Regression Rate and Combustion Efficiency of Composite Hybrid Rocket Grains Based on Modular Fuel Units

Abstract

1. Introduction

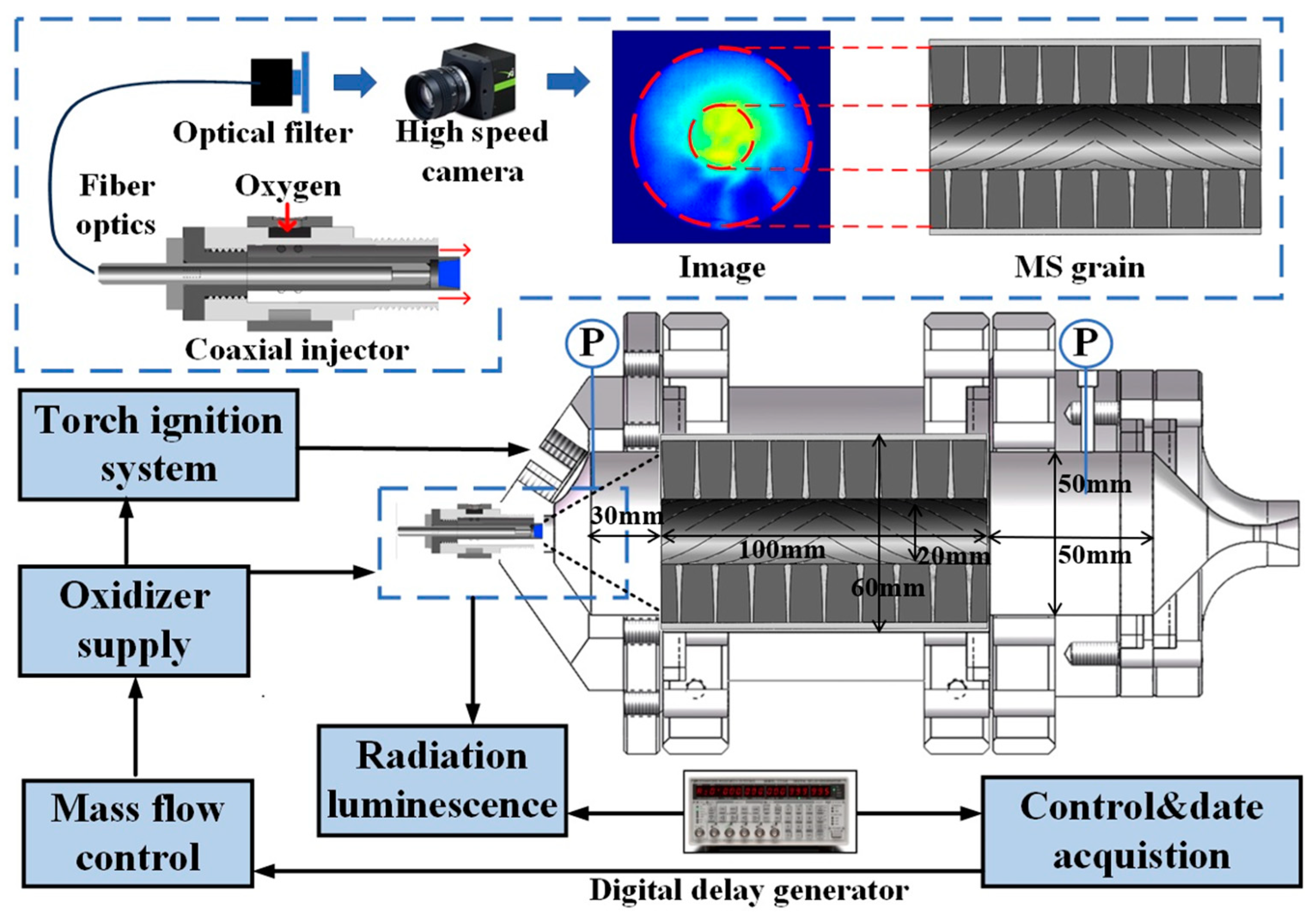

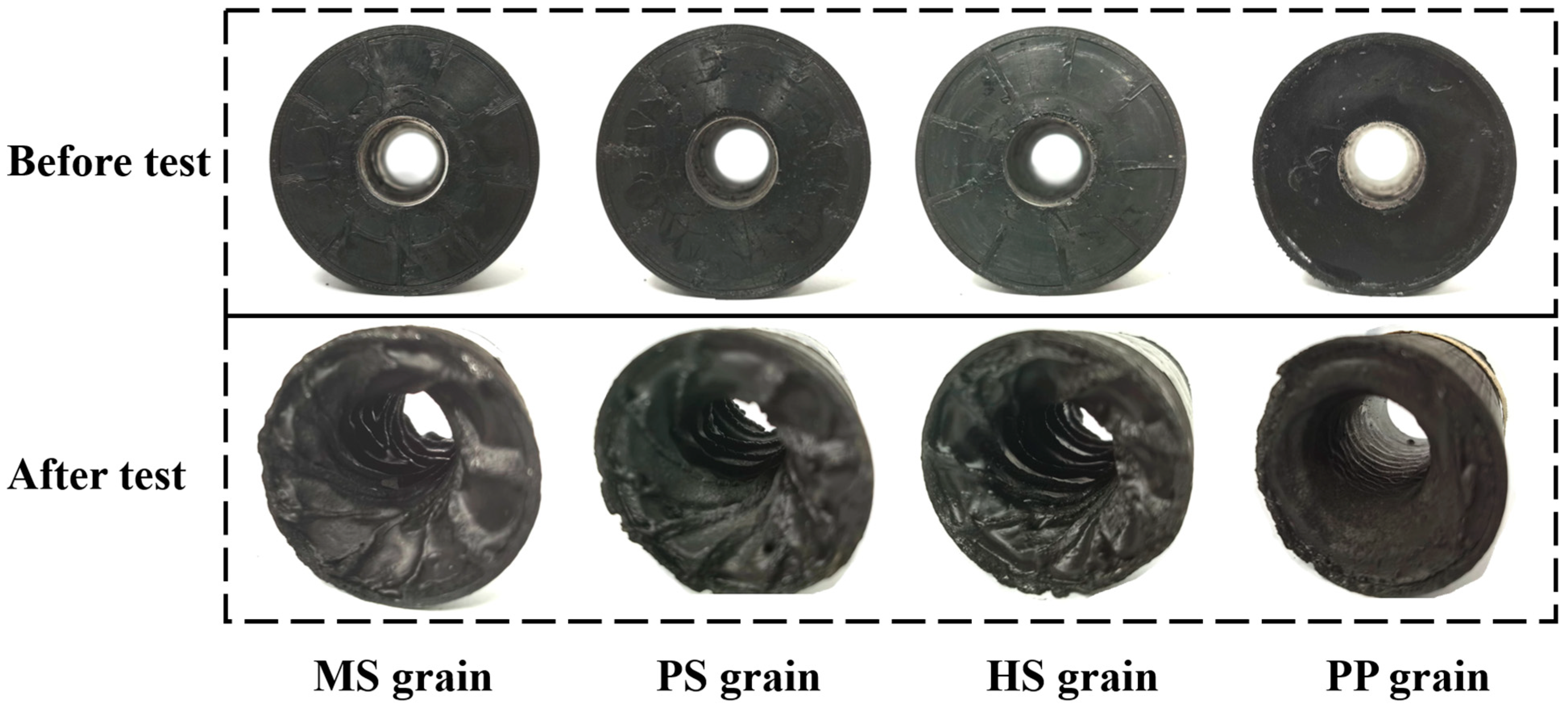

2. Materials and Methods

2.1. Modular Unit Framework

2.2. Laboratory-Scale Hybrid Rocket Engine

3. Results and Discussion

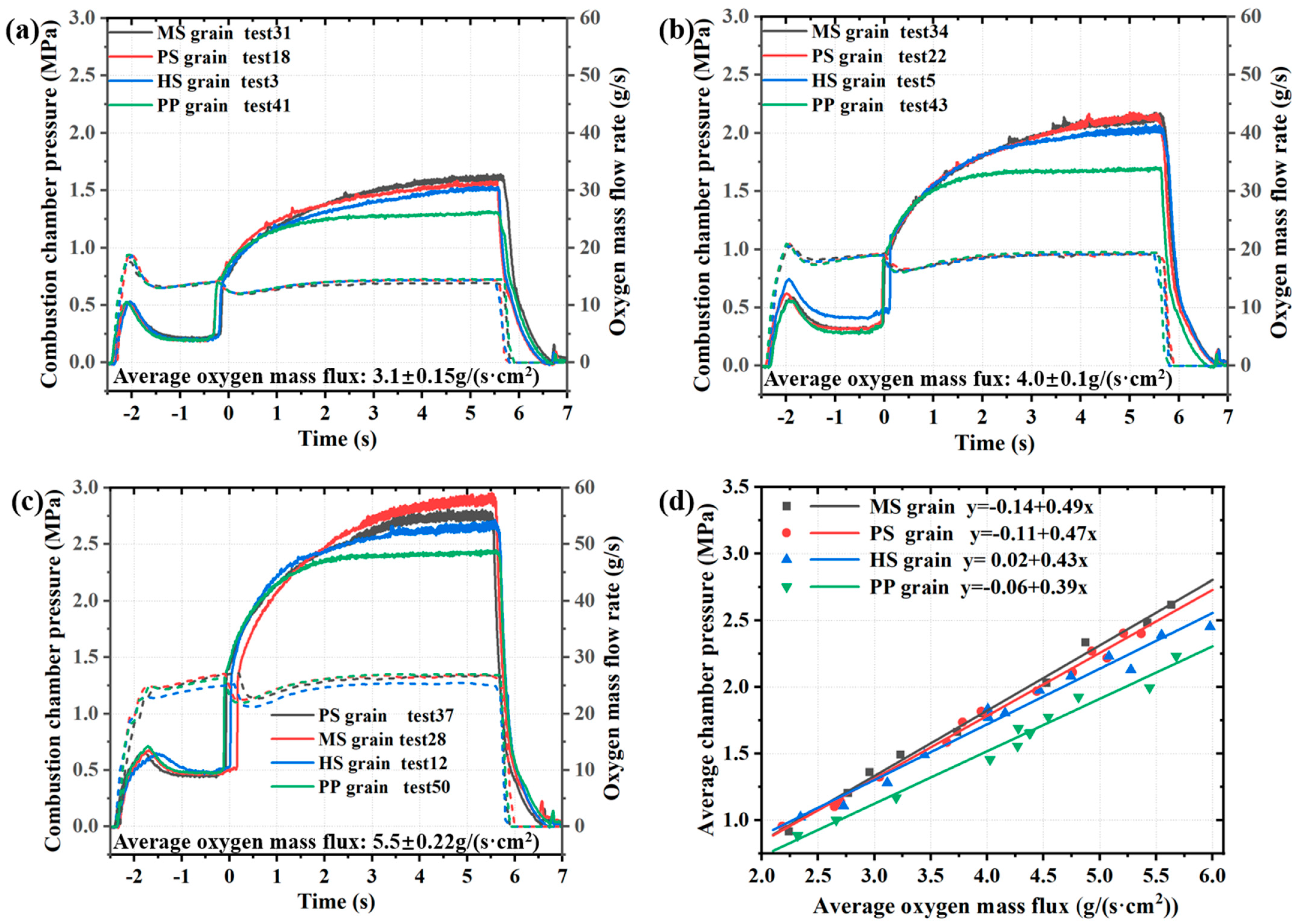

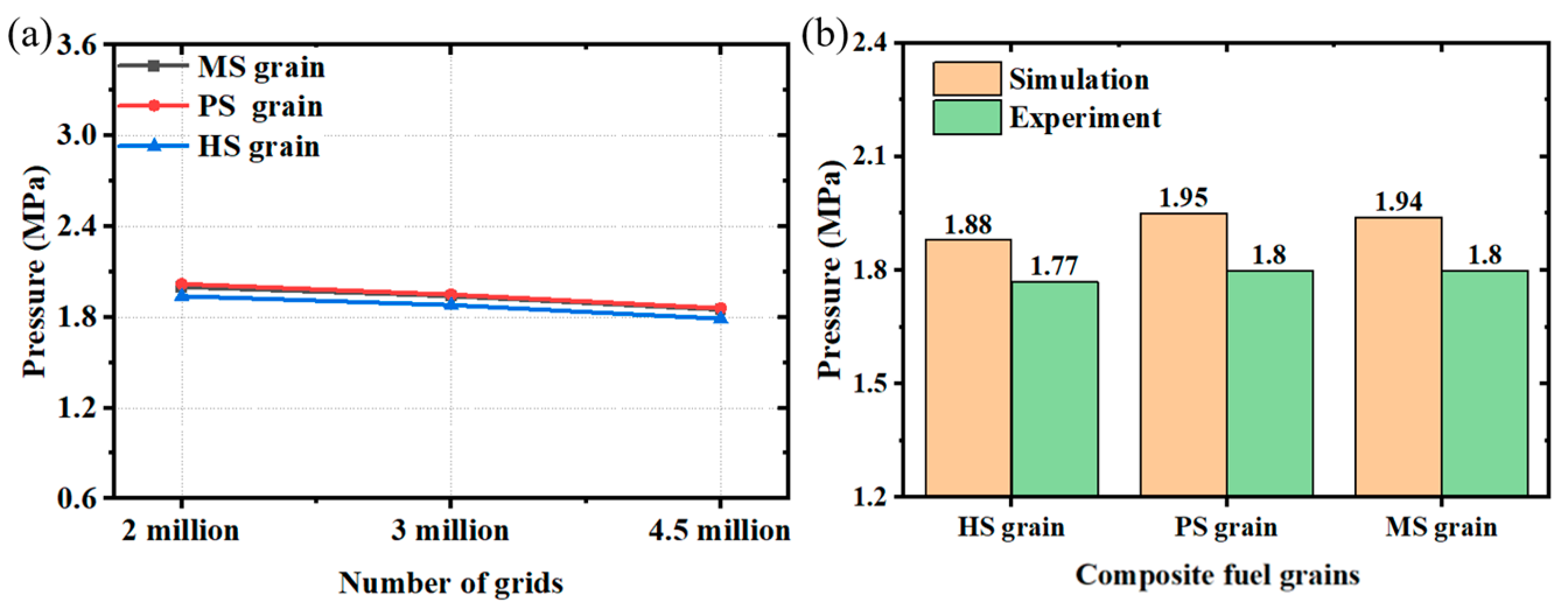

3.1. Combustion Chamber Pressure

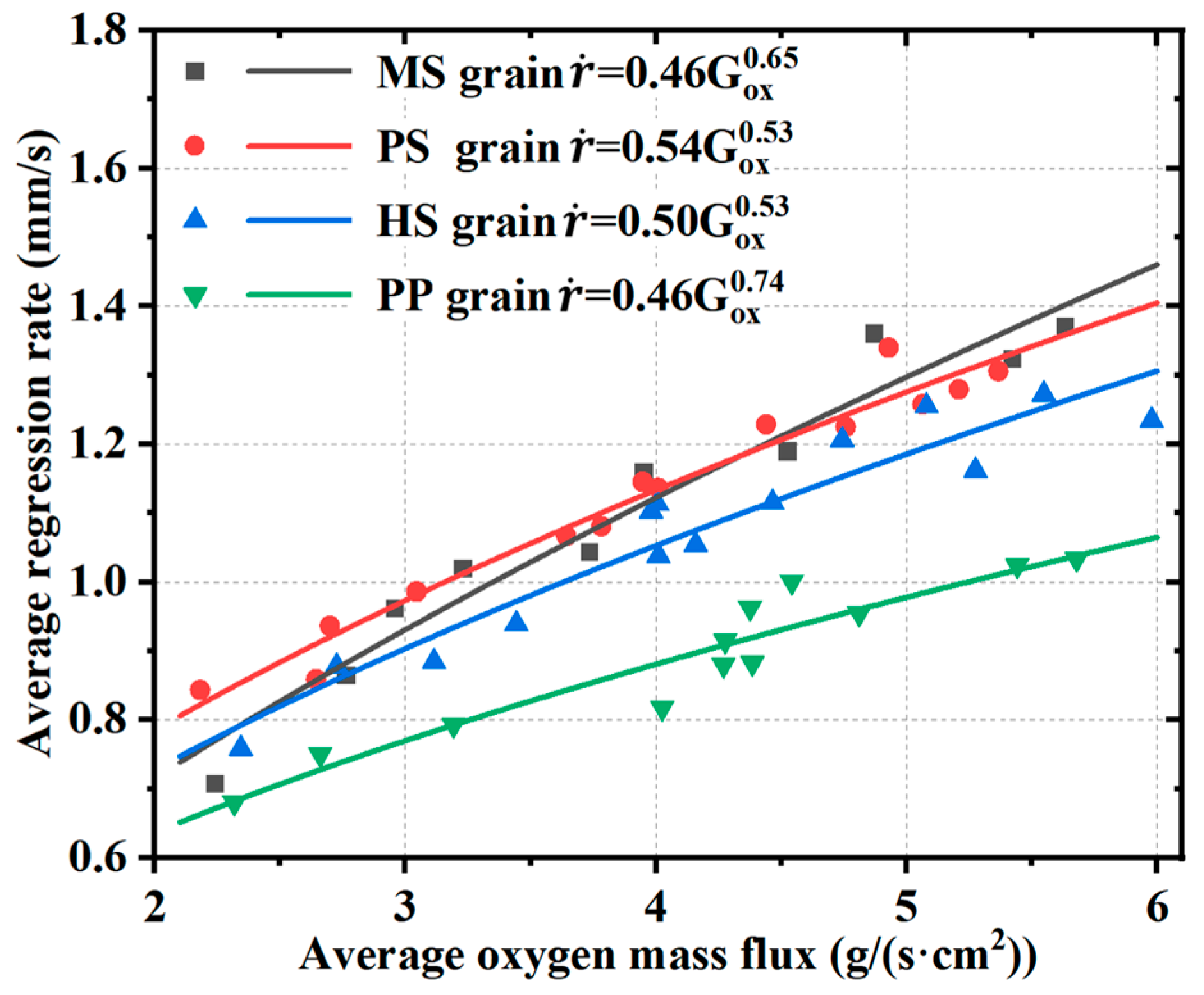

3.2. Regression Rate and Combustion Efficiency

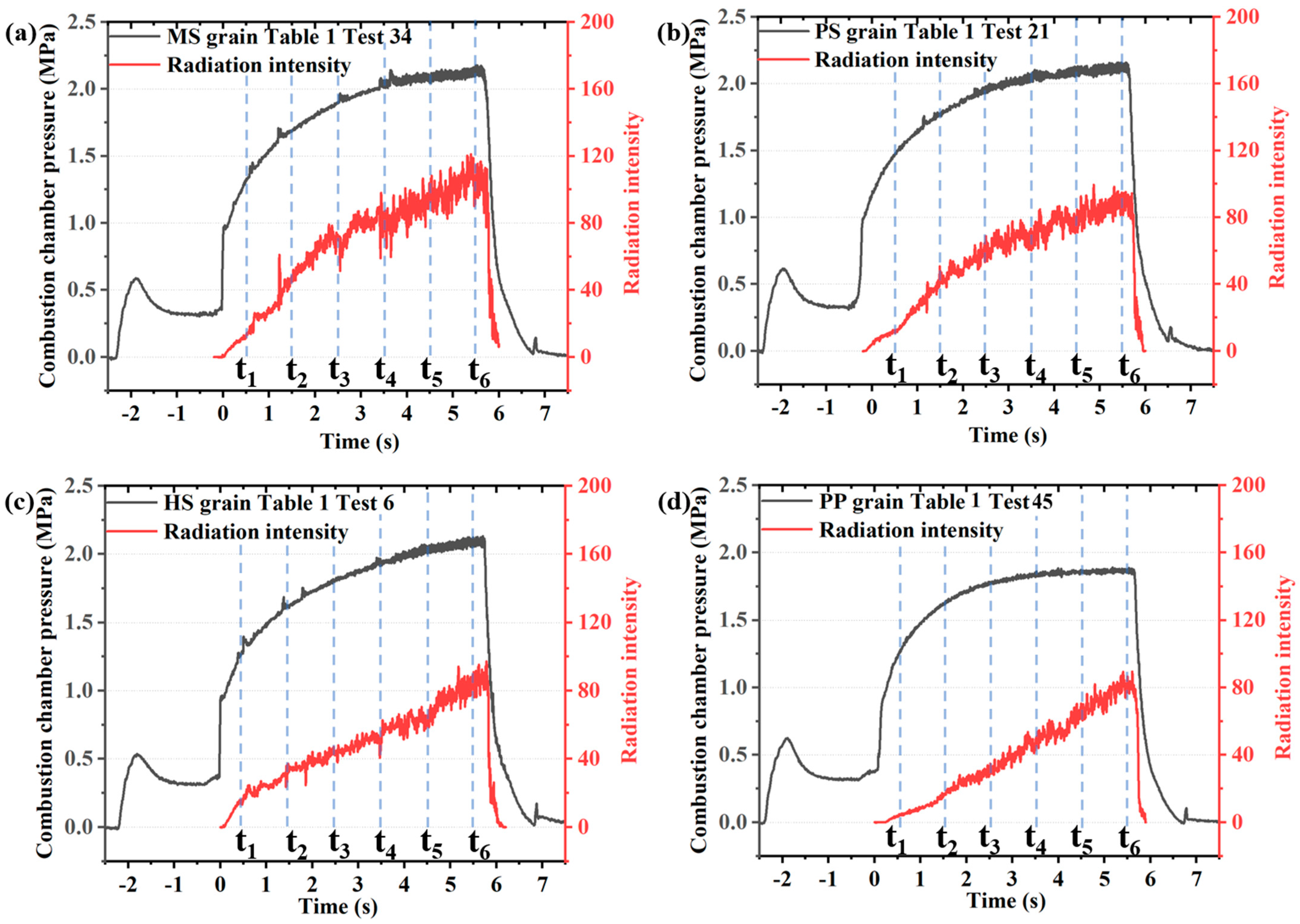

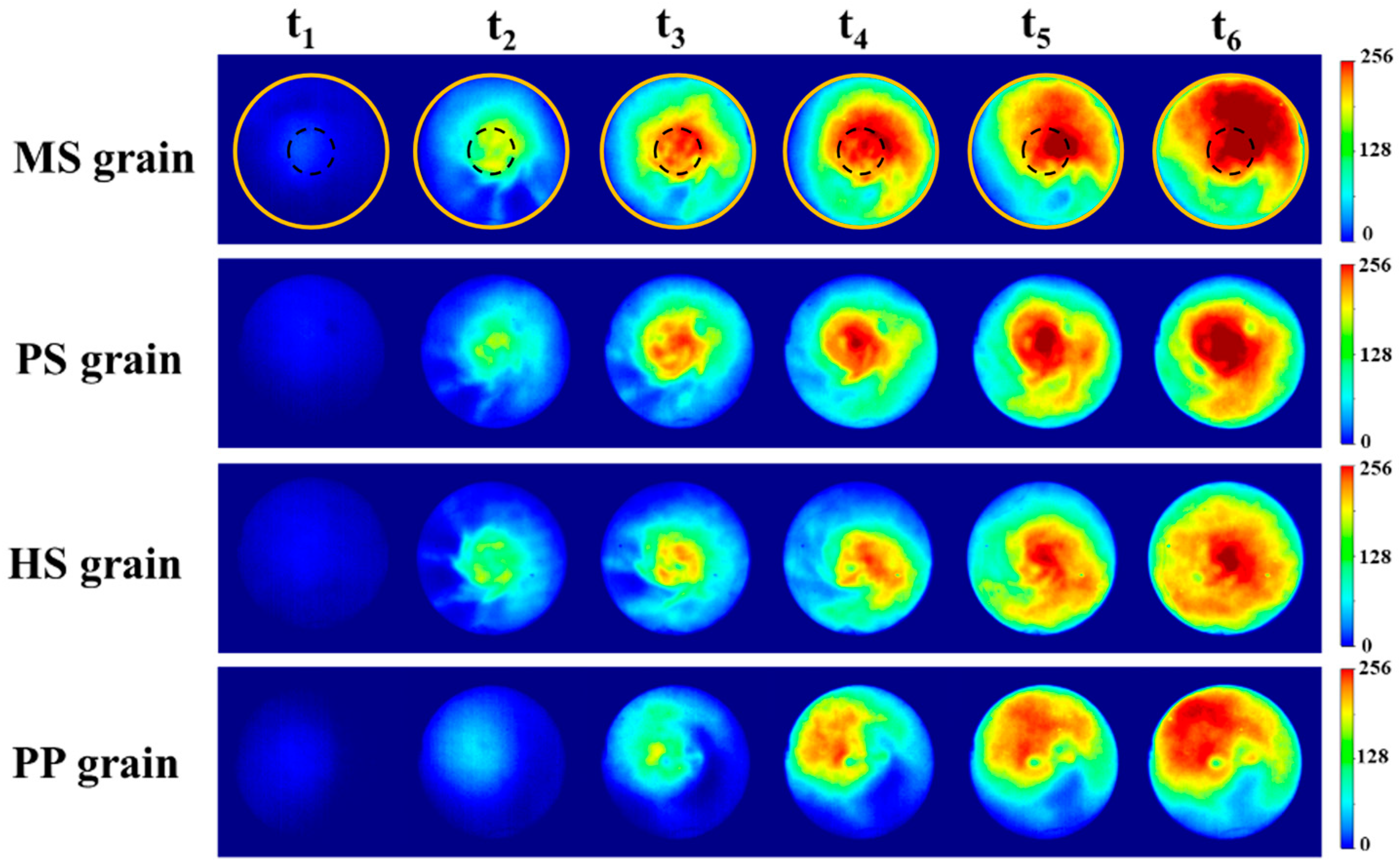

3.3. Radiation Luminescence

4. Combustion Simulation

4.1. Model Description and Precision Estimates

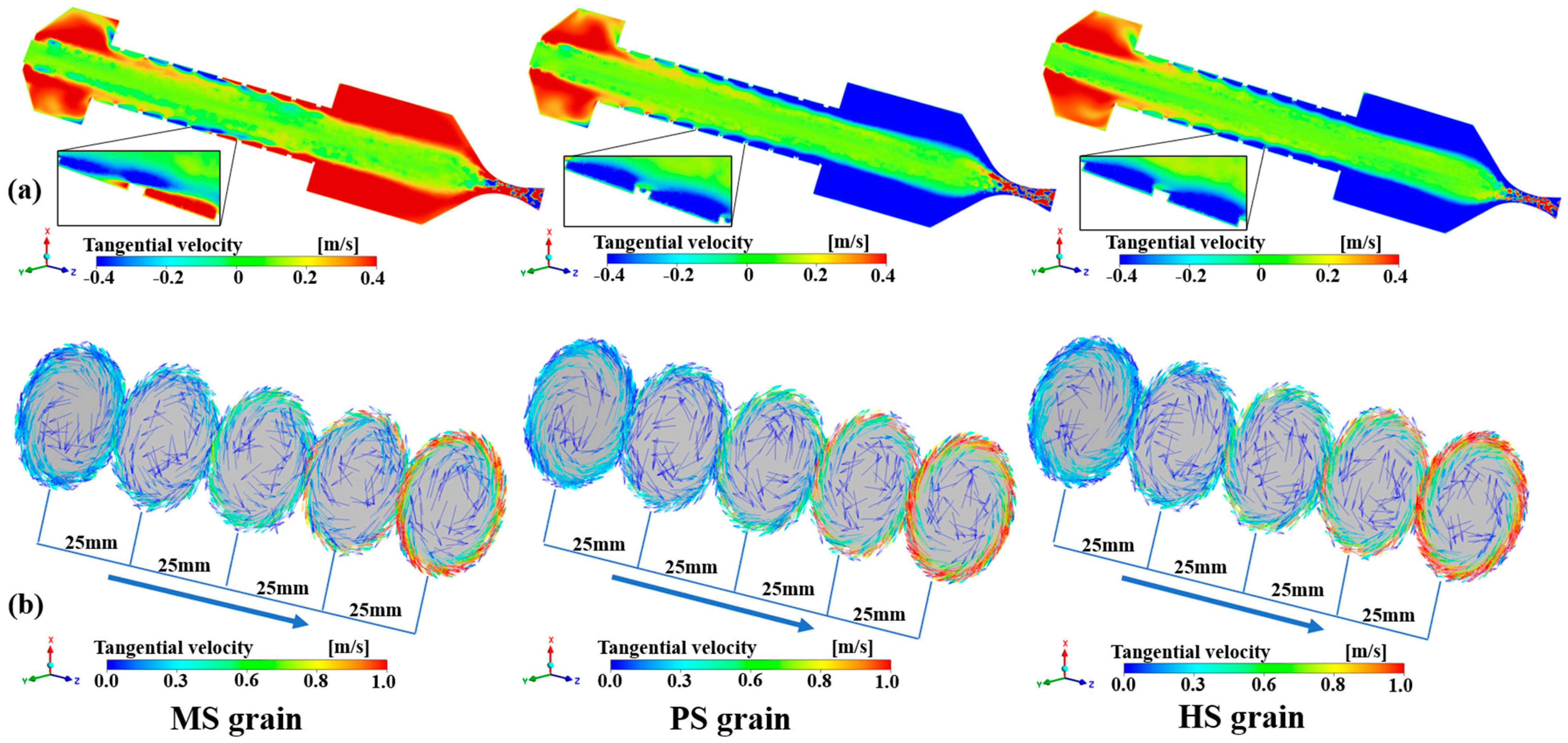

4.2. Flow Characteristics

5. Conclusions

- (1)

- Composite fuel grains with the modified modular units are more conducive to increasing the regression rates. Under an oxygen mass flux of 6.0 g/(s·cm2), the regression rates of the MS and PS grains increased by 8.0% and 14.1%, respectively, compared with that of the HS grain.

- (2)

- Experimental results show that the composite fuel grains have the advantage of rapidly increasing the radiant intensity and flame thickness. The MS grain had the most significant improvement on combustion performance. The centralized O/F distribution and stable combustion efficiency further illustrated superiority in combustion of the mirrored helical structure.

- (3)

- Simulation results showed that the pores of the PS grain promoted the development of swirl flow, which increased the regression rate. Two opposite swirling flows resulting from the mirroring configuration significantly fostered the development of turbulence in the MS grain, which improved the mixing of propellant and gas and thus promoted combustion efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| HRE | hybrid rocket engine |

| ABS | acrylonitrile–butadiene–styrene |

| MS/PS/HS grain | composite fuel grains with mirrored/perforated/helical blades, respectively |

| PP grain | paraffin-based grain |

| 3D | three-dimensional |

| POD | proper orthogonal decomposition |

| O/F | oxidizer to fuel ratio |

| average oxygen mass flow rate | |

| Gox | oxidizer mass flux |

| average chamber pressure | |

| average regression rate | |

| d0 | the initial inner diameter of the fuel grain |

| df | the inner diameter of the fuel grain after firing experiments |

| initial mass of the fuel grain | |

| the mass of the fuel grain after firing experiments | |

| combustion efficiency | |

| theoretical characteristic velocity | |

| experimentally obtained characteristic velocity | |

| average mass flow rate of the oxidizer | |

| dt | throat diameter of the nozzle |

| t | working time of the engine |

| U | orthogonal modes of the flame series |

| S | corresponding mode energy |

| V | time coefficients |

| T | transpose of a matrix |

| eigenvalue | |

| E | normalized energy ratio of each mode |

References

- Mazzetti, A.; Merotto, L.; Pinarello, G. Paraffin-Based Hybrid Rocket Engines Applications: A Review and a Market Perspective. Acta Astronaut. 2016, 126, 286–297. [Google Scholar] [CrossRef]

- Martins, P.G.C.; De Souza, K.M.; Boschi, R.F.; Gouvêa, L.H.; Martins, C.A. Performance Comparison of Paraffin/Ethanol Fuel Blends in a Laboratory-Scale Hybrid Rocket Motor. J. Propuls. Power 2023, 39, 696–708. [Google Scholar] [CrossRef]

- Gu, X.; Tian, H.; Wang, J.; Liang, T.; Wei, T.; Niu, X.; Cai, G. Operational Instability of a High-Rotational-Speed Electric Pump in a Hybrid Rocket Motor. Aerosp. Sci. Technol. 2023, 140, 108496. [Google Scholar] [CrossRef]

- Pal, Y.; Mahottamananda, S.N.; Palateerdham, S.K.; Subha, S.; Ingenito, A. Review on the Regression Rate-Improvement Techniques and Mechanical Performance of Hybrid Rocket Fuels. FirePhysChem 2021, 1, 272–282. [Google Scholar] [CrossRef]

- Dhandapani, C.; Blanquart, G.; Karp, A.C.; Jens, E.T.; Rabinovitch, J. Combustion Studies of MMA/GO x for a Hybrid Rocket Motor. Combust. Flame 2023, 256, 112994. [Google Scholar] [CrossRef]

- Lee, J.; Woo, K.; Kim, S. Effect of Swirl Intensity Variation on Combustion Characteristics in End-Burning Hybrid Rocket Engines. Acta Astronaut. 2024, 217, 302–311. [Google Scholar] [CrossRef]

- Meng, X.; Gao, J.; Tian, H.; Niu, X.; Chen, R.; Cai, G. Study on the Dynamic Numerical Simulation of Flow and Combustion in Hybrid Rocket Motors Based on a Discrete Phase Model. Acta Astronaut. 2024, 215, 156–167. [Google Scholar] [CrossRef]

- Zolla, P.; Zavoli, A.; Migliorino, M.T.; Bianchi, D. Integrated Optimization of a Three-Stage Clustered Hybrid Rocket Launcher Using Neural Networks. In AIAA SCITECH 2024 Forum; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2024. [Google Scholar]

- Gallo, G.; Kamps, L.; Hirai, S.; Carmicino, C.; Harunori, N. Prediction of the Fuel Regression-Rate in a HDPE Single Port Hybrid Rocket Fed by Liquid Nitrous Oxide. Combust. Flame 2024, 259, 113160. [Google Scholar] [CrossRef]

- Sun, X.; Tian, H.; Li, Y.; Yu, N.; Cai, G. Regression Rate Behaviors of HTPB-Based Propellant Combinations for Hybrid Rocket Motor. Acta Astronaut. 2016, 119, 137–146. [Google Scholar] [CrossRef]

- Gallo, G.; Mungiguerra, S.; Savino, R.; Cardillo, D.; Battista, F. Effect of Grain Length on GOx-Paraffin Hybrid Rocket Engines Performance and Regression Rate. Int. J. Heat Mass Transf. 2024, 220, 124978. [Google Scholar] [CrossRef]

- Glaser, C.; Hijlkema, J.; Lestrade, J.-Y.; Anthoine, J. Interaction of Multiple Steps in Hybrid Rocket Engines: Experimental Investigation. Acta Astronaut. 2024, 217, 261–272. [Google Scholar] [CrossRef]

- Liu, L.; He, X.; Wang, Y.; Chen, Z.; Guo, Q. Regression Rate of Paraffin-Based Fuels in Hybrid Rocket Motor. Aerosp. Sci. Technol. 2020, 107, 106269. [Google Scholar] [CrossRef]

- Glaser, C.; Hijlkema, J.; Anthoine, J. Bridging the Technology Gap: Strategies for Hybrid Rocket Engines. Aerospace 2023, 10, 901. [Google Scholar] [CrossRef]

- Tianfang, W.; Guobiao, C.; Hui, T.; Hao, Z.; Yuanjun, Z.; Xintong, L. Optimization Design in Single Wagon-Wheel Fuel Grain of Hybrid Rocket Motor. FirePhysChem 2021, 1, 212–221. [Google Scholar] [CrossRef]

- Ahn, B.; Kang, H.; Lee, E.; Yun, Y.; Kwon, S. Design of Multiport Grain with Hydrogen Peroxide Hybrid Rocket. J. Propuls. Power 2018, 34, 1189–1197. [Google Scholar] [CrossRef]

- Yun, Y.; Huh, J.; Kim, Y.; Heo, S.; Kim, H.; Kwon, S. Scale-Up Validation of Hydrogen Peroxide/High-Density Polyethylene Hybrid Rocket with Multiport Solid Fuel. J. Spacecr. Rocket. 2021, 58, 552–565. [Google Scholar] [CrossRef]

- Wei, T.; Cai, G.; Tian, H.; Jiang, X. Experiment and Numerical Research on Regression Rate of Hybrid Rocket Motor with Single-Port Wagon Wheel Fuel Grain. Acta Astronaut. 2023, 207, 265–282. [Google Scholar] [CrossRef]

- Yu, X.; Yu, H.; Gao, H.; Zhang, W.; DeLuca, L.T.; Shen, R. 3D Printed Different Polymer Fuel Grains for Hybrid Rocket Engine. FirePhysChem, 2023; in press. Corrected Proof. [Google Scholar] [CrossRef]

- Viscor, T.; Kamps, L.; Yonekura, K.; Isochi, H.; Nagata, H. Large-Scale CAMUI Type Hybrid Rocket Motor Scaling, Modeling, and Test Results. Aerospace 2022, 9, 1. [Google Scholar] [CrossRef]

- Glaser, C.; Hijlkema, J.; Anthoine, J. Evaluation of Regression Rate Enhancing Concepts and Techniques for Hybrid Rocket Engines. Aerotec. Missili Spaz. 2022, 101, 267–292. [Google Scholar] [CrossRef]

- Altman, D.; Holzman, A. Overview and History of Hybrid Rocket Propulsion. In Fundamentals of Hybrid Rocket Combustion and Propulsion; Kuo, K.K., Chiaverini, M.J., Eds.; AIAA: Reston, VA, USA, 2007; Volume 218, pp. 1–36. ISBN 978-1-56347-703-4. [Google Scholar]

- Kumar, R.; Ramakrishna, P.A. Effect of Protrusion on the Enhancement of Regression Rate. Aerosp. Sci. Technol. 2014, 39, 169–178. [Google Scholar] [CrossRef]

- Kumar, R.; Ramakrishna, P.A. Enhancement of Hybrid Fuel Regression Rate Using a Bluff Body. J. Propuls. Power 2014, 30, 909–916. [Google Scholar] [CrossRef]

- Whitmore, S.A. Additively Manufactured Acrylonitrile-Butadiene-Styrene–Nitrous-Oxide Hybrid Rocket Motor with Electrostatic Igniter. J. Propuls. Power 2015, 31, 1217–1220. [Google Scholar] [CrossRef]

- Whitmore, S.A.; Walker, S.D.; Merkley, D.P.; Sobbi, M. High Regression Rate Hybrid Rocket Fuel Grains with Helical Port Structures. J. Propuls. Power 2015, 31, 1727–1738. [Google Scholar] [CrossRef]

- Whitmore, S.A.; Walker, S.D. Engineering Model for Hybrid Fuel Regression Rate Amplification Using Helical Ports. J. Propuls. Power 2017, 33, 398–407. [Google Scholar] [CrossRef]

- Bisin, R.; Paravan, C.; Alberti, S.; Galfetti, L. A New Strategy for the Reinforcement of Paraffin-Based Fuels Based on Cellular Structures: The Armored Grain—Mechanical Characterization. Acta Astronaut. 2020, 176, 494–509. [Google Scholar] [CrossRef]

- Bisin, R.; Paravan, C. A New Strategy for the Reinforcement of Paraffin-Based Fuels Based on Cellular Structures: The Armored Grain—Ballistic Characterization. Acta Astronaut. 2023, 206, 284–298. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Li, F.; Yu, X. Combustion Performance of a Novel Hybrid Rocket Fuel Grain with a Nested Helical Structure. Aerosp. Sci. Technol. 2020, 97, 105613. [Google Scholar] [CrossRef]

- Lin, X.; Qu, D.; Chen, X.; Wang, Z.; Luo, J.; Meng, D.; Liu, G.; Zhang, K.; Li, F.; Yu, X. Three-Dimensional Printed Metal-Nested Composite Fuel Grains with Superior Mechanical and Combustion Properties. Virtual Phys. Prototyp. 2022, 17, 437–450. [Google Scholar] [CrossRef]

- Qu, D.; Lin, X.; Zhang, K.; Li, Z.; Wang, Z.; Liu, G.; Meng, Y.; Luo, G.; Wang, R.; Yu, X. Additively Manufactured Aluminium Nested Composite Hybrid Rocket Fuel Grains with Breathable Blades. Virtual Phys. Prototyp. 2023, 18, e2235680. [Google Scholar] [CrossRef]

- Glaser, C.; Gelain, R.; Bertoldi, A.E.M.; Levard, Q.; Hijlkema, J.; Lestrade, J.-Y.; Hendrick, P.; Anthoine, J. Experimental Regression Rate Profiles of Stepped Fuel Grains in Hybrid Rocket Engines. Acta Astronaut. 2023, 204, 186–198. [Google Scholar] [CrossRef]

- Mastorakos, E. Ignition of Turbulent Non-Premixed Flames. Prog. Energy Combust. Sci. 2009, 35, 57–97. [Google Scholar] [CrossRef]

- Luo, J.; Zhang, Z.; Lin, X.; Wang, Z.; Kun, W.; Zhou, G.; Zhang, S.; Li, F.; Yu, X.; Wu, J. Flame Dynamics in the Combustion Chamber of Hybrid Rocket Using Multiangle Chemiluminescence. J. Propuls. Power 2023, 39, 482–491. [Google Scholar] [CrossRef]

- Tan, G.; Tian, H.; Gu, X.; Meng, X.; Wei, T.; Zhang, Y.; Cai, G. Flow Feedback Control Based on Variable Area Cavitating Venturi and Its Application in Hybrid Rocket Motors. Acta Astronaut. 2023, 211, 238–248. [Google Scholar] [CrossRef]

- Gordon, S.D.; Mcbride, B.J. Computer Program for Calculation of Complex Chemical Equilibrium Compositions; No. NAS 1.61: 1311; NASA Lewis Research Center: Cleveland, OH, USA, 1994. [Google Scholar]

- Zhang, C.; Yan, Y.; Shen, K.; Xue, Z.; You, J.; He, Z. Comparative Analysis of Combustion Stability and Flow Performance in Micro Combustor Based on the Synergistic Action of Slotted Blunt Body and Front-Baffle. Appl. Therm. Eng. 2024, 237, 121802. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Y.; Liu, H.; Chen, W.; Xu, Y. Comparative Study on Modal Decomposition Methods of Unsteady Separated Flow in Compressor Cascade. J. Northwestern Polytech. Univ. 2020, 38, 121–129. [Google Scholar] [CrossRef]

- Strang, G.; Press, W.-C. Introduction to Linear Algebra, 6th ed.; Wellesley-Cambridge Press: Wellesley, MA, USA, 1993. [Google Scholar]

- Taira, K.; Brunton, S.L.; Dawson, S.T.M.; Rowley, C.W.; Colonius, T.; McKeon, B.J.; Schmidt, O.T.; Gordeyev, S.; Theofilis, V.; Ukeiley, L.S. Modal Analysis of Fluid Flows: An Overview. AIAA J. 2017, 55, 4013–4041. [Google Scholar] [CrossRef]

- Løvås, T.; Malik, N.; Mauss, F. Global Reaction Mechanism for Ethylene Flames with Preferential Diffusion. Combust. Sci. Technol. 2010, 182, 1945–1960. [Google Scholar] [CrossRef]

- Cassese, S.; Mungiguerra, S.; Guida, R.; Cecere, A.; Savino, R. Regression Rate and Performance Analysis via Ballistic Reconstruction of a Small-Scale H2O2-Based Hybrid Rocket Fuelled by Polyvinyl Chloride. Aerosp. Sci. Technol. 2024, 146, 108911. [Google Scholar] [CrossRef]

- Nagata, H.; Nakayama, H.; Watanabe, M.; Wakita, M.; Totani, T. Accuracy and Applicable Range of a Reconstruction Technique for Hybrid Rockets. Adv. Aircr. Spacecr. Sci. 2014, 1, 273–289. [Google Scholar] [CrossRef]

| No. | Grain | (g/s) | Gox g/(s·cm2) | (MPa) | (mm/s) | O/F |

|---|---|---|---|---|---|---|

| 1 | HS grain | 10.06 | 2.34 | 1.02 | 0.76 | 1.95 |

| 2 | 12.03 | 2.73 | 1.11 | 0.88 | 1.95 | |

| 3 | 13.76 | 3.11 | 1.28 | 0.88 | 2.22 | |

| 4 | 15.33 | 3.44 | 1.49 | 0.94 | 2.29 | |

| 5 | 18.37 | 3.98 | 1.74 | 1.1 | 2.22 | |

| 6 | 18.25 | 4.01 | 1.77 | 1.04 | 2.45 | |

| 7 | 18.50 | 4.01 | 1.83 | 1.11 | 2.29 | |

| 8 | 19.09 | 4.16 | 1.81 | 1.05 | 2.44 | |

| 9 | 20.71 | 4.47 | 1.97 | 1.12 | 2.51 | |

| 10 | 22.36 | 4.74 | 2.08 | 1.21 | 2.44 | |

| 11 | 24.11 | 5.08 | 2.23 | 1.26 | 2.50 | |

| 12 | 24.40 | 5.28 | 2.13 | 1.16 | 2.81 | |

| 13 | 26.27 | 5.55 | 2.39 | 1.27 | 2.73 | |

| 14 | 28.09 | 5.98 | 2.45 | 1.23 | 3.01 | |

| 15 | PS grain | 9.61 | 2.18 | 0.95 | 0.84 | 1.65 |

| 16 | 11.60 | 2.64 | 1.10 | 0.86 | 1.95 | |

| 17 | 12.11 | 2.70 | 1.14 | 0.94 | 1.81 | |

| 18 | 13.79 | 3.04 | 1.33 | 0.99 | 1.95 | |

| 19 | 16.75 | 3.64 | 1.59 | 1.07 | 2.14 | |

| 20 | 17.45 | 3.78 | 1.74 | 1.08 | 2.20 | |

| 21 | 18.47 | 3.95 | 1.82 | 1.15 | 2.16 | |

| 22 | 18.59 | 4.01 | 1.80 | 1.14 | 2.23 | |

| 23 | 20.87 | 4.44 | 1.97 | 1.23 | 2.26 | |

| 24 | 22.40 | 4.76 | 2.11 | 1.22 | 2.44 | |

| 25 | 23.73 | 4.93 | 2.27 | 1.34 | 2.27 | |

| 26 | 24.06 | 5.06 | 2.22 | 1.26 | 2.50 | |

| 27 | 24.66 | 5.21 | 2.40 | 1.28 | 2.57 | |

| 28 | 25.70 | 5.37 | 2.41 | 1.35 | 2.51 | |

| 29 | MS grain | 9.49 | 2.24 | 0.92 | 0.71 | 1.98 |

| 30 | 12.12 | 2.76 | 1.20 | 0.86 | 2.01 | |

| 31 | 13.34 | 2.96 | 1.36 | 0.96 | 1.93 | |

| 32 | 14.73 | 3.23 | 1.49 | 1.02 | 1.96 | |

| 33 | 16.96 | 3.74 | 1.66 | 1.04 | 2.21 | |

| 34 | 18.43 | 3.95 | 1.80 | 1.16 | 2.13 | |

| 35 | 21.18 | 4.53 | 2.03 | 1.19 | 2.34 | |

| 36 | 23.51 | 4.87 | 2.33 | 1.36 | 2.21 | |

| 37 | 25.69 | 5.42 | 2.48 | 1.32 | 2.43 | |

| 38 | 27.02 | 5.63 | 2.62 | 1.37 | 2.54 | |

| 39 | PP grain | 9.77 | 2.32 | 0.89 | 0.68 | 2.15 |

| 40 | 11.42 | 2.66 | 1.00 | 0.75 | 2.22 | |

| 41 | 13.90 | 3.19 | 1.17 | 0.79 | 2.52 | |

| 42 | 17.46 | 4.03 | 1.46 | 0.82 | 3.08 | |

| 43 | 18.74 | 4.27 | 1.56 | 0.88 | 3.03 | |

| 44 | 18.92 | 4.28 | 1.69 | 0.91 | 2.93 | |

| 45 | 19.60 | 4.38 | 1.66 | 0.88 | 3.13 | |

| 46 | 19.17 | 4.38 | 1.65 | 0.96 | 2.84 | |

| 47 | 20.58 | 4.54 | 1.78 | 1.00 | 2.84 | |

| 48 | 21.42 | 4.81 | 1.92 | 0.95 | 3.21 | |

| 49 | 24.64 | 5.44 | 2.00 | 1.02 | 3.34 | |

| 50 | 25.87 | 5.68 | 2.23 | 1.03 | 3.46 |

| No. | Reaction |

|---|---|

| 1 | O2 + C2H42CO + 2H2 |

| 2 | O + CO(+M) CO2 (+M) |

| 3 | OH + CO H + CO2 |

| 4 | O2 + H2 OH + OH |

| 5 | O2 + H OH + O |

| 6 | OH + H2 H + H2O |

| 7 | O + H2 + M H2O + M |

| 8 | 2H+ H2 + M |

| 9 | C2H4 C2H2 + H2 |

| 10 | C2H2 + 2OH 2H2 + 2CO |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, J.; Lin, X.; Wang, Z.; Wang, R.; Wu, K.; Liang, J.; Yu, X. Regression Rate and Combustion Efficiency of Composite Hybrid Rocket Grains Based on Modular Fuel Units. Aerospace 2024, 11, 262. https://doi.org/10.3390/aerospace11040262

Pan J, Lin X, Wang Z, Wang R, Wu K, Liang J, Yu X. Regression Rate and Combustion Efficiency of Composite Hybrid Rocket Grains Based on Modular Fuel Units. Aerospace. 2024; 11(4):262. https://doi.org/10.3390/aerospace11040262

Chicago/Turabian StylePan, Junjie, Xin Lin, Zezhong Wang, Ruoyan Wang, Kun Wu, Jinhu Liang, and Xilong Yu. 2024. "Regression Rate and Combustion Efficiency of Composite Hybrid Rocket Grains Based on Modular Fuel Units" Aerospace 11, no. 4: 262. https://doi.org/10.3390/aerospace11040262

APA StylePan, J., Lin, X., Wang, Z., Wang, R., Wu, K., Liang, J., & Yu, X. (2024). Regression Rate and Combustion Efficiency of Composite Hybrid Rocket Grains Based on Modular Fuel Units. Aerospace, 11(4), 262. https://doi.org/10.3390/aerospace11040262