1. Introduction

The 4R-UAV project is supported by the Latvian Council of Science to develop aerodynamically efficient, environmentally friendly UAVs. According to the European Commission as part of the European green deal [

1], the EU is responsible for 10% of global greenhouse gas emissions and is a worldwide leader in transitioning towards a net-zero-greenhouse gas emissions economy. The EU has set an objective of reducing emissions by 80–95% by 2050. The existing 3R (Reduce, Recycle, Reuse) based on circular economy is insufficient for the aviation industry; the secret to Circular Aviation is 4R (Reduce, Recycle, Reuse, Redesign), which is only possible with improved aerodynamic designs for future aircraft/UAVs. The most significant aspect of 4R is “Redesign”; a highly improved design of aircraft is crucial for future zero-emission and climate neutrality goals. Therefore, aerodynamic improvements in the existing designs are the key to achieving this goal.

In order to achieve this goal, this study is specifically dedicated to investigations into the performance improvement of the 4R-UAV wing by implementing the PFCDs (Passive Flow Control Devices). Two types of PFCDs, i.e., MVGs (Micro Vortex Generators) and winglets, were designed, optimized, and analyzed for final implementation on the 4R-UAV wing. The idea of such PFCDs is not new at all, and they have been successfully implemented for decades in large-scale aircraft; however, designing and implementing MVGs and winglets on a small-scale UAV with a wingspan of less than 2 m is not very common in nature, as information on PFCDs for low Re small-scale UAVs is limited. This limitation is further affected due to the requirement for decreased UAV weight and precise manufacturing (of small-scale MVGs with a height less than 1 mm). Additional challenges appear in designing, optimizing, integrating, and finally retrieving the enhanced performance for such small-scale UAV wings.

To understand the fundamental nature of the PFCDs, during recent decades, researchers have extensively investigated methods of optimization of UAVs using different wings, fuselage shapes, the application of passive flow control methods, etc. For instance, the bioinspired technique of leading-edge serrations has been investigated for different purposes experimentally and numerically. Wang and Zhuang [

2] designed modified wind turbine blades with sinusoidal wave serrations applied on the leading edge to control the boundary layer separation in near-stall conditions. The numerical results of this study indicated that the leading-edge serration delayed the flow separation by employing the generation of the counter-rotating vortex pairs at a high angle of attack. In another study, Cai et al. [

3] numerically investigated a modified airfoil with a single leading-edge protuberance at a low Reynolds number. Only one leading-edge serration was designed to isolate the serration geometry’s impact on the wings’ aerodynamic characteristics. The results showed that the stall angle of the modified airfoil was reduced compared to the original design. Furthermore, the pre-stall performance of the modified airfoil was decreased, whereas post-stall characteristics were enhanced. Moreover, Wei et al. [

4] performed another experimental study that investigated the hydrodynamic characteristics of hydrofoils with leading-edge serrations at the Reynolds number of 1.4 × 10

4. The results of this study revealed that the effects of flow separation declined with the use of leading-edge serrations.

Another passive flow control method was designed by Kasper [

5], which proposed the application of airfoils with a cavity. Theoretically, the principle of this concept was to create a convenient pressure gradient when two counter-rotating vortices inside the cavity are produced. These generated eddies over the suction surface can ensure an extra low-pressure region and cause a lower drag produced by the airfoil. This method has gained interest among aerodynamic researchers. Olsman and Colonius [

6] investigated an airfoil with a cavity at a Reynolds number of 2 × 10

4. Their results revealed that the stall phenomenon was delayed utilizing counter-rotating separated flows, resulting in a reduced flow separation region. Still, aerodynamic efficiency (lift-to-drag ratio) throughout most AOA regimes was unclear in that study. A detailed numerical analysis regarding the aeroacoustics of NACA 0018 cavitied airfoil was reported by Lam and Leung [

7] and Olsman [

8] at Reynolds number 2 × 10

4. Cavitied airfoil produced less acoustic power, making it a less noisy airfoil design at low Reynolds number regimes compared to baseline designs. However, aerodynamic efficiency (C

L/C

D ratio) throughout most AOA regimes remains questionable.

Another approach to flow control is the application of the material surface roughness. The boundary layer flow gains momentum employing this passive flow control method, so the separated flow may be suppressed with re-energized flows, resulting in more stable flow characteristics without boundary layer separation [

9]. The flow control method, by applying roughness material, is performed by intervening in the flow with the help of vortexes. Vortex sheds produced by roughness cause the flow in the boundary layer to gain more energy. Energized flow mixes with the boundary layer, thus suppressing flow separation and ensuring the flow moves along the airfoil surface. Vortex shedding can be used for different purposes over the surface of wings. For instance, the study conducted on the turbine blades of the gas turbine engine by Bai et al. [

10] showed that the surface roughness could weaken the separation bubble of the turbine blade at a low Reynolds number, thus reducing the aerodynamic loss while, at high Reynolds number, the surface roughness will trigger transient progress so that the losses can increase significantly.

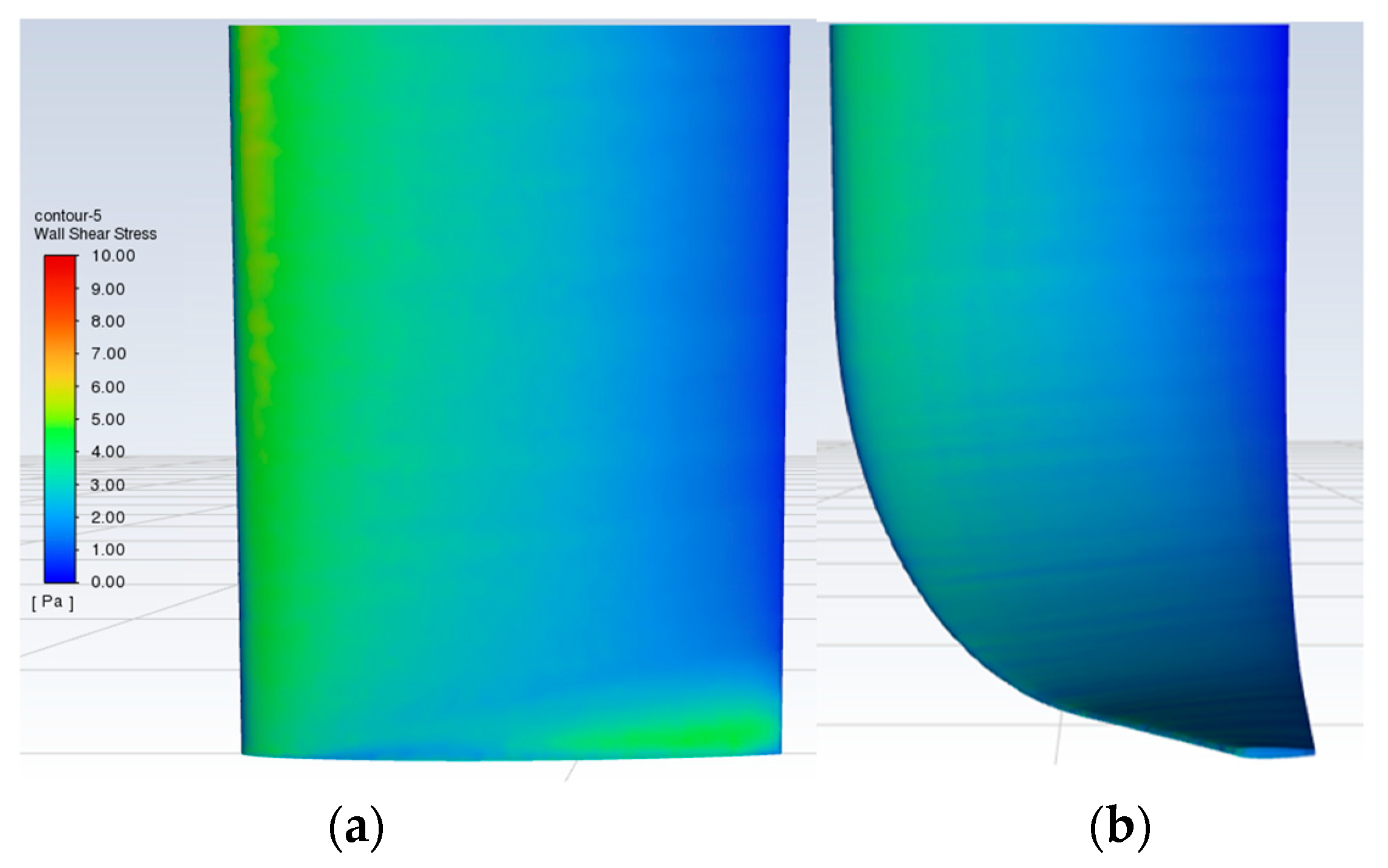

VGs (Vortex Generators) are another type of passive flow control that provides stall delay by producing counter-rotating vortices that induce mixing of high and low momentum flows by transforming the laminar flow into turbulent flow in the near-wall regions [

11]. VGs were employed in studies for reducing noise caused by flow separation, for reducing afterbody drag of fuselage and also for enhancing the performance of wind turbines. Many researchers have efficiently implemented Micro-Vortex Generators (MVGs). For example, Jirásek [

12] and many others efficiently implemented Micro-Vortex Generators (MVGs) in UAVs for the flow control of the S-duct diffuser inlet section. Dol [

13] enhanced the lift force of UAV from 160 N to 192 N and implemented VGs (at the leading edge of the wing) for lift improvement. These studies were good inspiration for implementing MVGs on the authors’ small-scale 4R-UAV wings, even though they were implemented on medium or larger-scale UAVs. Based on this, the authors performed a short study [

14] by implementing a limited number of MVGs on a small section of a UAV. Three types of MVGs (delta, rectangular, and trapezoidal) were designed and optimized for the small wing section at 19% chord location. The study was mainly conducted to see which type of MVGs are suitable for small-scale UAVs. With limited implementation, the trapezoidal MVGs performed relatively better than the other types. After the previous (preliminary) results, this paper extensively investigates the trapezoidal MVGs on the full wing of 4R-UAV, along with the winglets (as the two PFCDs).

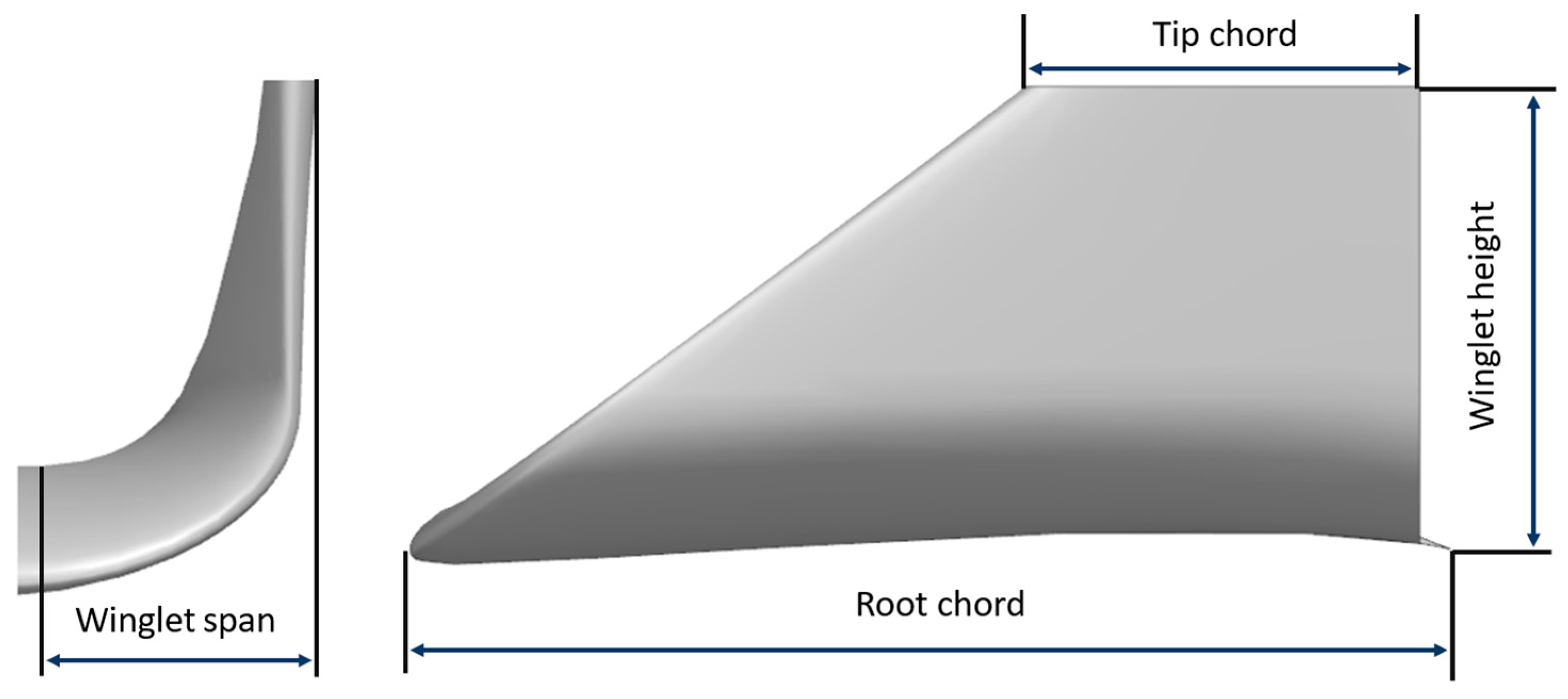

NASA developed the concept of winglets in the 1970s, using multiple designs for different aircraft. Winglets are somewhat common for aircraft and have proven to improve the overall efficiency of large-scale wings for subsonic speed; however, implementing winglets on UAVs that commonly operate at low Reynolds numbers is extremely rare. Very limited work can be found in the literature and, especially. the winglets for small-scale UAVs are novel. R. Dagur [

15] investigated the application of winglets on an operating UAV. A decrease in drag of 2.1% and 1.64% at 4° and 8° angles of attack was observed in the study. Similarly, Panagiotou [

16] used blended winglets for MALE UAVs and found a significant rise in the UAV’s aerodynamic performance and a 10% increase in endurance. Turanoğuz [

17] studied the application of winglets on a large-scale tactical UAV with a payload of 60 kg and a wingspan of 10 m. The investigations were conducted on three wing configurations (one baseline wing and two wings with winglets). As the investigations were performed on the large-scale UAV, the best-performing winglets exhibited improvement of up to 8% in C

L/C

D ratio, compared to the baseline design. These studies are good motivation, but as mentioned earlier, for small-scale UAVs, it is always a concern, due to the very small wingspan range of 0.5–2 m and operation at lower altitudes and speeds. Metrinho [

18] designed a variable-span morphing wing for a small-scale UAV and performed experiments for performance evaluation. At the cruising speed, the drag force was reduced by 20% compared to that of fixed-wing aircraft. The morphed wing is not exactly a winglet, but the study showed that the wing geometry alteration might deeply impact the performance.

In this study, a stepwise approach was adopted to investigate the feasibility of the PFCDs on the small-scale 4R-UAV’s wing. The baseline wing was designed with the authors’ SG6043mod airfoil, which was optimized for low Re range and enhanced aerodynamically. PFCDs (MVGs and winglets) were investigated in the next step by implementing them on the baseline wing. Finally, the overall impact of the PFCDs on the baseline wings was analyzed to understand the feasibility of their implementation in small-scale UAVs. The study found that both the PFCDs provided their respective benefits. For example, MVGs enhanced the wing’s near-stall properties and delayed the stall by up to 2°, while the wing’s maximum lift was increased up to 6% mainly at later angles of attack. Winglets, on the other hand, were especially useful at the lower angles of attack and enhanced pre-stall properties by decreasing the induced drag and improving the aerodynamic performance by more than 8%. Both the MVGs and winglets, when installed on the 4R-UAV wing, enhanced the overall aerodynamic performance at all angles of attack. In summary, the study successfully implements PFCDs on the small-scale UAV (4R-UAV) wing and recommends their use, together or separately, based on the mission requirements.

2. Investigation Methodology

For a smooth workflow, this computational study was performed in defined steps. In the first step, the baseline wing was designed after a series of aerodynamic and geometric calculations (based on the future 4R-UAV variants). Based on the authors’ previous study [

19] conducted for the aerodynamic improvement of the UAV wings, the wing of the small-scale 4R-UAV (in this study) was designed from the aerodynamically optimized airfoil. In the next step, the implementation of the Passive Flow Control Devices (PFCD) was carried out in two sub-steps: (i) Micro Vortex Generators (MVGs) and (ii) winglets. A short study on the MVGs on a wing segment was conducted by [

14] and, based on this, the implementation of MVGs was investigated for the performance analysis of the full-scale wing of the 4R-UAV. For the winglet(s) investigations, a detailed analysis was performed to design and optimize winglets suitable for the small-scale UAV class. In the final step, aerodynamic performance analysis was carried out for the full-scale 4R-UAV with integrated MVGs and (the most appropriate) winglets.

Figure 1 illustrates the workflow diagram of the implementation steps.

For the 4R-UAV wing design, the SG6043mod airfoil was chosen for its proven aerodynamic capabilities. This airfoil was developed by [

19] and was aerodynamically optimized for low Re and small-scale applications. The SG6043mod airfoil provides an enhanced lift-to-drag ratio as this is vital for the performance and endurance of the aircraft. A detailed comparison between the ordinary wing designed from the SG6043 and the optimized SG6043mod airfoil has already been studied by [

19], where the optimized wing manifested enhanced aerodynamic performance (compared to that of the parent wing). The original SG6043 airfoil (developed by Selig and Giguere [

20]) possesses several qualities that are advantageous in terms of endurance, which is a primary concern of today’s electrically powered UAVs. On the other hand, the SG6043mod is the optimized airfoil providing improved aerodynamic characteristics for the low Reynolds number range of 3 × 10

5 [

19]. 4R-UAV, which is a small-scale UAV, is designed to operate in the Re range of 2.5 × 10

5–3 × 10

5. Based on these advantages of SG6043mod airfoil, the baseline wing was designed from this airfoil.

Figure 2 shows the enhanced drag polar of the optimized airfoil (SG6043mod) compared to the original airfoil (SG6043). In summary, the first stage of the aerodynamic improvement for the 4R-UAV was already attained at the wing design stage.

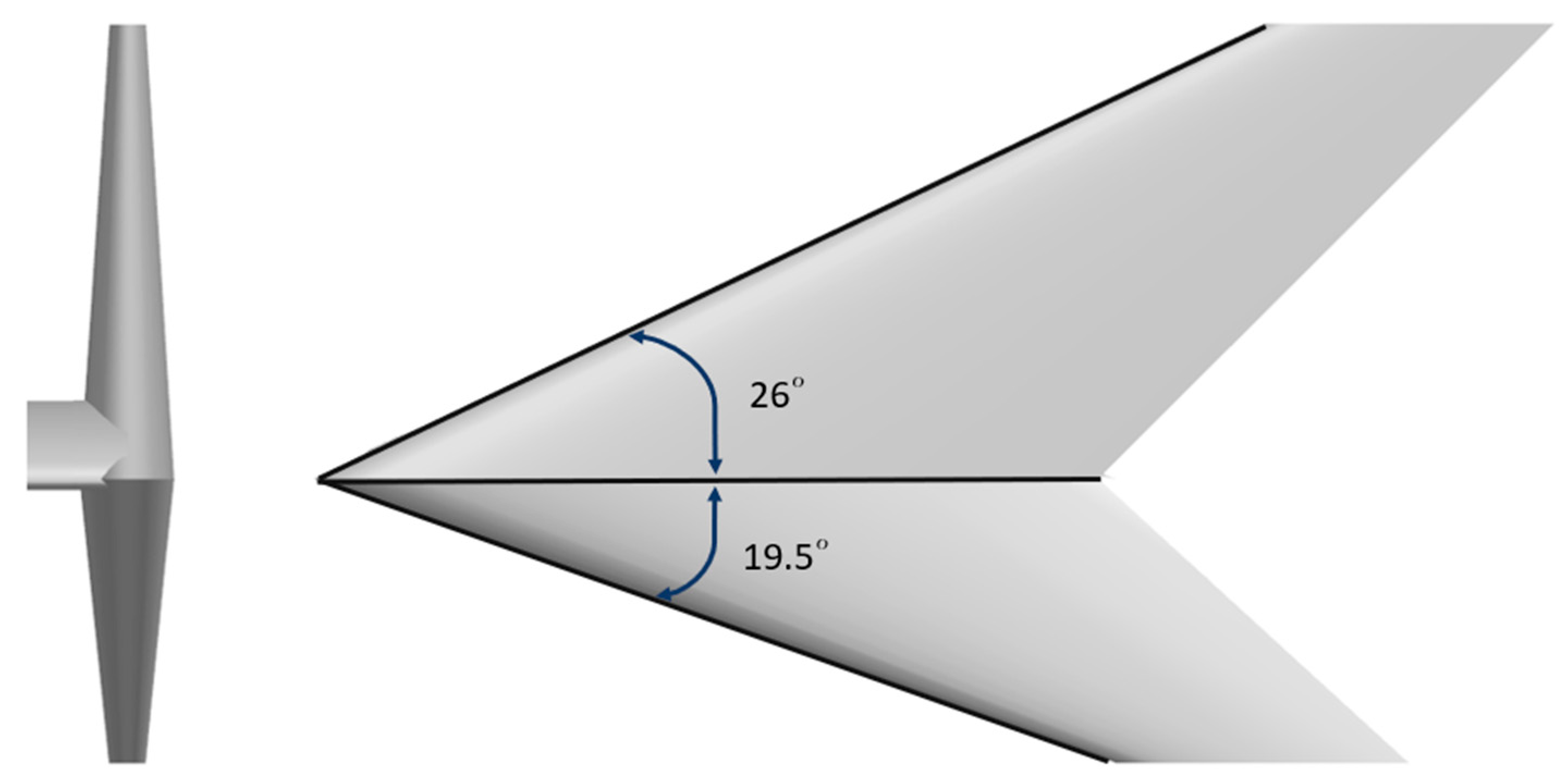

As 4R-UAV is not designed for a specific mission, the main goal is to design a multipurpose small-scale UAV for a range of civilian and defense applications. For the wing design parameters, Xiong [

21] suggested the relationship between the wingspan range and the maximum takeoff weight. Based on Xiong’s [

21] work, a range of 4–6 kg maximum takeoff weight and 1.5–2.0 m wingspan were selected as the initial design parameters of the 4R-UAV.

The weight to wingspan ratio is given in Equation (1):

where:

For the maximum takeoff weight of 6 kg, the calculated value (from Equation (1)) for the wingspan of the 4R-UAV was 1.86 m.

In the next step, wing surface area and lift force were evaluated. For the wing surface area, [

22] and other studies [

13,

21,

22,

23] suggested an iterative approach for the selection of cruising angle of attack and surface area. For this, the authors’ previous study [

19] was found to be useful, which provided an initial approximation for the wing area and expected values of C

L.

Figure 3 illustrates the C

L variations with angle of attack for the wing designed from SG6043mod airfoil for light aircraft applications. Usually, a hit and trial-based iterative analysis is relied on for the cruising angle and surface area calculations. Therefore, after the initial iterative analysis, a CFD analysis of the initial wing segment was carried out.

Figure 4 shows the plot of the aerodynamic efficiency against the angle of attack, where the maximum efficiency can be observed at 4° angle of attack. Based on this, the 4° angle was chosen as the cruising angle of the 4R-UAV. The surface area of the wing was calculated at the 4° cruising angle from the lift equation:

where: L—lift;

CL—lift coefficient;

r—air density;

V—freestream velocity;

S—wing area.

Figure 3.

Relation between lift coefficient and angle of attack of SG6043mod.

Figure 3.

Relation between lift coefficient and angle of attack of SG6043mod.

Figure 4.

Lift-to-drag ratio of the baseline wing segment vs. AOA.

Figure 4.

Lift-to-drag ratio of the baseline wing segment vs. AOA.

The calculated wing surface area was 0.289 m

2 at the planned cruise speed of 20 m/s, while the minimum chord length was calculated as 0.1558 m. In order to reduce the required angle of attack or flight speed, a safe chord length and surface area were chosen as 0.18 m and 0.334 m

2, respectively, for the final wing.

Table 1 summarizes the design parameters of the UAV baseline wing, while the 3D CAD model of the baseline wing is illustrated in

Figure 5.

4. Discussion and Conclusions

This investigative study tried to answer a unique question regarding the implementation of passive flow control devices (PFCDs) on small-scale low-speed UAVs. The use of winglets and Vortex Generators (VGs) for small-scale, low-speed UAVs is not very popular among researchers due to manufacturing complications and limited known benefits. The 4R-UAV project concerns innovations in aircraft/UAV designs and promoting green technologies in aviation. The project’s two main objectives are green manufacturing (additive manufacturing) and aerodynamically improved designs for aircraft/UAV components. For small-scale UAV classes, 3D printing-based additive manufacturing techniques provide possibilities for improved designs and complex geometries without the usual restrictions of conventional manufacturing. Thanks to modern 3D printing and additive manufacturing techniques, the realization of PFCD-integrated wings, even for small-scale UAVs, has become possible.

In this work, two PFCDs (MVGs and winglets) were investigated for a small-scale UAV wing (span less than 2 m). Both the winglets and MVGs provided their benefits simultaneously. Regarding the feasibility of the PFCDs for small-scale low-speed UAV wings (which was the main question), this study provides a positive answer depending on the applications and mission requirements. Even though the improvement is limited, at this small-scale low-speed and low altitudes, 5–10% performance improvement is considerable. For example, for UAV missions where higher angles of attack are important for stability (military predator UAV types), MVGs are a good choice for performance improvement and delayed stall. Winglets, on the other hand, are good for cruise flight conditions at lower angles of attack, which in turn provides positive impact on UAV endurance. Depending on the users’ requirements, the UAV can be equipped with either one of the PFCDs (winglets or MVGs) or both combined. In our case, future 4R-UAVs will be manufactured with wings integrated with both winglets and MVGs in order to gain the maximum aerodynamic advantage for all AOA ranges.

Following conclusions can be drawn from the study:

The computational based analysis of this study shows that PFCDs (Passive Flow Control Devices) are feasible for improving the aerodynamic performance of small-scale UAV wings.

Both the PFCDs investigated in this study (winglets and MVGs) improved the aerodynamic performance specifically, during the cruise and near-stall conditions.

The aerodynamic advantage (in terms of aerodynamic performance) achieved for the small-scale UAV’s wing is limited, but can be advantageous for different mission requirements.

MVGs (Micro Vortex Generators) enhanced the wing’s near-stall properties, especially in terms of maximum lift coefficient (up to 6% increase) and stall delay (up to 2°).

Winglets (blended winglets, configuration 4 in this study) enhanced pre-stall properties by decreasing the drag (up to 10%) of the wing.

PFCDs integrated to wing together, also provided a positive trend in performance improvement with nearly 6% aerodynamic efficiency in cruise conditions.

Further investigations are planned in the future for the verification of the results by wind tunnel experiments and 4R-UAV flight testing.