Abstract

The increase in greenhouse gas emissions, as well as the risk of fossil fuel depletion, has prompted a transition to electric transportation. The European Union aims to substantially reduce pollutant emissions by 2035 through the use of renewable energies. In aviation, this transition is particularly challenging, mainly due to the weight of onboard equipment. Traditional electric motors with radial magnetic flux have been replaced by axial magnetic flux motors with reduced weight and volume, high efficiency, power, and torque. These motors were initially developed for electric vehicles with in-wheel motors but have been adapted for aviation without modifications. Worldwide, there are already companies developing propulsion systems for various aircraft categories using such electric motors. One category of aircraft that could benefit from this electric motor development is traditionally constructed training aircraft with significant remaining flight resource. Electric repowering would allow their continued use for pilot training, preparing them for future electrically powered aircraft. This article presents a study on the feasibility of repowering a classic training aircraft with an electric propulsion system. The possibilities of using either a battery or a hybrid source composed of a battery and a fuel cell as an energy source are explored. The goal is to utilize components already in production to eliminate the research phase for specific aircraft components.

1. Introduction

The continuous progress of aviation has been achieved in successive stages, with each developmental phase having its own specifics. From the early studies on the aerodynamics of aircraft, through various stages of aircraft propulsion system development, to the challenges related to supersonic flight, there have been ongoing efforts to enhance flying machines. Various issues, such as flight safety, noise reduction, and passenger comfort improvement, have successively topped the research agenda in aviation development. These efforts have resulted in a rapid transition, over approximately 120 years, from the first flight of a heavier-than-air machine to the high-performance means of transportation used today by hundreds of millions of passengers annually. The era of the extensive and intensive development of propulsion systems based on fossil fuels is coming to an end. On the one hand, this is due to the prospects of depleting fossil fuel resources, and on the other hand, it is a response to the challenges posed by increasingly severe pollution on a global scale.

The reduction in pollutants emitted by aircraft is a challenge that requires the use of new, primarily renewable energy sources. Despite seemingly contributing only a small percentage in 2019 regarding emissions from transportation means (approximately 5% [1]), aviation is a significant consumer of fossil fuels. The share of emissions generated by aviation is increasing, partly due to the revitalization of air transport after the COVID pandemic and advancements in improving other modes of transportation using renewable energy sources in those domains. It is anticipated that the aviation sector’s share in emissions will rise to 24% by 2050 unless significant technological progress is made [1]. Another driving force for the development of new aviation propulsion systems comes from the continuous increase in fossil fuel prices. At the current rate, air transport is expected to face prohibitively high costs soon unless substantial technological advancements are achieved.

The challenges mentioned above have not gone unnoticed in the aviation world, ranging from passionate individual researchers to both smaller and larger aviation equipment manufacturers, as well as major research institutes and aircraft-producing conglomerates. There has already been a transition to sustained efforts. Electric motors that emit no pollutants, and are potentially usable as an alternative in aircraft propulsion, have gained significant attention. As of 2019, there were already 215 electrically propelled aircraft either developed or in progress [2]. The transition has moved from small electrically propelled UAVs to motor gliders, with some even utilizing solar energy. Gradually, efforts have been made to electrify aircraft of increasingly larger dimensions.

Regarding renewable energy sources, the first direction was the utilization of solar energy. The amount of energy that can be obtained on board a transport aircraft from solar energy is minuscule compared to its needs. Consequently, the focus has shifted to the use of other energy sources—electricity stored in batteries or electricity produced by hydrogen fuel cells. A third avenue of study involves using hydrogen as the fuel for internal combustion engines.

In addition to the existing concepts of flying devices, the concept of urban air mobility (UAM) has rapidly developed [2]. The issue of developing official regulations in the field for the entry into services of such flying devices by the end of this decade is already being addressed.

The possible energy sources currently considered for electric propulsion in aircraft are batteries and fuel cells. Intensive research is being conducted worldwide in both directions. Each of them has advantages and disadvantages. Batteries, for aviation propulsion energy requirements, are heavy and bulky but can provide high power rapidly. Fuel cells are lighter, can provide high power for extended periods, have higher energy efficiency than thermal engines, and are modular, reversible, reliable, operate silently, with no moving parts, but have a slow response time to consumption variations. The production of batteries requires rare earth elements, and resources in this direction are not unlimited. Therefore, the recovery of used batteries is necessary for the construction of new ones, but the involved processes are expensive. Fuel cells use hydrogen. It’s very important advantages include a very low mass, a very high mass-specific energy density, and no emissions; disadvantages include a very low volumetric energy density, high explosiveness, and the need for special safety measures in use. Given that these sources have complementary qualities, the combined use of these solutions is necessary for optimizing electric propulsion systems for aviation.

The paper first explores, in Section 2, the critical issues that need to be addressed in the case of electric propulsion for aircraft. Significant achievements in the development of components for electric propulsion systems are also presented in this section, including high-power density motors, state-of-the-art batteries, and fuel cells. In Section 3, the paper showcases several electrically powered aircraft utilizing fuel cells as energy sources. It provides an overview of aircraft that are already developed or in an advanced stage of design. This section offers insights into the performance already achieved by electric aircraft and trends in the short and medium term. Similarly, Section 4 presents an overview but for electrically powered aircraft fed by batteries. The section aims to provide a glimpse of the current state of battery-powered electric aircraft, highlighting their performance and near-to-medium-term trends. Section 5 briefly reviews possible architectures for electric propulsion systems of aircraft, offering an understanding of the design considerations in this field. In Section 6, a study is presented on the possibilities of electric retrofitting for a ZLIN 142-type training aircraft. Section 7 delves into numerical simulations of two potential approaches for the retrofitting. Finally, Section 8 presents the conclusions of the study, both concerning the specific case studied and the broader possibilities of electric retrofitting for older aircraft in general.

2. Challenges Regarding Electric Flight Implementation

From the information presented above, a credible alternative with potential is the use of hydrogen as an energy source, employing a conversion to electrical energy through fuel cells. The main advantages and disadvantages of using hydrogen on board were mentioned before. Another disadvantage is that the volumetric energy density is very low, even at pressures of 700 bar [3,4]. Current studies are exploring solutions to enhance safety and reduce volume, such as the use of liquid hydrogen. Currently, the most cost-effective solution appears to be storing hydrogen in tanks at a pressure of 700 bar. While the option of storing hydrogen in liquid form has the advantage of a considerably higher energy density, it involves maintaining hydrogen at temperatures of −250 °C. That means thermal insulation is needed, and in some versions, cooling systems are used. The result is a more complex system, which is useful on airliners but, for small aircraft, is bulky and difficult to fit on board. It is a trade-off between a lower mass on board and the volume of storage. Pressurized tanks are heavier, and liquid hydrogen tanks occupy more volume.

In aviation, where the mass of the battery system is a critical factor, unlike in automobiles, the mass of batteries decreases the useful load of the aircraft. The energy density of the most modern batteries currently used is much lower than the energy density of aviation fuel.

Battery-based systems have the advantage of directly supplying electrical energy from the battery to the motor, ensuring high efficiency of the energy source. However, in this case, the mass of the electric power source remains constant throughout the flight, unlike in kerosene-based propulsion systems where it decreases over time.

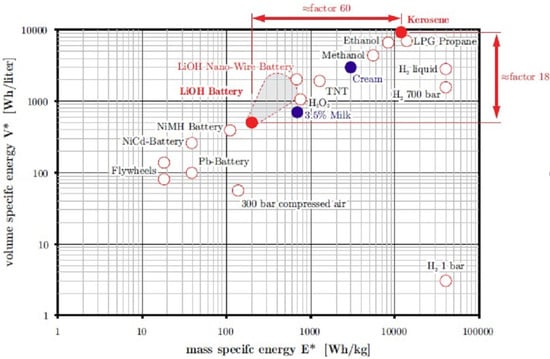

In Figure 1, a synthetic overview is presented regarding the energy density of various storage systems. Concerning the volumetric energy density, modern Li-Ion batteries are approximately 1/18th of the energy density of kerosene, while the mass energy density of these batteries is approximately 1/60th. From this perspective, batteries exhibit a clear disadvantage [3].

Figure 1.

The energy density for different storage systems [3].

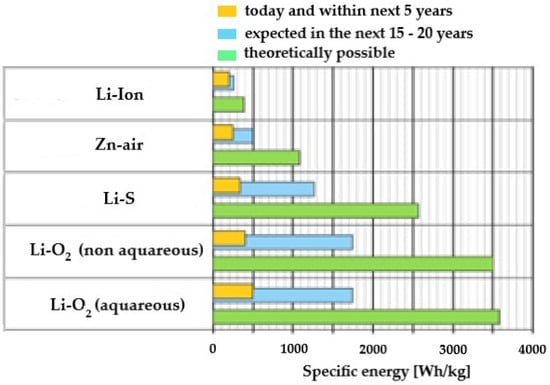

Regarding batteries, recently, a state-of-the-art technology based on lithium-ion batteries offered the highest energy density, around 200 Wh/kg, with prospects of reaching 250 Wh/kg, which is still insufficient for commercial flight. The most promising directions lie in lithium–Sulfur and lithium–Oxygen batteries. In theory, these batteries can achieve energy densities between 2500 and 3500 Wh/kg. These energy densities could potentially meet the requirements for commercial aviation up to the regional transport level. A summary of the research status and prospects for these batteries is presented in Figure 2, adapted from [3].

Figure 2.

The current status and prospects for various types of batteries adapted from [3].

The use of batteries is inevitable on board electric aircraft. Fuel cells, in general, do not handle load peaks and rapid variations in motor operation well. Additionally, the presence of batteries on board is useful in situations where the operation of fuel cells is abruptly interrupted. A few minutes of battery-powered navigation reserve is beneficial.

Globally, there are several major manufacturers of propulsion batteries for the automotive and aviation industries, including Advanced Energy Materials, Ilika PLC, Johnson Matthey, LG Chem, Morrow Batteries, NOHMs Technologies, OXIS Energy, PolyPlus, Sion Power, and Williams Advanced [5]. Detailed information about the products offered is generally not widely disseminated. Stealth EV, for instance, produces batteries for the automotive industry and offers modules of 5.3 kWh, 5.6 kWh, and 6.3 kWh with power densities ranging between 213 and 220 Wh/kg [6].

In March 2023, Amprius launched lithium-ion batteries with silicon cathodes, boasting a power density of 500 Wh/kg [7]. Shortly thereafter, in April 2023, CATL also announced the launch of innovative lithium-ion batteries with a power density of 500 Wh/kg [8]. It can be said that a new standard is emerging regarding the power density of propulsion batteries in aviation and the automotive industry.

However, the increase in battery energy density comes with innovative technologies that lead to increased system complexity, such as battery stack thermal management, computerized energy consumption management, real-time optimization of battery parameters, cold-resistant cathodes and electrolytes, and more.

Although the use of liquid hydrogen on aircraft involves many technical complications, Airbus has already invested in this direction, initiating an extensive research program for the development of aircraft using hydrogen as fuel [9]. Four research directions are considered; three of them involve using hydrogen as fuel in internal combustion engines, and the fourth involves using electric energy produced in hydrogen fuel cells to power electric motors. For all variants, the on-board storage of hydrogen in liquid form is envisioned. Research on on-board liquid hydrogen storage systems is already in progress, at a fairly advanced stage [10]. The ultimate goal is to install such cryogenic tanks on the A380 demonstrator aircraft (MSN1) by 2026–2028 [11].

The use of hydrogen as an energy source for commercial flights cannot be implemented without a corresponding infrastructure developed at airports served by such aircraft. Airbus has already initiated research in this regard in collaboration with Linde, a global leader in the gas industry [12]. In fact, worldwide is an intense effort made also by other companies, governments, and local authorities to develop the hydrogen infrastructure necessary for hydrogen flight.

Important achievements in the last few years consist of the reduction in electric motors mass. Electric motors with power densities of 6 kW/kg and even higher have been developed [13]. Several manufacturers have developed mainly axial flux electric motors with power densities compatible with aviation propulsion requirements and compact and with reduced dimensions. Siemens, for example, has created the SP260D motor with a power of 260 kW and a weight of only 50 kg [13], already tested on the Extra 330 LE aerobatic aircraft. Another electric motor in this category, already used in automotive applications but compatible with airplane propulsion, is YASA 750 R. This motor offers 200 kW power at only 37 kg mass. In Table 1, several currently available electric aviation motors are presented.

Table 1.

Currently available electric motors for aviation propulsion [14,15,16].

3. Electric Aircraft with Fuel Cells Already Developed and under Development

As mentioned earlier, a currently studied energy source for use in aircraft is hydrogen stored in tanks and converted into electricity by fuel cells or used as fuel in internal combustion engines. Here are some aircraft already developed or under development using fuel cell technology for propulsion.

A team consisting of various partners from Europe and led by the German Aerospace Center (DLR) has developed the HY4 aircraft with fuel cells. Following Antares DLR-H2 and Antares H3, HY4 is the latest version of a fuel cell-powered aircraft tested by DLR. The HY4 aircraft has four seats, electric propulsion, and a hybrid power source consisting of batteries and fuel cells. The aircraft structure is made of composite materials and has an unconventional configuration consisting of three fuselages [17,18,19]. The results of test flights in September 2023 indicated that using liquid hydrogen instead of gaseous hydrogen doubled the range of the HY4 aircraft from 750 km to 1500 km, making it well suited for zero-emission flights on medium to long distances.

A project similar to HY4 is undertaken by the company ZeroAvia which aims to create a commercial electric aircraft with fuel cells by the year 2024 [20,21]. Another hydrogen-powered aircraft is the Rapid 200-FC, built in 2010 by the Politecnico di Torino University in collaboration with several partners from Europe. The hybrid power source consists of a 20 kW fuel cell and a 20 kW Li-Po battery. The aircraft achieved a cruising speed of 135 km/h [22].

Intensive research, involving substantial investments, has also started regarding commuter aircraft or regional transport planes. In [23], the study explores how a regional aircraft with 50 passengers can be hybridized to achieve the lowest possible emissions by 2040.

Hear Aerospace is a company with significant interests in electric aviation. The company has developed a regional aircraft called ES-30. The aircraft can cover 200 km solely on electric power but also has a hybrid autonomy of up to 400 km when carrying 30 passengers. However, with only 25 passengers, the ES-30 has the potential to cover up to 800 km. The new Hear aircraft currently has 250 firm orders [24].

The company MagniX has already conducted a maiden flight with a modified DHC8-Q300 aircraft, where one of the turboprop engines was replaced with a 1 MW electric propulsion system powered by fuel cells [15].

The FUTPRINT50 project, funded by the EU, focuses on possible technologies for hybrid–electric commercial aircraft for the years 2035–2040 [25]. In [23], the authors have designed the hybrid regional aircraft HAIQU (Hydrogen Aircraft designed for Quick commuting). This aircraft offers a capacity of 50 passengers and features a hybrid power system based on fuel cell and battery technology, combining the advantages of both technologies.

Airbus has revealed that it is developing a cryogenic electric motor powered by hydrogen fuel cells [26,27]. The propulsion system is considered one of the potential solutions to equip its aircraft with zero emissions, expected to enter service by 2035. Airbus will commence ground and flight testing of this fuel cell architecture aboard its ZEROe demonstrator aircraft in the mid-2020s.

4. Batteries and Hybrid Electrical Airplanes

4.1. Light Training Airplanes

Pipistrel Velis Electra-One is a light two-seater airplane, already commercialized [28]. It has an electric motor for propulsion fed from batteries. Its main characteristics are presented in [28,29].

4.2. Sailplanes

Diamond Electric performed its maiden flight on 20 July 2023. It is certified by the EASA/FAA and has started sales. It is a two-seater with an electric motor from Safran Electrical & Power fed from a batteries system produced by Electric Power Systems (EPS). It is a pure electric solution on the platform of Diamond 40. It has a flight time of 1.2 h, a payload of 200 kg, two–three places, and a range of 210 km [30].

Diamond HEMEP has been produced by Diamond together with Siemens [31]. It performed the maiden flight in 2018. It has a hybrid propulsion system in series configuration. The distributed configuration of the propulsion system allows for the improvement of each component separately. It has a 10 kW thermal engine that drives the generators of two separate electric systems. Each electric system consists of a generator, inverter and electric motor. In each system is also a 12 kWh battery. The total takeoff power of the electric motors is 150 kW. Pure electric mode with an autonomy of 30 min, cruise mode (generators pass all the energy to the motors), and charge mode (generators charge the batteries) can be selected. In the hybrid system, the autonomy is up to 5 h. It is an improvement on the airplane DA36 E-Star [32].

Diamond DA36 E-Star was developed by Siemens together EADS and Diamond. It is a two-seater sailplane and performed the maiden flight on 8 June 2011. It has an 70 kW electric motor from Siemens fed from a generator. The generator is driven by a Wankel thermal motor with the function regime in constant power. Batteries ensure the supplemental power in takeoff and climb. The batteries are charged in the cruise regime.

4.3. Commuter Airplanes

The Electric Beaver DeHavilland is a six-seater airplane derived from Beaver De Havilland, launched in 1948 and repowered in an electric version. It has a propulsion system from MagniX provided with an electric motor with axial magnetic flux. This airplane is operated by the Harbour Air company that intends to transform its Beaver fleet into electric versions [33].

Eviation Alice is an airplane with nine seats and two pilots. It accomplished the maiden flight in September 2022. For propulsion, it has two electrical motors, each one of 850 HP, fed from 900 kWh batteries. The battery mass is 4000 kg. The airplane range is 450 km with a navigation reserve of 30 min [34].

Airplane NASA X57 Maxwell is a research platform for all electric aircraft that tests new solutions useful for commuter airplanes. Between these solutions figures also distributed propulsion [35]. It is anticipated to use high voltage Li-Ion batteries, provided with prevention systems against fire propagation and thermal management.

4.4. Performance Airplanes

Evolito (Rolls Royce Spirit of Innovation) [36] is an airplane developed for record achievements at the electric airplanes class. It is a one-seater airplane with a 400 kW YASA motor fed from 6840 battery cells. The electric system voltage is 750 V. The maximum speed reached on a 3 km distance is 555 km/h, and on a 15 km distance, it is 532 km/h. YASA is a path breaker in axial magnetic flux motors worldwide and has been bought by Mercedes-Benz in July 2021 [14].

Siemens Extra 330 LE is the electric version of the well-known aerobatic airplane Extra 330 [37]. It has been equipped with an electric motor from Siemens, enabling it to climb at 3000 m in only 4 min and 22 s, with a climb speed of 11.5 m/s. It established the climb speed world record in November 2016, registered by FAI [37].

Bye Aerospace Company has an ambitious development program that aims offer three electrical airplanes with two, four, and six + two seats. It is anticipated to certify these aircrafts for market launch [38]. Some technical data of eFlyer 2 are in [38].

We can mention also other projects developed for concept competitions as Flynk, Hybris, Flybird, and so on, but these projects have not entered in advanced studies and the development phase.

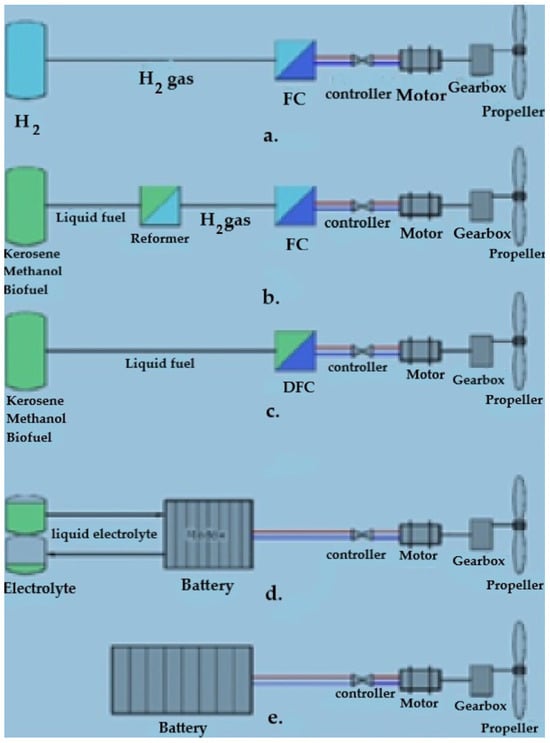

5. System Architectures for Electric Propulsion

In Figure 3 [3], we present five possible architectures for electric propulsion systems. The final part of these systems is the same (controller, motor, gear, and propeller). Different are the power sources feeding the controller. The first three versions use fuel cells, fueled either with hydrogen or liquid fuel. The simplest version (Figure 3a) uses directly hydrogen in the fuel cell, but we saw that the necessary hydrogen tanks are bulky. High energy densities are provided by liquid fuels such as kerosene, methanol, or bio-fuels. Using these fuels involves converting these fuels into hydrogen with a reformer (Figure 3b) or liquid-fueled fuel cells (Figure 3c). Fuel cells with liquid fuel are not yet well developed. Systems with liquid fuel conversion to hydrogen are already commercial for ground applications, but the reformer is very heavy, and this kind of system is not yet suited for aviation [39]. The last two versions in Figure 3 used different battery types, either with liquid electrolyte (Figure 3d) or classical ones (Figure 3e).

Figure 3.

Possible architectures for airplane electric propulsion systems [3].

In Figure 3, architectures with a single power source are presented. In fact, different power sources have advantages and disadvantages.

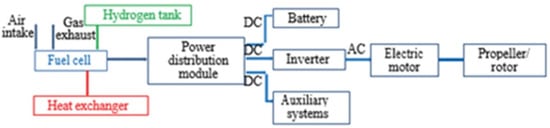

A more detailed structure of the propulsion system provided with hydrogen fuel cells is shown in Figure 4. There are also the auxiliary components along with the motor, inverter, and fuel cell.

Figure 4.

Electrical propulsion system with hydrogen fuel cells [40].

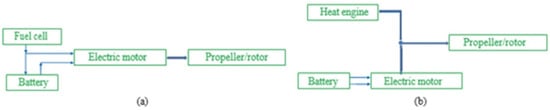

In Figure 5 [40], there are two versions for power source hybridization. The first version (Figure 5a) hybridizes the electrical power source. A battery is used together the fuel cell; these two have complementary qualities. The second version hybridizes the propeller drive (Figure 5b). There is, on board, a heat engine together with the electric motor. The propeller is driven by the two motors using a clutch.

Figure 5.

(a) Series hybrid propulsion system, (b) parallel [40].

6. Electric Repowering of a Training Aircraft

The previously presented issues referred to research on electric propulsion for completely new aircraft, with the exception of the electric variants from the Diamond aircraft company. Diamond has essentially repowered several of its production aircraft. The direction of electric repower for already operational aircraft may prove to be of interest in the near future. There are many sport aircraft currently in operation that still have significant flight resources and can be equipped with electric propulsion systems. This reduces the costs required to obtain an electrically powered aircraft, considering that there is no need for a complete redesign of the entire structure.

However, this approach is expected to encounter difficulties, considering that modern aircraft designed from scratch with electric propulsion systems also use modern carbon fiber-based structures. These structures are considerably lighter than traditional aluminum ones, and thus, part of the heavy battery weight can be offset by the reduced weight of the structure. Nevertheless, the authors of this study aim to assess the possibilities of repowering an existing school and training sports aircraft already in operation. The goal is to determine the performance that can be achieved by repowering this aircraft using commercially available equipment, thus reducing the time for the repowering process by eliminating the research–design–manufacturing phase for these components.

Studies concerning electrical propulsion implementation on board different aircraft are well developed at present. In [41], an electric propulsion system with a new architecture and a new control system is presented. In [42], extensive studies concerning on board hydrogen storages systems can be found. In [43], a design approach for aircraft propulsion electrification is presented. In [44], a preliminary design methodology for an aircraft powertrain with battery and fuel cell power sources is presented. In [45], the main problems concerning H2 fuel cells used for aircraft propulsion are highlighted.

One of the widely spread and extensively used aircraft by the Romanian Aeroclub is the ZLIN 142 (Figure 6). There are several such aircraft in the inventory of the Romanian Aeroclub, and they still have a significant flight resource, making them suitable for continued use as electric aircraft, both for sports purposes and for training pilots for future electric planes that are expected to enter the market soon.

Figure 6.

ZLIN 142 aircraft [46].

Some technical data for this aircraft are presented in Table 2 [46]. Based on this technical information, the first step is to estimate the aerodynamic characteristics of this aircraft. Regarding the propulsion system, the aim is to retain the same variable-pitch propeller driven by a constant speed electric engine.

Table 2.

Technical data for ZLIN 142 [46].

In the vast majority of cases, variable-pitch propellers are designed so that their speed is practically kept constant (with variations of up to 10%) over the entire operating range of the aircraft. The variation in thrust is achieved by adjusting the pitch of the propeller, aiming to achieve the best possible efficiency for the propeller at each flight regime. A typical good efficiency for a propeller, in the category used by the ZLIN 142 aircraft, is approximately 75%. We will adopt this efficiency value in this study to estimate the power requirements.

Considering the relation [47,48]

the propulsion power in maximum speed and cruising regime can be estimated. Using aerodynamic coefficients, the power of propulsion can be written in the following form:

Ppropulsion = Pshaft ηpropeller

Ppropulsion = ρ V3SCx/2

Therefore, using Equations (1) and (2), the drag coefficient Cx for the two flight regimes—cruising and maximum speed—can be determined. The lift coefficient for the two flight regimes can be estimated from the relation:

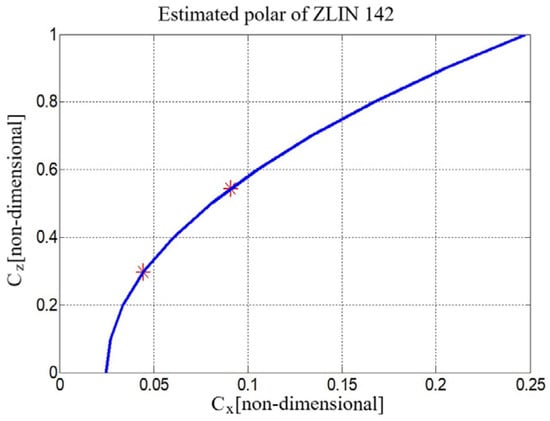

considering that the lift L must be equal to the weight of the aircraft in horizontal flight. Two points on the lift–drag polar Cz (Cx) can be determined using the data from Table 2.

L = ρ V2SCz/2

The aerodynamic polar Cz (Cx), for angles of attack below the theoretical angle of attack, is known to be given by

Cx = Cx0 + KCz2

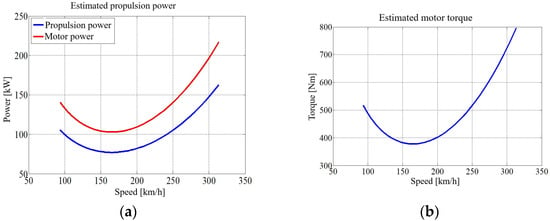

Knowing the two points on the polar determined earlier, Cx0 and K can be determined so that the Cz (Cx) polar is known. The estimated polar is presented in Figure 7. Using relations 2 and 3, the P(V) dependence for the ZLIN 142 aircraft can be determined, as shown in Figure 8a. The shaft moment determined from relation 5 is presented in Figure 8b.

Mshaft = Pshaft/Ω

Figure 7.

The estimated polar Cz (Cx) for ZLIN 142 aircraft. Marked points are for cruise flight regime and maximum speed regime.

Figure 8.

(a) Estimated powers; (b) estimated shaft moment.

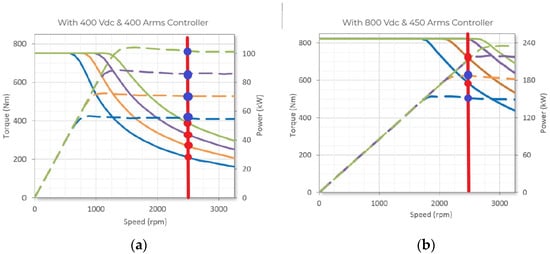

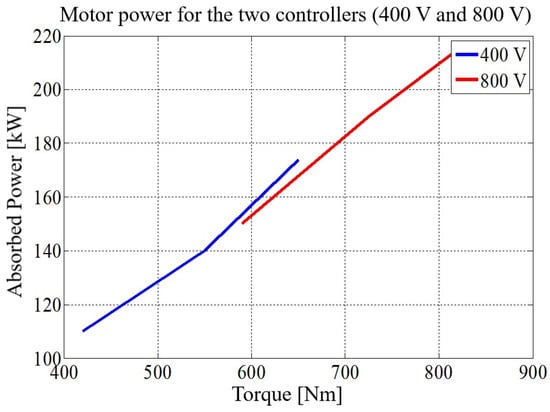

In the documentation of the YASA 750 R motor [14], the characteristics of this motor are presented for operation with a 400 V/400 A controller and for an 800 V/450 A controller. These characteristics are shown in Figure 9a,b. The continuous curves are the dependences torque–speed at the constant power. The dashed curves are power–speed curves at a constant torque. In this manner, the motor catalog is presented. To keep the same propeller, it is necessary for the motor to operate at approximately 2500 rpm and provide the required shaft torque for the propeller, as shown in Figure 9b. It can be observed that with the 400 V/400 A controller, a single motor cannot achieve the required shaft torque at 2500 rpm, but this type of motor easily allows the installation of multiple motors on the same shaft (for example, the Rolls Royce Evolito aircraft has three such motors mounted on the propeller shaft). In the version with the 800 V/450 A controller, the shaft torques can reach the necessary values. The choice of the convenient option arises. Two motors mean doubling the weight for (motor + controller), and the option with the 800 V/450 A controller means an inverter for the 800 V voltage or 800 V batteries. Usually, batteries with higher voltages are heavier. So, from the motor’s point of view, it can be said that implementing the electric propulsion system for the ZLIN 142 aircraft is possible. We present below an estimate of the two options regarding the power absorbed from the batteries.

Figure 9.

Characteristics of the YASA 750 R electric motor [14].

It is observed that from the perspective of absorbed power (Table 3 and Figure 10), the difference between the two variants is not significant in the torque domain they overlap, but the variant with two engines mounted on the same shaft, powered at 400 V, better covers the required torque domain. So, it seems that this is the more advantageous option, although it involves doubling the weight of the motor and controller.

Table 3.

The moment at the shaft and the absorbed power for the two controller variants.

Figure 10.

The power absorbed by the engines in the two controller variants.

Regarding the onboard energy requirement, we make an estimate for a 30 min cruise flight, considering a takeoff phase of approximately 2 min. Thus, during takeoff, the shaft power absorbed power is 154 kW, according to the aircraft’s datasheet [46]. This entails an energy of 5.15 kWh for a duration of 2 min. The cruise flight cannot start immediately after takeoff because it is necessary to reach the cruise speed. So, we also consider a 5 min acceleration period, during which the power decreases from 150 kW to 105 kW, averaging 127.5 kW. This average value for a period of 5 min requires energy of 10.6 kWh. For the remaining 23 min, consider cruising with a power of 105 kW, totaling 40.25 kWh. Overall, the flight requires a total energy of 56 kWh. It can be said that this would be a minimal requirement for a 30 min flight, considering that the aircraft only performs cruise flight and no other maneuvers in this flight. For the aircraft to be able to execute a reasonable flight, an 80 kWh battery would be necessary.

7. Possible Options for Repowering

In regards to the development of the electric propulsion system for the ZLIN 142 aircraft, we are exploring two possibilities. These options involve the use of two YASA 750 R motors mounted on the propeller shaft. The power supply voltage for the motors is considered to be 400 V (two YASA 750 R motors powered by 400 V/400 A converters). However, their power supply is planned to be carried out in two different ways: (1) using a hybrid energy source consisting of a fuel cell and a battery; and (2) using a simple energy source consisting of a battery. The study of the two considered options was further conducted through modeling and simulation using the Simcenter Academic Bundle software version 2304.

Option 1—Energy source composed by fuel cell and battery

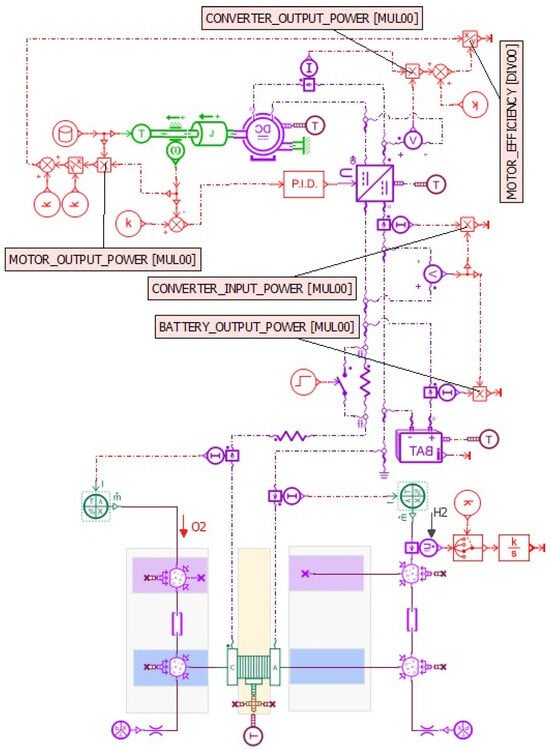

The electric propulsion system has been modeled in the Simcenter Academic Bundle, and the diagram in Figure 11 has been obtained.

Figure 11.

Simulation diagram for the electric propulsion system—option 1.

The system consists of a PEM-type fuel cell operating in parallel with a battery. They supply energy to the input of a controlled DC/DC converter, which powers the electric propeller drive motor. The control system for the motor in this variant is a PID loop that aims to maintain a constant propeller rotation speed. The torque at the propeller shaft is variable, allowing for power variation as described earlier. The fuel cell model is compatible with the parameters of the Ballard FCgen-HPS fuel cell. This type of fuel cell is well suited for aviation applications, with a volume power density of 4.3 kW/l, a mass power density of 4.7 kW/kg, a maximum power of 140 kW, a nominal current of 645 A, a nominal voltage of 202 V, and a mass of 55 kg [49].

The electric motor was considered a DC electric motor, equivalent to the two YASA 750 R motors mentioned above, capable of delivering an output power of 150 kW. Although, in reality, two axial flux magnetic motors will be used, the energy consumption is similar. The Simcenter Academic Bundle software does not yet have implemented models for axial flux motors. For the YASA 750 R motors, the datasheet specifies a peak efficiency of 95%. Due to the resistance of the windings of the considered DC electric motor, its efficiency will likely be lower than 95%, but we can say that the results will be close to the reality. On the one hand, the YASA 750 R motor does not provide 95% efficiency in all operating conditions. On the other hand, the DC motor will probably consume slightly more energy, so the actual situation will be somewhat more favorable than the simulation results. We can say that the results will be comprehensive.

The controlled converter ensures motor control. It is set to an efficiency of 95%, realistic for modern converters with semiconductor devices. Its output voltage is variable, so the motor provides the necessary power at that moment. The input voltage is provided by the battery connected in parallel with the fuel cell.

The battery is used to absorb load peaks during takeoff and during flight. During the cruise flight, the fuel cell provides a slight charge to the battery.

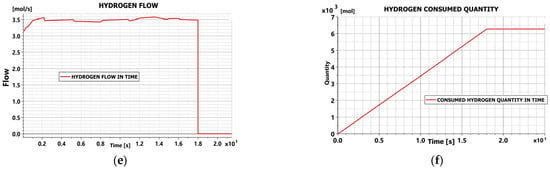

The load spectrum of the propulsion system (yellow color in Figure 12a) includes a startup phase, where the motor reaches maximum power at takeoff, the takeoff phase described earlier, an acceleration phase with a power of 130 kW, and a flight phase. In the flight phase, a cruise flight with a power of 105 kW was considered, followed by several power variations between cruise power and a maximum power of 145 kW. The load spectrum is somewhat more complex than the initially proposed one with a cruise flight over 23 min. We assumed that the operation of the fuel cell ends after 30 min (1800 s), and afterward, the propulsion system operates in cruise mode until the battery is discharged to a level of 20% of its nominal capacity. The motor efficiency, presented in Figure 12d, varies between 70% and 80%, which are realistic values, even though they are lower than the peak value of axial flux motors. We can say that the motor efficiency is close to a real motor, and the value is comprehensive.

Figure 12.

Simulations results for Option 1. (a). powers in the system; (b). energies in the system; (c). battery state of charge; (d). electric motor efficiency; (e). consumed hydrogen flow; (f). hydrogen amount consumed in time.

Over the course of the 30 min operation, the fuel cell provides 80 kWh of energy, and the battery provides 5 kWh, with its state of charge ranging from 90% to 75%. After the fuel cell operation is interrupted, the system continues to operate on the battery in cruise mode for a period of 400 s (approximately 6.7 min), during which the state of charge of the battery varies from 75% to 20%. The energy consumed from the battery during these 400 s is 15 kWh, resulting in a total of 20 kWh consumed from the battery.

The hydrogen flow rate consumed by the fuel cell is presented in Figure 12e, with the total quantity of hydrogen shown in Figure 12f. The total amount of hydrogen consumed during the 1800 s of fuel cell operation is 6200 mol, equivalent to 12.4 kg of H2.

In the technical datasheet for the ZLIN 142 aircraft (Table 2), the empty weight is specified as 730 kg. The weight of the aircraft’s internal combustion engine is approximately 100 kg. The fuel capacity can be 125 L for the aerobatic version or 230 L for the long-distance flight version. The maximum takeoff weight is specified to be 1090 kg with two pilots. Assuming the internal combustion engine is removed, the structural weight remains at 630 kg. Adding the weight of the two pilots, each weighing 80 kg, results in a total mass of 790 kg. Up to the value of 1090 kg, there are 300 kg available for the new propulsion system. Among these, 2 × 37 kg should be the mass of the two motors, and 2 × 15 kg the estimated mass of the controllers, with an additional 10 kg for the motor cooling system. In total, 186 kg are available for the onboard propulsion energy source.

In [49], the technical datasheet for FCgen-HPS fuel cells produced by Ballard is presented. These can develop a power of up to 140 kW, with a weight of 55 kg. From the available 186 kg, 131 kg are allocated for the hydrogen tank and the battery.

The mass of a 20 kWh battery with a density of 220 Wh/kg is 90 kg. This leaves 28.6 kg available for the hydrogen tank and its auxiliary systems. If a battery with a density of 500 Wh/kg is used, then the battery mass is 40 kg, leaving 78.6 kg available for the hydrogen tank and its auxiliary systems. In the version with the 220 Wh/kg battery, the available mass for the hydrogen tank seems to be very small. But, in [50], the company Universal Hydrogen affirms it will produce tanks, “either carbon fiber to hold H2 gas at 850 bar achieving a density of 50 kg/m3, or insulated metal tanks to hold liquid H2 (LH2) at standard pressure and temperature achieving a 71 kg/m3 density”. For the version with the 500 Wh/kg battery, the company Stealhead Composites offers hydrogen tanks at 700 bar with 76 l capacity and 23 kg tank mass [51]. Three such tanks mean a 228 l capacity at a 69 kg mass within the 78.6 kg available on board. Although the version with 220 Wh/kg batteries seems to be less feasible, the version with 500 Wh/kg batteries seems to be entirely feasible.

For hydrogen storage at a pressure of 700 bar, a tank volume of approximately 200 L is required, while storage at 350 bar would necessitate a volume of 400 L.

We summarized the results of this variant in Table 4.

Table 4.

Synthesized results for the first repowering option.

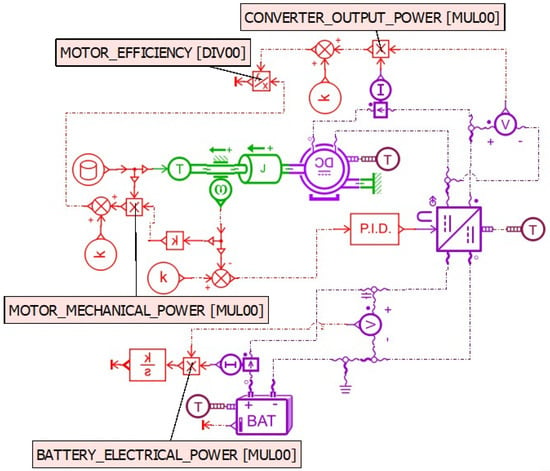

Option 2—Energy source composed of a battery with an energy density of 220 Wh/kg

The model of the electric propulsion system created in Simcenter Academic Bundle for this option is presented in Figure 13.

Figure 13.

Simulation diagram for the electric propulsion system—option 2.

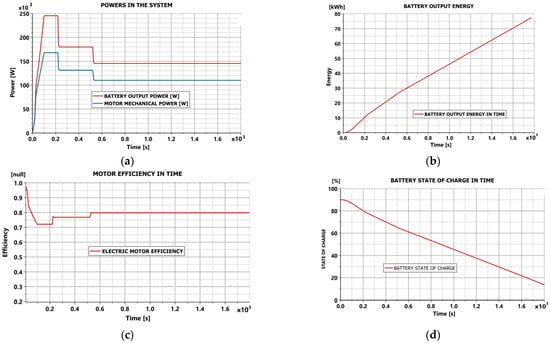

In this case, the simulation diagram is simplified as there is no longer a fuel cell. The simulation results are presented in Figure 14.

Figure 14.

Simulation results for option 2. (a). powers in the system; (b). battery output energy; (c). electric motor efficiency; (d). battery state of charge.

The spectrum of the motor load has been simplified in this case, after the takeoff and acceleration period, considering a cruise flight with a power of 105 kW. The motor efficiency is found to vary within the same limits as in the previous variant. The energy consumed from the battery over the 1800 s is approximately 80 kWh, and the battery’s state of charge varies during this period from 90% to 20%. The energy consumed is higher than the previously estimated 56 kWh, but the earlier estimates did not account for the efficiencies of the motor and the converter. Assuming a battery with an energy density of 220 Wh/kg, the battery mass is estimated to be 363 kg. Table 5 provides a summary of the situation for option 2.

Table 5.

Synthesized results for the second repowering option.

From Table 5, it can be observed that in this case, the maximum takeoff weight is exceeded. Therefore, this option cannot be accepted. If, however, it is still desired to limit the total mass of the aircraft to 1090 kg, then the battery mass must be limited to 186 kg, resulting in a total energy reserve of 40.9 kWh. According to the graph in Figure 14b, this energy is consumed in a time interval of 800 s (13.5 min). This time, there is no longer a reserve for navigation for a few minutes.

If a battery with a power density of 500 Wh/kg is used, with an available battery mass of 186 kg, the battery energy is 93.0 kWh. Using the graph in Figure 14b, this energy is consumed in approximately 2100 s (35 min).

Table 6 provides a comparison between the initial powering with the internal combustion engine and the proposed powering options.

Table 6.

Comparison between the ZLIN aircraft with thermal propulsion and electric propulsion.

In [52], a study is performed concerning the repowering of a SOCATA TB 9 aircraft into an electric propulsion. It is an airplane in the same category as ZLIN 142 but has a 630 kg structure mass and maximum takeoff mass 1060 kg, with four–five passengers. The authors consider an electric propulsion system provided only with a battery of 500 Wh/kg power density and remove two passengers. The propulsion power of SOCATA TB 9 is close to that of ZLIN 142. With a 387 kg mass battery, the airplane studied by the authors reaches a one-hour flight time. These results are compatible with the results obtained in this work. In that study, by removing two of the four passengers, a 160 kg mass remains available for the new propulsion system. The SOCATA TB 9 empty weight is 630 kg, unlike ZLIN 142, the empty weight of which is 730 kg. So, the new propulsion system of SOCATA TB 9 benefits from around 200 kg more weight than the propulsion system for ZLIN 142 proposed in this study.

8. Conclusions

The electric repowering of the ZLIN 142 aircraft with the proposed variants in this study offers limited prospects in terms of achievable performance. Repowering using only batteries results in a very short flight time for batteries with an energy density of 220 Wh/kg and a somewhat acceptable 35 min for a power density of 500 Wh/kg. A similar performance to the second case can be achieved by using hydrogen fuel cells in combination with a 20 kWh battery. A flight time of 30 min, powered by fuel cells, plus a navigation reserve of approximately 7 min, solely with battery power, can be attained. The fuel cell option offers the advantage of realizing a more complex flight profile during the 30 min, unlike the battery case where only a 30 min cruise flight was considered.

It can be said that the use of recently emerged fuel cells on the market provides the prospect of better performances for electric propulsion aircraft. The use of hydrogen stored in pressurized tanks at 700 bar seems to offer the optimal balance between the complexity of the hydrogen system and its volume. For a flight like the one mentioned earlier, 12.4 kg of hydrogen is required, occupying a volume of 200 L at a pressure of 700 bar. Such a tank volume is acceptable for the ZLIN 142 aircraft. Reducing the pressure to 350 bar results in double the volume, i.e., 400 L, that is already too large for this aircraft. Storing hydrogen in liquid state is not justified in this case due to the issues raised by this solution. Liquid hydrogen storage, even though it has less weight than the pressurized ones, needs thermal insulation and, in some situations, cooling systems. Due to the thermal insulation, liquid hydrogen storages are more voluminous and difficult to place on board. Using cooling systems implies more complex installation, taking into account the needed temperature is—256 °C.

While electrifying the propulsion of an older aircraft, as was carried out with the DeHavilland Beaver [33], may seem like a more cost-effective solution, it has very limited possibilities, leading to a drastic reduction in flight time and payload capacity. In the case of the De Havilland Beaver aircraft, the initial flight time was approximately 5 h; after electric repowering using battery power, only a 24 min flight has been achieved so far. The situation is similar for the studied ZLIN 142 aircraft. Initially, the cruise flight time was 5 h and 30 min; after repowering, an estimated flight time of approximately 30 min with a navigation reserve of 7 min is anticipated.

Electric propulsion aircraft have been developed with power ranging from 20 kW. The power requirements for the ZLIN 142 aircraft are higher due to its design for higher flight speeds with acrobatic and training capabilities. It would be interesting to study, in the future, either the electrification of an aircraft in the same category but with a much lighter modern structure or the electrification of a recreational category aircraft with lower flight speeds, where the power and stored energy requirements on board are significantly lower.

Given the very low weight of carbon fiber structures, technological advancements in the field, and the reduction in financial and time costs related to the design and execution of such structures, it seems that the option of electric repowering for older aircraft has limited prospects. A modern aircraft, designed from scratch around an electric propulsion system, will have a considerably better performance than an older aircraft repowered with electric motors. The reduced financial and time costs for repowering might be offset by the improved performance of a new aircraft.

Considering the findings presented in this study, an important conclusion is that sustained research efforts are still needed in the field. The performance of electric aircraft, even when newly designed, has not yet reached the level of performance achieved by thermally powered airplanes.

Author Contributions

Conceptualization, J.-I.C. and L.D.; methodology, G.C.; software, A.I.; validation M.N. and A.-A.C.; formal analysis, R.B.; writing—original draft preparation, G.C., A.I., M.N. and A.-A.C.; writing—review and editing, J.-I.C., L.D. and R.B. All authors have read and agreed to the published version of the manuscript.

Funding

The studies in this work are funded in the internal research program of the Electric, Energetic and Aerospace Engineering Department of the University of Craiova.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fleck, A. Cars Cause Biggest Share of Transportation CO2 Emissions. Available online: https://www.statista.com/chart/30890/estimated-share-of-co2-emissions-in-the-transportation-sector/#:~:text=Cars%20and%20vans%20accounted%20for,Energy%20Agency%20data%20(IEA) (accessed on 10 November 2023).

- Shadbolt, L. Technical Study Electric Aviation in 2022; HDI Global Specialty Study Electric Aviation; HDI: Hannover, Germany, 2022. [Google Scholar]

- Hepperle, M. Electric Flight—Potential and Limitations; STO-MP-AVT-209; NATO, UNCLASSIFIED: Washington, DC, USA, 2012. [Google Scholar]

- Nicolay, S.; Karpuk, Y.; Liu, A.E. Conceptual design and optimization of a general aviation aircraft with fuel cells and hydrogen. Int. J. Hydrogen Energy 2021, 46, 32676–32694. [Google Scholar] [CrossRef]

- Lithium Sulfur Battery Market Size, Share, Competitive Landscape and Trend Analysis Report by Type, Power Capacity and End Use: Global Opportunity Analysis and Industry Forecast, 2021–2030. Available online: https://www.alliedmarketresearch.com/lithium-sulfur-battery-market-A12076 (accessed on 14 November 2023).

- TESLA 6.3 KWH BATTERY MODULE (100 KWH PACK). Available online: https://stealthev.com/product/tesla-6-3-kwh-battery-module-100-kwh-pack/ (accessed on 17 November 2023).

- Kadletz, Z.; Motlagh, B. The All-New Amprius 500 Wh/kg Battery Platform Is Here. Available online: https://amprius.com/the-all-new-amprius-500-wh-kg-battery-platform-is-here/ (accessed on 23 November 2023).

- Blain, L. CATL Launches Ultra-High Density 500-Wh/kg “Condensed Battery”. Available online: https://newatlas.com/energy/catl-500-wh-kg-condensed-battery/ (accessed on 24 November 2023).

- Benquet, L. Airbus Reveals Hydrogen-Powered Zero-Emission Engine. Available online: https://www.airbus.com/en/newsroom/press-releases/2022-11-airbus-reveals-hydrogen-powered-zero-emission-engine (accessed on 27 November 2023).

- Redfern, C. The Cold Heart That Powers Our ZEROe Aircraft. Available online: https://www.airbus.com/en/newsroom/stories/2022-11-the-cold-heart-that-powers-our-zeroe-aircraft (accessed on 28 November 2023).

- Duvelleroy, M. Airbus and CFM International to Pioneer Hydrogen Combustion Technology. Available online: https://www.airbus.com/en/newsroom/press-releases/2022-02-airbus-and-cfm-international-to-pioneer-hydrogen-combustion (accessed on 30 November 2023).

- Benquet, L. Airbus and Linde to Cooperate on Hydrogen Infrastructure for Airports. Available online: https://www.airbus.com/en/newsroom/press-releases/2022-06-airbus-and-linde-to-cooperate-on-hydrogen-infrastructure-for (accessed on 4 December 2023).

- Rossi, N. Conceptual Design of Hybrid-Electric Aircraft. Master’s Thesis, Politecnico di Milano, Milan, Italy, 2017. [Google Scholar]

- YASA 750 R Axial Flux Electric Motor Datasheet. Available online: https://yasa.com/yasa-750-r/ (accessed on 7 December 2023).

- MagniX Is Leading the Electrification of Aviation. Available online: https://www.magnix.aero/ (accessed on 7 December 2023).

- Nagel, L. Big Brushless Motor Manufacturers for Drones and eVTOL. Available online: https://www.tytorobotics.com/blogs/articles/brushless-motor-manufacturers-for-evtol-and-aviation (accessed on 7 December 2023).

- McDonald, R. H2FLY And Partners Complete World’s First Piloted Flight of Liquid Hydrogen Powered Electric Aircraft. Available online: https://www.h2fly.de/2023/09/07/h2fly-and-partners-complete-worlds-first-piloted-flight-of-liquid-hydrogen-powered-electric-aircraft/ (accessed on 11 December 2023).

- Petridou, C. HY4 Aircraft Sets Hydrogen-Electric World Record Flying above 7000 Feet. Available online: https://www.designboom.com/technology/hy4-aircraft-hydrogen-electric-world-record-flying-7000-feet-05-31-2022/ (accessed on 15 December 2023).

- Cormack, R. This Bonkers Aircraft Just Completed the World’s First Piloted Electric Flight Powered by Liquid Hydrogen. Available online: https://robbreport.com/motors/aviation/h2fly-hy4-electric-aircraft-1234893415/ (accessed on 15 December 2023).

- ZeroAvia Makes Aviation History, Flying World’s Largest Aircraft Powered with a Hydrogen-Electric Engine. Available online: https://www.prnewswire.com/news-releases/zeroavia-makes-aviation-history-flying-worlds-largest-aircraft-powered-with-a-hydrogen-electric-engine-301726022.html (accessed on 15 December 2023).

- ZeroAvia, Inc. The First Practical True Zero Emission Aviation Powertrain. Available online: https://www.zeroavia.com (accessed on 18 December 2023).

- ENFICA-FC’s Rapid 200-FC Electric Aircraft Sets Speed and Endurance Records. Available online: https://ecofriend.com/enfica-fc-s-rapid-200-fc-electric-aircraft-sets-speed-and-endurance-records.html (accessed on 18 December 2023).

- Eissele, J.; Lafer, S.; Mejía Burbano, C.; Schließus, J.; Wiedmann, T.; Mangold, J.; Strohmayer, A. Hydrogen-Powered Aviation—Design of a Hybrid-Electric Regional Aircraft for Entry into Service in 2040. Aerospace 2023, 10, 277. [Google Scholar] [CrossRef]

- Pullen, J. Electric Aviation Continues to Progress in 2023. Available online: https://www.aviationtoday.com/2023/06/12/electric-aviation-continues-to-progress-in-2023 (accessed on 19 December 2023).

- 2nd FUTPRINT Academy. FUTPRINT50 Aircraft Design Challenge 2022 Takes off! Available online: https://futprint50.eu/2nd-futprint-academy (accessed on 19 December 2023).

- Towards the World’s First Hydrogen-Powered Commercial Aircraft. Available online: https://www.airbus.com/en/innovation/low-carbon-aviation/hydrogen/zeroe (accessed on 19 December 2023).

- UK Hydrogen Strategy. Available online: https://www.gov.uk/government/publications/uk-hydrogen-strategy (accessed on 20 December 2023).

- Technical Data Pipistrel Velis Electro. Available online: https://www.pipistrel-aircraft.com/products/velis-electro/ (accessed on 20 December 2023).

- Pipistrel Velis Electro. Available online: https://en.wikipedia.org/wiki/Pipistrel_Velis_Electro (accessed on 20 December 2023).

- Maiden Flight of the Diamond Aircraft eDA40. Available online: https://www.diamondaircraft.com/en/about-diamond/newsroom/news/article/maiden-flight-of-the-diamond-aircraft-eda40/ (accessed on 21 December 2023).

- Volck, M. HEMEP – Hybrid Electric Multi Engine Plane. Available online: https://www.airtn.eu/downloads/2015-06-30_airtn_nextgen_hemep.pdf (accessed on 21 December 2023).

- Lentsch, A. Diamond Aircraft Proudly Presents the World’s First Serial Hybrid Electric Aircraft “DA36 E-Star”. Available online: https://www.diamondaircraft.com/en/about-diamond/newsroom/news/article/diamond-aircraft-proudly-presents-the-worlds-first-serial-hybrid-electric-aircraft-da36-e-star/ (accessed on 21 December 2023).

- Harbour Air’s All-Electric Aircraft Operates First Point to Point Test Flight! Available online: https://harbourair.com/harbour-airs-all-electric-aircraft-operates-first-point-to-point-test-flight/ (accessed on 22 December 2023).

- Lambrecht, A. Eviation CEO Talks Electrifying the Skies with Its Upcoming Plane. Available online: https://insideevs.com/news/676120/eviation-electric-airplane-ceo-talk/ (accessed on 22 December 2023).

- Clarke, S.; Borer, N. X-57 Maxwell NASA’s Distributed Electric Propulsion Research Platform. Available online: https://ntrs.nasa.gov/api/citations/20210025904/downloads/NASA%20X-57%20lessons%202021-DEC_revised.pdf (accessed on 23 October 2023).

- Rolls-Royce ‘Spirit of Innovation’ Is Officially the World’s Fastest All-Electric Aircraft. Available online: https://www.designboom.com/technology/rolls-royce-spirit-of-innovation-worlds-fastest-all-electric-aircraft-03-10-2022/ (accessed on 23 October 2023).

- Extra 330LE Electric Aircraft. Available online: https://www.aerospace-technology.com/projects/extra-330le-electric-aircraft/ (accessed on 24 October 2023).

- World Leader and Innovator of Electric Aircraft. Available online: https://byeaerospace.com/ (accessed on 25 October 2023).

- Accelerating a Clean, Electric Future with Methanol Fuel Cells. Available online: https://www.blue.world/ (accessed on 25 October 2023).

- González-Espasandín, Ó.; Leo, T.J.; Navarro-Arévalo, E. Fuel Cells: A Real Option for Unmanned Aerial Vehicles Propulsion. Hindawi Publ. Corp. Sci. World J. 2014, 2014, 497642. [Google Scholar] [CrossRef] [PubMed]

- Shuangqi, L.; Chenghong, G.; Pengfei ZShuang, C. A novel hybrid propulsion system configuration and power distribution strategy for light electric aircraft. Energy Convers. Manag. 2021, 238, 114147. [Google Scholar] [CrossRef]

- Massaro, M.C.; Biga, R.; Kolisnichenko, A.; Marocco, P.; Monteverde, A.H.A.; Santarelli, M. Potential and technical challenges of on-board hydrogen storage technologies coupled with fuel cell systems for aircraft electrification. J. Power Sources 2023, 555, 232397. [Google Scholar] [CrossRef]

- Zhang, J.; Roumeliotis, I.; Zhang, X.; Zolotas, A. Techno-economic-environmental evaluation of aircraft propulsion electrification: Surrogate-based multi-mission optimal design approach. Renew. Sustain. Energy Rev. 2023, 175, 113168. [Google Scholar] [CrossRef]

- Sparano, M.; Sorrentino, M.; Troiano, G.; Cerino, G.; Piscopo, G.; Basaglia, M.; Pianese, C. The future technological potential of hydrogen fuel cell systems for aviation and preliminary co-design of a hybrid regional aircraft powertrain through a mathematical tool. Energy Convers. Manag. 2023, 281, 116822. [Google Scholar] [CrossRef]

- Gao, Y.; Jausseme, C.; Huang, Z.; Yang, T. Hydrogen powered aircraft. IEEE Electrif. Mag. 2022, 10, 17–26. [Google Scholar] [CrossRef]

- European Union Aviation Safety Agency. EASA Type Certificat Data Sheet for ZLIN Z 42 Series—EASA A.027 Issue 9; EASA: Cologne, Germany, 18 August 2020. [Google Scholar]

- Dinca, L.; Corcău, J.I. Mecanica si Dinamica Zborului Avionului; Editura Universitaria: Craiova, Romania, 2018; 335p, ISBN 978-606-14-1360-7. [Google Scholar]

- Dinca, L.; Corcau, J.I.; Marinescu, A. Avioane electrice: Provocari, oportunitati, realizari, tendinte actuale, perspective de viitor. In Proceedings of the Actualitati si Perspective in Domeniul Masinilor Electrice, Bucuresti, Romania, 24 November 2023; Volume 19. Nr. 1 (2023): APME-2023. [Google Scholar]

- High Performance Fuel Cell Stack Datasheet. Available online: https://www.ballard.com/docs/default-source/spec-sheets/fcgen-hps.pdf?sfvrsn=704ddd80_6 (accessed on 15 November 2023).

- Gardiner, G. Carbon Fiber in Pressure Vessels for Hydrogen. Available online: https://www.compositesworld.com/articles/cfrp-pressure-vessels-for-hydrogen (accessed on 16 November 2023).

- Lightweight Hydrogen Storage Datasheet. Available online: https://steelheadcomposites.com/wp-content/uploads/2022/10/Hydrogen-COPV-Brochure-1001.pdf (accessed on 17 November 2023).

- Bagarello, S.; Benedetti, I. Electric Conversion of a General Aviation Aircraft: A Case Study Aeronautics and Astronautics—AIDAA XXVII International Congress. Mater. Res. Proc. 2023, 37, 431–434. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).