Position Normalization of Propellant Grain Point Clouds

Abstract

1. Introduction

- (1)

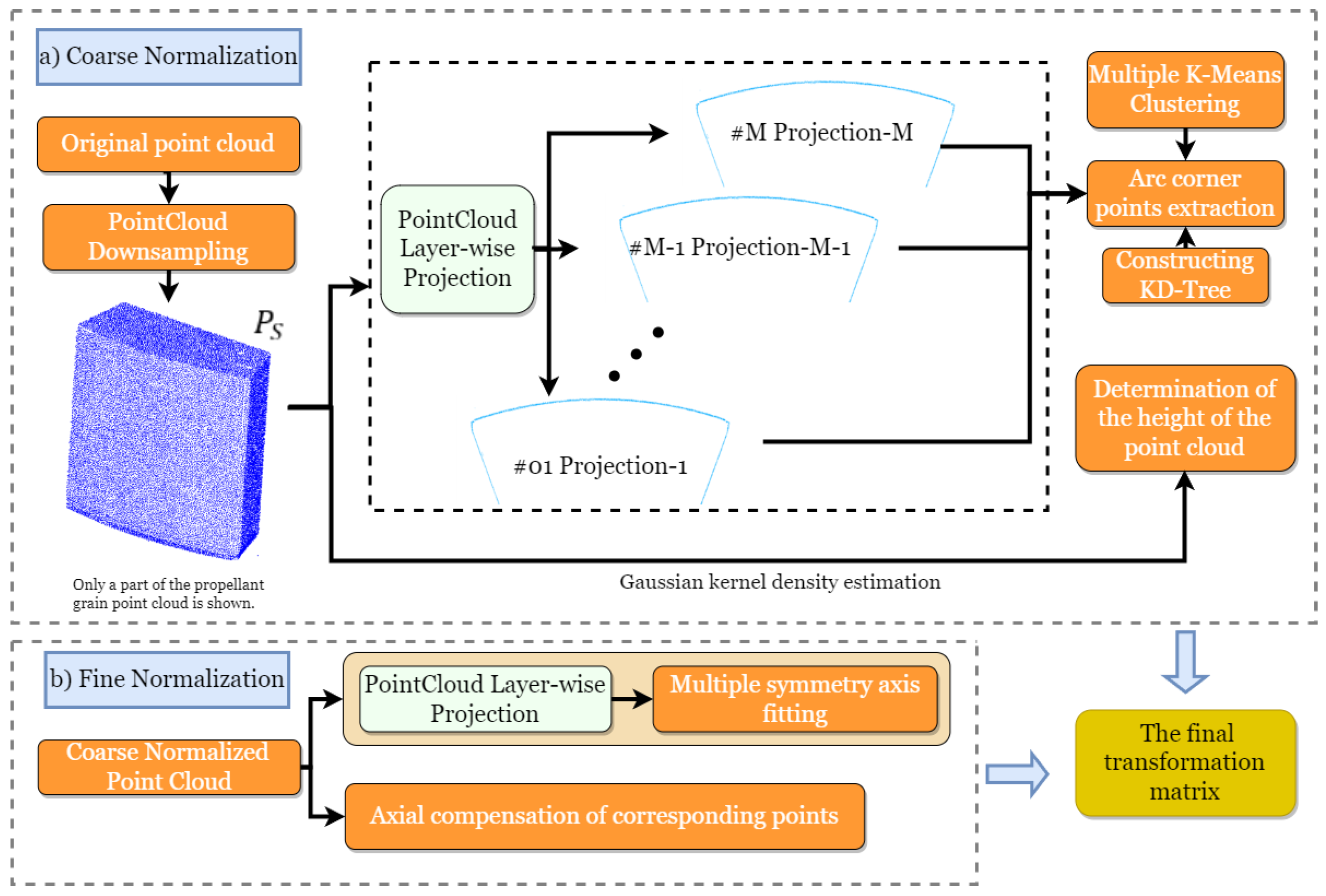

- The algorithm first performs down-sampling on the point cloud. The 3D laser scanning generates a large volume of point cloud data for the propellant grain. Without appropriate down-sampling, the subsequent processing would consume a significant amount of computational resources.

- (2)

- The proposed algorithm consists of two stages: coarse normalization and fine normalization. In the coarse normalization stage, the algorithm extracts the feature points of the point cloud based on clustering segmentation. In the fine normalization stage, firstly, reduce angular errors through multiple symmetry axis fittings. Finally, it compensates for the axial offset through point correspondence to complete the position normalization of the point cloud.

- (3)

- In the experimental section, the accuracy of this algorithm is evaluated by comparing it with the most representative algorithms in point cloud registration: RANSAC and ICP.

2. Related Work

2.1. Point Cloud Registration

2.1.1. RANSAC

2.1.2. ICP

3. Method

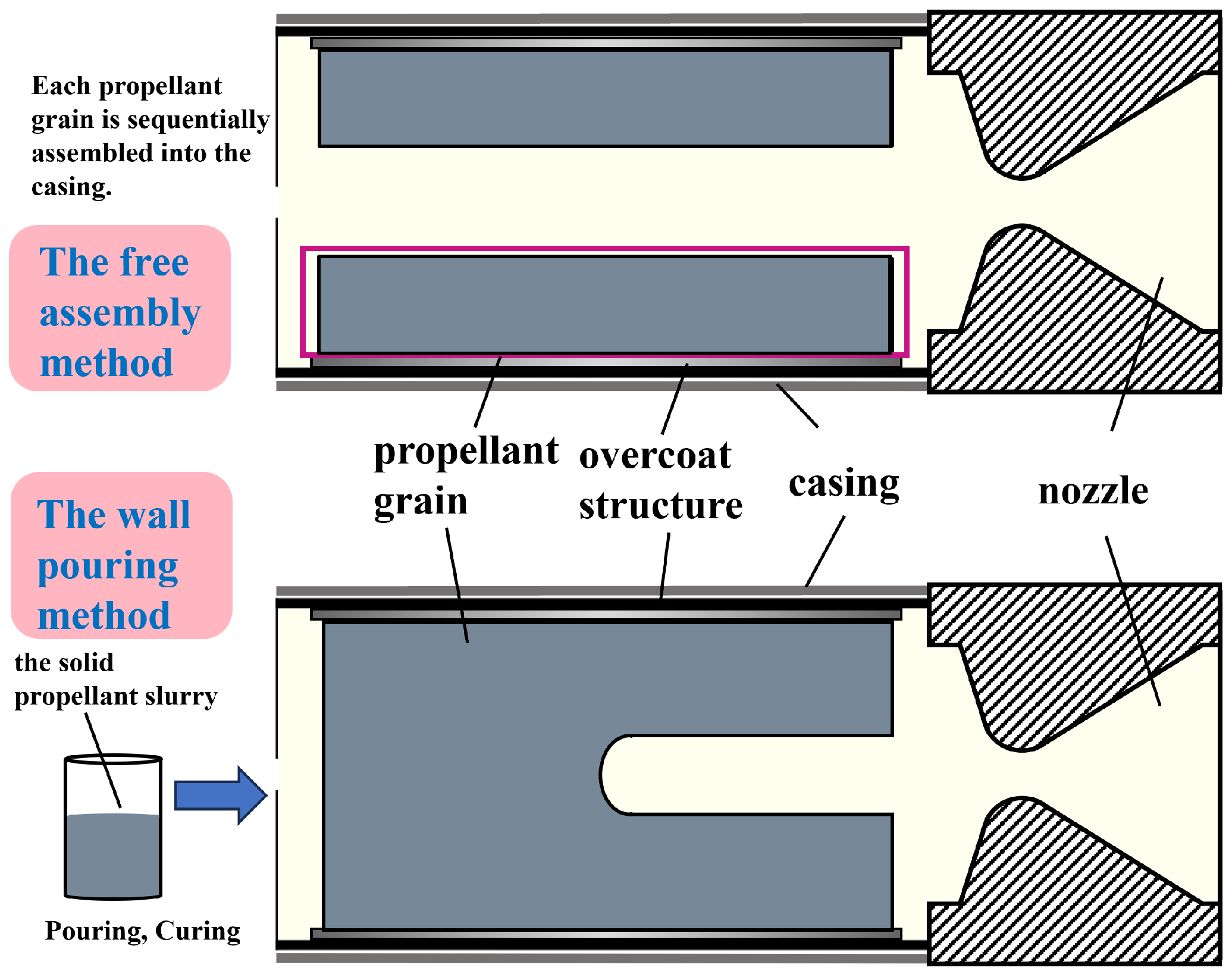

3.1. Geometric Features

3.2. Method Overview

3.3. Problem Setting

3.4. Coarse Position Normalization

3.4.1. Point Cloud Downsampling

3.4.2. Point Cloud Layer-Wise Projection

3.4.3. Arc Corner Points Extraction

- (a)

- if , the angle change on both sides of the point is gradual, so the point is discarded.

- (b)

- if , the angle change on both sides of the point is significant, so the point is stored in the corner point set.

3.4.4. Determination of the Height of the Point Cloud

3.4.5. Coarse Normalization Transformation Matrix

3.5. Fine Position Normalization

3.5.1. Partitioning of Intervals

3.5.2. Multiple Symmetry Axis Fitting

3.5.3. Axial Compensation of Corresponding Points

4. Experiments

4.1. Experimental Setup

4.1.1. Propellant Grain Point Clouds and Experimental Environment

4.1.2. Definition of the Target Point Cloud

4.1.3. Parameter Settings

4.1.4. Evaluation Criterion

4.2. Downsampling Experiments

4.3. Single-Variable Experiments

Single-Variable Experiments Results Analysis

4.4. Multivariable Experiments

Multivariable Experiments Results Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Variables or Symbols | Annotations |

|---|---|

| P | The original point cloud |

| Downsampled point cloud | |

| Coarse normalized point cloud | |

| Fine normalized point cloud | |

| The point set obtained by projecting onto the plane. | |

| The i-th target point cloud. | |

| For clarity, the point clouds processed by various algorithms () are collectively referred to as . | |

| The i-th layer contains the point cloud | |

| The scatter point set of projected onto the plane | |

| is projected layer by layer onto the i-th scatter point set of the plane. | |

| The coordinates of each point in | |

| The coordinates of each point in (Since , is omitted.) | |

| The coordinates of each point in | |

| The nearest neighbor point set of | |

| The length of the subinterval. | |

| and | Clusters |

| Distance matrix | |

| Set of cluster centers | |

| Set of cluster centers after removing nearby points | |

| Final set of cluster centers(set of corner points) | |

| Parameters of the transformation matrix | |

| and | Four degrees of freedom of the displacement of the propellant grain point cloud |

| and | The differences between the rotation matrices and the translation vectors. |

| \ | Difference set operator |

Appendix B

Appendix B.1. KD-Tree

Appendix B.2. K-Means

References

- DeLuca, L.T.; Annovazzi, A. Survey of burning rate measurements in small solid rocket motors. FirePhysChem 2024, 4, 146–165. [Google Scholar] [CrossRef]

- Lee, H.S.; Ko, S.C.; Kwon, S.W.; Lee, J.S. Optimization of a Solid Rocket Motor Design through Neural Network-Assisted Performance Prediction. IEEE Trans. Aerosp. Electron. Syst. 2023, 59, 8769–8781. [Google Scholar] [CrossRef]

- Weiqiang Pang, L.T.D. Nano and Micro-Scale Energetic Materials: Propellants and Explosives; John Wiley & Sons: Hoboken, NJ, USA, 2023; Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/9783527835348 (accessed on 14 October 2024).

- Fang, C.; Lou, Y.; Wang, J.; Zhao, Y.; Cheng, W.; Yuan, B.; Ma, X. A fast heat transfer calculation and optimization method for solid rocket motor overcoat structure based on Python. In Proceedings of the 2023 2nd International Symposium on Aerospace Engineering and Systems (ISAES), Nanjing, China, 19–21 May 2023; pp. 101–105. [Google Scholar] [CrossRef]

- Abdelaziz, A.; Trache, D.; Tarchoun, A.F.; Boukeciat, H.; Kadri, D.E.; Hassam, H.; Ouahioune, S.; Sahnoun, N.; Thakur, S.; Klapötke, T.M. Application of co-crystallization method for the production of ammonium perchlorate/ammonium nitrate oxidizer for solid rocket propellants. Chem. Eng. J. 2024, 487, 150654. [Google Scholar] [CrossRef]

- Ghedjatti, I.; Shiwei, Y.; Haixing, W. A Review on the Application and Usefulness of Metal Nanosized Particles in Solid Rocket Propellants. In Proceedings of the 2018 3rd International Conference on Smart and Sustainable Technologies (SpliTech), Split, Croatia, 26–29 June 2018; pp. 1–6. Available online: https://ieeexplore.ieee.org/document/8448308 (accessed on 14 October 2024).

- Xu, F.; Aravas, N.; Sofronis, P. Constitutive modeling of solid propellant materials with evolving microstructural damage. J. Mech. Phys. Solids 2008, 56, 2050–2073. [Google Scholar] [CrossRef]

- Lysien, K.; Stolarczyk, A.; Jarosz, T. Solid Propellant Formulations: A Review of Recent Progress and Utilized Components. Materials 2021, 14, 6657. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Dave, P.N. Solid propellants: AP/HTPB composite propellants. Arab. J. Chem. 2019, 12, 2061–2068. [Google Scholar] [CrossRef]

- Trache, D.; Klapötke, T.M.; Maiz, L.; Abd-Elghany, M.; DeLuca, L.T. Recent advances in new oxidizers for solid rocket propulsion. Green Chem. 2017, 19, 4711–4736. [Google Scholar] [CrossRef]

- Bills, K.W.; Wiegand, J.H. Relation Of Mechanical Properties To Solid Rocket Motor Failure. AIAA J. 1963, 1, 2116–2123. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Z.; Liu, P.; Han, Y.; Jin, B. Dewetting Stress of Solid Propellant under Tensile Loading. In Proceedings of the 2018 9th International Conference on Mechanical and Aerospace Engineering (ICMAE), Budapest, Hungary, 10–13 July 2018; pp. 570–573. [Google Scholar] [CrossRef]

- Simões Hoffmann, L.F.; Parquet Bizarria, F.C.; Parquet Bizarria, J.W. Detection of liner surface defects in solid rocket motors using multilayer perceptron neural networks. Polym. Test. 2020, 88, 106559. [Google Scholar] [CrossRef]

- Rao, B. Fracture of solid rocket propellant grains. Eng. Fract. Mech. 1992, 43, 455–459. [Google Scholar] [CrossRef]

- Lei, M.; Ren, S.; Chen, E.; Zhang, Z.; Xiao, J.; Wen, L.; Hou, X. Correlation between solid propellant failure and interface debonding in solid rocket motors. Polym. Test. 2022, 115, 107755. [Google Scholar] [CrossRef]

- Wang, G.; Cai, E. Solid Rocket Motor Design; Northwestern Polytechnical University Press: Xi’an, China, 1994; Available online: https://www.shukui.net/book/861646.html (accessed on 14 October 2024).

- Zhang, L. Experimental and Applied Research on Constitutive Model of Composite Solid Propellant under Superimposed Pressure and Changing Rates. Ph.D. Thesis, National University of Defense Technology, Changsha, China, 2020. [Google Scholar]

- Deng, K.; Zhang, L.; Pang, A.; Yu, R.; Yang, L.; Xin, P. Analysis on structural integrity of a free loading solid propellant grains under ignition loading at low temperature. J. Solid Rocket Technol. 2018, 41, 428–434. [Google Scholar]

- Zhang, X.; Zhang, X.; Zhang, H.L.; Zhong, W. Structure Integrity Analysis of Free Loading Solid Rocket Grain under Internal Pressure. Computer Simulation 2012, 29, 13–16. [Google Scholar]

- Guo, Y.; Wang, H.; Hu, Q.; Liu, H.; Liu, L.; Bennamoun, M. Deep Learning for 3D Point Clouds: A Survey. arXiv 2019, arXiv:1912.12033. [Google Scholar] [CrossRef]

- Dong, Z.; Liang, F.; Yang, B.; Xu, Y.; Zang, Y.; Li, J.; Wang, Y.; Dai, W.; Fan, H.; Hyyppä, J.; et al. Registration of large-scale terrestrial laser scanner point clouds: A review and benchmark. ISPRS J. Photogramm. Remote Sens. 2020, 163, 327–342. Available online: https://api.semanticscholar.org/CorpusID:216449537 (accessed on 14 October 2024). [CrossRef]

- Huang, X.; Mei, G.; Zhang, J.; Abbas, R. A comprehensive survey on point cloud registration. arXiv 2021, arXiv:2103.02690. [Google Scholar]

- Landrieu, L.; Simonovsky, M. Large-Scale Point Cloud Semantic Segmentation with Superpoint Graphs. arXiv 2017, arXiv:1711.09869. [Google Scholar]

- Hu, Q.; Yang, B.; Xie, L.; Rosa, S.; Guo, Y.; Wang, Z.; Trigoni, N.; Markham, A. RandLA-Net: Efficient Semantic Segmentation of Large-Scale Point Clouds. arXiv 2019, arXiv:1911.11236. [Google Scholar]

- Xu, Y.; Jung, C.; Chang, Y. Head pose estimation using deep neural networks and 3D point clouds. Pattern Recognit. 2022, 121, 108210. Available online: https://api.semanticscholar.org/CorpusID:237712154 (accessed on 14 October 2024). [CrossRef]

- Yu, J.; Ren, L.; Zhou, W.; Zhang, Y.; Lin, L.; Dai, G. PEAL: Prior-embedded Explicit Attention Learning for Low-overlap Point Cloud Registration. In Proceedings of the 2023 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Vancouver, BC, Canada, 17–24 June 2023; pp. 17702–17711. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Dong, Z.; Guo, Y.; Liu, Y.S.; Wang, W.; Yang, B. Robust Multiview Point Cloud Registration with Reliable Pose Graph Initialization and History Reweighting. In Proceedings of the 2023 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Vancouver, BC, Canada, 17–24 June 2023; pp. 9506–9515. [Google Scholar] [CrossRef]

- Qin, Z.; Yu, H.; Wang, C.; Peng, Y.; Xu, K. Deep Graph-based Spatial Consistency for Robust Non-rigid Point Cloud Registration. In Proceedings of the 2023 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Vancouver, BC, Canada, 17–24 June 2023; pp. 5394–5403. Available online: https://api.semanticscholar.org/CorpusID:257622836 (accessed on 14 October 2024).

- Yao, Y.; Deng, B.; Xu, W.; Zhang, J. Fast and Robust Non-Rigid Registration Using Accelerated Majorization-Minimization. IEEE Trans. Pattern Anal. Mach. Intell. 2022, 45, 9681–9698. Available online: https://api.semanticscholar.org/CorpusID:249431444 (accessed on 14 October 2024). [CrossRef]

- Chen, L.; Feng, C.; Ma, Y.; Zhao, Y.; Wang, C. A review of rigid point cloud registration based on deep learning. Front. Neurorobot. 2024, 17, 1281332. Available online: https://www.frontiersin.org/articles/10.3389/fnbot.2023.1281332/full (accessed on 14 October 2024). [CrossRef] [PubMed]

- Charles, R.Q.; Su, H.; Kaichun, M.; Guibas, L.J. PointNet: Deep Learning on Point Sets for 3D Classification and Segmentation. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; pp. 77–85. [Google Scholar] [CrossRef]

- Qi, C.R.; Yi, L.; Su, H.; Guibas, L.J. PointNet++: Deep Hierarchical Feature Learning on Point Sets in a Metric Space. arXiv 2017, arXiv:1706.02413. [Google Scholar]

- Ni, H.; Lin, X.; Ning, X.; Zhang, J. Edge Detection and Feature Line Tracing in 3D-Point Clouds by Analyzing Geometric Properties of Neighborhoods. Remote Sens. 2016, 8, 710. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, B. An Efficient Global Constraint Approach for Robust Contour Feature Points Extraction of Point Cloud. IEEE Trans. Geosci. Remote Sens. 2023, 61, 1–16. Available online: https://ieeexplore.ieee.org/document/10229227 (accessed on 14 October 2024). [CrossRef]

- Gumhold, S.; Wang, X.; Macleod, R. Feature Extraction from Point Clouds. In Proceedings of the International Meshing Roundtable Conference, Newport Beach, CA, USA, 7–10 October 2001; Available online: https://api.semanticscholar.org/CorpusID:18343879 (accessed on 14 October 2024).

- Demarsin, K.; Vanderstraeten, D.; Volodine, T.; Roose, D. Detection of closed sharp edges in point clouds using normal estimation and graph theory. Comput.-Aided Des. 2007, 39, 276–283. Available online: https://www.sciencedirect.com/science/article/pii/S0010448506002260 (accessed on 14 October 2024). [CrossRef]

- Pauly, M.; Keiser, R.; Gross, M. Multi-Scale Feature Extraction on Point-Sampled Surfaces. Comput. Graph. Forum 2003, 22, 281–289. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1111/1467-8659.00675 (accessed on 14 October 2024). [CrossRef]

- Liu, X.; Jin, C. Feature line extraction from unorganized noisy point clouds. J. Comput. Inf. Syst. 2014, 10, 3503–3510. [Google Scholar]

- Hackel, T.; Wegner, J.D.; Schindler, K. Contour Detection in Unstructured 3D Point Clouds. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 1610–1618. [Google Scholar] [CrossRef]

- Lu, X.; Liu, Y.; Li, K. Fast 3D Line Segment Detection From Unorganized Point Cloud. arXiv 2019, arXiv:1901.02532. [Google Scholar]

- Fischler, M.A.; Bolles, R.C. Random sample consensus: A paradigm for model fitting with applications to image analysis and automated cartography. Commun. ACM 1981, 24, 381–395. Available online: https://api.semanticscholar.org/CorpusID:972888 (accessed on 14 October 2024). [CrossRef]

- Rusu, R.B.; Blodow, N.; Beetz, M. Fast Point Feature Histograms (FPFH) for 3D registration. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 3212–3217. Available online: https://api.semanticscholar.org/CorpusID:15022990 (accessed on 14 October 2024).

- Tsai, C.Y.; Wang, C.W.; Wang, W.Y. Design and implementation of a RANSAC RGB-D mapping algorithm for multi-view point cloud registration. In Proceedings of the 2013 CACS International Automatic Control Conference (CACS), Nantou, Taiwan, 2–4 December 2013; pp. 367–370. [Google Scholar] [CrossRef]

- Dou, J.; Lin, X.; Niu, D.; Zhao, X. Non-rigid point set registration based on DIS&ANG descriptor and RANSAC. In Proceedings of the 2017 2nd International Conference on Image, Vision and Computing (ICIVC), Chengdu, China, 2–4 June 2017; pp. 693–697. [Google Scholar] [CrossRef]

- Peng, C.C. K-means based RANSAC Algorithm for ICP Registration of 3D Point Cloud with Dense Outliers. In Proceedings of the 2021 IEEE International Conference on Consumer Electronics-Taiwan (ICCE-TW), Penghu, Taiwan, 15–17 September 2021; pp. 1–2. [Google Scholar] [CrossRef]

- Besl, P.; McKay, N.D. A method for registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Yu, J.; Yu, C.; Lin, C.; Wei, F. Improved Iterative Closest Point (ICP) Point Cloud Registration Algorithm based on Matching Point Pair Quadratic Filtering. In Proceedings of the 2021 International Conference on Computer, Internet of Things and Control Engineering (CITCE), Guangzhou, China, 12–14 November 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Chen, A.; Zhuang, J.; Han, X. An Improved ICP Algorithm for 3D Point Cloud Registration. In Proceedings of the 2022 3rd International Conference on Pattern Recognition and Machine Learning (PRML), Chengdu, China, 22–24 July 2022; pp. 205–210. [Google Scholar] [CrossRef]

| Number of Downsampled Points: | 140,000 | 130,000 | 120,000 | 110,000 | 100,000 | 90,000 | 80,000 | 70,000 | 600,000 | 500,000 |

| Processing Time (s): | 484.13 | 457.39 | 428.39 | 396.12 | 352.46 | 321.16 | 277.90 | 254.07 | 215.04 | 174.95 |

| Point Cloud | Number of Points | After Down Sampling |

|---|---|---|

| FP-1 | 13,333,095 | 49,987 |

| FP-2 | 20,128,476 | 50,728 |

| FP-3 | 15,943,085 | 51,301 |

| FP-4 | 17,933,175 | 48,375 |

| Point Cloud | Algorithm Model | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| FP-1 | RANSAC | [2.7519 | 71.3267 | [45.6162 | 308.2656 | |||||

| ICP | [9.4203 | 246.8501 | ||||||||

| Ours | Coarse normalization | [2.7828 | 1.4542 | 4.2702] | ||||||

| Fine normalization | − | |||||||||

| FP-2 | RANSAC | [1.7348 | 67.2147 | [36.8562 | 359.3677 | |||||

| ICP | [6.3411 | 315.9922 | ||||||||

| Ours | Coarse normalization | [2.959 | 3.9315 | 28.1718] | ||||||

| Fine normalization | − | |||||||||

| FP-3 | RANSAC | [2.593 | 117.2881 | [45.2615 | 793.146 | |||||

| ICP | [8.6269 | 650.5938 | ||||||||

| Ours | Coarse normalization | [6.5244 | 2.4333 | 2.9202] | ||||||

| Fine normalization | − | |||||||||

| FP-4 | RANSAC | [1.4392 | 105.2849 | [42.2502 | 517.5345 | |||||

| ICP | [4.7415 | 409.91 | ||||||||

| Ours | Coarse normalization | [2.7779 | ||||||||

| Fine normalization | − | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Tian, F.; Li, R.; Li, Z.; Zhang, B.; Si, X. Position Normalization of Propellant Grain Point Clouds. Aerospace 2024, 11, 859. https://doi.org/10.3390/aerospace11100859

Wang J, Tian F, Li R, Li Z, Zhang B, Si X. Position Normalization of Propellant Grain Point Clouds. Aerospace. 2024; 11(10):859. https://doi.org/10.3390/aerospace11100859

Chicago/Turabian StyleWang, Junchao, Fengnian Tian, Renfu Li, Zhihui Li, Bin Zhang, and Xuelong Si. 2024. "Position Normalization of Propellant Grain Point Clouds" Aerospace 11, no. 10: 859. https://doi.org/10.3390/aerospace11100859

APA StyleWang, J., Tian, F., Li, R., Li, Z., Zhang, B., & Si, X. (2024). Position Normalization of Propellant Grain Point Clouds. Aerospace, 11(10), 859. https://doi.org/10.3390/aerospace11100859