Experimental Study on Ice Shedding Behaviors for Aero-Engine Fan Blade Icing during Ground Idle

Abstract

1. Introduction

2. Experimental Method

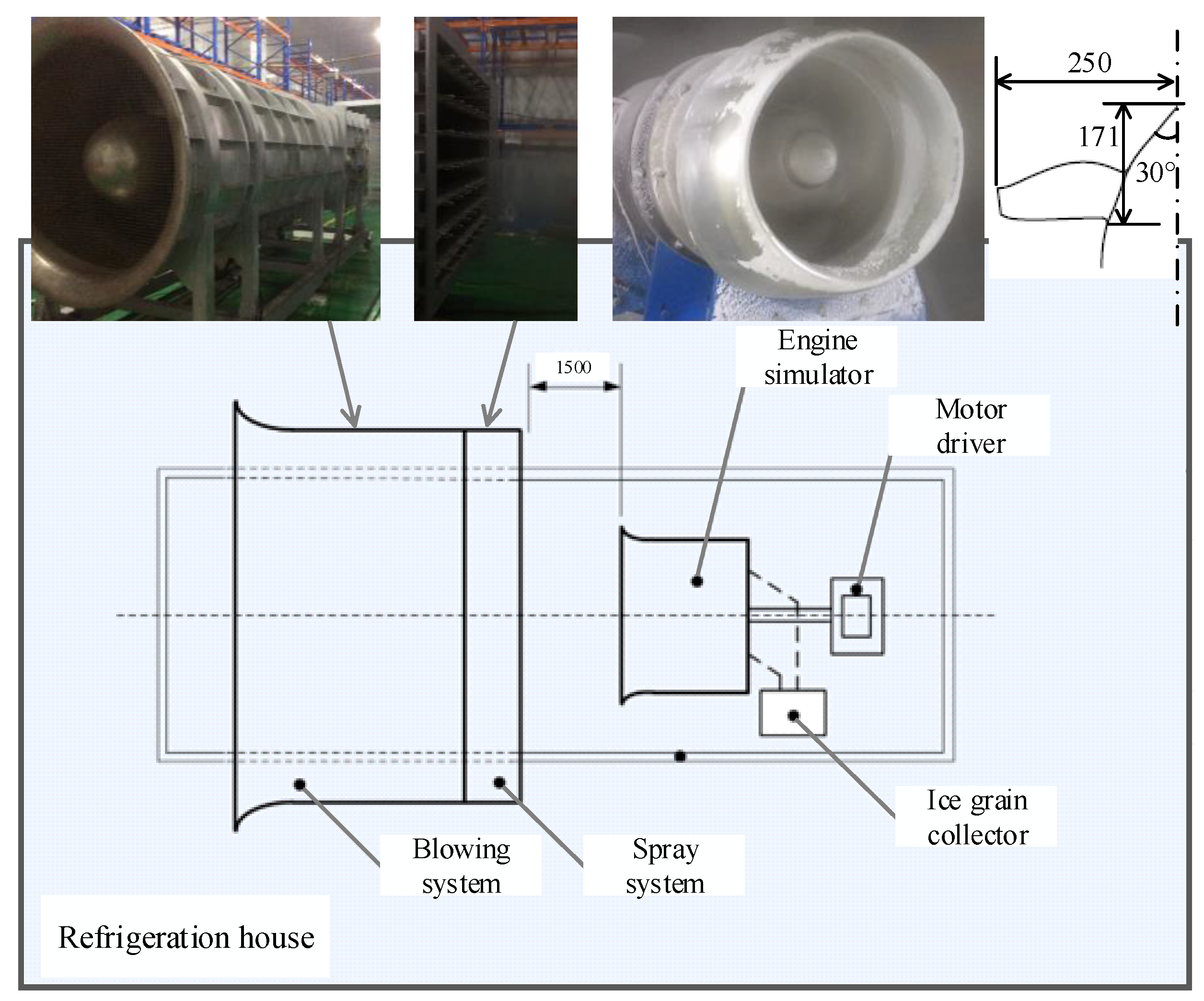

2.1. Experimental Setup

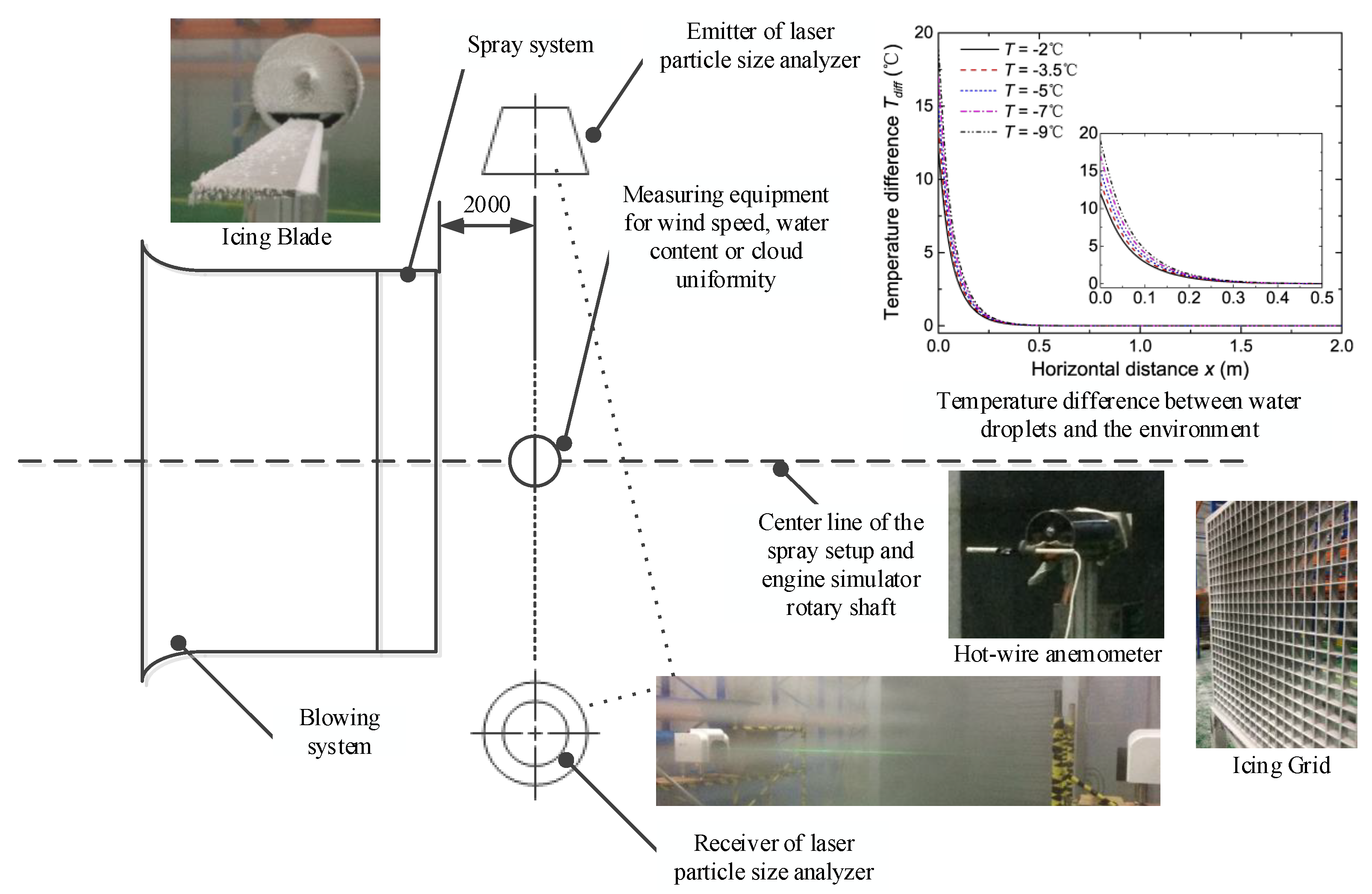

2.2. Spray Parameter Measurement and Calibration

2.3. Experimental Measurement

2.4. Experimental Conditions

3. Results and Discussion

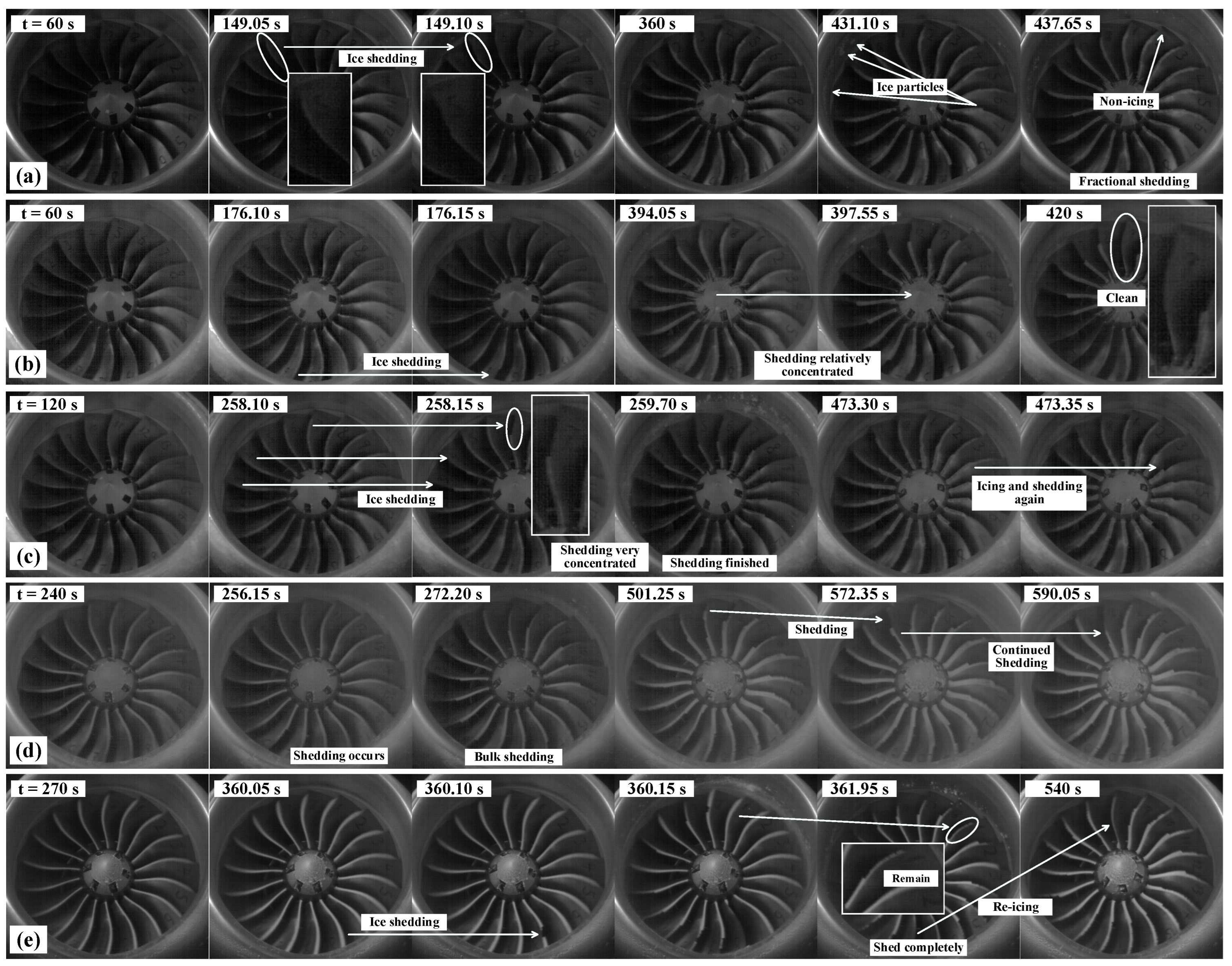

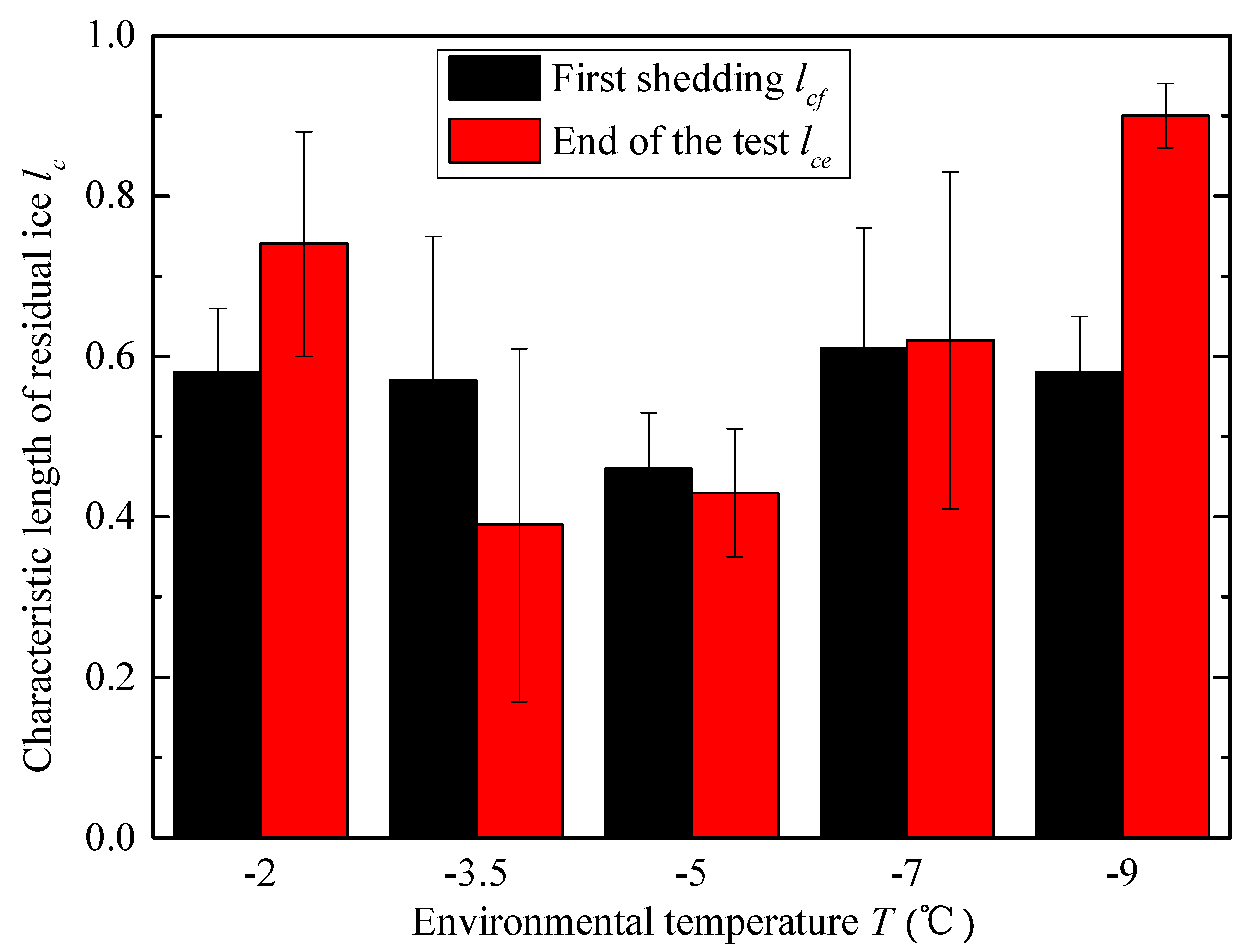

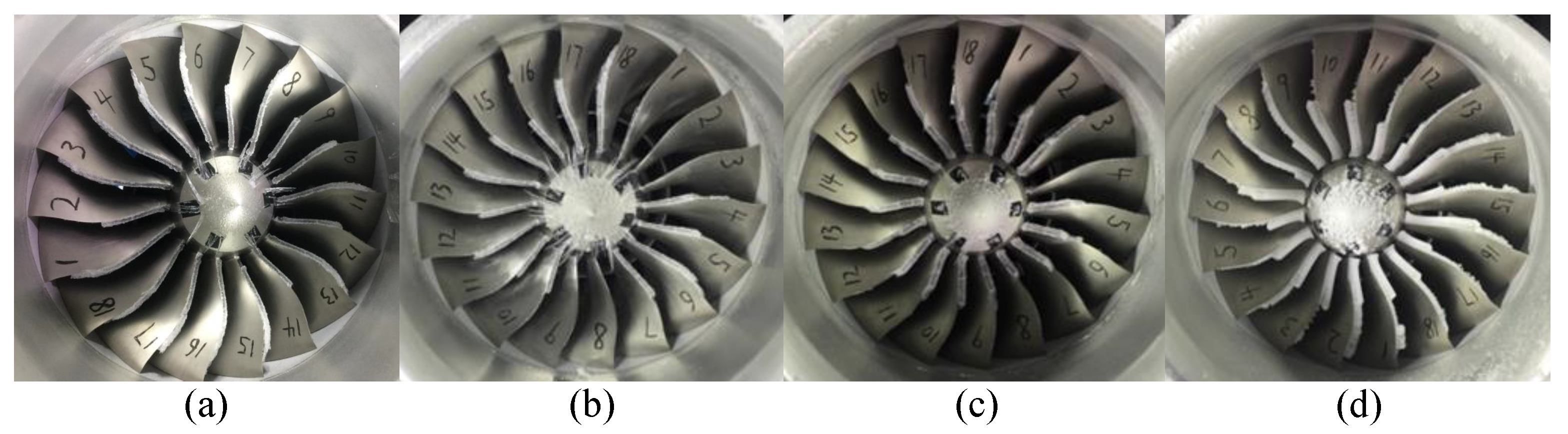

3.1. Effect of Environmental Temperature T

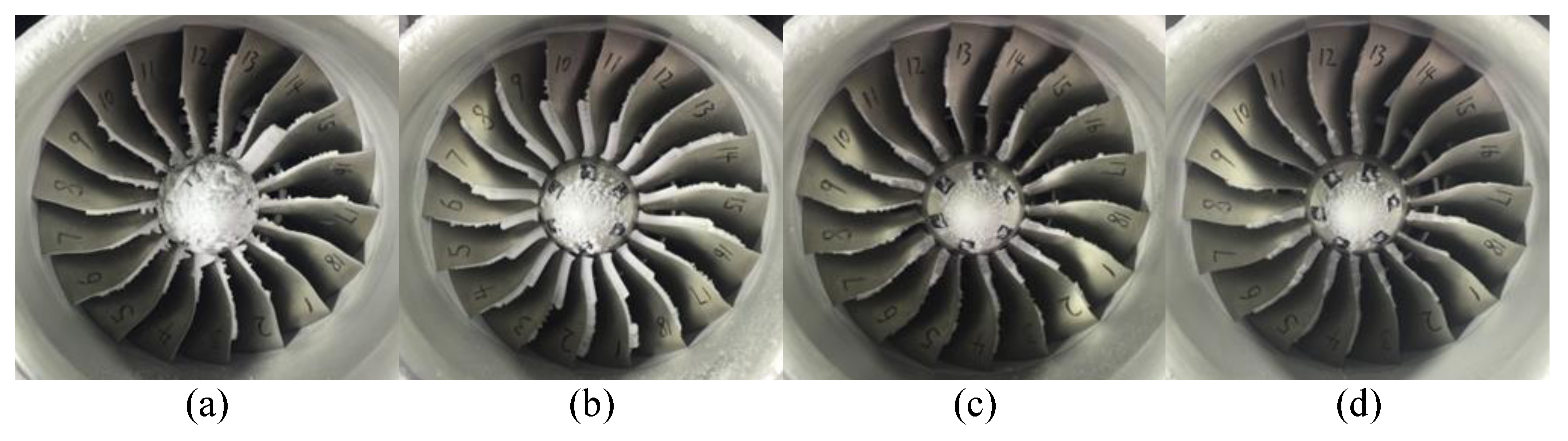

3.2. Effect of Engine Speed n

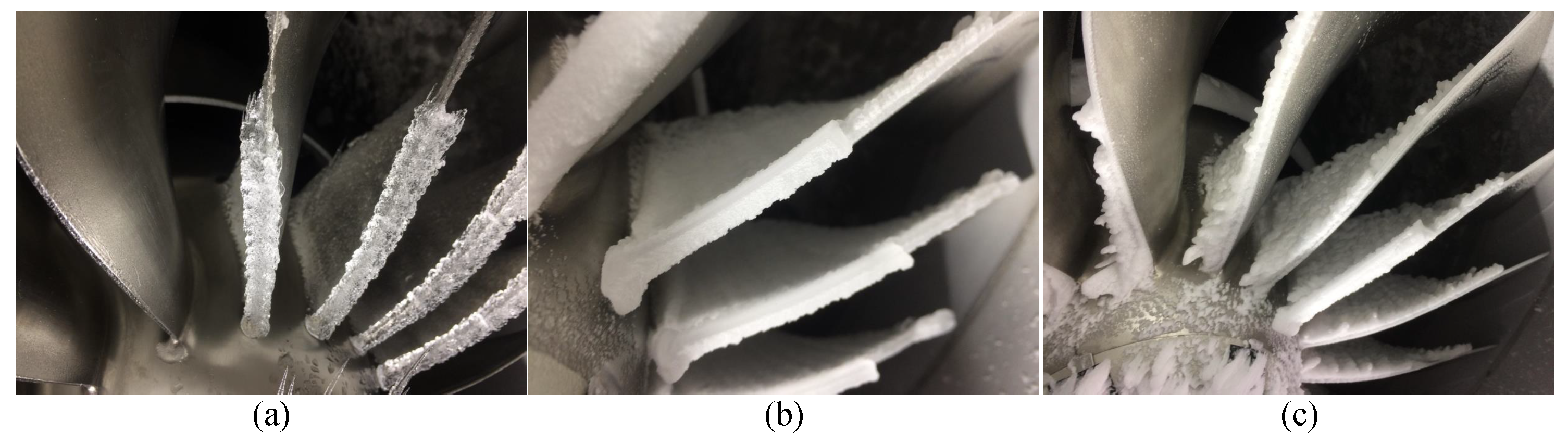

3.3. Ice Accumulation on the High-Pressure Side

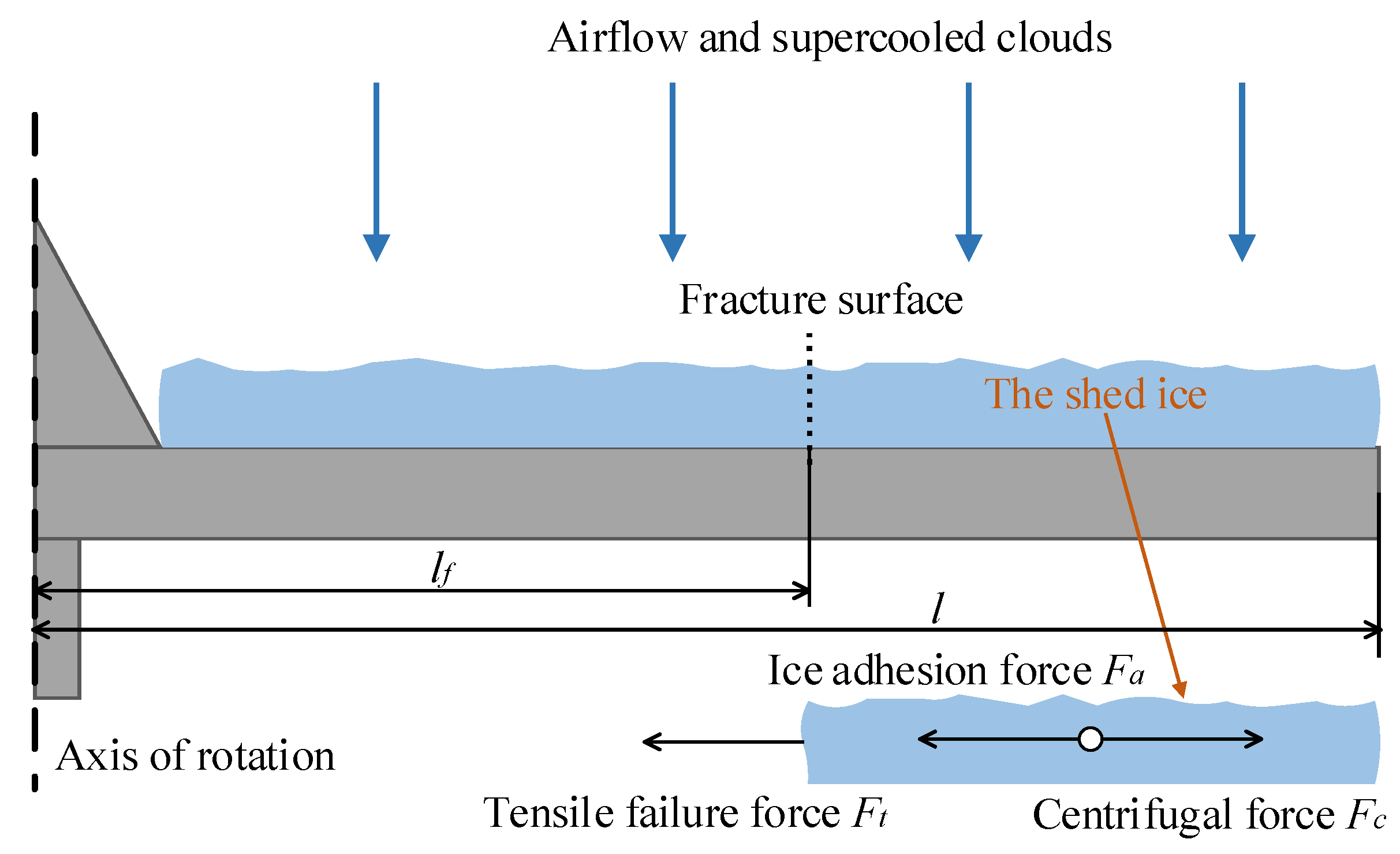

3.4. Explanation of Ice-Shedding Characteristics Based on Simplified Force Analysis

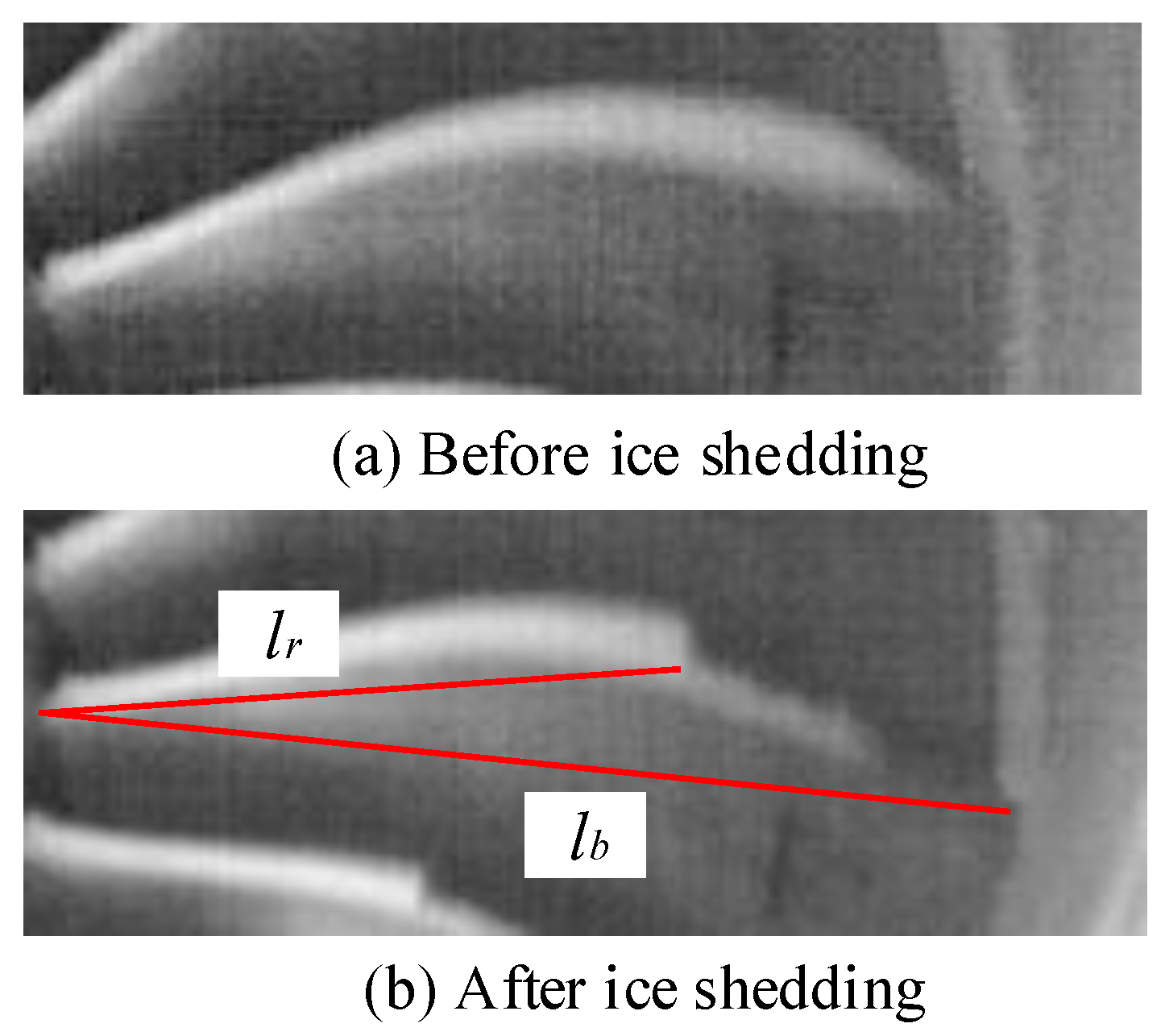

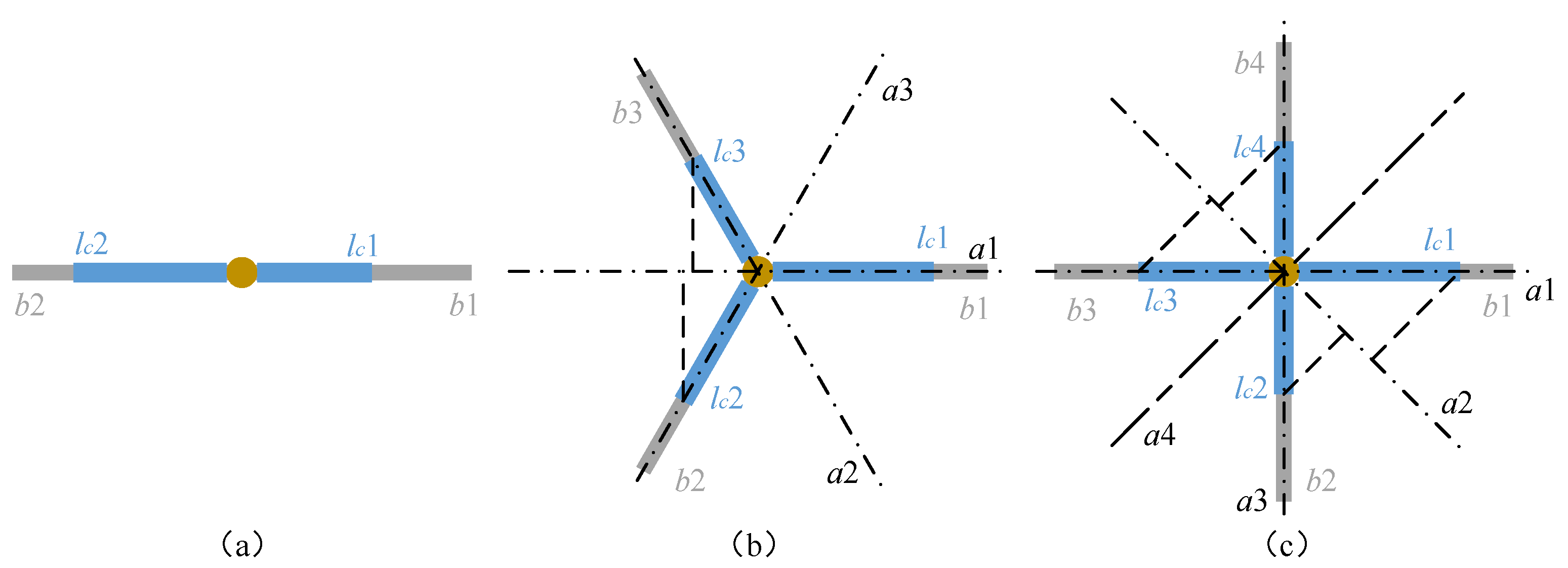

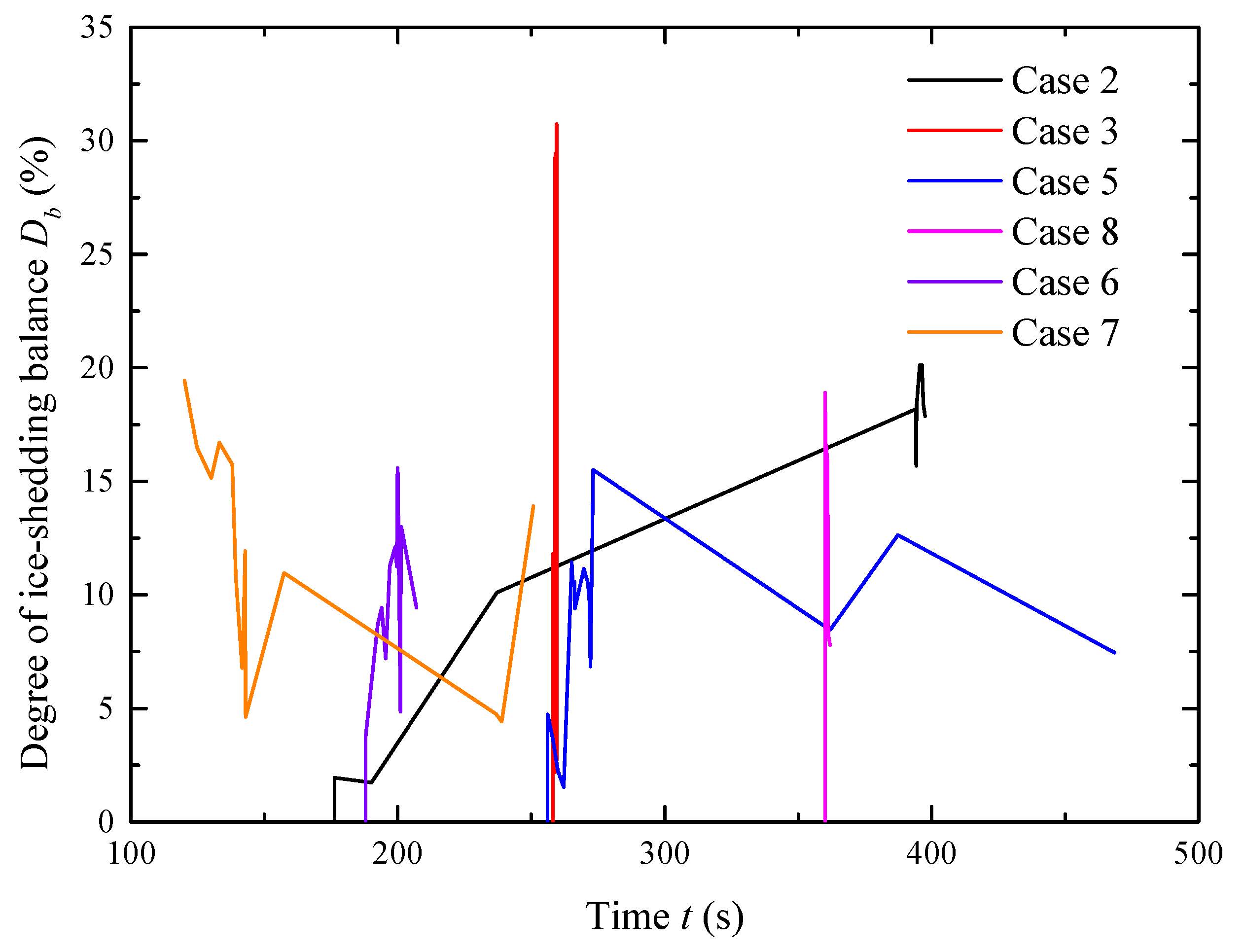

3.5. Degree of Ice-Shedding Balance

4. Conclusions

- (1)

- When the engine speed n is constant at 2400 rpm, the average of ice-shedding time is about 250 to 350 s and the characteristic length of the residual ice is about 0.4 to 0.6 in general. Both reduce first and then increase as the environmental temperature T decreases. Combined with experimental results and force analysis, it is indicated that there is a critical temperature at about −C, below which the extent of ice accretion will be significantly aggravated, including the increase in the amount of accumulated ice, the prolongation in , and the increase in ;

- (2)

- When the engine speed n is low, it can take hours for ice shedding, resulting in severe ice accretion. As n increases, decreases drastically and then slowly to one to two minutes or less, and gradually reduces. There is a critical engine speed , above which the purpose of natural ice shedding under rotation can be achieved initially within minutes. is about 2400 rpm when T = −C in the experiments;

- (3)

- The degree of ice-shedding balance can reach up to 30% in severe cases. The ice in Cases 3 (T = −C, n = 2400 rpm) and 9 (T = −C, n = 2400 rpm) falls off in a short period, resulting in sharp fluctuations in , which are dangerous conditions that need attention for icing operation;

- (4)

- Combining the amount of ice accretion, the time of ice shedding, and the degree of ice-shedding balance, the range of critical ambient temperature is −C to −C for aero-engine fan blade icing tests during ground idle. Furthermore, the ice accreted at the roots of the blades is difficult to shed even at high engine speeds. Effective anti-/de-icing methods need to be developed.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cebeci, T.; Kafyeke, F. Aircraft Icing. Annu. Rev. Fluid Mech. 2003, 35, 11–21. [Google Scholar] [CrossRef]

- Green, S. A Study of U.S. Inflight Icing Accidents and Incidents, 1978 to 2002. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2006; p. AIAA 2006-82. [Google Scholar] [CrossRef]

- Palacios, J.; Smith, E.; Rose, J.; Royer, R. Ultrasonic De-Icing of Wind-Tunnel Impact Icing. J. Aircr. 2011, 48, 1020–1027. [Google Scholar] [CrossRef]

- Cao, Y.; Tan, W.; Wu, Z. Aircraft icing: An ongoing threat to aviation safety. Aerosp. Sci. Technol. 2018, 75, 353–385. [Google Scholar] [CrossRef]

- Jones, S.M.; Reveley, M.S.; Evans, J.K.; Barrientos, F.A. Subsonic Aircraft Safety Icing Study; Report NASA TM-2008-215107; National Aeronautics and Space Administration: Washington, DC, USA, 2008. [Google Scholar]

- Hayashi, R.; Yamamoto, M. Numerical Investigation of Ice Shedding Associated with Engine Fan Icing; SAE Technical Paper 2015-01-2091; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Song, J.; Wu, J.; Qiu, C.; Luo, S.; Zha, X. Civil Turboshaft engine induction system icing test. J. Aerosp. Power 2020, 35, 1089–1098. (In Chinese) [Google Scholar] [CrossRef]

- Tetteh, E.; Loth, E.; Neuteboom, M.O.; Fisher, J. In-Flight Gas Turbine Engine Icing: Review. AIAA J. 2022, 60, 5610–5632. [Google Scholar] [CrossRef]

- Saxena, S.; Woo, G.T.K.; Singh, R.; Breeze-Stringfellow, A.; Nakano, T.; Szucs, P. Effect of Ice and Blade Interaction Models on Compressor Stability. J. Turbomach. 2017, 139, 041001. [Google Scholar] [CrossRef]

- Han, Y.; Soltis, J.; Palacios, J. Engine Inlet Guide Vane Ice Impact Fragmentation. AIAA J. 2018, 56, 3680–3690. [Google Scholar] [CrossRef]

- Li, L.; Liu, Y.; Hu, H. An experimental study on dynamic ice accretion process over the surfaces of rotating aero-engine spinners. Exp. Therm. Fluid Sci. 2019, 109, 109879. [Google Scholar] [CrossRef]

- Hirose, K.; Fukudome, K.; Mamori, H.; Yamamoto, M. Three-Dimensional Trajectory and Impingement Simulation of Ice Crystals Considering State Changes on the Rotor Blade of an Axial Fan. Aerospace 2023, 11, 2. [Google Scholar] [CrossRef]

- Al-Khalil, K.M.; Keith, T.G.; De Witt, K.J. Icing Calculations on a Typical Commercial Jet Engine Inlet Nacelle. J. Aircr. 1997, 34, 87–93. [Google Scholar] [CrossRef]

- Yang, Q.; Guo, X.; Dong, W.; Wang, A. Ice accretion and aerodynamic effects on a turbofan engine nacelle under takeoff conditions. Aerosp. Sci. Technol. 2022, 126, 107571. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, L.; Liu, Z. Preliminary Research on Rotating Icing Test Scaling Law. Res. J. Appl. Sci. Eng. Technol. 2014, 8, 803–810. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, L.F.; Li, Y.D.; Liu, Z.X.; Zhu, P.F. Experimental investigation of the icing scaling test method for a rotating cone. Proc. Inst. Mech. Eng. Part G-J. Aerosp. Eng. 2019, 233, 3368–3380. [Google Scholar] [CrossRef]

- Zheng, M.; Guo, Z.; Dong, W.; Guo, X. Experimental investigation on ice accretion on a rotating aero-engine spinner with hydrophobic coating. Int. J. Heat Mass Transf. 2019, 136, 404–414. [Google Scholar] [CrossRef]

- Gao, X.; Qiu, B.; Wang, Z.; Li, H. Influence of Spinner Shape on Droplet Impact over Rotating Spinners. Aerospace 2023, 10, 68. [Google Scholar] [CrossRef]

- Das, K.; Hamed, A.; Basu, D. Ice Shape Prediction for Turbofan Rotating Blades. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006; Aerospace Sciences Meetings. American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2006. [Google Scholar] [CrossRef]

- Isobe, K.; Suzuki, M.; Yamamoto, M. Numerical investigation on super-cooled large droplet icing of fan rotor blade in jet engine. J. Therm. Sci. 2014, 23, 432–437. [Google Scholar] [CrossRef]

- Nilamdeen, S.; Zhang, Y.; Ozcer, I.; Baruzzi, G.S. An Ice Shedding Model for Rotating Components; SAE Technical Paper 2019-01-2003; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Tian, L.; Li, L.; Hu, H.; Hu, H. An Experimental Study on the Dynamic Ice Accretion Process over the Surfaces of the Rotating Fan Blades of an Aero-Engine Model. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2022; AIAA SciTech Forum. American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2022. [Google Scholar] [CrossRef]

- Dong, W.; Zhu, J.; Zheng, M.; Lei, G.L.; Zhou, Z.X. Experimental Study on Icing and Anti-Icing Characteristics of Engine Inlet Guide Vanes. J. Propuls. Power 2015, 31, 1330–1337. [Google Scholar] [CrossRef]

- Dong, W.; Zheng, M.; Zhu, J.; Lei, G.; Zhao, Q. Experimental Investigation on Anti-Icing Performance of an Engine Inlet Strut. J. Propuls. Power 2017, 33, 379–386. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, F.; Wang, D.; Li, S. Numerical and Experimental Study of Ice Accretion Process and Ice Protection on Turbo-Fan Engine Splitter. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. Volume 2D: Turbomachinery. [Google Scholar] [CrossRef]

- Nelepovitz, D.O.N.; Rosenthal, H.; Rockholt, H. Test and analysis of electro-impulse de-icing systems in turbine engine inlets. In Proceedings of the 26th Aerospace Sciences Meeting, Reno, NV, USA, 11–14 January 1988; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1988; p. AIAA-88–0020. [Google Scholar] [CrossRef]

- Lian, W.; Xuan, Y. Experimental investigation on a novel aero-engine nose cone anti-icing system. Appl. Therm. Eng. 2017, 121, 1011–1021. [Google Scholar] [CrossRef]

- Li, L.; Liu, Y.; Tian, L.; Hu, H.; Hu, H.; Liu, X.; Hogate, I.; Kohli, A. An experimental study on a hot-air-based anti-/de-icing system for aero-engine inlet guide vanes. Appl. Therm. Eng. 2020, 167, 114778. [Google Scholar] [CrossRef]

- Hou, N.; Zheng, L.; Yu, F.; Yang, K. The influence of fan blade icing on aero-engine rotor unbalance. Sci. Technol. Eng. 2018, 18, 363–366. (In Chinese) [Google Scholar]

- Li, Y.; Tagawa, K.; Feng, F.; Li, Q.; He, Q. A wind tunnel experimental study of icing on wind turbine blade airfoil. Energy Convers. Manag. 2014, 85, 591–595. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Y.; Hu, H. An experimental investigation of dynamic ice accretion process on a wind turbine airfoil model considering various icing conditions. Int. J. Heat Mass Transf. 2019, 133, 930–939. [Google Scholar] [CrossRef]

- Tarquini, S.; Antonini, C.; Amirfazli, A.; Marengo, M.; Palacios, J. Investigation of ice shedding properties of superhydrophobic coatings on helicopter blades. Cold Reg. Sci. Technol. 2014, 100, 50–58. [Google Scholar] [CrossRef]

- Muhammed, M.; Virk, M.S. Ice Accretion on Rotary-Wing Unmanned Aerial Vehicles—A Review Study. Aerospace 2023, 10, 261. [Google Scholar] [CrossRef]

- Hayashi, R.; Yamamoto, M. Numerical Simulation on Ice Shedding Phenomena in Turbomachinery. J. Energy Power Eng. 2015, 9. [Google Scholar] [CrossRef][Green Version]

- Chen, Y.; Dong, W.; Wang, Z.; Fu, L. Numerical Simulation of Ice Shedding From a Fan Blade. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015. Volume 1: Aircraft Engine; Fans and Blowers; Marine. [Google Scholar] [CrossRef]

- Zhou, H.; Yu, F.; Yang, K. Critical icing temperature analysis of aircraft engine fan in ground idle. Sci. Technol. Eng. 2017, 17, 324–328. (In Chinese) [Google Scholar]

- Chen, G.; Yang, K.; Wang, L.; Kong, W.; Wang, F. Test of ice shedding on turbofan engine blade in refrigerator environment. J. Beijing Univ. Aeronaut. Astronaut. 2018, 44, 2106–2114. (In Chinese) [Google Scholar] [CrossRef]

- Ide, R.; Oldenburg, J. Icing cloud calibration of the NASA Glenn Icing Research Tunnel. In Proceedings of the 39th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 8–11 January 2001; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2001; p. AIAA 2001-234. [Google Scholar] [CrossRef][Green Version]

- SAE. Calibration and Acceptance of Icing Wind Tunnels; Report SAE ARP5905; SAE Aerospace: Warrendale, PA, USA, 2009. [Google Scholar]

- Department of Policy and Regulation, Civil Aviation Administration of China. Aircraft Engine Airworthiness Standards; Report CCAR-33-R2; Civil Aviation Administration of China: Beijing, China, 2016. [Google Scholar]

- Fortin, G.; Perron, J. Ice Adhesion Models to Predict Shear Stress at Shedding. J. Adhes. Sci. Technol. 2012, 26, 523–553. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Q.; Han, D.; Xue, Y.; Qu, J.; Yao, H. Experimental study of the quasi-static and dynamic fracture toughness of freshwater ice using notched semi-circular bend method. Eng. Fract. Mech. 2021, 247, 107696. [Google Scholar] [CrossRef]

- Blackmore, R.Z.; Makkonen, L.; Lozowski, E.P. A new model of spongy icing from first principles. J. Geophys. Res. 2002, 107, 4563. [Google Scholar] [CrossRef]

| Case | Set Temperature T (°C) | Engine Speed n (rpm) | Mean Temperature of Air Flow (°C) |

|---|---|---|---|

| 1 | −2 | 2400 | −1.67 |

| 2 | −3.5 | 2400 | −3.48 |

| 3 | −5 | 2400 | −4.97 |

| 4 | −7 | 1800 | −7.08 |

| 5 | −7 | 2400 | −6.56 |

| 6 | −7 | 2700 | −6.53 |

| 7 | −7 | 3000 | −6.79 |

| 8 | −9 | 2400 | −8.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Yang, K.; Yu, F.; Wang, F. Experimental Study on Ice Shedding Behaviors for Aero-Engine Fan Blade Icing during Ground Idle. Aerospace 2024, 11, 853. https://doi.org/10.3390/aerospace11100853

Wang L, Yang K, Yu F, Wang F. Experimental Study on Ice Shedding Behaviors for Aero-Engine Fan Blade Icing during Ground Idle. Aerospace. 2024; 11(10):853. https://doi.org/10.3390/aerospace11100853

Chicago/Turabian StyleWang, Liping, Kun Yang, Fang Yu, and Fuxin Wang. 2024. "Experimental Study on Ice Shedding Behaviors for Aero-Engine Fan Blade Icing during Ground Idle" Aerospace 11, no. 10: 853. https://doi.org/10.3390/aerospace11100853

APA StyleWang, L., Yang, K., Yu, F., & Wang, F. (2024). Experimental Study on Ice Shedding Behaviors for Aero-Engine Fan Blade Icing during Ground Idle. Aerospace, 11(10), 853. https://doi.org/10.3390/aerospace11100853