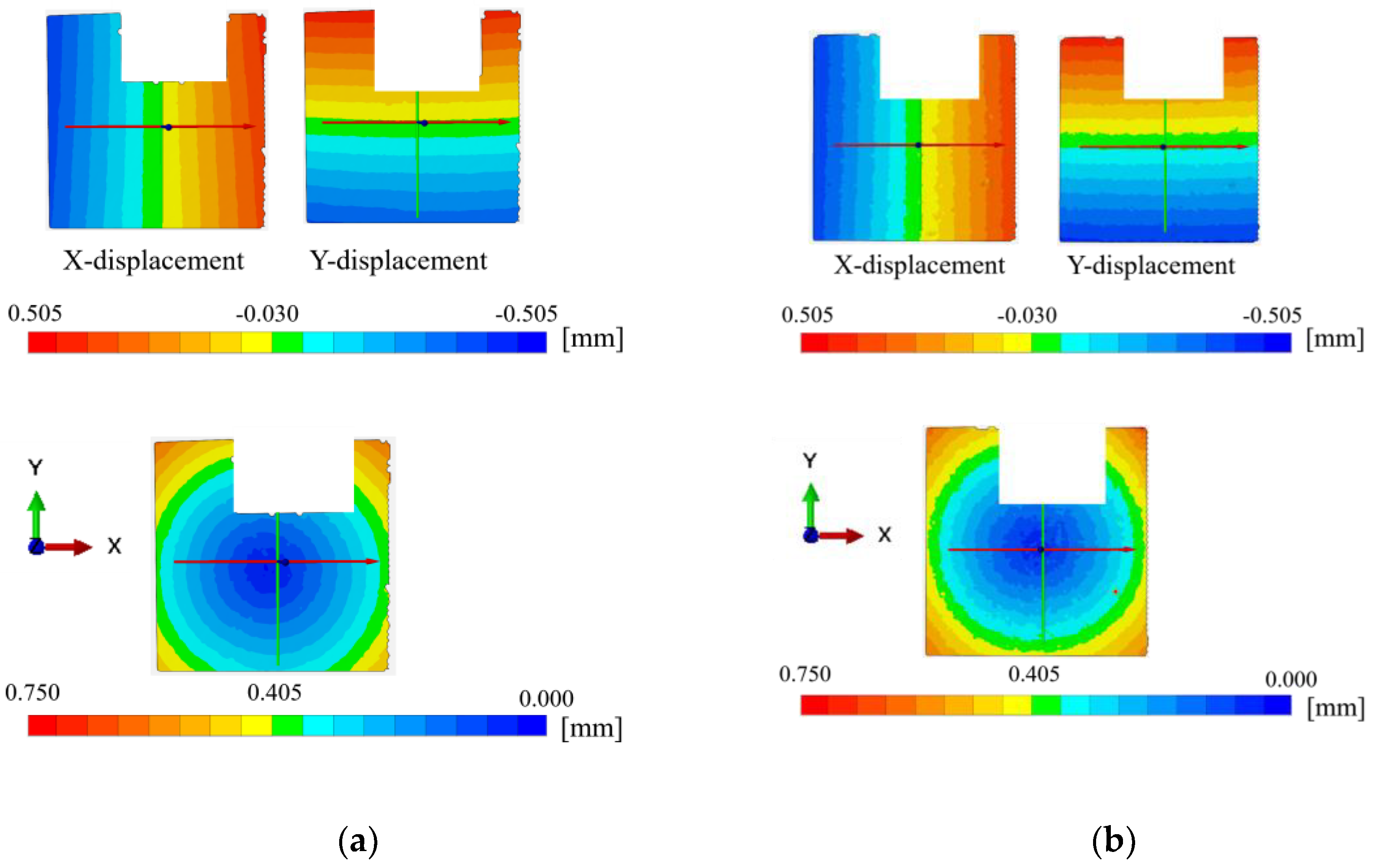

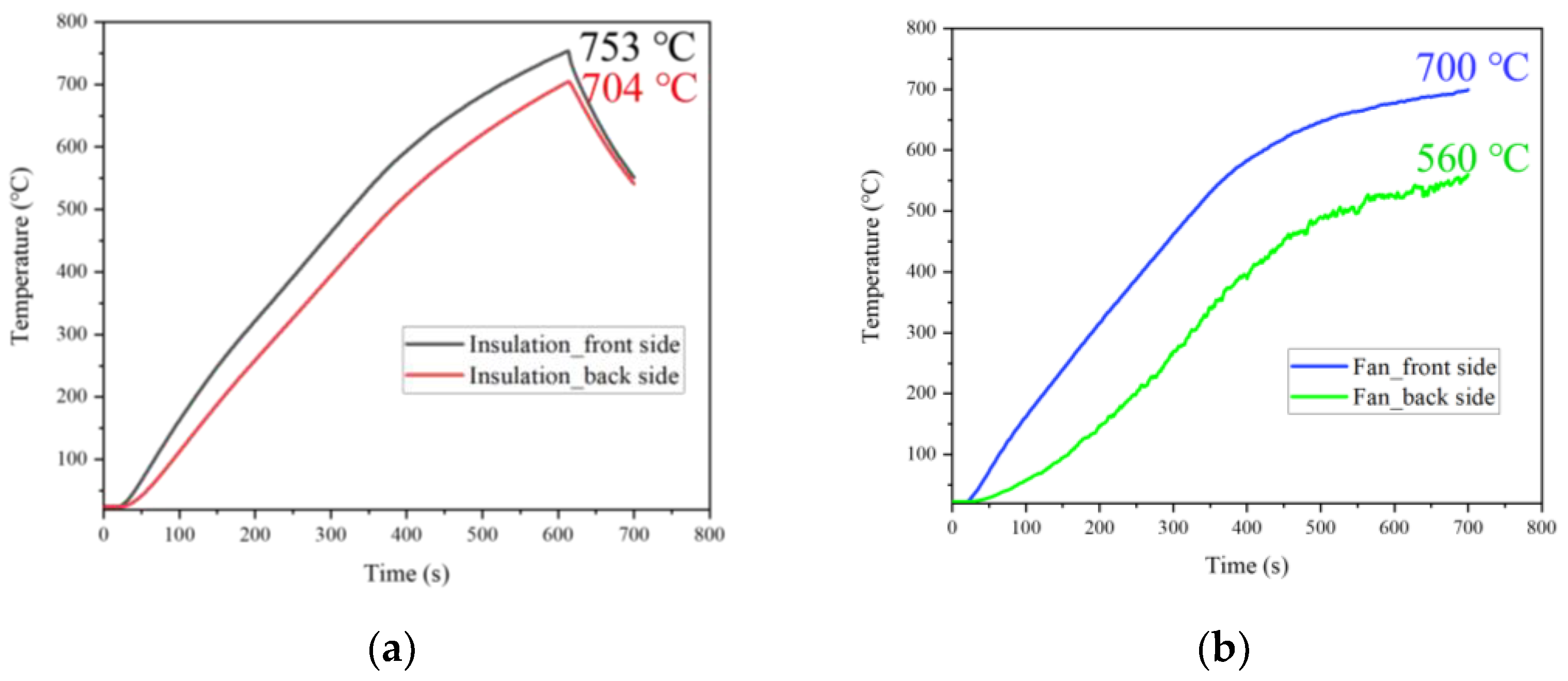

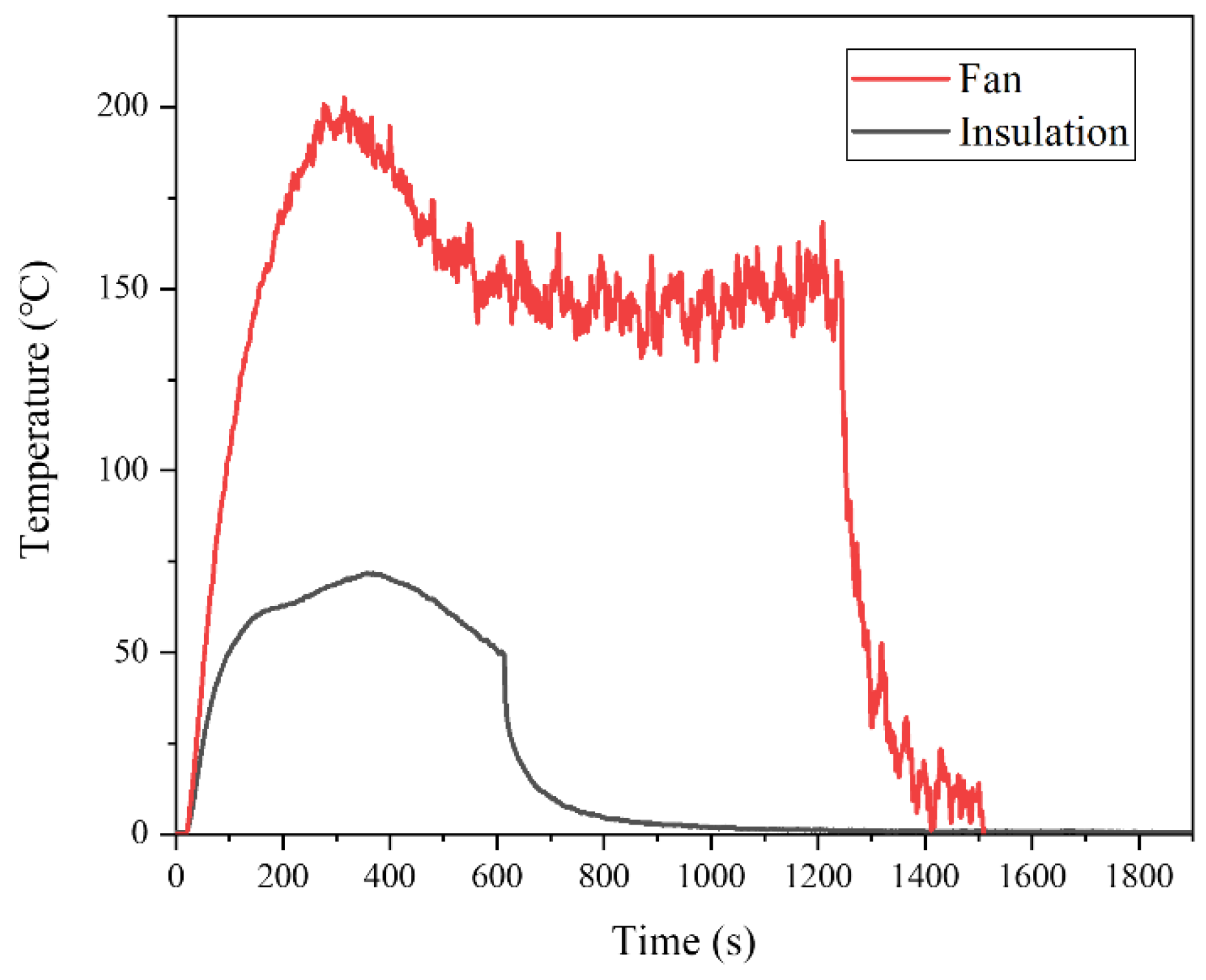

4.3. Heat Haze Effect

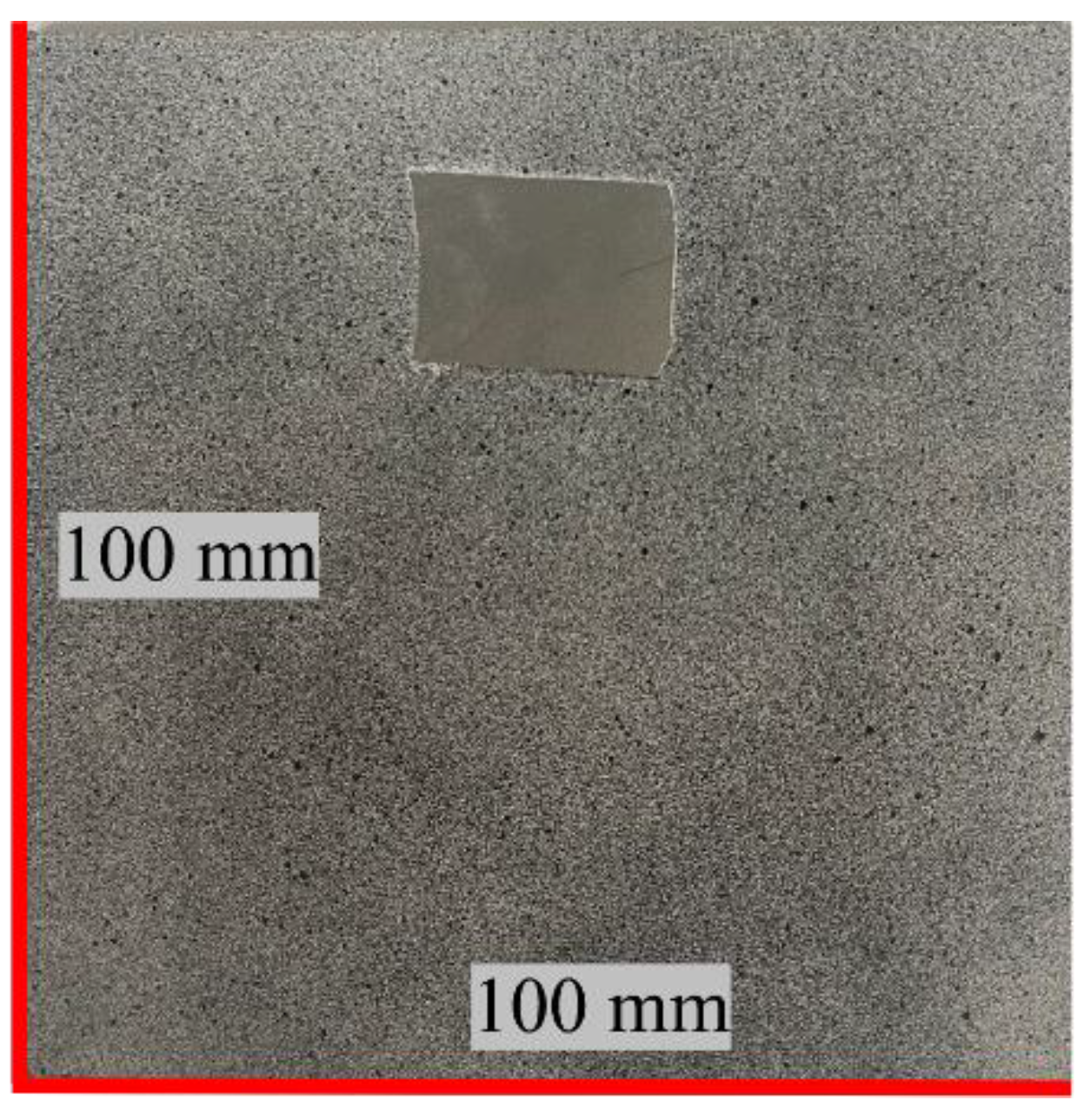

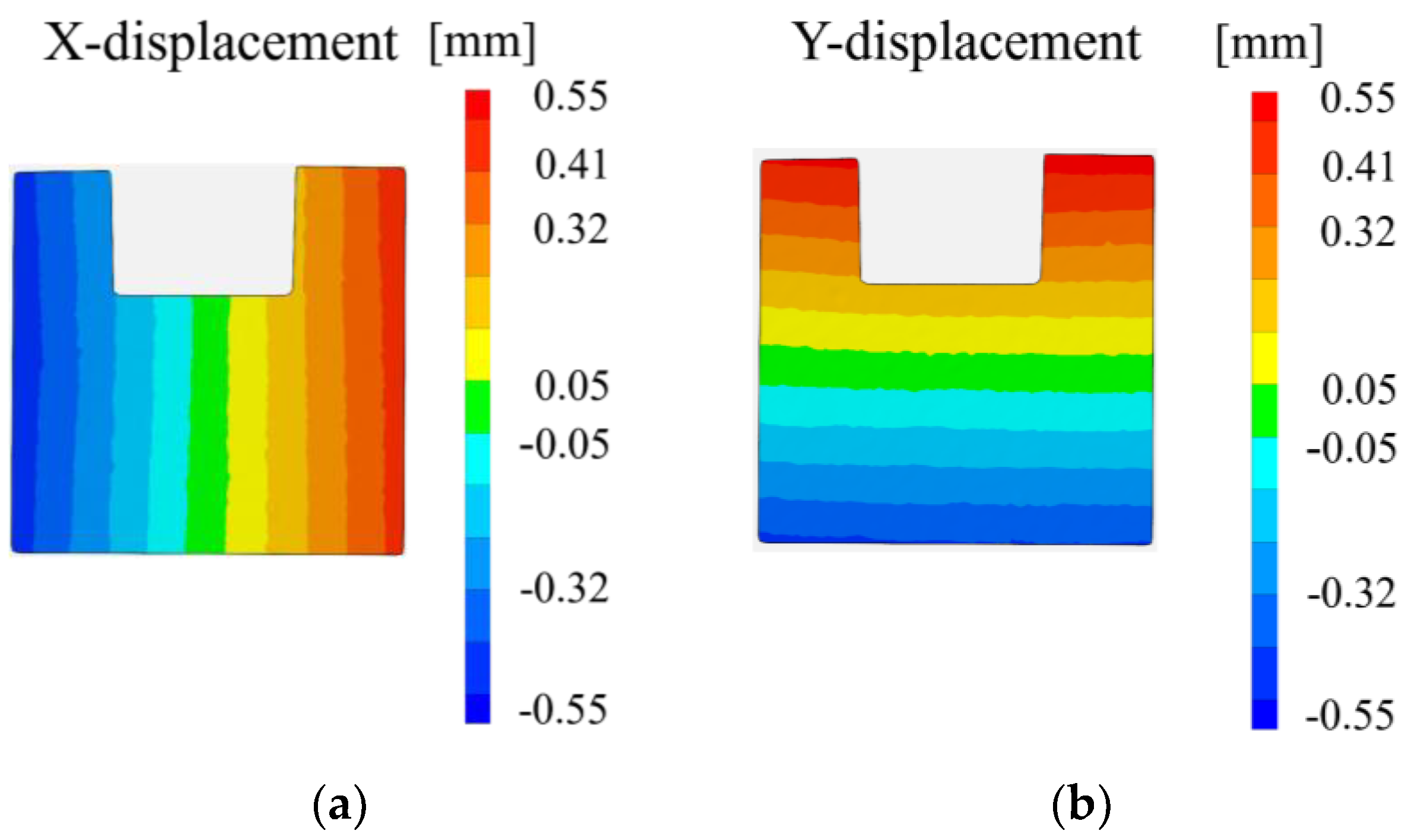

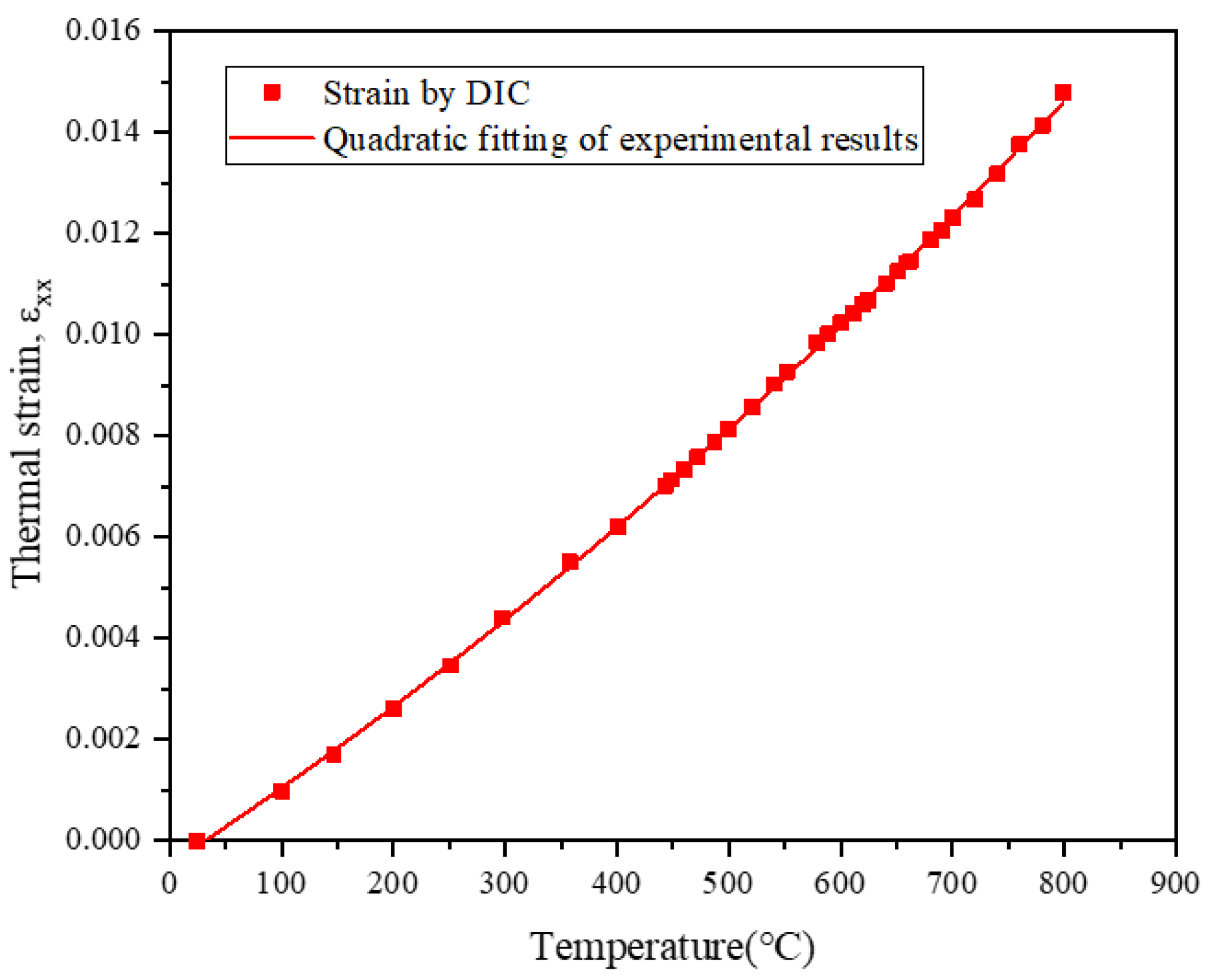

4.4. CTE of a Stainless Steel 304 Specimen

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pineau, A.; Antolovich, S.D. High temperature fatigue of nickel-base superalloys—A review with special emphasis on deformation modes and oxidation. Eng. Fail. Anal. 2009, 16, 2668–2697. [Google Scholar]

- Thornton, E.A. Thermal Structures for Aerospace Applications; AIAA: Reston, VA, USA, 1996. [Google Scholar]

- Sziroczak, D.; Smith, H. A review of design issues specific to hypersonic flight vehicles. Prog. Aerosp. Sci. 2016, 84, 1–28. [Google Scholar] [CrossRef]

- Kayser, P.; Godefroy, J.; Leca, L.J.S.; Physical, A.A. High-temperature thin-film strain gauges. Sens. Actuators A Phys. 1993, 37, 328–332. [Google Scholar] [CrossRef]

- Lee, S.-K.; Yoo, J.-H.; Yang, M.-S. Effect of thermal deformation on machine tool slide guide motion. Tribol. Int. 2003, 36, 41–47. [Google Scholar] [CrossRef]

- Yu, L.; Pan, B. Overview of high-temperature deformation measurement using digital image correlation. Exp. Mech. 2021, 61, 1121–1142. [Google Scholar] [CrossRef]

- Sivanandi, P.; Gupta, C.; Durai, H. A review on evolution of aeroelastic assisted wing. Int. J. Aeronaut. Space Sci. 2023, 24, 652–688. [Google Scholar] [CrossRef]

- Yang, J.S.; Choi, M.K.; Kim, C.-G. Numerical Prediction of the Impact Fracture of a Projectile Through Oblique Target. Int. J. Aeronaut. Space Sci. 2023, 24, 798–811. [Google Scholar] [CrossRef]

- Le, V.T.; Goo, N.S. Dynamic characteristics and damage detection of a metallic thermal protection system panel using a three-dimensional point tracking method and a modal assurance criterion. Sensors 2020, 20, 7185. [Google Scholar] [CrossRef] [PubMed]

- Meyer, P.; Waas, A.M. Measurement of in situ-full-field strain maps on ceramic matrix composites at elevated temperature using digital image correlation. Exp. Mech. 2015, 55, 795–802. [Google Scholar] [CrossRef]

- Liang, J.; Wang, Z.; Xie, H.; Li, X. In situ scanning electron microscopy-based high-temperature deformation measurement of nickel-based single crystal superalloy up to 800 °C. Opt. Lasers Eng. 2018, 108, 1–14. [Google Scholar] [CrossRef]

- Ha, N.S.; Le, V.T.; Goo, N.S.; Kim, J.Y. Thermal strain measurement of austin stainless steel (ss304) during a heating-cooling process. Int. J. Aeronaut. Space Sci. 2017, 18, 206–214. [Google Scholar] [CrossRef]

- Jin, T.; San Ha, N.; Le, V.T.; Goo, N.S.; Jeon, H.C. Thermal buckling measurement of a laminated composite plate under a uniform temperature distribution using the digital image correlation method. Compos. Struct. 2015, 123, 420–429. [Google Scholar] [CrossRef]

- Jin, T.L.; Ha, N.S.; Goo, N.S. A study of the thermal buckling behavior of a circular aluminum plate using the digital image correlation technique and finite element analysis. Thin-Walled Struct. 2014, 77, 187–197. [Google Scholar] [CrossRef]

- Jin, T.L.; Lee, S.H.; Goo, N.S. Thermal stress measurement of a double ring structure using digital image correlation method. Exp. Tech. 2016, 40, 195–205. [Google Scholar] [CrossRef]

- Lyons, J.S.; Liu, J.; Sutton, M.A. High-temperature deformation measurements using digital-image correlation. Exp. Mech. 1996, 36, 64–70. [Google Scholar] [CrossRef]

- Grant, B.M.B.; Stone, H.J.; Withers, P.J.; Preuss, M. High-temperature strain field measurement using digital image correlation. J. Strain Anal. Eng. Des. 2009, 44, 263–271. [Google Scholar] [CrossRef]

- Pan, B.; Wu, D.; Wang, Z.; Xia, Y. High-temperature igital image correlation method for full-field deformation measurement at 1200 °C. Meas. Sci. Technol. 2010, 22, 015701. [Google Scholar] [CrossRef]

- Dong, Y.; Kakisawa, H.; Kagawa, Y. Optical system for microscopic observation and strain measurement at high temperature. Meas. Sci. Technol. 2013, 25, 025002. [Google Scholar] [CrossRef]

- Berke, R.B.; Lambros, J. Ultraviolet digital image correlation (UV-DIC) for high temperature applications. Rev. Sci. Instrum. 2014, 85, 045121. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Pan, B. In-situ 3D shape and recession measurements of ablative materials in an arc-heated wind tunnel by UV stereo-digital image correlation. Opt. Lasers Eng. 2019, 116, 75–81. [Google Scholar] [CrossRef]

- Pan, Z.; Huang, S.; Su, Y.; Qiao, M.; Zhang, Q. Strain field measurements over 3000 C using 3D-Digital image correlation. Opt. Lasers Eng. 2020, 127, 105942. [Google Scholar] [CrossRef]

- Pan, B.; Lu, Z.; Xie, H. Mean intensity gradient: An effective global parameter for quality assessment of the speckle patterns used in digital image correlation. Opt. Lasers Eng. 2010, 48, 469–477. [Google Scholar] [CrossRef]

- Turner, J.L.; Russell, S.S. Application of digital image analysis to strain measurement at elevated temperature. Strain 1990, 26, 55–59. [Google Scholar] [CrossRef]

- Guo, X.; Liang, J.; Tang, Z.; Cao, B.; Yu, M. High-temperature digital image correlation method for full-field deformation measurement captured with filters at 2600 C using spraying to form speckle patterns. Opt. Eng. 2014, 53, 063101. [Google Scholar] [CrossRef]

- Xin, R.; Le, V.T.; Goo, N.S. Buckling identification in composite cylindrical shells with measured imperfections using a Multi-DIC method and finite element analysis. Thin-Walled Struct. 2022, 177, 109436. [Google Scholar] [CrossRef]

- Leplay, P.; Lafforgue, O.; Hild, F. Analysis of asymmetrical creep of a ceramic at 1350 C by digital image correlation. J. Am. Ceram. Soc. 2015, 98, 2240–2247. [Google Scholar] [CrossRef]

- Wang, Y.G.; Tong, W. A high resolution DIC technique for measuring small thermal expansion of film specimens. Opt. Lasers Eng. 2013, 51, 30–33. [Google Scholar] [CrossRef]

- Novak, M.D.; Zok, F.W. High-temperature materials testing with full-field strain measurement: Experimental design and practice. Rev. Sci. Instrum. 2011, 82, 115101. [Google Scholar] [CrossRef]

- Yuile, A.; Schwerz, R.; Röllig, M.; Metasch, R.; Wiese, S. Heat haze effects in thermal chamber tensile tests on Digital Image Correlation. In Proceedings of the 2018 19th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Toulouse, France, 15–18 April 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Davis, J.R. Stainless Steels; ASM International: Almere, The Netherlands, 1994. [Google Scholar]

- Shrivastava, A.; Lambade, V.; Chaudhuri, P. Measurement of Thermal Expansion for Stainless Steel 304, Copper, Aluminium and Brass by Push Rod Dilatometry; Technical report; IPR/TR-603; Institute for Plasma Research: Gandhinagar, India, 2020. [Google Scholar]

- Gschneidner, K.A.; Beaudry, B.J.; Capellen, J. Properties and selection: Nonferrous alloys and special-purpose materials. In Metals Handbook, 10th ed.; ASM International: Almere, The Netherlands, 1990; Volume 2, pp. 720–732. [Google Scholar]

| Length | Width | Height | Measuring Volume | Camera Angle | Calibration Deviation |

|---|---|---|---|---|---|

| 130 mm | 130 mm | 90 mm | 130 × 110 × 90 mm3 | 11.0° | 0.029 pixels |

| No. | Figure 6 Dot Diameter (mm) | Figure 7 Dot Diameter (mm) |

|---|---|---|

| 1 | 0.270 | 0.121 |

| 2 | 0.247 | 0.111 |

| 3 | 0.215 | 0.086 |

| 4 | 0.168 | 0.111 |

| 5 | 0.217 | 0.234 |

| 6 | 0.213 | 0.123 |

| 7 | 0.225 | 0.094 |

| 8 | 0.284 | 0.131 |

| 9 | 0.202 | 0.161 |

| Average | 0.227 | 0.130 |

| Temperature | X-Directional Strain (εxx) | Difference with Respect to “With Insulation” Condition | |

|---|---|---|---|

| Without any devices | 500 °C | 1.20% | 42.9% |

| Fan | 500 °C | 1.12% | 33.3% |

| Insulation | 500 °C | 0.84% | 0% |

| Front Side | Back Side | Difference | Strain | Strain Difference | |

|---|---|---|---|---|---|

| Fan | 482 °C | 280 °C | 202 °C | 0.55% | 27.9% |

| Insulation | 343 °C | 280 °C | 63 °C | 0.43% |

| Temperature Range | 25 to 500 °C | 25 to 600 °C | 25 to 700 °C | 25 to 800 °C |

|---|---|---|---|---|

| Reference CTE (ppm/°C) | 17.9 | 18.3 | 18.8 | 19.2 |

| Experimental CTE (ppm/°C) | 17.6 | 18.3 | 18.8 | 19.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.M.; Goo, N.S. High-Temperature DIC Deformation Measurement under High-Intensity Blackbody Radiation. Aerospace 2024, 11, 479. https://doi.org/10.3390/aerospace11060479

Han SM, Goo NS. High-Temperature DIC Deformation Measurement under High-Intensity Blackbody Radiation. Aerospace. 2024; 11(6):479. https://doi.org/10.3390/aerospace11060479

Chicago/Turabian StyleHan, Seng Min, and Nam Seo Goo. 2024. "High-Temperature DIC Deformation Measurement under High-Intensity Blackbody Radiation" Aerospace 11, no. 6: 479. https://doi.org/10.3390/aerospace11060479

APA StyleHan, S. M., & Goo, N. S. (2024). High-Temperature DIC Deformation Measurement under High-Intensity Blackbody Radiation. Aerospace, 11(6), 479. https://doi.org/10.3390/aerospace11060479