Numerical Study on the Corner Separation Control for a Compressor Cascade via Bionic Herringbone Riblets

Abstract

1. Introduction

2. Cascade Geometry and Numerical Method

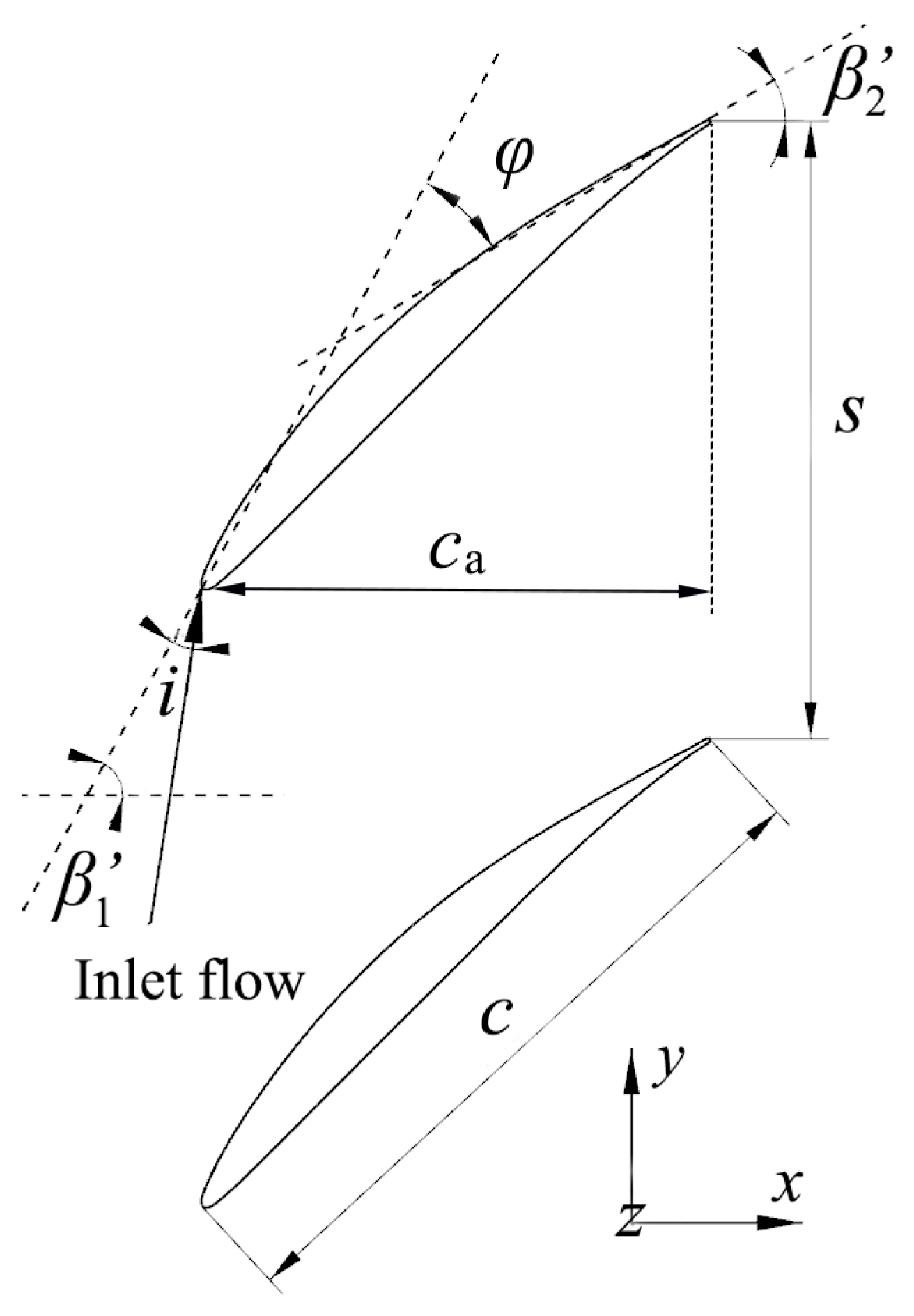

2.1. Geometric Parameters of Prototype Cascade

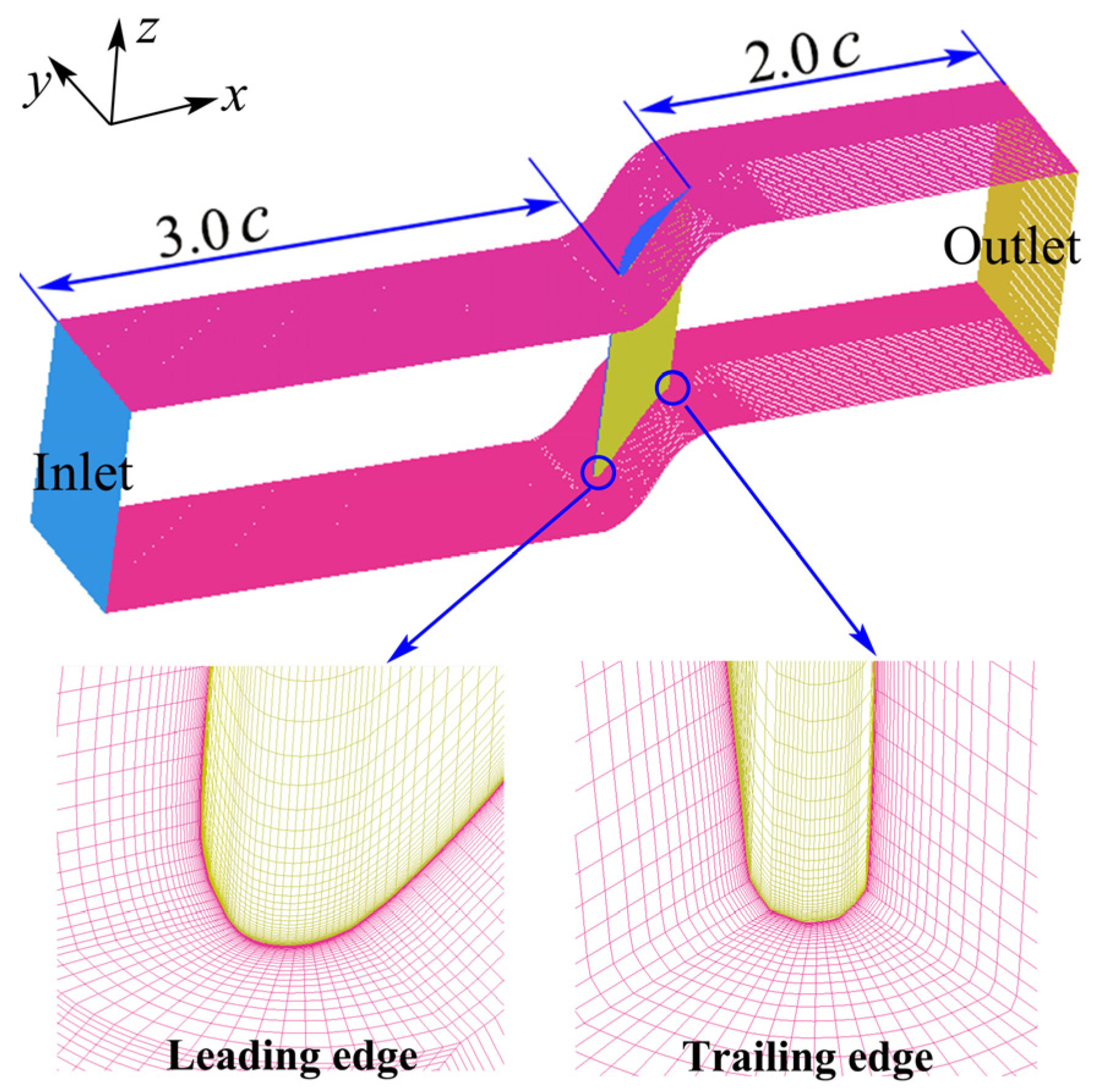

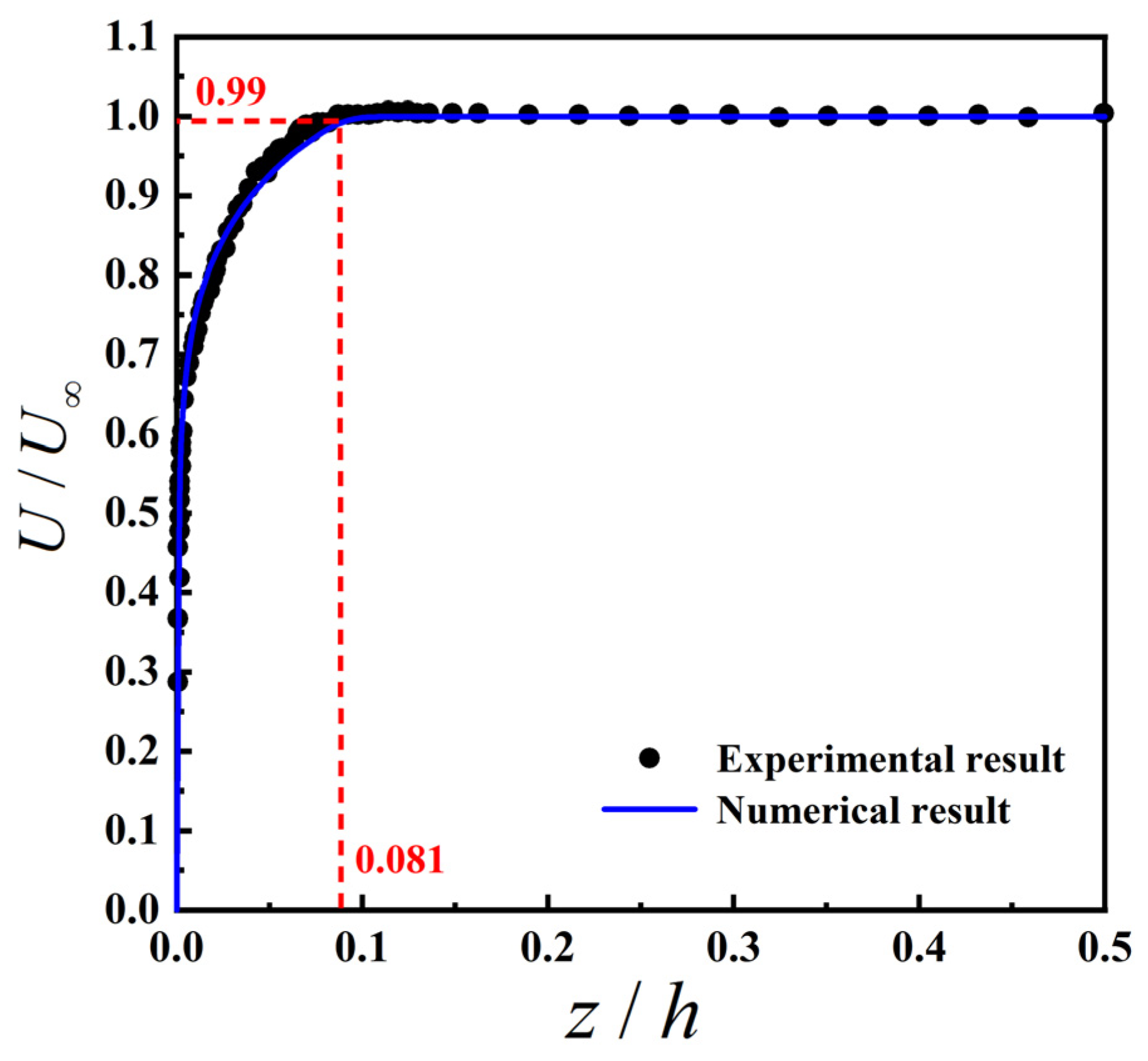

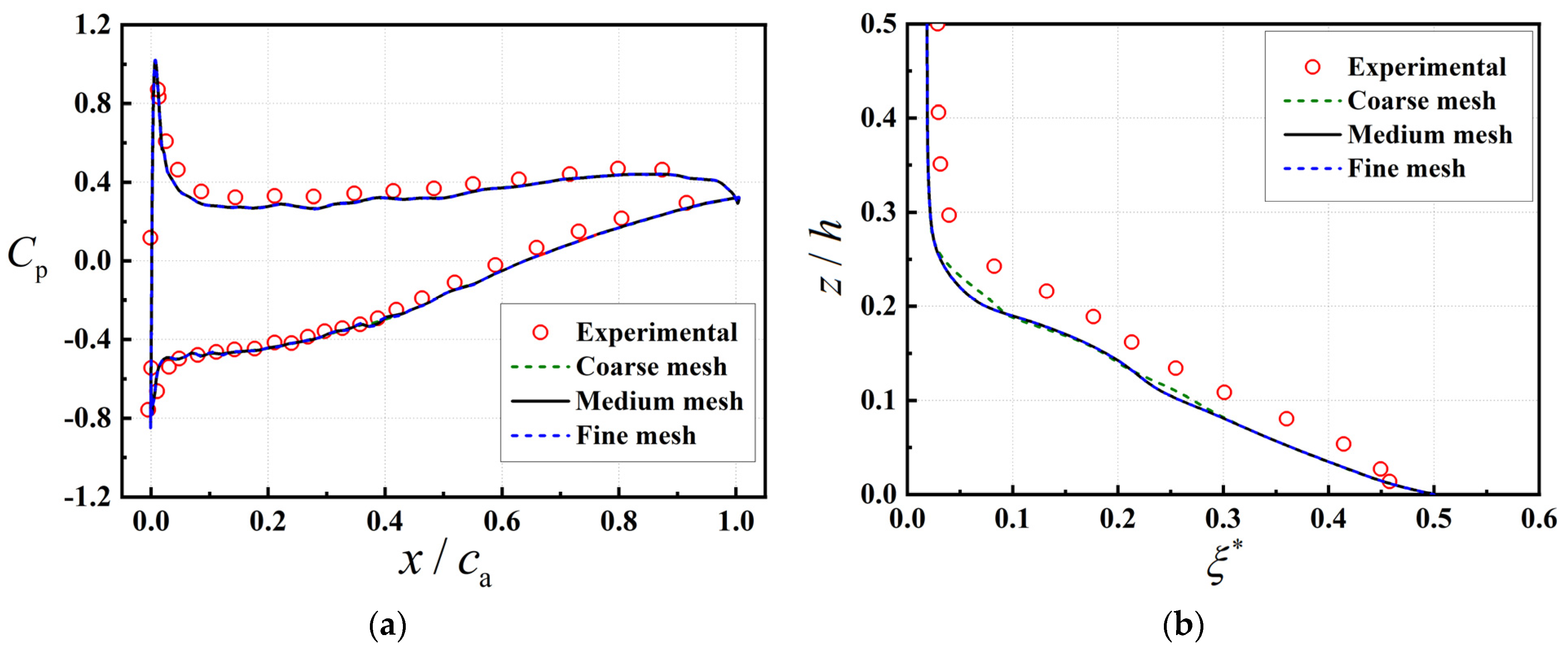

2.2. Numerical Method and Experimental Validation

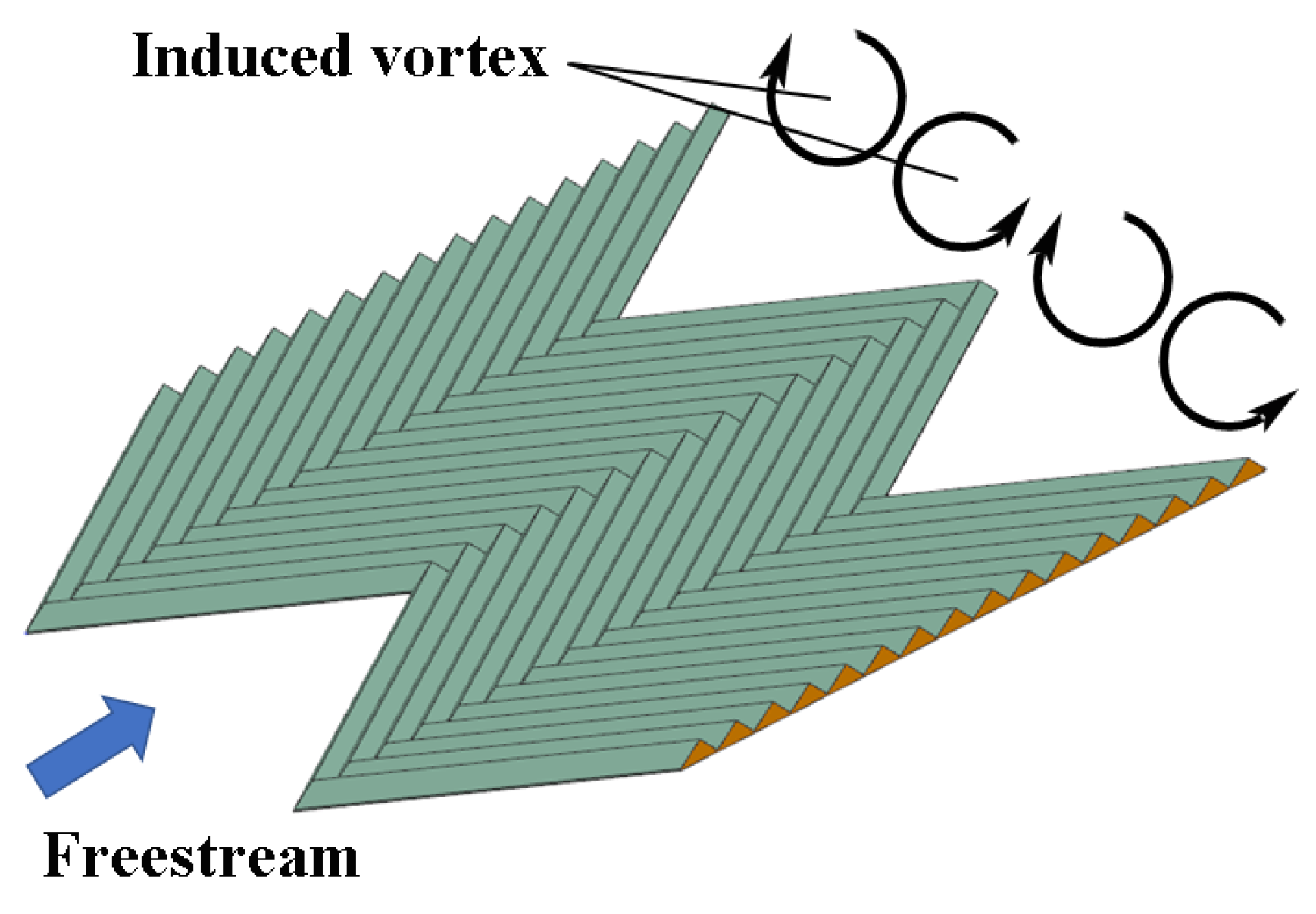

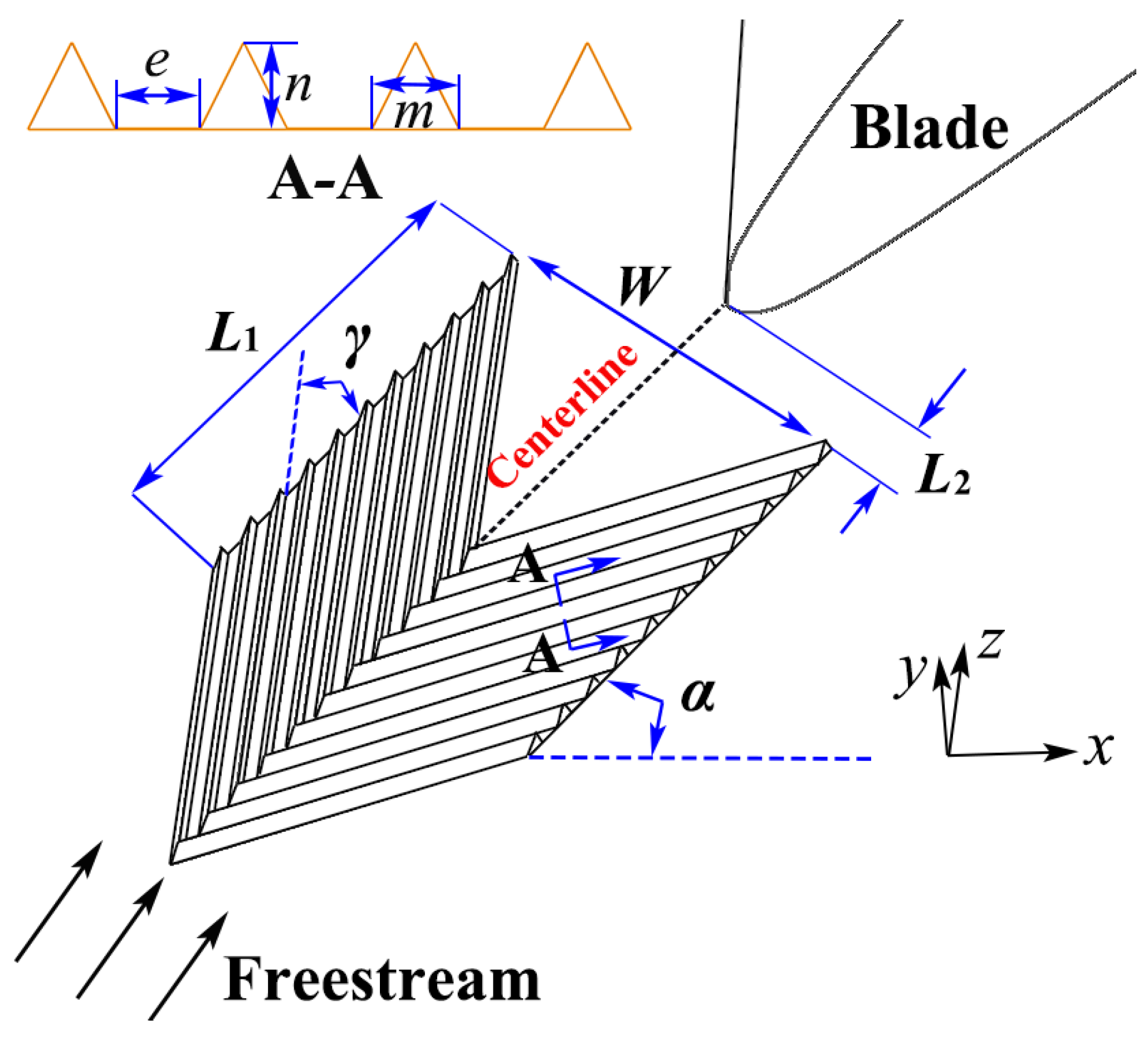

3. Placement Scheme of Bionic Herringbone Riblets

3.1. Geometric Parameters of Herringbone Riblets

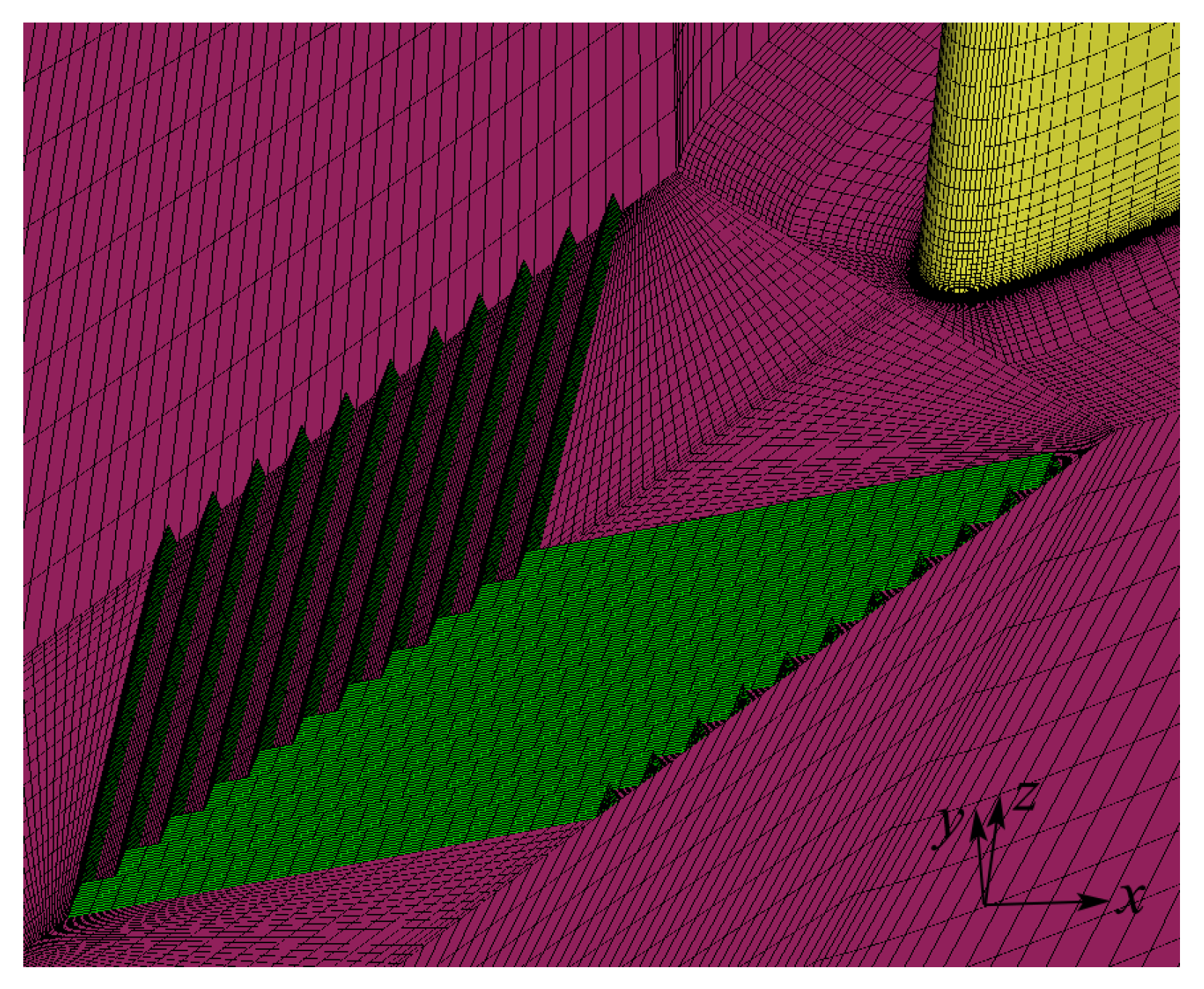

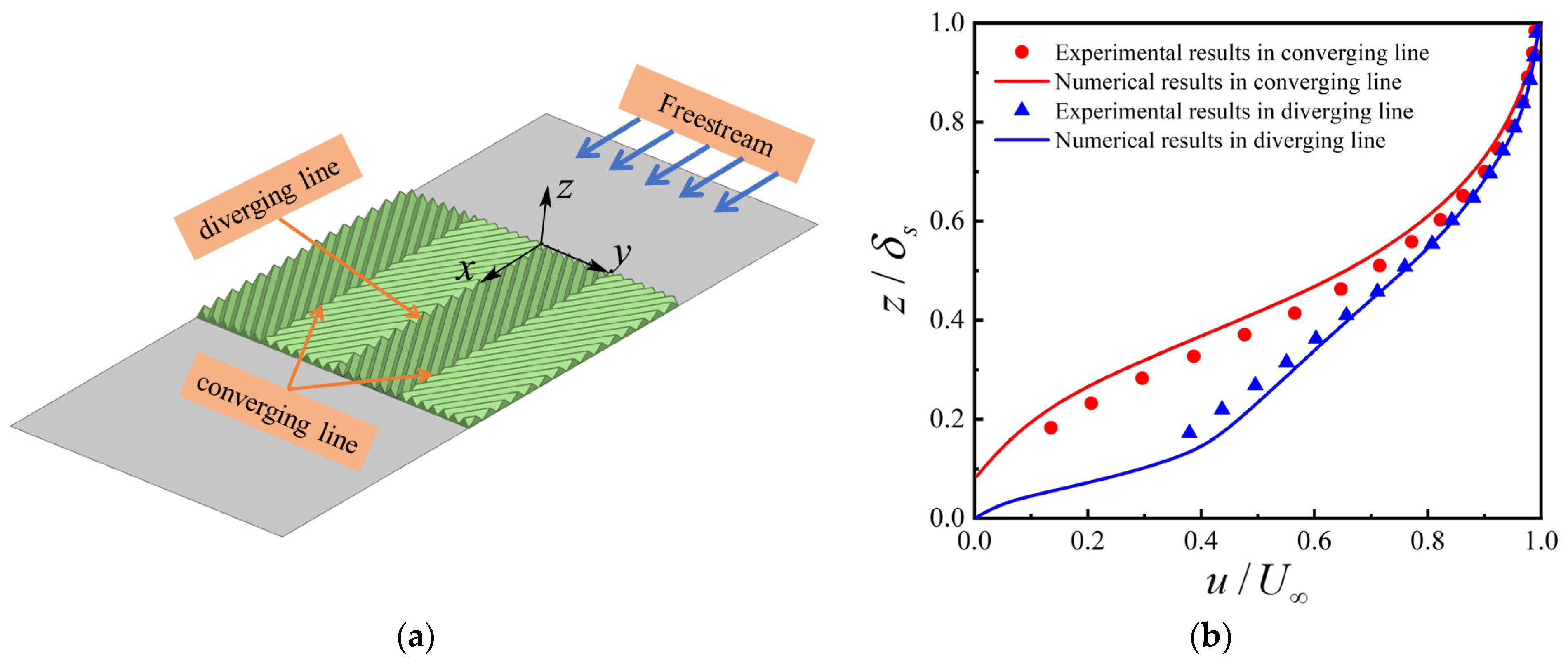

3.2. Computational Grid and Experimental Validation

4. Results and Discussion

4.1. Data Analysis Method

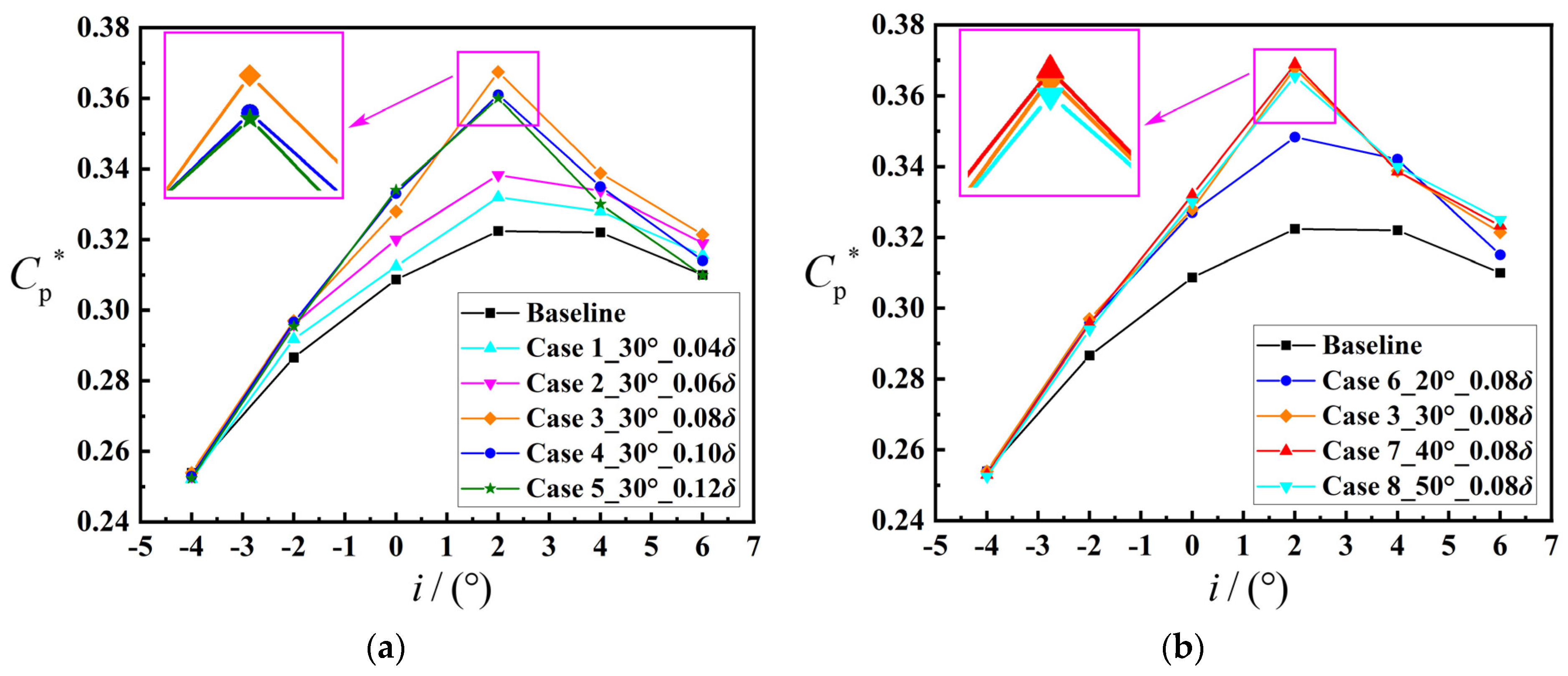

4.2. Performance over the Stable Working Range

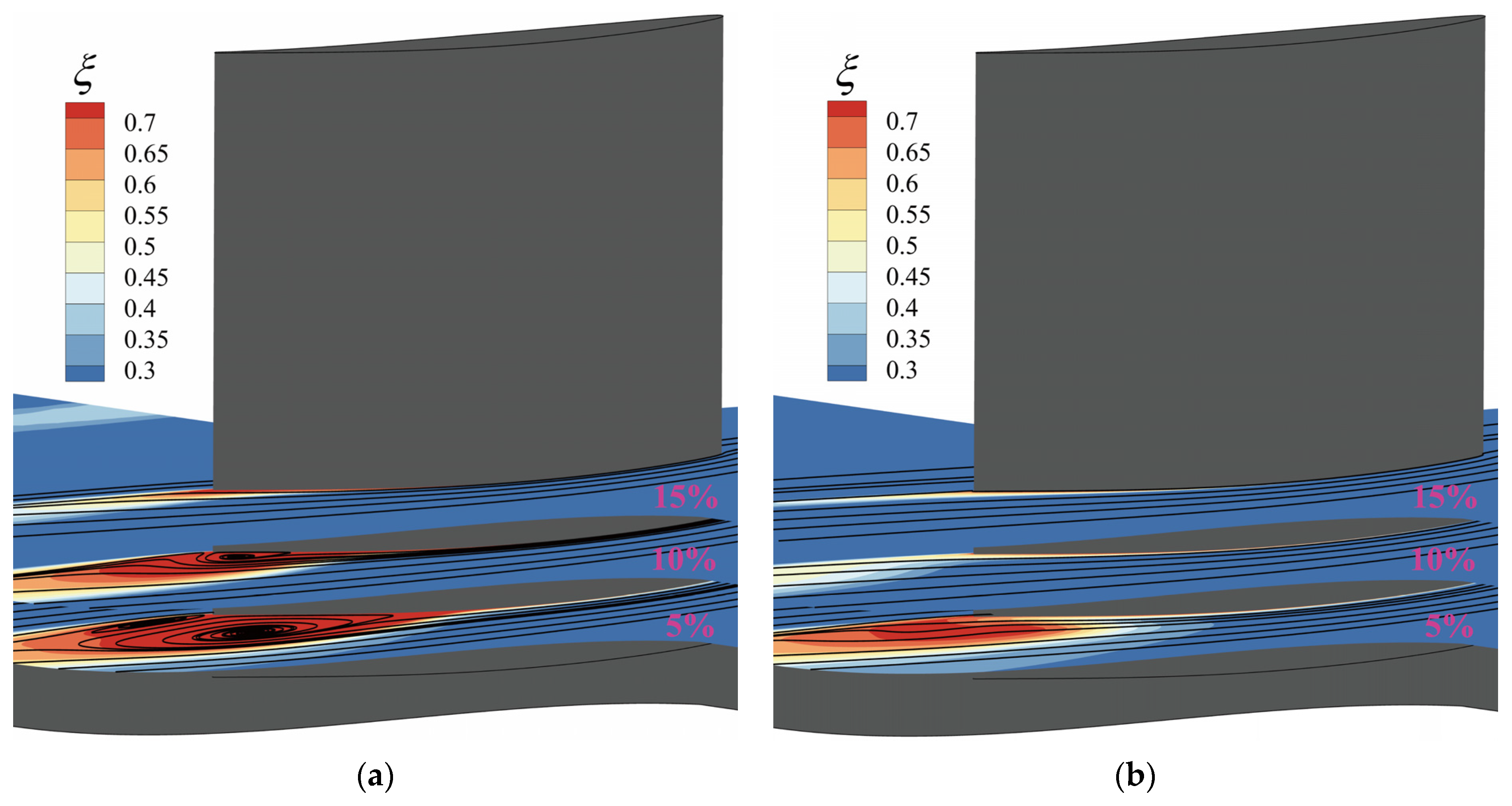

4.3. Flow Analysis of Case 3 When

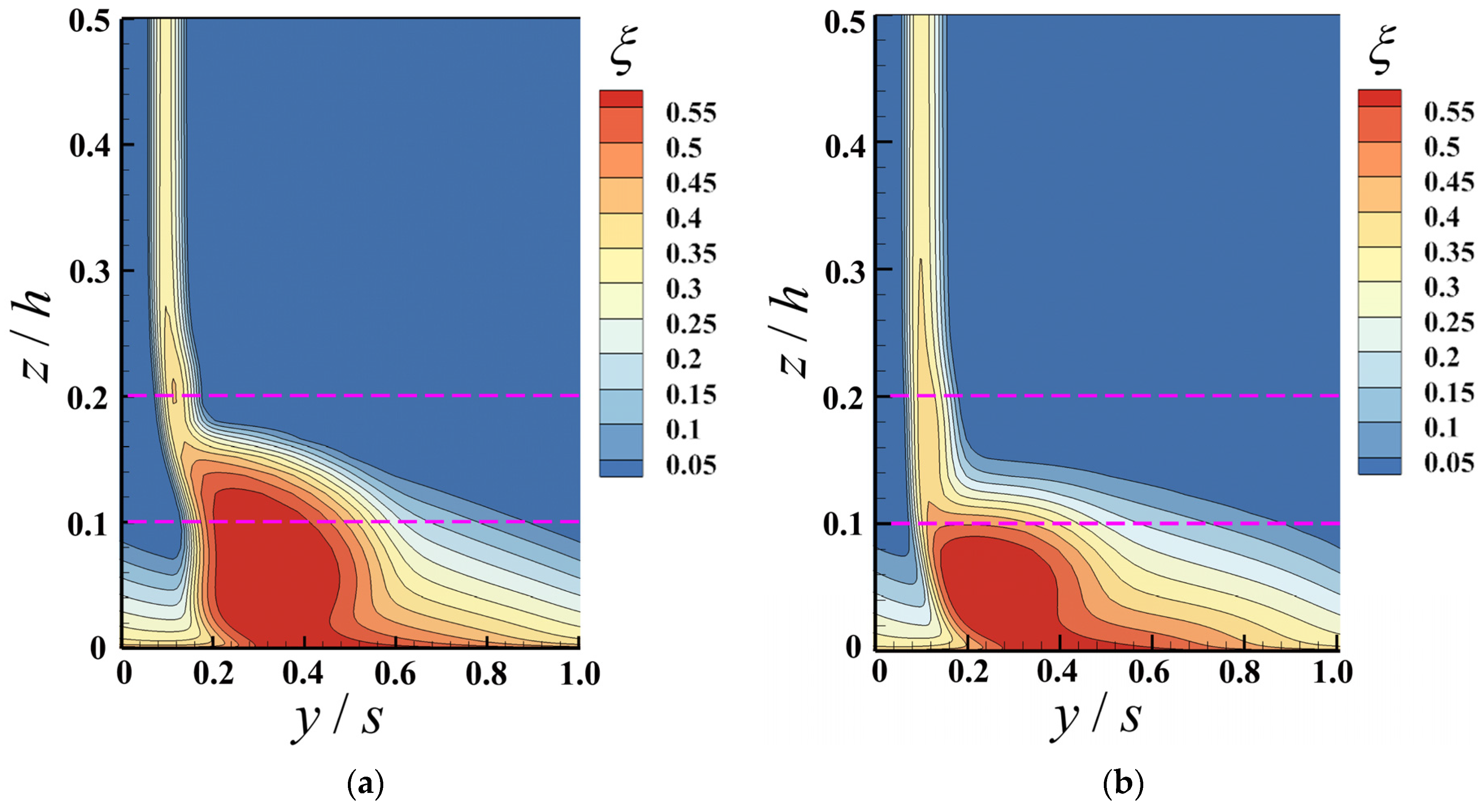

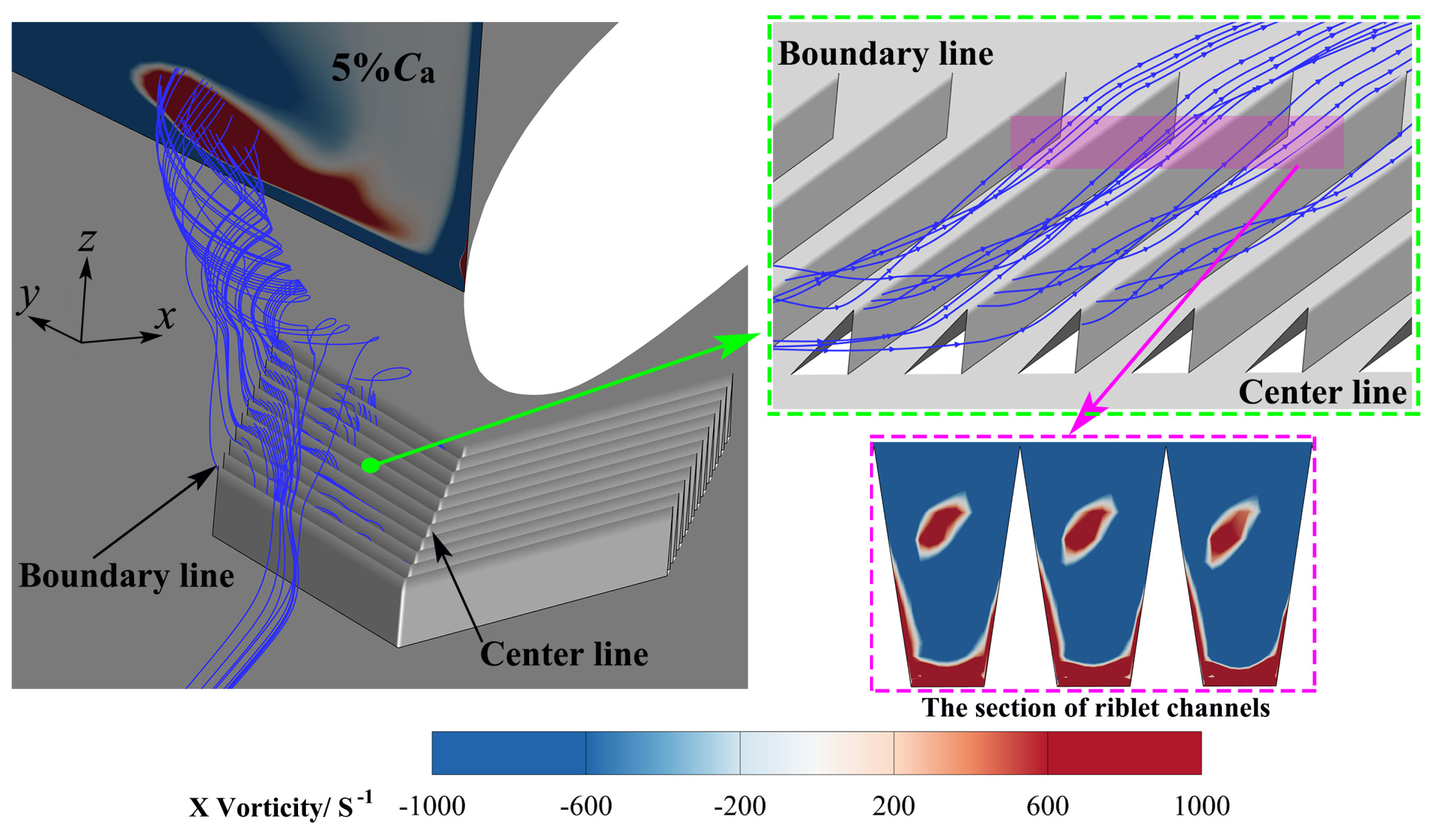

4.4. Control Mechanism Analysis

5. Conclusions

- (1)

- Except for the incidence angle, the bio-inspired herringbone riblets can effectively improve the flow in the corner region within the entire stable working range of the cascade. The riblet height and yaw angle are the two main parameters that affect the control effect of corner separation. Both the total pressure loss improvement and the static pressure coefficient improvement exhibit an initial increase followed by a decrease as the riblet height or yaw angle increases. Optimal results can be achieved when the riblet height is 0.08 and the yaw angle is . The maximum total pressure loss improvement can reach 9.89%, and the maximum static pressure coefficient improvement can reach 12.27% under this design condition.

- (2)

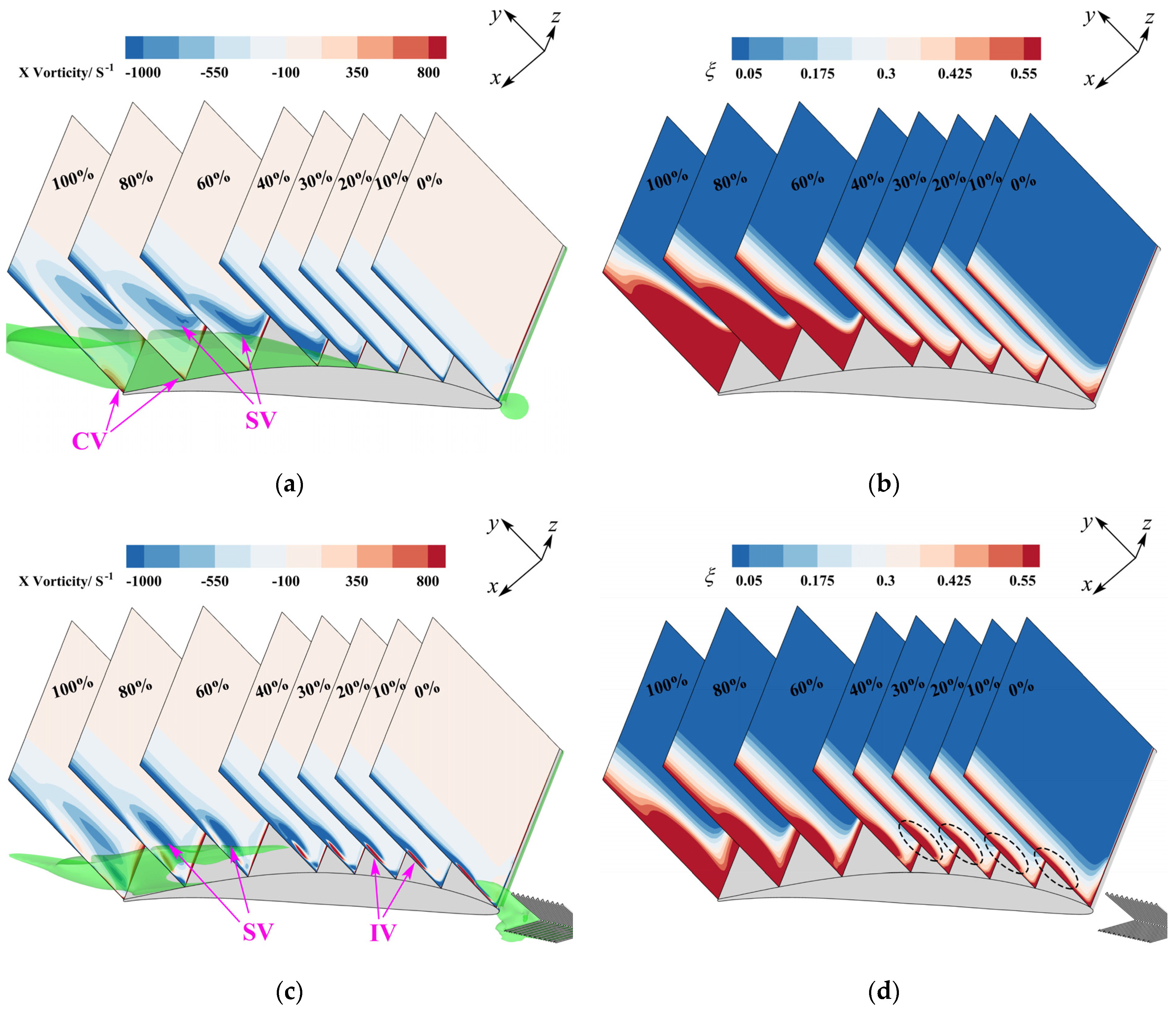

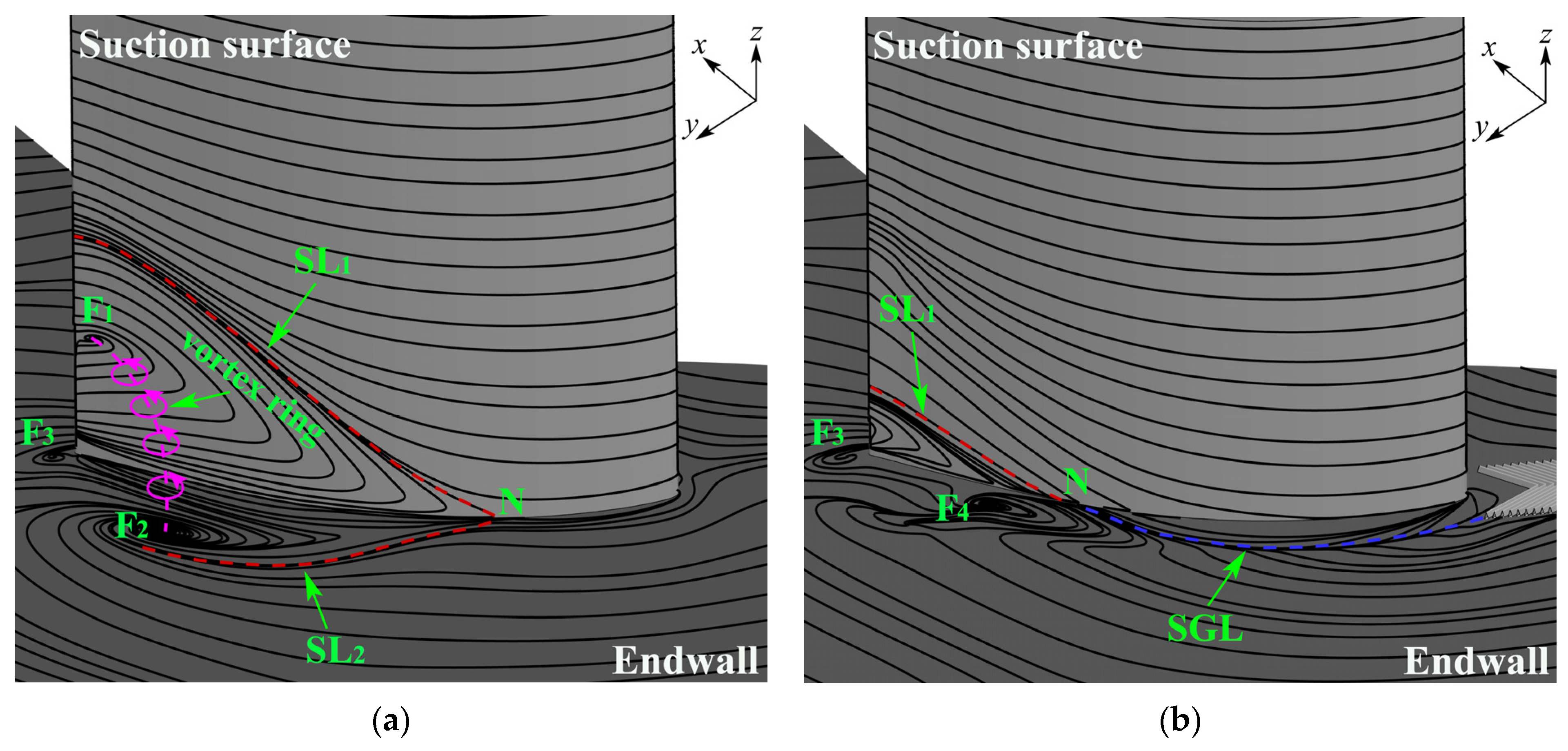

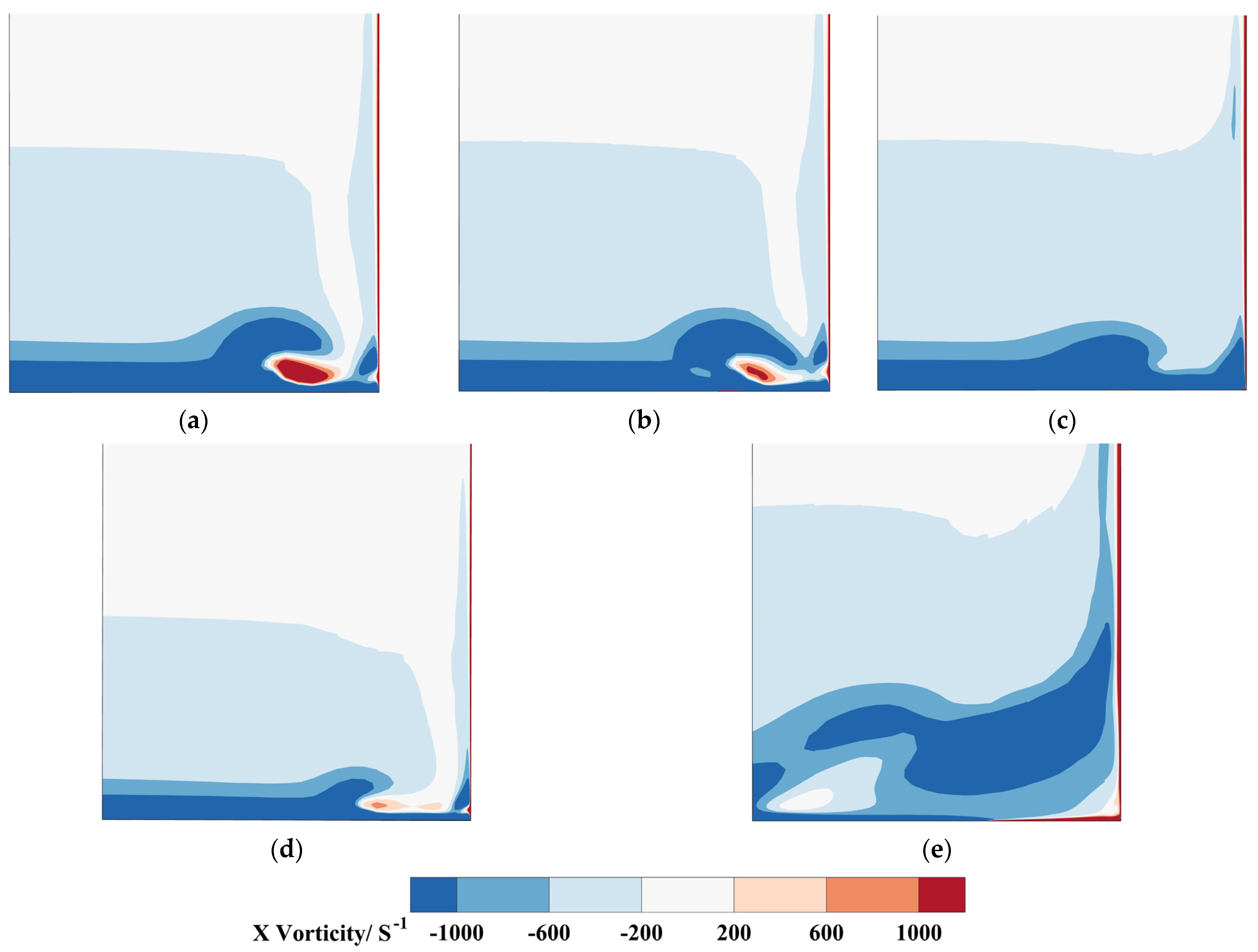

- The herringbone riblets can be viewed as multiple ribbed micro-vortex generators arranged in parallel along a certain direction. Due to the pressure difference between the two sides of each riblet, multiple small-scale induced vortices are formed in the channel of each riblet. These small-scale induced vortices leaving the riblet channels interact with the fluid outside the channels to form the upwash flow and eventually develop together into a large-scale induced vortex along the freestream direction via the accumulation effect. Since the size of the herringbone riblets is smaller than that of a traditional vortex generator, its induced vortex can be placed closer to the bottom of the boundary layer, which can reduce the damage of the induced vortex to the mainstream and enhance its control over the bottom of the boundary layer, thereby effectively reducing additional losses.

- (3)

- The induced vortex of the herringbone riblets enhances the mixing between the boundary layer and the mainstream, effectively inhibits the accumulation of low-energy fluid in the corner region, and makes the separation point move downstream, thus delaying the formation of the separation vortex, eliminating the vortex ring in the corner region, further suppressing the development of corner separation. The geometric parameters and incidence angle of the herringbone riblets further affect the control effect of corner separation by affecting the strength and position of the induced vortex.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| camber angle | |

| pitch spacing | |

| blade span | |

| Reynolds number | |

| incidence angle | |

| total pressure loss coefficient | |

| mass-averaged total pressure loss coefficient | |

| maximum total pressure loss improvement | |

| average total pressure loss improvement | |

| static pressure coefficient | |

| mass-averaged static pressure coefficient | |

| maximum static pressure coefficient improvement | |

| average static pressure coefficient improvement | |

| chord length | |

| axial chord length | |

| local total pressure | |

| local static pressure | |

| static pressure of the incoming flow | |

| total pressure of the incoming flow | |

| mass flow rate | |

| velocity | |

| inflow velocity | |

| boundary layer thickness | |

| length of herringbone riblets | |

| distance between herringbone riblets trailing edge and blade leading edge | |

| wavelength | |

| yaw angle | |

| stagger angle | |

| riblet spacing | |

| riblet width | |

| riblet height | |

| the number of incidence angles involved in the evaluation | |

| deviation angle | |

| design upstream flow angle | |

| design downstream flow angle | |

| axial direction | |

| pitchwise direction | |

| spanwise direction |

References

- Slotnick, J.P.; Khodadoust, A.; Alonso, J.J.; Darmofal, D.L.; Gropp, W.D.; Lurie, E.A.; Mavriplis, D.J.; Venkatakrishnan, V. Enabling the environmentally clean air transportation of the future: A vision of computational fluid dynamics in 2030. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130317. [Google Scholar] [CrossRef]

- Yan, H.; Liu, Y.; Li, Q.; Lu, L. Turbulence characteristics in corner separation in a highly loaded linear compressor cascade. Aerosp. Sci. Technol. 2018, 75, 139–154. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, B.; Zhang, T.; Yang, X.; Chen, P. Influence of coupled boundary layer suction and bowed blade on flow field and performance of a diffusion cascade. Chin. J. Aeronaut. 2017, 30, 249–263. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, J.; Lu, L. Corner separation control by boundary layer suction applied to a highly loaded axial compressor cascade. Energies 2014, 7, 7994–8007. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Y.; Zhou, M.; Su, C.; Zhang, X.; Zhu, J. Control of the corner separation in a compressor cascade by steady and unsteady plasma aerodynamic actuation. Exp. Fluids 2010, 48, 1015–1023. [Google Scholar] [CrossRef]

- Akcayoz, E.; Duc, V.H.; Mahallati, A. Controlling corner stall separation with plasma actuators in a compressor cascade. J. Turbomach. 2016, 138, 081008. [Google Scholar] [CrossRef]

- Staats, M.; Nitsche, W. Active control of the corner separation on a highly loaded compressor cascade with periodic nonsteady boundary conditions by means of fluidic actuators. J. Turbomach. 2016, 138, 031004. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; De Luca, C.G.; Ficarella, A.; Marra, F. Comparison between synthetic jets and continuous jets for active flow control: Application on a NACA 0015 and a compressor stator cascade. Aerosp. Sci. Technol. 2015, 43, 256–280. [Google Scholar] [CrossRef]

- Meng, T.; Yang, G.; Zhou, L.; Ji, L. Full blended blade and endwall design of a compressor cascade. Chin. J. Aeronaut. 2021, 34, 79–93. [Google Scholar] [CrossRef]

- Chu, W.; Li, X.; Wu, Y.; Zhang, H. Reduction of end wall loss in axial compressor by using non-axisymmetric profiled end wall: A new design approach based on end wall velocity modification. Aerosp. Sci. Technol. 2016, 55, 76–91. [Google Scholar] [CrossRef]

- Fu, H.; Zhou, L.; Ji, L. Influence of sub boundary layer vortex generator height and attack angle on cross-flows in the hub region of compressors. Chin. J. Aeronaut. 2022, 35, 30–44. [Google Scholar] [CrossRef]

- Ma, S.; Chu, W.; Zhang, H.; Li, X.; Kuang, H. Effects of modified micro-vortex generators on aerodynamic performance in a high-load compressor cascade. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 233, 309–323. [Google Scholar] [CrossRef]

- Ma, S.; Sun, X. Optimization study on the influence of little blades’ spatial position on a compressor cascade performance. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2021, 236, 1799–1816. [Google Scholar] [CrossRef]

- Li, J.; Ji, L. Efficient design method for applying vortex generators in turbomachinery. J. Turbomach. 2019, 141, 081005. [Google Scholar] [CrossRef]

- Sun, J.; Ottavy, X.; Liu, Y.; Lu, L. Corner separation control by optimizing blade end slots in a linear compressor cascade. Aerosp. Sci. Technol. 2021, 114, 106737. [Google Scholar] [CrossRef]

- Tang, Y.; Liu, Y.; Lu, L.; Lu, H.; Wang, M. Passive separation control with blade-end slots in a highly loaded compressor cascade. AIAA J. 2020, 58, 85–97. [Google Scholar] [CrossRef]

- Lin, J.C.; Howard, F.G.; Bushnell, D.M.; Selby, G.V. Investigation of several passive and active methods for turbulent flow separation control. In Proceedings of the 21st Fluid Dynamics, Plasma Dynamics and Lasers Conference, Seattle, WA, USA, 18–20 June 1990; p. 1598. [Google Scholar]

- Chen, H.; Rao, F.; Zhang, D.; Shang, X. Drag Reduction Study about Bird Feather Herringbone Riblets. Appl. Mech. Mater. 2014, 461, 201–205. [Google Scholar] [CrossRef]

- Chen, H.; Rao, F.; Shang, X.; Zhang, D.; Hagiwara, I. Flow over bio-inspired 3D herringbone wall riblets. Exp. Fluids 2014, 55, 1698. [Google Scholar] [CrossRef]

- Quan, P.; Zhong, S.; Liu, Q.; Li, L. Attenuation of flow separation using herringbone riblets at M∞ = 5. AIAA J. 2019, 57, 142–152. [Google Scholar] [CrossRef]

- Liu, Q.; Zhong, S.; Li, L. Investigation of riblet geometry and start locations of herringbone riblets on pressure losses in a linear cascade at low Reynolds numbers. J. Turbomach. 2020, 142, 101010. [Google Scholar] [CrossRef]

- Benschop, H.O.G.; Breugem, W.P. Drag reduction by herringbone riblet texture in direct numerical simulations of turbulent channel flow. J. Turbul. 2017, 18, 717–759. [Google Scholar] [CrossRef]

- Nugroho, B.; Hutchins, N.; Monty, J.P. Large-scale spanwise periodicity in a turbulent boundary layer induced by highly ordered and directional surface roughness. Int. J. Heat Fluid Flow 2013, 41, 90–102. [Google Scholar] [CrossRef]

- Kevin, K.; Monty, J.P.; Bai, H.L.; Pathikonda, G.; Nugroho, B.; Barros, J.M.; Christensen, K.T.; Hutchins, N. Cross-stream stereoscopic particle image velocimetry of a modified turbulent boundary layer over directional surface pattern. J. Fluid Mech. 2017, 813, 412–435. [Google Scholar] [CrossRef]

- Xu, F.; Zhong, S.; Zhang, S. Vortical structures and development of laminar flow over convergent-divergent riblets. Phys. Fluids 2018, 30, 051901. [Google Scholar] [CrossRef]

- Guo, T.; Zhong, S.; Craft, T. Control of laminar flow separation over a backward-facing rounded ramp with C-D riblets—The effects of riblet height, spacing and yaw angle. Int. J. Heat Fluid Flow 2020, 85, 108629. [Google Scholar] [CrossRef]

- Liu, Q.; Zhong, S.; Li, L. Effects of bio-inspired micro-scale surface patterns on the profile losses in a linear cascade. J. Turbomach. 2019, 141, 121006. [Google Scholar] [CrossRef]

- Ma, W.; Ottavy, X.; Lu, L.; Leboeuf, F.; Gao, F. Experimental study of corner stall in a linear compressor cascade. Chin. J. Aeronaut. 2011, 24, 235–242. [Google Scholar] [CrossRef]

- Ma, W.; Xavier, O.; Lu, L.; Leboeuf, F. Intermittent corner separation in a linear compressor cascade. Exp. Fluids 2013, 54, 1546. [Google Scholar]

- Degroot, C.T.; Wang, C.; Floryan, J.M. Drag Reduction Due to Streamwise Grooves in Turbulent Channel Flow. J. Fluids Eng. 2016, 138, 121201-1–121201-10. [Google Scholar] [CrossRef]

- Lu, H.; Yang, Y.; Guo, S.; Pang, W.; Yang, F.; Zhong, J. Control of corner separation via dimpled surface for a highly loaded compressor cascade under different inlet Mach number. Aerosp. Sci. Technol. 2019, 85, 48–60. [Google Scholar] [CrossRef]

| Parameter | Magnitude |

|---|---|

| Chord, /mm | 150 |

| Axial chord, /mm | 110 |

| Camber angle, /(°) | 23.22 |

| Pitch spacing, /mm | 134 |

| Blade span, /mm | 370 |

| Design upstream flow angle, /(°) | 54.31 |

| Design downstream flow angle, /(°) | 31.09 |

| Incidence angle, /(°) | −4~6 |

| Boundary layer thickness at the endwall, /mm | 30 |

| Reynolds number, |

| Parameter | Magnitude |

|---|---|

| Length, / | 0.73 |

| Wavelength, / | 0.53 |

| Distance to the leading edge of the blade, / | 0.1 |

| Riblet spacing, / | 0.033 |

| Riblet width, / | 0.033 |

| Stagger angle, /(°) | 54.31 |

| Scheme | Yaw Angle, /(°) | Riblet Height, / |

|---|---|---|

| Case 1 | 30 | 0.04 |

| Case 2 | 30 | 0.06 |

| Case 3 | 30 | 0.08 |

| Case 4 | 30 | 0.10 |

| Case 5 | 30 | 0.12 |

| Case 6 | 20 | 0.08 |

| Case 7 | 40 | 0.08 |

| Case 8 | 50 | 0.08 |

represents a decrease in value;

represents a decrease in value;  represents an increase in value).

represents an increase in value).

represents a decrease in value;

represents a decrease in value;  represents an increase in value).

represents an increase in value).| Scheme | ||||

|---|---|---|---|---|

| Case 1 | 1.24% | 2.51% | 1.46% | 2.89% |

| Case 2 | 2.63%  | 4.58%  | 2.89%  | 4.70%  |

| Case 3 | 4.21%  | 9.89%  | 5.03%  | 12.27%  |

| Case 4 | 3.74%  | 8.65%  | 4.35%  | 10.69%  |

| Case 5 | 3.55%  | 8.63%  | 3.87%  | 10.64%  |

| Case 6 | 4.13% | 7.10% | 3.93% | 7.44% |

| Case 3 | 4.21%  | 9.89%  | 5.03%  | 12.27%  |

| Case 7 | 4.05%  | 9.75%  | 5.21%  | 12.53%  |

| Case 8 | 3.74%  | 9.09%  | 5.07%  | 12.15%  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Cheng, R.; Li, Y. Numerical Study on the Corner Separation Control for a Compressor Cascade via Bionic Herringbone Riblets. Aerospace 2024, 11, 90. https://doi.org/10.3390/aerospace11010090

Zhang P, Cheng R, Li Y. Numerical Study on the Corner Separation Control for a Compressor Cascade via Bionic Herringbone Riblets. Aerospace. 2024; 11(1):90. https://doi.org/10.3390/aerospace11010090

Chicago/Turabian StyleZhang, Peng, Rixin Cheng, and Yonghong Li. 2024. "Numerical Study on the Corner Separation Control for a Compressor Cascade via Bionic Herringbone Riblets" Aerospace 11, no. 1: 90. https://doi.org/10.3390/aerospace11010090

APA StyleZhang, P., Cheng, R., & Li, Y. (2024). Numerical Study on the Corner Separation Control for a Compressor Cascade via Bionic Herringbone Riblets. Aerospace, 11(1), 90. https://doi.org/10.3390/aerospace11010090