Design and Verification of Continuous Tube Forming Process Parameters for PEEK-Based Rod Aimed at Space Manufacturing Applications

Abstract

:1. Introduction

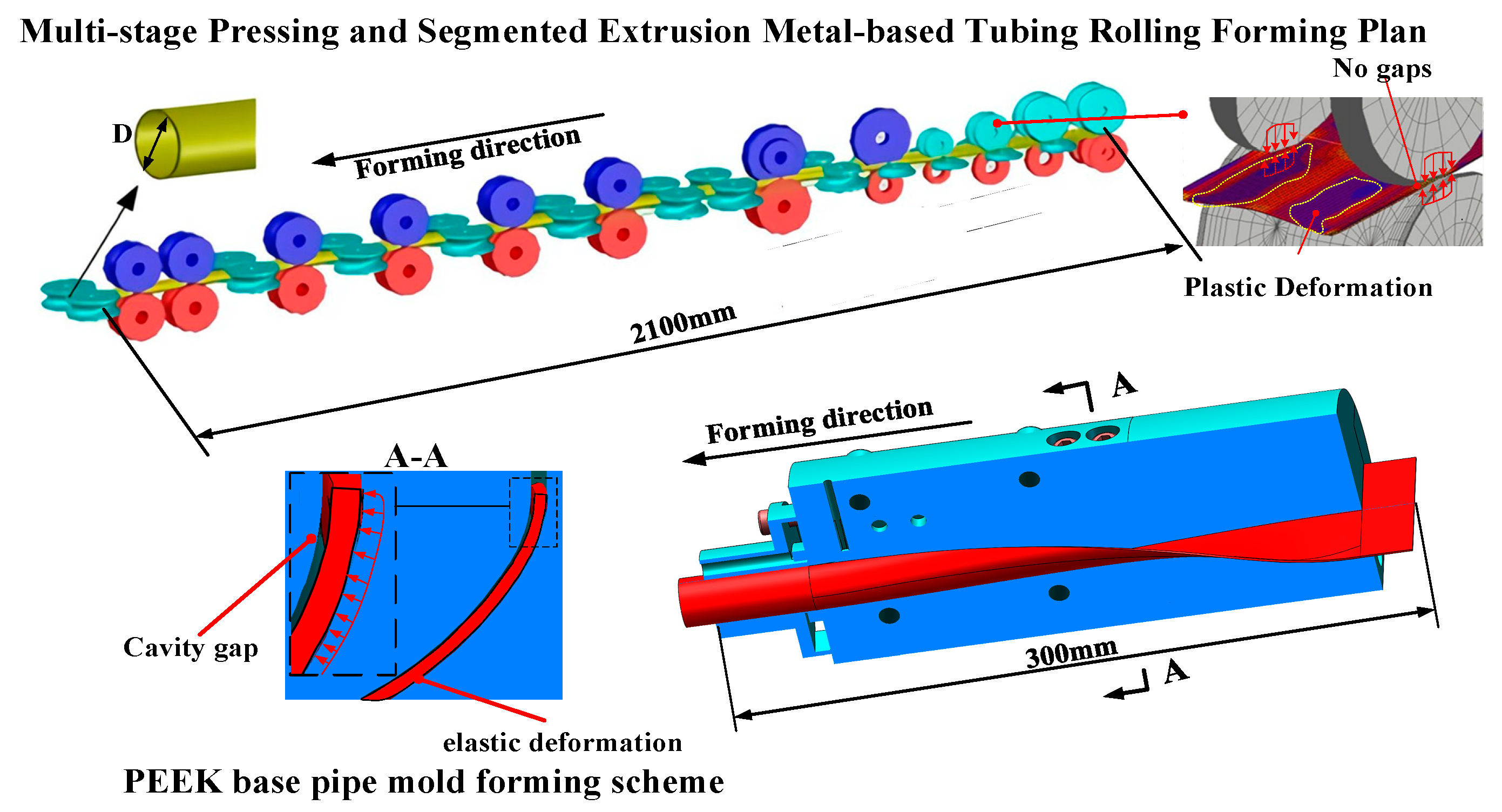

2. PEEK-Based Rod In-Orbit Rolling Forming Method

2.1. Design of the In-Orbit Rolling Forming Scheme for PEEK-Based Rod Components

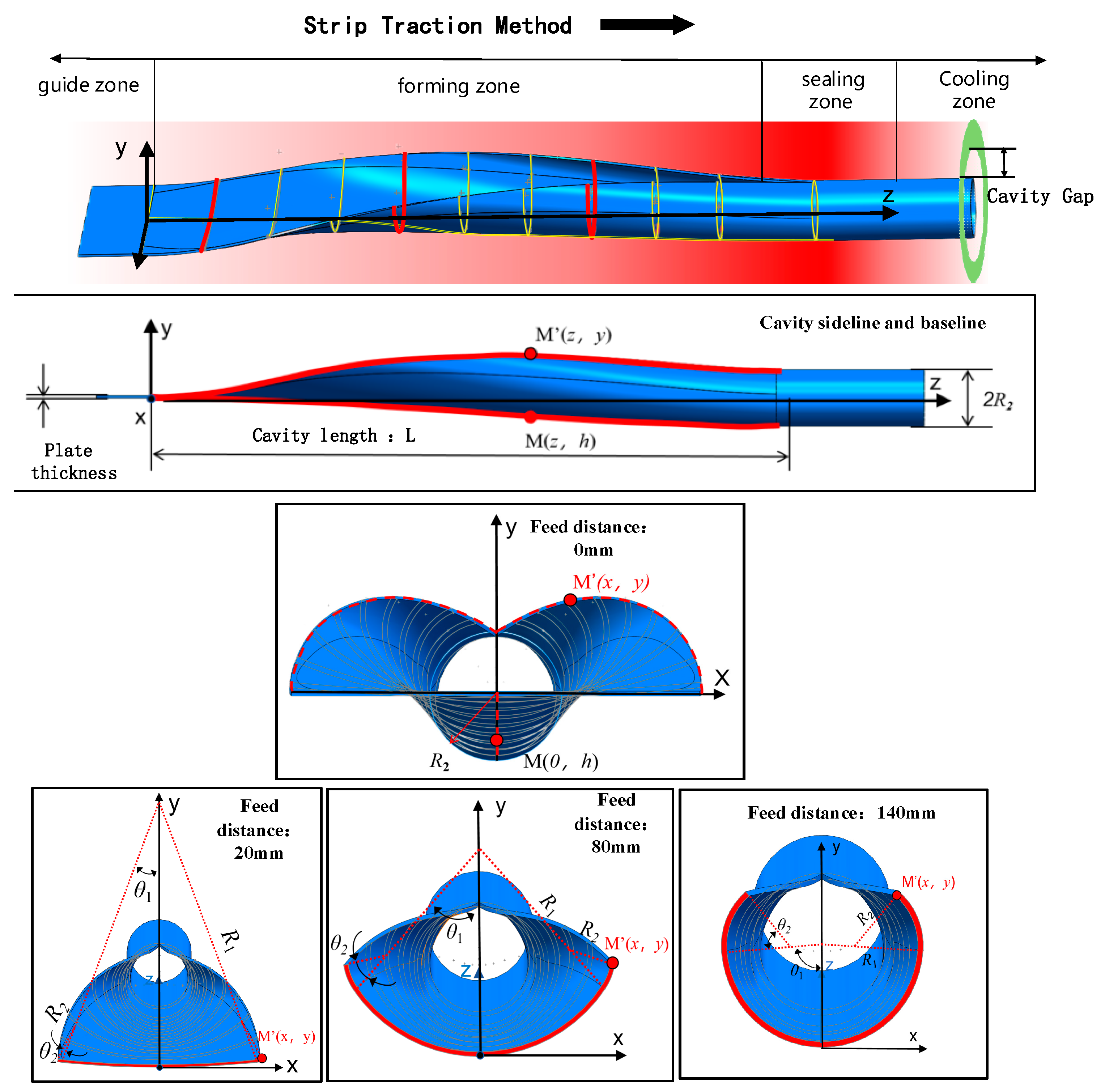

2.2. Parametric Design of the Tube Rolling Forming Die Cavity Surface

2.2.1. Parametric Modeling of the Cavity Configuration Surface

- (1)

- Design Concept of the Forming Die Cavity.

- (2)

- Forming Surface Modeling

- (3)

- Solution of the Parametric Equations for the Forming Surface

2.2.2. Temperature Gradient Boundary Conditions of the Cavity

3. Simulation Analysis of PEEK Rod Curling and Sewing Behavior

3.1. Establishment of Simulation Models

3.1.1. Simulation Model of the Curling Forming Process

3.1.2. Simulation Model of the Butt Sewing Process

3.2. Finite Element Simulation Analysis of the Coiling Forming Process

3.3. Optimization of Key Cavity Parameters in the Forming Process

3.3.1. Analysis of the Impact of Forming Method and Tape Thickness on Forming Quality

3.3.2. Analysis of the Impact of Cavity Length on the Forming Process

3.3.3. Analysis of the Impact of Cavity Clearance on the Forming Process

3.3.4. Analysis of the Impact of Tape Width on the Forming Process

3.3.5. Analysis of the Impact of Seam Temperature and Melting Depth

3.3.6. Analysis of the Impact of Seam Pressure on Melting Depth

4. Verification of Roll Forming Load and Forming Quality

4.1. Construction of the Filament Winding Pipe Forming Characteristic Test Platform

4.2. Verification Analysis of Temperature Distribution

4.3. Impact of Cavity Design Parameters on the Forming Process

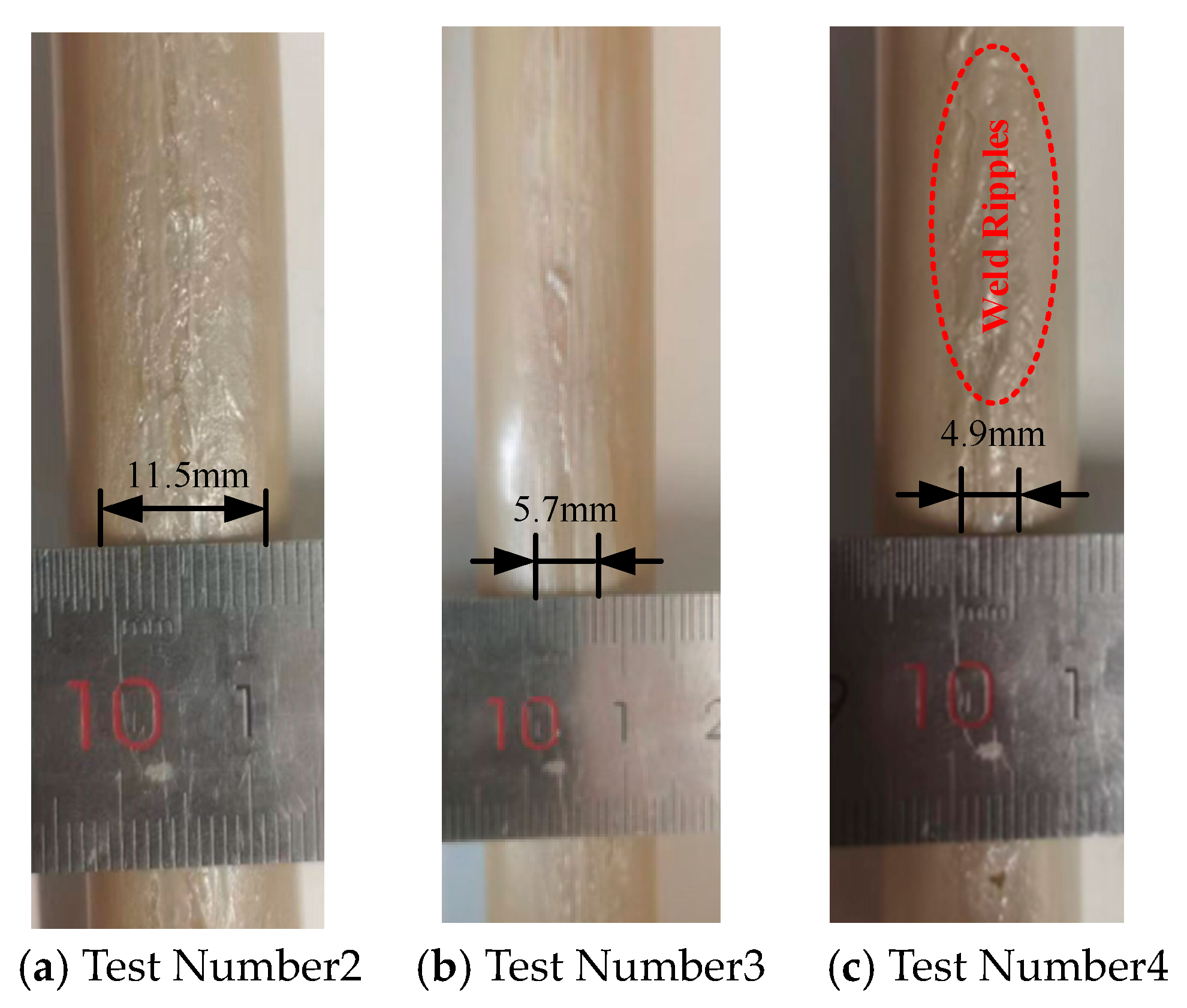

4.3.1. Curled Effect Analysis

4.3.2. Forming Load Analysis

4.4. Impact of Forming Process Parameters on Quality

5. Conclusions

- (1)

- A continuous roll forming scheme for PEEK rod components aimed at in-orbit manufacturing is proposed. By controlling the temperature gradient and designing the continuous deformation surface cavity, the material properties of PEEK tape are matched with the forming process. The cavity section and baseline configuration parameters are determined through scheme selection.

- (2)

- A simulation analysis model of the continuous roll forming and stitching process for the structure of PEEK rod components is established. The impact of the cavity and tape configuration parameters on the forming process is analyzed. The combined bending method is more effective in controlling material deformation compared with the circumferential bending method. Increasing the length of the cavity deformation zone can effectively reduce the maximum strain of the PEEK tape, and its forming load fluctuates within a certain range. Reducing the gap between the tape and the cavity will significantly increase the forming load, and increasing the width and thickness of the tape will increase the forming load and strain. When the rod diameter is 20 mm, selecting a cavity deformation zone length of 210 mm, cavity gap of 0.1 mm, and plate width of 61 mm can improve the rod forming quality.

- (3)

- The influence of the forming process parameters on the roundness and straightness of the tube material is verified. Increasing the feed rate and welding temperature reduces the roundness and straightness of the rod components to some extent. Experimental results show that the rod forming quality can be improved by using the “combined bending section + downhill baseline” with a feed rate of 1 mm/s and cavity starting, cavity midpoint, and stitching temperatures of 173 °C, 242 °C, and 343 °C, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiayong, Y.; Baorong, L.; Kai, Y.; Hanliang, L.; Bin, Z.; Lixin, Z.; Cunyi, W. Research of Materials and Manufacturing Technology System for on-Orbit Manufacturing. E3S Web Conf. 2023, 385, 1015. [Google Scholar] [CrossRef]

- Yan, Y.; Li, J.; Huang, H.; Wang, C.; Li, P.; Mei, J.; Cheng, B.; Zhang, D. Design and Investigation of Flexible Solar Wing: In-Plane Dynamics. Int. J. Mech. Sci. 2024, 283, 109673. [Google Scholar] [CrossRef]

- Son, M.Y.; Chae, B.G.; Sung, H.M.; Oh, H.U. Numerical Investigation on the Thermal Characteristics of Lightweight Metal Mesh-Based Reflector Antenna with various Knitting Conditions. Aerospace 2024, 11, 780. [Google Scholar] [CrossRef]

- Qi, R.; Wang, L.; Zhou, X.; Xue, J.; Jin, J.; Yuan, L.; Shen, Z.; Deng, G. Embedded Piezoelectric Actuation Method for Enhanced Solar Wings Vibration Control. Int. J. Mech. Sci. 2024, 274, 109271. [Google Scholar] [CrossRef]

- Yu, Y.; Fu, T.; Wang, S.; Yang, C. Dynamic Response of Novel Sandwich Structures with 3D Sinusoid-Parallel-Hybrid Honeycomb Auxetic Cores: The Cores Based on Negative Poisson’s Ratio of Elastic Jump. Eur. J. Mech. A Solids 2025, 109, 105449. [Google Scholar] [CrossRef]

- Jorgensen, G.; Bains, E. SRMS History, Evolution and Lessons Learned. In Proceedings of the AIAA SPACE 2011 Conference & Exposition, Long Beach, CA, USA, 27–29 September 2011; pp. 3–5. [Google Scholar]

- Stieber, E.M.; Hunter, G.D.; Abramovici, A. Overview of the Mobile Servicing System for theInternational Space Station. Artif. Intell. Robot. Autom. Space 1999, 440, 37. [Google Scholar]

- Xie, C.; Zhang, E.; Yan, B.; Gao, F.; Yang, J.; Fang, G.; Wang, Z. Configuration Design and Verification of Space Deployable Membrane Array Antenna. J. Mech. Eng. 2024, 60, 11–19. [Google Scholar]

- Han, J.; Yang, X.; Ma, X. A System and Method for Cold and Hot Compound Forming of Spiral Ducts with a Biting Mechanism. Patent CN114101375B, 27 September 2024. [Google Scholar]

- Li, Z.H.; Han, J.T.; Zhang, Y.F.; Lu, R.L. Continuous Stretch Bending Forming Equipment for One-Dimensional Linear Reel-Type Boom Used in Aerospace. Forg. Stamp. Technol. 2022, 47, 208–215. [Google Scholar] [CrossRef]

- Fish, J. Preface: Revolutionizing Engineering Practice Bymultiscale Methods. Int. J. Multiscale Comput. Eng. 2021, 19, v–vi. [Google Scholar] [CrossRef]

- Chen, J.; Chen, B. Progress in Additive Manufacturing of Magnesium Alloys: A Review. Materials 2024, 17, 3851. [Google Scholar] [CrossRef]

- Anil Kumar, V.; Gupta, R.K.; Prasad, M.J.N.V.; Narayana Murty, S.V.S. Recent Advances in Processing of Titanium Alloys and Titanium Aluminides for Space Applications: A Review. J. Mater. Res. 2021, 36, 689–716. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, X.; Chen, X.; Liang, J.; Zeng, D.; Gan, Y. Effect of Moisture Content in Polyether-Ether-Ketone (PEEK) Filament on 3D Printed Parts. SN Appl. Sci. 2024, 6, 394. [Google Scholar] [CrossRef]

- Francis, J.N.; Banerjee, I.; Chugh, A.; Singh, J. Additive Manufacturing of Polyetheretherketone and its Composites: A Review. Polym. Compos. 2022, 43, 5802–5819. [Google Scholar] [CrossRef]

- Chen, Y.; Shan, Z.; Yang, X.; Song, Y.; Zou, A. Preparation of CCF/PEEK Filaments Together with Property Evaluation for Additive Manufacturing. Compos. Struct. 2022, 281, 114975. [Google Scholar] [CrossRef]

- Khatri, B.; Roth, M.F.; Balle, F. Ultrasonic Welding of Additively Manufactured PEEK and Carbon-Fiber-Reinforced PEEK with Integrated Energy Directors. J. Manuf. Mater. Process. 2023, 7, 2. [Google Scholar] [CrossRef]

- Xia, Y.; Jiang, L.; Chen, Y.; Zhao, Y.; Yang, L.; Ge, D. Bidirectional-Reinforced Carbon Fiber/Polyether-Ether-Ketone Composite Thin-Walled Pipes Via Pultrusion-Winding for on-Orbit Additive Manufacturing. Materials 2024, 17, 293. [Google Scholar] [CrossRef]

- Geng, P.; Zhao, J.; Wu, W.; Ye, W.; Wang, Y.; Wang, S.; Zhang, S. Effects of Extrusion Speed and Printing Speed on the 3D Printing Stability of Extruded PEEK Filament. J. Manuf. Process. 2019, 37, 266–273. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Zahedi, S.A.; Ismail, S.O.; Omigbodun, F.T. 3D Printing of PEEK and its Composite to Increase Biointerfaces as a Biomedical Material—A Review. Colloids Surf. B Biointerfaces 2021, 203, 111726. [Google Scholar] [CrossRef] [PubMed]

- Lapointe, F.; Lebel, L.L. Fiber Damage and Impregnation during multi-die Vacuum Assisted Pultrusion of carbon/PEEK Hybrid Yarns. Polym. Compos. 2019, 40, E1015–E1028. [Google Scholar] [CrossRef]

- Lee, Y.; Park, S.; Byun, C.; Lee, S.-K. Liquid Cooling of Laser-Driven Head Light Employing Heat Spreader Manufactured by 3D Metal Printing. Int. J. Precis. Eng. Manuf. -Green Technol. 2018, 5, 295–301. [Google Scholar] [CrossRef]

- Yang, X.; Sun, S.; Zhou, Z.; Chen, X.; Chen, G. Continuous Extrusion Forming Technology of Magnesium Alloy Thin-Walled Tubules. Materials 2023, 16, 5803. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.; Wang, X.; Ruan, K.; Cheng, J.; Wei, Z.; Zhao, R. Numerical Simulation Research on UDF Flexible Roll Forming of Multi-Specification Thin-Walled Circular Tubes. Int. J. Adv. Manuf. Technol. 2023, 127, 4503–4517. [Google Scholar] [CrossRef]

- Åström, B.T.; Larsson, P.H.; Pipes, R.B. Development of a facility for pultrusion of thermoplastic-matrix composites. Compos. Manuf. 1991, 2, 114–123. [Google Scholar] [CrossRef]

- Cao, G.F. Re-understanding of the Baseline for Uphill Forming in High-Frequency Longitudinal Welded Pipe. Steel Pipe 2018, 47, 59–63. [Google Scholar]

- Ye, L.; Friedrich, K.; Cutolo, D.; Savadori, A. Manufact. of CF/PEEK composites from powder/sheath fibre preforms. Compos. Manuf. 1994, 5, 41–50. [Google Scholar] [CrossRef]

- Jin, S.Z. Structural Design of CCF/PEEK Composite Tubes and Simulation Study on the Extrusion Process of PEEK Sheets; Jilin University: Changchun, China, 2020. [Google Scholar] [CrossRef]

- Pulipaka, A.; Gide, K.M.; Beheshti, A.; Bagheri, Z.S. Effect of 3D Printing Process Parameters on Surface and Mechanical Properties of FFF-Printed PEEK. J. Manuf. Process. 2023, 85, 368–386. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of Thermal Processing Conditions in 3D Printing on the Crystallinity and Mechanical Properties of PEEK Material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Sano, J.; Matsuzaki, R. High Accuracy 3D Printing of Composite Materials using CNT Yarns. Compos. Struct. 2023, 325, 117577. [Google Scholar] [CrossRef]

- Zhu, C.J.; Nan, F.Q.; Liang, Y. Numerical Simulation of Extrusion Molding of Single—Hole Propellant. Mater. Sci. Forum 2018, 917, 269–275. [Google Scholar]

| Parameter | Physical Quantity | Value Range | Unit |

|---|---|---|---|

| Density | ρ | 1095.8 | kg/m3 |

| Specific Heat Capacity | c | 2124 | J/kg °C |

| Thermal Conductivity | k | 0.321 | W/m °C |

| Reference Shear Stress | τ0 | 124,139 | Pa |

| Coefficient of Thermal Expansion | α | 0.00001 | 1/°C |

| Glass Transition Temperature | Tg | 143 | °C |

| Viscous Flow Temperature | Tf | 343 | °C |

| Low-Temperature Curling Zone Temperature | T1 | 173–242 | °C |

| High-Temperature Curling Zone Temperature | T2 | 242–343 | °C |

| Fusion Seam Temperature | T3 | 343 | °C |

| Test Number | Tape Thickness (mm) | Forming Section Curve | Feed Rate (mm/s) | Seam Temperature (°C) |

|---|---|---|---|---|

| 1 | 1 | combined bending | 1 | 335 |

| 2 | 0.8 | combined bending | 1 | 335 |

| 3 | 0.8 | combined bending | 1.3 | 335 |

| 4 | 0.8 | combined bending | 1.6 | 335 |

| 5 | 0.6 | combined bending | 1 | 335 |

| 6 | 0.6 | combined bending | 1.3 | 335 |

| 7 | 0.6 | combined bending | 1.6 | 335 |

| 8 | 0.6 | combined bending | 1 | 325 |

| 9 | 0.6 | combined bending | 1 | 335 |

| 10 | 0.6 | combined bending | 1 | 340 |

| 11 | 0.6 | combined bending | 1 | 350 |

| 12 | 0.4 | circumferential bending | 1 | 335 |

| 13 | 0.4 | combined bending | 1 | 335 |

| 14 | 0.2 | circumferential bending | 1 | 335 |

| 15 | 0.2 | combined bending | 1 | 335 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Tian, S.; Duan, Y.; Yan, J.; Zhang, L. Design and Verification of Continuous Tube Forming Process Parameters for PEEK-Based Rod Aimed at Space Manufacturing Applications. Aerospace 2024, 11, 954. https://doi.org/10.3390/aerospace11110954

Li P, Tian S, Duan Y, Yan J, Zhang L. Design and Verification of Continuous Tube Forming Process Parameters for PEEK-Based Rod Aimed at Space Manufacturing Applications. Aerospace. 2024; 11(11):954. https://doi.org/10.3390/aerospace11110954

Chicago/Turabian StyleLi, Peng, Shuai Tian, Yingjia Duan, Jiayong Yan, and Lixin Zhang. 2024. "Design and Verification of Continuous Tube Forming Process Parameters for PEEK-Based Rod Aimed at Space Manufacturing Applications" Aerospace 11, no. 11: 954. https://doi.org/10.3390/aerospace11110954

APA StyleLi, P., Tian, S., Duan, Y., Yan, J., & Zhang, L. (2024). Design and Verification of Continuous Tube Forming Process Parameters for PEEK-Based Rod Aimed at Space Manufacturing Applications. Aerospace, 11(11), 954. https://doi.org/10.3390/aerospace11110954