1. Introduction

The design of new gas turbine engines starts with the engine performance and structural specifications imposed by a customer or the manufacturer itself trying to fulfill a new market need [

1]. The first step is the preliminary design phase, where the potential of a new engine design is assessed in terms of fuel efficiency, stable operation, and production, operation, and maintenance costs. In aero-engines, the design should also comply with the top-level aircraft requirements and environmental regulations. To fulfill this objective, a multi-disciplinary preliminary design framework is required that integrates robust, reliable, and fast predictive models for different design disciplines.

Part of any conceptual design framework should also be the mechanical design of critical structural components (e.g., [

2,

3,

4]). An accurate mechanical design, as early as possible, not only provides an assessment of the engine’s safe operation and production and maintenance costs, but it also provides consistent inputs for the detail design, thus minimizing the iterations between the preliminary and detailed design phases.

One of the most crucial parts in any gas turbine engine is the disk. Disks are designed to withstand centrifugal and thermal loads, while in aero-engines they should additionally cope with landing and thrust forces [

5]. Overall, disks are designed as life-limited parts with overspeed and low cycle fatigue (LCF) capabilities [

6]. Since they are a significant part of the total weight of gas turbine engines, they also need to be optimized for minimum weight while satisfying geometry and stress criteria.

In the past, many teams of researchers and engineers have developed methodologies and tools for the preliminary design and weight assessment of turbomachinery disks, as well as their integration in platforms for the conceptual design of gas turbine engines [

2,

3,

4,

5,

7,

8,

9,

10,

11,

12,

13]. In most of those, the disk design is formulated as a weight minimization problem subjected to geometry and stress constraints [

2,

5,

8,

9,

10,

11,

12,

13]. In other approaches, the disk design is conducted analytically [

7] or the optimum geometry is obtained iteratively until the produced disk geometry fulfills the imposed stress constraints [

3,

4].

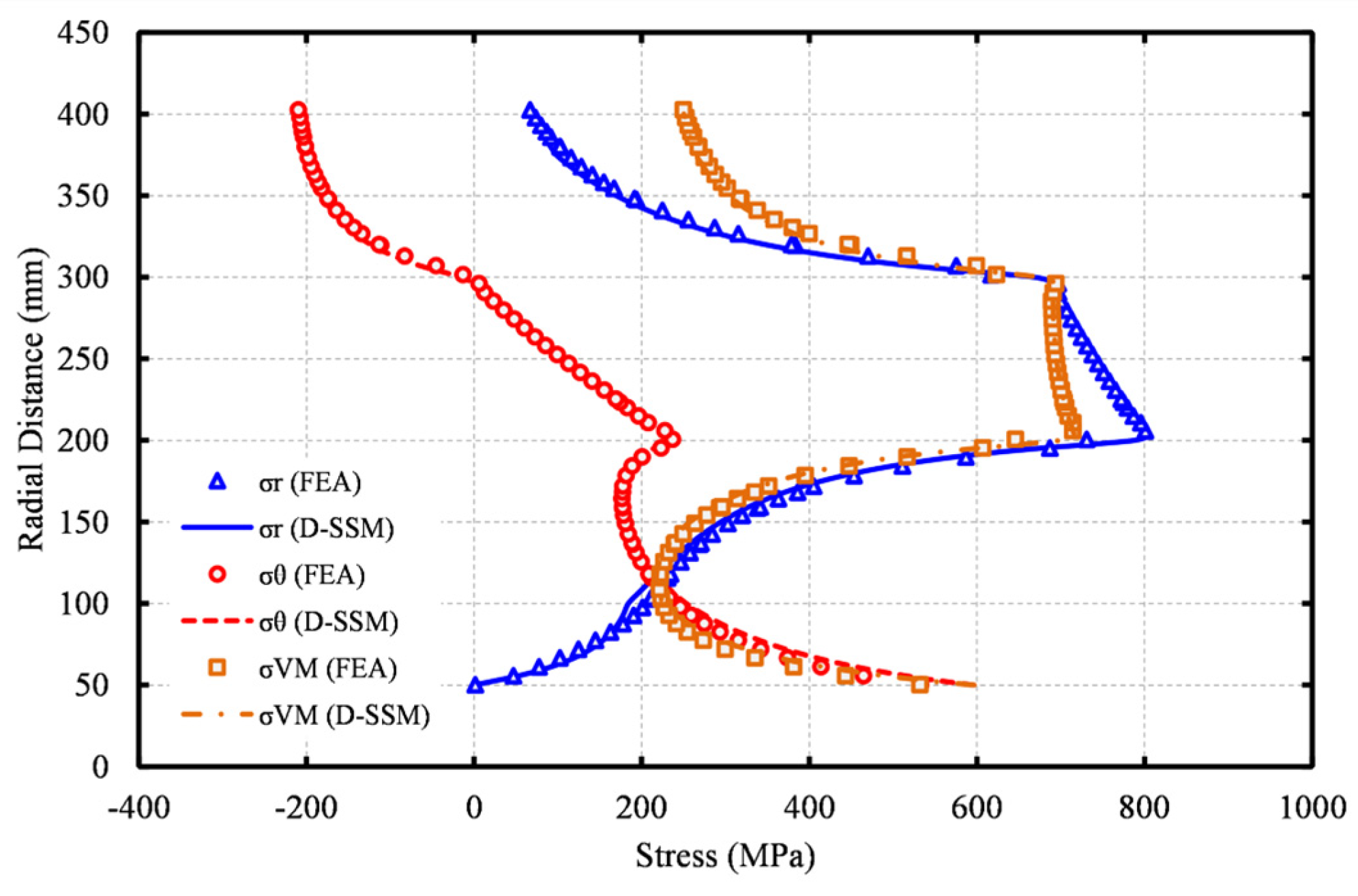

An essential part of any disk design methodology is the estimation of the stress levels developed in the disk during its operation. The reliable assessment of the stress profiles not only yields a correct disk design with respect to the imposed stress constraints, but it can also give a glimpse of the life expectancy of the disk in terms of LCF. In this regard, some methods solve simplified (but more accurate) 1D differential equations for the plane stress equilibrium on axisymmetric bodies of variable thickness [

2,

5,

8,

9,

10,

11,

12], while other methods rely on approximate analytical solutions of rather poor or ambiguous accuracy for simplicity and computational efficiency [

3,

4,

7,

13]. Thermal stresses, which can be significant in hot-end components, are approximated using simplified analytical solutions of Fourier’s law for heat conduction [

2,

8] and user-defined simple polynomial laws for the temperature distribution [

5,

9,

13]. Meanwhile, for some codes, no information is provided about the estimation of thermal loads whatsoever.

In the present paper, the development of a method and its materialization into a tool for the preliminary design of turbomachinery disks is described, called Rotating Disk Optimizer (RDO). RDO was built and integrated into the framework for the preliminary design and assessment of novel aero-engines that the team of authors has been building in recent years [

14,

15,

16,

17]. The framework has been developing in PROOSIS [

18], an object-oriented coding environment for modeling and simulating gas turbine engines, which allows consistent modeling, easy code maintainability, and transparent integration of different design modules under the same, user-friendly software environment. Currently, the framework also includes modules for multi-point (steady-state) design and performance prediction, aerodynamic design and geometry estimation, weight calculations, off-design simulations, mission analysis and emissions, control system design, and transient performance prediction.

RDO formulates the disk design as a constrained optimization problem and exhibits a number of original features. Compared to other tools in which the disk design is formulated as a constrained weight minimization (e.g., [

2,

5,

8,

9,

10,

11,

12,

13]), in RDO the optimal disk geometry in terms of minimum weight is obtained by maximizing appropriately defined stress margins. Among the other publicly available approaches, the only one that offers this design option is GasTurb Details 5 [

9], but no information about its formulation or efficiency is publicly available. An originality of RDO is that it introduces a number of computationally efficient approaches for the estimation of the developed stresses. For example, it incorporates a more accurate temperature model for the correct estimation of the thermal stresses compared to other tools suitable for preliminary design (e.g., [

2,

5,

8,

9,

13]). Finally, the tool capabilities are demonstrated through appropriate validation and optimization test cases. For the latter, the NASA/GE E3 HPC [

19,

20] disks will serve as a demonstration for the tool’s functionality as far as the required baseline geometries are concerned.

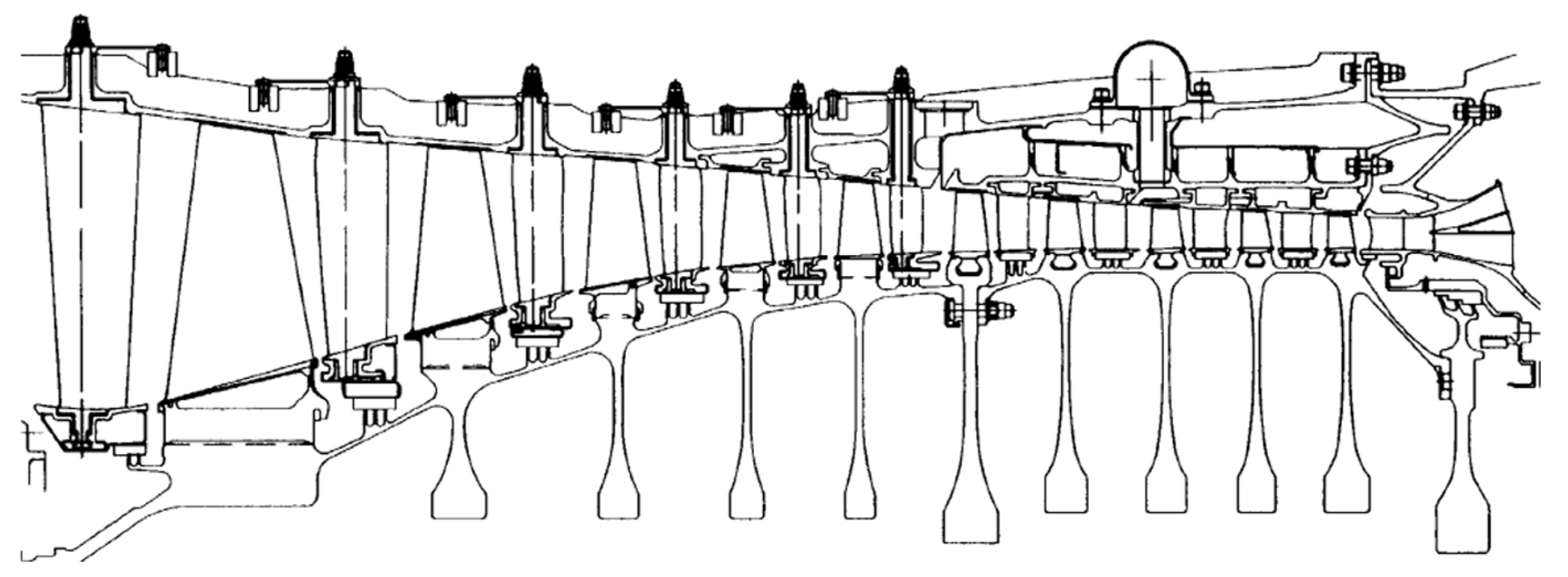

3. Disk Geometry Modeling and Weight Estimation

In most gas turbine engines, the geometry of the disks can be classified into one of the following three basic types [

8]: ring, web, and hyperbolic. Disks with continuous slope sections have also been proposed and studied in the open literature [

12], but they are currently not modeled in RDO.

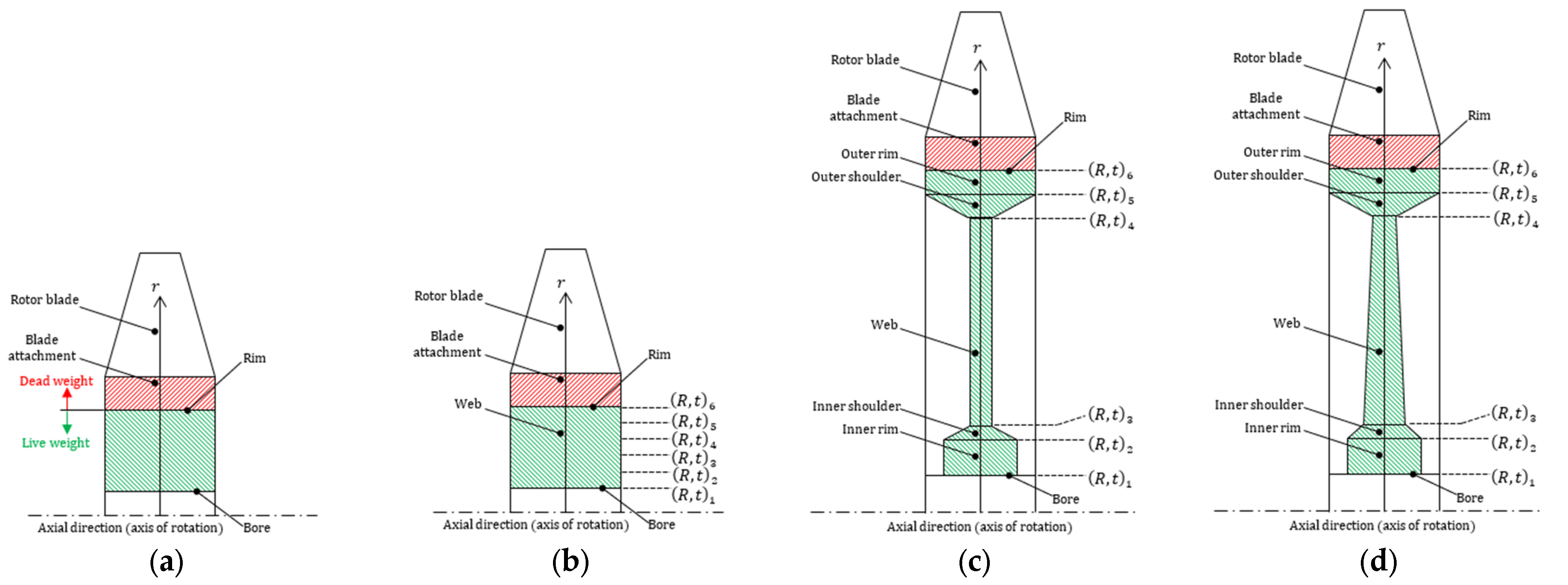

Each disk shape is divided into two portions: the live disk and the dead weight disk [

9]. The rotor blades and blade attachment constitute the dead mass that produces the majority of the pull stress exerted on the rim of the live disk. The blade and attachment dimensions (and thus, weights) and the required loads (rotational speed, temperatures, and pressures) are produced by the aerothermodynamic design and are then fed into RDO, which conducts the design of the live disk geometry. The live disk shape is defined by six radial stations or, equivalently, by five segments, characterized by the values of a radius (

) and a thickness (

).

Figure 2 illustrates diagrammatically the meridional view and the relevant nomenclature of the disk shapes considered in RDO.

For each of the five disk segments (

) seen in

Figure 2, the thickness variation with radius is described by [

12]:

The subscripts and denote the inner and outer station of a disk segment, and is a disk shape factor that can have different values in different disk segments. For , a linear thickness variation is defined, while values of give the flexibility to define more complex thickness distributions.

The thickness profile of Equation (1), which applies at each of the five disk segments, leads to the following formula for calculating the disk total weight. Note that this expression can be used for disks consisting of any number of segments.

4. Disk Thermal Modeling and Validation

Temperature gradients in disks, especially in turbines, can be high enough to create significant thermal stresses. RDO employs a Disk-Simplified Thermal Model (D-STM) for calculating the temperature profile along the disk radius which, in turn, is needed for estimating the developed thermal stresses. This model is described below.

4.1. D-STM Formulation

Most disk design codes assume that the temperature varies according to a polynomial law (e.g., linearly in [

9] or according to a 5th degree polynomial in [

5]) or use empirical curves of proprietary nature (as, e.g., in [

13]). Some tools (e.g., [

8]) use more physics-based approaches to obtain the temperature profile along the disk span, which are nevertheless approximate. The latter come in the form of Fourier’s law for heat conduction, which, for constant material conductivity and for constant disk thickness, gives [

21]:

The above equation does not account for the disk thickness variation. However, as shown later, this omission leads to inaccurate physical solutions and results in the introduction of significant inaccuracy in the calculation of the disk mechanical stresses. In RDO, a more accurate model was introduced, although the calculation option given by Equation (3) is still available to the user.

For axisymmetric bodies of variable (axial) thickness, Fourier’s law for heat conduction assuming constant conductivity is expressed by a 2nd order differential equation, which, with the accompanying boundary conditions, reads [

22]:

where

is the disk circumferential area at an arbitrary radius

. The above equation is discretized using a 2nd order accurate finite difference approach [

23], which leads to a tridiagonal system of equations for obtaining the temperature profile

. The latter is solved quickly using a tridiagonal system algorithm [

24].

Equations (3) and (4) will be referred to as the “analytical” and “numerical” thermal models, respectively.

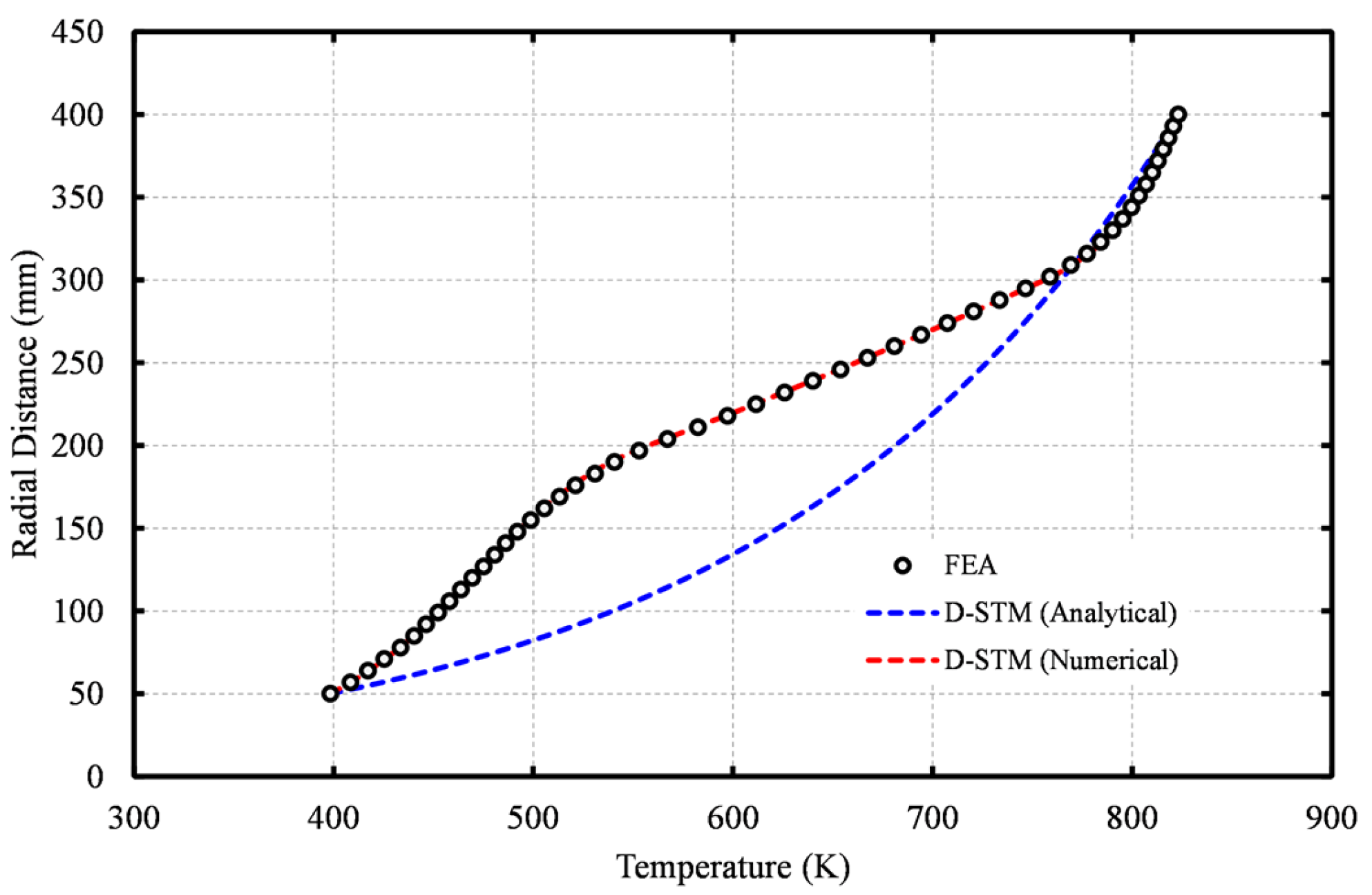

4.2. D-STM Validation

The numerical temperature model was validated against a 3D finite element analysis (FEA) model [

25], which was itself validated against Equation (3) for a ring disk geometry assuming constant material conductivity. The example disk geometry and boundary conditions used for validating the numerical D-STM are shown in

Figure 3.

The comparison between the analytical and numerical D-STMs with the FEA results is shown in

Figure 4. The analytical D-STM, Equation (3), fails to capture the correct temperature trend altogether, where differences in temperature up to 21% can be observed. It will be shown later that this difference leads to significant errors in the estimation of the developed stresses. The numerical method, on the other hand, produces values practically identical to those of the FEA model, thus demonstrating its ability to capture the correct temperature profile when the disk thickness is accounted for.

It is worth noting that in a desktop PC (Windows 7 64-bit, Intel® CoreTM2 Duo CPU@3 GHz, 4GB RAM), both the analytical and numerical D-STMs required about 70 ms each on a grid of the same size (101 nodes were used after a mesh independence study). For comparison, the FEA model required ~2 min. In conclusion, the numerical D-STM offers far greater accuracy with a computational effort not greater than that of the analytical model, and significantly less than the FEA model.

7. Application Test Cases

RDO’s capabilities are demonstrated on optimization test cases for ring-, web-, and hyperbolic-type disks. For this reason, the 1st, 2nd, and 3rd stage disks of the NASA/GE E3 HPC were considered as far as the required baseline geometries, since they approximate disks of ring-, hyperbolic-, and web-shape, respectively. The baseline geometries and calculation inputs for the disks of the NASA/GE E3 HPC are given in

Appendix B. The disk overspeed factor for evaluating the burst margin was set at 120%. The safety factors were set equal to

and

. Finally, no heat transfer effects were considered and the temperature was set constant along the disk and equal to that at the disk rim.

According to [

5], the NASA/GE E3 HPC disks were designed but not optimized for minimum weight. Therefore, to first assess how much more the disk masses can be reduced compared to the baseline disks, Equations (11) and (12) are “switched-off” during the optimization process and the respective dimensions are kept constant and equal to those of the baseline disks:

mm for the 2nd stage (hyperbolic) disk, and

mm for the 3rd stage (web) disk. That is, only the dimensions directly varied by the design variables are changed during the optimization. The results of the optimization are shown in

Table 3.

The weight reduction achieved by RDO is significant for all three stages, ranging from 9.3% (2nd stage disk) to 39.1% (1st stage disk). In all cases, the disk weight minimization is accomplished by maximizing the burst margin () with a simultaneous increase in the design margin (). For all three disks, the optimizer tends to minimize the disk weight by increasing as much as possible (i.e., has a greater relative change compared to the other design variables).

The convergence history for all three cases is shown in

Figure 7, where the logarithm (base 10) of

(left diagram) and the values of

(right diagram) are plotted against the optimization cycle. The optimization of the 1st stage requires less than one-third of the number of cycles required for the 2nd and 3rd stage disks (one design variable compared to five). For all optimization cases, the convergence is deep (

).

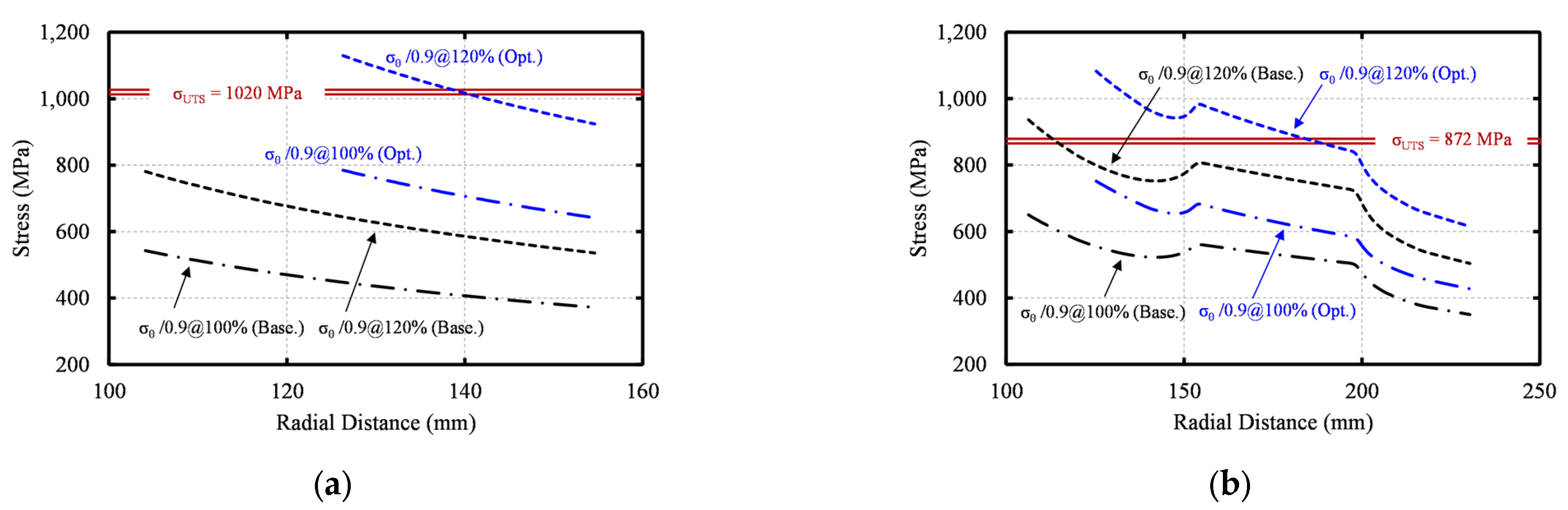

Figure 8 illustrates the tangential stress distributions (

) for the baseline and optimized disk geometries at 100% and 120% design speed for the 1st and 3rd stage disks. Note that the respective trends for the 2nd stage disk were similar to those of the 3rd stage disk and were omitted for brevity. This figure demonstrates the shift of the stress curve (

) at 120% of design speed towards the UTS line for meeting the

criterion and the maximization of the disk stress (

). For all optimized disks, the tangential stress at 120% of design speed (blue dashed curve) has both greater and lower values than the respective UTS limit. This is because, according to Equation (10),

is formulated considering the average values of

and

. Therefore, the optimizer updates the disk geometry until the

curve is shifted to be half above-half below the UTS line. We also observed that the tangential stress at 120% of design speed (black dashed curve) for the 3rd stage baseline disk is greater than

along the inner rim and inner shoulder sections of the disk, contrary to the 1st stage baseline disk for which the respective curve is well below the UTS limit. Therefore, for the 1st stage disk, there is more room for meeting the

criterion than that required for the optimization of the 3rd (and 2nd) stage disk(s). Hence, greater weight reduction is achieved by RDO for the 1st stage disk compared to that for the 3rd (and 2nd) stage disk(s).

Next, the optimization of all ten (10) stage disks of the NASA/GE E3 HPC is conducted following two approaches: the re-design approach described above, and an approach in which Equations (11) and (12) are “switched-on” during the optimization, i.e., the disks are designed “from scratch”. The results of the two optimization approaches are presented in

Table 4.

It is observed that the “from scratch” design achieves a greater overall weight reduction than the “re-design” (26.2% compared to 21.3%). Note, however, that both design approaches obtained the same weight reduction for the 1st stage disk (ring-type) since Equations (11) and (12) are not applicable for the design of ring-type disks and, therefore, the two design approaches are essentially the same.

Figure 9 shows the meridional view of the compressor after the two designs. Regarding the time required for optimizing ten disks twice, it was less than 5 s in a desktop PC (Windows 7 64-bit, Intel

® CoreTM2 Duo CPU@3 GHz, 4GB RAM).

Finally, the “from scratch” design is repeated, but this time heat transfer effects are accounted for by solving the numerical D-STM. For this calculation, the temperature at the bore of the disks was considered constant and equal to 20 °C (room temperature) across the compressor. The meridional view of the compressor after the new design is shown in

Figure 10. The overall weight reduction is now 16.7% (compared to 26.2% without heat transfer effects). The weight reduction is smaller since more material is required to compensate for the increased stresses.

9. Discussion

The main advantage of the presented formulation is that it allows to define initial disk geometries that lie in the feasible solutions section of the design space, since the only constraints that the initial disk geometry must fulfil are related to the dimensions of the disk and not the stress levels. This, in turn, allows search techniques to be used, which are faster than evolutionary techniques, thus enabling the robust design of multistage machines within acceptable times. The test cases presented showed that the design of the disks of a ten-stage compressor required about 5 s in a home desktop PC to design each disk twice!

For estimating the stress levels in a disk, some design tools use semi-analytical models of rather poor accuracy, while other tools use more accurate 1D ODEs that are solved numerically (see Introduction). In either case, all codes estimate the developed thermal stresses by assuming simplified models for the temperature radial profile. In this paper, a more accurate temperature model was proposed and integrated into RDO, which considers the variation of the disk thickness. It was shown that not including the thickness variation or using simple polynomial laws to establish the temperature profile leads to inaccurate results regarding the developed stress levels. This problem is expected to be more prevalent in hot-end components of gas turbines in which there are significant temperature gradients and, thus, the correct modeling of thermal stresses is essential. The thermal model employed in RDO essentially requires the same computational time compared to analytical approaches, but offers significantly higher accuracy.

10. Conclusions

A tool for the preliminary, optimal design of turbomachinery disks (RDO) was presented. It formulates the disk weight minimization problem as an equivalent, constrained maximization problem of the stresses developed in the disk. This is accomplished by appropriately defined design and overspeed (burst) margins that express the level of the developed radial and tangential stresses. This formulation and its efficiency with regard to engine optimization problems are presented in the open literature for the first time.

In this study, it was also shown that the RDO stress models can accurately model and predict the stresses developed in disks, thus leading to reasonable designs from the very start of the design process. In fact, this is achieved without the need for FEA tools, which are computationally costly, difficult to integrate into preliminary design platforms, and require a certain level of expertise in setting-up the model and the calculation sequence.

Finally, real-case optimization problems demonstrated that the proposed formulation leads to robust, fast, and deep-converging optimization problems and, therefore, it can be integrated in platforms used for the preliminary design of gas turbine engines.