Recycling Space Beverage Packaging into LDPE-Based Composite Materials

Abstract

1. Introduction

2. Materials and Methods

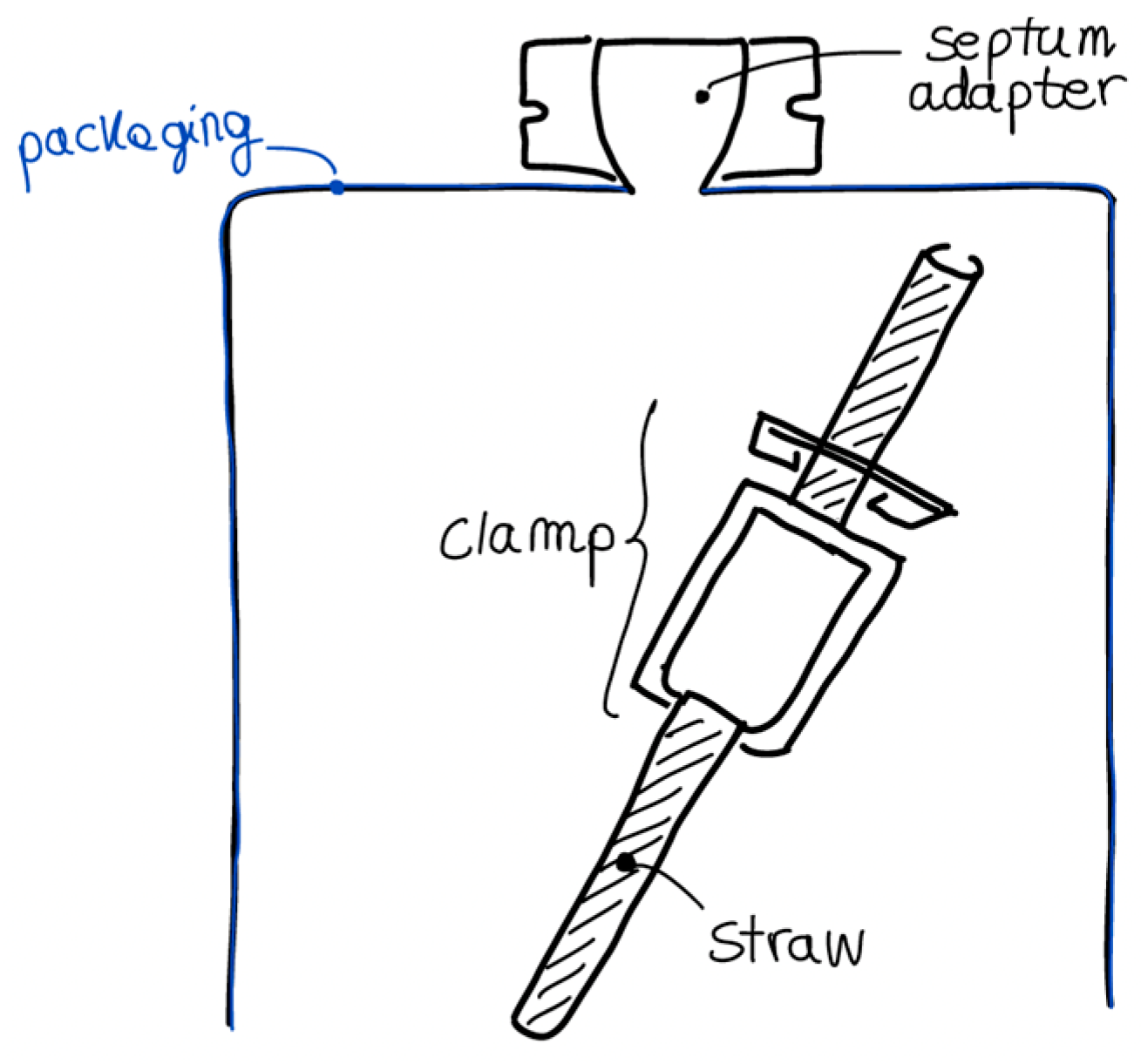

2.1. Sample Preparation

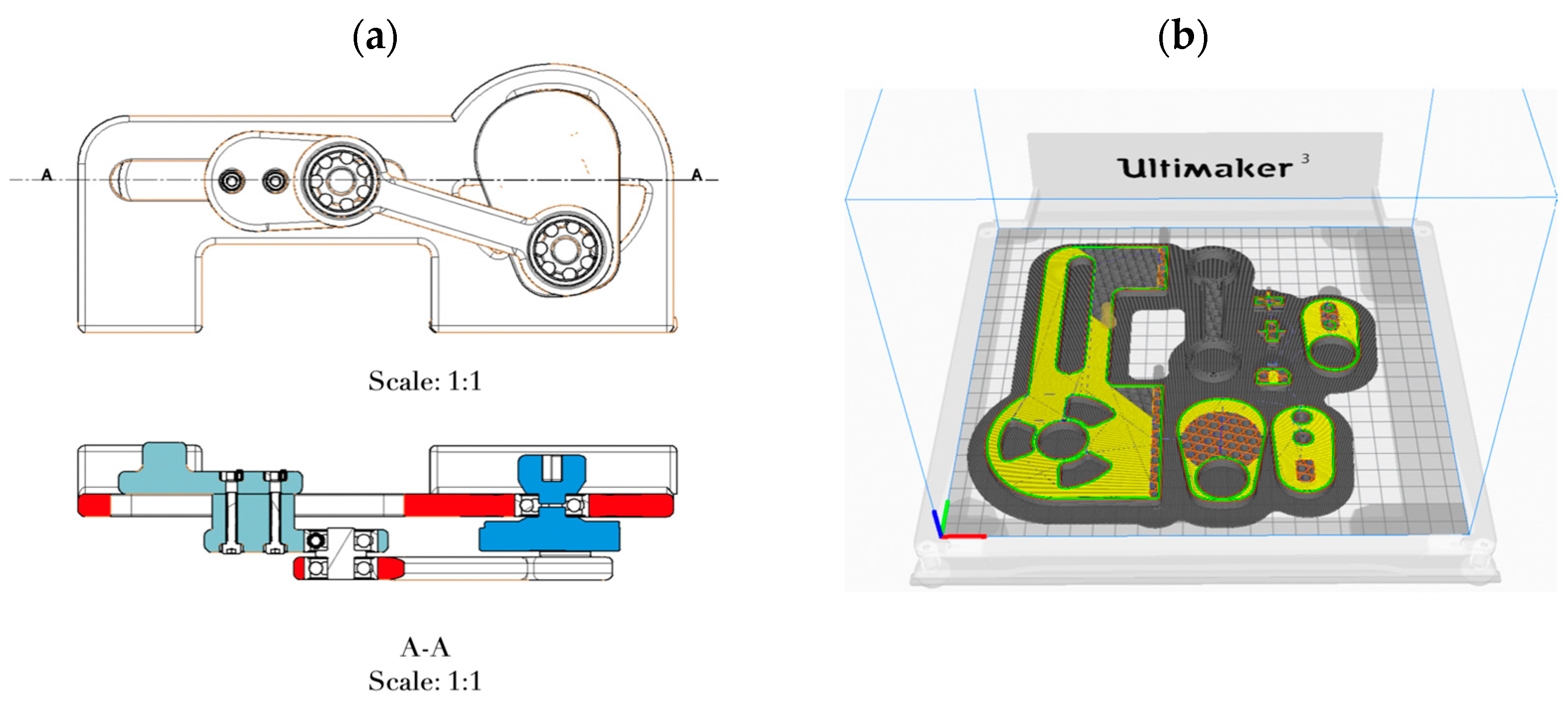

2.2. Extrusion Process for Filament Fabrication

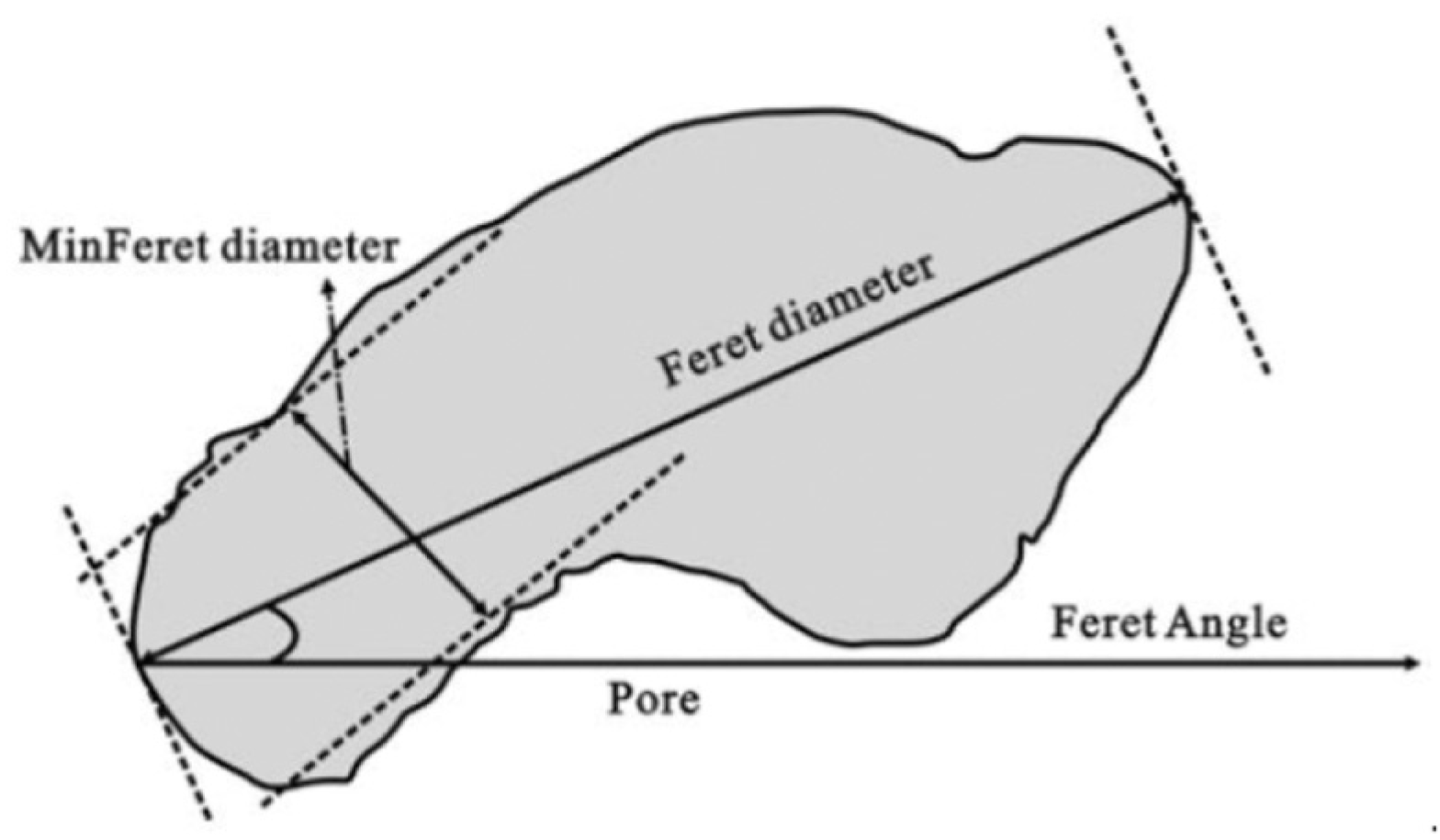

2.3. Characterization Methods

3. Results

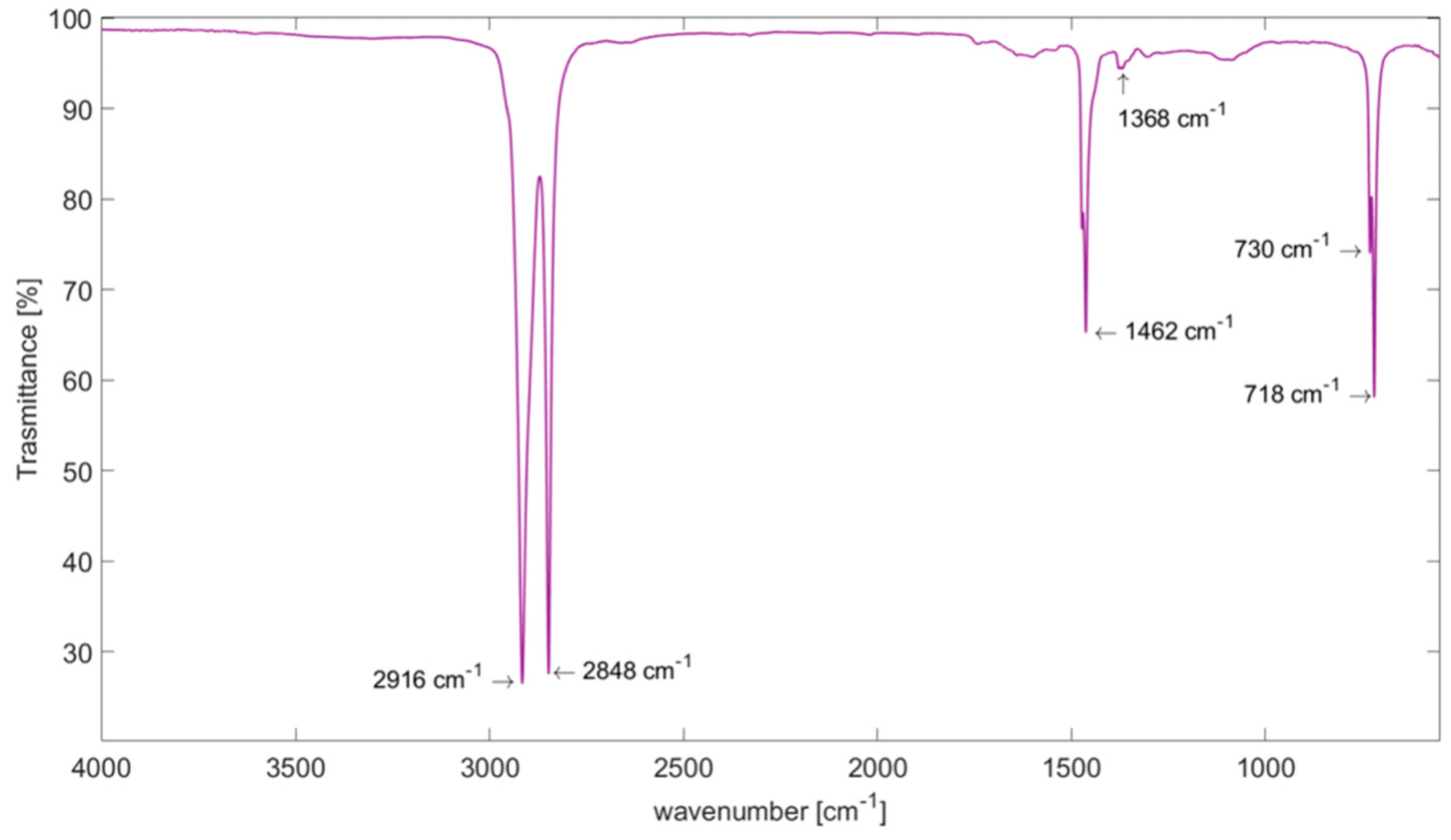

3.1. Fourier Transform Infrared Spectroscopy

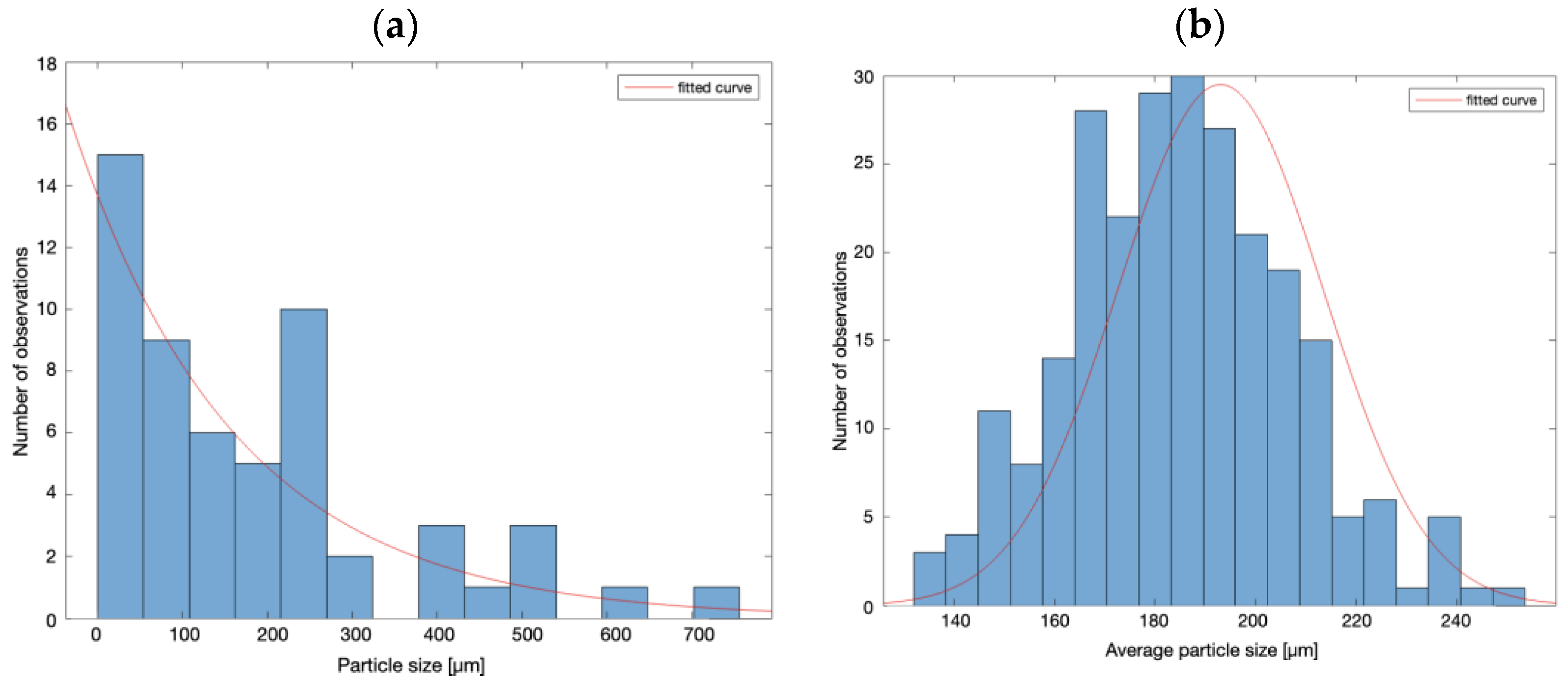

3.2. SEM Analysis

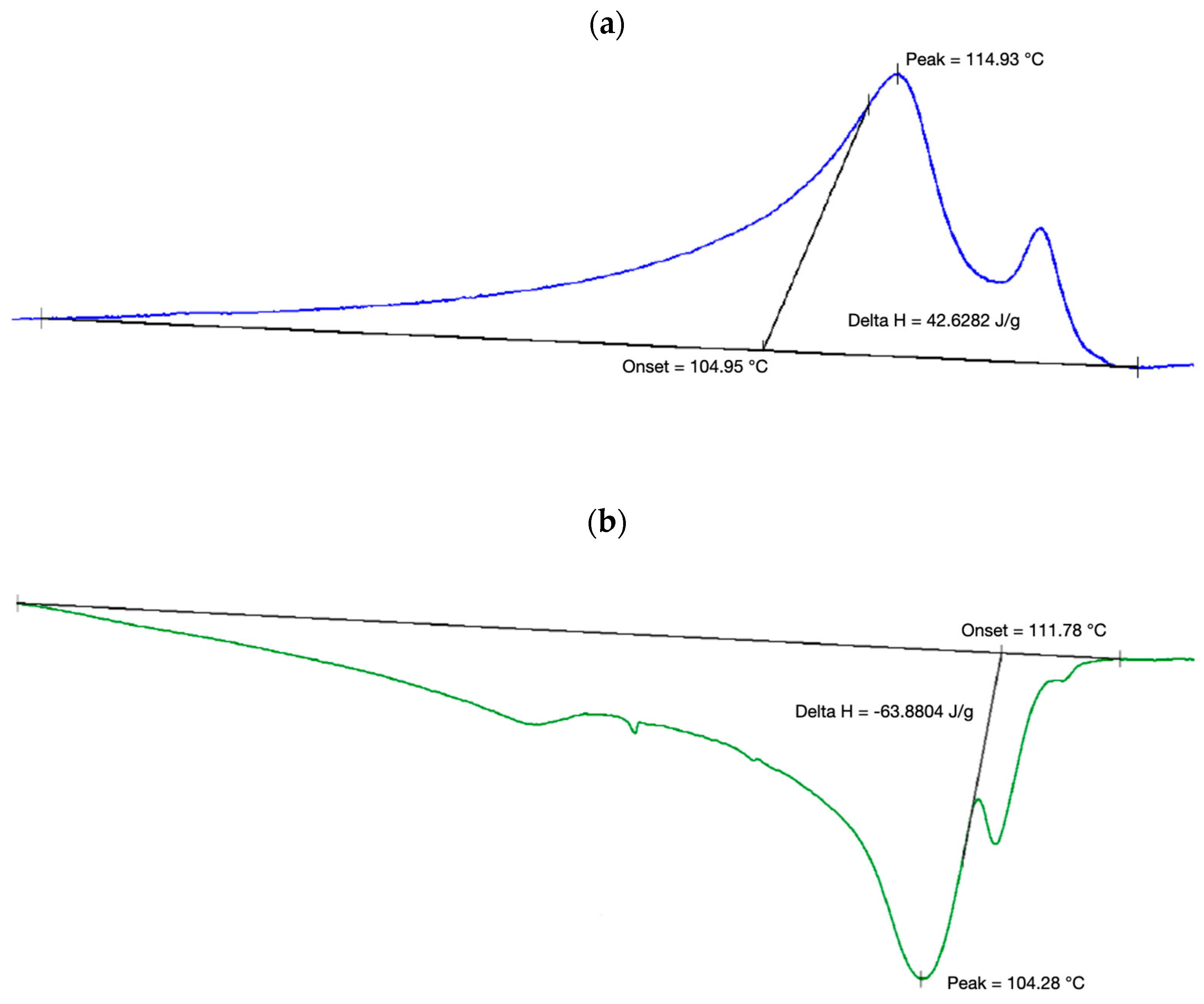

3.3. Differential Scanning Calorimeter

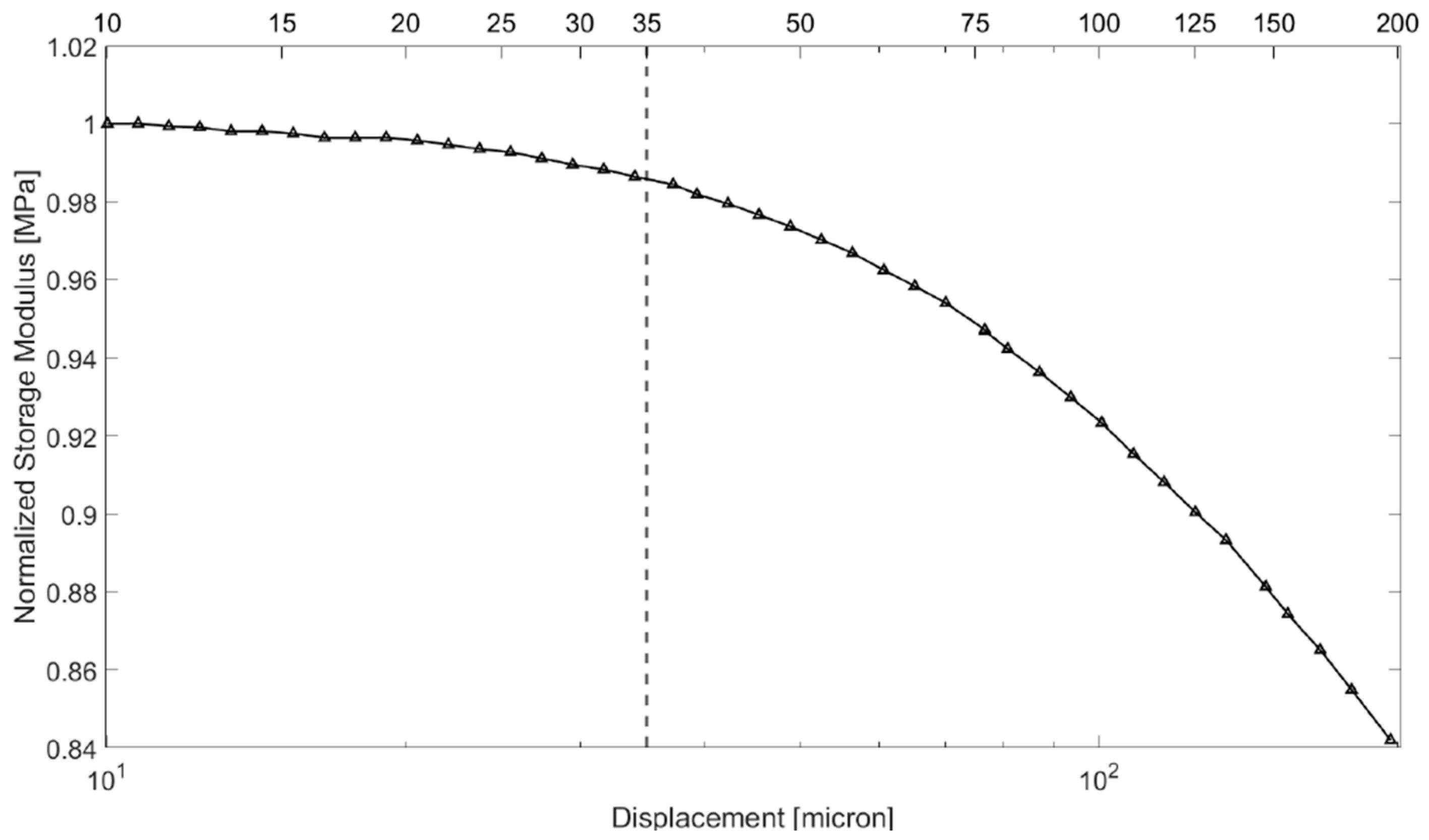

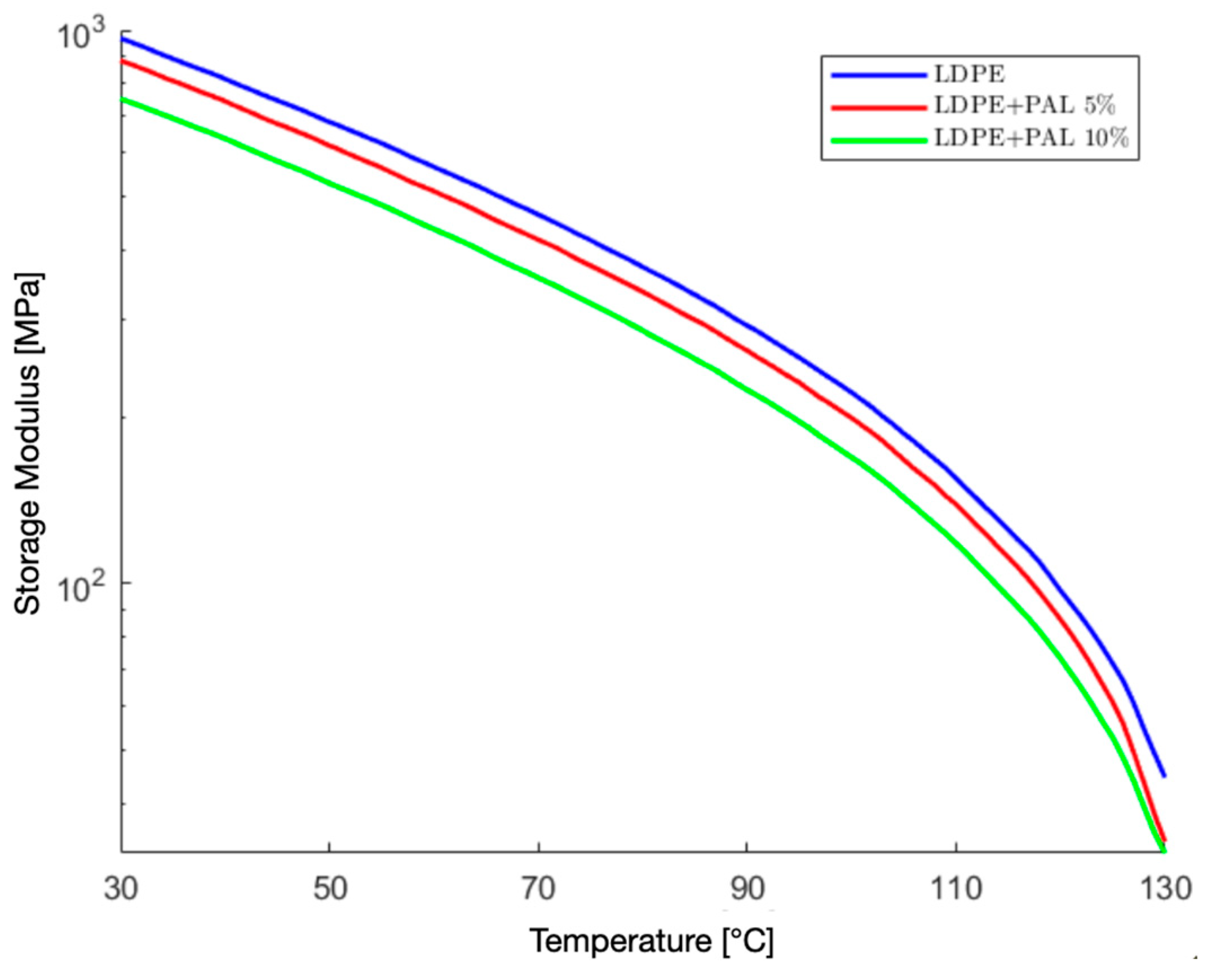

3.4. Dynamic Mechanical Analysis

3.5. Thermal Conductivity Analysis

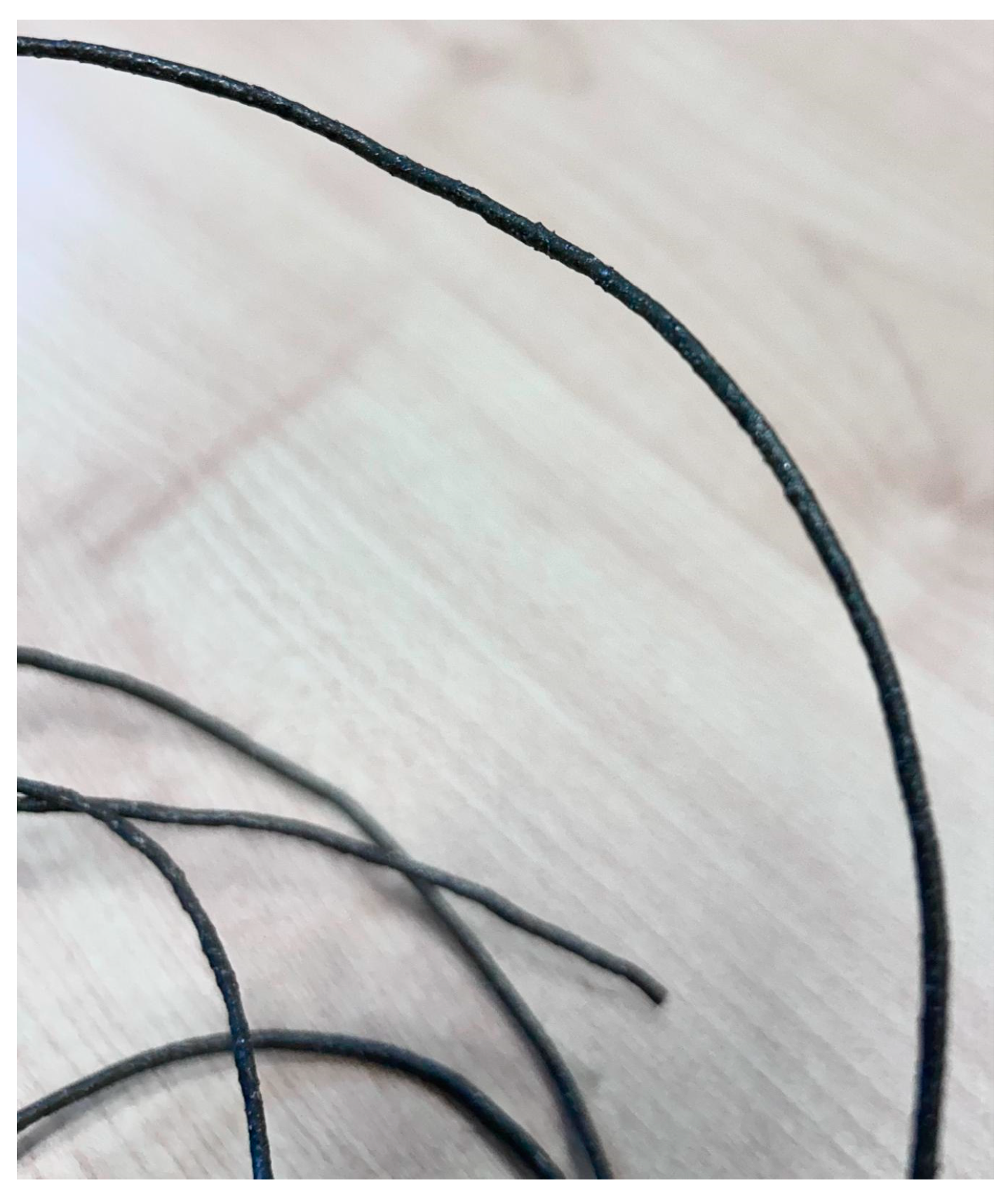

3.6. Extruded Filament

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile butadiene styrene |

| AM | Additive manufacturing |

| AMF | Additive manufacturing facility |

| ATR | Attenuated total reflectance |

| DSC | Differential scanning calorimetry |

| DMA | Dynamic mechanical analysis |

| FTIR | Fourier transform infrared spectroscopy |

| FFF | Fused filament fabrication |

| HDPE | High-density polyethylene |

| IR | Infrared radiation |

| ISM | In-space manufacturing |

| ISS | International Space Station |

| LEO | Low Earth orbit |

| LDPE | Low-density polyethylene |

| MIS | Made in space |

| NASA | National Aeronautics and Space Administration |

| PAL | PET-aluminum-LDPE |

| SEM | Scanning electron microscopy |

| TUI | Tethers Unlimited, Inc. |

References

- Bizzarri, M.; Gaudenzi, P.; Angeloni, A. The biomedical challenge associated with the Artemis space program. Acta Astronaut. 2023, 212, 14–28. [Google Scholar] [CrossRef]

- Creech, S.; Guidi, J.; Elburn, D. Artemis: An overview of NASA’s activities to return humans to the Moon. In Proceedings of the 2022 IEEE Aerospace Conference (AERO), Big Sky, MT, USA, 5–12 March 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar]

- Von Ehrenfried, M. The Artemis Lunar Program Overview. In The Artemis Lunar Program: Returning People to the Moon; Springer: Cham, Switzerland, 2020; pp. 7–47. [Google Scholar]

- Hoffman, J.A.; Hinterman, E.R.; Hecht, M.H.; Rapp, D.; Hartvigsen, J.J. 18 Months of MOXIE (Mars oxygen ISRU experiment) operations on the surface of Mars—Preparing for human Mars exploration. Acta Astronaut. 2023, 210, 547–553. [Google Scholar] [CrossRef]

- de Curtò, J.; de Zarzà, I. Analysis of Transportation Systems for Colonies on Mars. Sustainability 2024, 16, 3041. [Google Scholar] [CrossRef]

- Zaccardi, F.; Laurenzi, S.; Santonicola, M. Shielding evaluation of polyethylene/regolith composites in the Martian radiation environment. In International Astronautical Congress: IAC Proceedings; International Astronautical Federation: IAF: Paris, France, 2021; Volume 2. [Google Scholar]

- SpaceX. Available online: https://www.spacex.com (accessed on 28 September 2024).

- Home/Blue Origin. Available online: https://www.blueorigin.com (accessed on 21 May 2024).

- Musk, E. Making Humans a Multi-Planetary Species. New Space 2017, 5, 46–61. [Google Scholar] [CrossRef]

- Musk, E. Making Life Multi-Planetary. New Space 2018, 6, 2–11. [Google Scholar] [CrossRef]

- Parker, J.S.; Ott, C.; Koehler, A.; Baskar, S.; Rosen, M.; Sullivan, T. Escape, plasma and acceleration dynamics explorers (escapade) mission design. In Proceedings of the 44th Annual American Astronautical Society Guidance, Navigation, and Control Conference, Breckenridge, CO, USA, 4–9 February 2022; Springer International Publishing: Cham, Switzerland, 2024. [Google Scholar]

- Burrows, W. The survival imperative: Using space to protect Earth. In Proceedings of the 2004 Planetary Defense Conference: Protecting Earth from Asteroids, Orange County, CA, USA, 23–26 February 2004. [Google Scholar]

- Szocik, K.; Reiss, M.J. Why space exploitation may provide sustainable development: Climate ethics and the human future as a multi-planetary species. Futures 2023, 147, 103110. [Google Scholar] [CrossRef]

- Jones, H.W. Take Material to Space or Make It There? ASCEND 2023, 2023, 4618. [Google Scholar]

- Anih, S. Crewed Space Mission Waste-Streams and Impact on Human Exploration of Mars. In Assessing a Mars Agreement Including Human Settlements; Springer International Publishing: Cham, Switzerland, 2021; pp. 129–146. [Google Scholar]

- Anih, S.I. Waste-Stream Management Optimization in Long-Duration Crewed Space Missions. Ph.D. Thesis, University of Cape Town, Rondebosch, South Africa, 2022. [Google Scholar]

- Olson, J.; Rinderknecht, D.; Essumang, D.; Kruger, M.; Golman, C.; Norvell, A.; Meier, A. A comparison of potential trash-to-gas waste processing systems for long-term crewed spaceflight. In Proceedings of the 50th International Conference on Environmental Systems, Lisbon, Portugal, 12–15 July 2021. [Google Scholar]

- Voyager Space|Nanoracks|Trash Deployment. Available online: http://voyagerspace.com/explore/bishop-airlock/ (accessed on 28 September 2024).

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Laurenzi, S.; Zaccardi, F.; Toto, E.; Santonicola, M.G.; Botti, S.; Scalia, T. Fused Filament Fabrication of Polyethylene/Graphene Composites for In-Space Manufacturing. Materials 2024, 17, 1888. [Google Scholar] [CrossRef]

- Kumar, L.J.; Nair, C.G.K. Current trends of additive manufacturing in the aerospace industry. In Advances in 3D Printing & Additive Manufacturing Technologies; Springer: Singapore, 2017; pp. 39–54. [Google Scholar]

- Hoffmann, M.; Elwany, A. In-space additive manufacturing: A review. J. Manuf. Sci. Eng. 2023, 145, 020801. [Google Scholar] [CrossRef]

- Singh, S.; Singh, G.; Prakash, C.; Ramakrishna, S. Current status and future directions of fused filament fabrication. J. Manuf. Process. 2020, 55, 288–306. [Google Scholar] [CrossRef]

- Prater, T.; Werkheiser, N.; Ledbetter, F.; Timucin, D.; Wheeler, K.; Snyder, M. 3D Printing in Zero G Technology Demonstration Mission: Complete experimental results and summary of related material modeling efforts. Int. J. Adv. Manuf. Technol. 2018, 101, 391–417. [Google Scholar] [CrossRef] [PubMed]

- Zocca, A.; Wilbig, J.; Waske, A.; Günster, J.; Widjaja, M.P.; Neumann, C.; Clozel, M.; Meyer, A.; Ding, J.; Zhou, Z.; et al. Challenges in the technology development for additive manufacturing in space. Chin. J. Mech. Eng. Addit. Manuf. 2022, 1, 100018. [Google Scholar] [CrossRef]

- Cushing, J.; Freedman, M.; Turner, K.; Muhlbauer, R.L.; Levedahl, B.; Slostad, J.; Hoyt, R.P.; Kim, T.; Werkheiser, M.J. Building a sustainable in-space manufacturing ecosystem: Positrusion and crissp. AIAA SPACE 2016, 2016, 5396. [Google Scholar]

- Prater, T.J.; Werkheiser, M.J.; Jehle, A.; Ledbetter, F.; Bean, Q.; Wilkerson, M.; Soohoo, H.; Hipp, B. NASA’s in-space manufacturing project: Development of a multimaterial fabrication laboratory for the international space station. In Proceedings of the AIAA SPACE and Astronautics Forum and Exposition, Orlando, FL, USA, 12–14 September 2017. [Google Scholar]

- Avcioğlu, S. LDPE matrix composites reinforced with dysprosium-boron containing compounds for radiation shielding applications. J. Alloys Compd. 2022, 927, 166900. [Google Scholar] [CrossRef]

- Zeb, J.; Arshad, W.; Rashid, A.; Akhter, P. Gamma Shielding by Aluminum (Al-Shielder Manual); No. PINSTECH—219; Pakistan Institute of Nuclear Science and Technology: Islamabad, Pakistan, 2010. [Google Scholar]

- Perchonok, M. The Challenges of Developing a Nutritious Food System for a Mars Mission; No. JSC-CN-31374; National Aeronautics and Space Administration: Washington, DC, USA, 2014. [Google Scholar]

- Kumar, L.; Gaikwad, K.K. Advanced food packaging systems for space exploration missions. Life Sci. Space Res. 2023, 37, 7–14. [Google Scholar] [CrossRef]

- Available online: https://www.goglioespress.com/medias/S4S.1001-PRT.pdf (accessed on 25 October 2024).

- NASA. NASA Handbook|Human Integration Design Handbook (HIDH)|NASA/SP-2010-3407/REV1; National Aeronautics and Space Administration: Washington, DC, USA, 2010.

- Fournier, R.; Persad, A.H. A low-cost adapter for the rehydration of commercially available food and beverages for spaceflight. Acta Astronaut. 2023, 210, 529–534. [Google Scholar] [CrossRef]

- Zaccardi, F.; Laurenzi, S.; Santilli, A.; Toto, E.; Santonicola, M. 3D printed polyethylene-based composites filled with Martian regolith simulant using fused filament fabrication. In International Astronautical Congress: IAC Proceedings; International Astronautical Federation: IAF: Paris, France, 2020. [Google Scholar]

- Zaccardi, F.; Toto, E.; Santonicola, M.G.; Laurenzi, S. 3D printing of radiation shielding polyethylene composites filled with Martian regolith simulant using fused filament fabrication. Acta Astronaut. 2022, 190, 1–13. [Google Scholar] [CrossRef]

- ImageJ—Image Processing and Analysis in Java. Available online: https://imagej.net/ij/ (accessed on 28 September 2024).

- Walton, W.H. Feret‘s statistical diameter as a measure of particle size. Nature 1948, 162, 329–330. [Google Scholar] [CrossRef]

- Zoubir, A.M.; Iskandler, D.R. Bootstrap methods and applications. IEEE Signal Process. Mag. 2007, 24, 10–19. [Google Scholar] [CrossRef]

- Tian, S.; Guo, Y.; Dong, Z.; Li, Z. Pore Microstructure and multifractal characterization of lacustrine oil-prone shale using high-resolution SEM: A case sample from natural Qingshankou shale. Fractal Fract. 2022, 6, 675. [Google Scholar] [CrossRef]

- Blaine, R.L. Thermal applications note. In Polymer Heats of Fusion; TA Instruments: New Castle, DE, USA, 2002. [Google Scholar]

- Vaniman, D.; Reedy, R.; Heiken, G.; Olhoeft, G.; Mendell, W. The lunar environment. Lunar Sourceb. 1991, 1, 27–60. [Google Scholar]

- Malla, R.B.; Brown, K.M. Determination of temperature variation on lunar surface and subsurface for habitat analysis and design. Acta Astronaut. 2015, 107, 196–207. [Google Scholar] [CrossRef]

- DeVieneni, A.; Velez, C.A.; Benjamin, D.; Hollenbeck, J. Cost-Effective Additive Manufacturing in Space: HELIOS Technology Challenge Guide; No. M12-2259; National Aeronautics and Space Administration: Washington, DC, USA, 2012. [Google Scholar]

- Smith, B. The infrared spectra of polymers, part I: Introduction. Spectroscopy 2021, 36, 17–22. [Google Scholar]

- Veerasingam, S.; Ranjani, M.; Venkatachalapathy, R.; Bagaev, A.; Mukhanov, V.; Litvinyuk, D.; Mugilarasan, M.; Gurumoorthi, K.; Guganathan, L.; Aboobacker, V.M.; et al. Contributions of Fourier transform infrared spectroscopy in microplastic pollution research: A review. Crit. Rev. Environ. Sci. Technol. 2020, 51, 2681–2743. [Google Scholar] [CrossRef]

- Kochetov, R.; Christen, T.; Gullo, F. FTIR analysis of LDPE and XLPE thin samples pressed between different protective anti-adhesive films. In Proceedings of the 2017 1st International Conference on Electrical Materials and Power Equipment (ICEMPE), Xi’an, China, 14–17 May 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Smith, B.C. The infrared spectra of polymers II: Polyethylene. Spectroscopy 2021, 36, 24–29. [Google Scholar] [CrossRef]

- Mahdavi, H.; Nook, M.E. Characterization and microstructure study of low-density polyethylene by Fourier transform infrared spectroscopy and temperature rising elution fractionation. J. Appl. Polym. Sci. 2008, 109, 3492–3501. [Google Scholar] [CrossRef]

- Djebara, M.; Stoquert, J.P.; Abdesselam, M.; Muller, D.; Chami, A.C. FTIR analysis of polyethylene terephthalate irradiated by MeV He+. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2012, 274, 70–77. [Google Scholar] [CrossRef]

- Dintcheva, N.; Jilov, N.; La Mantia, F. Recycling of plastics from packaging. Polym. Degrad. Stab. 1997, 57, 191–203. [Google Scholar] [CrossRef]

- Khanna, Y.P.; Turi, E.A.; Taylor, T.J.; Vickroy, V.V.; Abbott, R.F. Dynamic mechanical relaxations in polyethylene. Macromolecules 1985, 18, 1302–1309. [Google Scholar] [CrossRef]

- Lopes, C.M.; Felisberti, M.I. Thermal conductivity of PET/(LDPE/AI) composites determined by MDSC. Polym. Test. 2004, 23, 637–643. [Google Scholar] [CrossRef]

- Sabet, M.; Soleiman, H. Graphene Impact on Thermal Characteristics of LDPE. Polym. Sci. Ser. A 2019, 61, 922–930. [Google Scholar] [CrossRef]

- Lee, E.; Lee, S.; Shanefield, D.J.; Cannon, W.R. Enhanced Thermal Conductivity of Polymer Matrix Composite via High Solids Loading of Aluminum Nitride in Epoxy Resin. J. Am. Ceram. Soc. 2008, 91, 1169–1174. [Google Scholar] [CrossRef]

| Wavenumber (cm−1) | Functional Group Modes |

|---|---|

| 2916 | C–H stretching |

| 2848 | C–H stretching |

| 1462 | CH2 bending |

| 1368 | CH2 wagging |

| 730 | C–H rocking |

| 718 | C–H rocking |

| Wavenumber [cm−1] | Functional Group Modes |

|---|---|

| 2923 | CH2 stretching |

| 1711 | C=O stretching |

| 1614 | Parasubstituted benzene ring |

| 1580 | Benzene normal modes |

| 1505 | Parasubstituted benzene ring |

| 1472 | Trans CH2 bending |

| 1409 | Parasubstituted benzene ring |

| 1339 | CH2 wagging |

| 1237 | (C=O)–C stretching of ester |

| 1092 | O–CH2 stretching |

| 1016 | Parasubstituted benzene ring |

| 968 | Trans O–CH2 stretching |

| 871 | Ring C–H out of plane vibration |

| 848 | Trans CH2 rocking |

| 791 | C=O+CCO bending |

| 720 | Ring C–C bending and ring C–H out of plane |

| Onset temperature, Ton | 104.40 ± 0.56 °C |

| Starting temperature, Tst | 61.36 ± 12.45 °C |

| Ending temperature, Tee | 129.43 ± 3.78 °C |

| Peak temperature, Tmp | 113.41 ± 0.87 °C |

| Specific enthalpy, ΛHf | 32.97 ± 7.97 J/g |

| Onset temperature, Tc,on | 110.45 ± 2.55 °C |

| Starting temperature, Tc,st | 120.13 ± 1.62 °C |

| Ending temperature, Tc,ee | 20.37 ± 0.1 °C |

| Peak temperature, Tcp | 104.06 ± 0.46 °C |

| Specific enthalpy, ΛHc | 67.51 ± 5.24 J/g |

| Sample | λ [W ⋅ m−1 ⋅ K−1] |

|---|---|

| LDPE | 0.332 |

| LDPE + PAL 5 wt% | 0.475 |

| LDPE + PAL 10 wt% | 0.513 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Rosa, F.; Palmeri, F.; Laurenzi, S. Recycling Space Beverage Packaging into LDPE-Based Composite Materials. Aerospace 2024, 11, 957. https://doi.org/10.3390/aerospace11120957

De Rosa F, Palmeri F, Laurenzi S. Recycling Space Beverage Packaging into LDPE-Based Composite Materials. Aerospace. 2024; 11(12):957. https://doi.org/10.3390/aerospace11120957

Chicago/Turabian StyleDe Rosa, Federica, Flavia Palmeri, and Susanna Laurenzi. 2024. "Recycling Space Beverage Packaging into LDPE-Based Composite Materials" Aerospace 11, no. 12: 957. https://doi.org/10.3390/aerospace11120957

APA StyleDe Rosa, F., Palmeri, F., & Laurenzi, S. (2024). Recycling Space Beverage Packaging into LDPE-Based Composite Materials. Aerospace, 11(12), 957. https://doi.org/10.3390/aerospace11120957